torque SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 772 of 1463

OM600 ENGINE CONTROLS 1F3-43

Tools Required

617 589 08 21 00 Position Sensor

Adjustment Procedure

1. Position the No. 1 cylinder at ATDC 15°

Notice

Do not rotate the engine in opposite direction of engine

rotation.

2. Remove the bolt (2) at the supporting bracket.

3. Remove the bolt (4).

4. Turn the adjusting screw (1) until both lamps ‘A’ + ‘B’ on

the position sensor light up.

Notice

If the adjustment range is not adequate, remove the injection

pump and reinstall.

Position Sensor 617 589 08 21 00

5. After adjusting, retighten all the bolt to the specified torque.

To the right

To the leftStart of delivery retarded

Start of delivery advanced

Page 779 of 1463

1F3-50 OM600 ENGINE CONTROLS

10. Connect the fuel pipes

Notice

Replace the seal.

Box Wrench Insert 000 589 77 03 00

Return Line

Fuel Injection Line

Fuel feed Line

Suction and Pressure Line46 Nm

18 Nm

13 Nm

13 Nm

5. Coat the new seal (23) with engine oil and install it.

6. Insert the fuel injection pump (25) and tighten the bolts

(22).

7. Remove the locking screw (32).

Tightening Torque 23 Nm

8. Tighten the bolt(12).

9. Insert the washer (21) and tighten the bolts (20) and then

remove the assembly cage (29).

Tightening Torque 23 Nm

Tightening Torque 46 Nm

Page 783 of 1463

M162 ENGINE INTAKE & EXHAUST 1G1-3

Removal & Installation Procedure

1. Release the clamp securing HFM sensor and air cleaner.

2. Disengage the air cleaner assembly and HFM sensor

assembly.

3. Unserew the mounting bolt(6) from the bracket.

Installation Notice

Tightening Torque 22.5 - 27.5 Nm

4. Release the clamp from air cleaner assembly housing and

remove the cover.

5. Remove the air cleaner assembly.

6. Remove the air cleaner housing from insulator.

Notice

Make sure the air cleaner to be seated in insulator.

7. Disengage the air duct hose and air cleaner housing and

remove the housing.

8. Remove the air duct hose.

9. Unscrew the two bolts(7) from air inlet duct.

Installation Notice

10. Remove the air inlet duct.

11. Installation should follow the removal procedure in the

reverse order.

Tightening Torque 8 - 9 Nm

Page 786 of 1463

1G1-6 M162 ENGINE INTAKE & EXHAUST

Removal & Installation Procedure

lUpper Intake Manifold

1. Disconnect the vacuum hose (8,9).

2. Loosen the clip (22).

3. Remove the upper intake manifold (5) after unscrewing the

bolt (6).

Installation Notice

Notice

Check the gasket and replace it if necessary.

4. Installation should follow the removal procedure in the

reverse order.

lLower Intake Manifold

Preceding work : removal of upper intake manifold

1. Remove the hose of brake booster vacuum line and idle

speed connector.

2. Disconnect the hot water inlet pipe from the bottom of lower

intake manifold.

3. Unscrew the bolt (17) and remove the lower intake manifold

(16).

Installation Notice

4. Start the engine and check for leaks at each connection

part.

Tightening Torque 22.5 - 27.5 Nm

Tightening Torque 22.5 - 27.5 Nm

Page 788 of 1463

1G1-8 M162 ENGINE INTAKE & EXHAUST

Function Description

A pneumatically actuated resonance flap (5) is located on the

intake manifold, and will be opened and closed by load, which

operates resonance flap according to engine and controlled

by ECU and rpm.

1. Resonance flap closed (at idle/partial load : less than

3,800/rpm)

The switch valve (7) will be adjusted by ECU and resonance

falp will be colosed. By increasing air flow passage through

dividing intaking air flow toward both air collection housing

(8). This leads to a signficant increase in the torque in the

lower speed range.

2. Resonance flap open (at full load : over 3,800/rpm)

The switch valve (7) will not be adjusted by ECU and

resonance falp (5) will be open. The colllected air in the air

collection housing (8) will not be divided and intaking air

passage will be shorten.

