SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 261 of 2870

LI-7

LIGHTING SYSTEM

Back-up Light System

6. Back-up Light System

A: WIRING DIAGRAM

1. BACK-UP LIGHT

B: INSPECTION

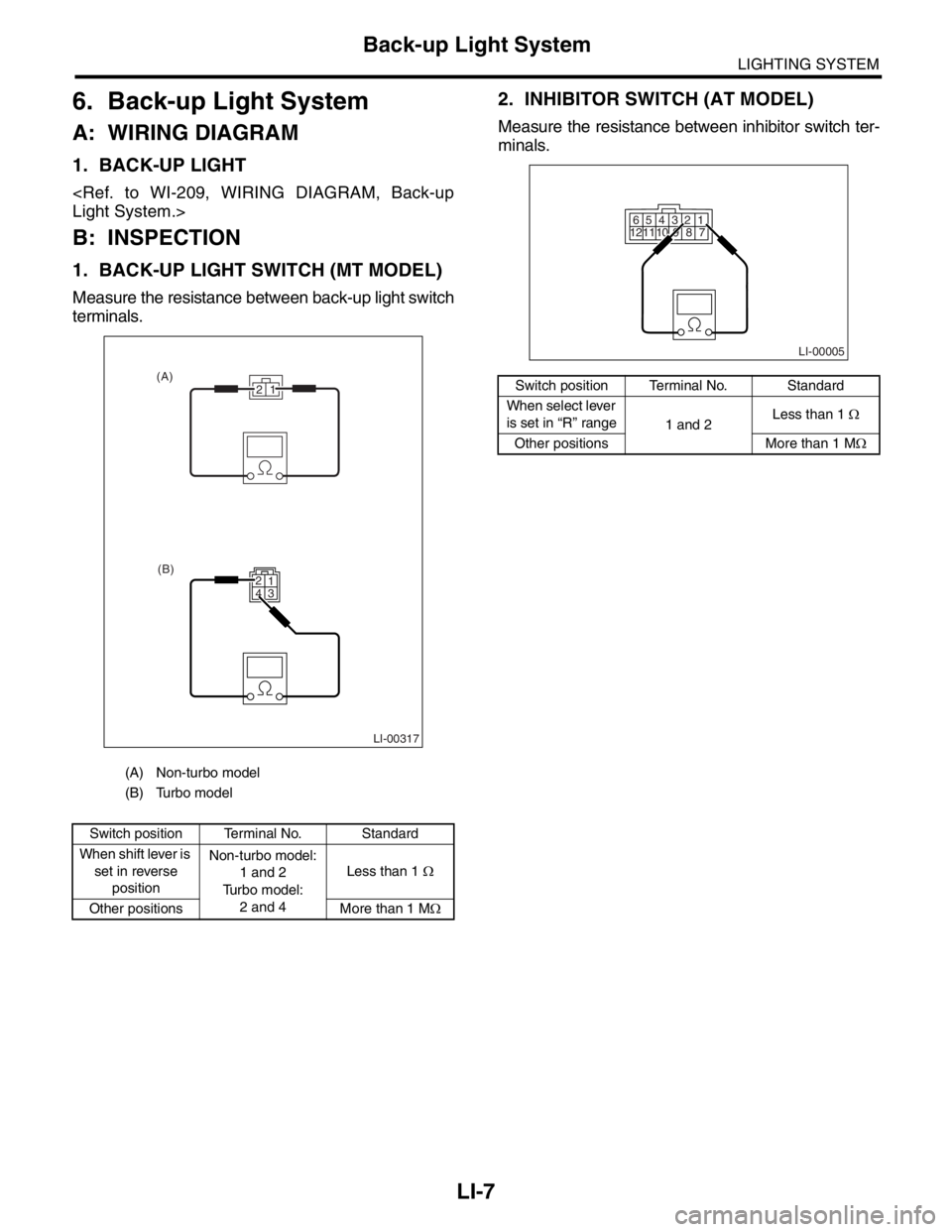

1. BACK-UP LIGHT SWITCH (MT MODEL)

Measure the resistance between back-up light switch

terminals.

2. INHIBITOR SWITCH (AT MODEL)

Measure the resistance between inhibitor switch ter-

minals.

(A) Non-turbo model

(B) Turbo model

Switch position Terminal No. Standard

When shift lever is

set in reverse

positionNon-turbo model:

1 and 2

Turbo model:

2 and 4Less than 1 Ω

Other positions More than 1 MΩ

LI-00317 1 2

1 2

3 4

(A)

