SSANGYONG KORANDO 1997 Service Manual PDF

KORANDO 1997

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57502/w960_57502-0.png

SSANGYONG KORANDO 1997 Service Manual PDF

Trending: high beam, jacking, sport mode, fuel cap, spark plugs replace, air condition, fuel type

Page 61 of 2053

M162 ENGINE MECHANICAL 1B1 -- 29

D AEW OO M Y_2000

Tools Required

617589001000 AllenWrenchSocket

116 589 01 34 00 Threaded Pin

116 589 20 33 00 Sliding Hammer

Removal & Installation Procedure

1. Rotate the crankshaft so that the piston of number 1

cylinder is at TDC.

Notice:Rotate the crankshaft in the normal engine di-

rection.

2. Put the alignment marks (arrows) on the timing chain

and camshaft sprocket.

3. Drain the coolant from the crankcase.

4. Remove the three flange bolts in the exhaust cam-

shaft sprocket.

Installation Notice

Ti

ghteningTo rque

1st step: 18 -- 22 NSm

(13 -- 16 lb-ft)

TighteningTorque

2nd step: 60°±5°

Do not reuse the removed bolts.

5. Separate the chain from the camshaft sprocket.

Notice:Be careful not to drop the chain into the timing

case.

6. Remove the guide rail fixing pin using threaded pin

116 589 01 34 00 (1) and sliding hammer 116 589 33

00 (2).

