SSANGYONG KORANDO 1997 Service Repair Manual

KORANDO 1997

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57502/w960_57502-0.png

SSANGYONG KORANDO 1997 Service Repair Manual

Trending: Throttle body, fuel pressure, mileage, fuel cap release, OBD port, dashboard, fuel cap

Page 941 of 2053

MASTER CYLINDER 4B-5

SSANGYONG MY2002

KAA4B060

4. Remove and discard the brake fluid reservoir seals

from the master cylinder body.

Installation Notice:

Lubricate the new brake fluid reservoir seals with

clean brake fluid.

After the installation, bleed the brake system.

Refer to Section 4F, Antilock Brake System and

Traction Control System.

5. Installation should follow the removal procedure

in the reverse order.

YAD4A340

YAD4A350

YAD4A360

3. Remove the master cylinder.

Retain the master cylinder in the vice and

remove the retainer ring from the master cylinder

using the snap ring plier. 2. Loosen the mounting nut of the master cylinder

and remove the master cylinder from the power

booster.

MASTER CYLINDER

Removal Procedure

1. Disconnect the brake lines from the master

cylinder.

Notice: The brake fluid may damage paintwork, if

spillage onto paintwork, wash with cold water

immediately.

Page 942 of 2053

SSANGYONG MY2002

4B-6 MASTER CYLINDER

YAD4A370

Remove the 1st piston and 2nd piston assembly

from the master cylinder assembly.

YAD4A380

YAD4A390

YAD4A400

Check the cylinder for excessive wear.

Notice:

Replace the cylinder assembly when there

occurs any damage or wear in the cylinder.

Clean the contaminated oil of the assembly.

Install the 1st piston and 2nd piston assembly

from the master cylinder assembly.

Installation Procedure

1. Install the retainer ring using the snap ring plier.

2. Install the master cylinder into the booster.

Installation Notice

Tightening Torque8 - 12 Nm

(71 - 106 lb-in)

Page 943 of 2053

SSANGYONG MY2002

4B-8 MASTER CYLINDER

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

13

16

18 Brake Lines Fitting (M10)

Brake Lines Fitting (M12)

Master Cylinder Mounting NuntsN•m Application

Lb-InLb-Ft

17

22

25-

-

-

Page 944 of 2053

Description and Operation....................................4C-2

General Description..............................................4C-2

Component Locator..............................................4C-3

Diagnostic Information and Procedures...............4C-4

Power Booster Functional Check..........................4C-4

Repair Instructions................................................4C-5On-Vehicle Service.................................................4C-5

Power Booster Assembly.....................................4C-5

Vacuum Hose......................................................4C-6

Specifications.......................................................4C-7

General Specification ...........................................4C-7

Fastener Tightening Specifications.......................4C-7

SECTION 4C

POWER BOOSTER

TABLE OF CONTENTS

Page 945 of 2053

SSANGYONG MY2002

4C-2 POWER BOOSTER

DESCRIPTION AND OPERATION

GENERAL DESCRIPTION

The power booster is a double-diaphragm, vacuum-sus

pended unit. In normal operating mode, with the service

brakes in the release position, a vacuum-suspended

booster operates with a vacuum on both sides of its

diaphragm. When the brakes are applied, air at

atmospheric pressure is admitted to one side of the

diaphragm to provide the power assist.When the brakes are released, atmospheric air is shut

off from that side of the diaphragm. The air is then

drawn from the booster through the vacuum check

valve by the vacuum source.

Important: If any hydraulic component is removed or

disconnected, it may be necessary to bleed all or part

of the brake system. Refer to Section 4F, Antilock

Brake System and Traction Control System.

Page 946 of 2053

POWER BOOSTER 4C-3

SSANGYONG MY2002

KAA4C080

COMPONENT LOCATOR

1 Brake Fluid Level Switch Connector

2 Brake Fluid Reservoir

3 Power Booster4 Brake Lines

(Master Cylinder-to-Hydraulic Modulator)

