SSANGYONG MUSSO 1998 Workshop Repair Manual

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Repair Manual

Trending: technical specifications, fuel pressure, trunk, lights, engine oil, coolant capacity, power steering fluid

Page 391 of 1463

OM600 ENGINE MECHANICAL 1B3-89

14. Measure crankshaft bearing journal diameter (F).

Notice

When measured in A and B, the runout should not exceed

0.010mm.

8. Thoroughly clean the oil gallery.

9. Select a proper new bearing shells with reference to table.

10. Coat the new bearing shells with oil and insert into the

crankcase and into the crankshaft bearing caps.

Notice

Do not mix up upper and lower crankshaft bearing shells.

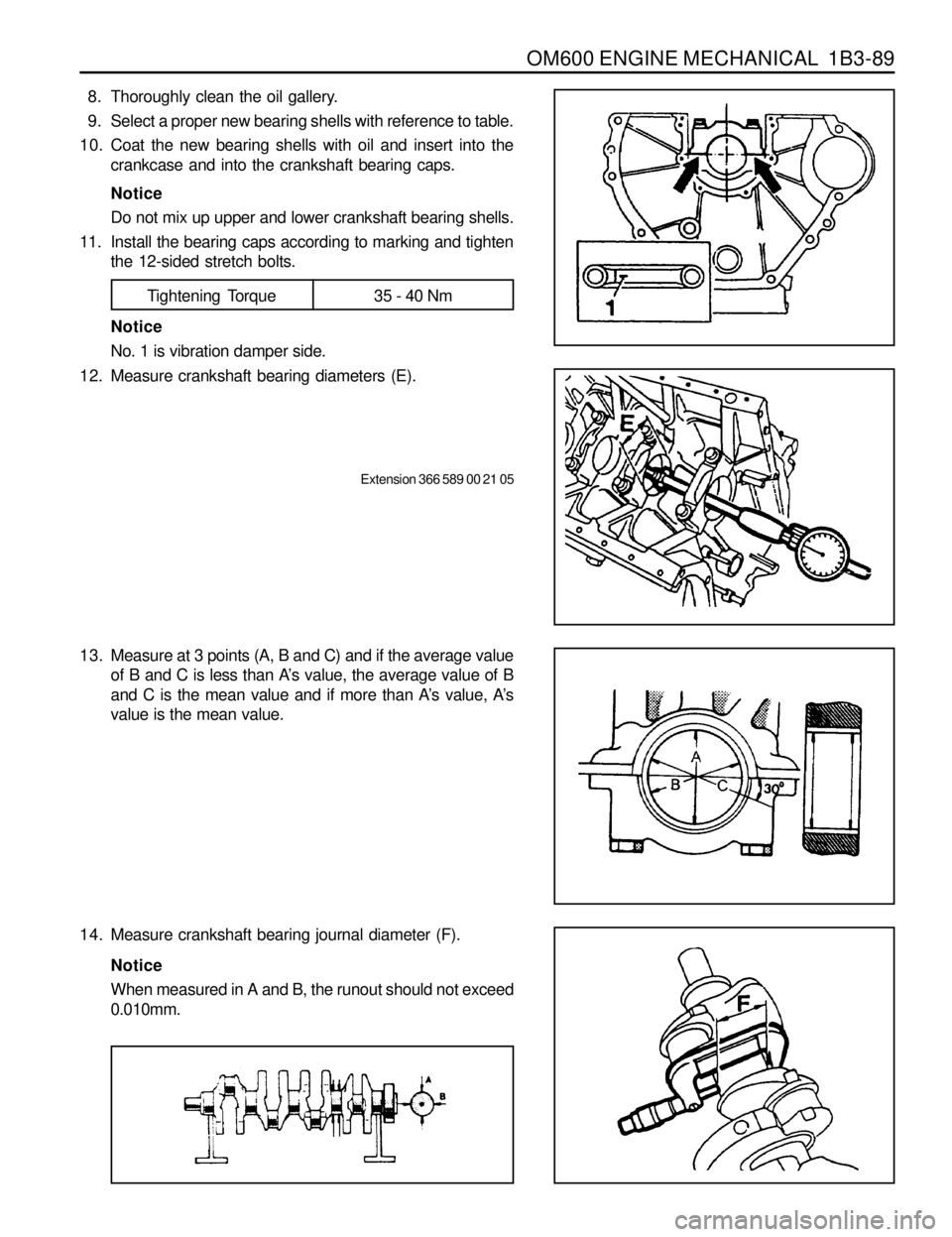

11. Install the bearing caps according to marking and tighten

the 12-sided stretch bolts.

