SSANGYONG KORANDO 1997 Service Owner's Guide

Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 31 of 2053

GENERAL ENGINE INFORMATION 1A1 -- 11

D AEW OO M Y_2000

Leakage Test

1. Warm the engine up to normal operating tempera-

ture.

2. Disconnect the negative battery cable.

3. Remove the spark plugs.

4. Check the coolant level by opening the coolant

surge tank cap and replenish if insufficient.

5. Open the engine oil filler cap.

6. Connect the tester to air pressure line and adjust the

scale of tester.

7. Install the connecting hose to spark plug hole.

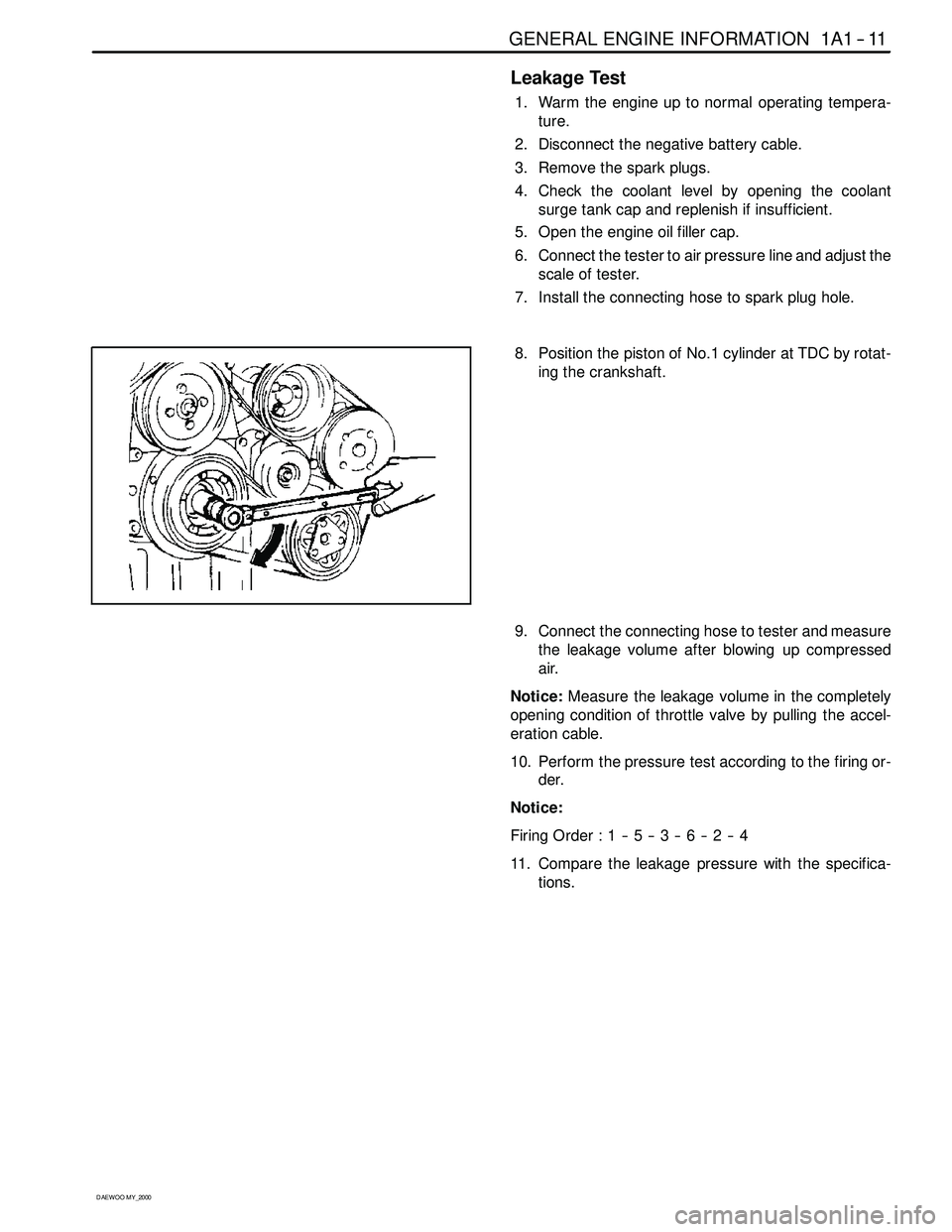

8. Position the piston of No.1 cylinder at TDC by rotat-

ing the crankshaft.

9. Connect the connecting hose to tester and measure

the leakage volume after blowing up compressed

air.

Notice:Measure the leakage volume in the completely

opening condition of throttle valve by pulling the accel-

eration cable.

10. Perform the pressure test according to the firing or-

der.