Page 790 of 1463

1G1-10 M162 ENGINE INTAKE & EXHAUST

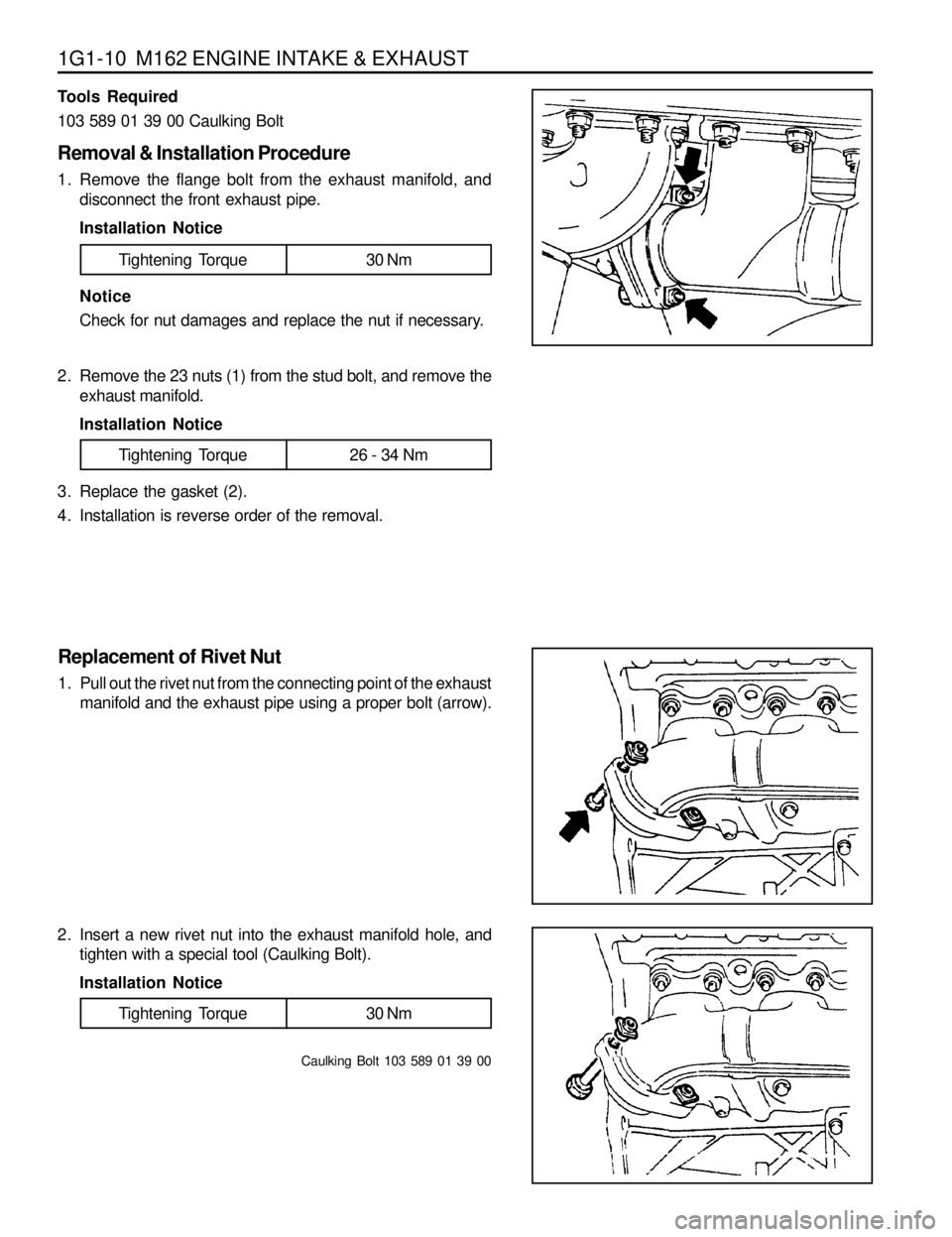

Tools Required

103 589 01 39 00 Caulking Bolt

Removal & Installation Procedure

1. Remove the flange bolt from the exhaust manifold, and

disconnect the front exhaust pipe.

