SUBARU FORESTER 2004 Service Repair Manual

FORESTER 2004

SUBARU

SUBARU

https://www.carmanualsonline.info/img/17/57426/w960_57426-0.png

SUBARU FORESTER 2004 Service Repair Manual

Trending: wheel bolts, brake, brakes, radiator cap, headlight bulb, air conditioning, diagram

Page 291 of 2870

WW-3

WIPER AND WASHER SYSTEM

General Description

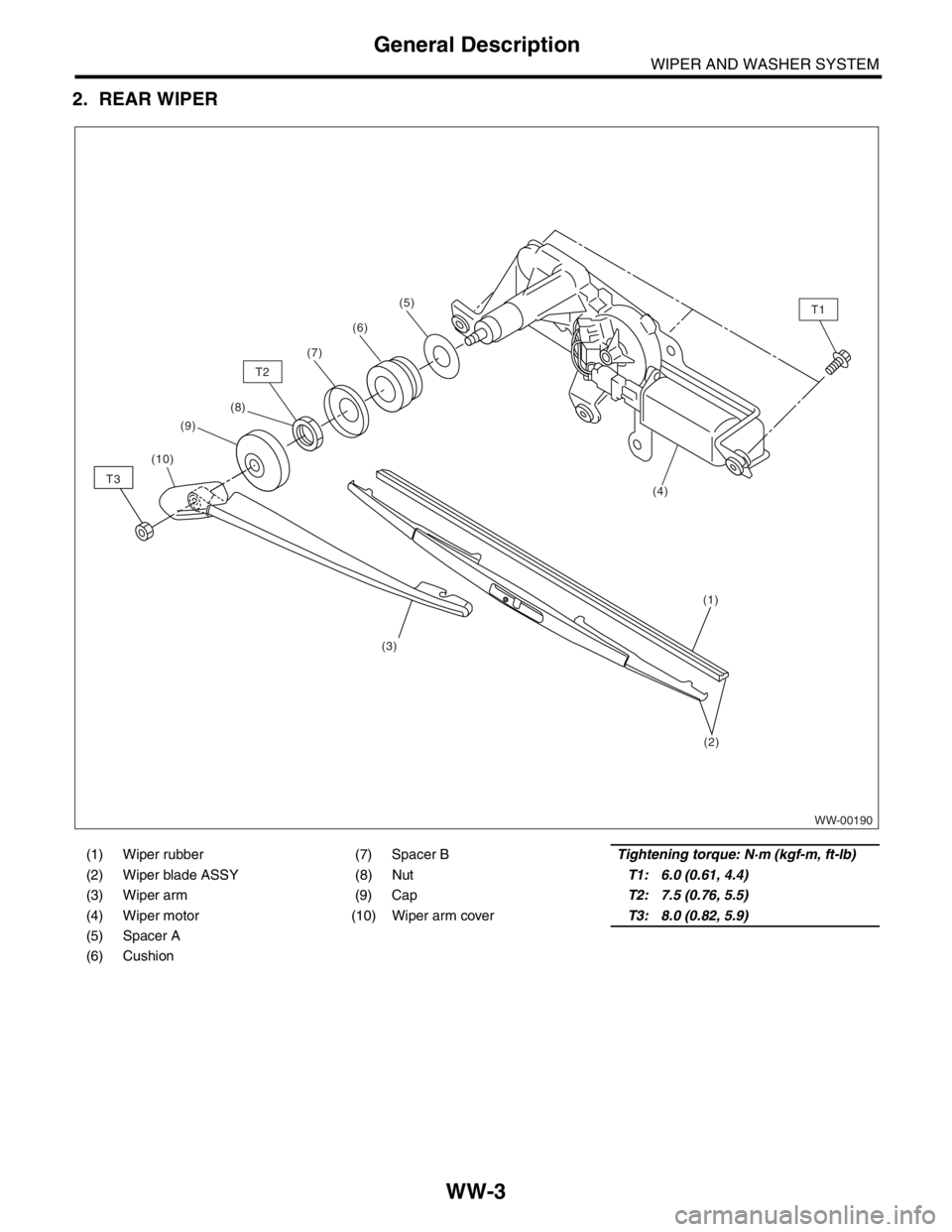

2. REAR WIPER

(1) Wiper rubber (7) Spacer BTightening torque: N·m (kgf-m, ft-lb)

(2) Wiper blade ASSY (8) NutT1: 6.0 (0.61, 4.4)

(3) Wiper arm (9) CapT2: 7.5 (0.76, 5.5)

(4) Wiper motor (10) Wiper arm coverT3: 8.0 (0.82, 5.9)

(5) Spacer A

(6) Cushion

WW-00190

T1(5)

(1)

T2

T3

(2)

(6)

(7)

(9)

(3) (8)

(4)

(10)