Notice:

FiringOrder:1--5--3--6--2--4

11. Compare the leakage pressure with the specifica-

tions.

Page 32 of 2053

1A1 -- 12 GENERAL ENGINE INFORMATION

D AEW OO M Y_2000

GENERAL INFORMATION

CLEANLINESS AND CARE

An automobile engine is a combination of many ma-

chined, honed, polished and lapped surfaces with toler-

ances that are measured in the ten-thousandths of an

inch. When any internal engine parts are serviced, care

and cleanliness are important. A liberal coating of enigne

oil should be applied to friction areas during assembly, to

protect and lubricate the surfaces on initial operation.

Proper cleaning and protection of machined surfaces and

friction areas is part of the repair procedure. This is con-

sidered standard shop practice even if not specifically

stated.

Whenever valve train components are removed for ser-

vice, they should be kept in order. They should be

installed in the same locations, and with the same mating

surfaces, as when they were removed.

Battery cables should be disconnected before any major

work is performed on the engine. Failure to disconnectcables may result in damage to wire harness or other

electrical parts.

ON-ENGINE SERVICE

Caution: Disconnect the negative battery cable be -

fore removing or installing any electrical unit, or

when a tool or equipment could easily come in con-

tact with exposed electrical terminals. Disconnect -

ing this cable will help prevent personal injury and

damage to the vehicle. The ignition must also be in

LOCK unless otherwise noted.

Notice:Any time the air cleaner is removed, the intake

opening should be covered. Thiswill protect against ac-

cidental entrance of foreign material, which could follow

the intake passage into the cylinder and cause exten-

sive damage when the engine is started.

Page 33 of 2053

D AEW OO M Y_2000

SECTION 1B1

M162 ENGINE MECHANICAL

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless other -

wise noted.

TABLE OF CONTENTS

Specifications 1B1 -- 2............................

Fastener Tightening Specifications 1B1 -- 2..........

Special Tools 1B1 -- 4.............................

Special Tools Table 1B1-- 4.......................

Maintenance and Repair 1B1 -- 7...................

On-- Vehicle Service 1B1-- 7.........................

Engine Assembly 1B1-- 7.........................

Crankcase Ventilation System 1B1-- 14.............

Generator 1B1-- 16..............................

Engine Mount 1B1-- 17...........................

Poly V-- Belt 1B1 -- 18.............................

Tensioning Device 1B1-- 20.......................

Poly V-- Belt Inspection 1B1-- 21...................

Cylinder Head Cover 1B1-- 24.....................

Cylinder Head Front Cover 1B1 -- 26...............

Cylinder Head 1B1-- 28...........................

Timing Gear Case Cover 1B1-- 31.................

Crankshaft Sealing Rear Cover 1B1-- 33...........

Belt Pulley and Vibration Damper 1B1-- 35..........

Crankshaft Front Radial Seal 1B1-- 38.............

Crankshaft Rear Radial Seal 1B1-- 40..............

Crankshaft 1B1-- 41.............................

Flywheel / Driven Plate 1B1 -- 47...................

Camshaft Adjuster 1B1-- 50.......................

Camshaft Sprocket Bolt 1B1-- 52..................

Camshaft 1B1-- 54..............................

Camshaft Timing Position 1B1 -- 59................Valve Spring 1B1 -- 62............................

Valve Stem Seal 1B1-- 66........................

Chain Tensioner 1B1-- 67.........................

Timing Chain 1B1-- 70............................

Tensioning Rail 1B1-- 75..........................

Cylinder Head Guide Rail 1B1-- 76.................

Crankcase Guide Rail 1B1-- 77....................

Crankshaft Sprocket 1B1-- 78.....................

Piston 1B1-- 80..................................

Connecting Rod 1B1-- 83.........................

Piston Ring 1B1 -- 85.............................

Engine Oil Specification 1B1-- 87..................

Oil Pan 1B1-- 88.................................

Engine Oil and Oil Filter Element 1B1-- 90..........

Oil Filter 1B1-- 92................................

Oil Pump 1B1-- 94...............................

Oil Pressure Relief Valve 1B1-- 96.................

Oil Non-Return Valve 1B1-- 97....................

Oil Dipstick Guide Tube 1B1-- 98..................

Unit Repair 1B1 -- 99..............................

Oil Gallery in Crankcase 1B1 -- 99..................

Oil Gallery in Cylinder Head 1B1-- 101..............

Core Plugs in Crankcase 1B1-- 104................

Cylinder Bore 1B1-- 106..........................

Crankcase Mating Surface 1B1-- 108..............

Cylinder Head Mating Surface 1B1-- 110...........