(B)Switch position Terminal No. Standard

When select lever

is set in “R” range

1 and 2Less than 1 Ω

Other positions More than 1 MΩ

9

LI-000054321 5 6

7 8 10 11 12

Page 262 of 2870

LI-8

LIGHTING SYSTEM

Stop Light System

7. Stop Light System

A: WIRING DIAGRAM

1. STOP LIGHT

B: INSPECTION

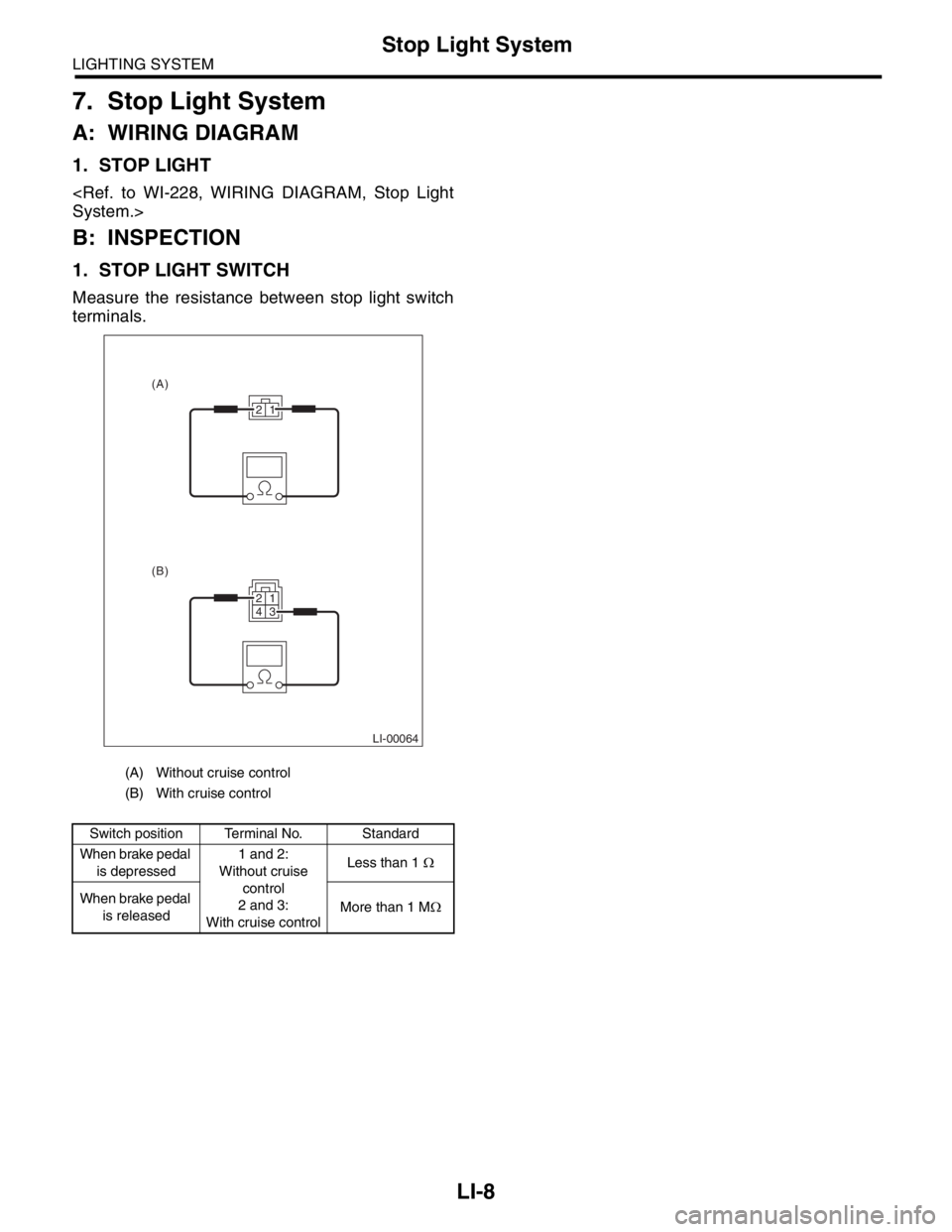

1. STOP LIGHT SWITCH

Measure the resistance between stop light switch

terminals.

(A) Without cruise control

(B) With cruise control

Switch position Terminal No. Standard

When brake pedal

is depressed1 and 2:

Without cruise

control

2 and 3:

With cruise controlLess than 1 Ω

When brake pedal

is releasedMore than 1 MΩ

3 4

1 2

1 2

LI-00064

(A)

(B)