Page 292 of 2870

WW-4

WIPER AND WASHER SYSTEM

General Description

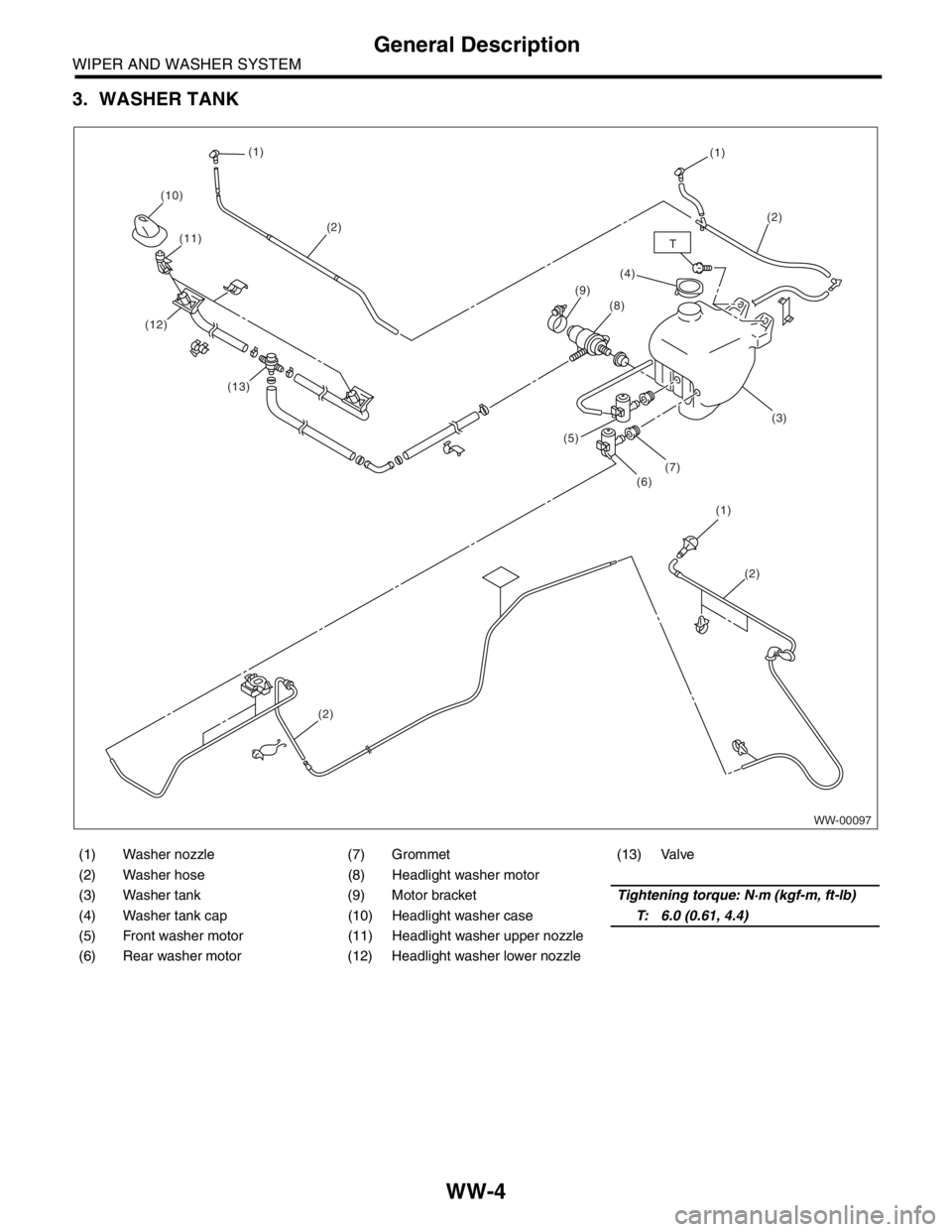

3. WASHER TANK

(1) Washer nozzle (7) Grommet (13) Valve

(2) Washer hose (8) Headlight washer motor

(3) Washer tank (9) Motor bracketTightening torque: N·m (kgf-m, ft-lb)

(4) Washer tank cap (10) Headlight washer caseT: 6.0 (0.61, 4.4)

(5) Front washer motor (11) Headlight washer upper nozzle

(6) Rear washer motor (12) Headlight washer lower nozzle

WW-00097

(1) (1)

(1)(2)

(2) (10)

(11)

(12)

(13)

(2)

(2)(8)

(7)

(6) (5)(9)

T

(3)

(4)

Page 293 of 2870

WW-5

WIPER AND WASHER SYSTEM

General Description

C: CAUTION

Reconnect the connectors and hoses securely.

After reconnecting, confirm that each function oper-

ates normally.

Be careful that wiring harnesses of airbag sys-

tem pass near electrical parts and switches.

Wiring harnesses and connectors of all airbag

system are yellow color. Do not use a tester on

these circuits.

Care must be taken when installing the piping

hose so that no bending, jamming, etc. are caused.

If even a little oil or grease such as silicon oil gets

in the tank and washer passages, an oil film easily

forms on the glass, causing the wiper to chatter and

judder. Therefore, be careful not to let this happen.