Page 34 of 2053

1B1 -- 2 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

SPECIFICATIONS

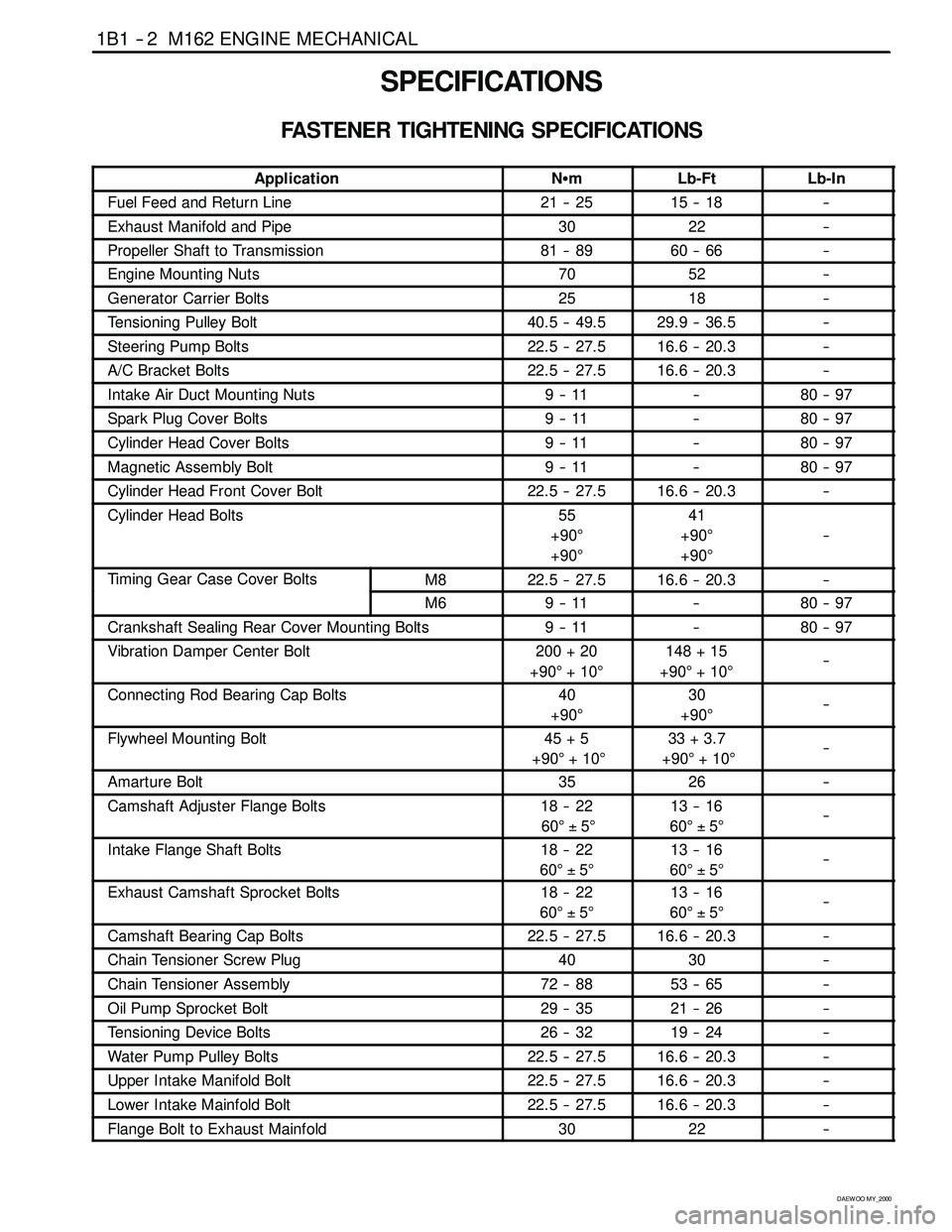

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb-FtLb-In

Fuel Feed and Return Line21 -- 2515 -- 18--

Exhaust Manifold and Pipe3022--

Propeller Shaft to Transmission81 -- 8960 -- 66--

Engine Mounting Nuts7052--

Generator Carrier Bolts2518--

Tensioning Pulley Bolt40.5 -- 49.529.9 -- 36.5--

Steering Pump Bolts22.5 -- 27.516.6 -- 20.3--

A/C Bracket Bolts22.5 -- 27.516.6 -- 20.3--

Intake Air Duct Mounting Nuts9--11--80 -- 97

Spark Plug Cover Bolts9--11--80 -- 97

Cylinder Head Cover Bolts9--11--80 -- 97

Magnetic Assembly Bolt9--11--80 -- 97

Cylinder Head Front Cover Bolt22.5 -- 27.516.6 -- 20.3--

Cylinder Head Bolts55

+90°

+90°41

+90°

+90°

--

Timing Gear Case Cover BoltsM822.5 -- 27.516.6 -- 20.3--g

M69--11--80 -- 97

Crankshaft Sealing Rear Cover Mounting Bolts9--11--80 -- 97

