SUBARU FORESTER 2004 Service Owner's Guide

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 31 of 2870

AC-29

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

Refrigerant Charging Procedure

22) Set up the vehicle to the following status:

A/C switch ON

Engine running at 1,500 rpm

Blower speed setting to “HI”

Temperature setting to “MAX COOL”

Air inlet setting to “RECIRC”

Window open

23) Open the low-pressure valve and charge the

specified amount of refrigerant.

24) Close all valves and disconnect the hoses from

service port after charging the refrigerant.

25) Install the cap to service port.

Page 32 of 2870

AC-30

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

Refrigerant Leak Check

5. Refrigerant Leak Check

A: INSPECTION

1) Operate the A/C system for approx. 10 minutes,

and confirm that the high-pressure side shows at

least 690 kPa (7.03 kg/cm

2, 100 psi). Then stop the

engine to start the leak test.

2) Starting from the connection between the high-

pressure pipe and evaporator, check the system for

leaks along the high-pressure side through the

compressor. The following items must be checked

thoroughly.

3) Check the joint and seam between the pressure

switch (triple pressure switch) and high-pressure

pipe.

4) Check the connections between the condenser

and pipes, and welded joints on the condenser.

The leak tester may detect the oil on the condenser

fins as a leak.

5) Check the joint between the compressor and

hoses.

6) Check the machined area of compressor and

other joints on the compressor.

7) Check the compressor shaft seal at the area

near the center of compressor clutch pulley.

Some shaft seals show a slight amount of leakage

about 28 g (1.0 oz) per year. This is not a problem.

8) Starting from the connection between the low-

pressure pipe and evaporator, check the system for

leakage along the low-pressure side through the

compressor. The following items must be checked

thoroughly.

Connection between two parts

Connection between the pipe and plate

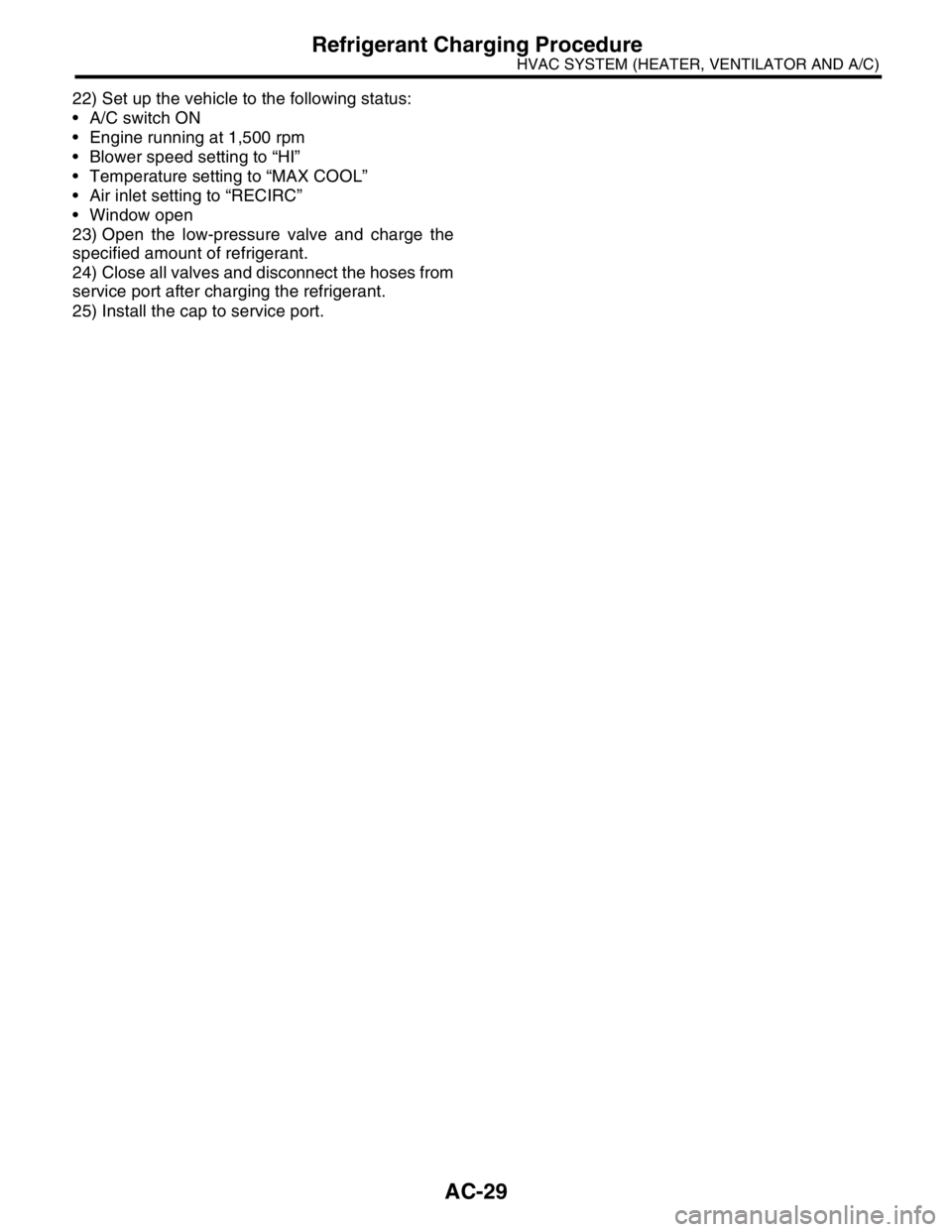

9) Visually check the rubber area of the flexible

hose for cracks.