Page 263 of 2870

LI-9

LIGHTING SYSTEM

Room Light System

8. Room Light System

A: WIRING DIAGRAM

1. ROOM LIGHT

B: INSPECTION

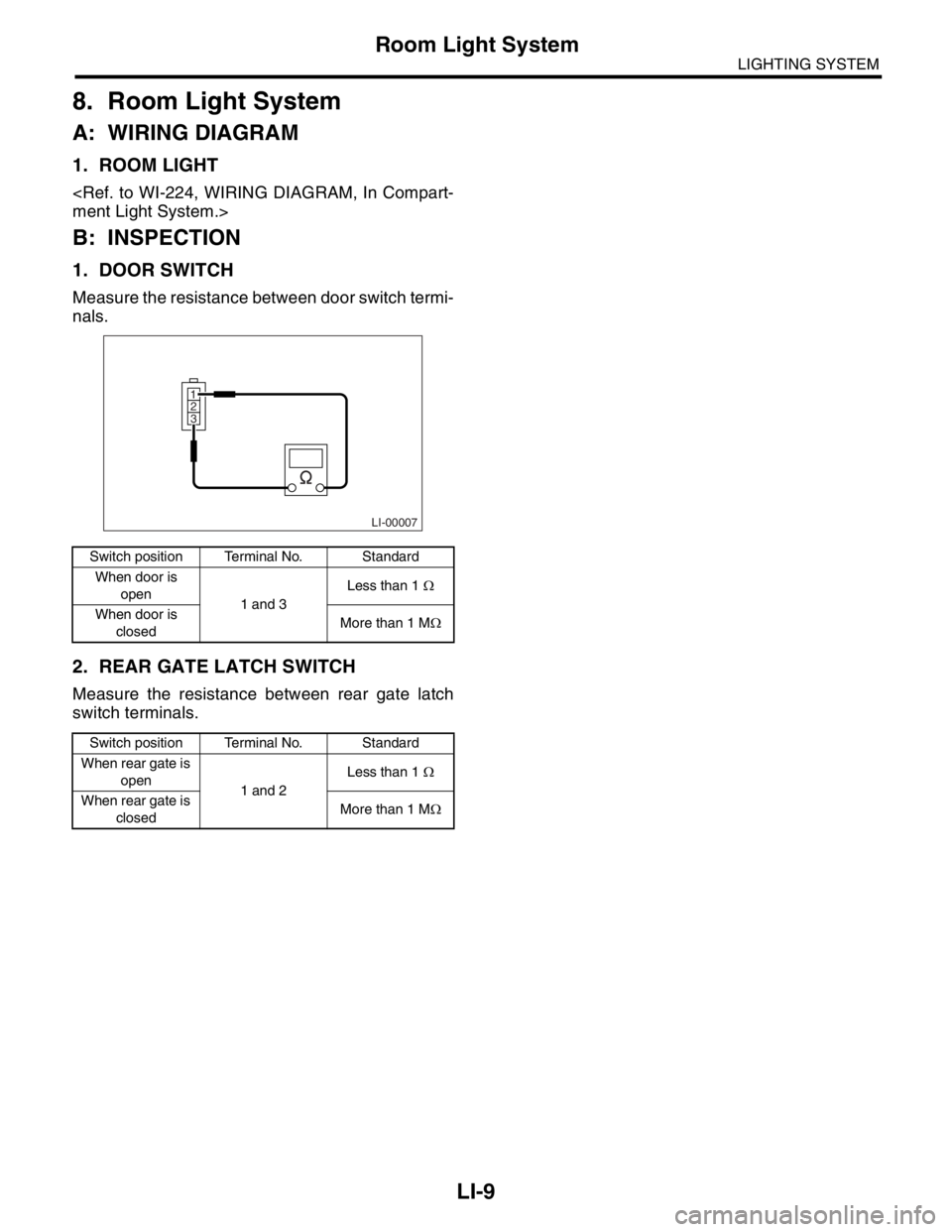

1. DOOR SWITCH

Measure the resistance between door switch termi-

nals.

2. REAR GATE LATCH SWITCH

Measure the resistance between rear gate latch

switch terminals.

Switch position Terminal No. Standard

When door is

open

1 and 3Less than 1 Ω

When door is

closedMore than 1 MΩ

Switch position Terminal No. Standard

When rear gate is

open

1 and 2Less than 1 Ω

When rear gate is

closedMore than 1 MΩ

123

LI-00007

Page 264 of 2870

LI-10

LIGHTING SYSTEM

Headlight Beam Leveler System

9. Headlight Beam Leveler Sys-

tem

A: WIRING DIAGRAM

1. HEADLIGHT BEAM LEVELER

B: INSPECTION

1. HEADLIGHT BEAM LEVELER ACTUA-

TOR

1) Turn on the headlights.

2) Confirm the headlight beam level is lowered by

changing the switch position to 0 → 1 → 2 → 3 →

4 → 5.

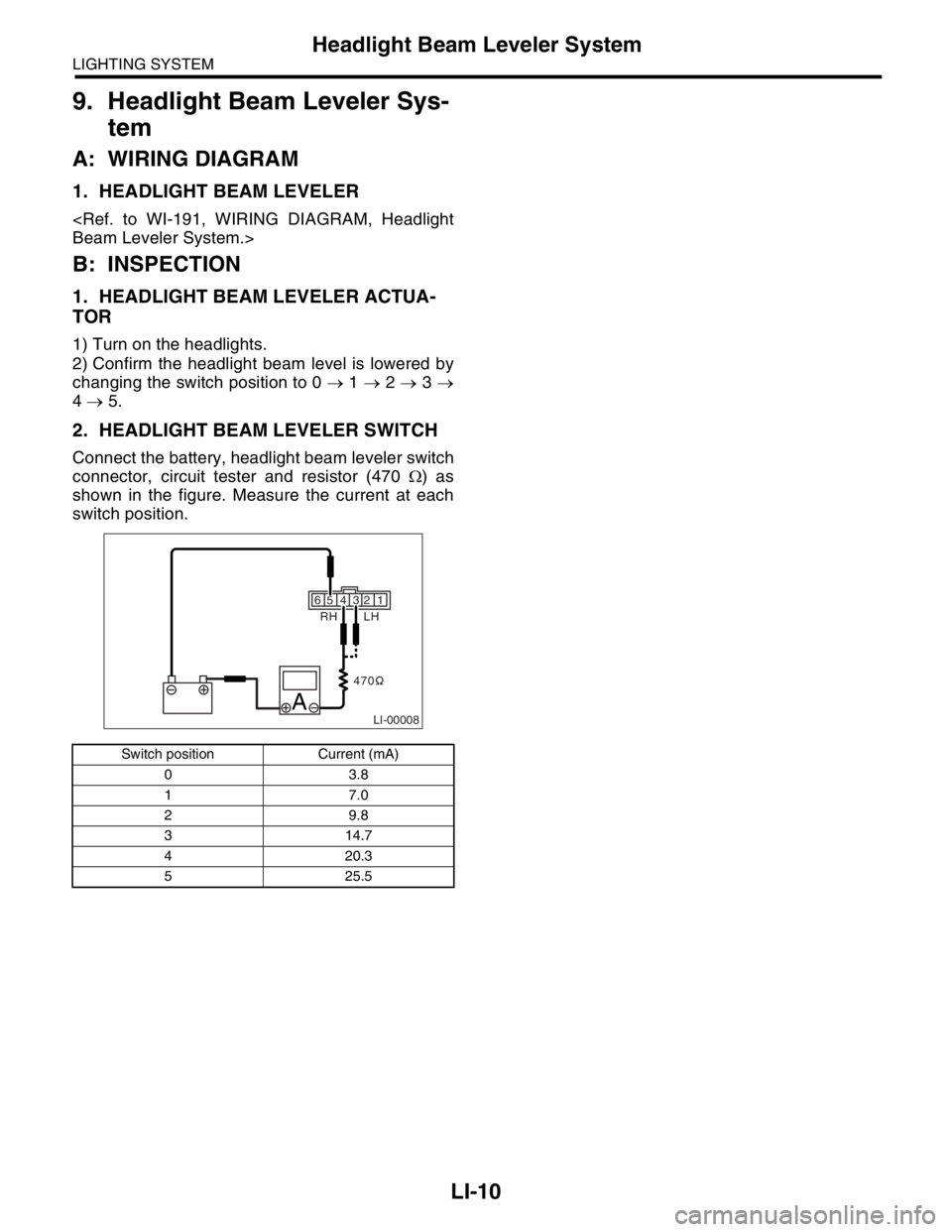

2. HEADLIGHT BEAM LEVELER SWITCH

Connect the battery, headlight beam leveler switch

connector, circuit tester and resistor (470 Ω) as

shown in the figure. Measure the current at each

switch position.