Vibration Damper Center Bolt200 + 20

+90°+10°148 + 15

+90°+10°--

Connecting Rod Bearing Cap Bolts40

+90°30

+90°--

Flywheel Mounting Bolt45 + 5

+90°+10°33 + 3.7

+90°+10°--

Amarture Bolt3526--

Camshaft Adjuster Flange Bolts18 -- 22

60°±5°13 -- 16

60°±5°--

Intake Flange Shaft Bolts18 -- 22

60°±5°13 -- 16

60°±5°--

Exhaust Camshaft Sprocket Bolts18 -- 22

60°±5°13 -- 16

60°±5°--

Camshaft Bearing Cap Bolts22.5 -- 27.516.6 -- 20.3--

Chain Tensioner Screw Plug4030--

Chain Tensioner Assembly72 -- 8853 -- 65--

Oil Pump Sprocket Bolt29 -- 3521 -- 26--

Tensioning Device Bolts26 -- 3219 -- 24--

Water Pump Pulley Bolts22.5 -- 27.516.6 -- 20.3--

Upper Intake Manifold Bolt22.5 -- 27.516.6 -- 20.3--

Lower Intake Mainfold Bolt22.5 -- 27.516.6 -- 20.3--

Flange Bolt to Exhaust Mainfold3022--

Page 35 of 2053

M162 ENGINE MECHANICAL 1B1 -- 3

D AEW OO M Y_2000

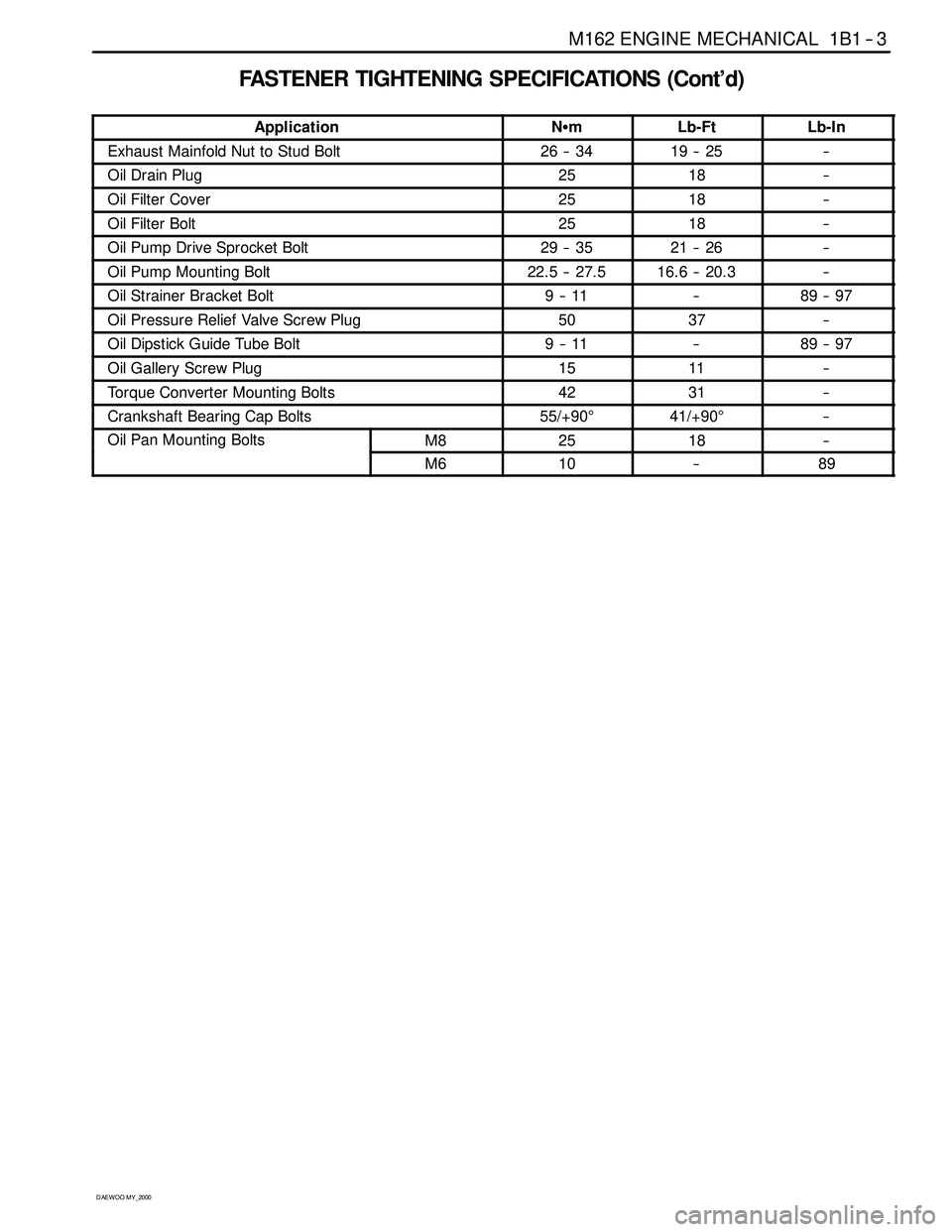

FASTENER TIGHTENING SPECIFICATIONS (Cont’d)

