torque SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 724 of 1463

M161 ENGINE CONTROLS 1F2-75

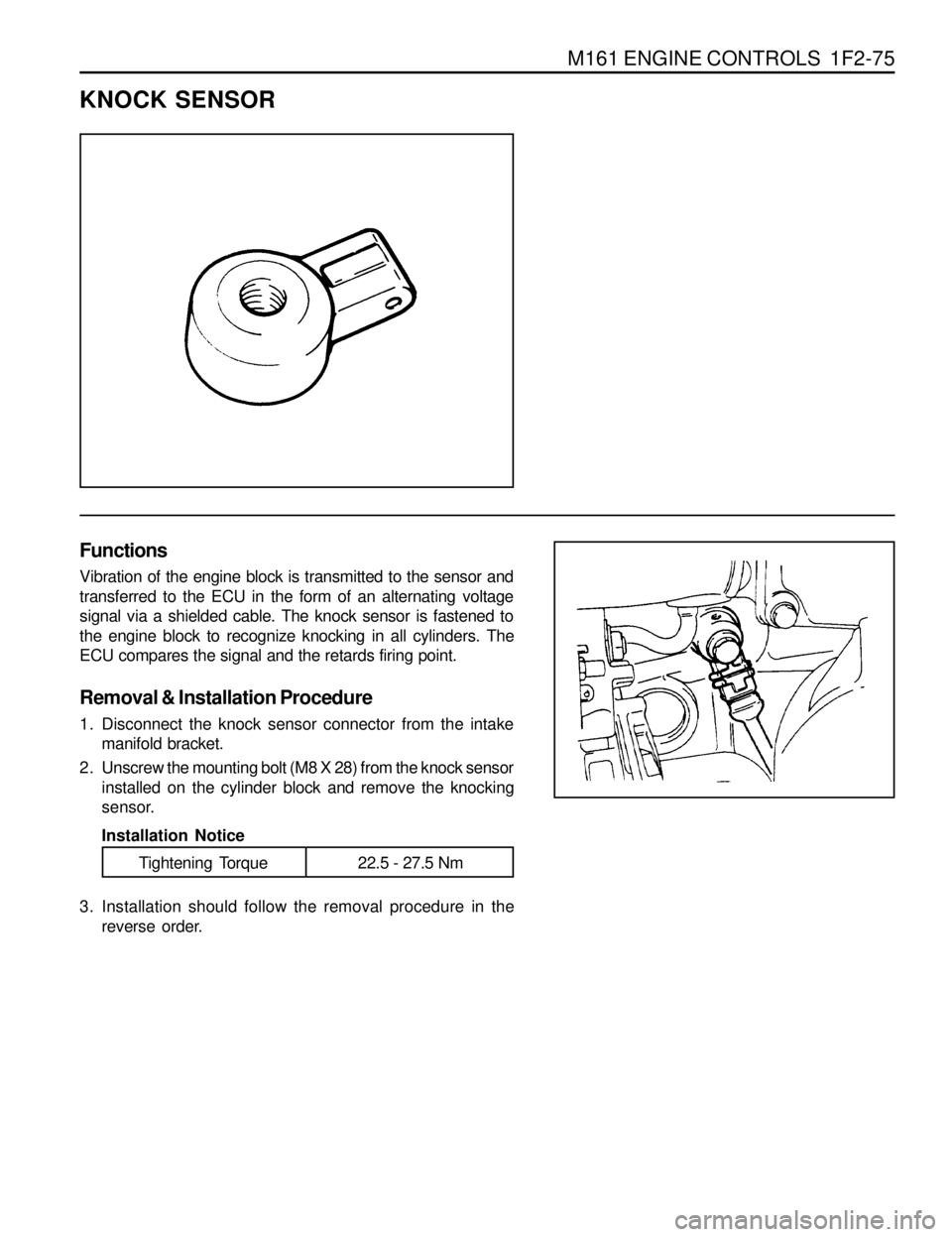

KNOCK SENSOR

Functions

Vibration of the engine block is transmitted to the sensor and

transferred to the ECU in the form of an alternating voltage

signal via a shielded cable. The knock sensor is fastened to

the engine block to recognize knocking in all cylinders. The

ECU compares the signal and the retards firing point.

