SUBARU FORESTER 2004 Service Owner's Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 21 of 2870

AC-19

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

General Description

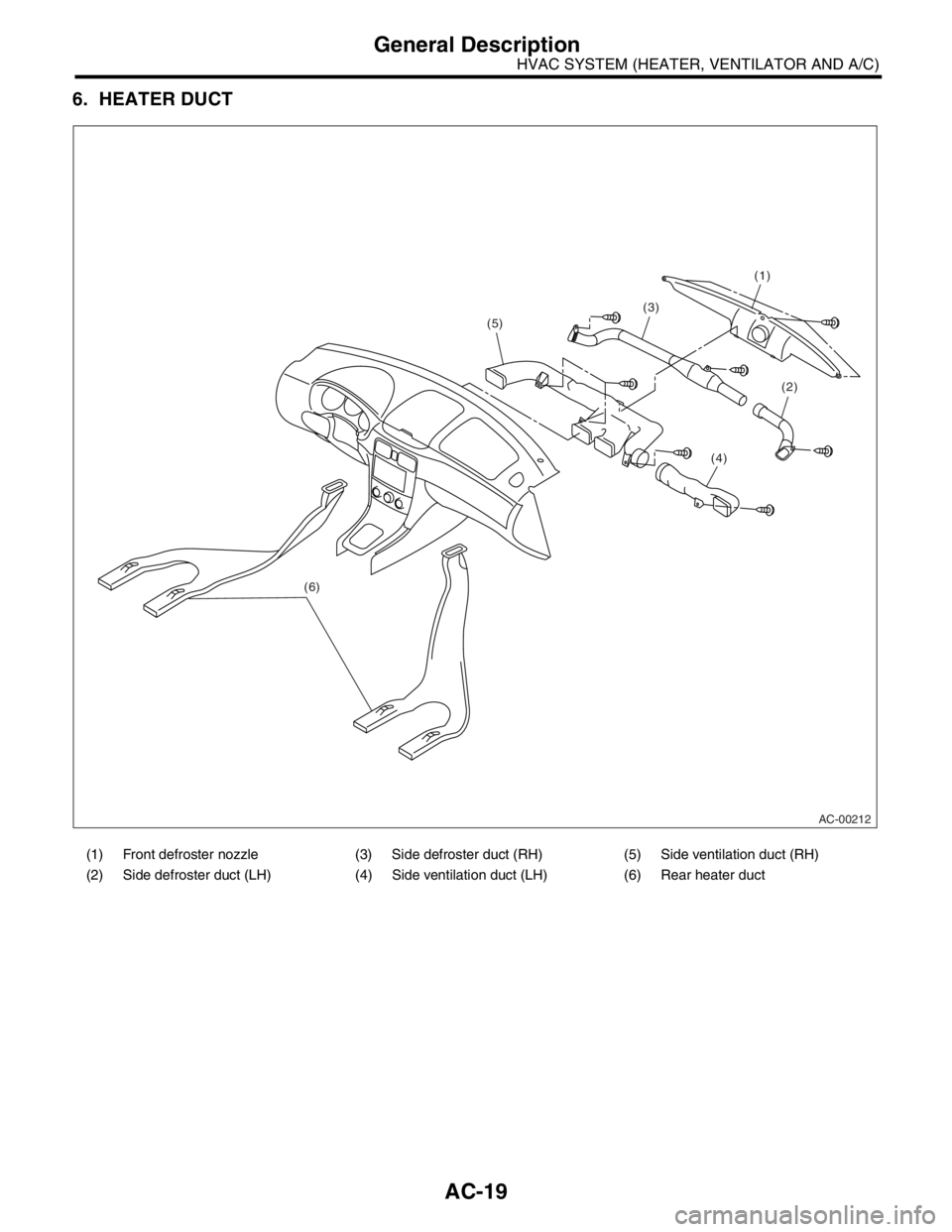

6. HEATER DUCT

(1) Front defroster nozzle (3) Side defroster duct (RH) (5) Side ventilation duct (RH)

(2) Side defroster duct (LH) (4) Side ventilation duct (LH) (6) Rear heater duct

AC-00212

(1)

(3)

(5)

(6)

(2)

(4)

Page 22 of 2870

AC-20

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

General Description

C: CAUTION

1. HFC-134a A/C SYSTEM

The cooling system components for the HFC-

134a system such as the refrigerant and compres-

sor oil are different from the old conventional HFC-

12 system components and they are incompatible

with each other.

Vehicles with the HFC-134a system can be iden-

tified by the label (A) attached to the vehicle.

Before maintenance, check which A/C system is in-

stalled in the vehicle.

2. COMPRESSOR OIL

HFC-134a compressor oil has no compatibility

with that for R12 system.

Use only the manufacturer-authorized compres-

sor oil for the HFC-134a system; only use

ZXL200PG.

Do not mix multiple compressor oils.

If HFC-12 compressor oil is used in a HFC-134a A/

C system, the compressor may become stuck due

to poor lubrication, or the refrigerant may leak due

to swelling of rubber parts.

On the other hand, if HFC-134a compressor oil is

used in a HFC-12 A/C system, the durability of the

A/C system will be lowered.

HFC-134a compressor oil is very hygroscopic.

When replacing or installing/removing A/C parts,

immediately isolate the oil from the atmosphere us-

ing a plug or tape. In order to avoid moisture, store

the oil in a container with its cap securely closed.

3. REFRIGERANT

The HFC-12 refrigerant cannot be used in the

HFC-134a A/C system. The HFC-134a refrigerant,

also, cannot be used in the HFC-12 A/C system.

