SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2751 of 2870

5MT-39

MANUAL TRANSMISSION AND DIFFERENTIAL

Transmission Mounting System

4. Transmission Mounting Sys-

tem

A: REMOVAL

1. PITCHING STOPPER

1) Disconnect the ground cable from battery.

2) Remove the air intake duct and cleaner case.

3) Remove the air intake duct. (Non-turbo model)

4) Remove the air cleaner case. (Non-turbo model)

5) Remove the intercooler (Turbo model).

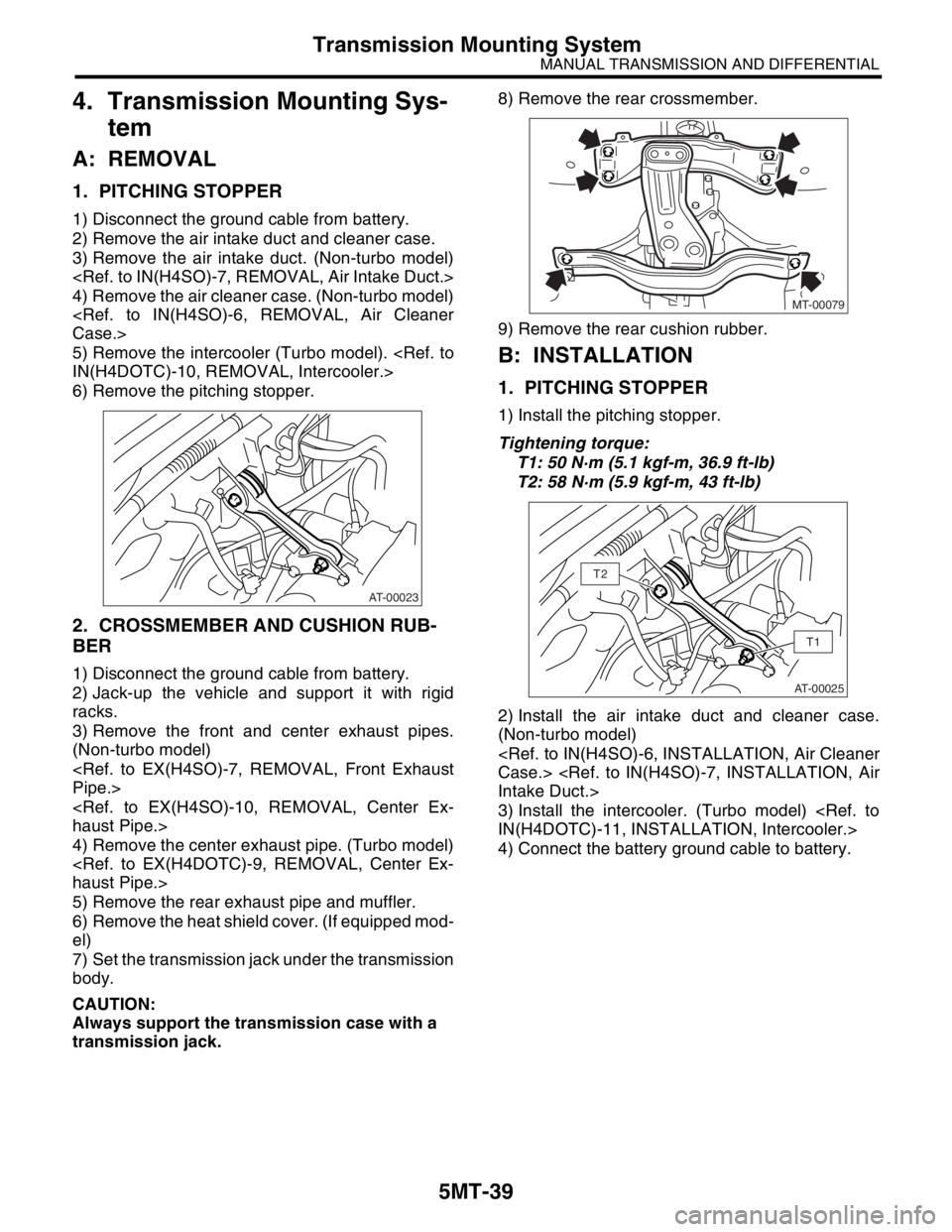

6) Remove the pitching stopper.

2. CROSSMEMBER AND CUSHION RUB-

BER

1) Disconnect the ground cable from battery.

2) Jack-up the vehicle and support it with rigid

racks.

3) Remove the front and center exhaust pipes.

(Non-turbo model)

4) Remove the center exhaust pipe. (Turbo model)

5) Remove the rear exhaust pipe and muffler.

6) Remove the heat shield cover. (If equipped mod-

el)

7) Set the transmission jack under the transmission

body.

CAUTION:

Always support the transmission case with a

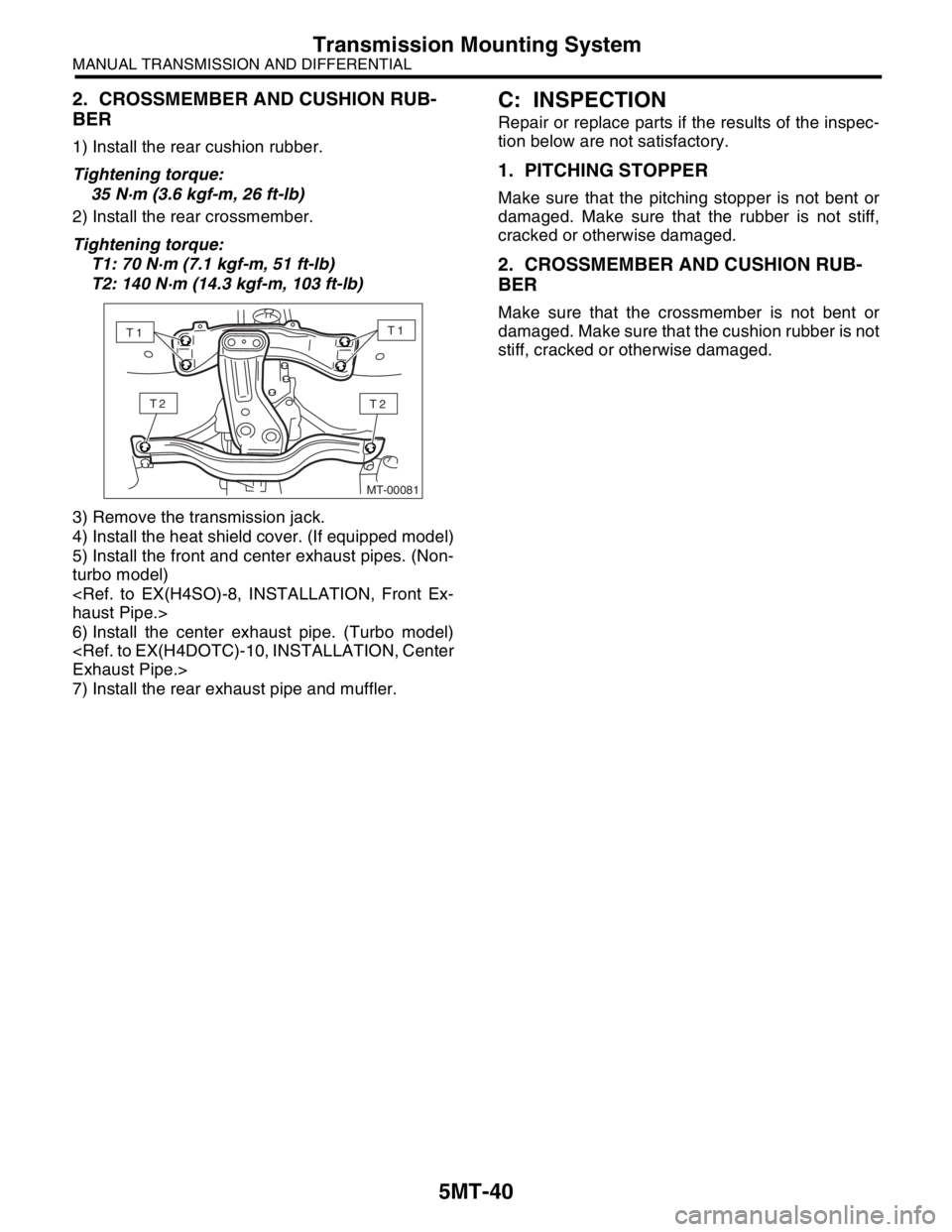

transmission jack. 8) Remove the rear crossmember.

9) Remove the rear cushion rubber.

B: INSTALLATION

1. PITCHING STOPPER

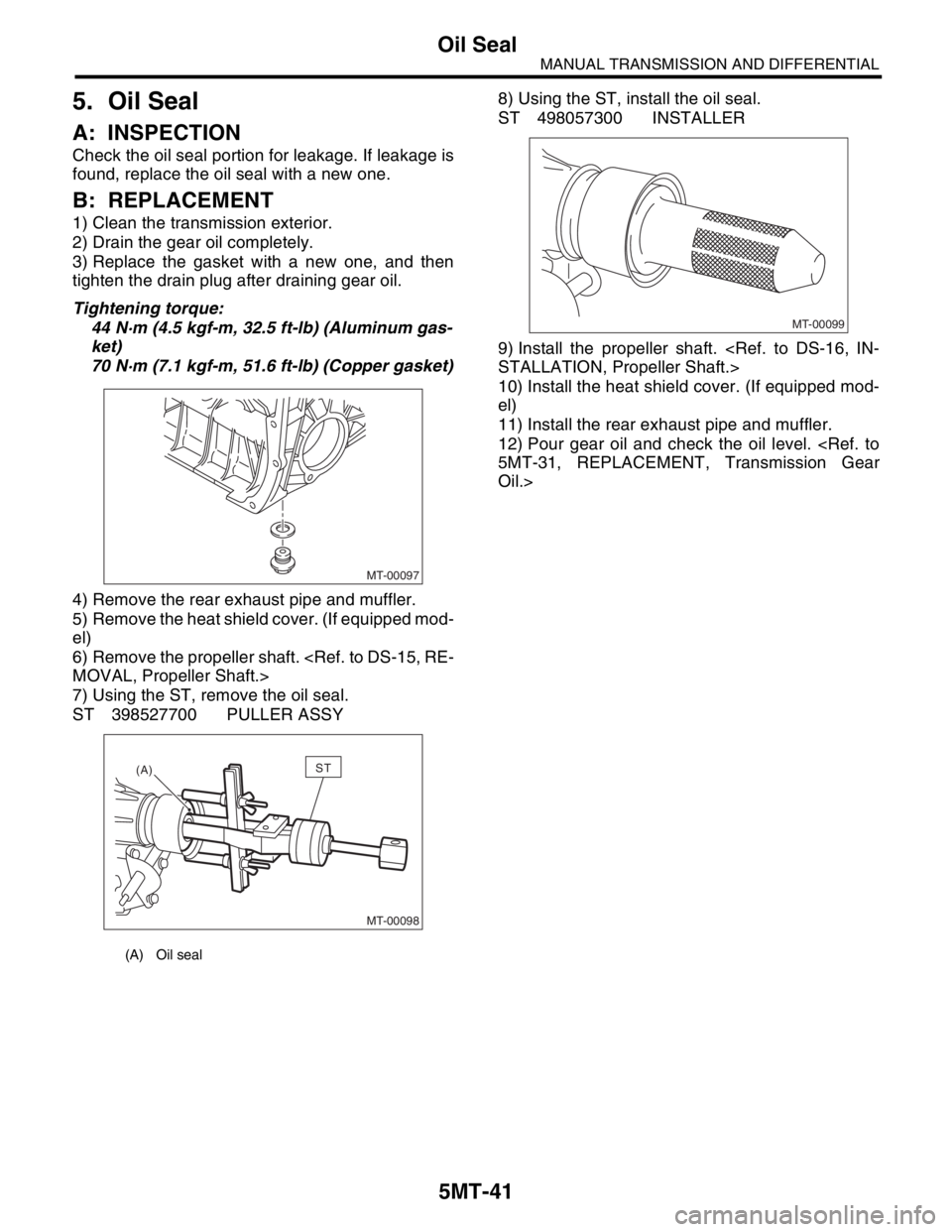

1) Install the pitching stopper.