Page 294 of 2870

WW-6

WIPER AND WASHER SYSTEM

Wiper and Washer System

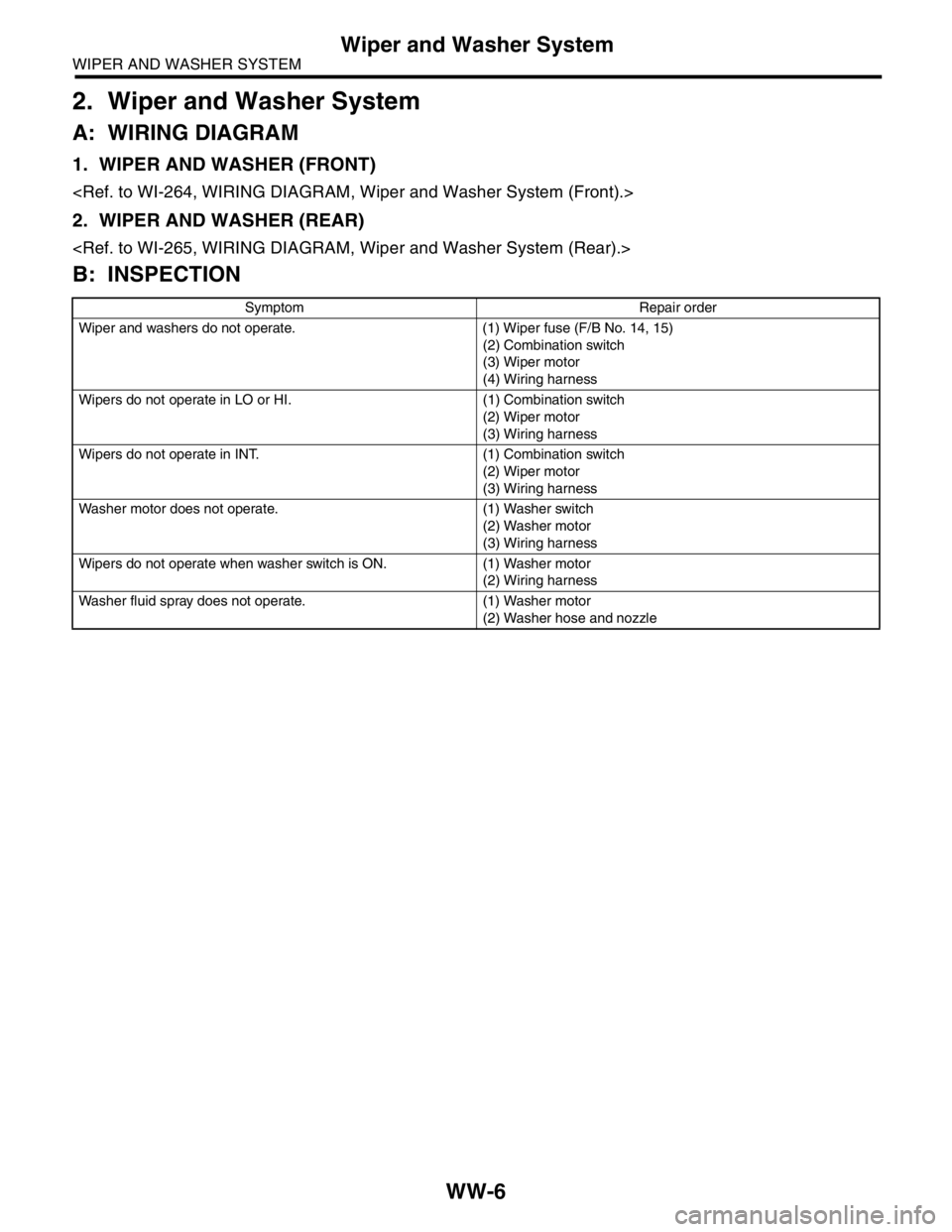

2. Wiper and Washer System

A: WIRING DIAGRAM

1. WIPER AND WASHER (FRONT)

2. WIPER AND WASHER (REAR)

B: INSPECTION

Symptom Repair order

Wiper and washers do not operate. (1) Wiper fuse (F/B No. 14, 15)

(2) Combination switch

(3) Wiper motor

(4) Wiring harness

Wipers do not operate in LO or HI. (1) Combination switch

(2) Wiper motor

(3) Wiring harness

Wipers do not operate in INT. (1) Combination switch

(2) Wiper motor

(3) Wiring harness

Washer motor does not operate. (1) Washer switch

(2) Washer motor

(3) Wiring harness

Wipers do not operate when washer switch is ON. (1) Washer motor

(2) Wiring harness

Washer fluid spray does not operate. (1) Washer motor

(2) Washer hose and nozzle

Page 295 of 2870

WW-7

WIPER AND WASHER SYSTEM

Combination Switch (Wiper)

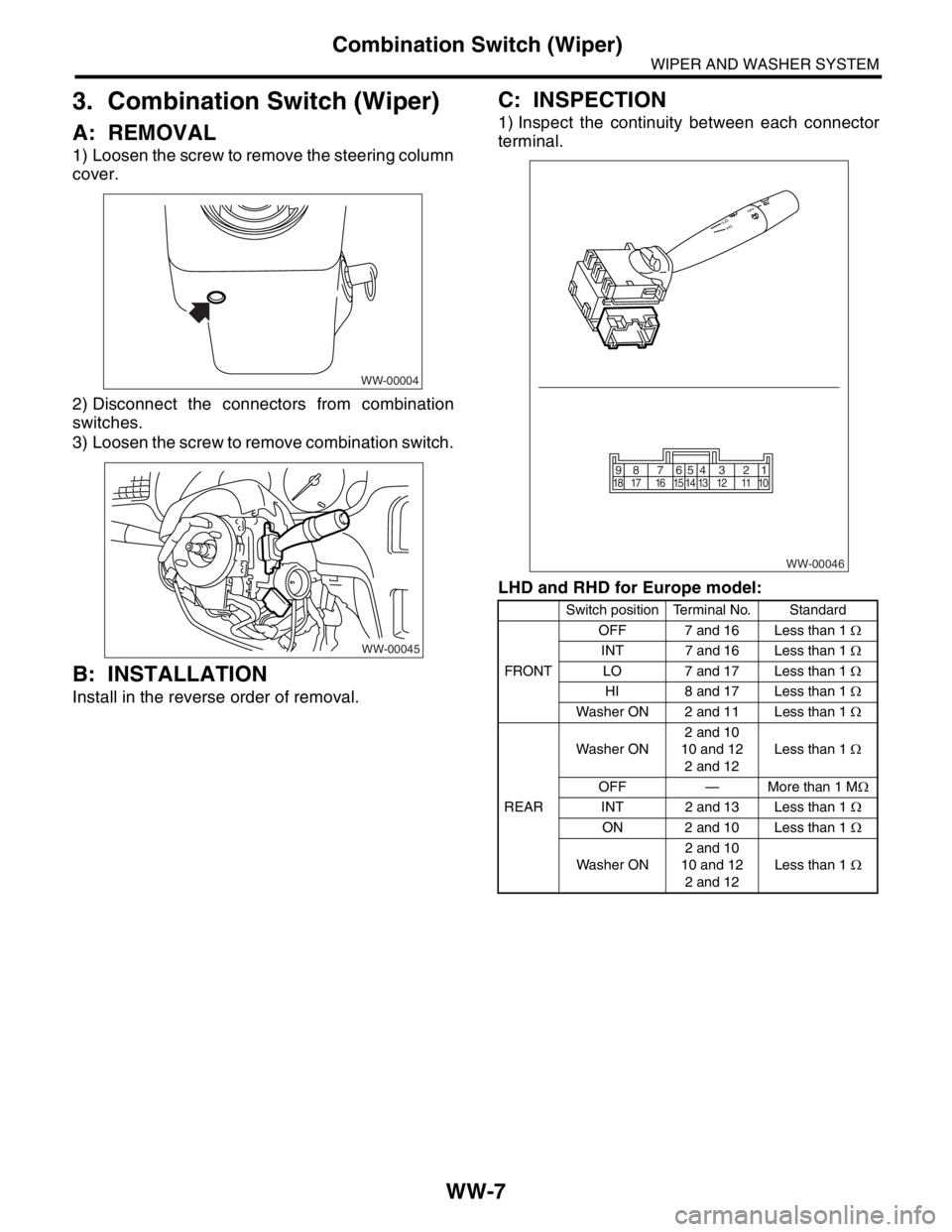

3. Combination Switch (Wiper)

A: REMOVAL

1) Loosen the screw to remove the steering column

cover.

2) Disconnect the connectors from combination

switches.

3) Loosen the screw to remove combination switch.

B: INSTALLATION

Install in the reverse order of removal.

C: INSPECTION

1) Inspect the continuity between each connector

terminal.