If an incorrect or no refrigerant is used, poor lu-

brication will result and the compressor itself may

be damaged.

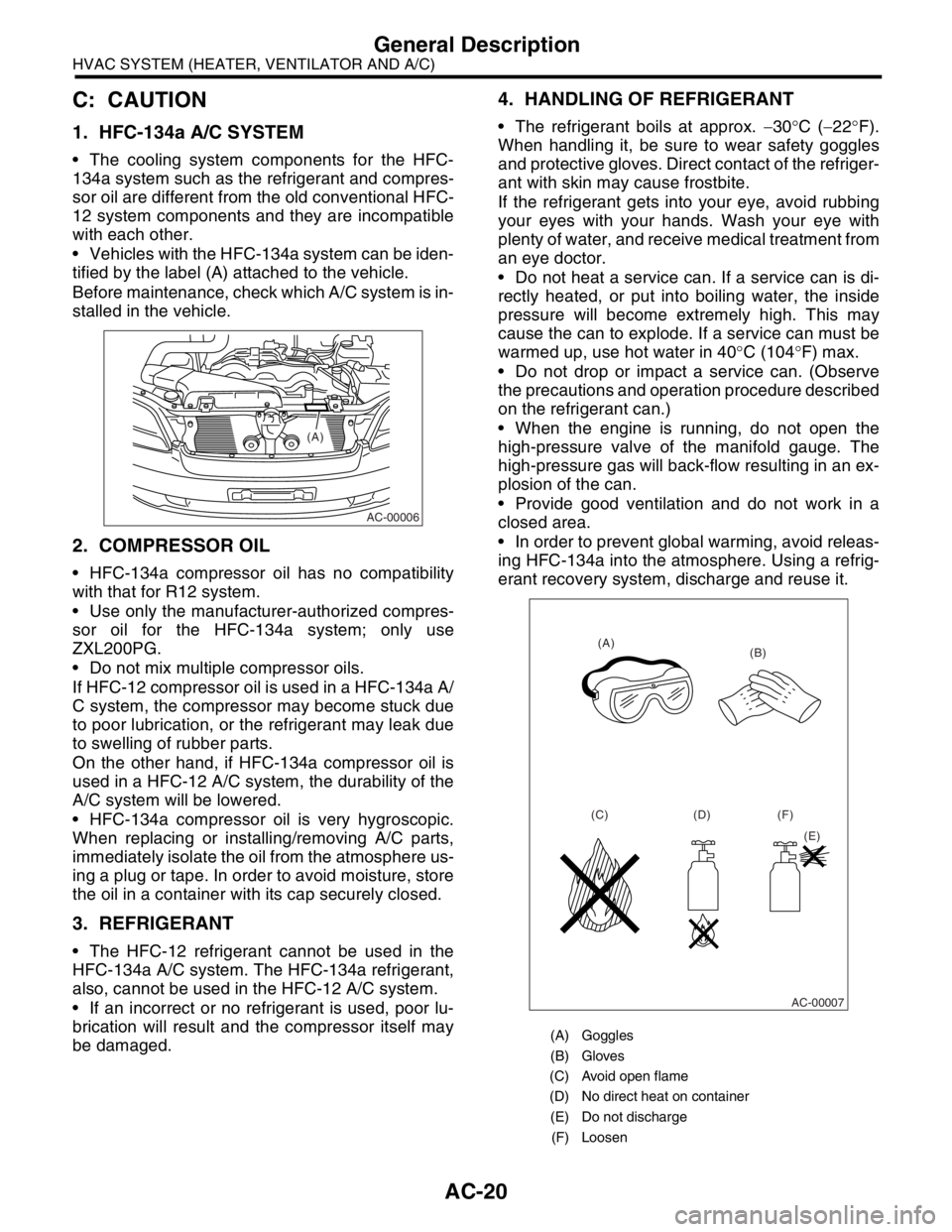

4. HANDLING OF REFRIGERANT

The refrigerant boils at approx. −30°C (−22°F).

When handling it, be sure to wear safety goggles

and protective gloves. Direct contact of the refriger-

ant with skin may cause frostbite.

If the refrigerant gets into your eye, avoid rubbing

your eyes with your hands. Wash your eye with

plenty of water, and receive medical treatment from

an eye doctor.

Do not heat a service can. If a service can is di-

rectly heated, or put into boiling water, the inside

pressure will become extremely high. This may

cause the can to explode. If a service can must be

warmed up, use hot water in 40°C (104°F) max.

Do not drop or impact a service can. (Observe

the precautions and operation procedure described

on the refrigerant can.)

When the engine is running, do not open the

high-pressure valve of the manifold gauge. The

high-pressure gas will back-flow resulting in an ex-

plosion of the can.

Provide good ventilation and do not work in a

closed area.

In order to prevent global warming, avoid releas-

ing HFC-134a into the atmosphere. Using a refrig-

erant recovery system, discharge and reuse it.

