SSANGYONG MUSSO 1998 Workshop Repair Manual

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Repair Manual

Trending: check engine light, drain bolt, ABS, height, wipers, relay, wheel torque

Page 1091 of 1463

5A-114 AUTOMATIC TRANSMISSION

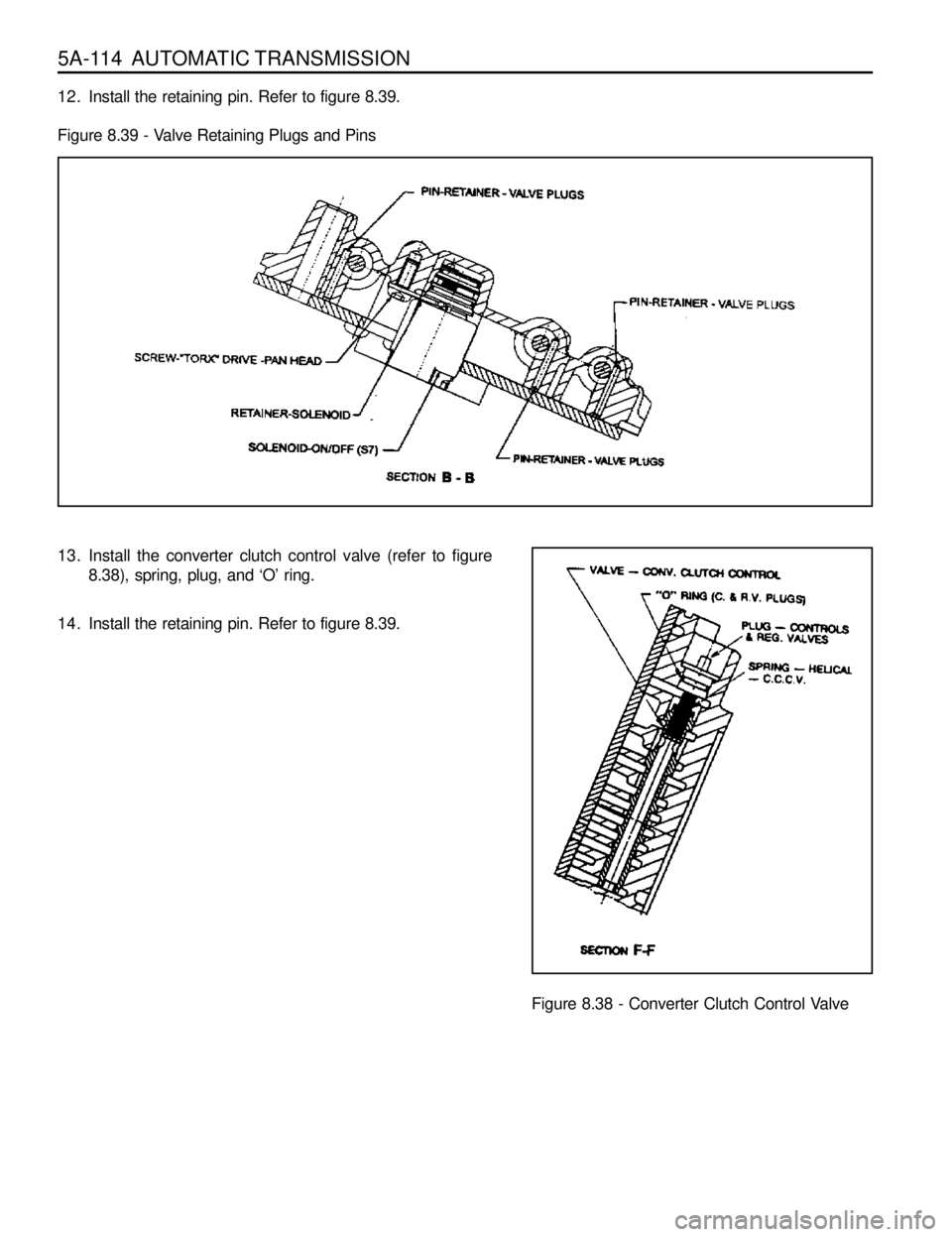

13. Install the converter clutch control valve (refer to figure

8.38), spring, plug, and ‘O’ ring.

14. Install the retaining pin. Refer to figure 8.39.

Figure 8.39 - Valve Retaining Plugs and Pins

Figure 8.38 - Converter Clutch Control Valve 12. Install the retaining pin. Refer to figure 8.39.