Page 62 of 2053

1B1 -- 30 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

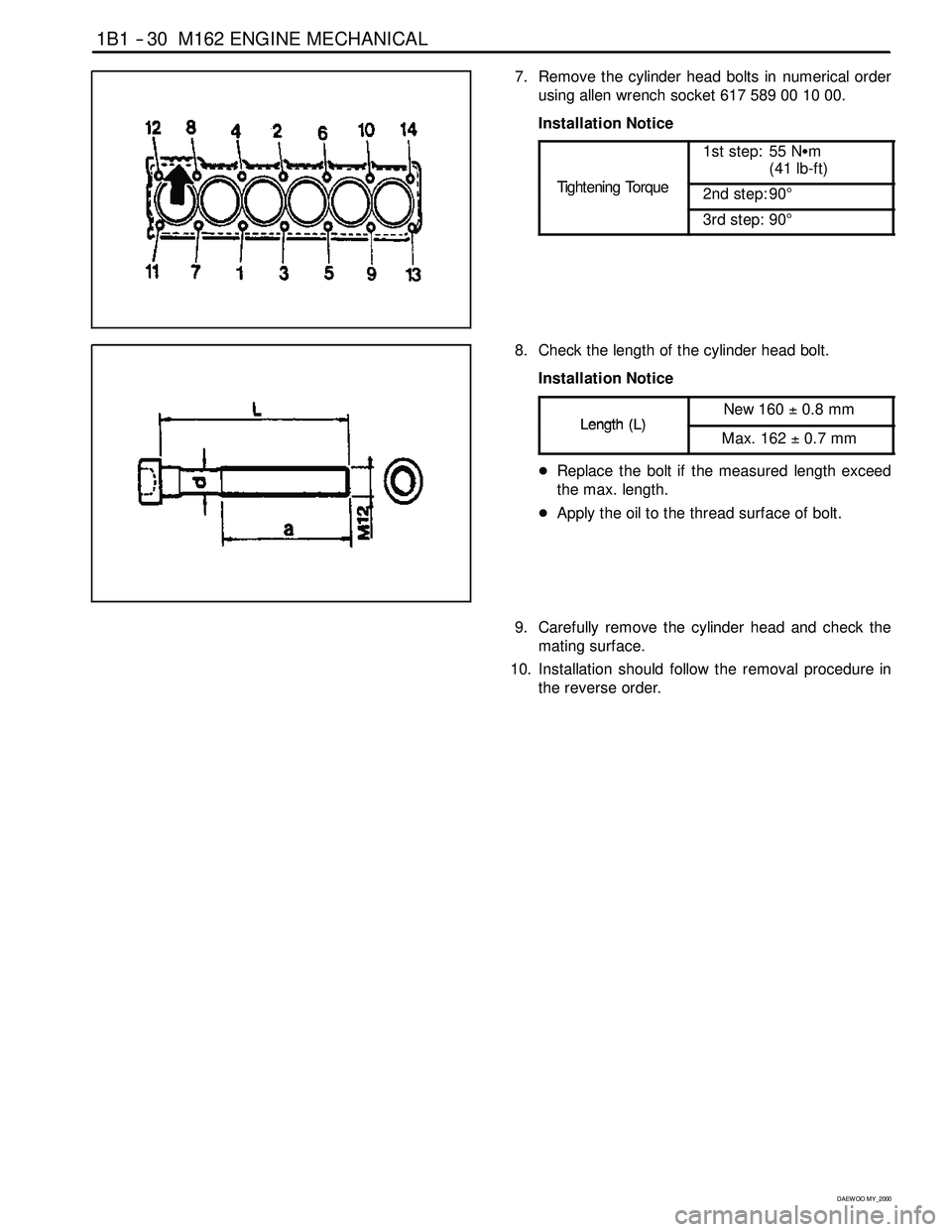

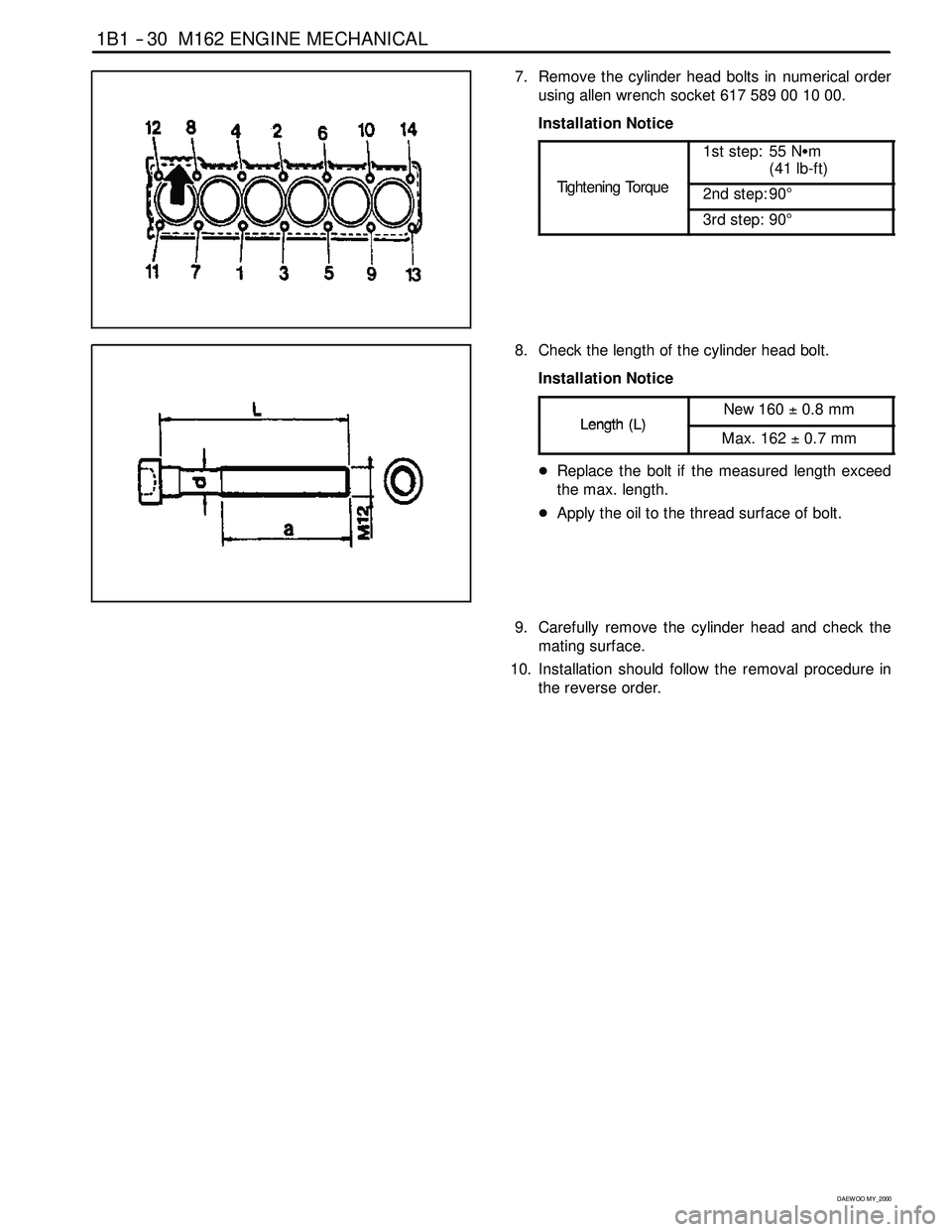

7. Remove the cylinder head bolts in numerical order

usingallenwrenchsocket617589001000.

Installation Notice

TihtiT

1st step: 55 NSm

(41 lb-ft)

Tightening Torque2nd step: 90°

3rd step: 90°

8. Check the length of the cylinder head bolt.

Installation Notice

Length(L)New 160±0.8 mmLength(L)Max. 162±0.7 mm

DReplace the bolt if the measured length exceed

the max. length.

DApply the oil to the thread surface of bolt.

9. Carefully remove the cylinder head and check the

mating surface.

10. Installation should follow the removal procedure in

the reverse order.

Page 63 of 2053

M162 ENGINE MECHANICAL 1B1 -- 31

D AEW OO M Y_2000

TIMING GEAR CASE COVER

Preceding Work: Removal of cylinder head front cover

Removal of generator bracket

Removal of tensioning device

Removal of belt pulley and vibration damper

1 Bolt (M8 x 60, 3 pieces)

22.5-- 27.5 NSm (16.6-- 20.3 lb-ft) .............

2 A/C Bracket

3 Bolt (M8 x 65, 3 pieces)

22.5-- 27.5 NSm (16.6-- 20.3 lb-ft) .............

4 Bolt (M8 x 40, 1 piece)

22.5-- 27.5 NSm (16.6-- 20.3 lb-ft) .............5 Bolt (M8 x 60, 1 piece)

22.5-- 27.5 NSm (16.6--20.3 lb-ft) .............

6Seal

7 Timing Gear Case Cover

8RollPin

9 Bolt (M6 x 22, 6 pieces)

9--11 NSm (80-- 97 lb-in) .....................