Tightening torque:

T1: 50 N·m (5.1 kgf-m, 36.9 ft-lb)

T2: 58 N·m (5.9 kgf-m, 43 ft-lb)

2) Install the air intake duct and cleaner case.

(Non-turbo model)

3) Install the intercooler. (Turbo model)

4) Connect the battery ground cable to battery.

AT-00023

MT-00079

AT-00025

T1

T2

Page 2752 of 2870

5MT-40

MANUAL TRANSMISSION AND DIFFERENTIAL

Transmission Mounting System

2. CROSSMEMBER AND CUSHION RUB-

BER

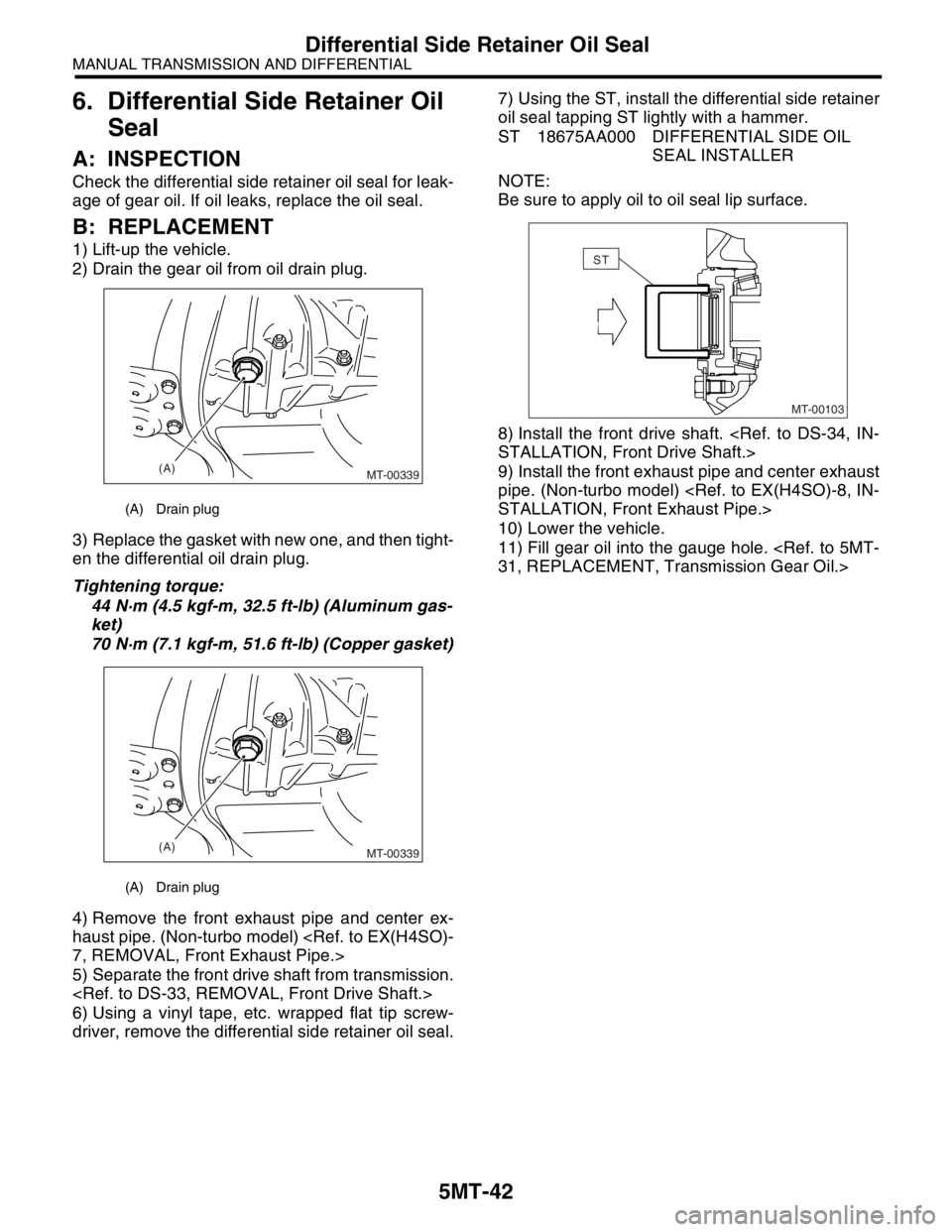

1) Install the rear cushion rubber.

Tightening torque:

35 N·m (3.6 kgf-m, 26 ft-lb)

2) Install the rear crossmember.

Tightening torque:

T1: 70 N·m (7.1 kgf-m, 51 ft-lb)

T2: 140 N·m (14.3 kgf-m, 103 ft-lb)

3) Remove the transmission jack.

4) Install the heat shield cover. (If equipped model)

5) Install the front and center exhaust pipes. (Non-

turbo model)

6) Install the center exhaust pipe. (Turbo model)

7) Install the rear exhaust pipe and muffler.

C: INSPECTION

Repair or replace parts if the results of the inspec-

tion below are not satisfactory.