LHD and RHD for Europe model:

WW-00004

WW-00045

Switch position Terminal No. Standard

FRONTOFF 7 and 16 Less than 1 Ω

INT 7 and 16 Less than 1 Ω

LO 7 and 17 Less than 1 Ω

HI 8 and 17 Less than 1 Ω

Washer ON 2 and 11 Less than 1 Ω

REARWasher ON2 and 10

10 and 12

2 and 12Less than 1 Ω

OFF — More than 1 MΩ

INT 2 and 13 Less than 1 Ω

ON 2 and 10 Less than 1 Ω

Washer ON2 and 10

10 and 12

2 and 12Less than 1 Ω

WW-00046

87654321 917 16 15 14 13 12 11 10 18

Page 296 of 2870

WW-8

WIPER AND WASHER SYSTEM

Combination Switch (Wiper)

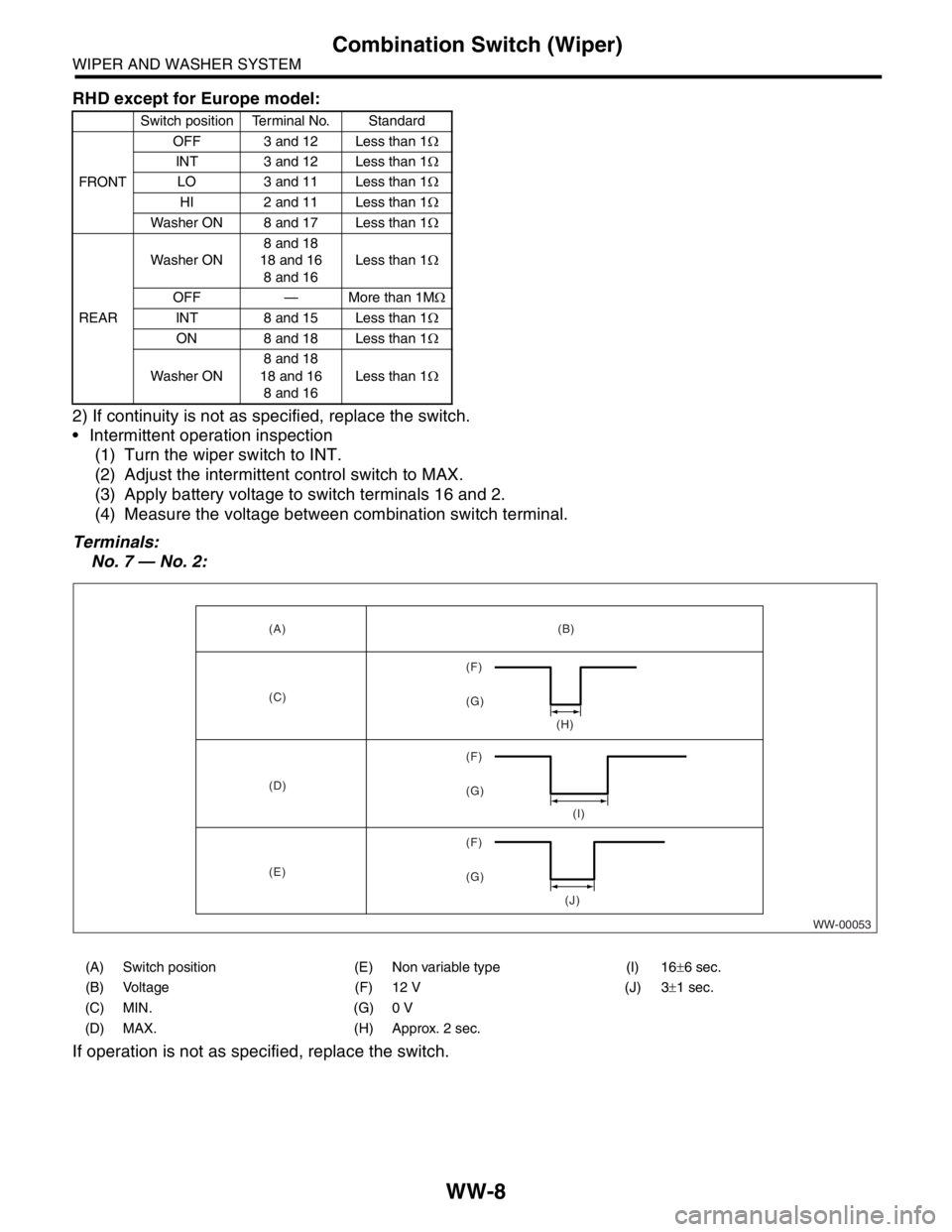

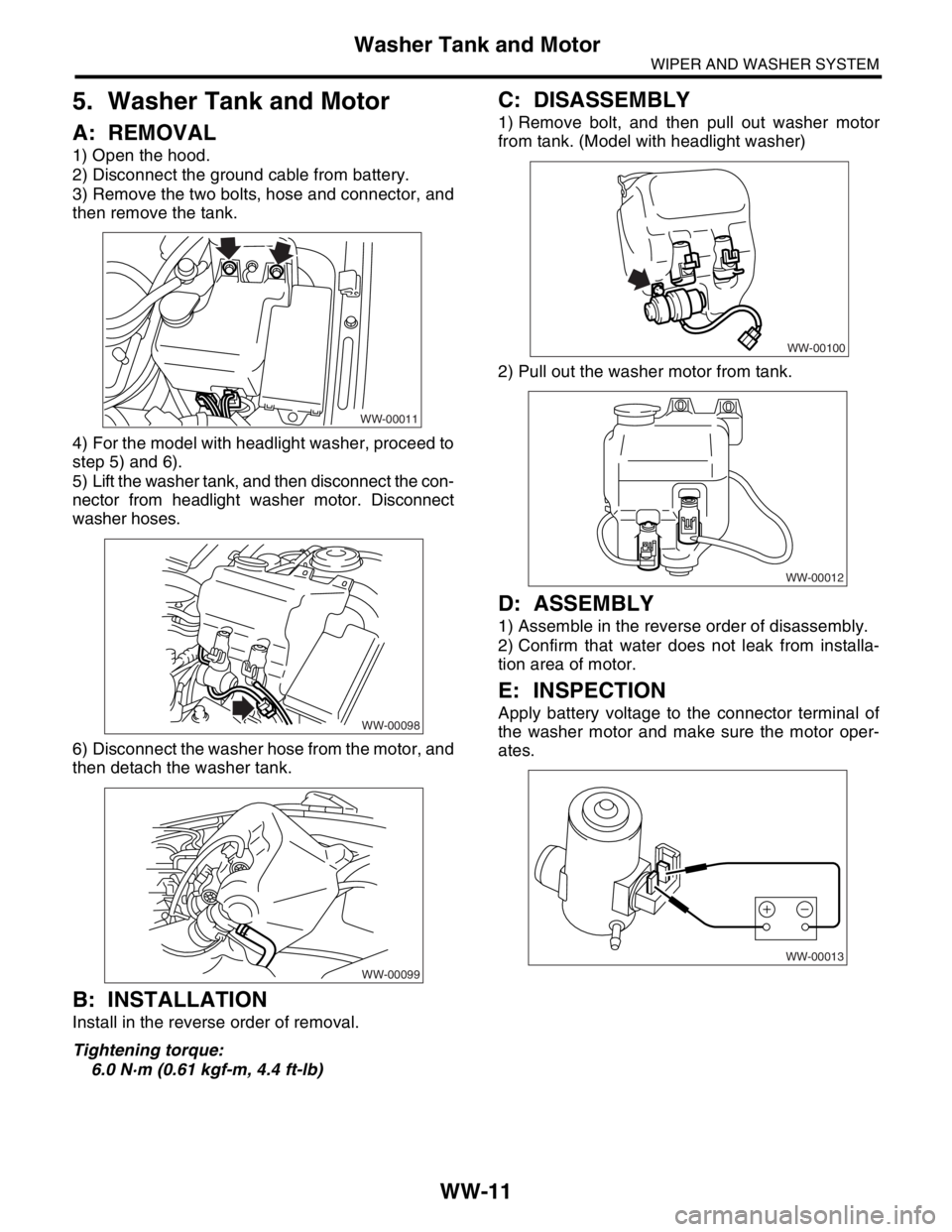

RHD except for Europe model:

2) If continuity is not as specified, replace the switch.

Intermittent operation inspection

(1) Turn the wiper switch to INT.

(2) Adjust the intermittent control switch to MAX.

(3) Apply battery voltage to switch terminals 16 and 2.

