SSANGYONG KORANDO 1997 Service Repair Manual

Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 921 of 2053

SECTION 4A

HYDRAULIC BRAKES

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when

a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this

cable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK

unless otherwise noted.

TABLE OF CONTENTS

Description and Operation...................................4A-2

General Description.............................................4A-2

Diagnostic Information and Procedures..............4A-3

Brake System Testing ..........................................4A-3

Brake Hose Inspection.........................................4A-3

Brake Warning Lamp Circuit Description..............4A-4

Brake Warning Lamp Diagnosis...........................4A-5

LCRV (Load Conscious Reducing Valve)..............4A-8

Repair Instructions..............................................4A-10On-Vehicle Service...............................................4A-10

Manual Bleeding The Brakes.............................4A-10

Front Brake Hose...............................................4A-13

Rear Brake Hose...............................................4A-13

Stoplamp Switch................................................4A-14

Brake Pedal.......................................................4A-14

Specifications.....................................................4A-15

General Specification .........................................4A-15

Fastener Tightening Specifications.....................4A-16

Page 922 of 2053

SSAMGYONG MY2002

4A-2 HYDRAULIC BRAKES

DESCRIPTION AND OPERATION

GENERAL DESCRIPTION

Brake fluid should meet the DOT 4 specification. Use

only clear fluid from a sealed container.

Fluid that is exposed to the air will absorb moisture.

Water in the brake fluid will cause the fluid to boil and

the rubber components to deteriorate.

Thoroughly clean the master cylinder reservoir cap be-

fore removing it. Do not let any dirt or foreign material

fall into the fluid reservoir.

There is a brake fluid level switch under the master

cylinder reservoir.When the fluid level is low, the BRAKE lamp in the

instrument cluster will turn on.

The correct brake fluid level is marked on the both

side of the brake fluid reservoir. If the fluid level is

below the MIN indicator mark, check the hydraulic brake

system for leaks. Fix any leaks. Then refill the reservoir

to the MAX indicator mark.

The hydraulic brake system is parallel split on Antilock

Brake Systems. This means the left front and left rear

brakes are on one hydraulic circuit and the right front

and right rear are on the other.

Page 923 of 2053

HYDRAULIC BRAKES 4A-3

SSANGYONG MY2002

DIAGNOSTIC INFORMATION AND PROCEDURES

BRAKE SYSTEM TESTING

Brakes should be tested on a dry, clean, reasonably

smooth and level roadway. A true test of brake perfor-

mance cannot be made if the roadway is wet, greasy,

or covered with loose dirt which can cause tires not to

grip the road unequally. Testing also will be inaccurate

on a crowned roadway because the wheels tend to

bounce.

Test the brakes at different vehicle speeds with both

light-and heavy-pedal pressure; however, avoid locking

the brakes and sliding the tires. Locked brakes and

slid-ing tires do not indicate brake efficiency since

heavily braked but turning wheels will stop the vehicle

in less distance than locked brakes. More tire-to-road

friction is present with a heavily braked, turning tire

than with a sliding tire.

Because of the high deceleration capability, a firmer

pedal may be felt at higher deceleration levels.

There are three major external conditions that affect

brake performance:

•Tires having unequal contact and grip of the road

will cause unequal braking. Tires must be equally

inflated, and the tread pattern of the right and the

left tires must be approximately equal.

Unequal loading of the vehicle can affect the brake

performance since the most heavily loaded wheels

require more braking power, and thus more braking

effort, than the others.

Misalignment of the wheels, particularly conditions

of excessive camber and caster, will cause the

brakes to pull to one side.

To check for brake fluid leaks, hold constant foot pres-

sure on the pedal with the engine running at idle and

the shift lever in NEUTRAL. If the pedal gradually falls

away with the constant pressure, the hydraulic system

may be leaking. Perform a visual check to confirm any

suspected leaks.