1. PITCHING STOPPER

Make sure that the pitching stopper is not bent or

damaged. Make sure that the rubber is not stiff,

cracked or otherwise damaged.

2. CROSSMEMBER AND CUSHION RUB-

BER

Make sure that the crossmember is not bent or

damaged. Make sure that the cushion rubber is not

stiff, cracked or otherwise damaged.

MT-00081

T2T2

T1T1

Page 2753 of 2870

5MT-41

MANUAL TRANSMISSION AND DIFFERENTIAL

Oil Seal

5. Oil Seal

A: INSPECTION

Check the oil seal portion for leakage. If leakage is

found, replace the oil seal with a new one.

B: REPLACEMENT

1) Clean the transmission exterior.

2) Drain the gear oil completely.

3) Replace the gasket with a new one, and then

tighten the drain plug after draining gear oil.

Tightening torque:

44 N·m (4.5 kgf-m, 32.5 ft-lb) (Aluminum gas-

ket)

70 N·m (7.1 kgf-m, 51.6 ft-lb) (Copper gasket)

4) Remove the rear exhaust pipe and muffler.

5) Remove the heat shield cover. (If equipped mod-

el)

6) Remove the propeller shaft.

7) Using the ST, remove the oil seal.

ST 398527700 PULLER ASSY8) Using the ST, install the oil seal.

ST 498057300 INSTALLER

9) Install the propeller shaft.

10) Install the heat shield cover. (If equipped mod-

el)

11) Install the rear exhaust pipe and muffler.

12) Pour gear oil and check the oil level.

Oil.>

(A) Oil seal

MT-00097

MT-00098

(A)ST

MT-00099

Page 2754 of 2870

5MT-42

MANUAL TRANSMISSION AND DIFFERENTIAL

Differential Side Retainer Oil Seal

6. Differential Side Retainer Oil

Seal

A: INSPECTION

Check the differential side retainer oil seal for leak-

age of gear oil. If oil leaks, replace the oil seal.

B: REPLACEMENT

1) Lift-up the vehicle.

2) Drain the gear oil from oil drain plug.

3) Replace the gasket with new one, and then tight-

en the differential oil drain plug.

Tightening torque:

44 N·m (4.5 kgf-m, 32.5 ft-lb) (Aluminum gas-

ket)

70 N·m (7.1 kgf-m, 51.6 ft-lb) (Copper gasket)

4) Remove the front exhaust pipe and center ex-

haust pipe. (Non-turbo model)

5) Separate the front drive shaft from transmission.

6) Using a vinyl tape, etc. wrapped flat tip screw-

driver, remove the differential side retainer oil seal.7) Using the ST, install the differential side retainer

oil seal tapping ST lightly with a hammer.

ST 18675AA000 DIFFERENTIAL SIDE OIL

SEAL INSTALLER

NOTE:

Be sure to apply oil to oil seal lip surface.

8) Install the front drive shaft.

9) Install the front exhaust pipe and center exhaust

pipe. (Non-turbo model)

10) Lower the vehicle.

11) Fill gear oil into the gauge hole.

(A) Drain plug

(A) Drain plug

(A)

MT-00339

(A)