Removal & Installation Procedure

1. Disconnect the knock sensor connector from the intake

manifold bracket.

2. Unscrew the mounting bolt (M8 X 28) from the knock sensor

installed on the cylinder block and remove the knocking

sensor.

Installation Notice

3. Installation should follow the removal procedure in the

reverse order.

Tightening Torque 22.5 - 27.5 Nm

Page 725 of 1463

1F2-76 M161 ENGINE CONTROLS

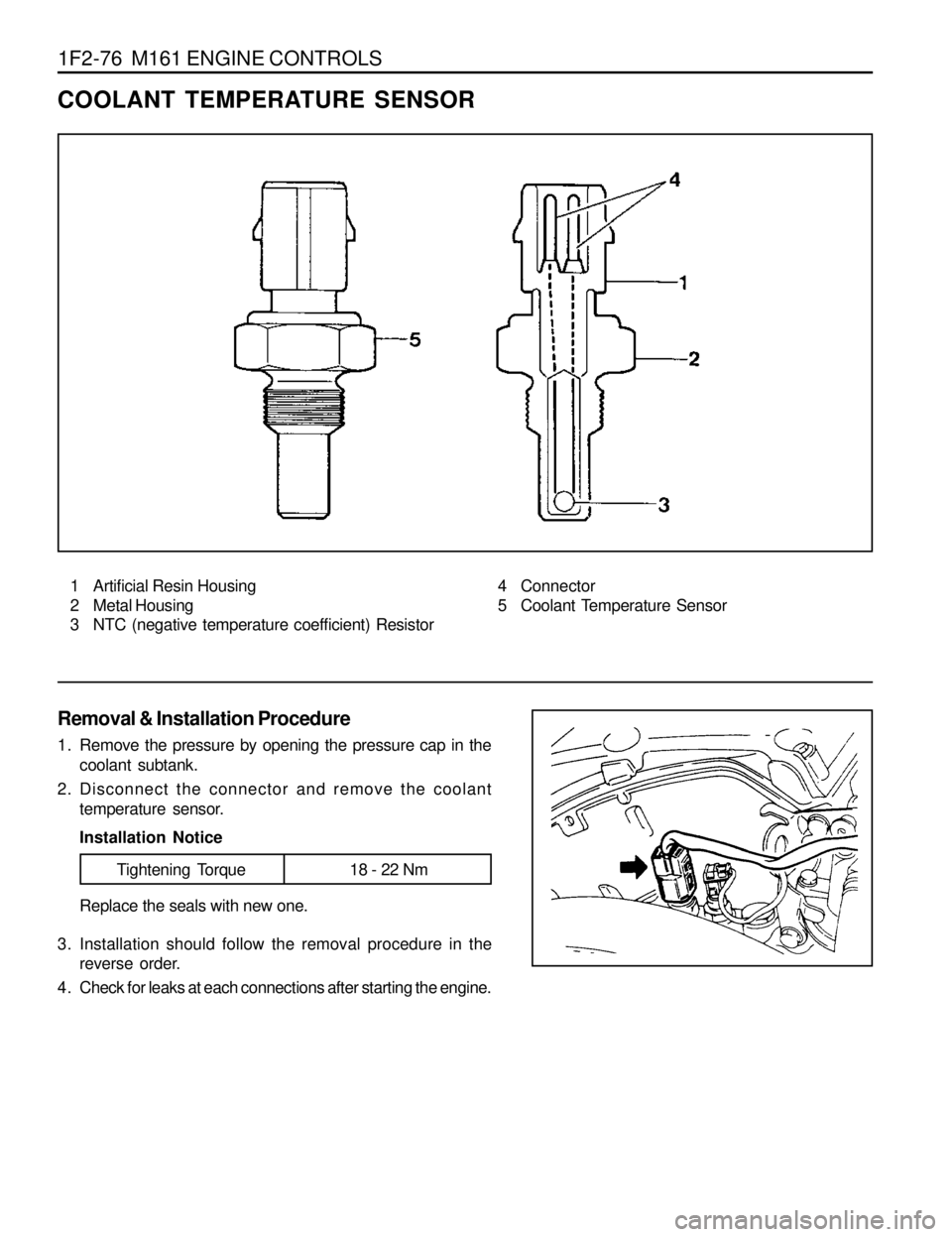

COOLANT TEMPERATURE SENSOR

1 Artificial Resin Housing

2 Metal Housing

3 NTC (negative temperature coefficient) Resistor

Removal & Installation Procedure

1. Remove the pressure by opening the pressure cap in the

coolant subtank.

2. Disconnect the connector and remove the coolant

temperature sensor.

Installation Notice

Replace the seals with new one.

3. Installation should follow the removal procedure in the

reverse order.