Switch position Current (mA)

03.8

17.0

29.8

3 14.7

4 20.3

5 25.5

65 4 2 1

LI-00008A

RH LH

470 3

Page 265 of 2870

LI-11

LIGHTING SYSTEM

Combination Switch (Light)

10.Combination Switch (Light)

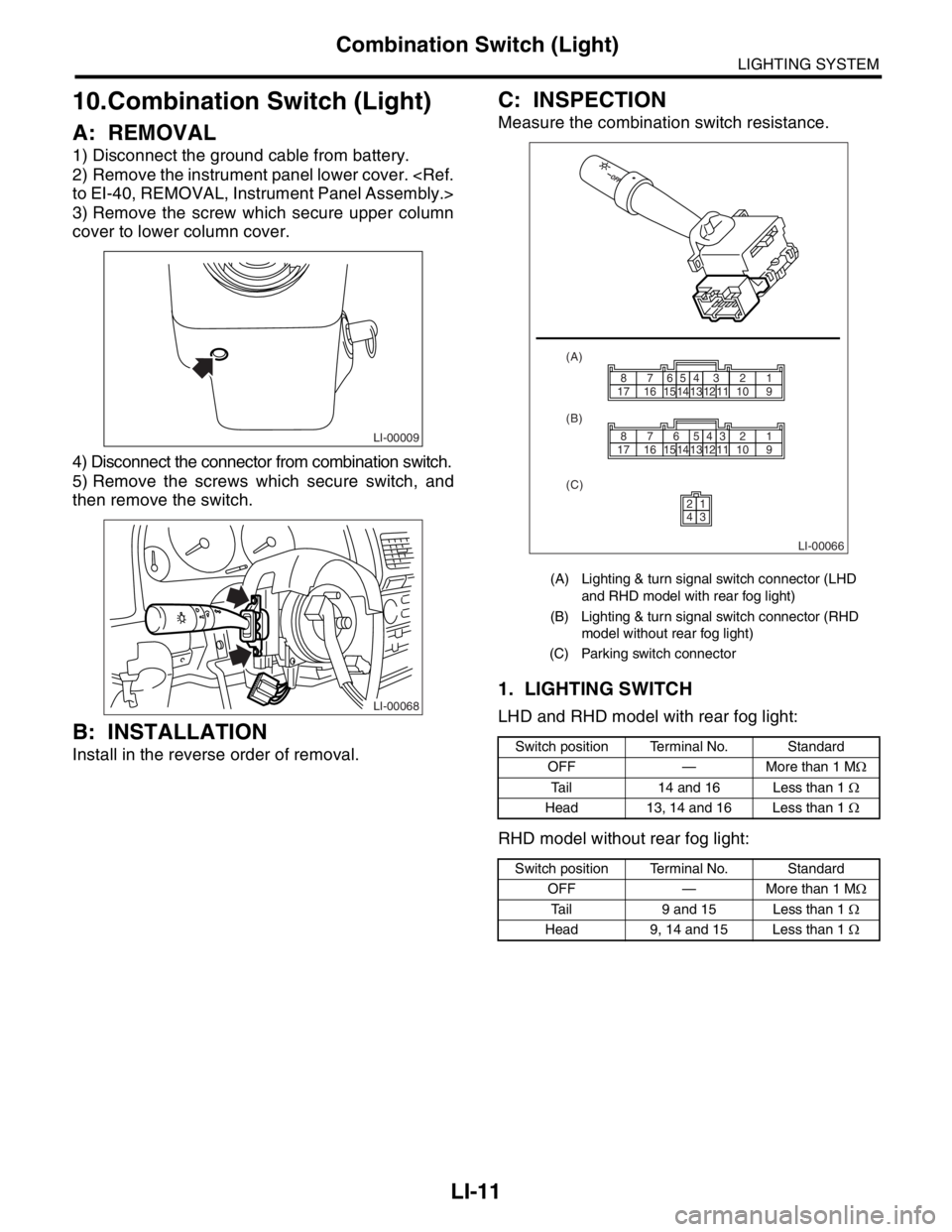

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the instrument panel lower cover.

3) Remove the screw which secure upper column

cover to lower column cover.

4) Disconnect the connector from combination switch.

5) Remove the screws which secure switch, and

then remove the switch.

B: INSTALLATION

Install in the reverse order of removal.