AC-00006

(A)

(A) Goggles

(B) Gloves

(C) Avoid open flame

(D) No direct heat on container

(E) Do not discharge

(F) Loosen

(A)

(B)

(C) (D)

(E) (F)

AC-00007

Page 23 of 2870

AC-21

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

General Description

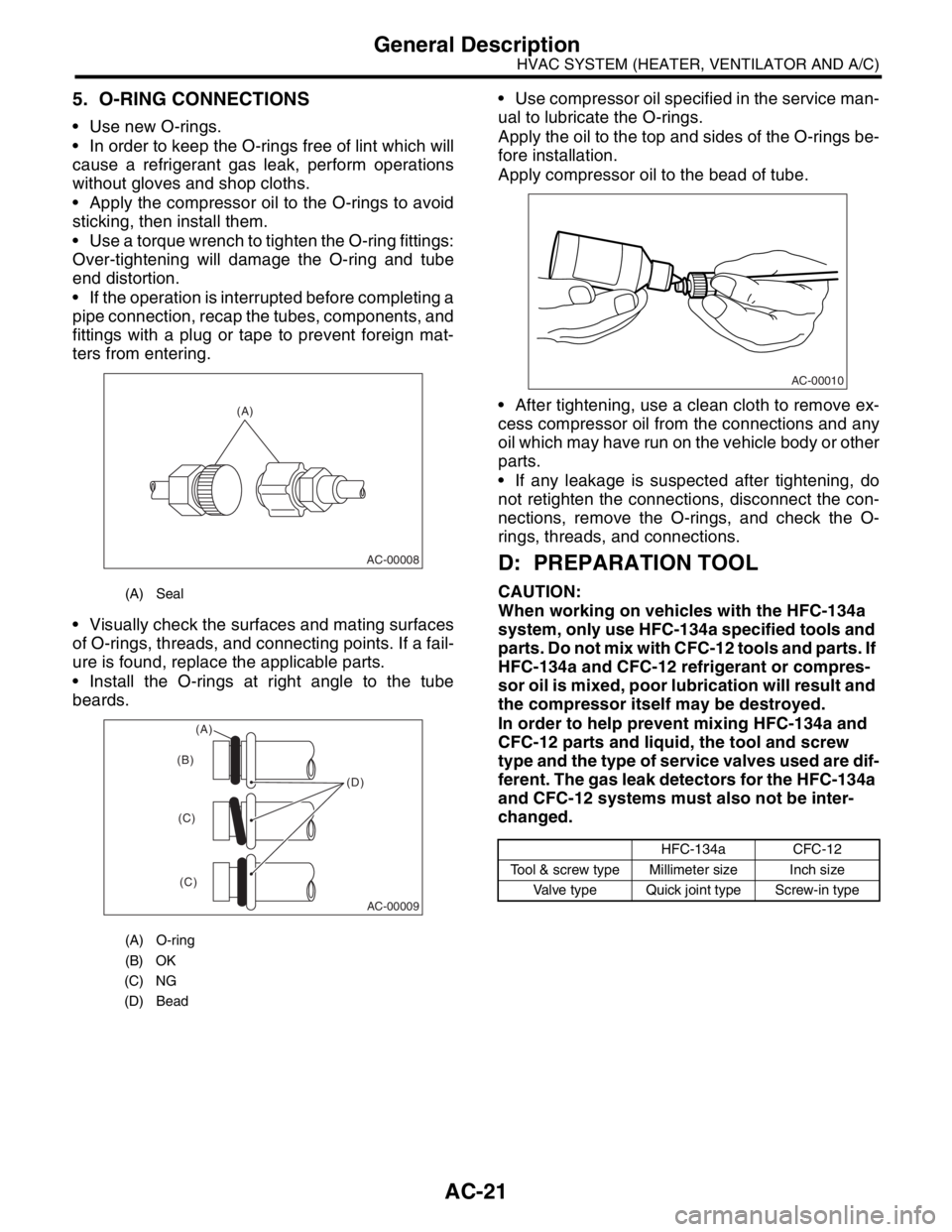

5. O-RING CONNECTIONS

Use new O-rings.

In order to keep the O-rings free of lint which will

cause a refrigerant gas leak, perform operations

without gloves and shop cloths.

Apply the compressor oil to the O-rings to avoid

sticking, then install them.

Use a torque wrench to tighten the O-ring fittings:

Over-tightening will damage the O-ring and tube

end distortion.

If the operation is interrupted before completing a

pipe connection, recap the tubes, components, and

fittings with a plug or tape to prevent foreign mat-

ters from entering.

Visually check the surfaces and mating surfaces

of O-rings, threads, and connecting points. If a fail-

ure is found, replace the applicable parts.

Install the O-rings at right angle to the tube

beards. Use compressor oil specified in the service man-

ual to lubricate the O-rings.

Apply the oil to the top and sides of the O-rings be-

fore installation.

Apply compressor oil to the bead of tube.

After tightening, use a clean cloth to remove ex-

cess compressor oil from the connections and any

oil which may have run on the vehicle body or other

parts.

If any leakage is suspected after tightening, do

not retighten the connections, disconnect the con-

nections, remove the O-rings, and check the O-

rings, threads, and connections.

D: PREPARATION TOOL

CAUTION:

When working on vehicles with the HFC-134a

system, only use HFC-134a specified tools and

parts. Do not mix with CFC-12 tools and parts. If

HFC-134a and CFC-12 refrigerant or compres-

sor oil is mixed, poor lubrication will result and

the compressor itself may be destroyed.

