SSANGYONG MUSSO 1998 Workshop Repair Manual

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Repair Manual

Trending: height adjustment, boot, ground clearance, lug pattern, flat tire, coolant reservoir, lights

Page 381 of 1463

OM600 ENGINE MECHANICAL 1B3-79

5. Install the timing sensor bracket.

Notice

See the ‘TDC setting’.

6. Install the cooling fan pulley.

Tightening Torque 10 Nm

7. Install the cooling fan.

8. Install the fan belt.

9. Remove the engine lock.

Page 382 of 1463

1B3-80 OM600 ENGINE MECHANICAL

CRANKSHAFT FRONT RADIAL SEAL

1 Radial Seal

2 Timing Case Cover

Tools Required

601 589 03 14 00 Sleeve3 Woodruff Key

Page 383 of 1463

OM600 ENGINE MECHANICAL 1B3-81

Notice

The sealing lip of the repair radial seal is offset to the inside

by 2mm to ensure that is does not run in any groove which

the standard radial seal may have left on the crankshaft

flange.

A Standard Radial Seal

B Repair Radial Seal

Replacement Procedure

1. Pull out the radial seal (1) and be careful not to damage the

sealing surface of timing case cover.

2. Thoroughly clean the mounting bore of the radial seal.

3. Coat a little oil on the sealing lip of new radial (1) and contact

surface.

Notice

Don’t use grease.

4. Install the radial seal (1) by using a sleeve (4).

Notice

Align the groove of sleeve and woodruff key(arrow).

Sleeve 601 589 03 14

Page 384 of 1463

1B3-82 OM600 ENGINE MECHANICAL

CRANKSHAFT BALL BEARING

1 Spacer

2 Cover ......................................... Replace

Notice

Manual transmission only.

Tools Required

000 589 33 33 00 Counter Support

000 589 25 33 00 Internal Extractor

Removal & Installation Procedure

1. Remove the manual transmission.

2. Using a puller, pull out the locking ring and ball bearing

together.

Counter Support 000 589 33 33 00

Internal Extractor 000 589 25 33 00

3. Apply Loctite 241 on the new ball bearing and then insert

the ball bearing to be stopped at the spacer ring by using a

proper mandrel.