4. Check for leaks at each connections after starting the engine.4 Connector

5 Coolant Temperature Sensor

Tightening Torque 18 - 22 Nm

Page 728 of 1463

M161 ENGINE CONTROLS 1F2-79

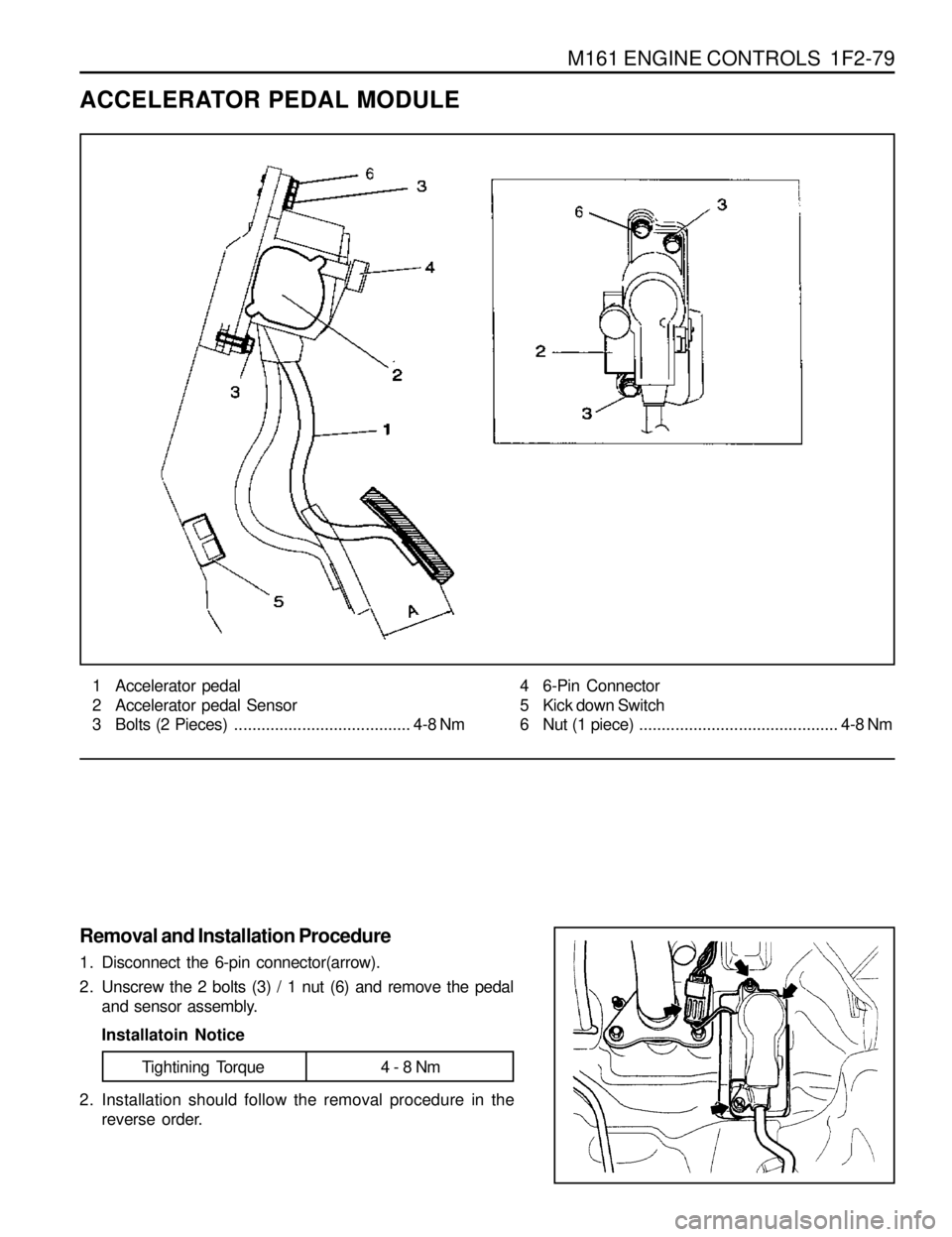

ACCELERATOR PEDAL MODULE

1 Accelerator pedal

2 Accelerator pedal Sensor

3 Bolts (2 Pieces).......................................4-8 Nm

Removal and Installation Procedure

1. Disconnect the 6-pin connector(arrow).

2. Unscrew the 2 bolts (3) / 1 nut (6) and remove the pedal

and sensor assembly.