In order to help prevent mixing HFC-134a and

CFC-12 parts and liquid, the tool and screw

type and the type of service valves used are dif-

ferent. The gas leak detectors for the HFC-134a

and CFC-12 systems must also not be inter-

changed.(A) Seal

(A) O-ring

(B) OK

(C) NG

(D) Bead

(A)

AC-00008

AC-00009

(D) (B)

(C)

(C)

(A)

HFC-134a CFC-12

Tool & screw type Millimeter size Inch size

Valve type Quick joint type Screw-in type

AC-00010

Page 24 of 2870

AC-22

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

General Description

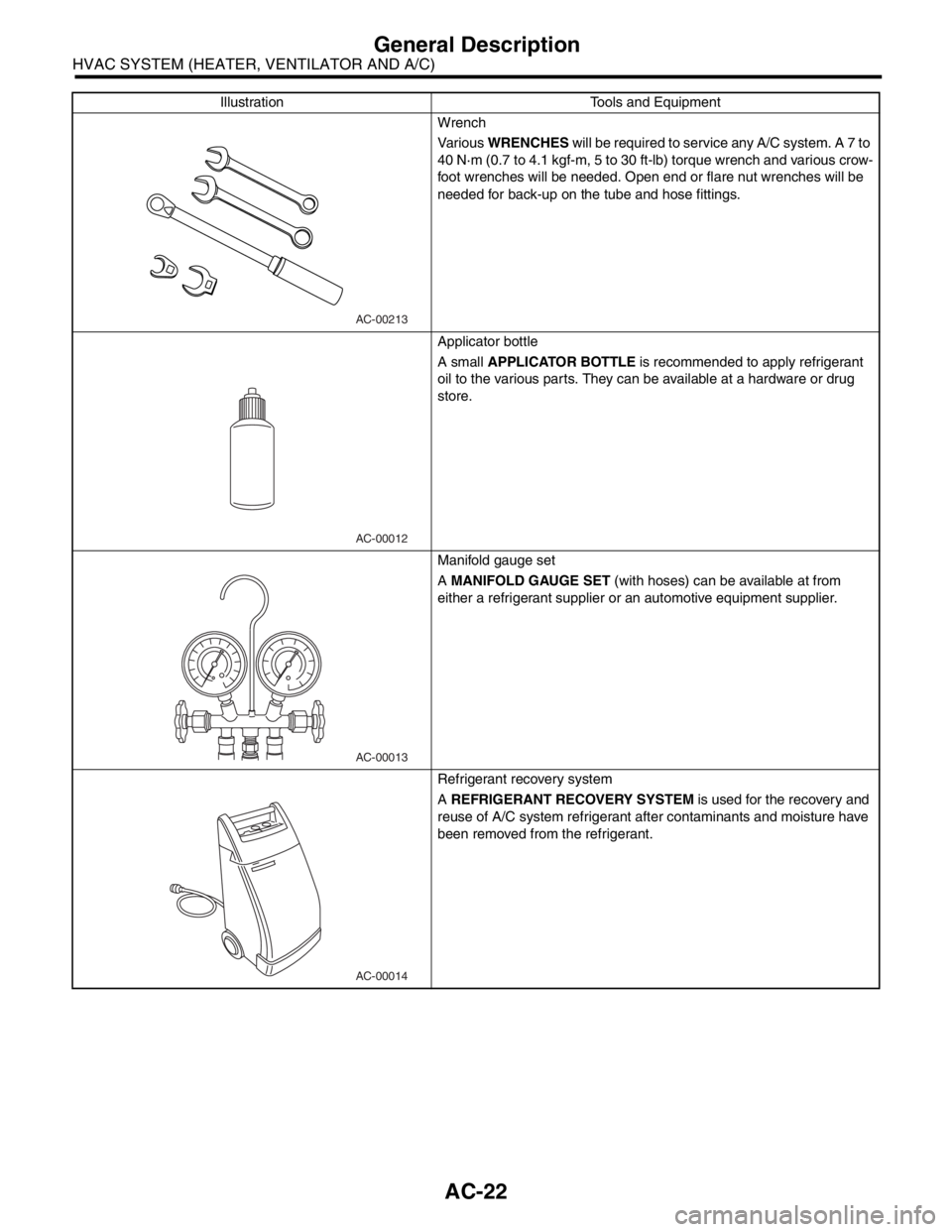

Illustration Tools and Equipment

Wrench

Va r i o u s WRENCHES will be required to service any A/C system. A 7 to

40 N·m (0.7 to 4.1 kgf-m, 5 to 30 ft-lb) torque wrench and various crow-

foot wrenches will be needed. Open end or flare nut wrenches will be

needed for back-up on the tube and hose fittings.

Applicator bottle

A small APPLICATOR BOTTLE is recommended to apply refrigerant

oil to the various parts. They can be available at a hardware or drug

store.

Manifold gauge set

A MANIFOLD GAUGE SET (with hoses) can be available at from

either a refrigerant supplier or an automotive equipment supplier.

Refrigerant recovery system

A REFRIGERANT RECOVERY SYSTEM is used for the recovery and

reuse of A/C system refrigerant after contaminants and moisture have

been removed from the refrigerant.

AC-00213

AC-00012

AC-00013

AC-00014

Page 25 of 2870

AC-23

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

General Description

Syringe

A graduated plastic SYRINGE will be needed to add oil back into the

system. The syringe can be available at a pharmacy or a drug store.

Vacuum pump

A VACUUM PUMP (in good working condition) is necessary, and can

be available at either a refrigerant supplier or an automotive equipment

supplier.

Can tap

A CAN TAP for the 397 g (14 oz) can is available at an automotive

equipment supplier.

Thermometer

Pocket THERMOMETERS are available at either a industrial hardware

store or a refrigerant suppliers. Illustration Tools and Equipment

AC-00015

AC-00016

AC-00017

AC-00018

Page 26 of 2870

AC-24

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

General Description

Electronic leak detector

An ELECTRONIC LEAK DETECTOR can be available at either a spe-

cialty tool supplier or an A/C equipment supplier.