(4) Measure the voltage between combination switch terminal.

Terminals:

No. 7 — No. 2:

If operation is not as specified, replace the switch.

Switch position Terminal No. Standard

FRONTOFF 3 and 12 Less than 1Ω

INT 3 and 12 Less than 1Ω

LO 3 and 11 Less than 1Ω

HI 2 and 11 Less than 1Ω

Washer ON 8 and 17 Less than 1Ω

REARWasher ON8 and 18

18 and 16

8 and 16Less than 1Ω

OFF — More than 1MΩ

INT 8 and 15 Less than 1Ω

ON 8 and 18 Less than 1Ω

Washer ON8 and 18

18 and 16

8 and 16Less than 1Ω

WW-00053 (A) (B)

(C)

(H)

(I)

(J) (D)

(F)

(G) (F)

(G) (F)

(G)

(E)

(A) Switch position (E) Non variable type (I) 16±6 sec.

(B) Voltage (F) 12 V (J) 3±1 sec.

(C) MIN. (G) 0 V

(D) MAX. (H) Approx. 2 sec.

Page 297 of 2870

WW-9

WIPER AND WASHER SYSTEM

Wiper Blade

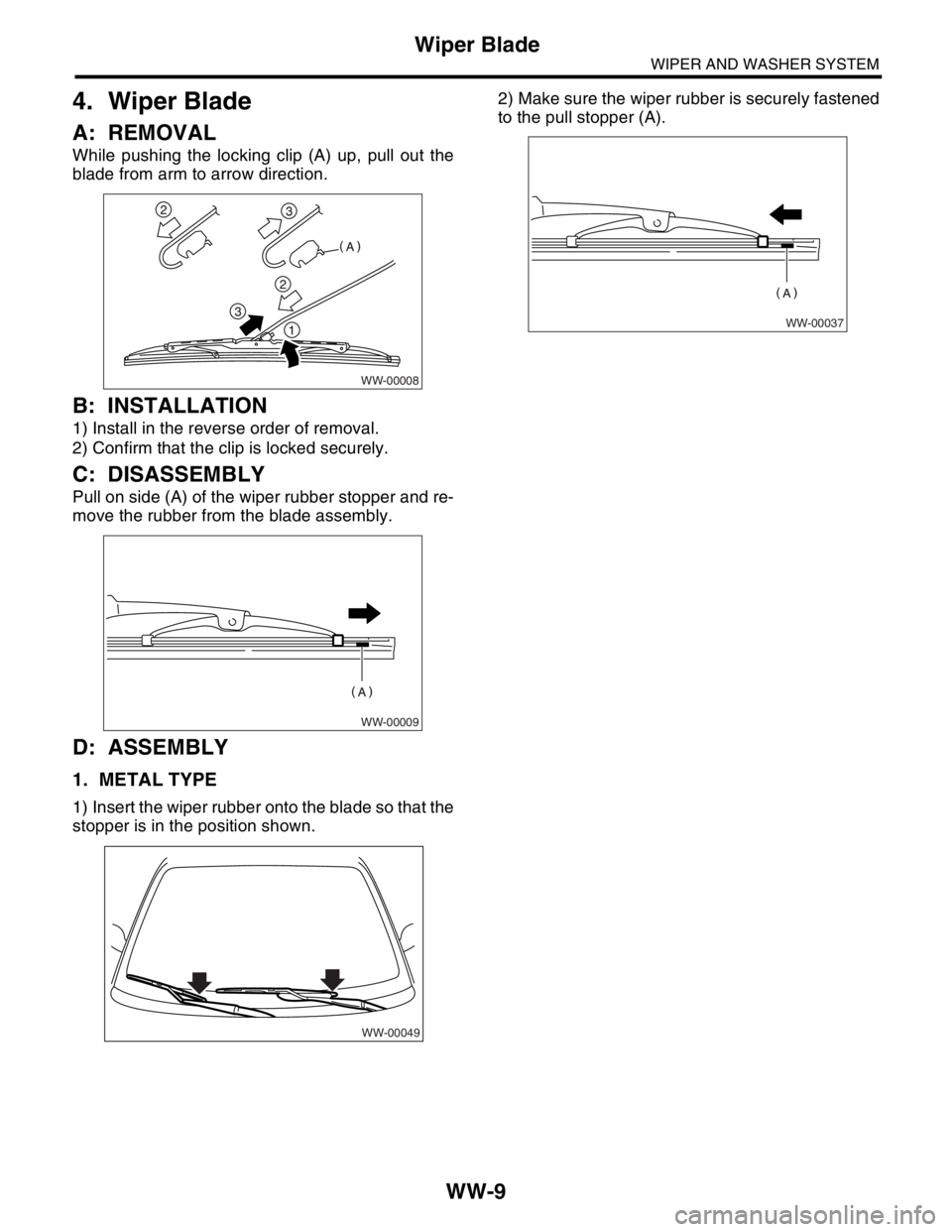

4. Wiper Blade

A: REMOVAL

While pushing the locking clip (A) up, pull out the

blade from arm to arrow direction.