Tightening Torque 35 - 40 Nm

Notice

No. 1 is vibration damper side.

12. Measure crankshaft bearing diameters (E).

Extension 366 589 00 21 05

13. Measure at 3 points (A, B and C) and if the average value

of B and C is less than A’s value, the average value of B

and C is the mean value and if more than A’s value, A’s

value is the mean value.

Page 392 of 1463

1B3-90 OM600 ENGINE MECHANICAL

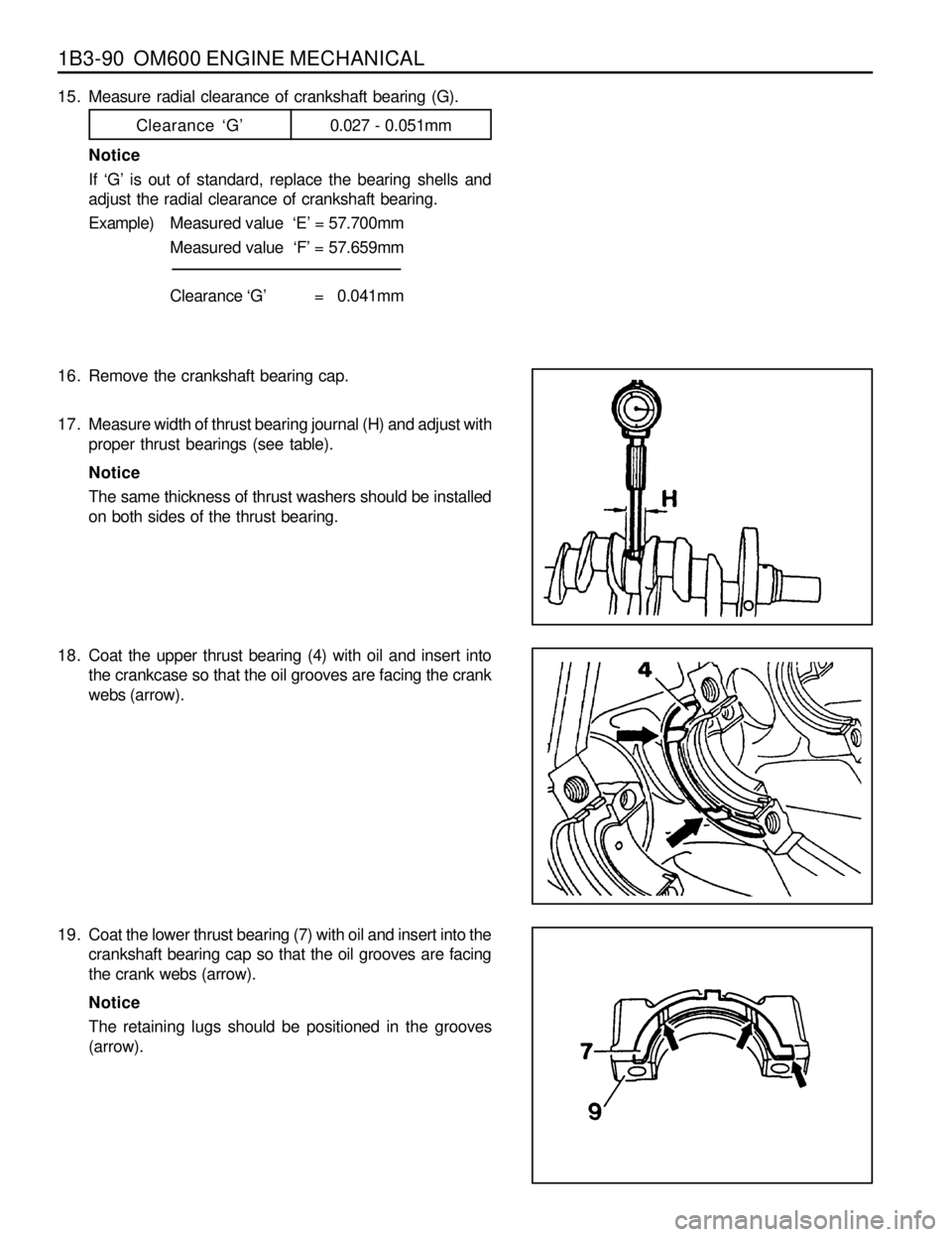

15. Measure radial clearance of crankshaft bearing (G).

Clearance ‘G’0.027 - 0.051mm

Notice

If ‘G’ is out of standard, replace the bearing shells and

adjust the radial clearance of crankshaft bearing.

