SSANGYONG MUSSO 1998 Workshop Repair Manual

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Repair Manual

Page 888 of 1463

3A-20 FRONT DRIVE AXLE

2. Assemble the parts of the drive pinion.

3. Assemble the parts of the differential carrier.

4. Measure backlash of the side gear and pinion.

5. Install the differential carrier assembly into the axle housing.

Notice

Be careful not to change the caps. Be sure to keep the

original position of the caps.

Tightening Torque of the

Lock Nut240 - 310 Nm

Tightening Torque of the

Ring Gear Bolts75 - 90 Nm

Standard 0 - 0.05 mm

Tightening Torque of the

Bearing Cap Bolts48 - 69 Nm

Page 889 of 1463

FRONT DRIVE AXLE 3A-21

6. Measure backlash of the drive pinion and ring gear.

7. Install the axle housing cover.

8. Assemble the parts of the front axle shaft and housing

mounting bracket.

Notice

Apply grease to the oil seal rib.

9. Align the axle shaft and differential carrier spline and insert

the axle shaft. Assemble the axle housing mounting bracket

to the axle housing.

Specified Value 0.13 - 0.20 mm

Tightening Torque 39 - 46 Nm

Tightening Torque 55 - 65 Nm

Page 897 of 1463

PROPELLER SHAFT 3C-7

Installation Procedure

Clean the disassembled parts and replace them if damaged.

1. Align the alignment marks of the yoke and assemble the

spider, bearing and snap ring.

2. Apply grease to the inner of the bearing cap of the needle

roller bearing and assemble the needle roller.

Grease EP #2

6. Possible cause of vibration.

lDrift away of balance weights.

lExcessive runout of the propeller shaft.

lUsing normal bolts.

lExcessive wear of the universal joint.

lSticks in sleeve joint.

lDrive angle changes in universal joints or cross causes

vibration and can be detected around 60~100 km/h. 5. Universal joint starting torque.

Starting Torque 3 - 8 kglcm

Page 898 of 1463

3C-8 PROPELLER SHAFT

3. Install the bearing cap to the yoke and insert the spider.

Install the opposite side cap by tapping with a plastic

hammer. Adjust clearance of the spider pin to be within 0.1

mm and install the snap ring.

4. Align the alignment marks and install the front and rear

propeller shaft. Tighten the nuts to the specified torque.

GasolineDiesel

Page 905 of 1463

REAR DRIVE AXLE 3D-7

Removal & Installation Procedure

1. Remove the tire.

Installation Notice

2. Release the parking brake.Steel Wheel

Aluminum Wheel

Tightening Torque

3. Remove the bolts and the brake caliper.

Installation Notice

Be careful not to damage the brake hose.

Tightening Torque 85 - 100 Nm

4. Remove the brake disc.

Notice

To remove the disc, install the bolts (M8 x 1.25) into the

service hole and uniformly tighten the bolts.

5. Disconnect the parking brake cable.

80 - 120 Nm

110 - 130 Nm

Page 906 of 1463

3D-8 REAR DRIVE AXLE

Tightening Torque 50 - 65 Nm

6. Remove the plug from the axle shaft flange and remove the

inner shaft mounting nuts.

Installation Notice

7. Remove the axle shaft, parking brake lining and back plate

assembly.

8. Installation should follow the removal precedure in the

reverse order.

Page 907 of 1463

REAR DRIVE AXLE 3D-9

AXLE

Removal & Installation Procedure

1. Lift up the vehicle and support the frame safely.

2. Remove the axle shaft.

Tightening Torque 150 - 180 Nm 3. Remove the propeller shaft from the rear axle input shaft.

Installation Notice

Notice

Place alignment marks before removal.

Tightening Torque 81 - 89 Nm

4. Disconnect the parking brake cable and brake hose.

5. Remove the lower arm mounting nuts and remove the lower

arm from the axle housing.

Installation Notice

Page 908 of 1463

3D-10 REAR DRIVE AXLE

6. Separate the lower shock absorber from the axle housing.

Installation Notice

7. Remove the upper arm mounting nuts and remove the

upper arm form the axle housing.

Installation Notice

Tightening Torque 50 - 65 Nm

8. Remove the stabilizer bar.

Installation Notice

Tightening Torque 150 - 180 Nm

9. Remove the lateral rod mounting nuts and remove the

lateral rod from the axle housing.

Installation Notice

Tightening Torque 30 - 45 Nm

10. Lowering the axle housing slowly, remove the coil springs

and spring seats.

11. Installation should follow the removal precedure in the

reverse order.