Weight scale

A WEIGHT SCALE such as an electronic charging scale or a bath-

room scale with digital display will be needed, if a 13.6 kg (30 lb) refrig-

erant container is used. Illustration Tools and Equipment

AC-00019

AC-00020

Page 27 of 2870

AC-25

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

Refrigerant Pressure with Manifold Gauge Set

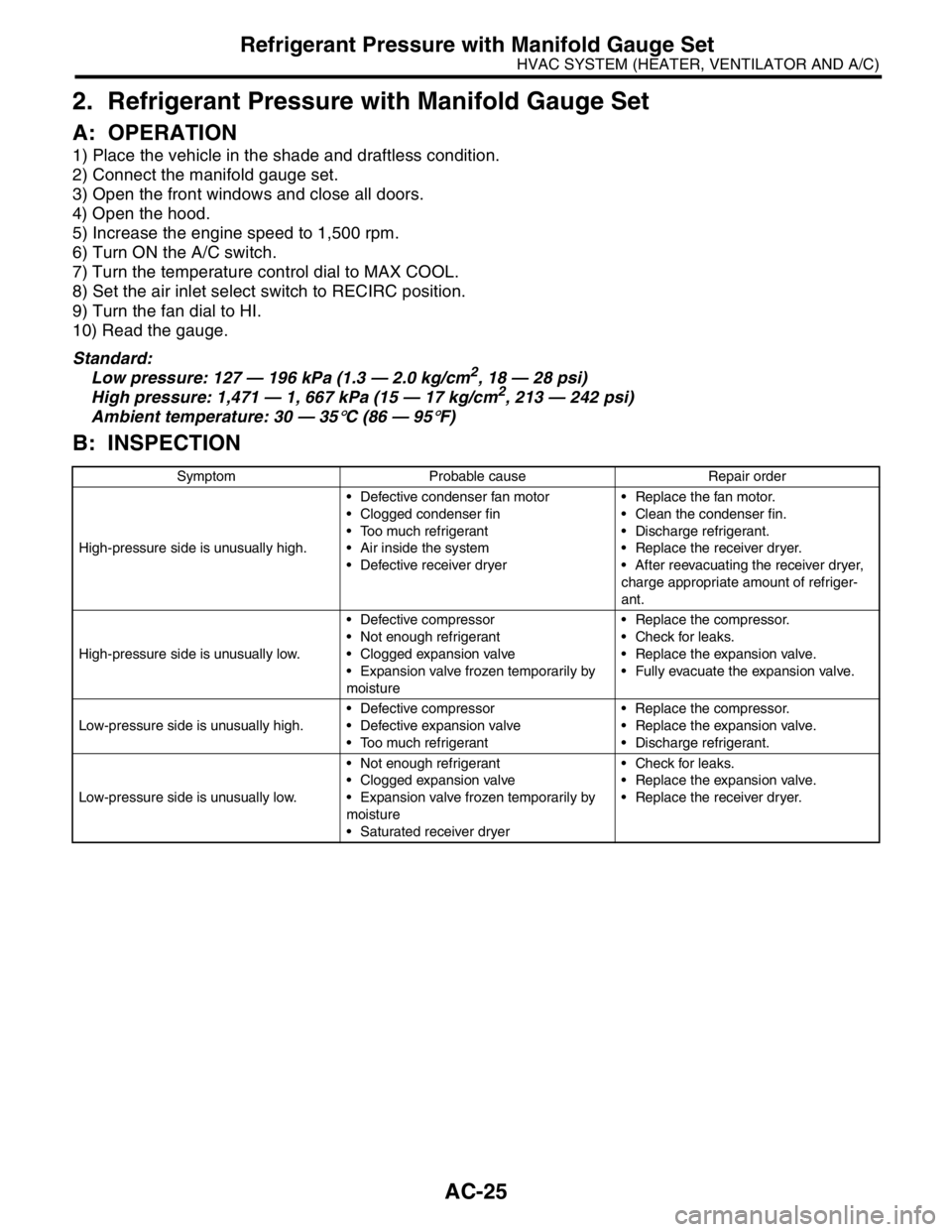

2. Refrigerant Pressure with Manifold Gauge Set

A: OPERATION

1) Place the vehicle in the shade and draftless condition.

2) Connect the manifold gauge set.

3) Open the front windows and close all doors.

4) Open the hood.

5) Increase the engine speed to 1,500 rpm.

6) Turn ON the A/C switch.

7) Turn the temperature control dial to MAX COOL.

8) Set the air inlet select switch to RECIRC position.

9) Turn the fan dial to HI.

10) Read the gauge.

Standard:

Low pressure: 127 — 196 kPa (1.3 — 2.0 kg/cm

2, 18 — 28 psi)

High pressure: 1,471 — 1, 667 kPa (15 — 17 kg/cm2, 213 — 242 psi)

Ambient temperature: 30 — 35

°C (86 — 95°F)

B: INSPECTION

Symptom Probable cause Repair order

High-pressure side is unusually high. Defective condenser fan motor

Clogged condenser fin

Too much refrigerant

Air inside the system

Defective receiver dryer Replace the fan motor.

Clean the condenser fin.

Discharge refrigerant.

Replace the receiver dryer.

After reevacuating the receiver dryer,

charge appropriate amount of refriger-

ant.

High-pressure side is unusually low. Defective compressor

Not enough refrigerant

Clogged expansion valve

Expansion valve frozen temporarily by

moisture Replace the compressor.

Check for leaks.

Replace the expansion valve.

Fully evacuate the expansion valve.

Low-pressure side is unusually high. Defective compressor

Defective expansion valve

Too much refrigerant Replace the compressor.

Replace the expansion valve.

Discharge refrigerant.

Low-pressure side is unusually low. Not enough refrigerant

Clogged expansion valve

Expansion valve frozen temporarily by

moisture

Saturated receiver dryer Check for leaks.

Replace the expansion valve.