B: INSTALLATION

1) Install in the reverse order of removal.

2) Confirm that the clip is locked securely.

C: DISASSEMBLY

Pull on side (A) of the wiper rubber stopper and re-

move the rubber from the blade assembly.

D: ASSEMBLY

1. METAL TYPE

1) Insert the wiper rubber onto the blade so that the

stopper is in the position shown.2) Make sure the wiper rubber is securely fastened

to the pull stopper (A).

WW-00008

WW-00009

WW-00049

WW-00037

Page 298 of 2870

WW-10

WIPER AND WASHER SYSTEM

Wiper Blade

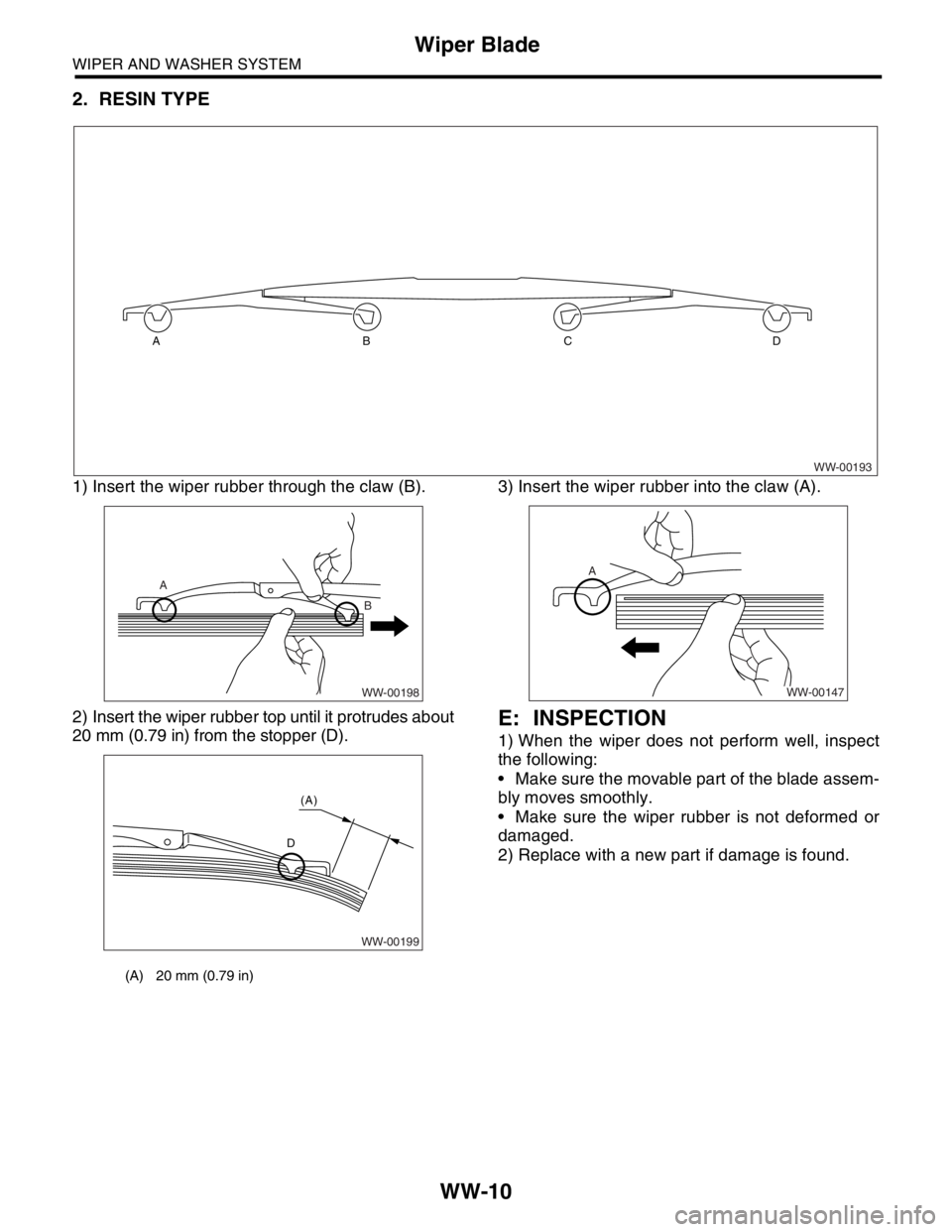

2. RESIN TYPE

1) Insert the wiper rubber through the claw (B).

2) Insert the wiper rubber top until it protrudes about

20 mm (0.79 in) from the stopper (D).3) Insert the wiper rubber into the claw (A).

E: INSPECTION

1) When the wiper does not perform well, inspect

the following:

Make sure the movable part of the blade assem-

bly moves smoothly.

Make sure the wiper rubber is not deformed or

damaged.

2) Replace with a new part if damage is found.