Installatoin Notice

Tightining Torque 4 - 8 Nm

2. Installation should follow the removal procedure in the

reverse order.4 6-Pin Connector

5 Kick down Switch

6 Nut (1 piece)............................................4-8 Nm

Page 743 of 1463

1F3-14 OM600 ENGINE CONTROLS

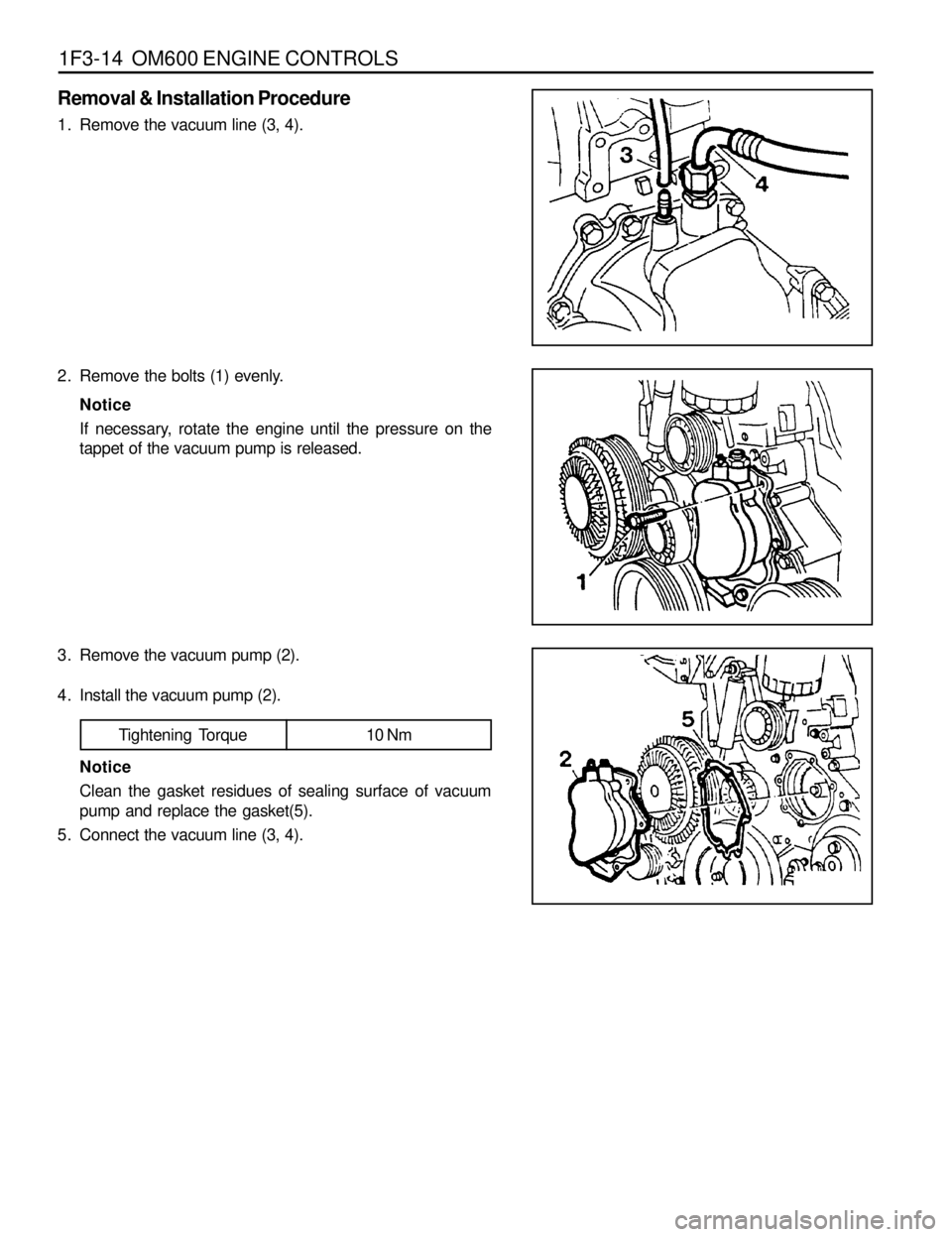

Removal & Installation Procedure

1. Remove the vacuum line (3, 4).

2. Remove the bolts (1) evenly.

Notice

If necessary, rotate the engine until the pressure on the

tappet of the vacuum pump is released.

3. Remove the vacuum pump (2).

4. Install the vacuum pump (2).

Tightening Torque 10 Nm

Notice

Clean the gasket residues of sealing surface of vacuum

pump and replace the gasket(5).