Check the master cylinder fluid level. While a slight

drop in the reservoir level results from normal lining

wear, an abnormally low level indicates a leak in the

system. The hydraulic system may be leaking either

internally or externally. Refer to the procedure below

to check the master cylinder. The system may appear

to pass this test while still having a slight leak. If the

fluid level is normal, check the vacuum booster pushrod

length. If an incorrect pushrod length is found, adjust

or replace the rod.Check the master cylinder using the following proce

dure:

Check for a cracked master cylinder casting or a

brake fluid leak around the master cylinder. Leaks

are indicated only if there is at least one drop of

fluid. A damp condition is not abnormal.

Check for a binding pedal linkage and for an

incorrect pushrod length. If both of these parts are

in satisfactory condition, disassemble the master

cylinder and check for an elongated or swollen

primary cylinder or piston seals. If swollen seals

are found, substandard or contaminated brake fluid

should be suspected. If contaminated brake fluid

is found, all the components should be

disassembled and cleaned, and all the rubber

components should be replaced. All of the pipes

must also be flushed.

Improper brake fluid, or mineral oil or water in the fluid,

may cause the brake fluid to boil or cause deterioration

of the rubber components. If the primary piston cups in

the master cylinder are swollen, the rubber parts have

deteriorated.

If deterioration of the rubber is evident, disassemble

all the hydraulic parts and wash the parts with alcohol.

Dry these parts with compressed air before reassembly

to keep the alcohol out of the system. Replace all the

rubber parts in the system, including the hoses. When

working on the brake mechanisms, check for fluid on

the linings. If excessive fluid is found, replace the

linings.

If the master cylinder piston seals are in satisfactory

condition, check for leaks or excessive heat conditions.

If these conditions are not found, drain the fluid, flush

the master cylinder with brake fluid, refill the master

cylinder, and bleed the system.

BRAKE HOSE INSPECTION

The hydraulic brake hoses should be inspected at least

twice a year. The brake hose assembly should be

checked for road hazard damage, cracks, chafing of

the outer cover, and for leaks or blisters. Inspect the

hoses for proper routing and mounting. A brake hose

that rubs on a suspension component will wear and

eventually fail. A light and a mirror may be needed for

an adequate inspection. If any of the above conditions

are observed on the brake hose, adjust or replace the

hose as necessary.

Page 924 of 2053

SSAMGYONG MY2002

4A-4 HYDRAULIC BRAKES

KAA4A010

BRAKE WARNING LAMP CIRCUIT DESCRIPTION

Diagnostic Aids

The BRAKE lamp glows brightly when the ignition is

ON and either the parking brake lever switch or the

brake fluid level switch is closed.

If neither switch is closed, the BRAKE lamp receives

a ground through the generator, and it glows dimly

when the ignition is ON and the engine is off. When

the engine starts, the generator creates voltage. With

voltage on both sides of the lamp, the lamp turns off.

Test Description

The numbers below refer to steps in the diagnostic

table.

1. This step begins the test sequence for a BRAKE

warning lamp that stays on when the engine is run-

ning.

2. This step begins the test sequence for a BRAKE

warning lamp that never turns on.

Page 925 of 2053

HYDRAULIC BRAKES 4A-5

SSANGYONG MY2002

Value(s)