Check the entire length of the flexible hose, espe-

cially the connection with the metal hose end.CAUTION:

Carefully check the external surface of hoses

and tubes at approx. 25 mm (0.98 in) per sec-

ond.

10) Disconnect the drain hose from the heater

case, and check the hose end for at least 10 sec-

onds.

After the test is finished, reconnect the drain hose.

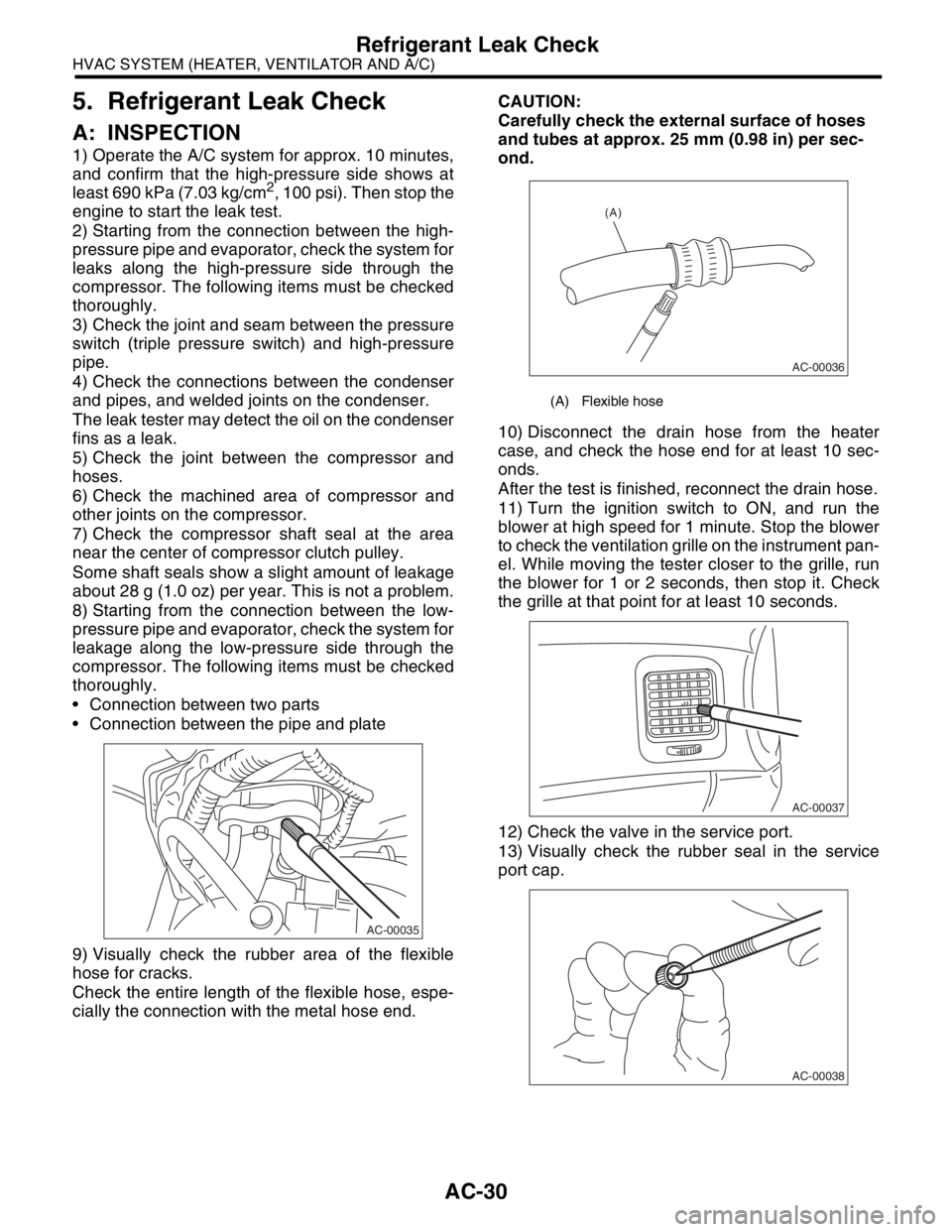

11) Turn the ignition switch to ON, and run the

blower at high speed for 1 minute. Stop the blower

to check the ventilation grille on the instrument pan-

el. While moving the tester closer to the grille, run

the blower for 1 or 2 seconds, then stop it. Check

the grille at that point for at least 10 seconds.