5. Connect the vacuum line (3, 4).

Page 755 of 1463

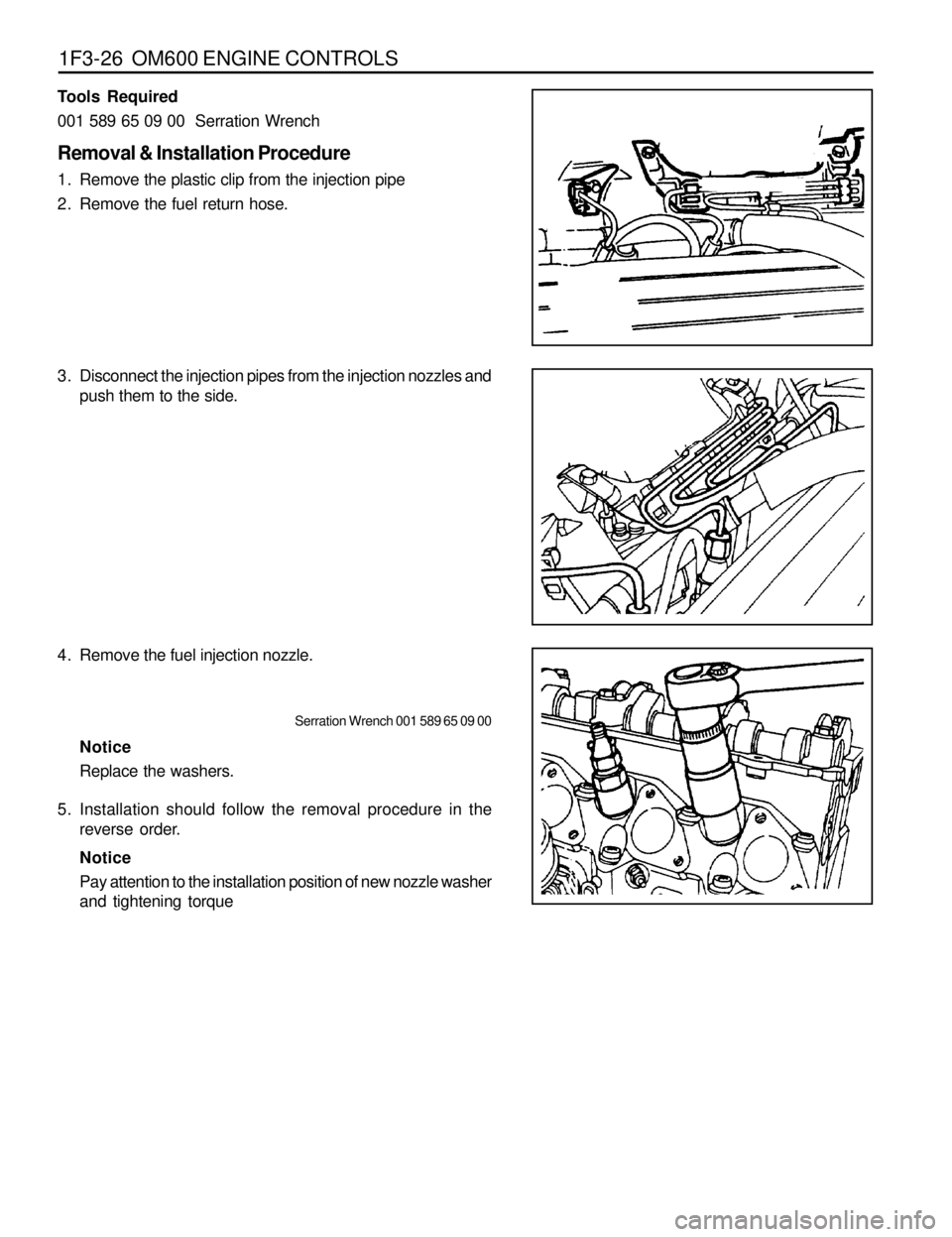

1F3-26 OM600 ENGINE CONTROLS

Tools Required

001 589 65 09 00 Serration Wrench

Removal & Installation Procedure

1. Remove the plastic clip from the injection pipe

2. Remove the fuel return hose.

3. Disconnect the injection pipes from the injection nozzles and

push them to the side.

4. Remove the fuel injection nozzle.

Serration Wrench 001 589 65 09 00

Notice

Replace the washers.

5. Installation should follow the removal procedure in the

reverse order.

Notice

Pay attention to the installation position of new nozzle washer

and tightening torque

Page 757 of 1463

1F3-28 OM600 ENGINE CONTROLS

Tools Required

001 589 65 09 00 Socket Wrench Insert

000 589 00 68 00 Cleaning Set

Repair Procedure

1. Clamp the nozzle holder (1) in a vice and remove the nozzle

tensioning nut (8).

Notice

Use protective jaws for clamping.

2. Disassemble the fuel injection nozzle.

Socket Wrench Insert 001 589 65 09 00

3. Clean the nozzle needle (6) and nozzle body (7) with an

abradant.

4. Clean the nozzle seat with cleaning cutter.

Cleaning Set 000 589 00 68 00

5. Immerse nozzle needle (6) and nozzle body (7) in filtered

diesel fuel. When the nozzle body is held vertical, the weight

of the nozzle needle must cause it to slide down toward the

nozzle needle seat.