-

-

-

-

-

-

-

-

-

-

-

-

-

-

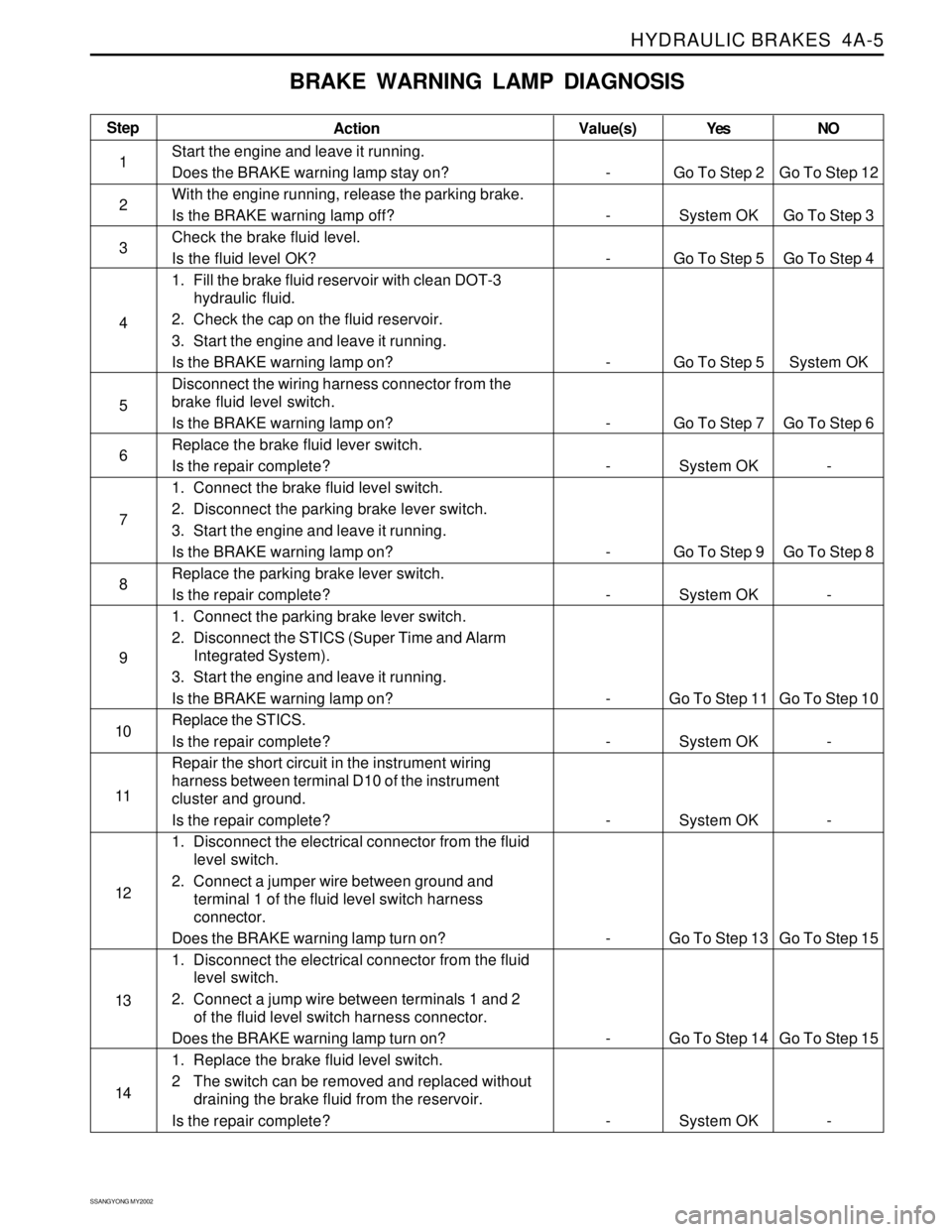

BRAKE WARNING LAMP DIAGNOSIS

Step

1

2

3

4

5

6

7

8

9

10

11

12

13

14Action

Start the engine and leave it running.

Does the BRAKE warning lamp stay on?

With the engine running, release the parking brake.

Is the BRAKE warning lamp off?

Check the brake fluid level.

Is the fluid level OK?

1. Fill the brake fluid reservoir with clean DOT-3

hydraulic fluid.

2. Check the cap on the fluid reservoir.

3. Start the engine and leave it running.

Is the BRAKE warning lamp on?

Disconnect the wiring harness connector from the

brake fluid level switch.

Is the BRAKE warning lamp on?

Replace the brake fluid lever switch.