ApplicationNSmLb-FtLb-In

Exhaust Mainfold Nut to Stud Bolt26 -- 3419 -- 25--

Oil Drain Plug2518--

Oil Filter Cover2518--

Oil Filter Bolt2518--

Oil Pump Drive Sprocket Bolt29 -- 3521 -- 26--

Oil Pump Mounting Bolt22.5 -- 27.516.6 -- 20.3--

Oil Strainer Bracket Bolt9--11--89 -- 97

Oil Pressure Relief Valve Screw Plug5037--

Oil Dipstick Guide Tube Bolt9--11--89 -- 97

Oil Gallery Screw Plug1511--

Torque Converter Mounting Bolts4231--

Crankshaft Bearing Cap Bolts55/+90°41/+90°--

Oil Pan Mounting BoltsM82518--g

M610--89

Page 36 of 2053

1B1 -- 4 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

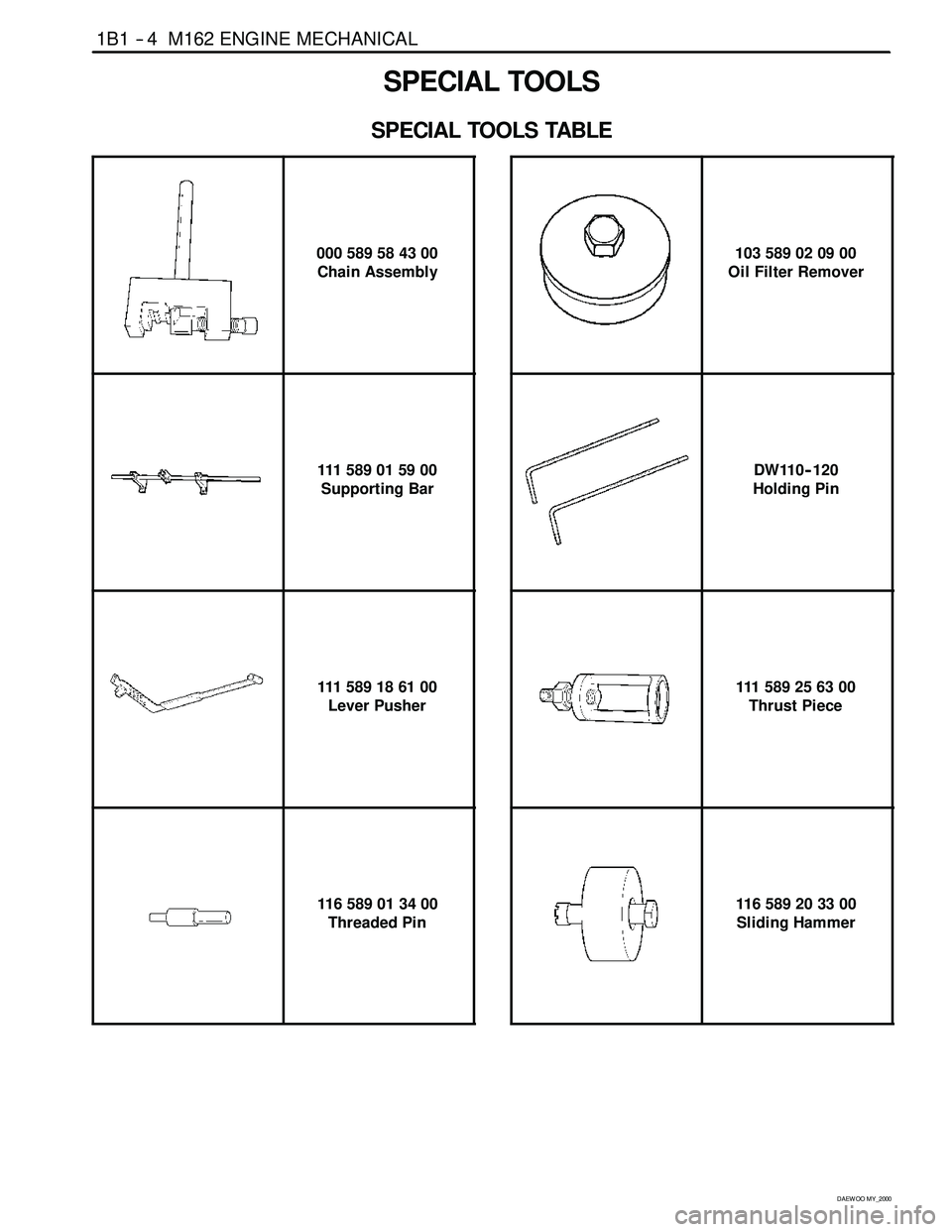

SPECIAL TOOLS

SPECIAL TOOLS TABLE

000 589 58 43 00

Chain Assembly

111 589 01 59 00

Supporting Bar

111 589 18 61 00

Lever Pusher

116 589 01 34 00

Threaded Pin

103 589 02 09 00

Oil Filter Remover

DW110 -- 120

Holding Pin

111 589 25 63 00

Thrust Piece

116 589 20 33 00

Sliding Hammer

Page 37 of 2053

M162 ENGINE MECHANICAL 1B1 -- 5

D AEW OO M Y_2000

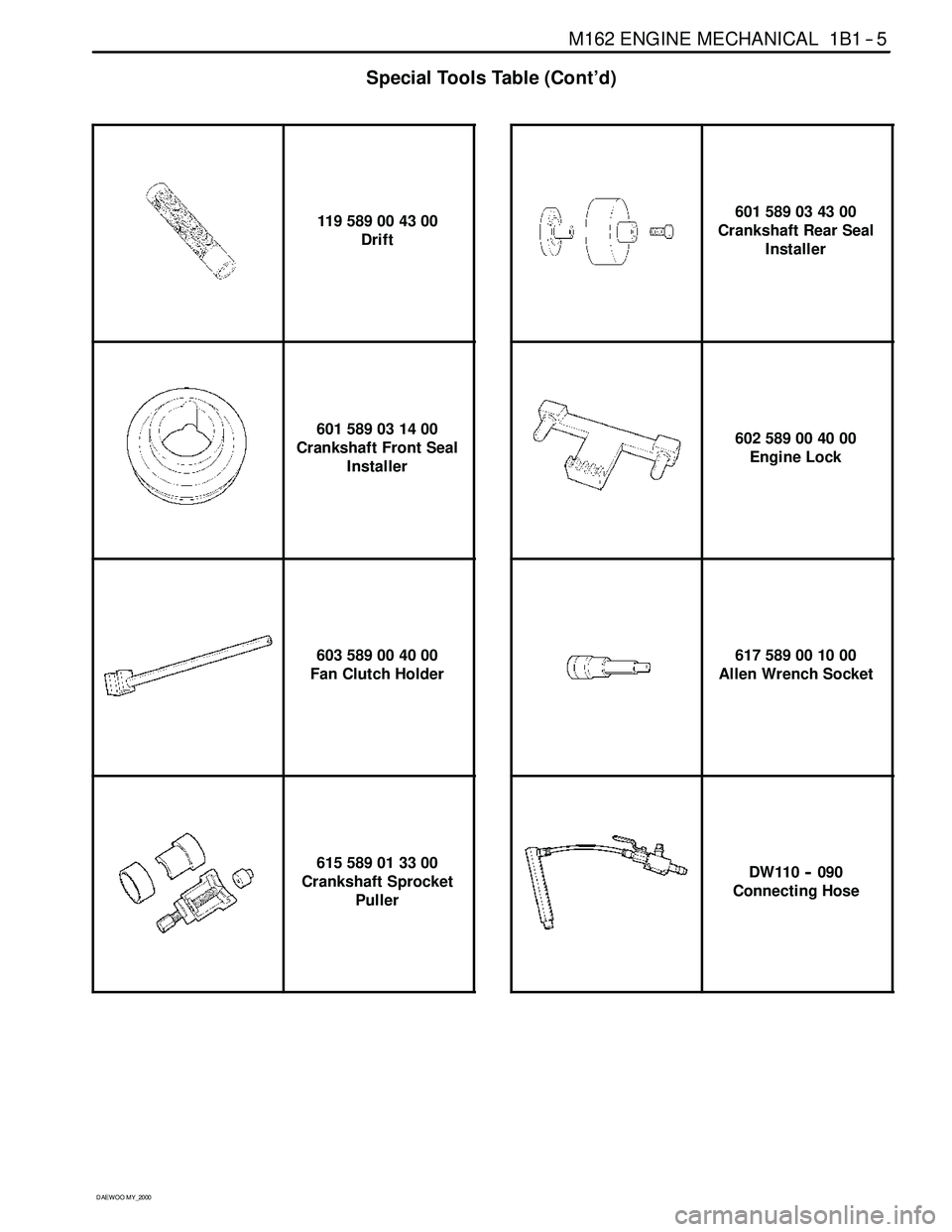

Special Tools Table (Cont’d)