Page 64 of 2053

1B1 -- 32 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

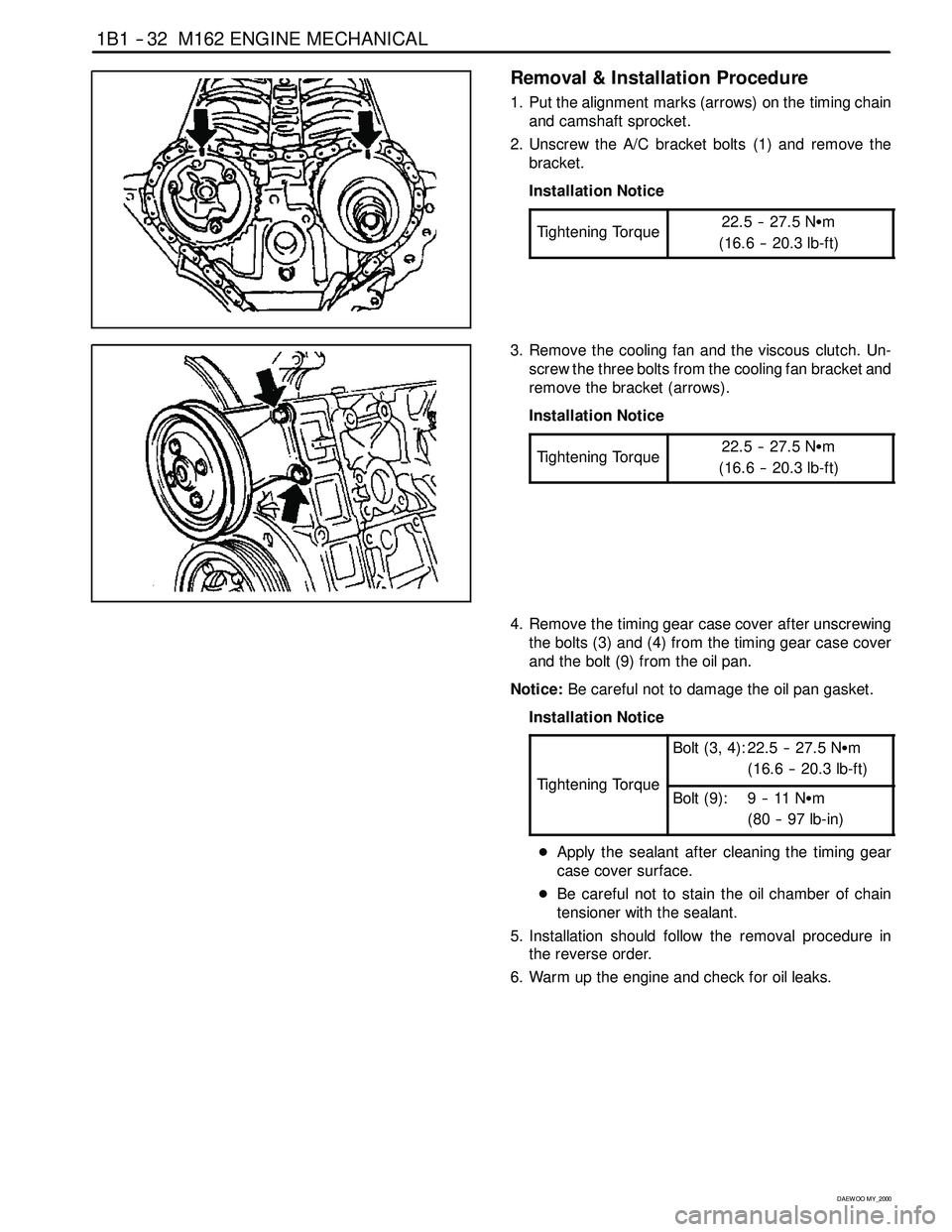

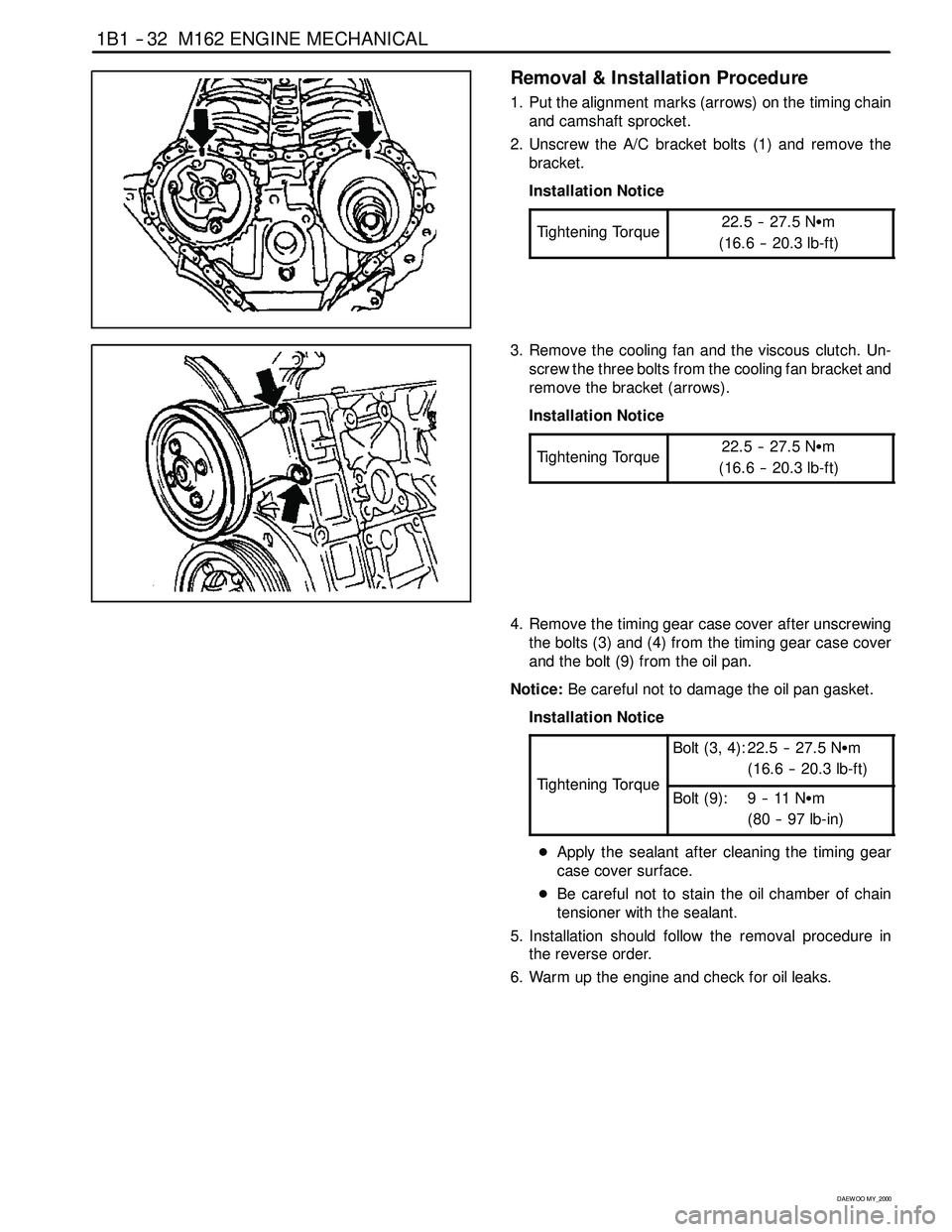

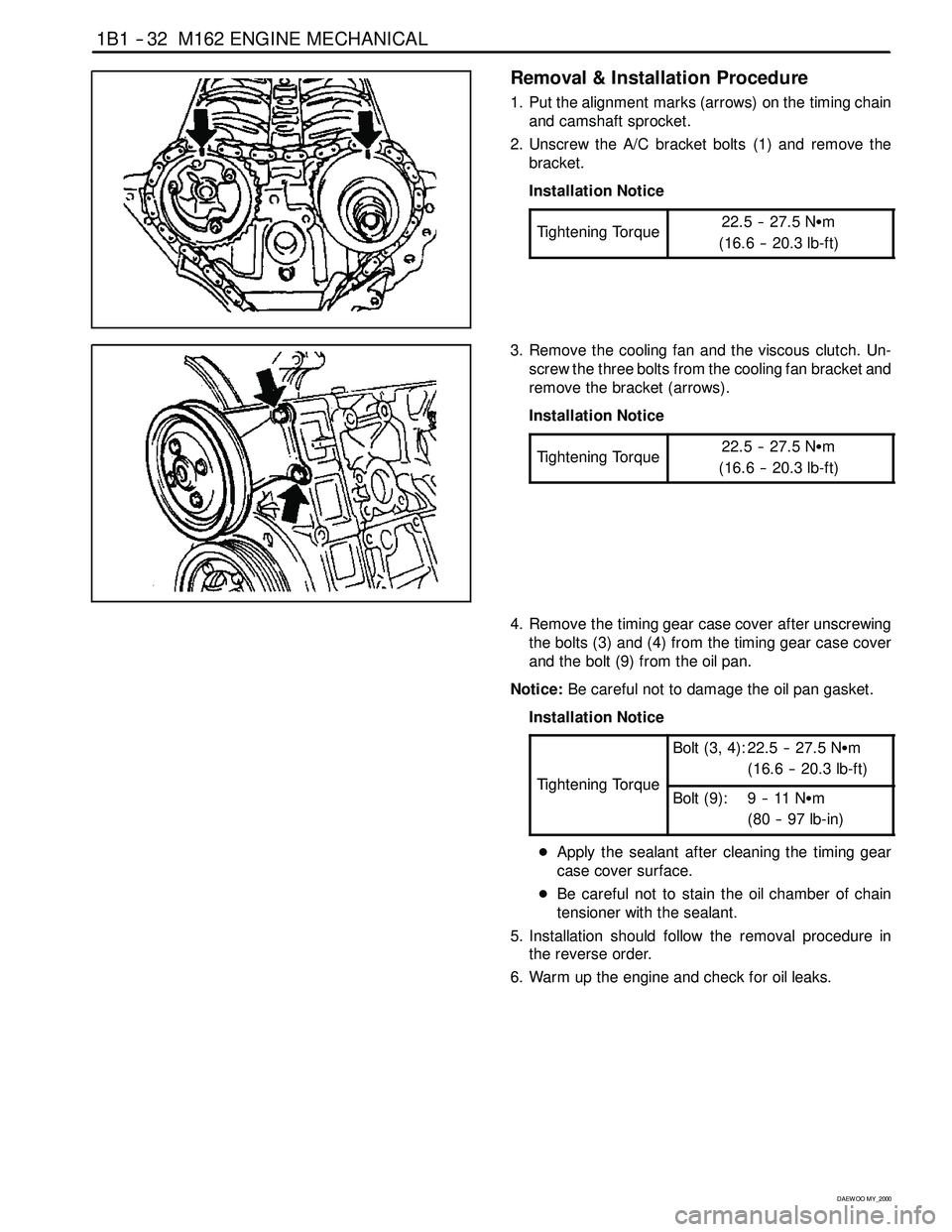

Removal & Installation Procedure

1. Put the alignment marks (arrows) on the timing chain

and camshaft sprocket.

2. Unscrew the A/C bracket bolts (1) and remove the

bracket.

Installation Notice

Tightening Torque

22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

3. Remove the cooling fan and the viscous clutch. Un-

screw the three bolts from the cooling fan bracket and

remove the bracket (arrows).

Installation Notice

Tightening Torque

22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

4. Remove the timing gear case cover after unscrewing

the bolts (3) and (4) from the timing gear case cover

and the bolt (9) from the oil pan.

Notice:Be careful not to damage the oil pan gasket.

Installation Notice

TighteningTorque

Bolt (3, 4): 22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

TighteningTorqueBolt (9): 9 -- 11 NSm

(80 -- 97 lb-in)

DApply the sealant after cleaning the timing gear

case cover surface.

DBe careful not to stain the oil chamber of chain

tensioner with the sealant.

5. Installation should follow the removal procedure in

the reverse order.