Is the repair complete?

1. Connect the brake fluid level switch.

2. Disconnect the parking brake lever switch.

3. Start the engine and leave it running.

Is the BRAKE warning lamp on?

Replace the parking brake lever switch.

Is the repair complete?

1. Connect the parking brake lever switch.

2. Disconnect the STICS (Super Time and Alarm

Integrated System).

3. Start the engine and leave it running.

Is the BRAKE warning lamp on?

Replace the STICS.

Is the repair complete?

Repair the short circuit in the instrument wiring

harness between terminal D10 of the instrument

cluster and ground.

Is the repair complete?

1. Disconnect the electrical connector from the fluid

level switch.

2. Connect a jumper wire between ground and

terminal 1 of the fluid level switch harness

connector.

Does the BRAKE warning lamp turn on?

1. Disconnect the electrical connector from the fluid

level switch.

2. Connect a jump wire between terminals 1 and 2

of the fluid level switch harness connector.

Does the BRAKE warning lamp turn on?

1. Replace the brake fluid level switch.

2 The switch can be removed and replaced without

draining the brake fluid from the reservoir.

Is the repair complete?Yes

Go To Step 2

System OK

Go To Step 5

Go To Step 5

Go To Step 7

System OK

Go To Step 9

System OK

Go To Step 11

System OK

System OK

Go To Step 13

Go To Step 14

System OKNO

Go To Step 12

Go To Step 3

Go To Step 4

System OK

Go To Step 6

-

Go To Step 8

-

Go To Step 10

-

-

Go To Step 15

Go To Step 15

-

Page 926 of 2053

SSAMGYONG MY2002

4A-6 HYDRAULIC BRAKES

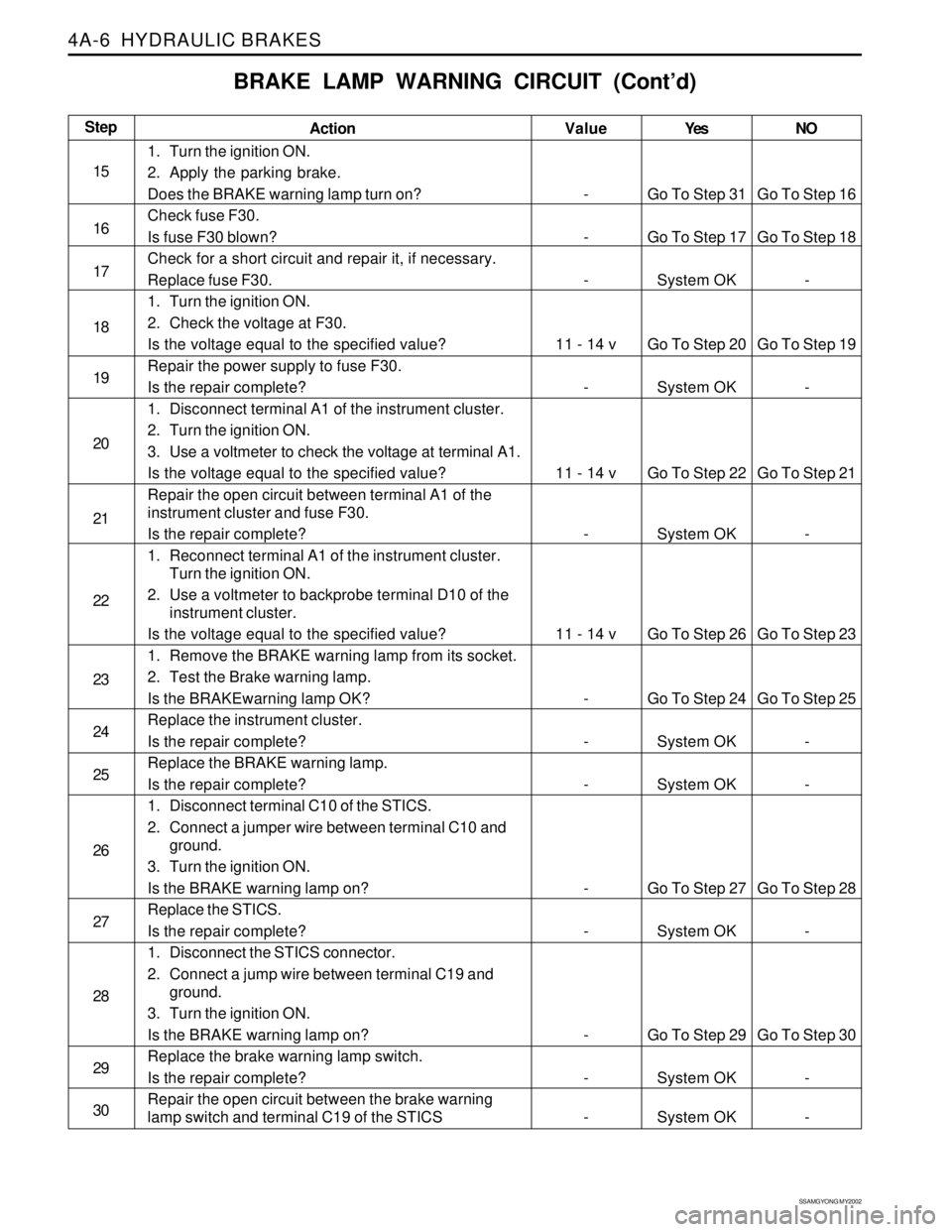

Action

1. Turn the ignition ON.

2. Apply the parking brake.

Does the BRAKE warning lamp turn on?

Check fuse F30.

Is fuse F30 blown?

Check for a short circuit and repair it, if necessary.

Replace fuse F30.

1. Turn the ignition ON.

2. Check the voltage at F30.

Is the voltage equal to the specified value?

Repair the power supply to fuse F30.

Is the repair complete?