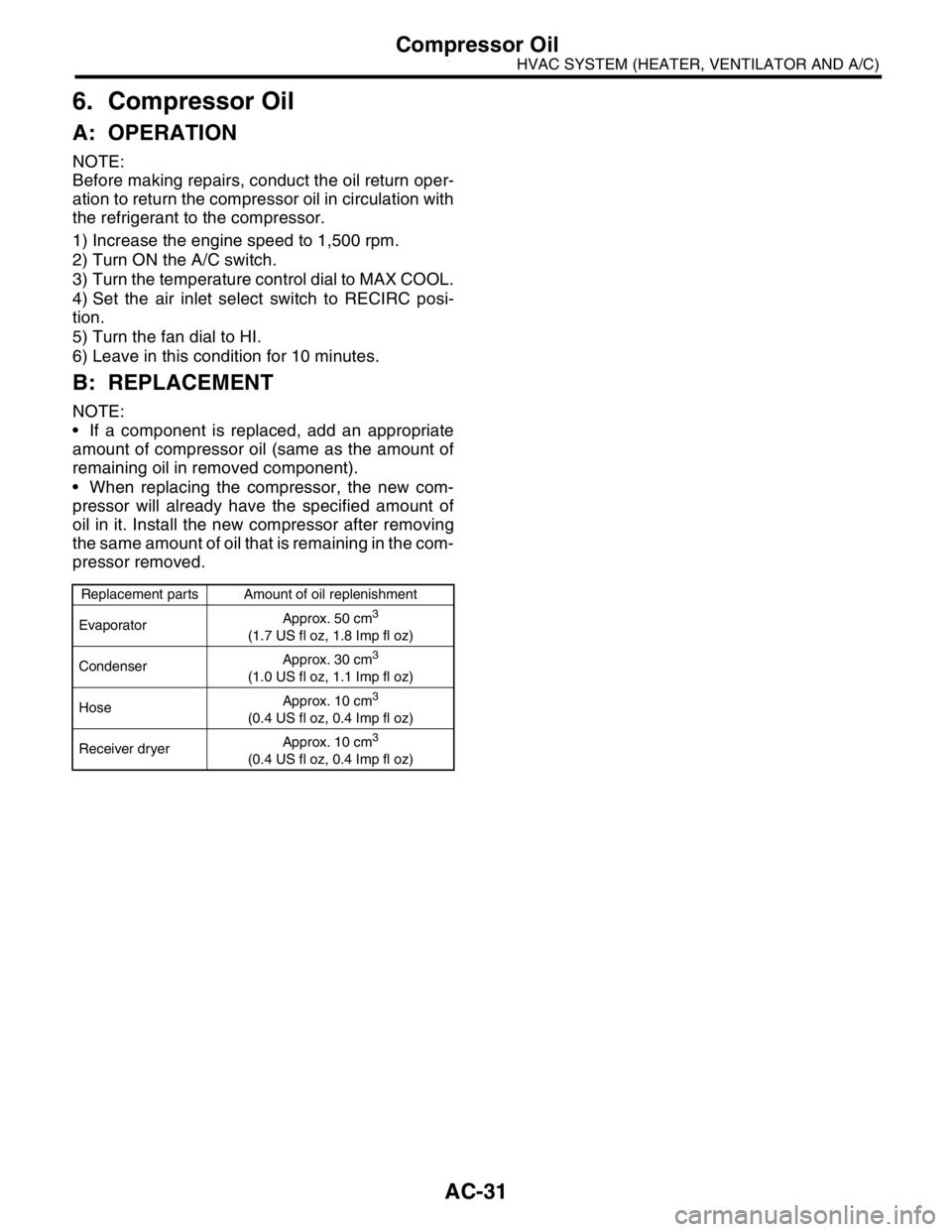

12) Check the valve in the service port.

13) Visually check the rubber seal in the service

port cap.

AC-00035

(A) Flexible hose

AC-00036

(A)

AC-00037

AC-00038

Page 33 of 2870

AC-31

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

Compressor Oil

6. Compressor Oil

A: OPERATION

NOTE:

Before making repairs, conduct the oil return oper-

ation to return the compressor oil in circulation with

the refrigerant to the compressor.

1) Increase the engine speed to 1,500 rpm.

2) Turn ON the A/C switch.

3) Turn the temperature control dial to MAX COOL.

4) Set the air inlet select switch to RECIRC posi-

tion.

5) Turn the fan dial to HI.

6) Leave in this condition for 10 minutes.

B: REPLACEMENT

NOTE:

If a component is replaced, add an appropriate

amount of compressor oil (same as the amount of

remaining oil in removed component).

When replacing the compressor, the new com-

pressor will already have the specified amount of

oil in it. Install the new compressor after removing

the same amount of oil that is remaining in the com-

pressor removed.

Replacement parts Amount of oil replenishment

EvaporatorApprox. 50 cm

3

(1.7 US fl oz, 1.8 Imp fl oz)

CondenserApprox. 30 cm

3

(1.0 US fl oz, 1.1 Imp fl oz)

HoseApprox. 10 cm

3

(0.4 US fl oz, 0.4 Imp fl oz)

Receiver dryerApprox. 10 cm

3

(0.4 US fl oz, 0.4 Imp fl oz)

Page 34 of 2870

AC-32

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

Blower Motor Unit Assembly

7. Blower Motor Unit Assembly

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the glove box.

3) Loosen the nut to remove the support beam

stay.

4) Disconnect the connectors of blower motor and

intake actuator resistor.

5) Loosen the bolt and nut to remove blower motor

unit assembly.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

Refer to COMPONENT in General Descrip-

tion.