6. Assemble the injection nozzle so that the tip of the thrust

(4) pin is facing toward the nozzle holder.

Tightening Torque 80 Nm

Notice

Nozzle needle (6) and nozzle body (7) should always be

replaced as a pair.

Page 760 of 1463

OM600 ENGINE CONTROLS 1F3-31

Tools Required

601 589 00 08 00Flange

601 589 05 21 00 Locking Screw

116 589 20 33 00 Sliding Hammer

116 589 02 34 00 Threaded Bolt

667 589 04 63 00 Retaining Plate

Removal & Installation Procedure

1. Remove the bolts (2) and then remove the cylinder head

cover (1) and gasket (3).

Installation Notice

Tightening Torque 10 Nm

Notice

Replace the gasket.

Rotate the engine 1 revolution by hand and check TDC

marking of the crankshaft and camshaft.

2. Loosen the camshaft sprocket bolt (14).

Notice

Do not remove the bolt.

Installation Notice

Notice

If max. length of bolt exceeds 53.6mm, replace it.

Tightening Torque 25Nm + 90°

3. Loosen the bolt (11) (left-hand thread).

Notice

Do not remove the bolt.

Page 761 of 1463

1F3-32 OM600 ENGINE CONTROLS

5. Remove the plug (6) and seal (5) from the fuel injection

pump and collect oil in a suitable vessel.

Installation Notice

Notice

Replace the seal.

Tightening Torque 30 Nm

6. Install the locking screw (18) into the injection pump.

Notice

Before tightening the bolts for the injection timing device

and the camshaft sprocket, always remove the locking screw

from the injection pump and reinstall the plug.

Locking Screw 601 589 05 21 00

7. Place alignment marks (arrow) on the timing chain (12) and

camshaft sprocket (15). 4. Position the no.1 cylinder at ATDC 15°.

Notice

Do not rotate the engine with camshaft sprocket bolt or

opposite direction of the engine rotation.