Replace the receiver dryer.

Page 28 of 2870

AC-26

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

Refrigerant Recovery Procedure

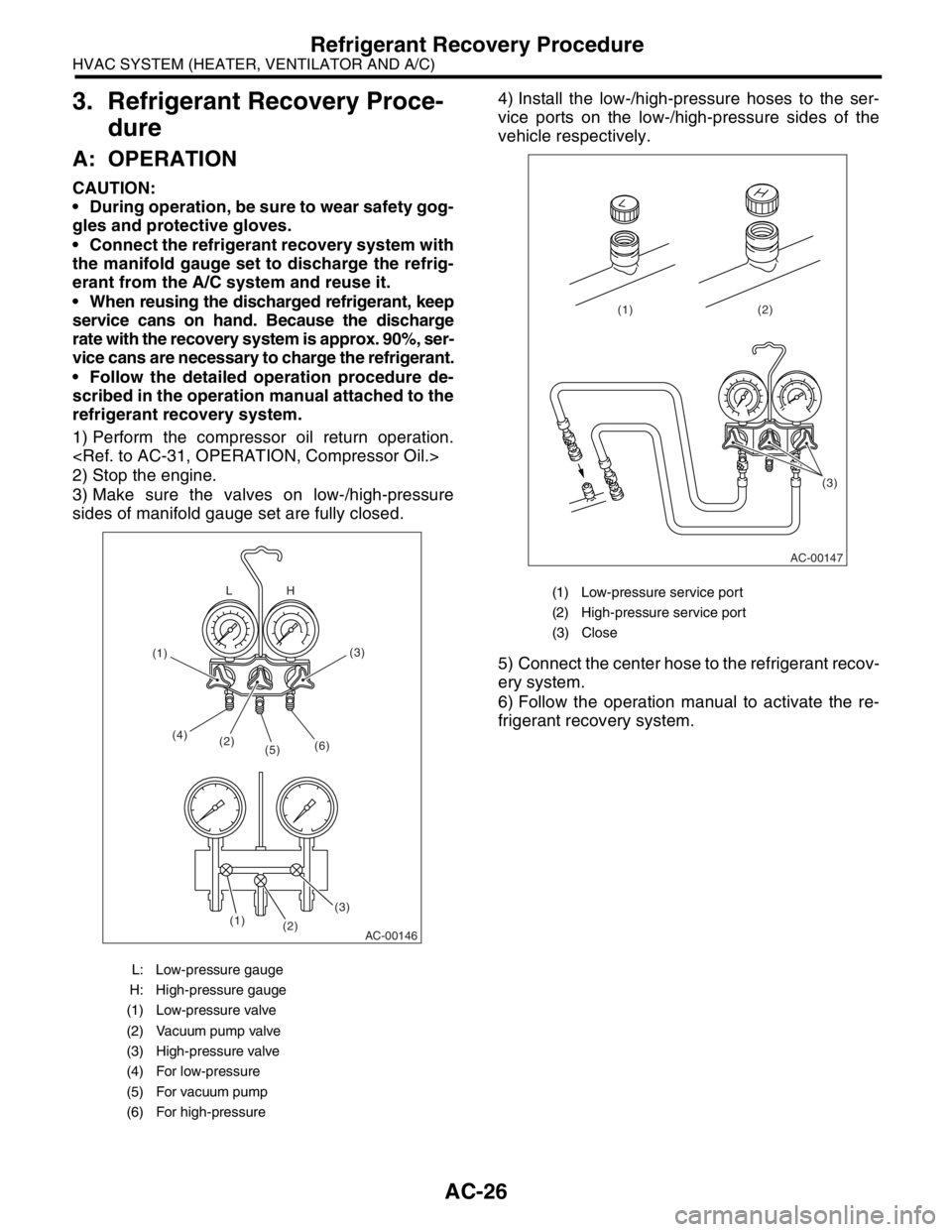

3. Refrigerant Recovery Proce-

dure

A: OPERATION

CAUTION:

During operation, be sure to wear safety gog-

gles and protective gloves.

Connect the refrigerant recovery system with

the manifold gauge set to discharge the refrig-

erant from the A/C system and reuse it.

When reusing the discharged refrigerant, keep

service cans on hand. Because the discharge

rate with the recovery system is approx. 90%, ser-

vice cans are necessary to charge the refrigerant.

Follow the detailed operation procedure de-

scribed in the operation manual attached to the

refrigerant recovery system.

1) Perform the compressor oil return operation.

2) Stop the engine.

3) Make sure the valves on low-/high-pressure

sides of manifold gauge set are fully closed.4) Install the low-/high-pressure hoses to the ser-

vice ports on the low-/high-pressure sides of the

vehicle respectively.

5) Connect the center hose to the refrigerant recov-

ery system.

6) Follow the operation manual to activate the re-

frigerant recovery system.

L: Low-pressure gauge

H: High-pressure gauge

(1) Low-pressure valve

(2) Vacuum pump valve

(3) High-pressure valve

(4) For low-pressure

(5) For vacuum pump

(6) For high-pressure

AC-00146

(2) (4)

(5)(6)

(3)(3)

(2) (1)H L

(1)

(1) Low-pressure service port

(2) High-pressure service port

(3) Close

AC-00147

(3) (2) (1)

Page 29 of 2870

AC-27

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

Refrigerant Charging Procedure

4. Refrigerant Charging Proce-

dure

A: OPERATION

CAUTION:

During operation, be sure to wear safety gog-

gles and protective gloves.

If air is mixed in refrigeration cycle, poor cool-

ing may result, and also if moisture is mixed in re-

frigeration cycle, clogging (freezing) or rust may

result.