6. Warm up the engine and check for oil leaks.

Page 65 of 2053

M162 ENGINE MECHANICAL 1B1 -- 33

D AEW OO M Y_2000

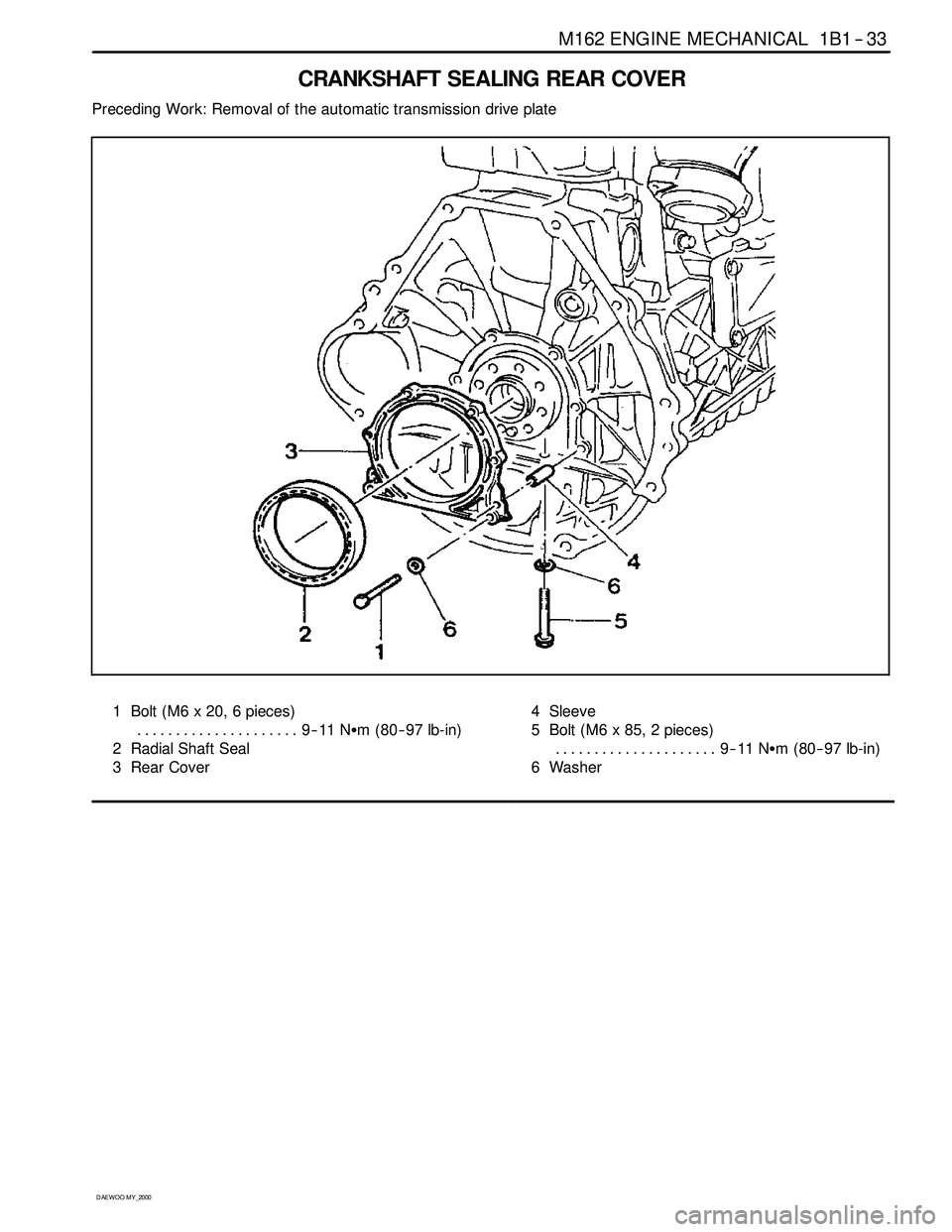

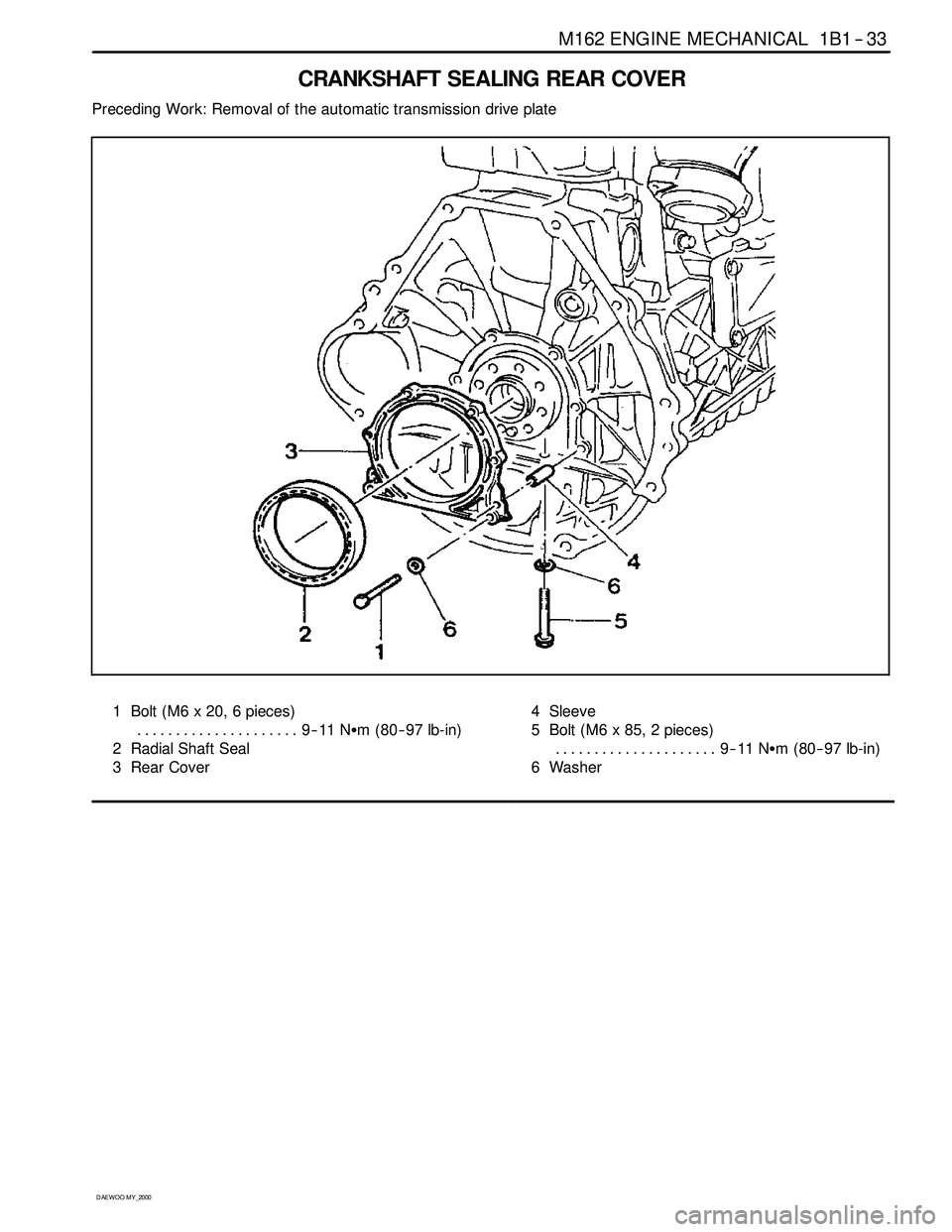

CRANKSHAFT SEALING REAR COVER

Preceding Work: Removal of the automatic transmission drive plate

1 Bolt (M6 x 20, 6 pieces)

9--11 NSm (80-- 97 lb-in) .....................

2 Radial Shaft Seal

3 Rear Cover4 Sleeve

5 Bolt (M6 x 85, 2 pieces)

9--11 NSm (80-- 97 lb-in) .....................

6Washer

Page 66 of 2053

1B1 -- 34 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

Tools Required

601 589 03 43 00 Crankshaft Rear Seal Installer

Removal & Installation Procedure

1. Unscrew the bolts (1) and (5) and remove the closing

cover by pulling the rear cover lug (arrows).

Notice:Be careful not to damage the oil pan gasket.

2. Clean the sealing surface of the crankcase and the

rear sealing cover.

3. Check the radial shaft seal and replace it if necessary.

4. Apply the Loctite 573 to the rear cover sealing sur-

face.

5. Apply the engine oil to the dust lip of the radial shaft

seal.

Notice:Do not use the grease.