General Description.>

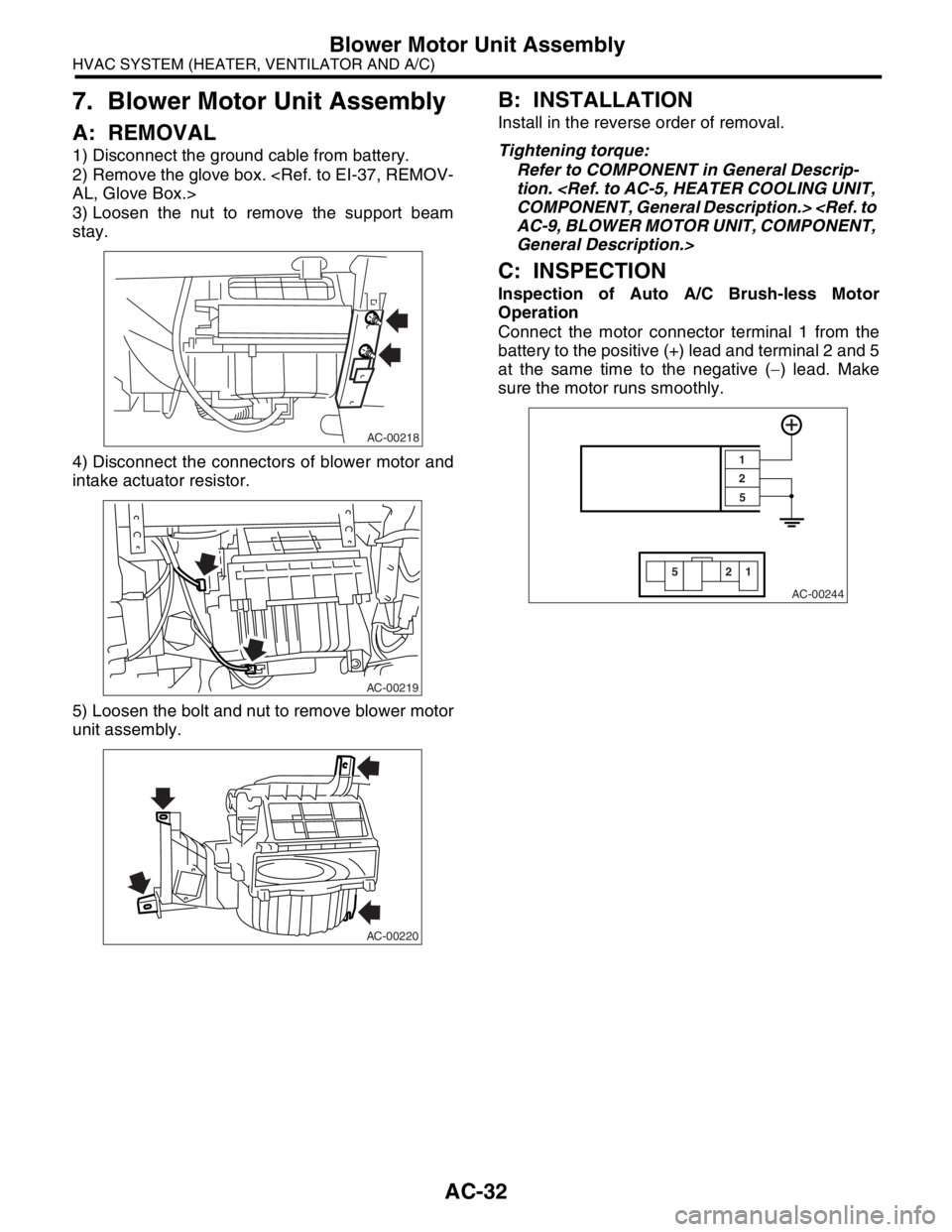

C: INSPECTION

Inspection of Auto A/C Brush-less Motor

Operation

Connect the motor connector terminal 1 from the

battery to the positive (+) lead and terminal 2 and 5

at the same time to the negative (−) lead. Make

sure the motor runs smoothly.