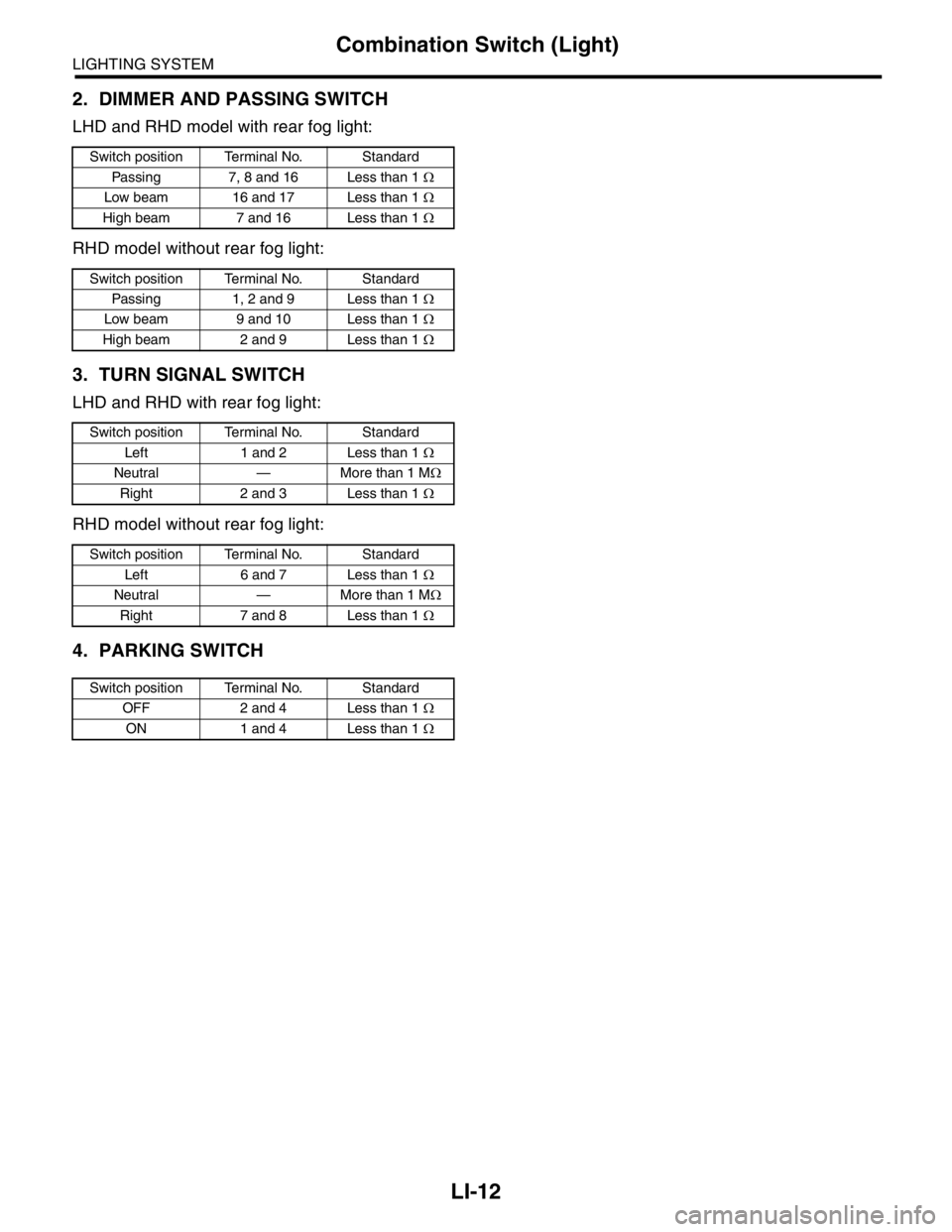

C: INSPECTION

Measure the combination switch resistance.

1. LIGHTING SWITCH

LHD and RHD model with rear fog light:

RHD model without rear fog light:

LI-00009

LI-00068

(A) Lighting & turn signal switch connector (LHD

and RHD model with rear fog light)

(B) Lighting & turn signal switch connector (RHD

model without rear fog light)

(C) Parking switch connector

Switch position Terminal No. Standard

OFF — More than 1 MΩ

Tail 14 and 16 Less than 1 Ω

Head 13, 14 and 16 Less than 1 Ω

Switch position Terminal No. Standard

OFF — More than 1 MΩ

Tail 9 and 15 Less than 1 Ω

Head 9, 14 and 15 Less than 1 Ω

LI-00066

1514131211109171665432187

1514

2143

131211109171665432187

(A)

(B)

(C)

Page 266 of 2870

LI-12

LIGHTING SYSTEM

Combination Switch (Light)

2. DIMMER AND PASSING SWITCH

LHD and RHD model with rear fog light:

RHD model without rear fog light:

3. TURN SIGNAL SWITCH

LHD and RHD with rear fog light:

RHD model without rear fog light:

4. PARKING SWITCH

Switch position Terminal No. Standard

Passing 7, 8 and 16 Less than 1 Ω

Low beam 16 and 17 Less than 1 Ω

High beam 7 and 16 Less than 1 Ω

Switch position Terminal No. Standard

Passing 1, 2 and 9 Less than 1 Ω

Low beam 9 and 10 Less than 1 Ω

High beam 2 and 9 Less than 1 Ω

Switch position Terminal No. Standard

Left 1 and 2 Less than 1 Ω

Neutral — More than 1 MΩ

Right 2 and 3 Less than 1 Ω

Switch position Terminal No. Standard

Left 6 and 7 Less than 1 Ω

Neutral — More than 1 MΩ

Right 7 and 8 Less than 1 Ω

Switch position Terminal No. Standard

OFF 2 and 4 Less than 1 Ω

ON 1 and 4 Less than 1 Ω

Page 267 of 2870

LI-13

LIGHTING SYSTEM

Headlight Assembly

11.Headlight Assembly

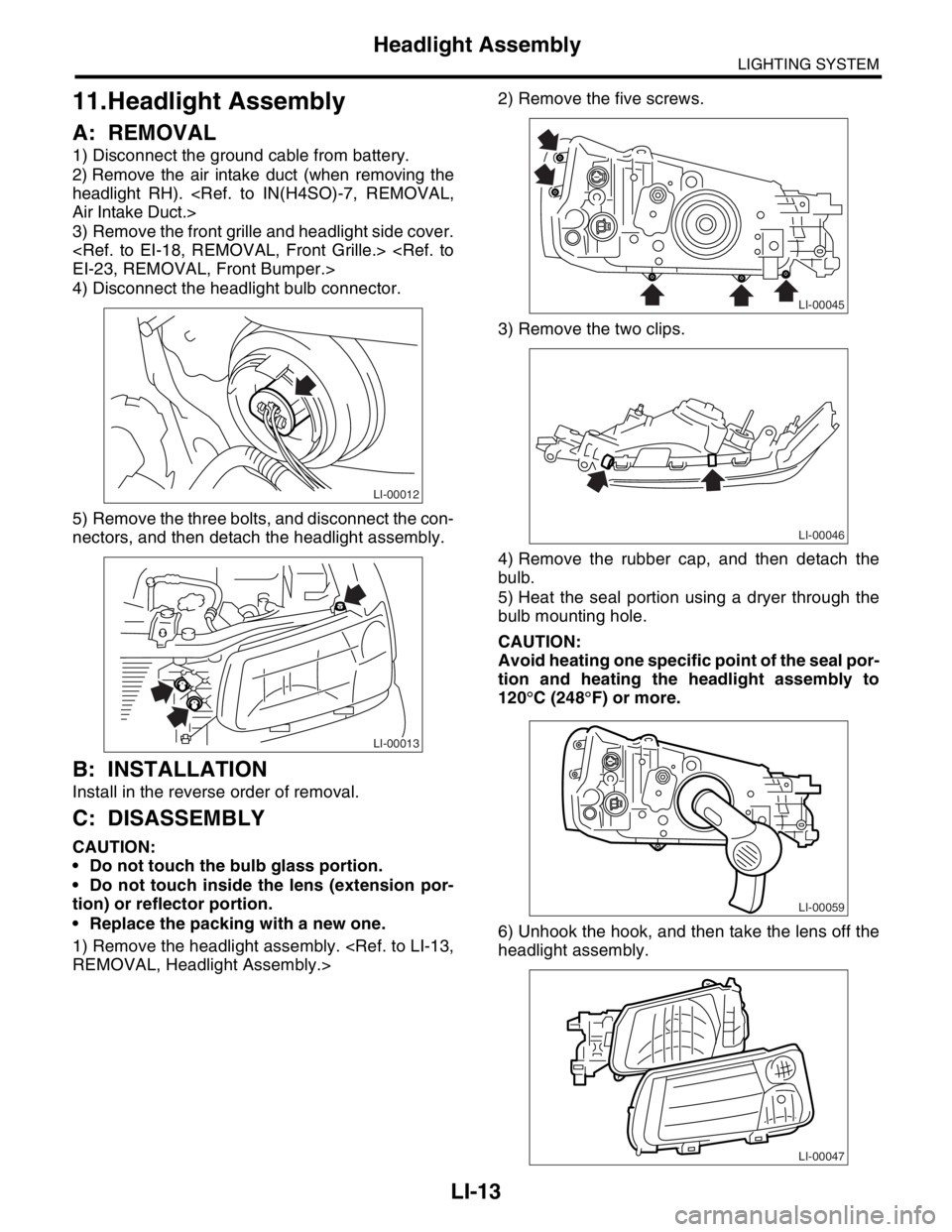

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the air intake duct (when removing the

headlight RH).

3) Remove the front grille and headlight side cover.

4) Disconnect the headlight bulb connector.

5) Remove the three bolts, and disconnect the con-

nectors, and then detach the headlight assembly.

B: INSTALLATION

Install in the reverse order of removal.

C: DISASSEMBLY

CAUTION:

Do not touch the bulb glass portion.

Do not touch inside the lens (extension por-

tion) or reflector portion.

Replace the packing with a new one.

1) Remove the headlight assembly.

3) Remove the two clips.

4) Remove the rubber cap, and then detach the

bulb.

5) Heat the seal portion using a dryer through the

bulb mounting hole.

CAUTION:

Avoid heating one specific point of the seal por-

tion and heating the headlight assembly to

120°C (248°F) or more.

6) Unhook the hook, and then take the lens off the

headlight assembly.