Page 1092 of 1463

AUTOMATIC TRANSMISSION 5A-115

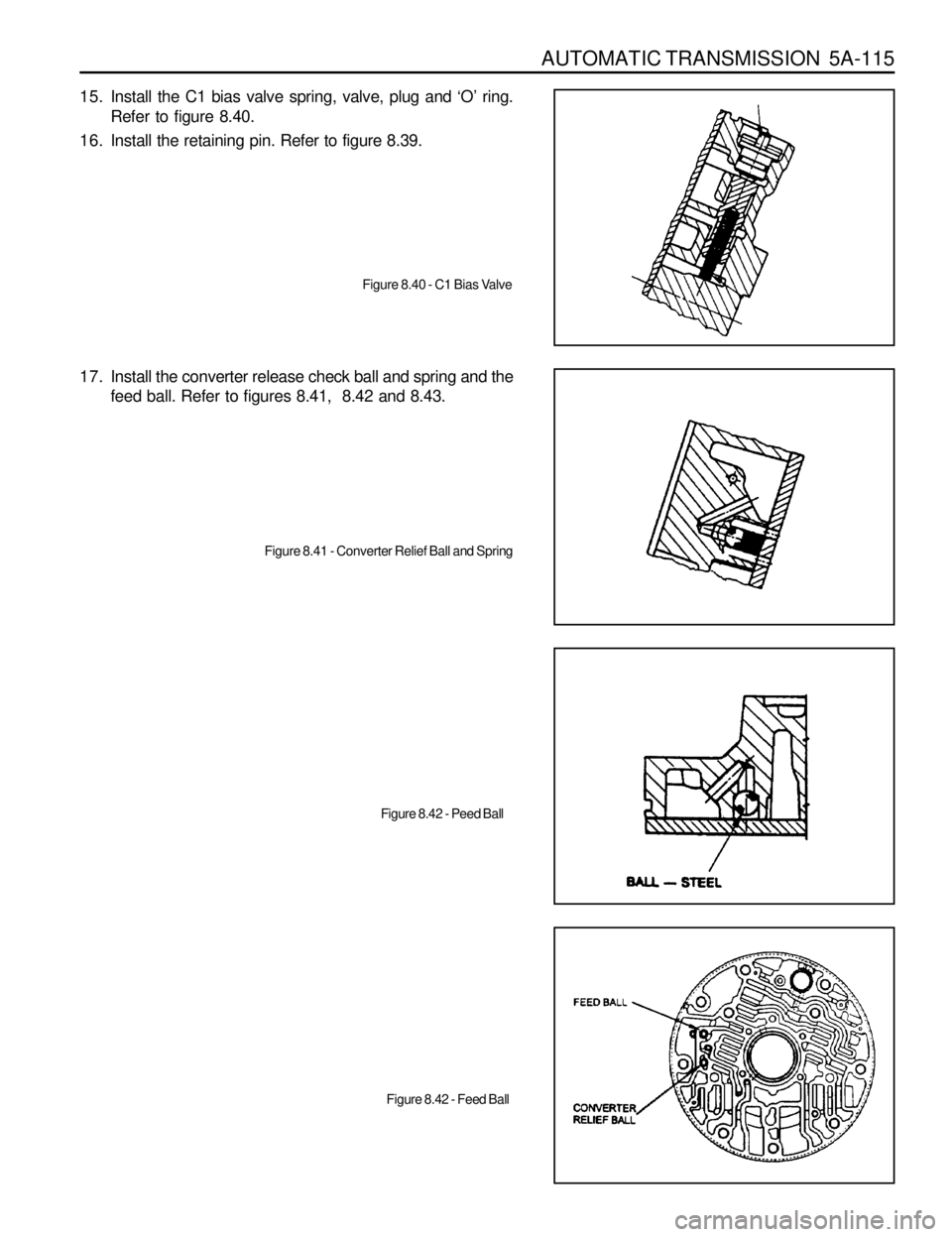

15. Install the C1 bias valve spring, valve, plug and ‘O’ ring.

Refer to figure 8.40.

16. Install the retaining pin. Refer to figure 8.39.

17. Install the converter release check ball and spring and the

feed ball. Refer to figures 8.41, 8.42 and 8.43.

Figure 8.40 - C1 Bias Valve

Figure 8.41 - Converter Relief Ball and Spring

Figure 8.42 - Peed Ball

Figure 8.42 - Feed Ball

Page 1093 of 1463

5A-116 AUTOMATIC TRANSMISSION

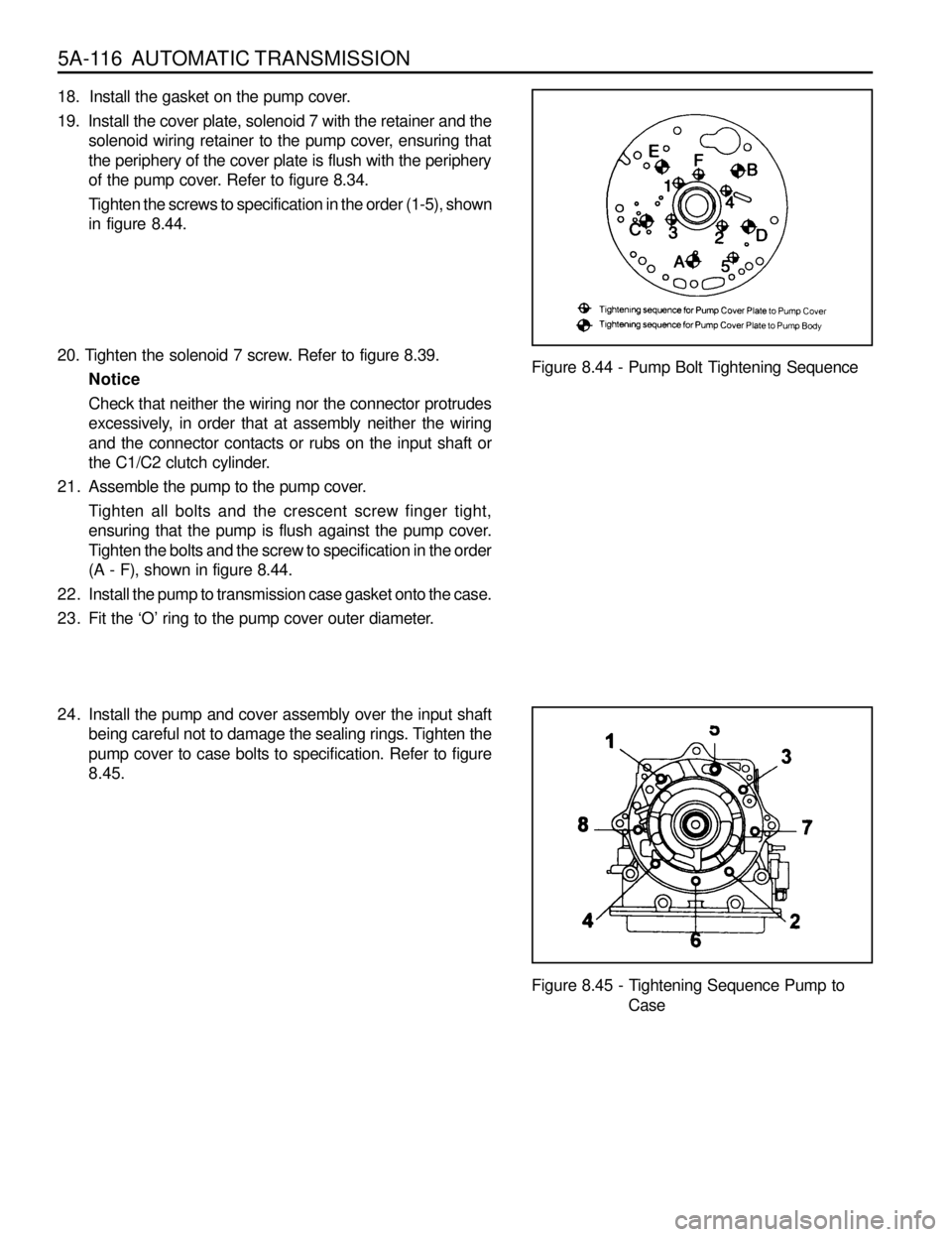

18. Install the gasket on the pump cover.

19. Install the cover plate, solenoid 7 with the retainer and the

solenoid wiring retainer to the pump cover, ensuring that

the periphery of the cover plate is flush with the periphery

of the pump cover. Refer to figure 8.34.