Installation Notice

Notice

Check for nut damages and replace the nut if necessary.

2. Remove the 23 nuts (1) from the stud bolt, and remove the

exhaust manifold.

Installation Notice

3. Replace the gasket (2).

4. Installation is reverse order of the removal.

Replacement of Rivet Nut

1. Pull out the rivet nut from the connecting point of the exhaust

manifold and the exhaust pipe using a proper bolt (arrow).

2. Insert a new rivet nut into the exhaust manifold hole, and

tighten with a special tool (Caulking Bolt).

Installation Notice

Caulking Bolt 103 589 01 39 00

Tightening Torque 30 Nm

Tightening Torque 26 - 34 Nm

Tightening Torque 30 Nm

Page 794 of 1463

M161 ENGINE INTAKE & EXHAUST 1G2-3

Removal & Installation Procedure

1. Release the clamp securing HFM sensor and air cleaner.

2. Disengage the air cleaner assembly and HFM sensor

assembly.

3. Unserew the mounting bolt(6) from the bracket.

Installation Notice

Tightening Torque 22.5 - 27.5 Nm

4. Release the clamp from air cleaner assembly housing and

remove the cover.

5. Remove the air cleaner assembly.

6. Remove the air cleaner housing from insulator.

Notice

Make sure the air cleaner to be seated in insulator.

7. Disengage the air duct hose and air cleaner housing and

remove the housing.

8. Remove the air duct hose.

9. Unscrew the two bolts(7) from air inlet duct.

Installation Notice

10. Remove the air inlet duct.

11. Installation should follow the removal procedure in the

reverse order.

Tightening Torque 8 - 9 Nm

Page 799 of 1463

1G2-8 M161 ENGINE INTAKE & EXHAUST

Removal & Installation Procedure

1. Disconnect the battery ground cable.

2. Remove idle speed control plug connector (arrow).

3. Disconnect the brake booster vacuum line and other

vacuum lines.

4. Disconnector the rod from bearing bracket assembly and

remove the connection piece (8).

Installation Notice

Tightening Torque 36 - 44 Nm

5. Unscrew the three bolts (4) and remove the idle regulator

and intermediate flange (6).

Installation Notice

Tightening Torque 22.5 - 27.5 Nm

6. Unscrew the two bolts (M8 X 16) and remove the support

assembly (arrow).

Installation Notice

7. Unscrew the intake manifold assembly mounting bolts (1)

and remove the intake manifold and gasket.

Installation Notice

Notice

Replace the gasket with new one.

8. Installation should follow the removal procedure in the

reverse order.

9. Start the engine and check for leaks in each connection.

Tightening Torque 22.5 - 27.5 Nm

Tightening Torque 22.5 - 27.5 Nm

Page 800 of 1463

M161 ENGINE INTAKE & EXHAUST 1G2-9

EXHAUST MANIFOLD

1 Oxygen Sensor..............................49.5-60.5 Nm

2 Bolt (4 pieces)........................................ 9-11 Nm

3 Upper Cover

4 Nut (11 pieces)...............................31.5-38.5 Nm5 Exhaust Manifold

6 Flange Bolt & Exhaust Pipe

Mounting Nut............................................ 30 Nm

7 Gasket ................................................... Replace

Removal & Installation Procedure

1. Remove the oxygen sensor if necessary.

Installation Notice

Tightening Torque 49.5 - 60.5 Nm

2. Unscrew the bolt (2) and remove the exhaust manifold upper

cover (3).

3. Unscrew the flange bolt (6) of front exhaust pipe and

separate the front exhaust pipe.

Installation Notice

Tightening Torque 30 Nm

Notice

Check the exhaust pipe mounting nut, and replace it with

new one if necessary.

Page 801 of 1463

1G2-10 M161 ENGINE INTAKE & EXHAUST

4. Unscrew the eleven nuts (4) and remove the exhaust

manifold (5) and gasket (7).

Installation Notice

Tightening Torque 31.5 - 38.5 Nm

5. Replace the gasket (7) with new one.

6. Installation should follow the removal procedure in the

reverse order.