3 Ball Bearing

4 Bolt.......................................45Nm + 90°

Page 385 of 1463

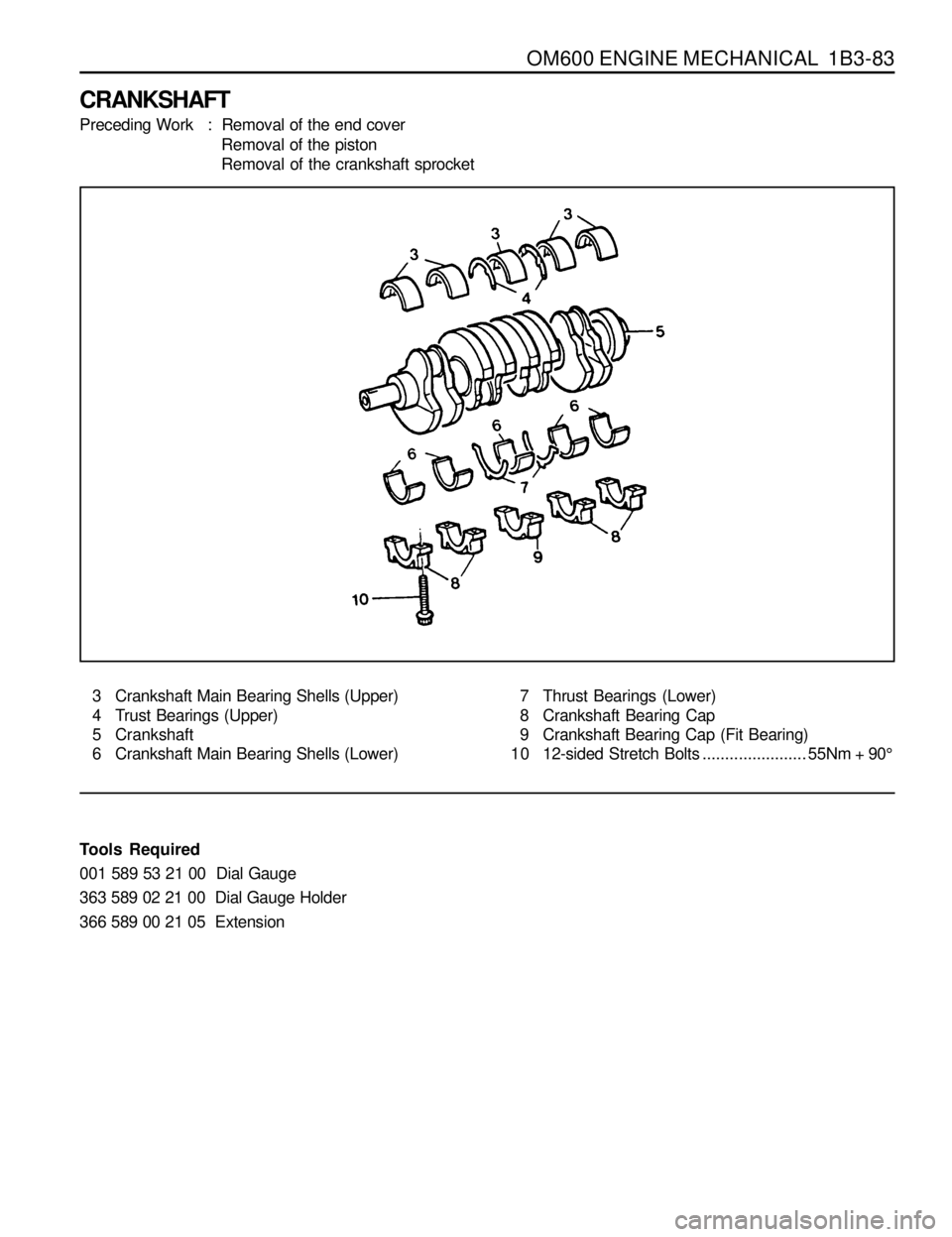

OM600 ENGINE MECHANICAL 1B3-83

CRANKSHAFT

Preceding Work : Removal of the end cover

Removal of the piston

Removal of the crankshaft sprocket

3 Crankshaft Main Bearing Shells (Upper)

4 Trust Bearings (Upper)

5 Crankshaft

6 Crankshaft Main Bearing Shells (Lower)7 Thrust Bearings (Lower)

8 Crankshaft Bearing Cap

9 Crankshaft Bearing Cap (Fit Bearing)

10 12-sided Stretch Bolts.......................55Nm + 90°