WW-00193 ABCD

(A) 20 mm (0.79 in)

WW-00198

A

B

WW-00199

D (A)

A

WW-00147

Page 299 of 2870

WW-11

WIPER AND WASHER SYSTEM

Washer Tank and Motor

5. Washer Tank and Motor

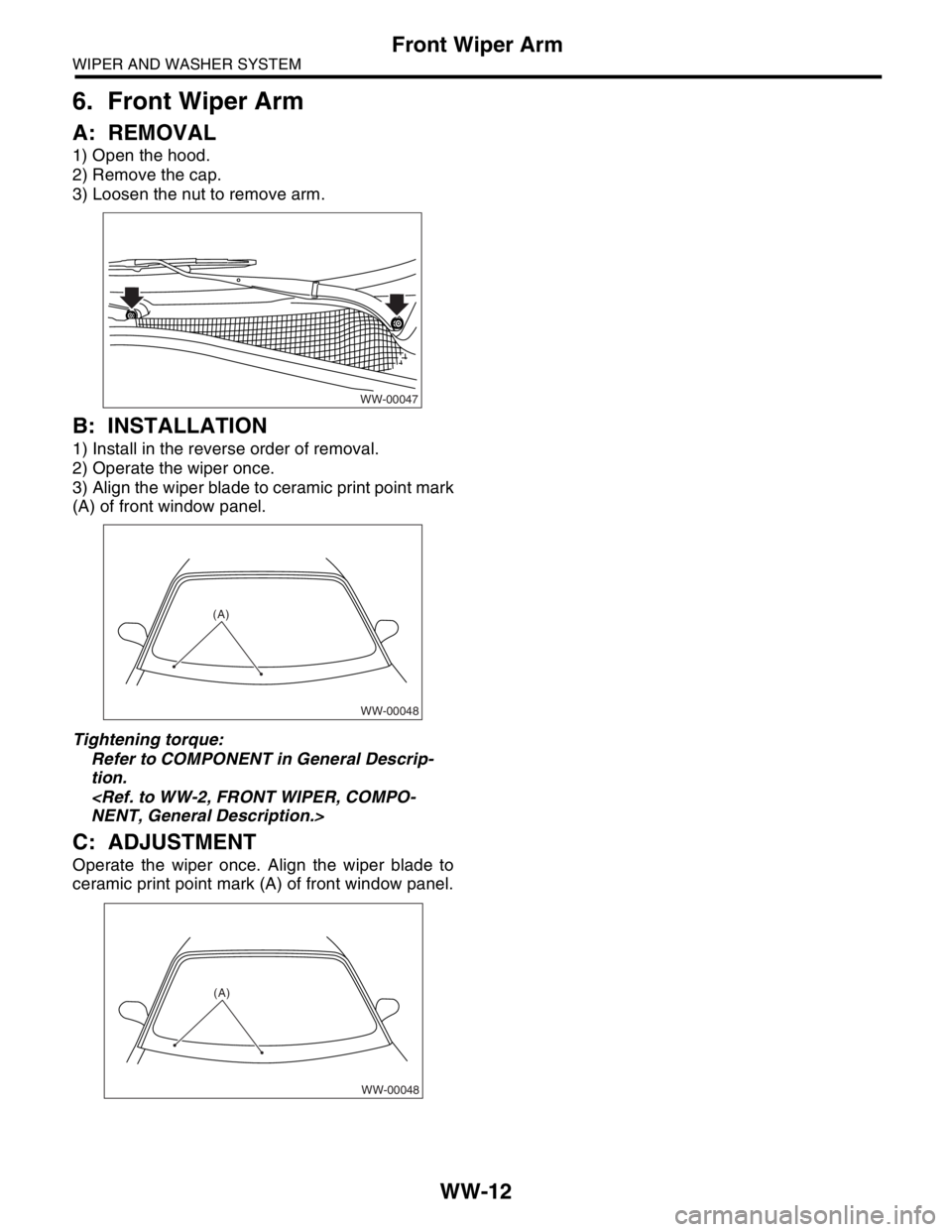

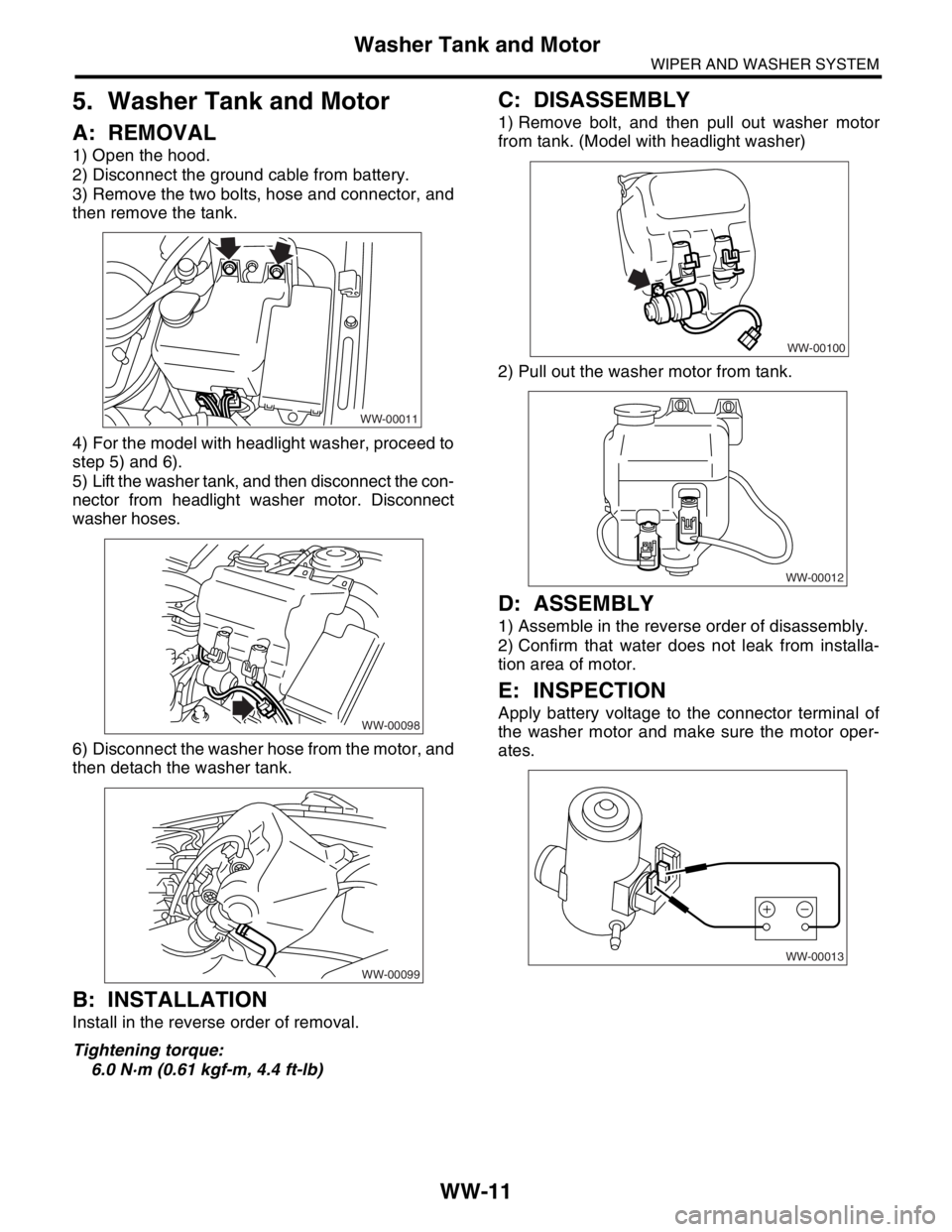

A: REMOVAL

1) Open the hood.