119 589 00 43 00

Drift

601 589 03 14 00

Crankshaft Front Seal

Installer

603 589 00 40 00

Fan Clutch Holder

615 589 01 33 00

Crankshaft Sprocket

Puller

601 589 03 43 00

Crankshaft Rear Seal

Installer

602 589 00 40 00

Engine Lock

617 589 00 10 00

Allen Wrench Socket

DW110 -- 090

Connecting Hose

Page 38 of 2053

1B1 -- 6 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

Special Tools Table (Cont’d)

DW110 -- 100

Valve Tappet Remover

Page 39 of 2053

M162 ENGINE MECHANICAL 1B1 -- 7

D AEW OO M Y_2000

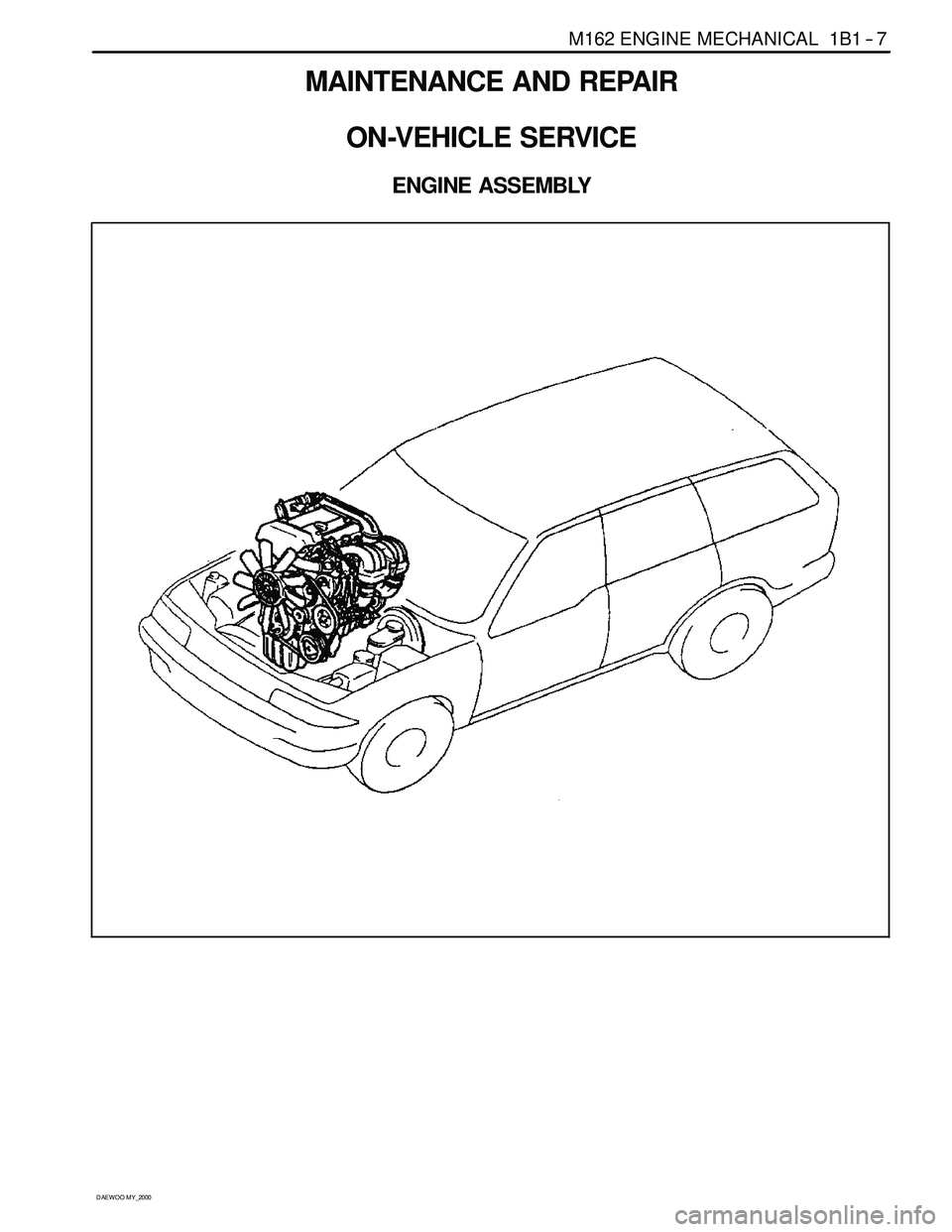

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

ENGINE ASSEMBLY

Page 40 of 2053

1B1 -- 8 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