Page 762 of 1463

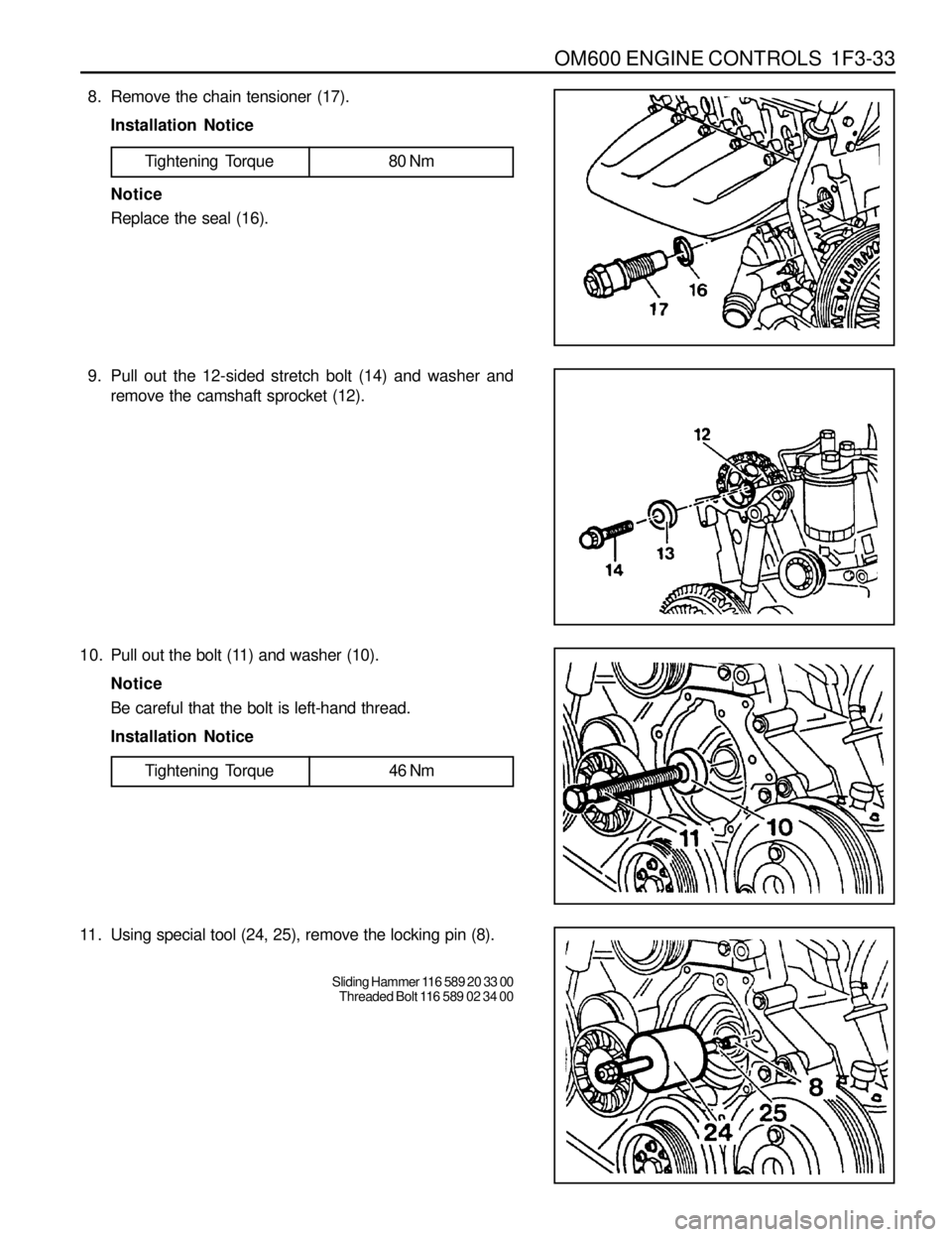

OM600 ENGINE CONTROLS 1F3-33

9. Pull out the 12-sided stretch bolt (14) and washer and

remove the camshaft sprocket (12).

Tightening Torque 46 Nm

11. Using special tool (24, 25), remove the locking pin (8).

Sliding Hammer 116 589 20 33 00

Threaded Bolt 116 589 02 34 00

8. Remove the chain tensioner (17).

Installation Notice

Tightening Torque 80 Nm

Notice

Replace the seal (16).

10. Pull out the bolt (11) and washer (10).

Notice

Be careful that the bolt is left-hand thread.

Installation Notice

Page 770 of 1463

OM600 ENGINE CONTROLS 1F3-41

With Pulse Generator Tools Required

617 589 09 21 00 Rl Sensor

617 589 10 21 00 Timing Tester

667 589 00 21 00 TDC Pulse Generator

Commercial Tools

Item

Digital Tester

Without Pulse GeneratorTools

Bosch, MOT 001.03

Hartmann & Braun, EOMT3

Bosch, ETD 019.00

Sun, DIT 9000

ALV, Diesel - Tester 875

Test Procedure

1. Remove the screw plug (7) and seal (8) collect oil in a suitable

vessel.

2. Install the Rl sensor into the governor housing of injection

pump (1).

Rl Sensor 617 589 10 21 00

3. Connect the digital tester and TDC pulse sender unit

according to connection diagram.

4. Run the engine at idle speed and check the Rl value on the

digital tester

Notice

If out of standard, adjust the start of delivery.

5. Stop the engine.

6. Remove the Rl sensor, digital tester and TDC pulse sender

unit.

7. Replace the seal and tighten the plug.

8. Check engine oil level and adjust if necessary.

Rl value ATDC 14° - 16°

Tightening Torque 30 Nm