Tools Required

001 589 53 21 00 Dial Gauge

363 589 02 21 00 Dial Gauge Holder

366 589 00 21 05 Extension

Page 386 of 1463

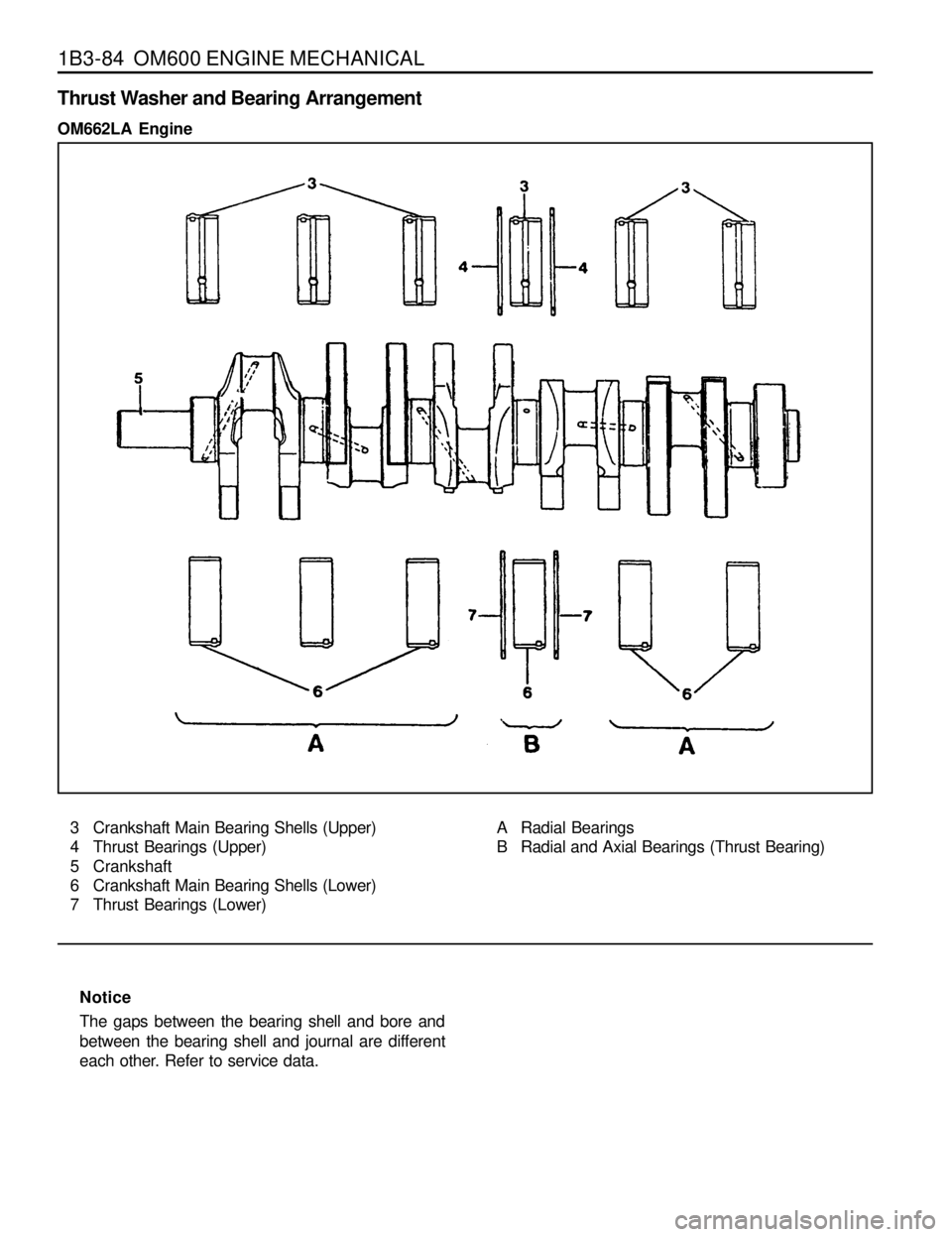

1B3-84 OM600 ENGINE MECHANICAL

3 Crankshaft Main Bearing Shells (Upper)

4 Thrust Bearings (Upper)

5 Crankshaft

6 Crankshaft Main Bearing Shells (Lower)

7 Thrust Bearings (Lower)A Radial Bearings

B Radial and Axial Bearings (Thrust Bearing)

Notice

The gaps between the bearing shell and bore and

between the bearing shell and journal are different

each other. Refer to service data.