Before charging the refrigerant, evacuate the

system using vacuum pump to remove air and

moisture in the system. Moisture can be evapo-

rated and removed easily even at normal tem-

perature, if the system is evacuated using

vacuum pump.

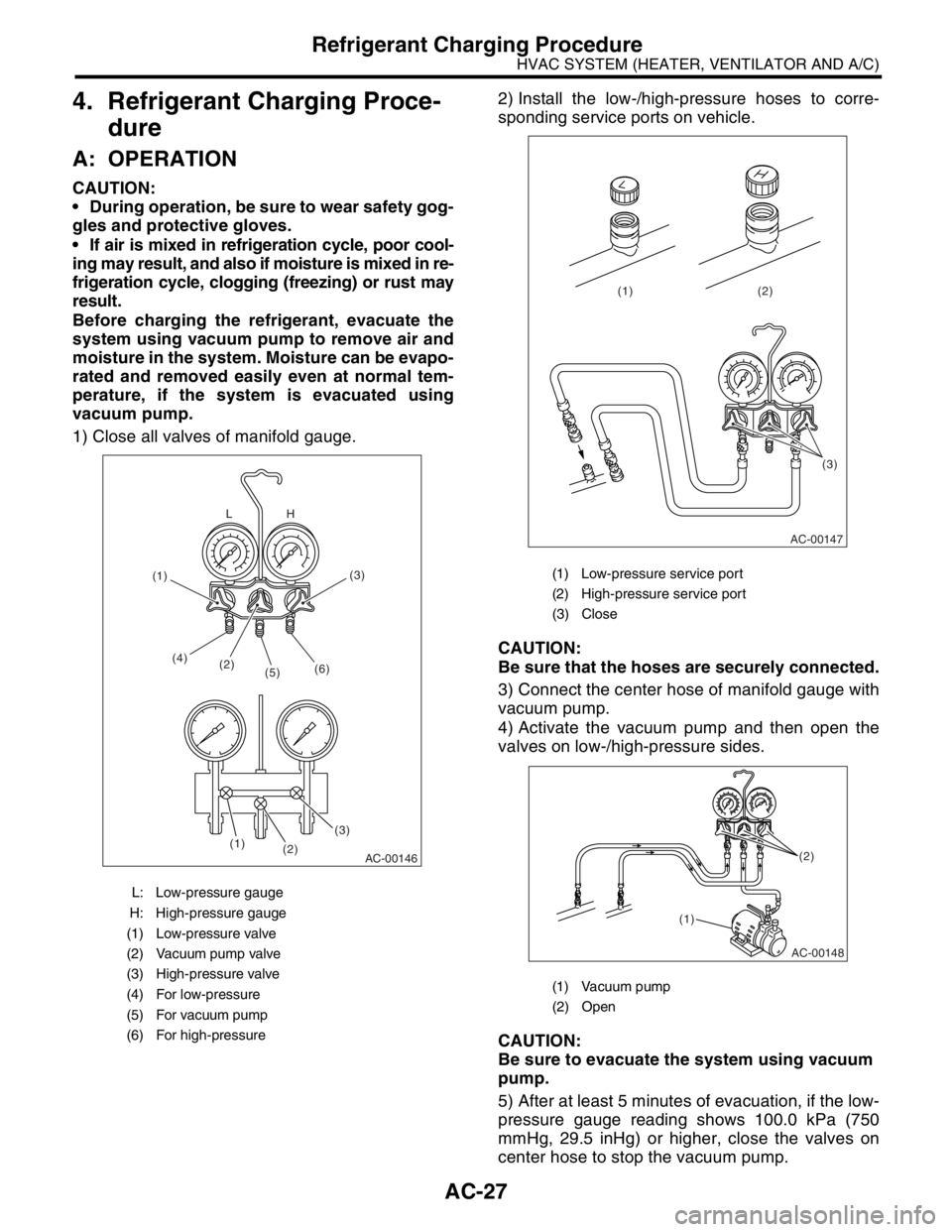

1) Close all valves of manifold gauge.2) Install the low-/high-pressure hoses to corre-

sponding service ports on vehicle.

CAUTION:

Be sure that the hoses are securely connected.

3) Connect the center hose of manifold gauge with

vacuum pump.

4) Activate the vacuum pump and then open the

valves on low-/high-pressure sides.

CAUTION:

Be sure to evacuate the system using vacuum

pump.

5) After at least 5 minutes of evacuation, if the low-

pressure gauge reading shows 100.0 kPa (750

mmHg, 29.5 inHg) or higher, close the valves on

center hose to stop the vacuum pump.

L: Low-pressure gauge

H: High-pressure gauge

(1) Low-pressure valve

(2) Vacuum pump valve

(3) High-pressure valve

(4) For low-pressure

(5) For vacuum pump

(6) For high-pressure

AC-00146

(2) (4)

(5)(6)

(3)(3)

(2) (1)H L

(1)

(1) Low-pressure service port

(2) High-pressure service port

(3) Close

(1) Vacuum pump

(2) Open

AC-00147

(3) (2) (1)

AC-00148

(1)(2)

Page 30 of 2870

AC-28

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

Refrigerant Charging Procedure

6) Leave it at least 5 to 10 minutes after closing the

valves on low-/high-pressure sides, and then check

the low-pressure gauge reading for any changes.

When the gauge reading changes, this is a sign of

leakage. Check the pipe or hose connector points,

and repair if necessary. Repeat the procedure from

1) after repairing the faulty part.

7) If there are no leaks, further evacuate the sys-

tem 20 to 30 minutes.