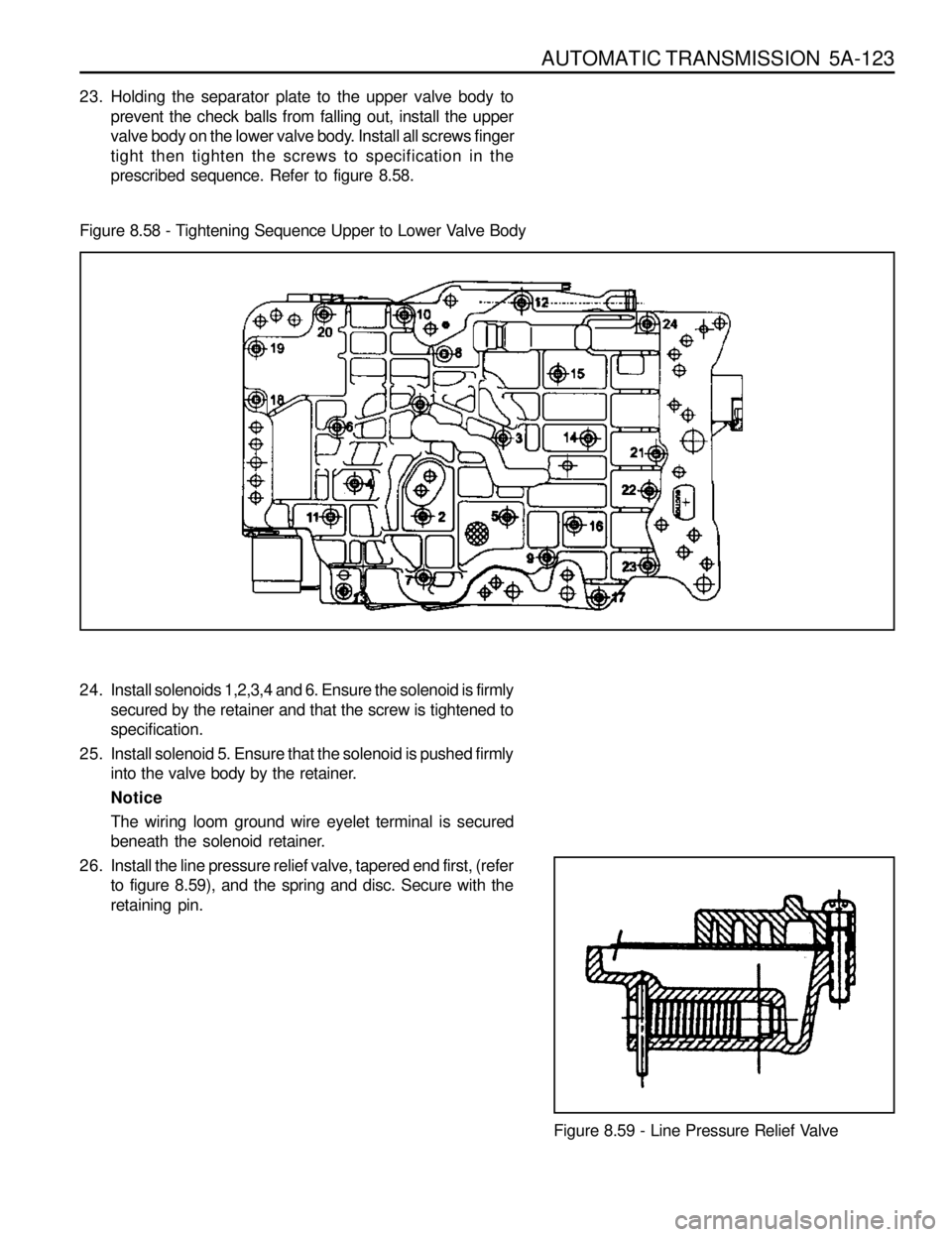

Tighten the screws to specification in the order (1-5), shown

in figure 8.44.

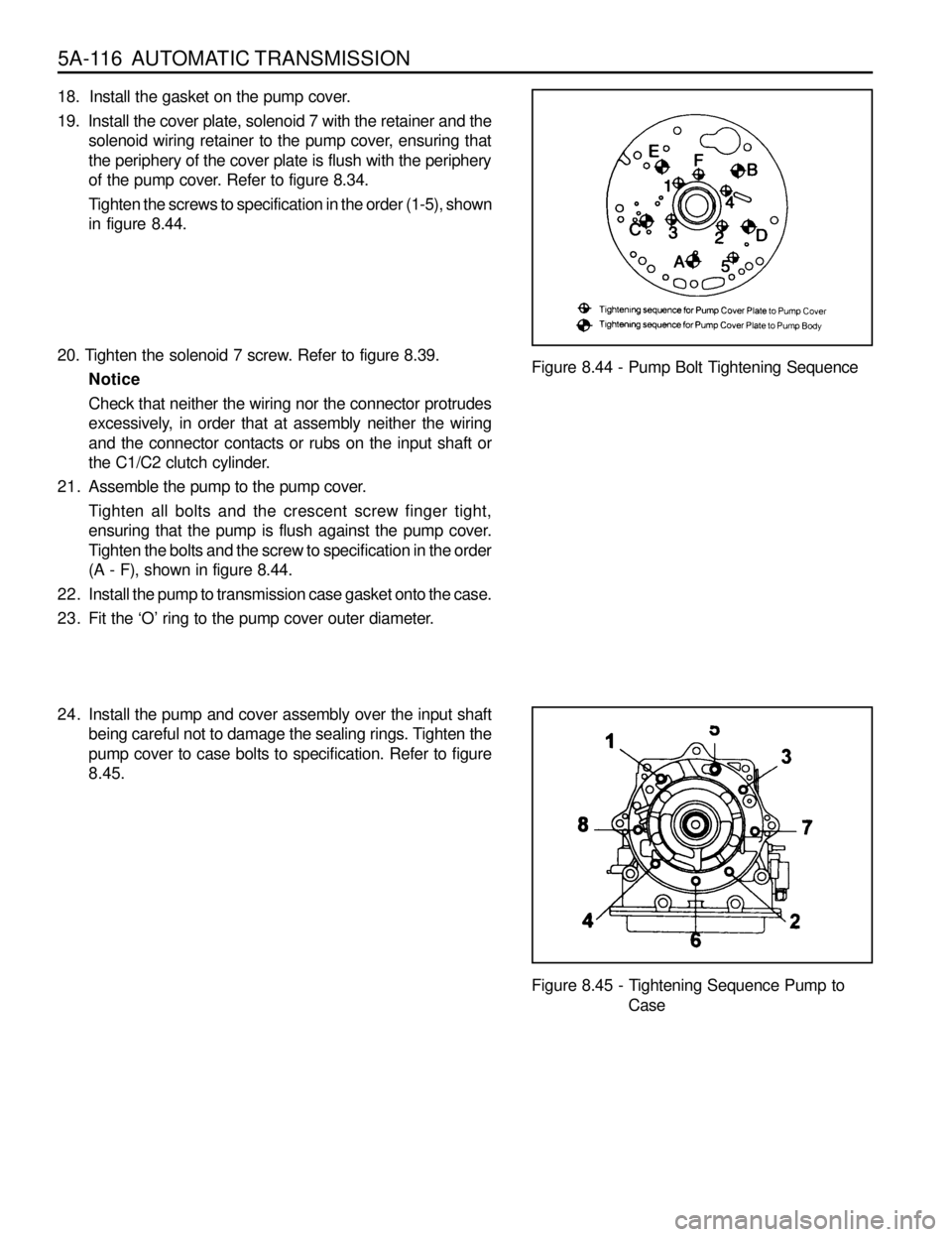

24. Install the pump and cover assembly over the input shaft

being careful not to damage the sealing rings. Tighten the

pump cover to case bolts to specification. Refer to figure

8.45. 20. Tighten the solenoid 7 screw. Refer to figure 8.39.