1. Disconnect terminal A1 of the instrument cluster.

2. Turn the ignition ON.

3. Use a voltmeter to check the voltage at terminal A1.

Is the voltage equal to the specified value?

Repair the open circuit between terminal A1 of the

instrument cluster and fuse F30.

Is the repair complete?

1. Reconnect terminal A1 of the instrument cluster.

Turn the ignition ON.

2. Use a voltmeter to backprobe terminal D10 of the

instrument cluster.

Is the voltage equal to the specified value?

1. Remove the BRAKE warning lamp from its socket.

2. Test the Brake warning lamp.

Is the BRAKEwarning lamp OK?

Replace the instrument cluster.

Is the repair complete?

Replace the BRAKE warning lamp.

Is the repair complete?

1. Disconnect terminal C10 of the STICS.

2. Connect a jumper wire between terminal C10 and

ground.

3. Turn the ignition ON.

Is the BRAKE warning lamp on?

Replace the STICS.

Is the repair complete?

1. Disconnect the STICS connector.

2. Connect a jump wire between terminal C19 and

ground.

3. Turn the ignition ON.

Is the BRAKE warning lamp on?

Replace the brake warning lamp switch.

Is the repair complete?

Repair the open circuit between the brake warning

lamp switch and terminal C19 of the STICS

BRAKE LAMP WARNING CIRCUIT (Cont’d)

Yes

Go To Step 31

Go To Step 17

System OK

Go To Step 20

System OK

Go To Step 22

System OK

Go To Step 26

Go To Step 24

System OK

System OK

Go To Step 27

System OK

Go To Step 29

System OK

System OKNO

Go To Step 16

Go To Step 18

-

Go To Step 19

-

Go To Step 21

-

Go To Step 23

Go To Step 25

-

-

Go To Step 28

-

Go To Step 30

-

-Step

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30Value

-

-

-

11 - 14 v

-

11 - 14 v

-

11 - 14 v

-

-

-

-

-

-

-

-

Page 927 of 2053

HYDRAULIC BRAKES 4A-7

SSANGYONG MY2002

BRAKE LAMP WARNING CIRCUIT (Cont’d)

Action

1. Disconnect the brake fluid level switch.

2. Use an ohmmeter to check the resistance between

terminal 2 of the switch connector and ground.