6. Install the crankshaft rear radial seal and the crank-

shaft sealing rear cover, using crankshaft rear seal in-

staller 601 589 03 43 00.

7. Install the crankshaft sealing rear cover mounting

bolts and remove the crankshaft rear seal installer

601 589 03 43 00.

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

8. Installation should follow the removal procedure in

the reverse order.

Page 67 of 2053

M162 ENGINE MECHANICAL 1B1 -- 35

D AEW OO M Y_2000

BELT PULLEY AND VIBRATION DAMPER

Preceding Work: Removal of cooling fan and viscous clutch

Removal of fan shroud

Removal of drive belt

1 Vibration Damper Center Bolt (M18 x 50)

1st step 200+20 NSm (148+15 lb-ft) ..........

2nd step 90°+10°

2 Vibration Damper Disk

3 Bolt (M6 x 20, 6 pieces)

7.7-- 9.5 NSm (68.1-- 84.1 lb-in) ...............4 Vibration Damper Assembly

5 Woodruff Key

6 Bolt (M6 x 12, 4 pieces)

9--11 NSm (80-- 97 lb-in) .....................

7 Cooling Fan Pulley

Page 68 of 2053

1B1 -- 36 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

Components

1 Center Bolt (M18 x 50)

2 Center Bolt Washer

3 Vibration Damper and Pulley Assembly

4Key

5 Crankshaft Front Seal

6 Timing Gear Case Cover7 Crankshaft Sprocket (Camshaft Driven)

8 Crankshaft Sprocket (Oil pump Driven)

9 Crankshaft

10 Oil Pan

11 Oil Pan Gasket

12 Oil Pan Mounting Bolt (M6 x 22)