Notice

Check that neither the wiring nor the connector protrudes

excessively, in order that at assembly neither the wiring

and the connector contacts or rubs on the input shaft or

the C1/C2 clutch cylinder.

21. Assemble the pump to the pump cover.

Tighten all bolts and the crescent screw finger tight,

ensuring that the pump is flush against the pump cover.

Tighten the bolts and the screw to specification in the order

(A - F), shown in figure 8.44.

22. Install the pump to transmission case gasket onto the case.

23. Fit the ‘O’ ring to the pump cover outer diameter.Figure 8.44 - Pump Bolt Tightening Sequence

Figure 8.45 - Tightening Sequence Pump to

Case

Page 1094 of 1463

AUTOMATIC TRANSMISSION 5A-117

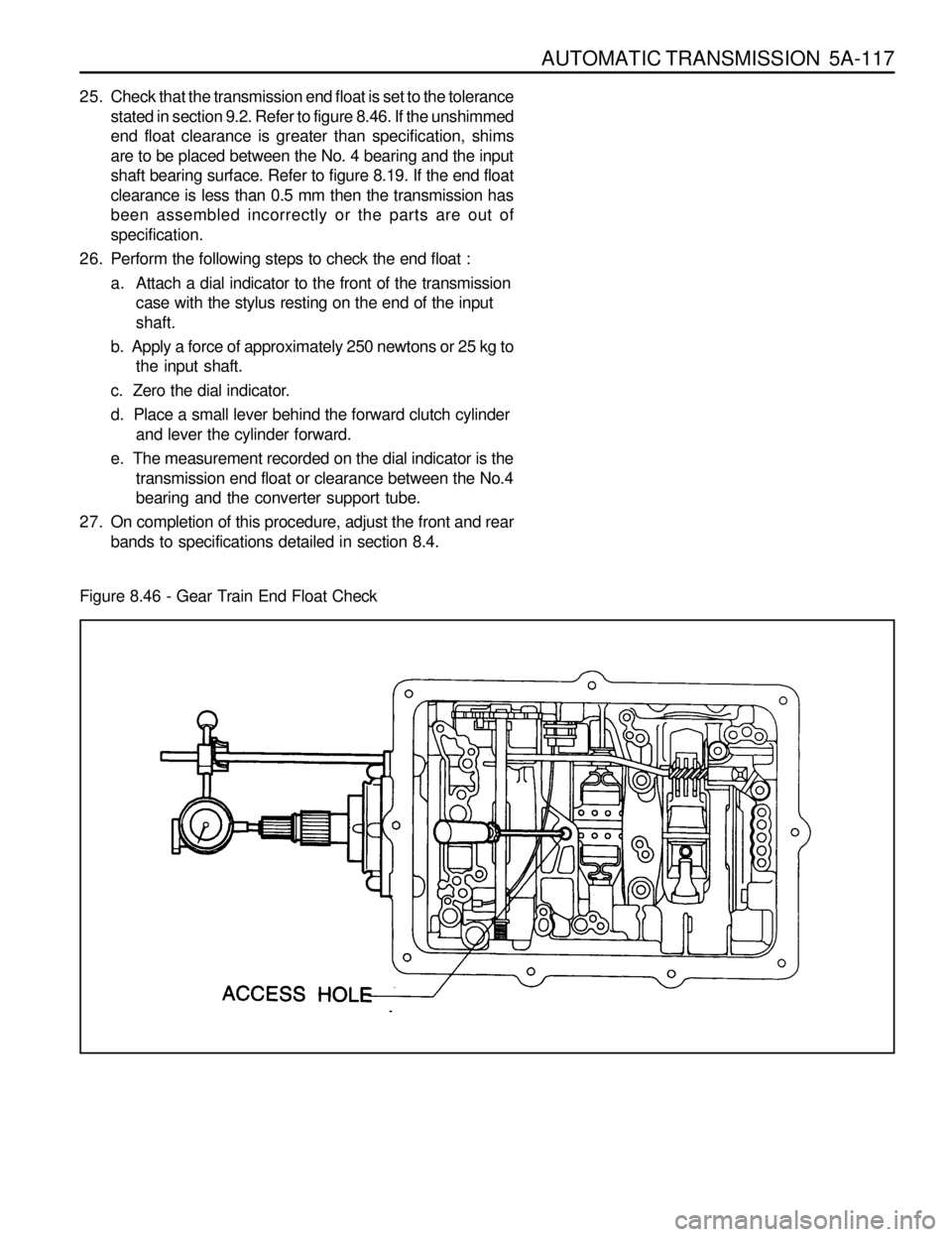

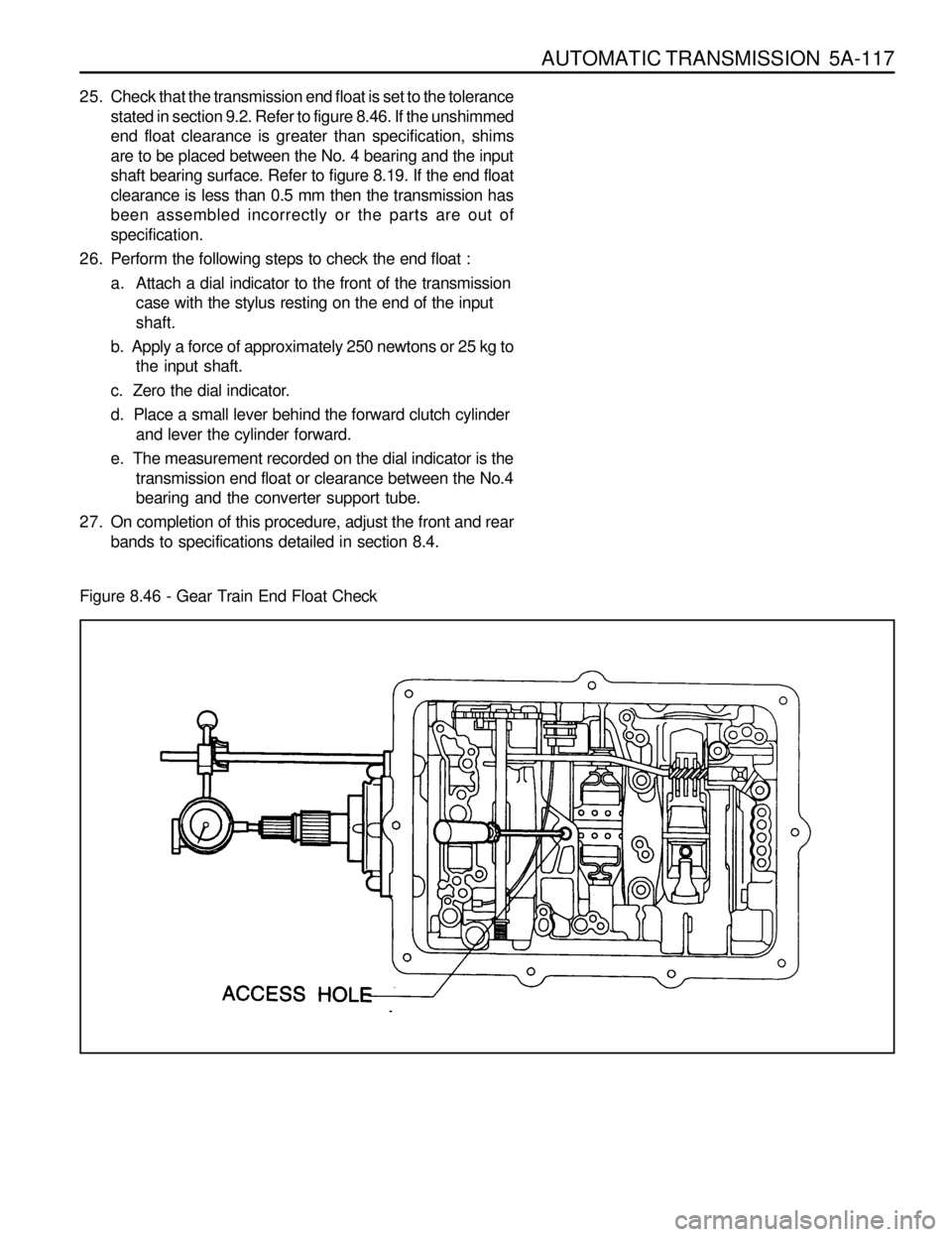

25. Check that the transmission end float is set to the tolerance

stated in section 9.2. Refer to figure 8.46. If the unshimmed

end float clearance is greater than specification, shims

are to be placed between the No. 4 bearing and the input

shaft bearing surface. Refer to figure 8.19. If the end float

clearance is less than 0.5 mm then the transmission has

been assembled incorrectly or the parts are out of

specification.

26. Perform the following steps to check the end float :

a. Attach a dial indicator to the front of the transmission

case with the stylus resting on the end of the input

shaft.

b. Apply a force of approximately 250 newtons or 25 kg to

the input shaft.

c. Zero the dial indicator.

d. Place a small lever behind the forward clutch cylinder

and lever the cylinder forward.

e. The measurement recorded on the dial indicator is the

transmission end float or clearance between the No.4

bearing and the converter support tube.

27. On completion of this procedure, adjust the front and rear

bands to specifications detailed in section 8.4.

Figure 8.46 - Gear Train End Float Check

Page 1095 of 1463

5A-118 AUTOMATIC TRANSMISSION

Valve Bodies

Notice

1. Do not wash the nose of solenoids in solvent.

2. Be aware of ball positions in the upper valve body.

3. Be aware of 1-2 and 3-4 shift valve positions, they can be

swapped.

4. Check the 4-3 sequence valve and spring orientation.

5. Check that the 12 mm ball is in the lower body.

6. Do not mix up the low first blow-off and the torque converter

blow-off ball springs.

7. Check the line pressure relief valve for swarf, and be aware

of replacing the shims.

8. The orifices in the valve body are for stability and safeguard;

do not drill them any larger.

9. When servicing the transmission, ensure that the solenoid

5 damper spring is not broken.

10. Locate the detent spring central to the detent lever.

To assemble the valve bodies, proceed as follows.