AC-00218

AC-00219

AC-00220

AC-00244

22

55

1 1

Page 35 of 2870

AC-33

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

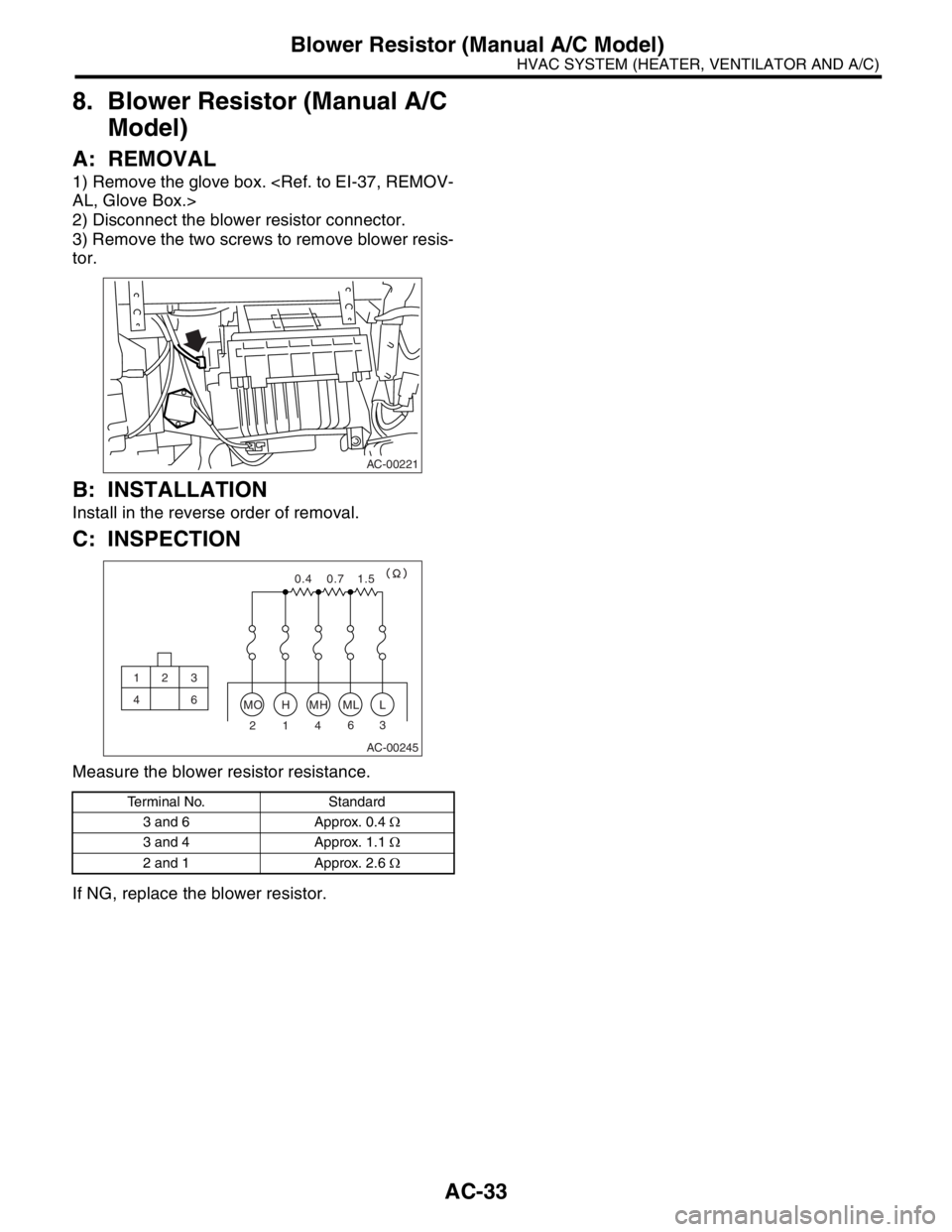

Blower Resistor (Manual A/C Model)

8. Blower Resistor (Manual A/C

Model)

A: REMOVAL

1) Remove the glove box.

2) Disconnect the blower resistor connector.

3) Remove the two screws to remove blower resis-

tor.

B: INSTALLATION

Install in the reverse order of removal.

C: INSPECTION

Measure the blower resistor resistance.

If NG, replace the blower resistor.