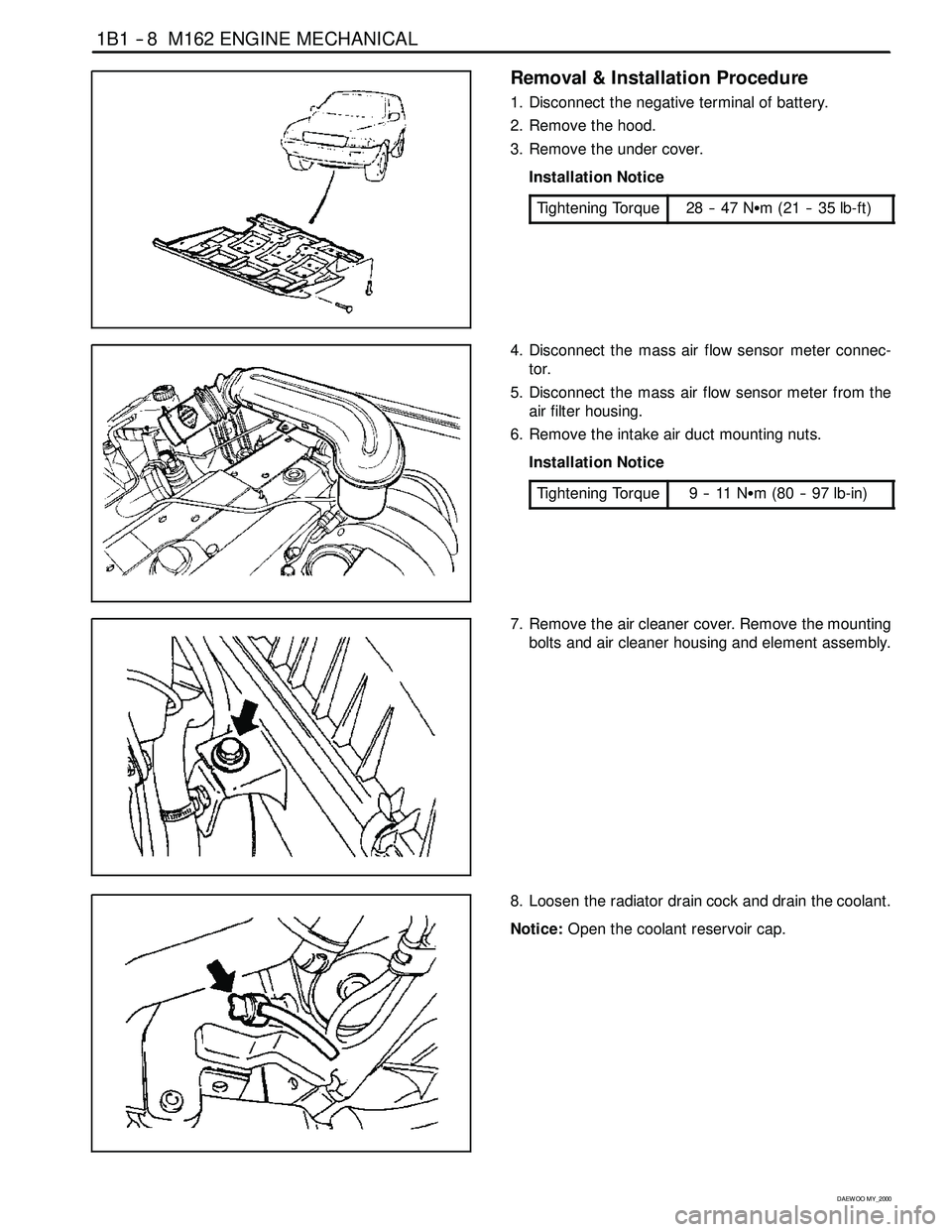

Removal & Installation Procedure

1. Disconnect the negative terminal of battery.

2. Remove the hood.

3. Remove the under cover.

Installation Notice

Tightening Torque

28 -- 47 NSm (21 -- 35 lb-ft)

4. Disconnect the mass air flow sensor meter connec-

tor.

5. Disconnect the mass air flow sensor meter from the

air filter housing.

6. Remove the intake air duct mounting nuts.

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

7. Remove the air cleaner cover. Remove the mounting

bolts and air cleaner housing and element assembly.

8. Loosen the radiator drain cock and drain the coolant.

Notice:Open the coolant reservoir cap.