Tightening Torque 150 - 180 Nm

Page 910 of 1463

3D-12 REAR DRIVE AXLE

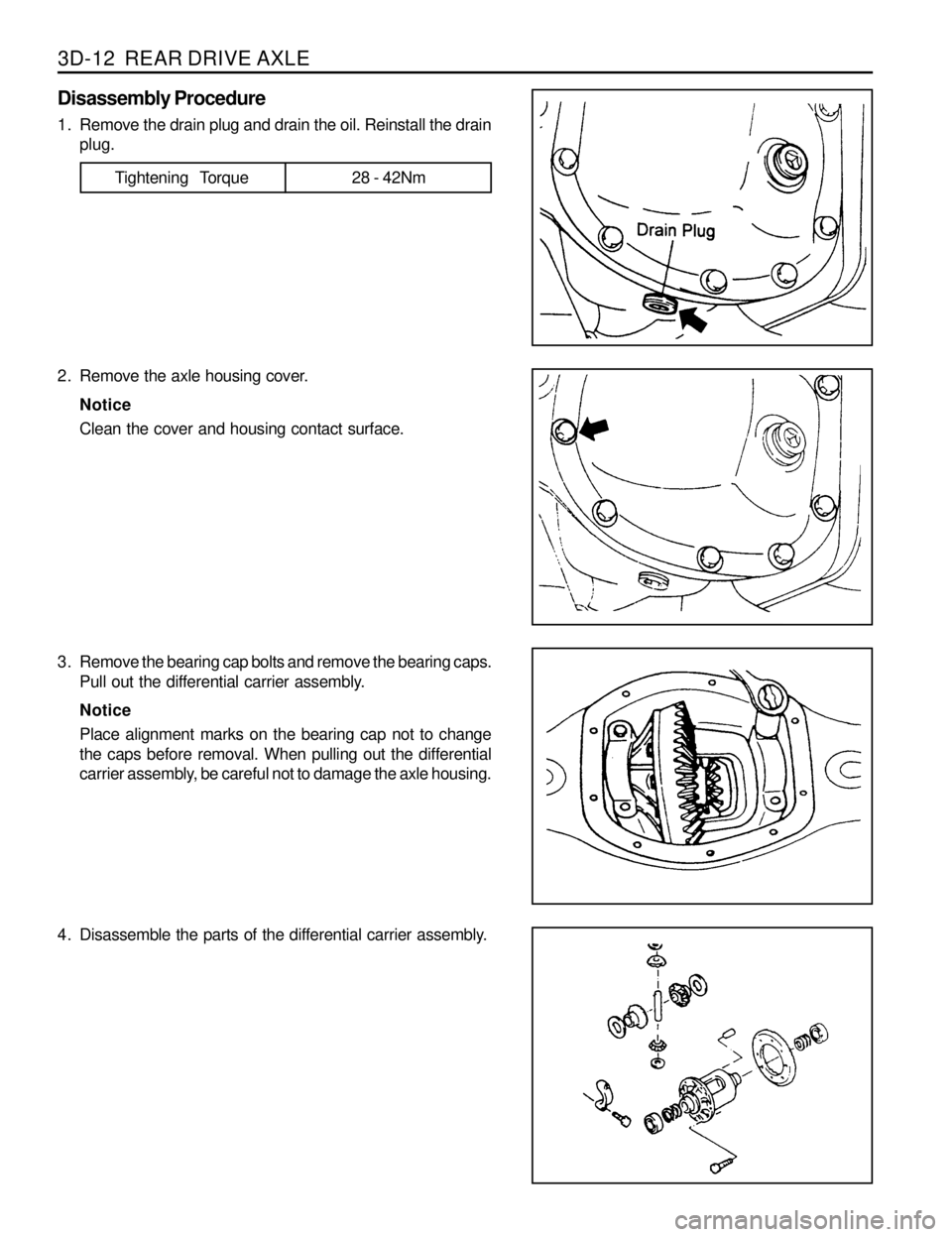

Disassembly Procedure

1. Remove the drain plug and drain the oil. Reinstall the drain

plug.

2. Remove the axle housing cover.

Notice

Clean the cover and housing contact surface.

3. Remove the bearing cap bolts and remove the bearing caps.

Pull out the differential carrier assembly.

Notice

Place alignment marks on the bearing cap not to change

the caps before removal. When pulling out the differential

carrier assembly, be careful not to damage the axle housing.