LI-00012

LI-00013

LI-00045

LI-00046

LI-00059

LI-00047

Page 268 of 2870

LI-14

LIGHTING SYSTEM

Headlight Assembly

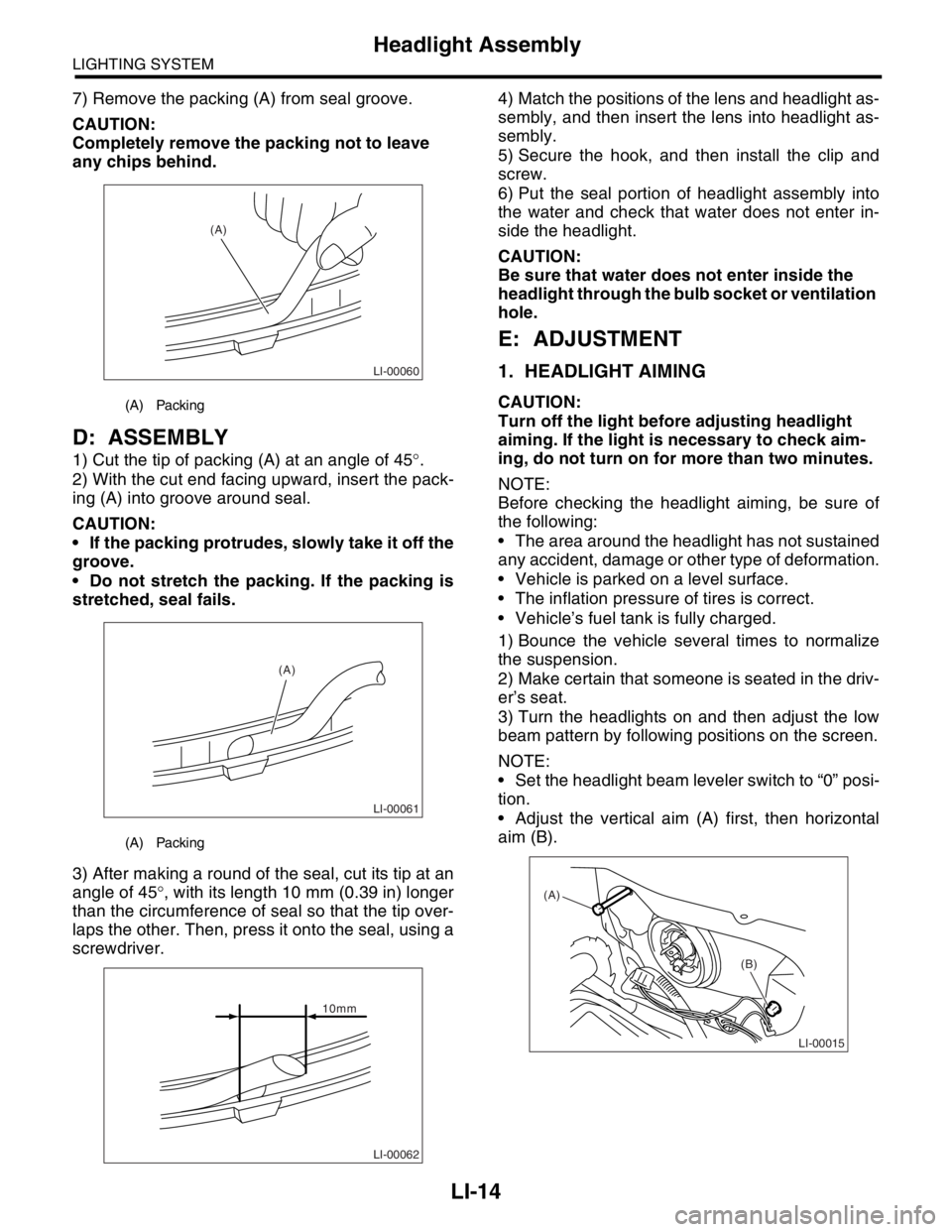

7) Remove the packing (A) from seal groove.

CAUTION:

Completely remove the packing not to leave

any chips behind.

D: ASSEMBLY

1) Cut the tip of packing (A) at an angle of 45°.

2) With the cut end facing upward, insert the pack-

ing (A) into groove around seal.

CAUTION:

If the packing protrudes, slowly take it off the

groove.

Do not stretch the packing. If the packing is

stretched, seal fails.

3) After making a round of the seal, cut its tip at an

angle of 45°, with its length 10 mm (0.39 in) longer

than the circumference of seal so that the tip over-

laps the other. Then, press it onto the seal, using a

screwdriver.4) Match the positions of the lens and headlight as-

sembly, and then insert the lens into headlight as-

sembly.

5) Secure the hook, and then install the clip and

screw.

6) Put the seal portion of headlight assembly into

the water and check that water does not enter in-

side the headlight.

CAUTION:

Be sure that water does not enter inside the

headlight through the bulb socket or ventilation

hole.

E: ADJUSTMENT

1. HEADLIGHT AIMING

CAUTION:

Turn off the light before adjusting headlight

aiming. If the light is necessary to check aim-

ing, do not turn on for more than two minutes.

NOTE:

Before checking the headlight aiming, be sure of

the following:

The area around the headlight has not sustained

any accident, damage or other type of deformation.

Vehicle is parked on a level surface.

The inflation pressure of tires is correct.

Vehicle’s fuel tank is fully charged.

1) Bounce the vehicle several times to normalize

the suspension.

2) Make certain that someone is seated in the driv-

er’s seat.

3) Turn the headlights on and then adjust the low

beam pattern by following positions on the screen.

NOTE:

Set the headlight beam leveler switch to “0” posi-

tion.

Adjust the vertical aim (A) first, then horizontal

aim (B).(A) Packing

(A) Packing

LI-00060

(A)

LI-00061

(A)

LI-00062

10mm

LI-00015

(A)

(B)

Page 269 of 2870

LI-15

LIGHTING SYSTEM

Headlight Assembly

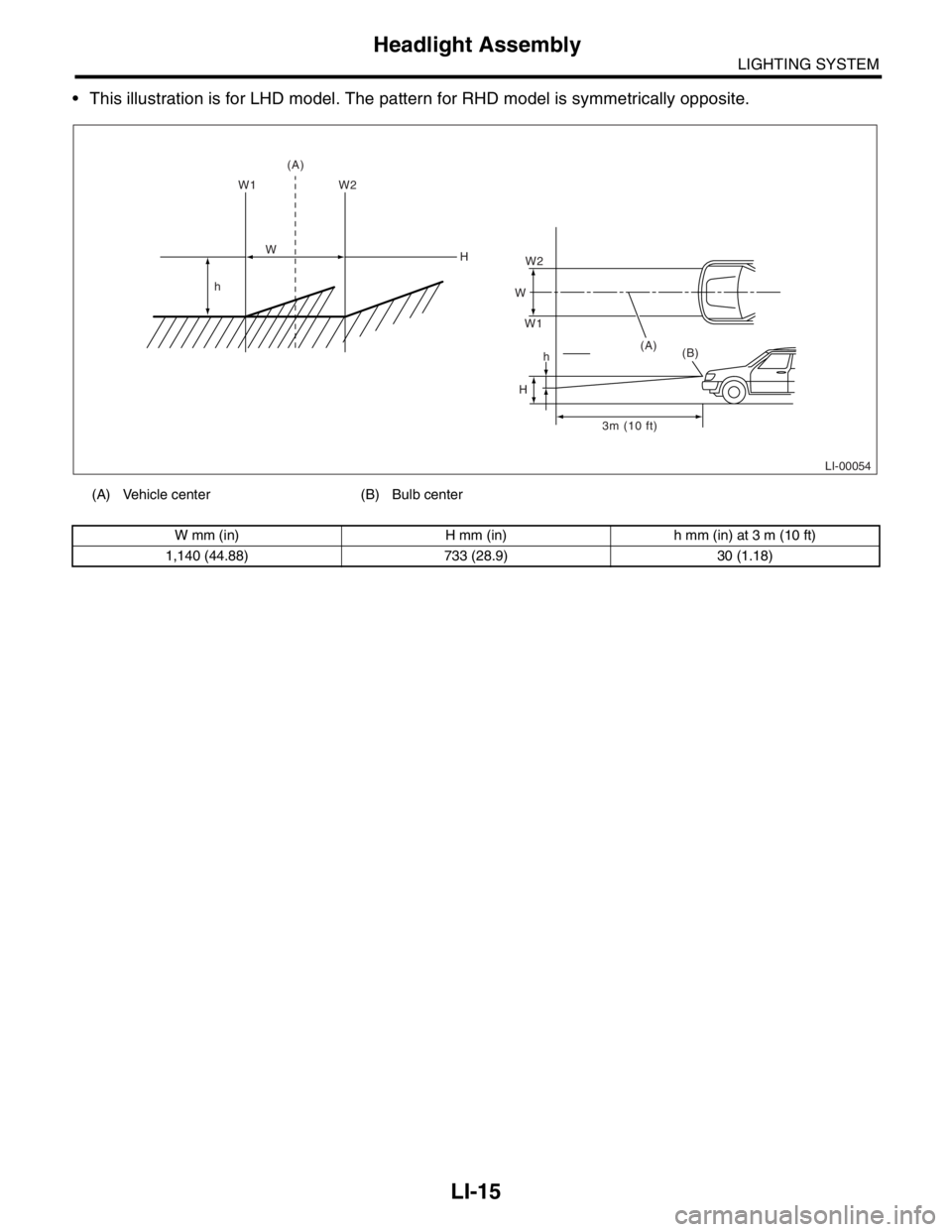

This illustration is for LHD model. The pattern for RHD model is symmetrically opposite.