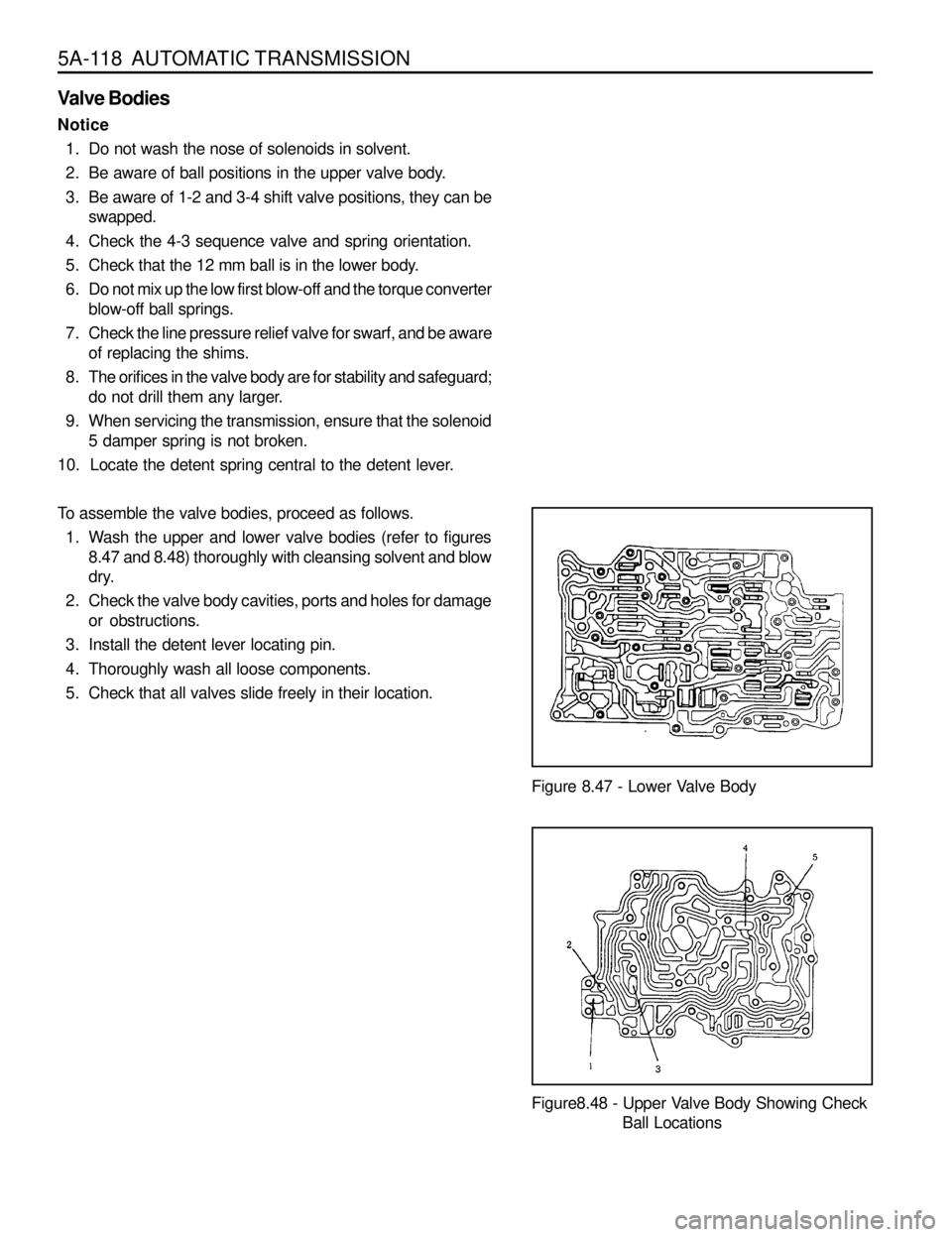

1. Wash the upper and lower valve bodies (refer to figures

8.47 and 8.48) thoroughly with cleansing solvent and blow

dry.

2. Check the valve body cavities, ports and holes for damage

or obstructions.