Thrust Washer and Bearing Arrangement

OM662LA Engine

Page 387 of 1463

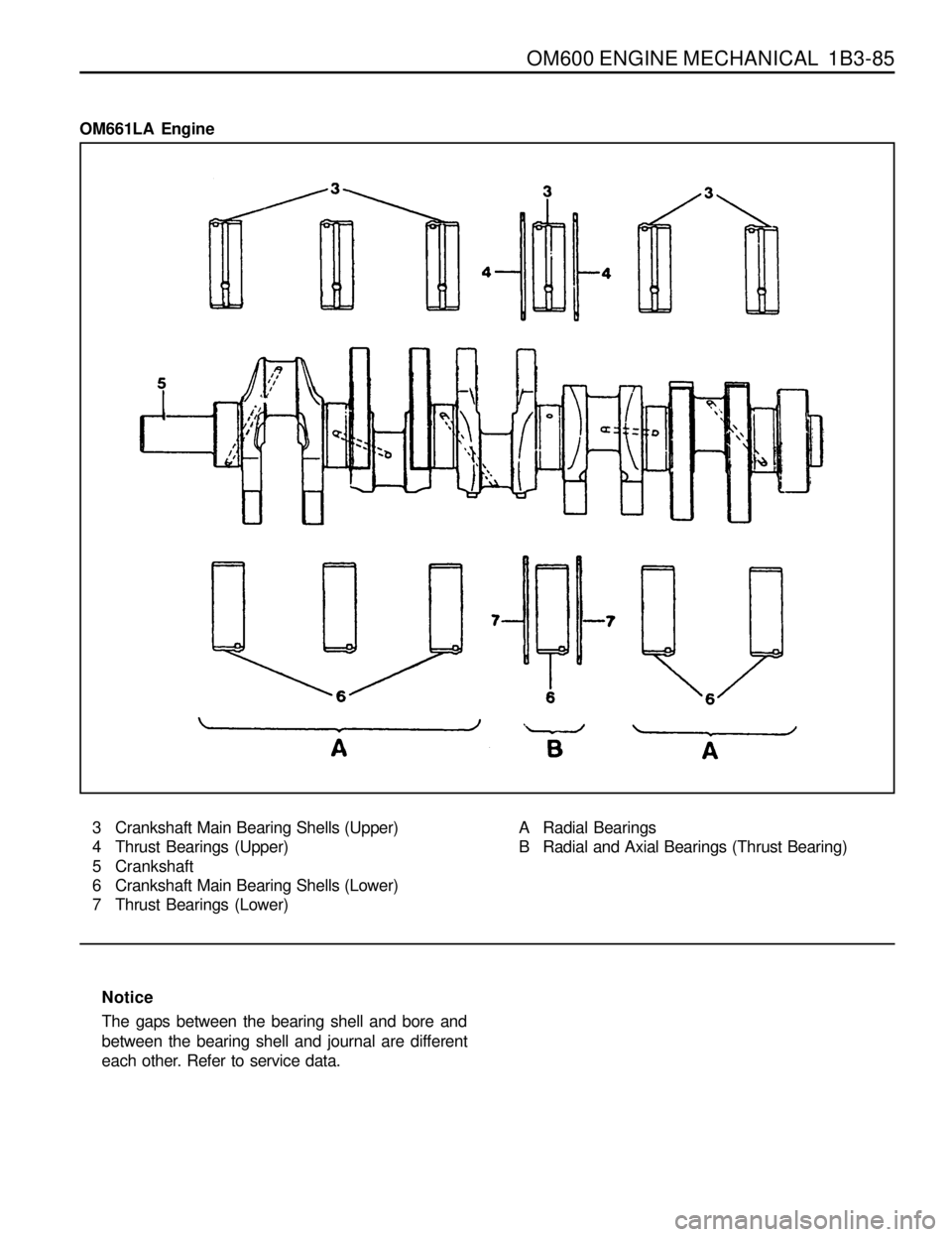

OM600 ENGINE MECHANICAL 1B3-85

3 Crankshaft Main Bearing Shells (Upper)

4 Thrust Bearings (Upper)

5 Crankshaft

6 Crankshaft Main Bearing Shells (Lower)

7 Thrust Bearings (Lower)A Radial Bearings

B Radial and Axial Bearings (Thrust Bearing)

Notice

The gaps between the bearing shell and bore and

between the bearing shell and journal are different

each other. Refer to service data.