(A) Vehicle center (B) Bulb center

W mm (in) H mm (in) h mm (in) at 3 m (10 ft)

1,140 (44.88) 733 (28.9) 30 (1.18)

LI-00054

H

H W1

W

W W2

W2

W1 (A)

(A)

3m (10 ft)(B) h

h

Page 270 of 2870

LI-16

LIGHTING SYSTEM

Headlight Bulb

12.Headlight Bulb

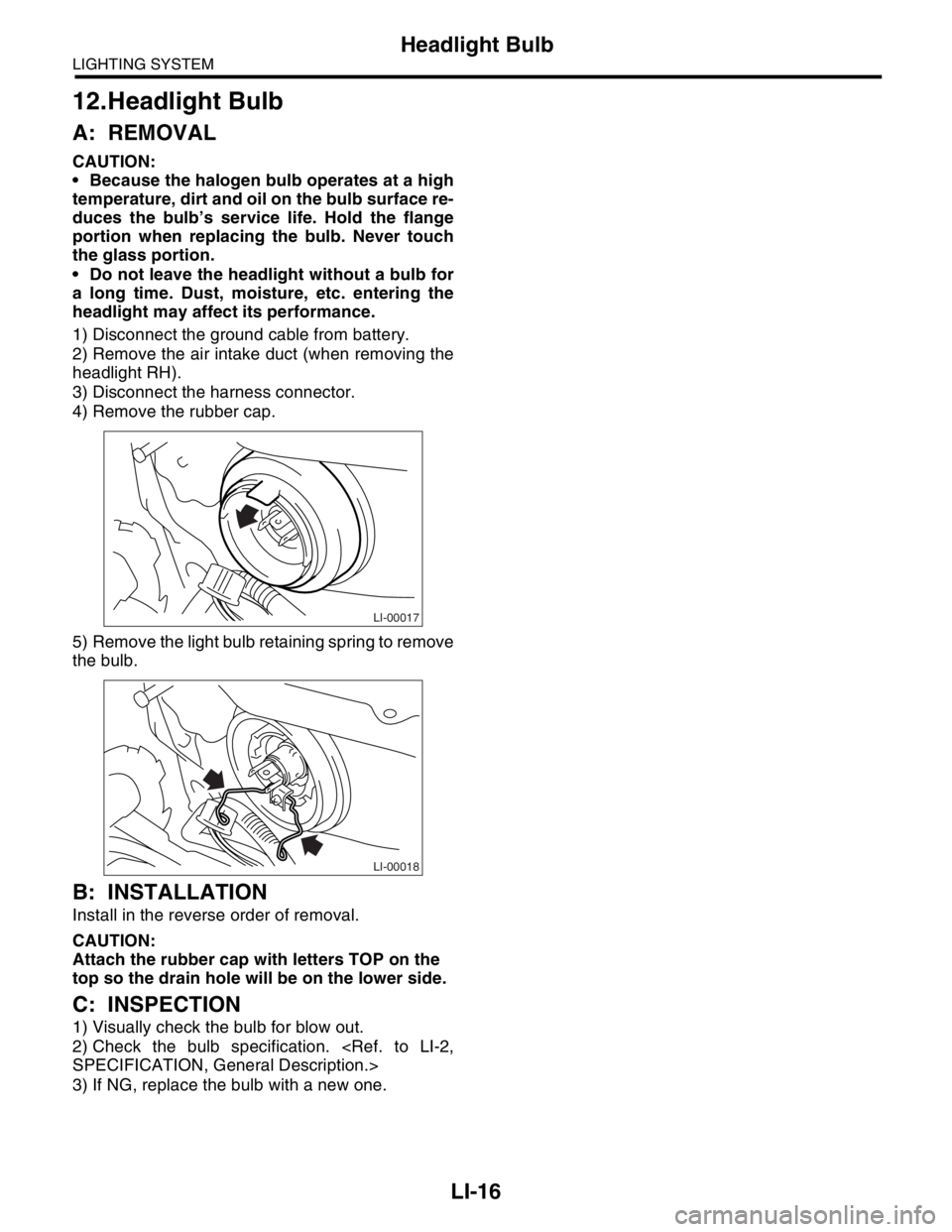

A: REMOVAL

CAUTION:

Because the halogen bulb operates at a high

temperature, dirt and oil on the bulb surface re-

duces the bulb’s service life. Hold the flange

portion when replacing the bulb. Never touch

the glass portion.

Do not leave the headlight without a bulb for

a long time. Dust, moisture, etc. entering the

headlight may affect its performance.

1) Disconnect the ground cable from battery.

2) Remove the air intake duct (when removing the

headlight RH).

3) Disconnect the harness connector.

4) Remove the rubber cap.

5) Remove the light bulb retaining spring to remove

the bulb.

B: INSTALLATION

Install in the reverse order of removal.

CAUTION:

Attach the rubber cap with letters TOP on the

top so the drain hole will be on the lower side.

C: INSPECTION

1) Visually check the bulb for blow out.

2) Check the bulb specification.

3) If NG, replace the bulb with a new one.

LI-00017

LI-00018