Is the resistance equal to the specified value?

Repair the open circuit between ground and the brake

fluid level switch.

Is the repair complete?

Repair the open circuit between terminal 1 of the brake

fluid level switch and terminal D10 of the instrument

cluster.

Is the repair complete?Yes

Go To Step 32

System OK

System OKNO

Go To Step 33

-

-Step

31

32

33Value(s)

≈ 0 Ω

-

-

Page 928 of 2053

SSAMGYONG MY2002

4A-8 HYDRAULIC BRAKES

YAD4A170

YAD4A180

LCRV (LOAD CONSCIOUS

REDUCING VALVE)

LCRV consists of sensing part and hydraulic control

part.

1. Sensing Part

It detects the changes of vehicle height caused

by vehicle load. It consists of load sensing spring

and control lever which change according to

vehicle load.

2. Hydraulic Control Part

It consists of valve stem devices which controls

hydraulic pressure according to load detected by

sensing part.

YAD4A190

4. Place alignment marks between the lock nut (b)

and adjusting screw (c) after the valve setting.

5. LCRV setting should be performed with unloaded

vehicle condition.

Setting Method

1. Install the connecting rod (a) to the No.1 hole.

2. Adjust the clearance “X” to be 0mm and tighten

the bolt (c) using the lock nut (b).

Installation Notice

Tightening Torque14 - 18 Nm

(10 - 13 lb-ft)

3. Remove the connecting rod (a) from the No.1 hole

and reinstall it to the No.2 hole.

Installation Notice

Tightening Torque14 - 18 Nm

(10 - 13 lb-ft)