5 Master Cylinder

Page 947 of 2053

SSANGYONG MY2002

4C-4 POWER BOOSTER

DIAGNOSTIC INFORMATION AND PROCEDURES

KAA4C020

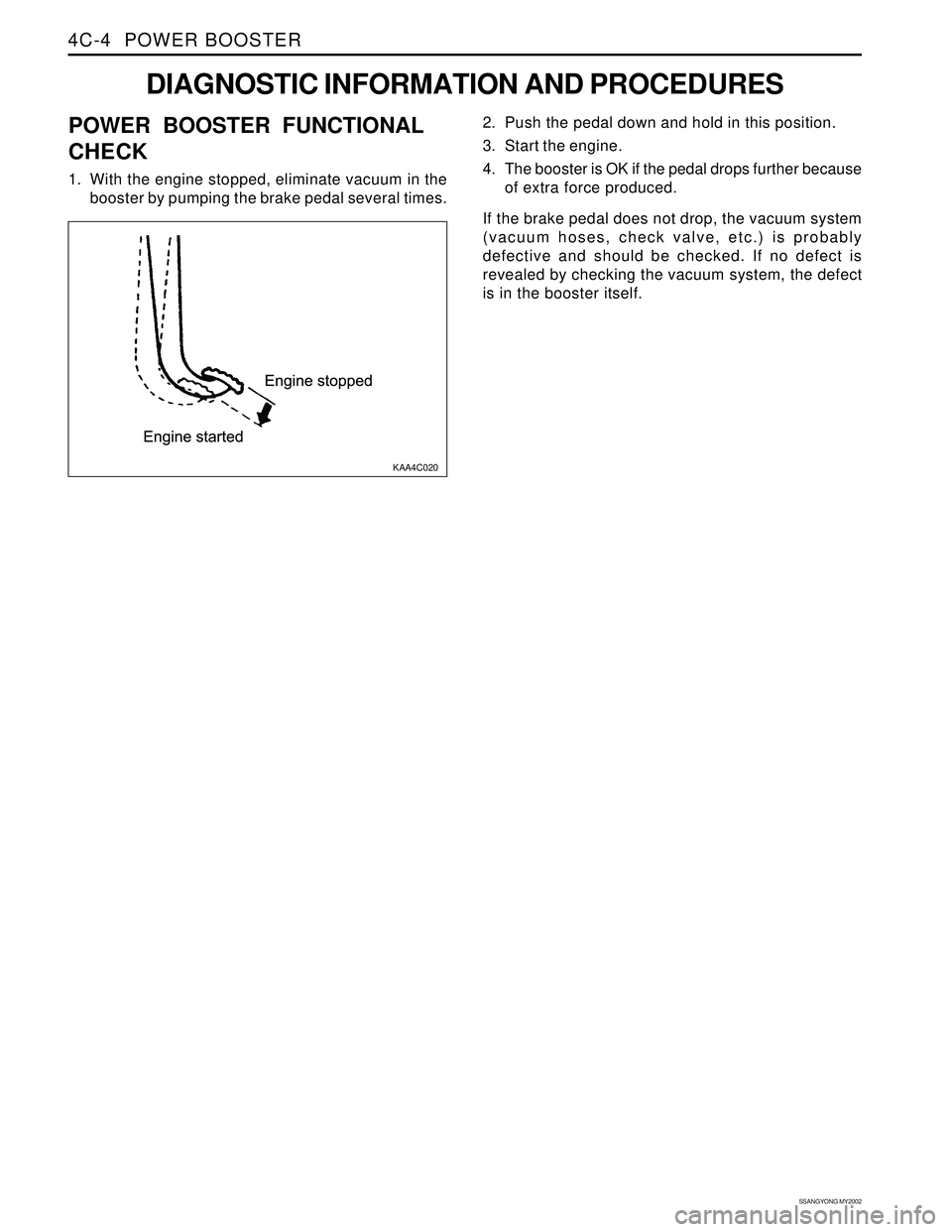

2. Push the pedal down and hold in this position.

3. Start the engine.

4. The booster is OK if the pedal drops further because

of extra force produced.

If the brake pedal does not drop, the vacuum system

(vacuum hoses, check valve, etc.) is probably

defective and should be checked. If no defect is

revealed by checking the vacuum system, the defect

is in the booster itself.POWER BOOSTER FUNCTIONAL

CHECK

1. With the engine stopped, eliminate vacuum in the

booster by pumping the brake pedal several times.

Page 948 of 2053

POWER BOOSTER 4C-5

SSANGYONG MY2002

REPAIR INSTRUCTIONS

KAA4C030

KAA4A040

KAA4C050

ON-VEHICLE SERVICE

POWER BOOSTER ASSEMBLY

Removal and Installation Procedure

1. Remove the master cylinder. Refer to Section 4B,

Master Cylinder.

2. Remove the vacuum hose from the booster.

3. Remove the clevis pin and disconnect the pedal

and brake booster push rod.

Installation Notice:

•Apply the grease around the hole of clevis pin.

4. Remove the power booster mounting nuts and re-

move the booster from the dash panel.

Installation Notice

Tightening Torque 17 Nm (13 lb-ft)

Install the new gasket.

5. Installation should follow the removal procedure

in the reverse order.

Page 949 of 2053

SSANGYONG MY2002

4C-6 POWER BOOSTER

3. Remove the vacuum hose from the booster.

4. Installation should follow the removal procedure in

the reverse order.

VACUUM HOSE

Removal and Installation Procedure

1. Remove the vacuum hose connection bolt to the

intake manifold.

Installation Notice

2. Remove the vacuum hose retaining bolt located

on the intake manifold.

Installation Notice

KAA4C060

KAA4C070

KAA4C030

Tightening Torque 40 Nm (30 lb-ft)

Tightening Torque 13 Nm (10 lb-ft)

Page 950 of 2053

POWER BOOSTER 4C-7

SSANGYONG MY2002

10

30

10 Power Booster Mounting Nuts

Vacuum Hose Connection Bolt

Vacuum Hose Retaining BoltN•m Application

Lb-In

FASTENER TIGHTENING SPECIFICATIONS

Lb-Ft

13

40

13-

-

-

SPECIFICATIONS

GENERAL SPECIFICATION

Application

Type

RetioDescription

Vacuum Assisted

5.6 : 1

Trending: transmission oil, load capacity, fuel filter, ABS, tire pressure, jump start, STARTER MOTOR