MT-00339

MT-00103

ST

Page 2755 of 2870

5MT-43

MANUAL TRANSMISSION AND DIFFERENTIAL

Switches and Harness

7. Switches and Harness

A: REMOVAL

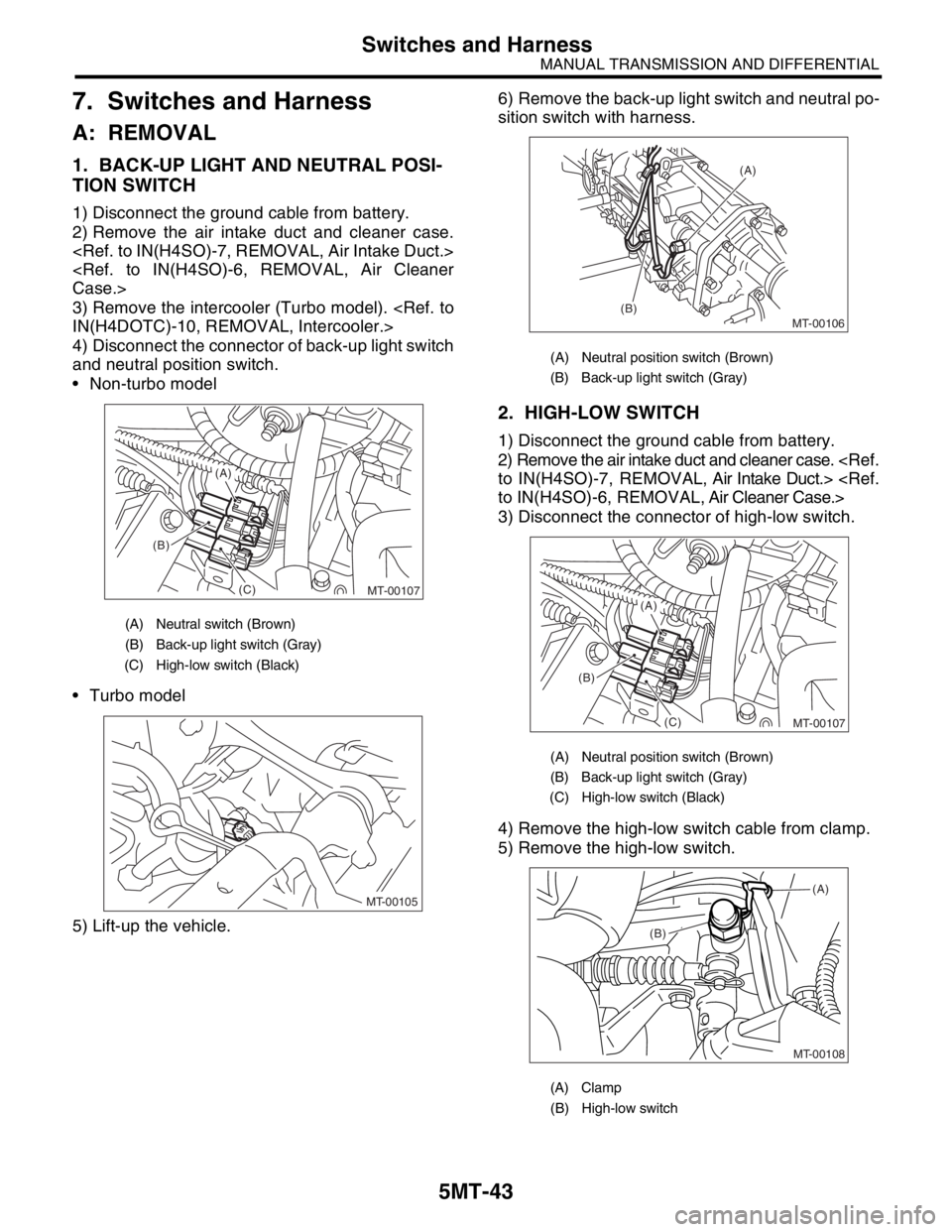

1. BACK-UP LIGHT AND NEUTRAL POSI-

TION SWITCH

1) Disconnect the ground cable from battery.

2) Remove the air intake duct and cleaner case.

3) Remove the intercooler (Turbo model).

4) Disconnect the connector of back-up light switch

and neutral position switch.

Non-turbo model

Turbo model

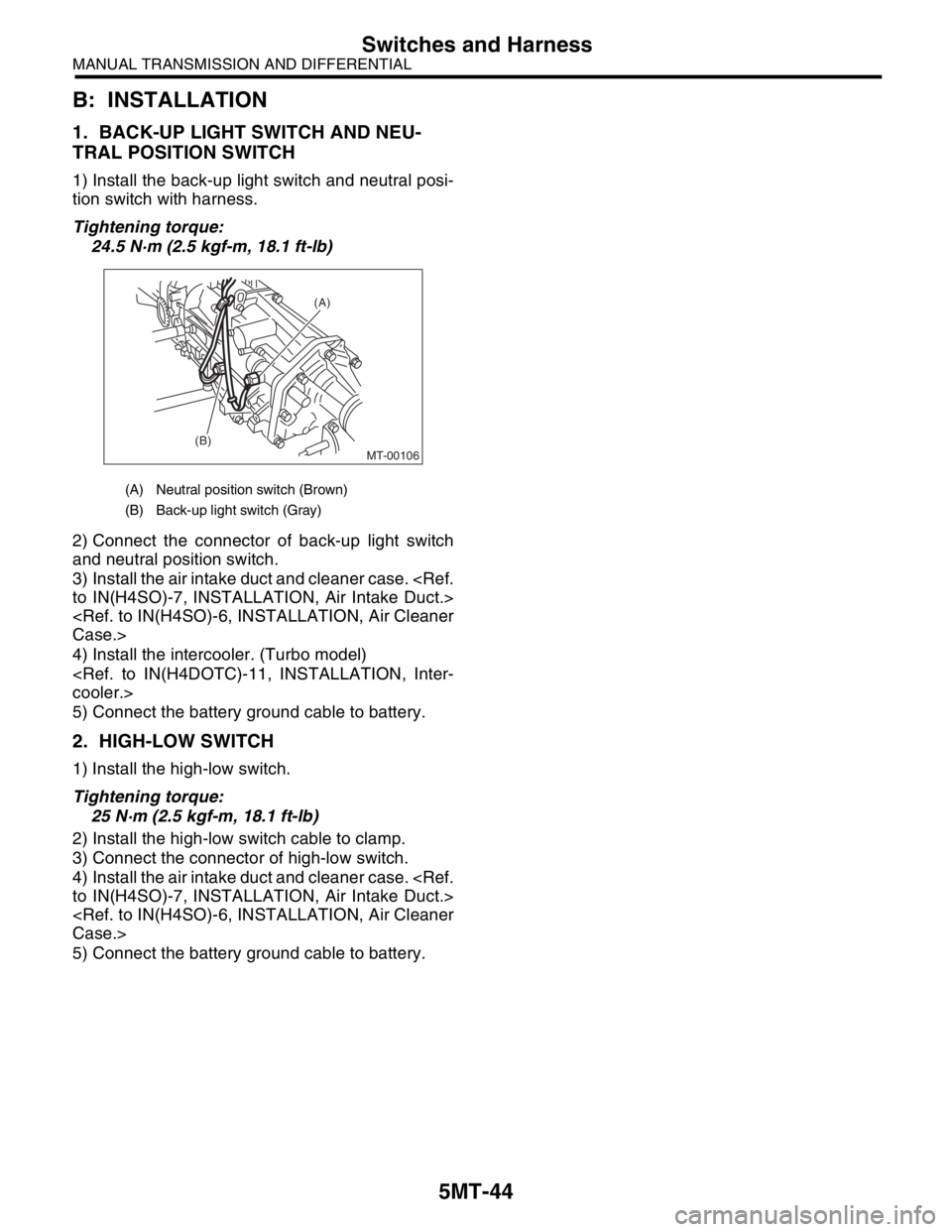

5) Lift-up the vehicle.6) Remove the back-up light switch and neutral po-

sition switch with harness.

2. HIGH-LOW SWITCH

1) Disconnect the ground cable from battery.

2) Remove the air intake duct and cleaner case.

3) Disconnect the connector of high-low switch.

4) Remove the high-low switch cable from clamp.

5) Remove the high-low switch.