4. Disassemble the parts of the differential carrier assembly.

Tightening Torque 28 - 42Nm

Page 911 of 1463

REAR DRIVE AXLE 3D-13

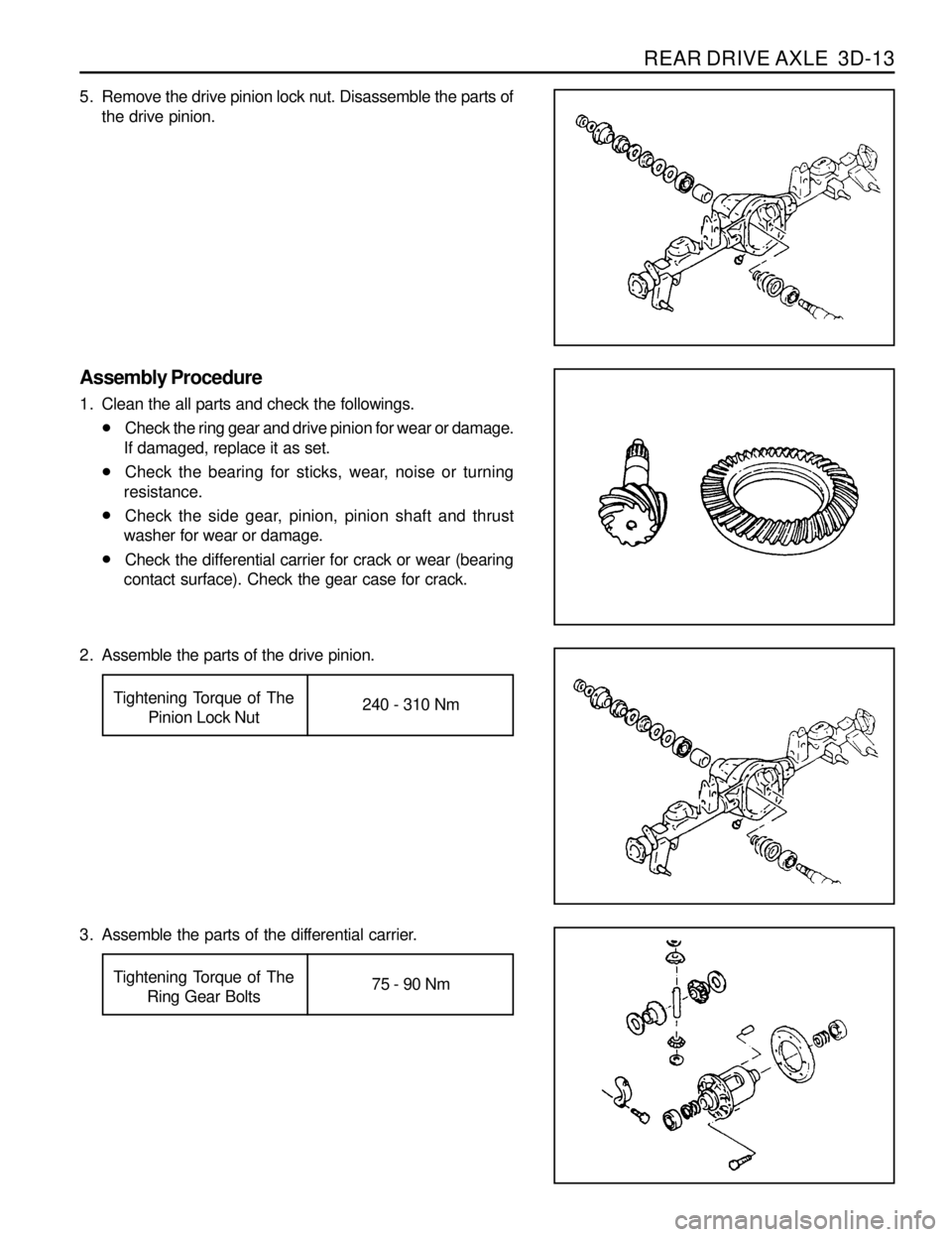

5. Remove the drive pinion lock nut. Disassemble the parts of

the drive pinion.

Assembly Procedure

1. Clean the all parts and check the followings.

lCheck the ring gear and drive pinion for wear or damage.

If damaged, replace it as set.

lCheck the bearing for sticks, wear, noise or turning

resistance.

lCheck the side gear, pinion, pinion shaft and thrust

washer for wear or damage.

lCheck the differential carrier for crack or wear (bearing

contact surface). Check the gear case for crack.

2. Assemble the parts of the drive pinion.

3. Assemble the parts of the differential carrier.

Tightening Torque of The

Pinion Lock Nut240 - 310 Nm

Tightening Torque of The

Ring Gear Bolts75 - 90 Nm