Page 929 of 2053

HYDRAULIC BRAKES 4A-9

SSANGYONG MY2002

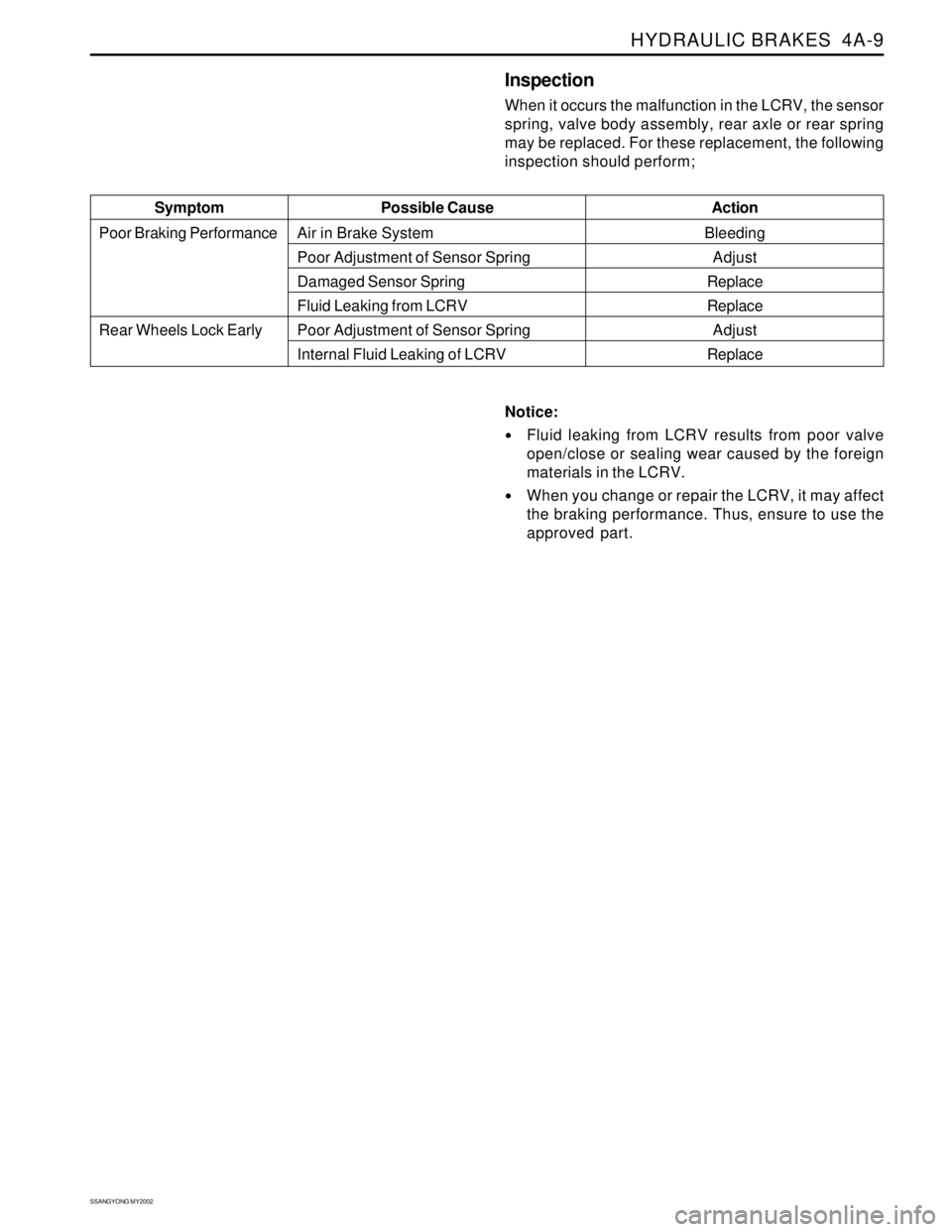

Inspection

When it occurs the malfunction in the LCRV, the sensor

spring, valve body assembly, rear axle or rear spring

may be replaced. For these replacement, the following

inspection should perform;

Symptom

Poor Braking Performance

Rear Wheels Lock EarlyPossible Cause

Air in Brake System

Poor Adjustment of Sensor Spring

Damaged Sensor Spring

Fluid Leaking from LCRV

Poor Adjustment of Sensor Spring

Internal Fluid Leaking of LCRVAction

Bleeding

Adjust

Replace

Replace

Adjust

Replace

Notice:

Fluid leaking from LCRV results from poor valve

open/close or sealing wear caused by the foreign

materials in the LCRV.

When you change or repair the LCRV, it may affect

the braking performance. Thus, ensure to use the

approved part.