Example)Measured value ‘E’ = 57.700mm

Measured value ‘F’ = 57.659mm

Clearance ‘G’ = 0.041mm

16. Remove the crankshaft bearing cap.

17. Measure width of thrust bearing journal (H) and adjust with

proper thrust bearings (see table).

Notice

The same thickness of thrust washers should be installed

on both sides of the thrust bearing.

18. Coat the upper thrust bearing (4) with oil and insert into

the crankcase so that the oil grooves are facing the crank

webs (arrow).

19. Coat the lower thrust bearing (7) with oil and insert into the

crankshaft bearing cap so that the oil grooves are facing

the crank webs (arrow).

Notice

The retaining lugs should be positioned in the grooves

(arrow).

Page 393 of 1463

OM600 ENGINE MECHANICAL 1B3-91

Notice

If the max. length of bolts(L) exceed 63.8mm, replace them.

19. Coat the new crankshaft with engine oil and place it on the

crankcase.

20. Install the crankshaft bearing caps according to marking

and tighten the bolts.

Tightening Torque 55 Nm + 90°

Notice

Install from No. 1 cap.

22. Rotate the crankshaft with hand and check whether it

rotates smoothly.

23. Measure crankshaft bearing axial clearance.

Clearance 0.100 - 0.245mm

Notice

If the clearance is out of standard, adjust the axial clearance

of crankshaft bearing by replacing the thrust washers.

Dial Gauge 001 589 53 21 00

Dial Gauge Holder 363 589 02 21 00

Notice

The same thickness of thrust washers should be installed

on both sides of the thrust bearing.

Page 394 of 1463

1B3-92 OM600 ENGINE MECHANICAL

28. Remove the connecting rod bearing cap.

29. Install the piston.

30. Rotate the crankshaft by hand and check whether it rotates

smoothly.

31. If the bearings are damaged,

- replace the oil presser relief valve.

- clean the oil pump and oil filter housing carefully and

replace the hose if necessary.

Notice

After assembling the engine, check the camshaft timing,

adjust the start of fuel injection and check the TDC sensor

bracket setting.

32. Fill oil and run the engine and then check the oil pressure

and oil level.

Notice

Install the original oil filter element and then change the

engine oil and oil filter element after 1,000 - 1,500km. 27. Measure the radial clearance (L) of the connecting rod

bearing.

Example)Measured value ‘J’ = 47.700mm

Measured value ‘K’ = 47.653mm

Clearance ‘L’ = 0.047mm

Radial Clearance ‘L’ 0.026 - 0.068mm

Notice

If the clearance is out of standard, adjust the radial

clearance of connecting rod bearing by replacing the

connecting rod bearing shells. 26. Measure connecting rod bearing journal diameter (K).

Notice

Refer to measurement of the crankshaft bearing journal

diameter.

24. Insert the new connecting rod bearing shells into the

connecting rod and connecting rod bearing cap and tighten

the 12-sided stretch bolts (11).

25. Measure inner diameter of connecting rod bearing.

Tightening Torque 40 Nm + 90°

Page 395 of 1463

OM600 ENGINE MECHANICAL 1B3-93

FLYWHEEL

Preceding Work : Removal of the transmission

Removal of the clutch

1 Oil Pan

2 Straight Pin

3 Flywheel4 12-Sided Stretch Bolt............Check, 45Nm + 90°

5 Drive Plate (Automatic Transmission)

6 Flywheel (Automatic Transmission)

Page 396 of 1463

1B3-94 OM600 ENGINE MECHANICAL

lManual transmission flywheel

lAutomatic transmission flywheel

OM661LA OM662LA

Page 397 of 1463

OM600 ENGINE MECHANICAL 1B3-95

3. Remove the flywheel (3), if equipped with manual

transmission.

Installation Notice

Correctly align the position of dowel pin (2).

Tools Required

602 589 00 40 00 Engine Lock

Removal & Installation Procedure

1. Install the engine lock.

Engine Lock 602 589 02 40 00

2. Remove the 12-sided stretch bolts (4).

Installation Notice

Tightening Torque 45 Nm + 90°

Notice

If the length ‘L’ of bolts exceeds 22.5mm, replace the bolts.

Page 398 of 1463

1B3-96 OM600 ENGINE MECHANICAL

4. Remove the flywheel (6) and driven plate (5), if equipped

with automatic transmission.

Installation Notice

Correctly align the position of dowel pin (2).