(A) Neutral switch (Brown)

(B) Back-up light switch (Gray)

(C) High-low switch (Black)

MT-00107

(B)

(C)

(A)

MT-00105

(A) Neutral position switch (Brown)

(B) Back-up light switch (Gray)

(A) Neutral position switch (Brown)

(B) Back-up light switch (Gray)

(C) High-low switch (Black)

(A) Clamp

(B) High-low switch

MT-00106

(A)

(B)

MT-00107

(B)

(C)

(A)

MT-00108

(B)(A)

Page 2756 of 2870

5MT-44

MANUAL TRANSMISSION AND DIFFERENTIAL

Switches and Harness

B: INSTALLATION

1. BACK-UP LIGHT SWITCH AND NEU-

TRAL POSITION SWITCH

1) Install the back-up light switch and neutral posi-

tion switch with harness.

Tightening torque:

24.5 N·m (2.5 kgf-m, 18.1 ft-lb)

2) Connect the connector of back-up light switch

and neutral position switch.

3) Install the air intake duct and cleaner case.

4) Install the intercooler. (Turbo model)

5) Connect the battery ground cable to battery.

2. HIGH-LOW SWITCH

1) Install the high-low switch.

Tightening torque:

25 N·m (2.5 kgf-m, 18.1 ft-lb)

2) Install the high-low switch cable to clamp.

3) Connect the connector of high-low switch.

4) Install the air intake duct and cleaner case.

5) Connect the battery ground cable to battery.

(A) Neutral position switch (Brown)

(B) Back-up light switch (Gray)

MT-00106

(A)

(B)

Page 2757 of 2870

5MT-45

MANUAL TRANSMISSION AND DIFFERENTIAL

Switches and Harness

C: INSPECTION

1. BACK-UP LIGHT SWITCH

Inspect the back-up light switch.

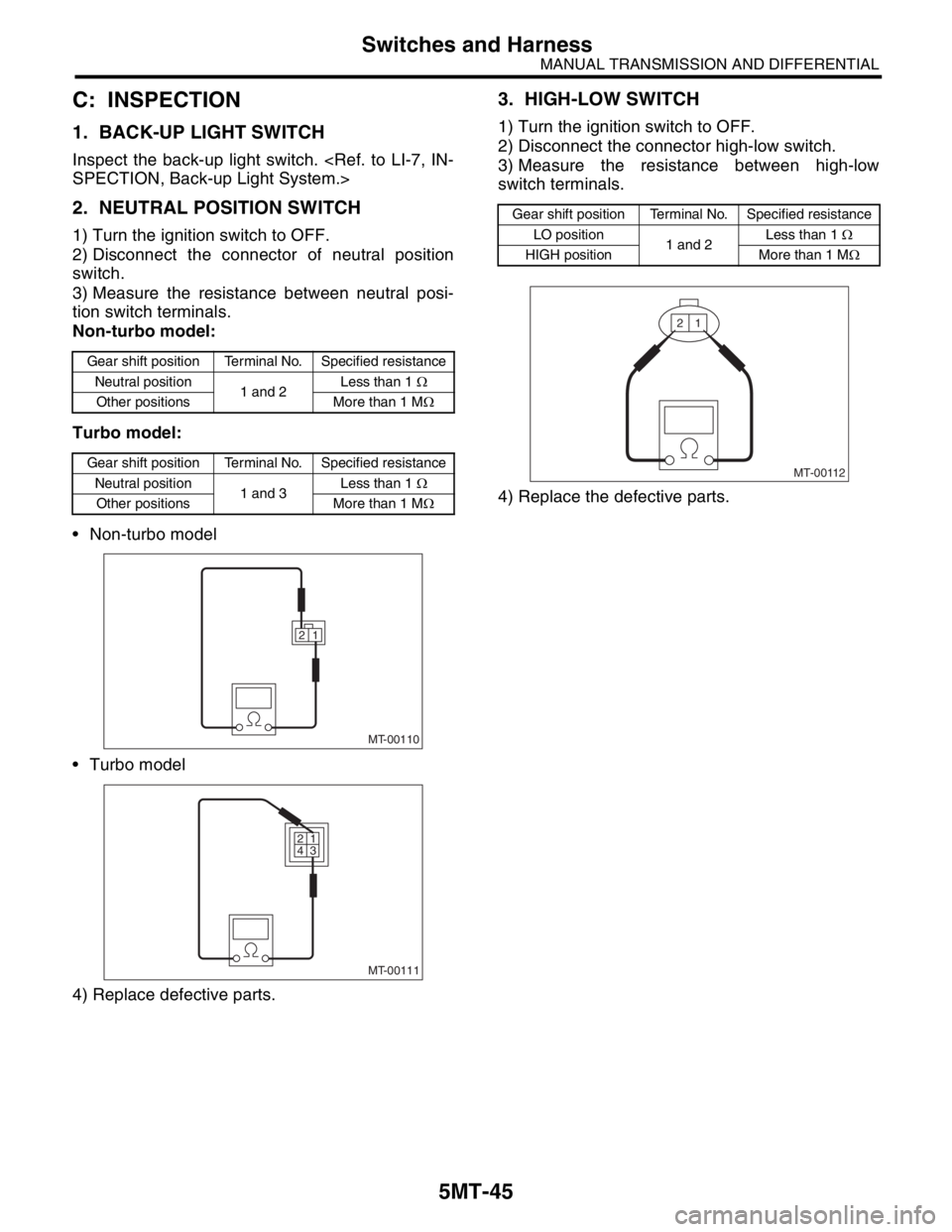

2. NEUTRAL POSITION SWITCH

1) Turn the ignition switch to OFF.

2) Disconnect the connector of neutral position

switch.

3) Measure the resistance between neutral posi-

tion switch terminals.

Non-turbo model:

Turbo model:

Non-turbo model

Turbo model

4) Replace defective parts.

3. HIGH-LOW SWITCH

1) Turn the ignition switch to OFF.