Terminal No. Standard

3 and 6 Approx. 0.4 Ω

3 and 4 Approx. 1.1 Ω

2 and 1 Approx. 2.6 Ω

AC-00221

AC-00245

MOHMHMLL

23 6

4 1

0.4 0.7 1.5

12 3

46

Page 36 of 2870

AC-34

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

Heater Core

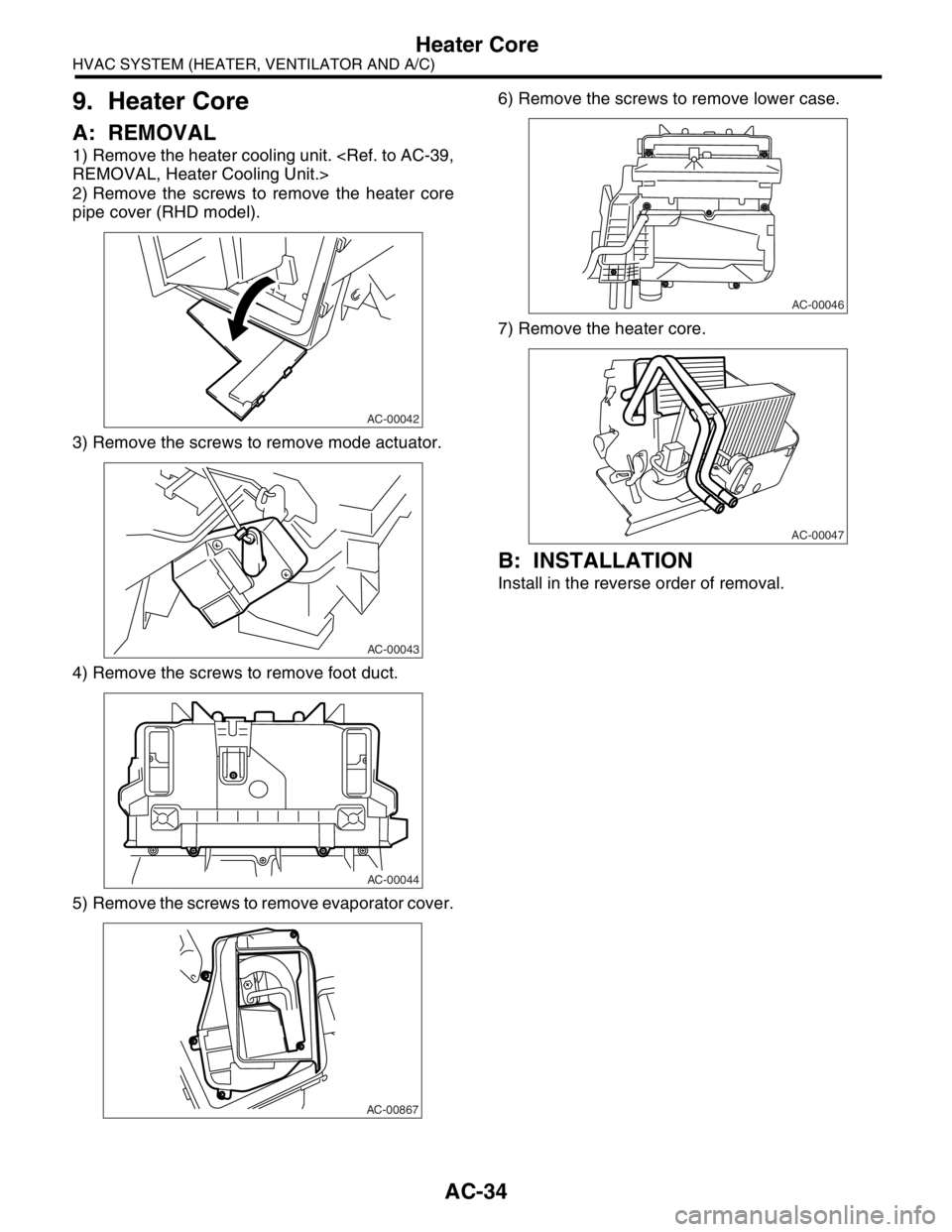

9. Heater Core

A: REMOVAL

1) Remove the heater cooling unit.

2) Remove the screws to remove the heater core

pipe cover (RHD model).

3) Remove the screws to remove mode actuator.

4) Remove the screws to remove foot duct.

5) Remove the screws to remove evaporator cover.6) Remove the screws to remove lower case.

7) Remove the heater core.

B: INSTALLATION

Install in the reverse order of removal.

AC-00042

AC-00043

AC-00044

AC-00867

AC-00046

AC-00047

Page 37 of 2870

AC-35

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

Control Unit

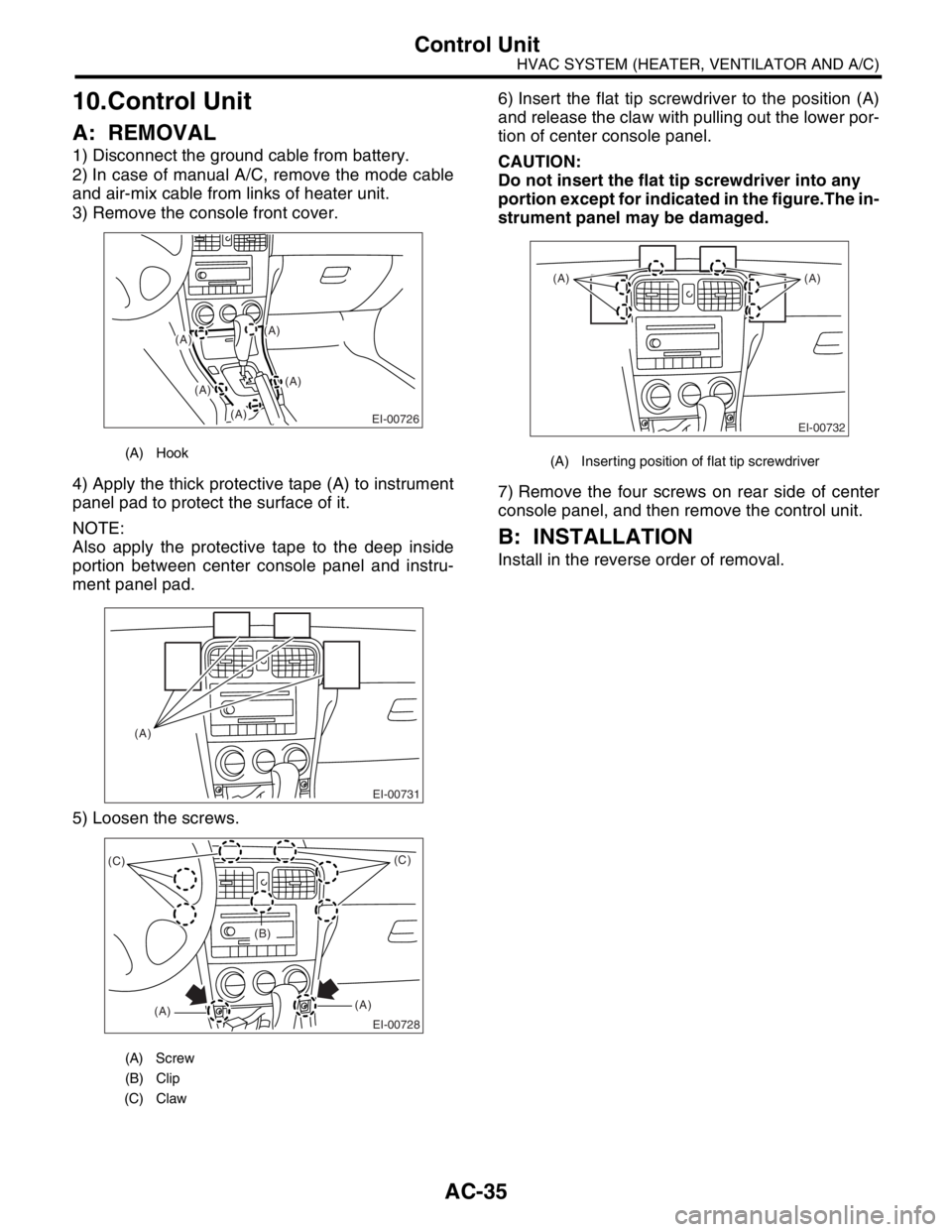

10.Control Unit

A: REMOVAL

1) Disconnect the ground cable from battery.