3. Install the detent lever locating pin.

4. Thoroughly wash all loose components.

5. Check that all valves slide freely in their location.

Figure 8.47 - Lower Valve Body

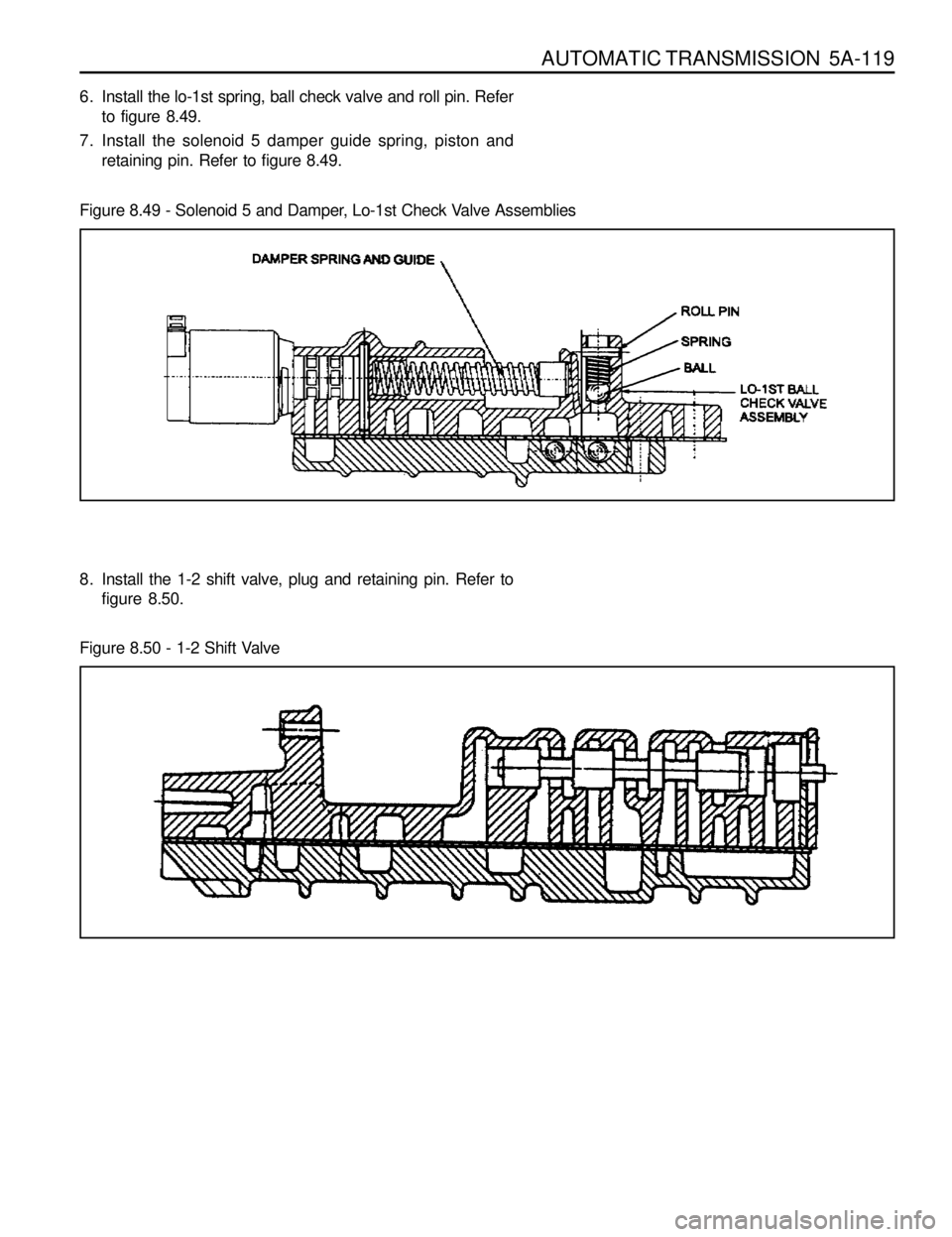

Figure8.48 - Upper Valve Body Showing Check

Ball Locations

Page 1096 of 1463

AUTOMATIC TRANSMISSION 5A-119

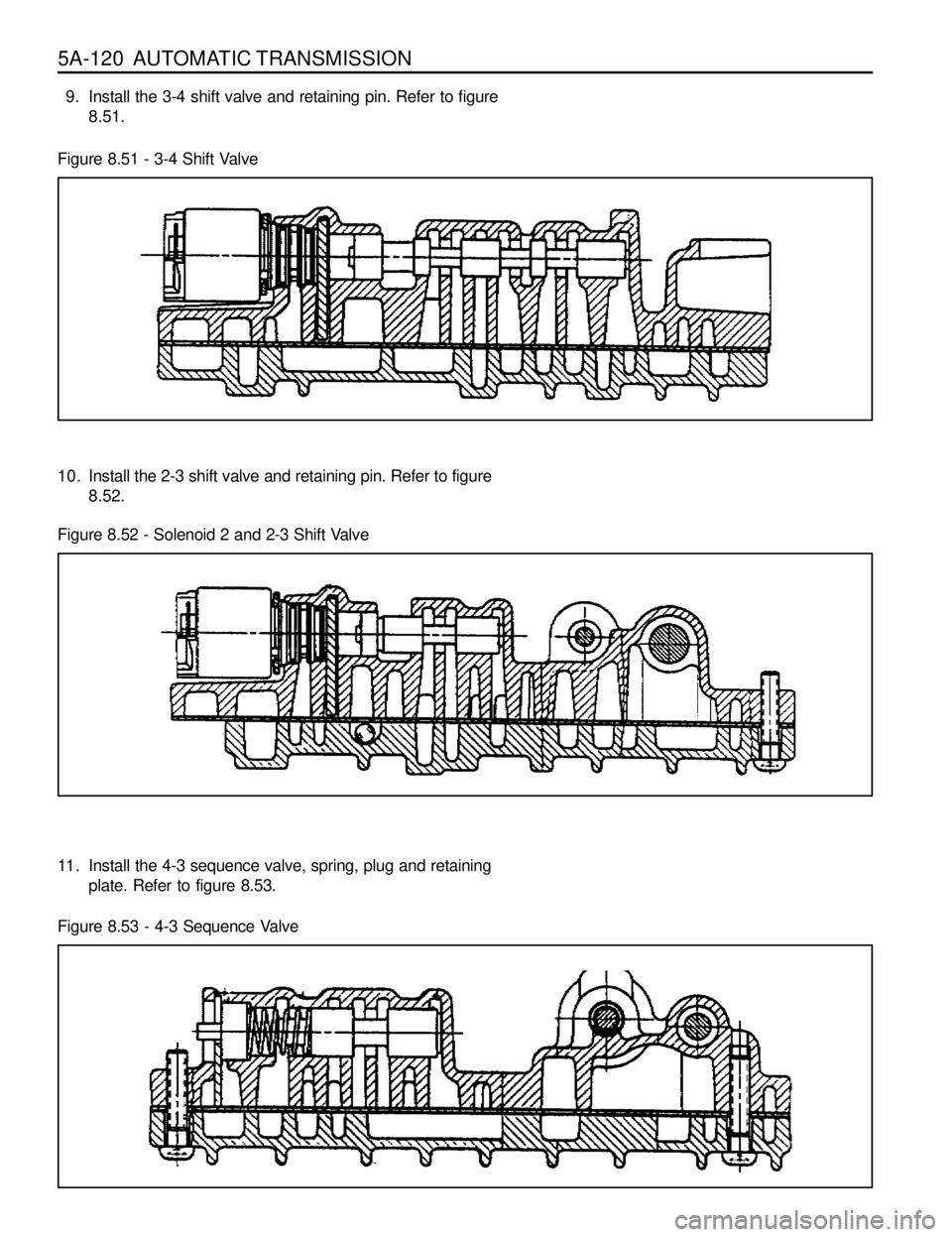

6. Install the lo-1st spring, ball check valve and roll pin. Refer

to figure 8.49.