OM661LA Engine

Page 388 of 1463

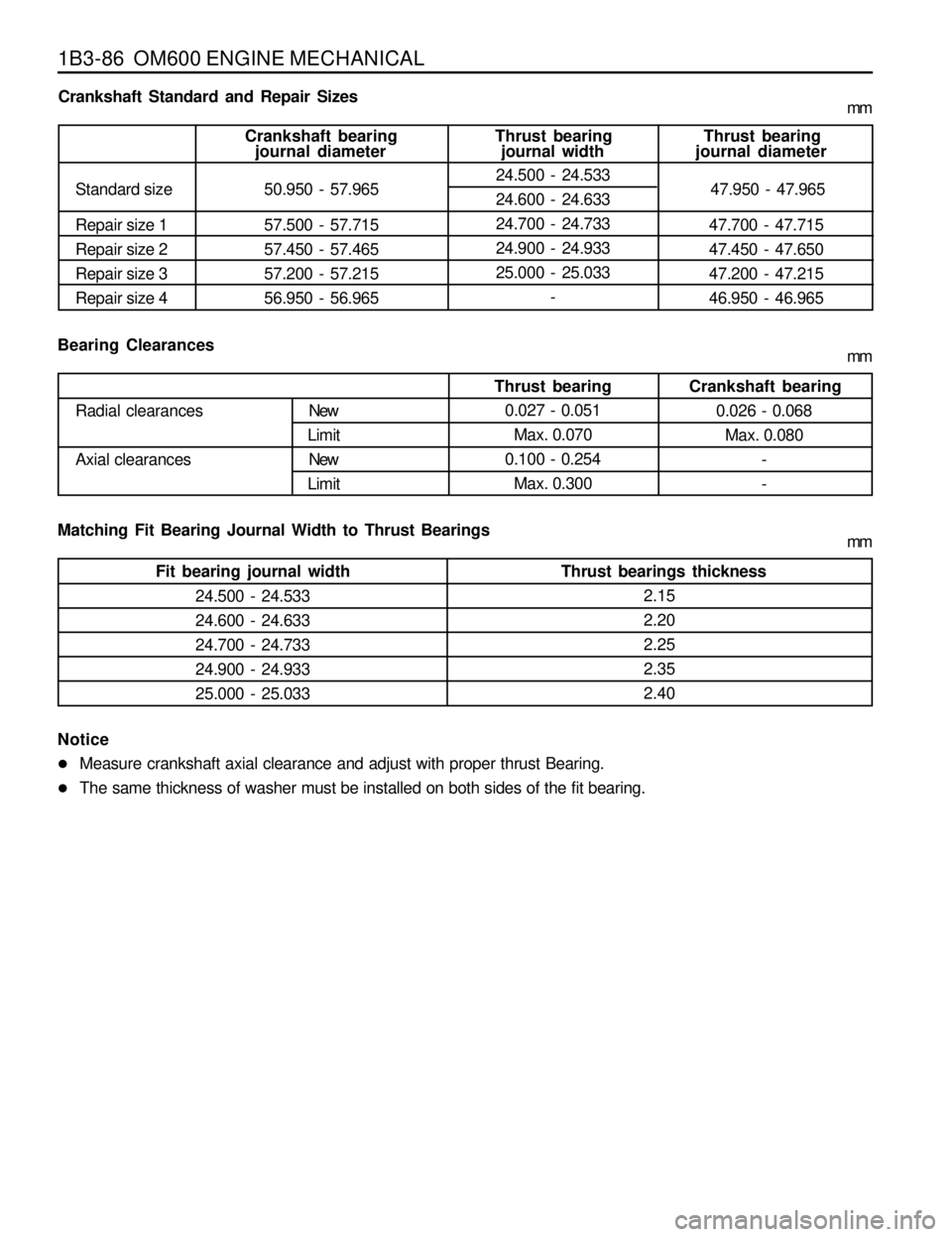

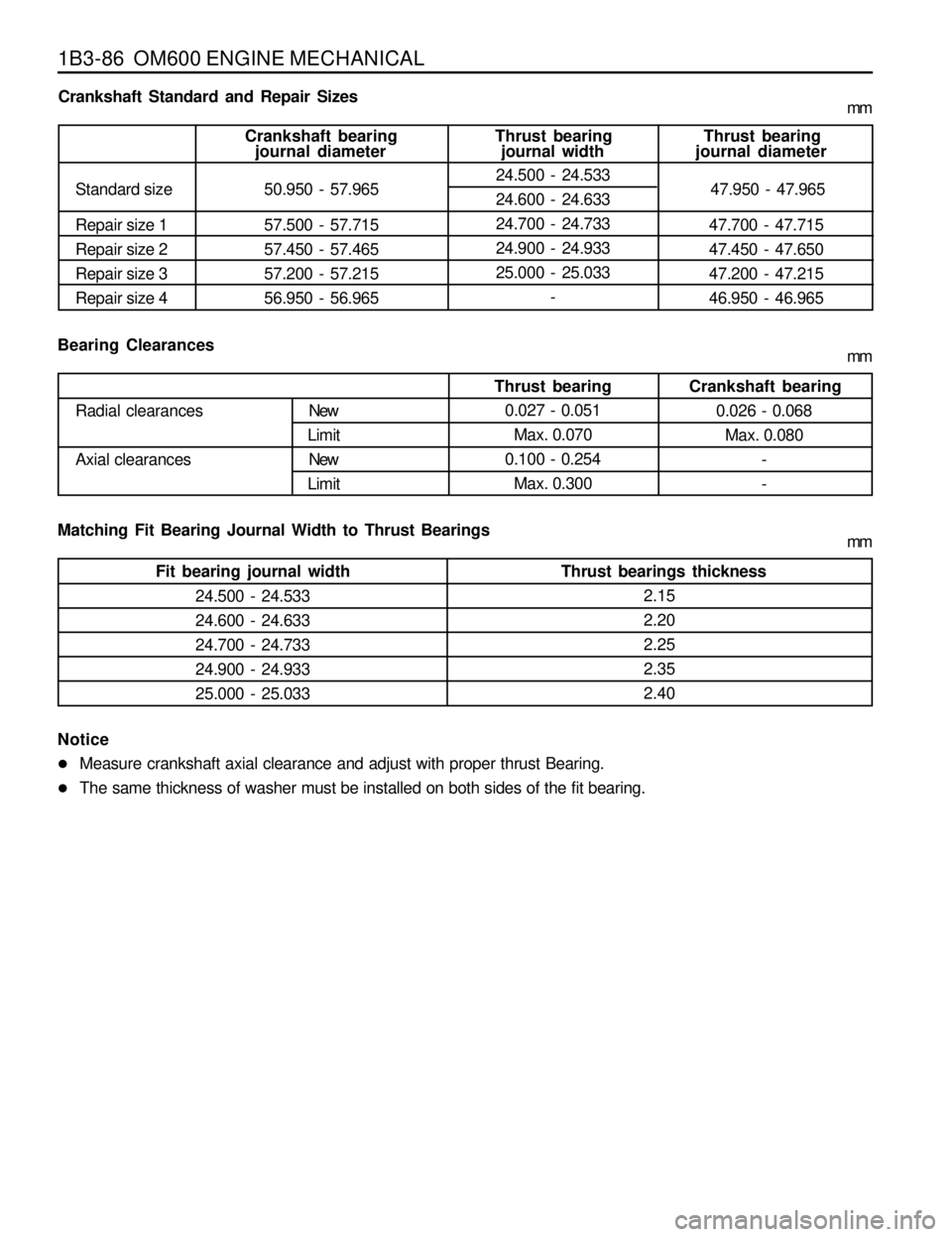

1B3-86 OM600 ENGINE MECHANICAL

24.500 - 24.533

24.600 - 24.633

24.700 - 24.733

24.900 - 24.933

25.000 - 25.033New

Limit

New

Limit Radial clearances

Axial clearancesCrankshaft bearing

journal diameter Crankshaft Standard and Repair Sizes

Standard size 50.950 - 57.965

journal width

24.500 - 24.533

24.600 - 24.633

24.700 - 24.733

24.900 - 24.933

25.000 - 25.033

-Thrust bearing

journal diameter

47.950 - 47.965 Thrust bearing

47.700 - 47.715

47.450 - 47.650

47.200 - 47.215

46.950 - 46.965 57.500 - 57.715

57.450 - 57.465

57.200 - 57.215

56.950 - 56.965 Repair size 1

Repair size 2

Repair size 3

Repair size 4

Bearing Clearances

Thrust bearingCrankshaft bearing

0.026 - 0.068

Max. 0.080

-

- 0.027 - 0.051

Max. 0.070

0.100 - 0.254

Max. 0.300

Matching Fit Bearing Journal Width to Thrust Bearings

Fit bearing journal width Thrust bearings thickness

2.15

2.20

2.25

2.35

2.40

Notice

lMeasure crankshaft axial clearance and adjust with proper thrust Bearing.

lThe same thickness of washer must be installed on both sides of the fit bearing.mm