Page 930 of 2053

SSAMGYONG MY2002

4A-10 HYDRAULIC BRAKES

KAA4A020

KAA4A030

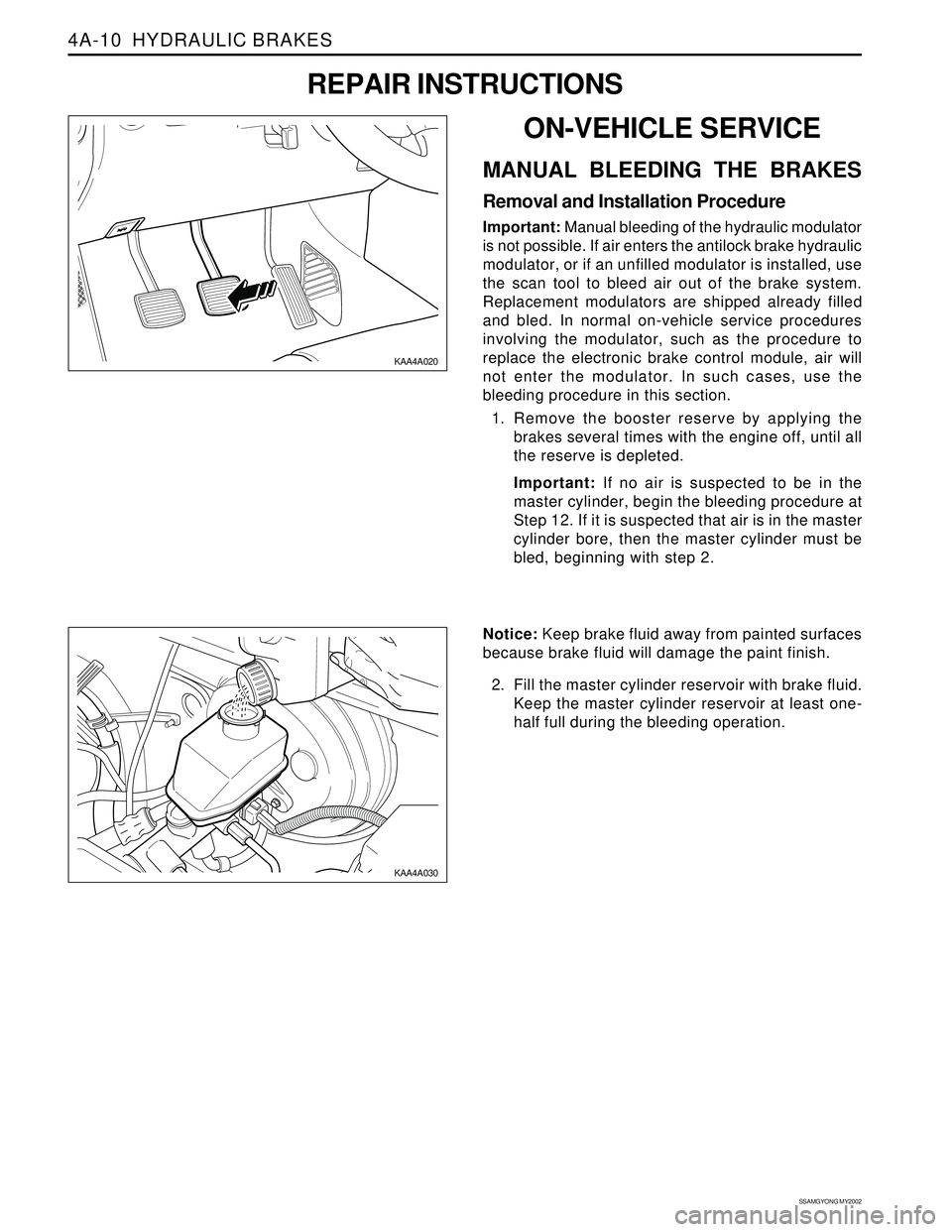

Notice: Keep brake fluid away from painted surfaces

because brake fluid will damage the paint finish.

2. Fill the master cylinder reservoir with brake fluid.

Keep the master cylinder reservoir at least one-

half full during the bleeding operation.

ON-VEHICLE SERVICE

MANUAL BLEEDING THE BRAKES

Removal and Installation Procedure

Important: Manual bleeding of the hydraulic modulator

is not possible. If air enters the antilock brake hydraulic

modulator, or if an unfilled modulator is installed, use

the scan tool to bleed air out of the brake system.

Replacement modulators are shipped already filled

and bled. In normal on-vehicle service procedures

involving the modulator, such as the procedure to

replace the electronic brake control module, air will

not enter the modulator. In such cases, use the

bleeding procedure in this section.

1. Remove the booster reserve by applying the

brakes several times with the engine off, until all

the reserve is depleted.

Important: If no air is suspected to be in the

master cylinder, begin the bleeding procedure at

Step 12. If it is suspected that air is in the master

cylinder bore, then the master cylinder must be

bled, beginning with step 2.

REPAIR INSTRUCTIONS