2) Disconnect the ground cable from battery.

3) Remove the two bolts, hose and connector, and

then remove the tank.

4) For the model with headlight washer, proceed to

step 5) and 6).

5) Lift the washer tank, and then disconnect the con-

nector from headlight washer motor. Disconnect

washer hoses.

6) Disconnect the washer hose from the motor, and

then detach the washer tank.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

6.0 N·m (0.61 kgf-m, 4.4 ft-lb)

C: DISASSEMBLY

1) Remove bolt, and then pull out washer motor

from tank. (Model with headlight washer)

2) Pull out the washer motor from tank.

D: ASSEMBLY

1) Assemble in the reverse order of disassembly.

2) Confirm that water does not leak from installa-

tion area of motor.

E: INSPECTION

Apply battery voltage to the connector terminal of

the washer motor and make sure the motor oper-

ates.

WW-00011

WW-00098

WW-00099

WW-00100

WW-00012

WW-00013

Page 300 of 2870

WW-12

WIPER AND WASHER SYSTEM

Front Wiper Arm

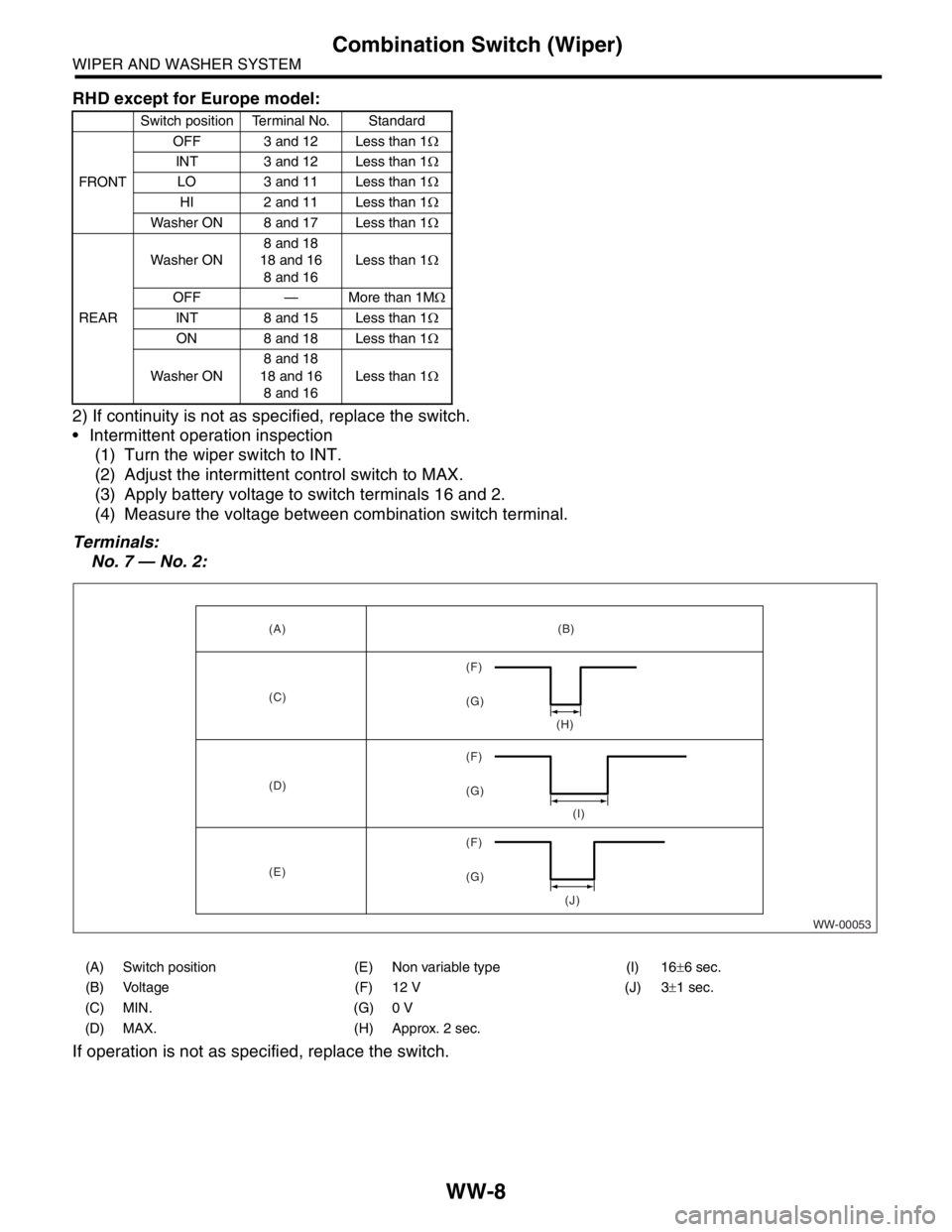

6. Front Wiper Arm

A: REMOVAL

1) Open the hood.

2) Remove the cap.

3) Loosen the nut to remove arm.

B: INSTALLATION

1) Install in the reverse order of removal.

2) Operate the wiper once.

3) Align the wiper blade to ceramic print point mark

(A) of front window panel.

Tightening torque:

Refer to COMPONENT in General Descrip-

tion.

NENT, General Description.>

C: ADJUSTMENT

Operate the wiper once. Align the wiper blade to

ceramic print point mark (A) of front window panel.

WW-00047

WW-00048

(A)

WW-00048

(A)

Trending: ABS, coolant temperature, jump cable, ESP inoperative, brake, ECO mode, low beam