mm

mm

Page 389 of 1463

OM600 ENGINE MECHANICAL 1B3-87

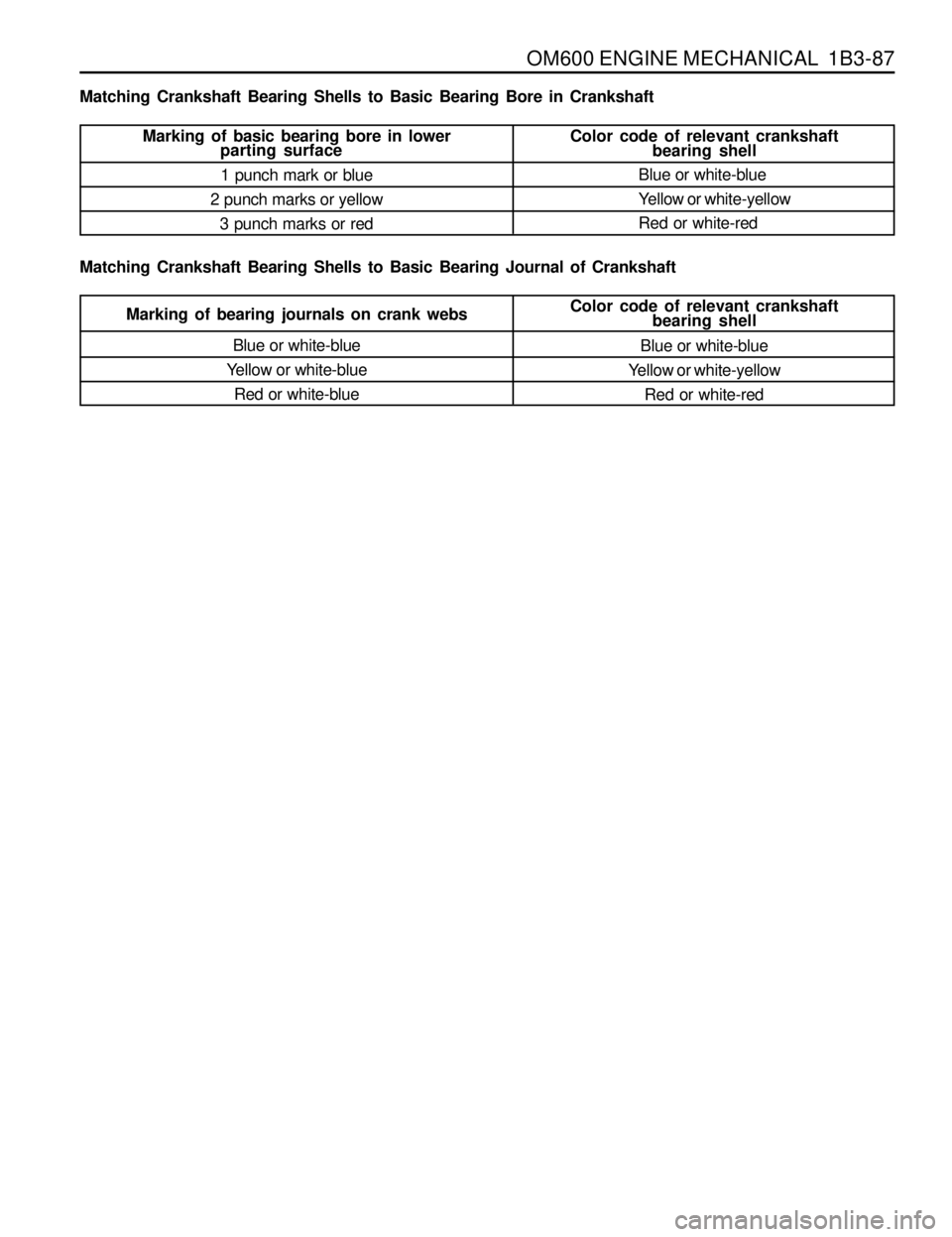

bearing shell Matching Crankshaft Bearing Shells to Basic Bearing Bore in Crankshaft