5. Installation should follow the removal procedure in the

reverse order.

Page 399 of 1463

OM600 ENGINE MECHANICAL 1B3-97

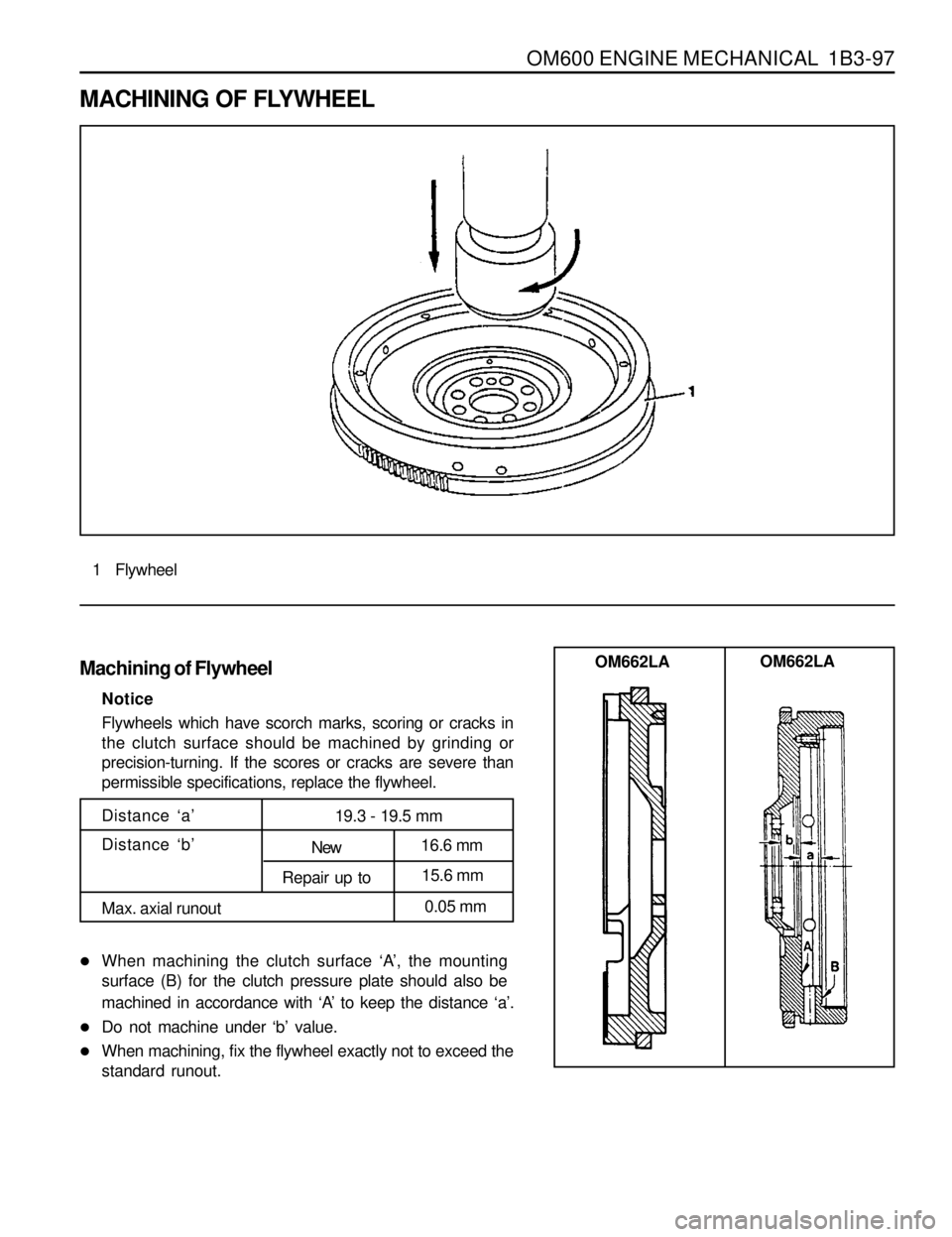

MACHINING OF FLYWHEEL

1 Flywheel

Machining of Flywheel

Notice

Flywheels which have scorch marks, scoring or cracks in

the clutch surface should be machined by grinding or

precision-turning. If the scores or cracks are severe than

permissible specifications, replace the flywheel.

lWhen machining the clutch surface ‘A’, the mounting

surface (B) for the clutch pressure plate should also be

machined in accordance with ‘A’ to keep the distance ‘a’.

lDo not machine under ‘b’ value.

lWhen machining, fix the flywheel exactly not to exceed the

standard runout.