2) In case of manual A/C, remove the mode cable

and air-mix cable from links of heater unit.

3) Remove the console front cover.

4) Apply the thick protective tape (A) to instrument

panel pad to protect the surface of it.

NOTE:

Also apply the protective tape to the deep inside

portion between center console panel and instru-

ment panel pad.

5) Loosen the screws.6) Insert the flat tip screwdriver to the position (A)

and release the claw with pulling out the lower por-

tion of center console panel.

CAUTION:

Do not insert the flat tip screwdriver into any

portion except for indicated in the figure.The in-

strument panel may be damaged.

7) Remove the four screws on rear side of center

console panel, and then remove the control unit.

B: INSTALLATION

Install in the reverse order of removal.

(A) Hook

(A) Screw

(B) Clip

(C) Claw

(A)

(A)

EI-00726

(A)

(A)

(A)

EI-00731

(A)

EI-00728

(C)

(A)(A)(C)

(B)

(A) Inserting position of flat tip screwdriver

EI-00732

(A) (A)

Page 38 of 2870

AC-36

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

Compressor

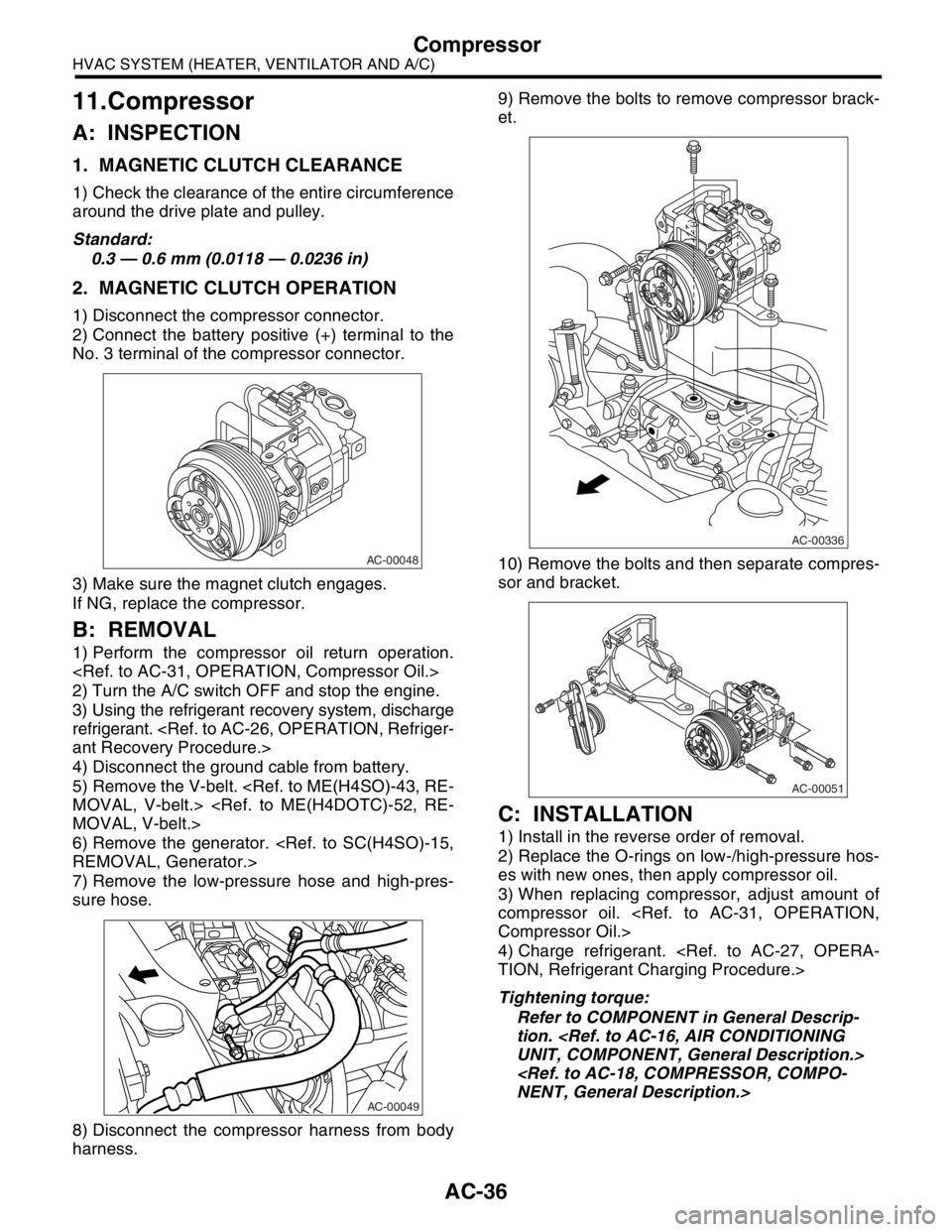

11.Compressor

A: INSPECTION

1. MAGNETIC CLUTCH CLEARANCE

1) Check the clearance of the entire circumference

around the drive plate and pulley.