7. Install the solenoid 5 damper guide spring, piston and

retaining pin. Refer to figure 8.49.

Figure 8.49 - Solenoid 5 and Damper, Lo-1st Check Valve Assemblies

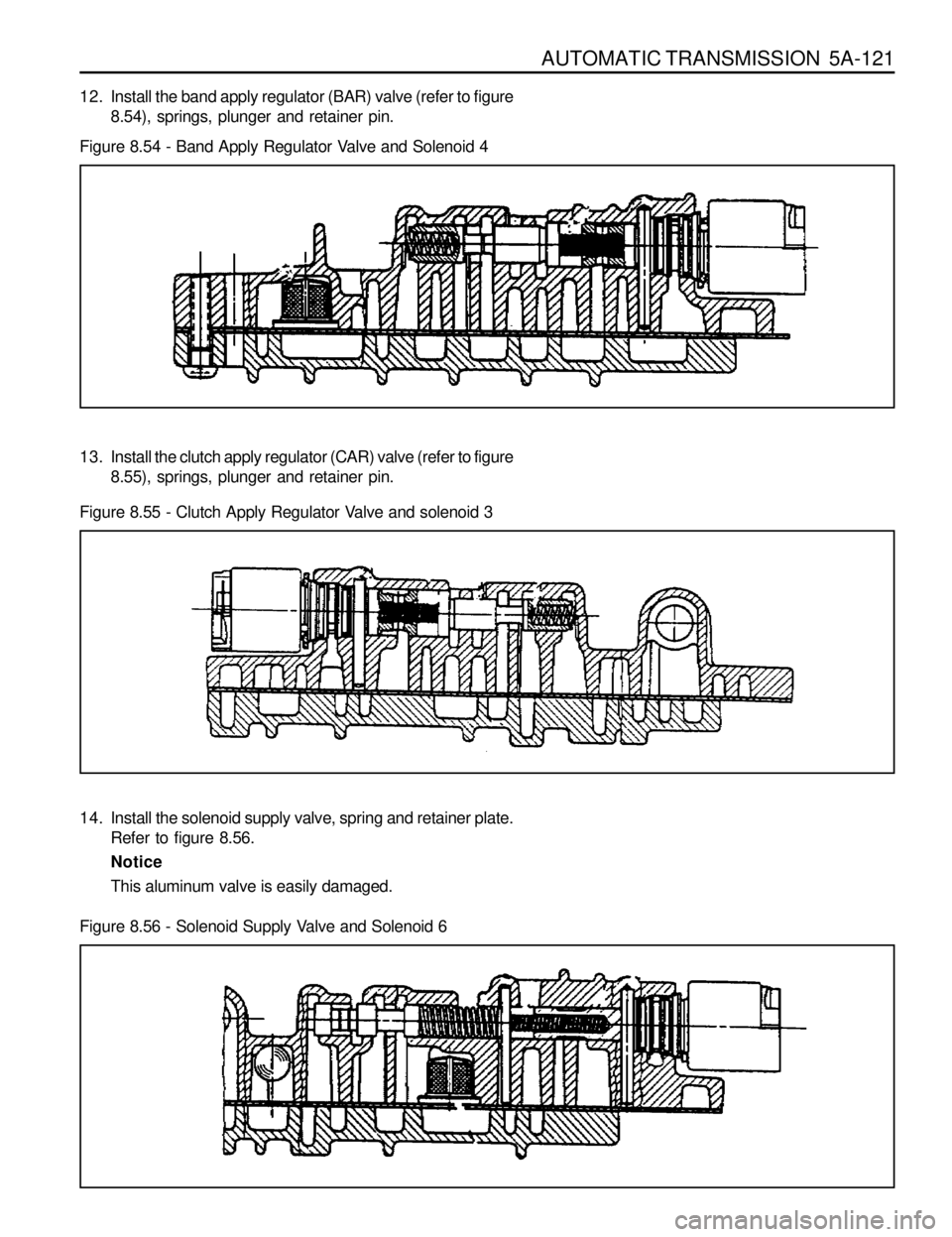

Figure 8.50 - 1-2 Shift Valve 8. Install the 1-2 shift valve, plug and retaining pin. Refer to

figure 8.50.

Page 1097 of 1463

5A-120 AUTOMATIC TRANSMISSION

9. Install the 3-4 shift valve and retaining pin. Refer to figure

8.51.