2) Disconnect the connector high-low switch.

3) Measure the resistance between high-low

switch terminals.

4) Replace the defective parts.

Gear shift position Terminal No. Specified resistance

Neutral position

1 and 2Less than 1 Ω

Other positions More than 1 MΩ

Gear shift position Terminal No. Specified resistance

Neutral position

1 and 3Less than 1 Ω

Other positions More than 1 MΩ

MT-00110

1 2

MT-00111

1 2

3 4

Gear shift position Terminal No. Specified resistance

LO position

1 and 2Less than 1 Ω

HIGH position More than 1 MΩ

MT-00112

1 2

Page 2758 of 2870

5MT-46

MANUAL TRANSMISSION AND DIFFERENTIAL

Vehicle Speed Sensor

8. Vehicle Speed Sensor

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Lift-up the vehicle.

3) Remove the front, center and rear exhaust pipe

and muffler.

4) Disconnect the connector from vehicle speed

sensor.

5) Turn and remove the vehicle speed sensor.

B: INSTALLATION

NOTE:

Discard the vehicle speed sensor and after re-

moval, replace with a new one.

Ensure the sensor mounting hole is clean and

free of foreign matter.

Align the tip end of key with key groove on end of

speedometer shaft during installation.

1) Hand tighten the vehicle speed sensor.

2) Tighten the vehicle speed sensor using suitable

tool.

Tightening torque:

5.9 N·m (0.6 kgf-m, 4.3 ft-lb)

3) Connect the connector to vehicle speed sensor.

4) Install the front and center exhaust pipe.

5) Lower the vehicle.

6) Connect the battery ground cable to battery.

C: INSPECTION

Inspect the vehicle speed sensor.

tic Procedure with Diagnostic Trouble Code

(DTC).>

Diagnostic Procedure with Diagnostic Trouble

Code (DTC).>

MT-00113

Page 2759 of 2870

5MT-47

MANUAL TRANSMISSION AND DIFFERENTIAL

Preparation for Overhaul

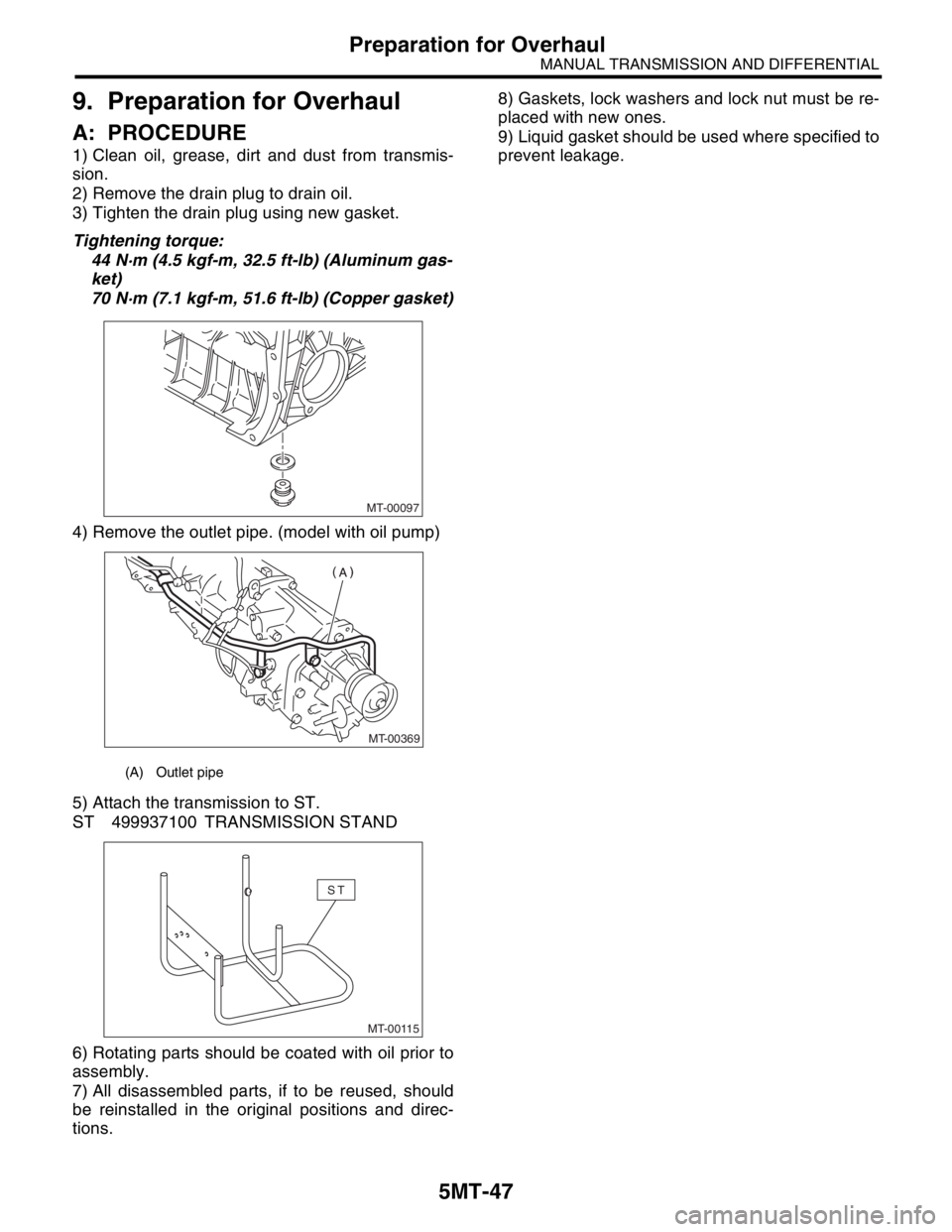

9. Preparation for Overhaul

A: PROCEDURE

1) Clean oil, grease, dirt and dust from transmis-

sion.