OM662LA

OM662LA

Max. axial runout

Distance ‘a’

New

Repair up to19.3 - 19.5 mm16.6 mm

15.6 mm

0.05 mmDistance ‘b’

Page 400 of 1463

1B3-98 OM600 ENGINE MECHANICAL

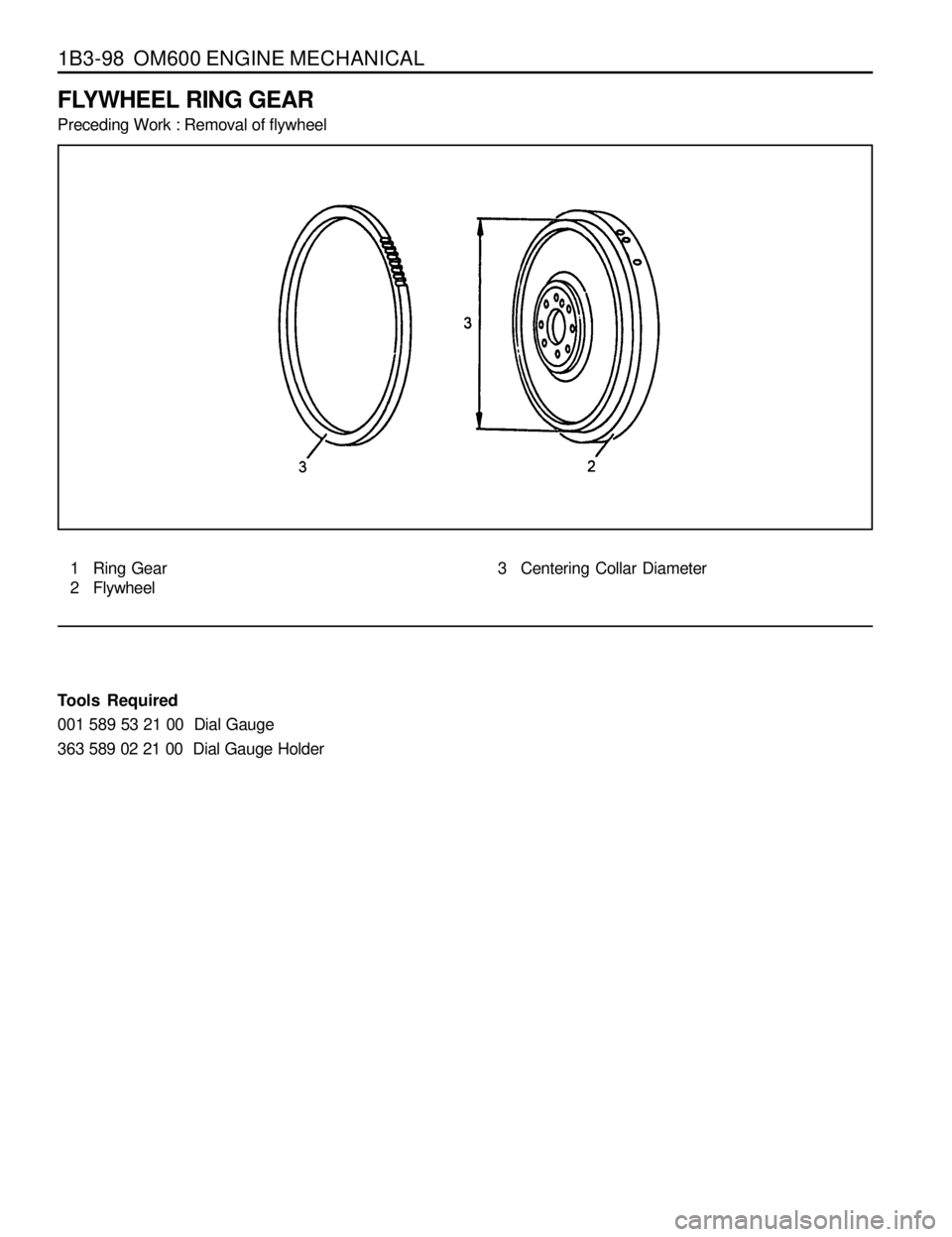

FLYWHEEL RING GEAR

Preceding Work : Removal of flywheel

1 Ring Gear

2 Flywheel3 Centering Collar Diameter

Tools Required

001 589 53 21 00 Dial Gauge

363 589 02 21 00 Dial Gauge Holder

Trending: check oil, spare tire, engine oil, jump cable, instrument cluster, headrest, octane