Matching Crankshaft Bearing Shells to Basic Bearing Journal of Crankshaft

Marking of basic bearing bore in lowerColor code of relevant crankshaft

parting surface

1 punch mark or blue

2 punch marks or yellow

3 punch marks or redbearing shell

Blue or white-blue

Yellow or white-yellow

Red or white-red

Marking of bearing journals on crank websColor code of relevant crankshaft

Blue or white-blue

Yellow or white-blue

Red or white-blueBlue or white-blue

Yellow or white-yellow

Red or white-red

Page 390 of 1463

1B3-88 OM600 ENGINE MECHANICAL

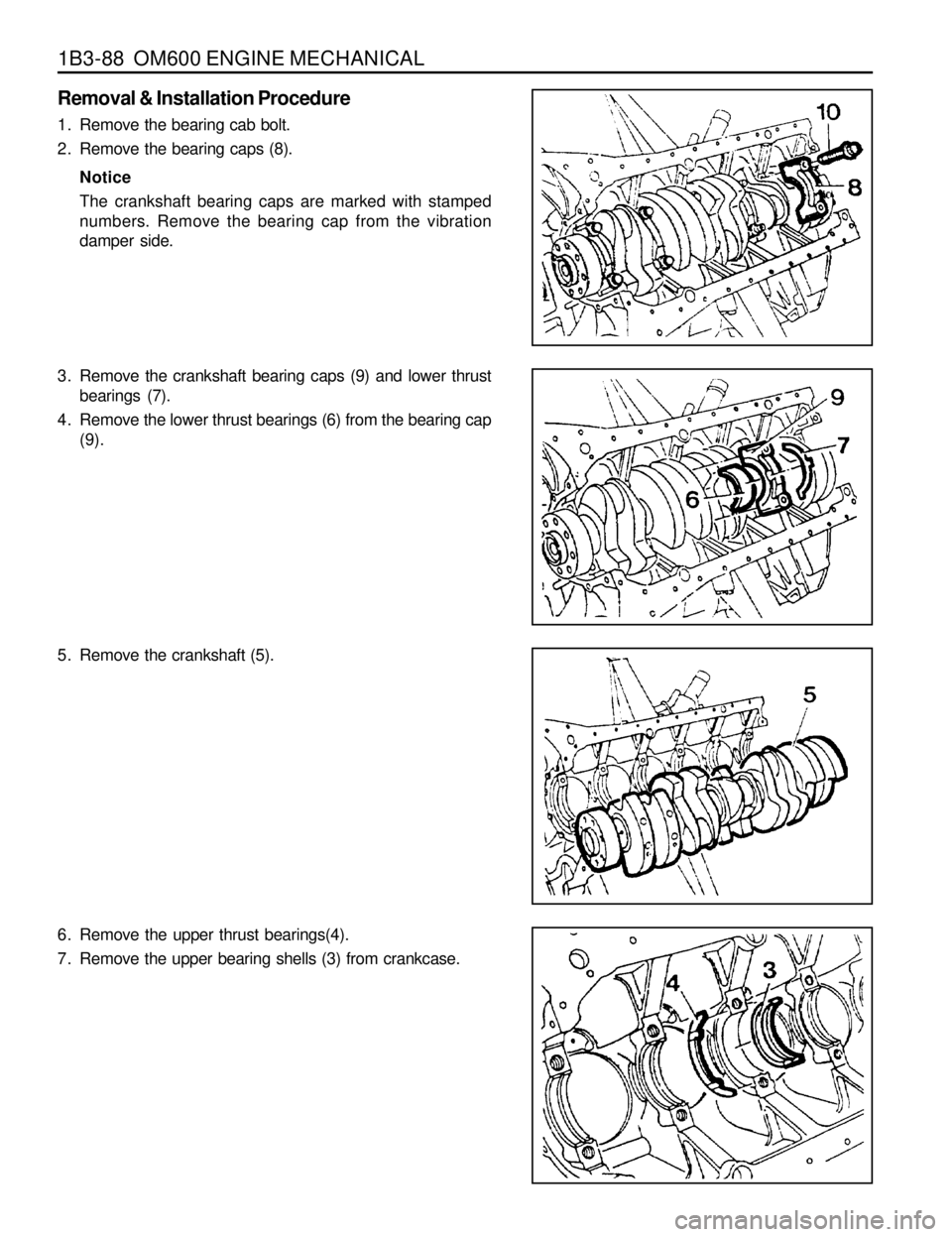

Removal & Installation Procedure

1. Remove the bearing cab bolt.

2. Remove the bearing caps (8).

Notice

The crankshaft bearing caps are marked with stamped

numbers. Remove the bearing cap from the vibration

damper side.

3. Remove the crankshaft bearing caps (9) and lower thrust

bearings (7).

4. Remove the lower thrust bearings (6) from the bearing cap

(9).

5. Remove the crankshaft (5).

6. Remove the upper thrust bearings(4).

7. Remove the upper bearing shells (3) from crankcase.

Trending: power steering, height, wheel bolt torque, headlamp, window, spark plugs replace, fuel tank removal