ServiceDataStandard

Permissble Deviation of The Vibration DamperRadial Runout0.6 mmp

Axial Runout0.6 mm

Page 69 of 2053

M162 ENGINE MECHANICAL 1B1 -- 37

D AEW OO M Y_2000

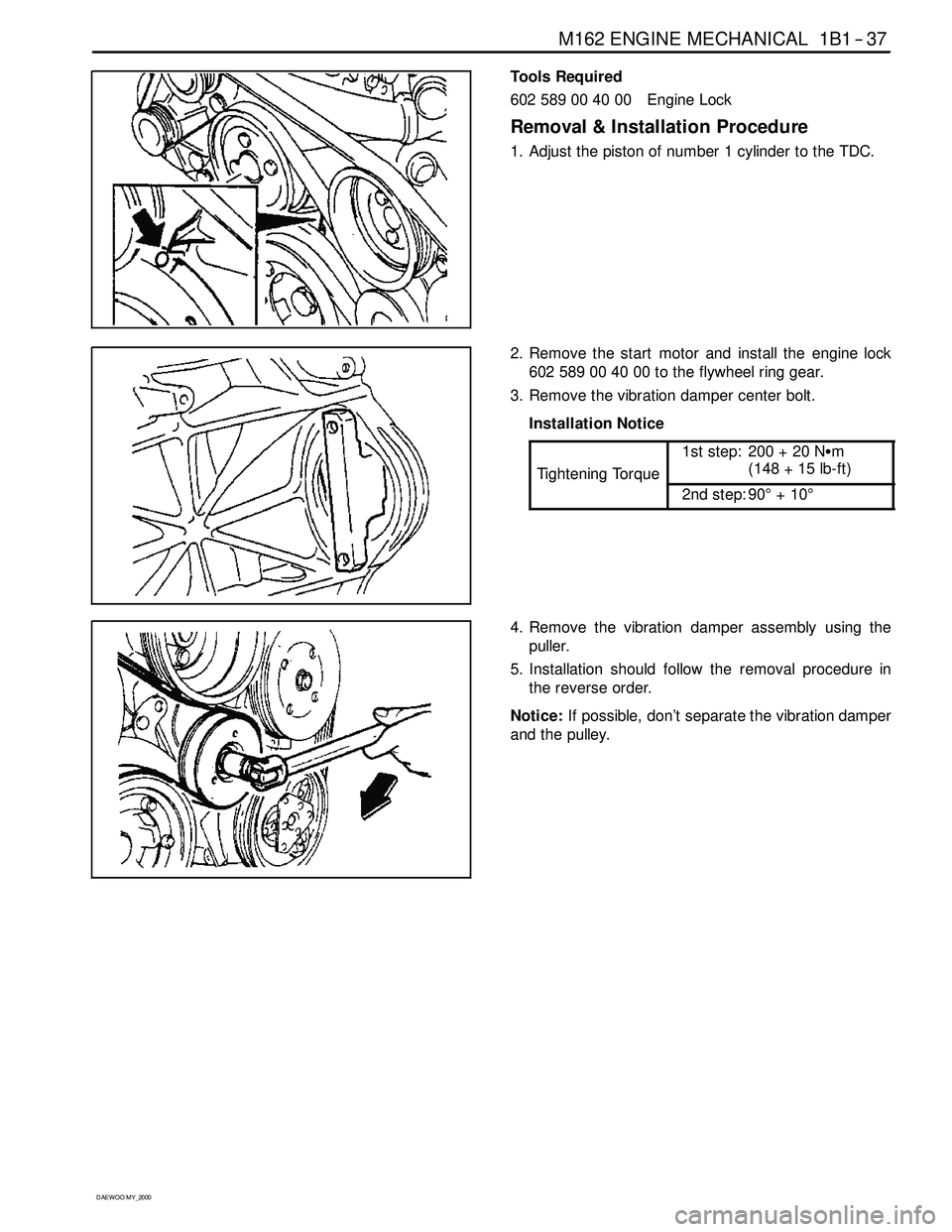

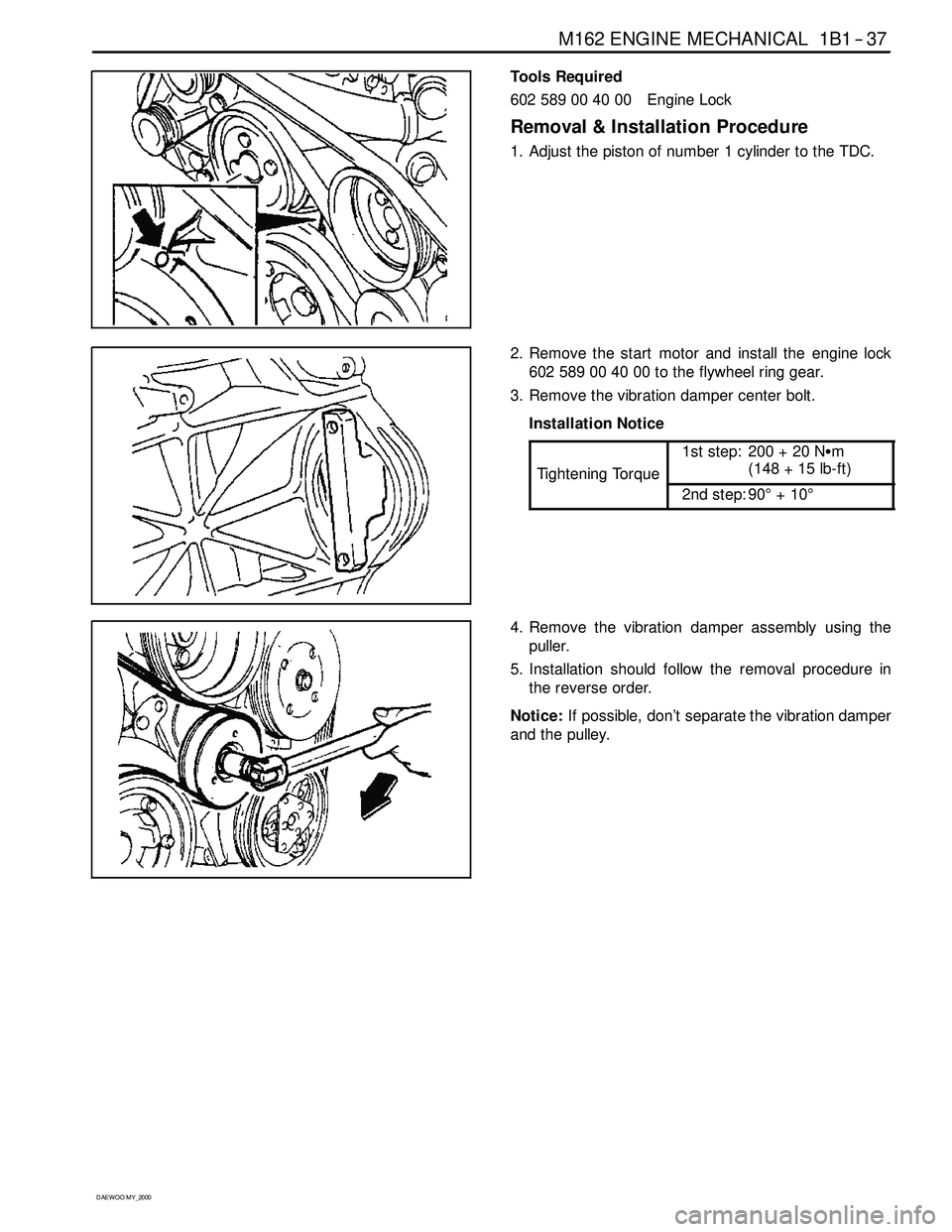

Tools Required

602589004000 EngineLock

Removal & Installation Procedure

1. Adjust the piston of number 1 cylinder to the TDC.

2. Remove the start motor and install the engine lock

602 589 00 40 00 to the flywheel ring gear.

3. Remove the vibration damper center bolt.

Installation Notice

Ti

ghteningTo rque

1st step: 200 + 20 NSm

(148 + 15 lb-ft)

TighteningTorque

2nd step: 90°+10°

4. Remove the vibration damper assembly using the

puller.

5. Installation should follow the removal procedure in

the reverse order.

Notice:If possible, don’t separate the vibration damper

and the pulley.

Page 70 of 2053

1B1 -- 38 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

CRANKSHAFT FRONT RADIAL SEAL

Preceding Work: Removal of belt pulley and vibration damper

1 Center Bolt (M18 x 50)

1st step 200+20 NSm (148+15 lb-ft) ..........

2nd step 90°+10°

2 Center Bolt Washer3 Crankshaft Front Seal Installer

4 Crankshaft Front Seal

5Key

Trending: change time, transmission, height adjustment, immobilizer, automatic transmission fluid, length, cruise control