2) Remove the drain plug to drain oil.

3) Tighten the drain plug using new gasket.

Tightening torque:

44 N·m (4.5 kgf-m, 32.5 ft-lb) (Aluminum gas-

ket)

70 N·m (7.1 kgf-m, 51.6 ft-lb) (Copper gasket)

4) Remove the outlet pipe. (model with oil pump)

5) Attach the transmission to ST.

ST 499937100 TRANSMISSION STAND

6) Rotating parts should be coated with oil prior to

assembly.

7) All disassembled parts, if to be reused, should

be reinstalled in the original positions and direc-

tions.8) Gaskets, lock washers and lock nut must be re-

placed with new ones.

9) Liquid gasket should be used where specified to

prevent leakage.

(A) Outlet pipe

MT-00097

MT-00369

MT-00115

ST

Page 2760 of 2870

5MT-48

MANUAL TRANSMISSION AND DIFFERENTIAL

Oil Pump

10.Oil Pump

A: REMOVAL

For extension case removal procedure, refer to

“Transfer Case and Extension Case Assembly”.

B: INSTALLATION

For extension case installation procedure, refer to

“Transfer Case Pump and Extension Case Assem-

bly”.

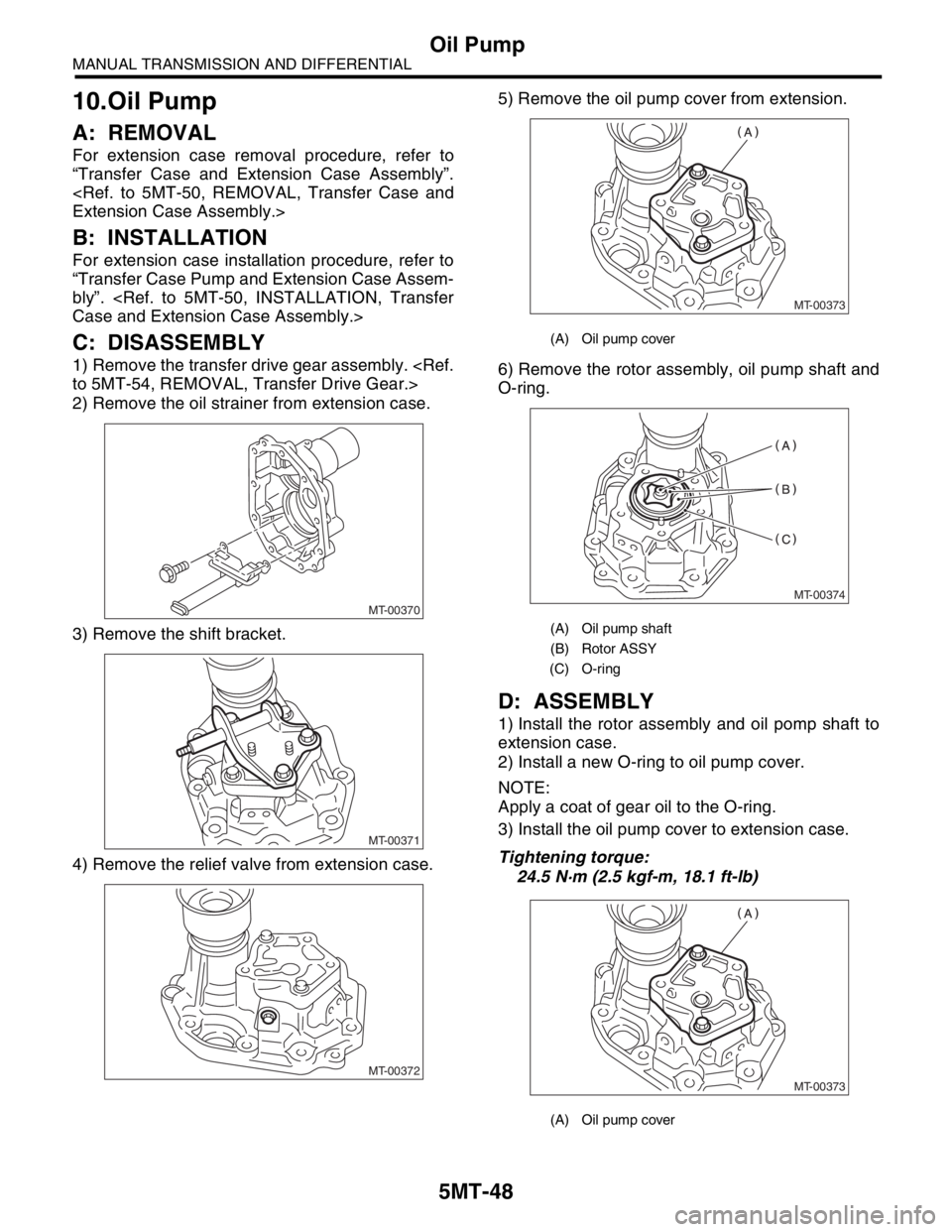

C: DISASSEMBLY

1) Remove the transfer drive gear assembly.

2) Remove the oil strainer from extension case.

3) Remove the shift bracket.

4) Remove the relief valve from extension case.5) Remove the oil pump cover from extension.

6) Remove the rotor assembly, oil pump shaft and

O-ring.

D: ASSEMBLY

1) Install the rotor assembly and oil pomp shaft to

extension case.

2) Install a new O-ring to oil pump cover.

NOTE:

Apply a coat of gear oil to the O-ring.

3) Install the oil pump cover to extension case.

Tightening torque:

24.5 N·m (2.5 kgf-m, 18.1 ft-lb)

MT-00370

MT-00371

MT-00372

(A) Oil pump cover

(A) Oil pump shaft

(B) Rotor ASSY

(C) O-ring

(A) Oil pump cover

MT-00373

MT-00374

MT-00373