8) Close all valves and stop the vacuum pump.

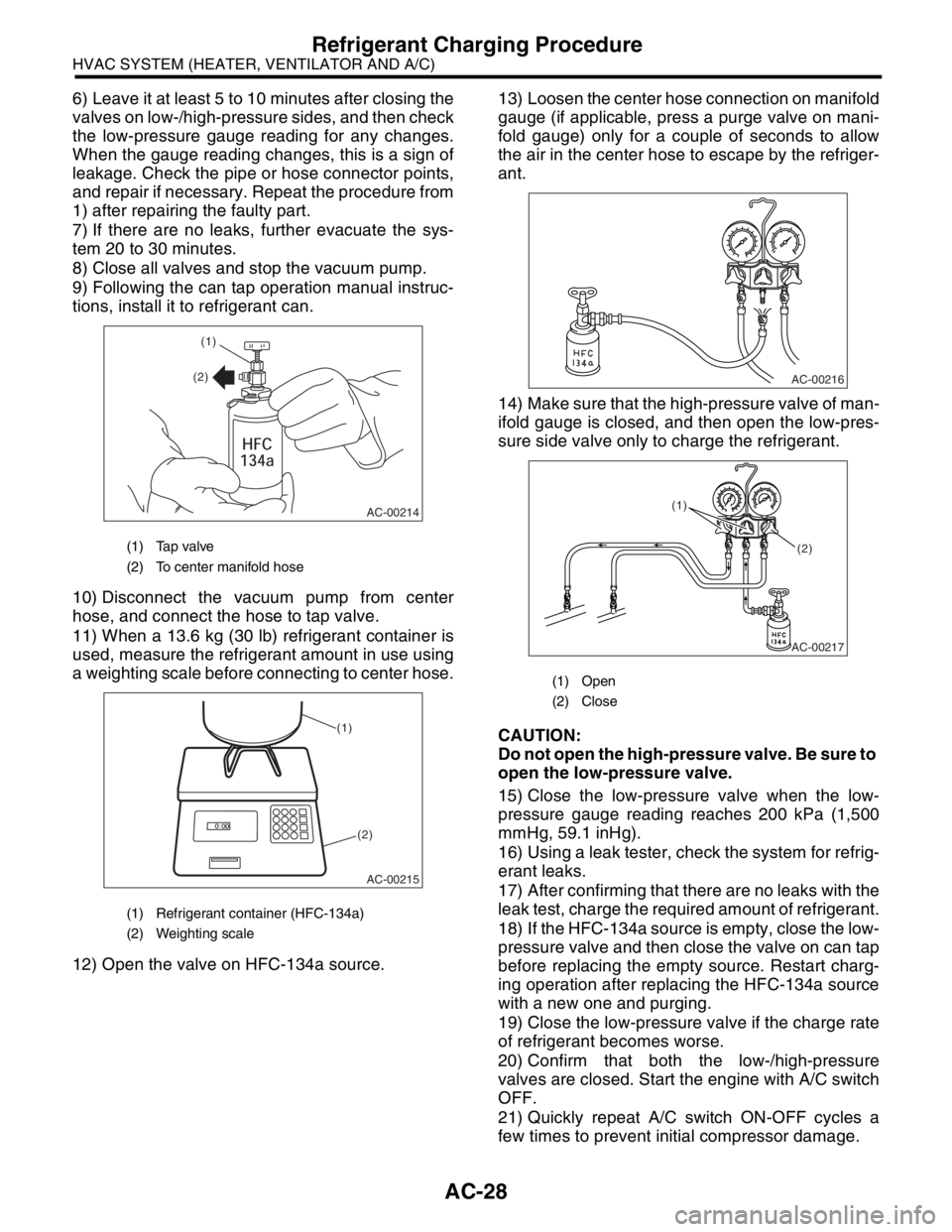

9) Following the can tap operation manual instruc-

tions, install it to refrigerant can.

10) Disconnect the vacuum pump from center

hose, and connect the hose to tap valve.

11) When a 13.6 kg (30 lb) refrigerant container is

used, measure the refrigerant amount in use using

a weighting scale before connecting to center hose.

12) Open the valve on HFC-134a source.13) Loosen the center hose connection on manifold

gauge (if applicable, press a purge valve on mani-

fold gauge) only for a couple of seconds to allow

the air in the center hose to escape by the refriger-

ant.

14) Make sure that the high-pressure valve of man-

ifold gauge is closed, and then open the low-pres-

sure side valve only to charge the refrigerant.

CAUTION:

Do not open the high-pressure valve. Be sure to

open the low-pressure valve.

15) Close the low-pressure valve when the low-

pressure gauge reading reaches 200 kPa (1,500

mmHg, 59.1 inHg).

16) Using a leak tester, check the system for refrig-

erant leaks.

17) After confirming that there are no leaks with the

leak test, charge the required amount of refrigerant.

18) If the HFC-134a source is empty, close the low-

pressure valve and then close the valve on can tap

before replacing the empty source. Restart charg-

ing operation after replacing the HFC-134a source

with a new one and purging.

19) Close the low-pressure valve if the charge rate

of refrigerant becomes worse.

20) Confirm that both the low-/high-pressure

valves are closed. Start the engine with A/C switch

OFF.

21) Quickly repeat A/C switch ON-OFF cycles a

few times to prevent initial compressor damage.

(1) Tap valve

(2) To center manifold hose

(1) Refrigerant container (HFC-134a)

(2) Weighting scale

AC-00214

(1)

(2)

AC-00215

(1)

(2)

(1) Open

(2) Close

AC-00216

AC-00217

(1)

(2)