Figure 8.51 - 3-4 Shift Valve

10. Install the 2-3 shift valve and retaining pin. Refer to figure

8.52.

Figure 8.52 - Solenoid 2 and 2-3 Shift Valve

11. Install the 4-3 sequence valve, spring, plug and retaining

plate. Refer to figure 8.53.

Figure 8.53 - 4-3 Sequence Valve

Page 1098 of 1463

AUTOMATIC TRANSMISSION 5A-121

12. Install the band apply regulator (BAR) valve (refer to figure

8.54), springs, plunger and retainer pin.

Figure 8.54 - Band Apply Regulator Valve and Solenoid 4

13. Install the clutch apply regulator (CAR) valve (refer to figure

8.55), springs, plunger and retainer pin.

Figure 8.55 - Clutch Apply Regulator Valve and solenoid 3

14. Install the solenoid supply valve, spring and retainer plate.

Refer to figure 8.56.

Notice

This aluminum valve is easily damaged.

Figure 8.56 - Solenoid Supply Valve and Solenoid 6

Page 1099 of 1463

5A-122 AUTOMATIC TRANSMISSION

15. Install solenoid 6 plunger, spring and retaining pin.

16. Position the third feed ball (large nylon) in the valve body

and install the solenoid 5 filter and the solenoid 6 filter.

Refer to figures 8.5 and 8.56.

17. Check the separator plate for burrs and damage. Repair

or replace the separator plate as necessary.

18. Check the upper and lower valve body gaskets for

damage. Replace the gaskets as necessary.

19. Install the lower valve body gasket on the lower valve body.

20. Install the reverse lockout valve, spring, plug and retainer

plate. Ensure that the valve is correctly oriented. Refer to

figure 8.57.

Figure 8.57 - Reverse Lockout Valve

21. Position the five nylon ball checks in the upper valve body.

Refer to figure 8.48.

22. Fit the upper valve body gasket. Install the separator plate

over the upper valve body.

Page 1100 of 1463

AUTOMATIC TRANSMISSION 5A-123

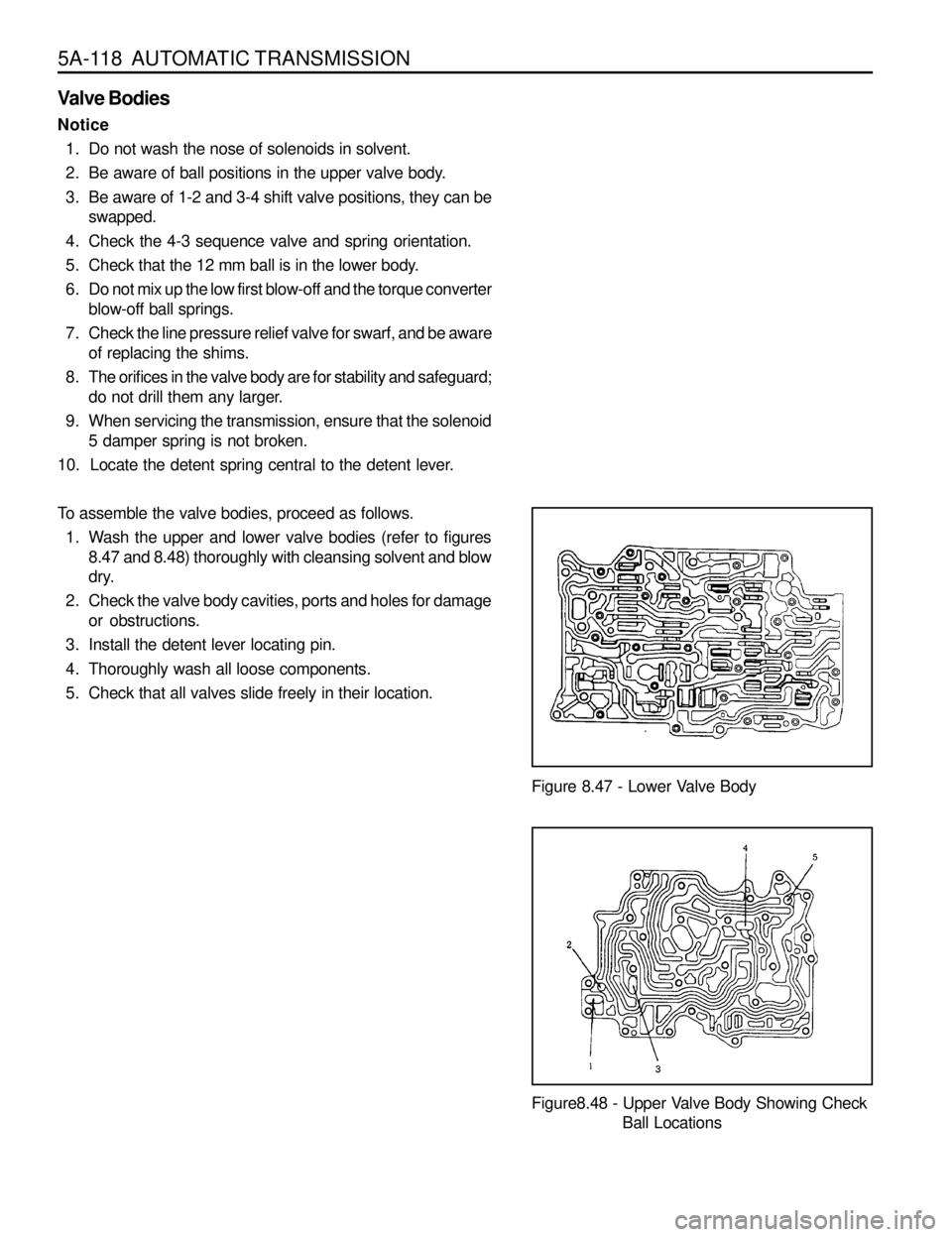

23. Holding the separator plate to the upper valve body to

prevent the check balls from falling out, install the upper

valve body on the lower valve body. Install all screws finger

tight then tighten the screws to specification in the

prescribed sequence. Refer to figure 8.58.

24. Install solenoids 1,2,3,4 and 6. Ensure the solenoid is firmly

secured by the retainer and that the screw is tightened to

specification.

25. Install solenoid 5. Ensure that the solenoid is pushed firmly

into the valve body by the retainer.

Notice

The wiring loom ground wire eyelet terminal is secured

beneath the solenoid retainer.

26. Install the line pressure relief valve, tapered end first, (refer

to figure 8.59), and the spring and disc. Secure with the

retaining pin. Figure 8.58 - Tightening Sequence Upper to Lower Valve Body

Figure 8.59 - Line Pressure Relief Valve

Trending: remote control, wheel size, automatic transmission fluid, instrument cluster, brake pads replacement, low beam, spare tire