Standard:

0.3 — 0.6 mm (0.0118 — 0.0236 in)

2. MAGNETIC CLUTCH OPERATION

1) Disconnect the compressor connector.

2) Connect the battery positive (+) terminal to the

No. 3 terminal of the compressor connector.

3) Make sure the magnet clutch engages.

If NG, replace the compressor.

B: REMOVAL

1) Perform the compressor oil return operation.

2) Turn the A/C switch OFF and stop the engine.

3) Using the refrigerant recovery system, discharge

refrigerant.

4) Disconnect the ground cable from battery.

5) Remove the V-belt.

6) Remove the generator.

7) Remove the low-pressure hose and high-pres-

sure hose.

8) Disconnect the compressor harness from body

harness.9) Remove the bolts to remove compressor brack-

et.

10) Remove the bolts and then separate compres-

sor and bracket.

C: INSTALLATION

1) Install in the reverse order of removal.

2) Replace the O-rings on low-/high-pressure hos-

es with new ones, then apply compressor oil.

3) When replacing compressor, adjust amount of

compressor oil.

4) Charge refrigerant.

Tightening torque:

Refer to COMPONENT in General Descrip-

tion.

AC-00048

AC-00049

AC-00336

AC-00051

Page 39 of 2870

AC-37

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

Condenser

12.Condenser

A: REMOVAL

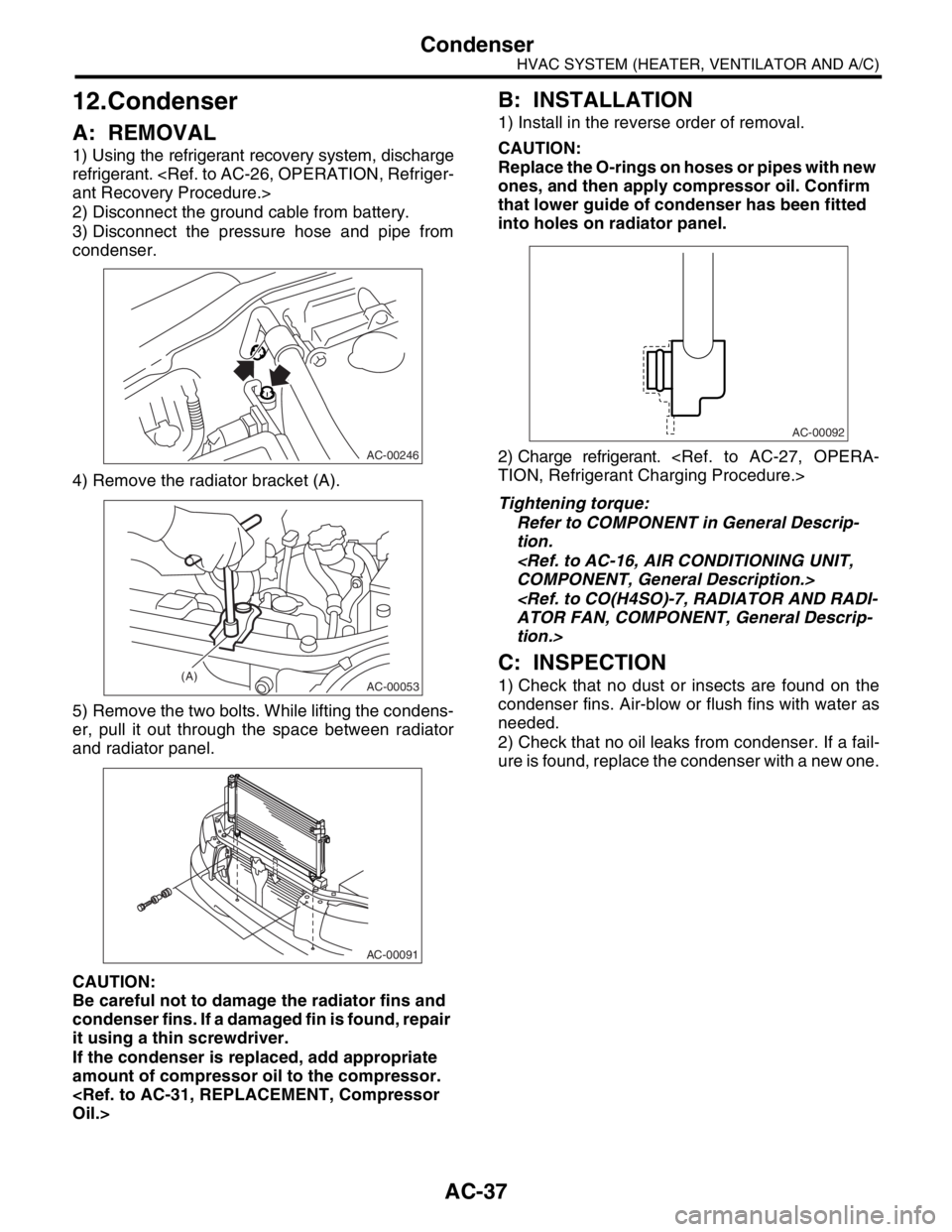

1) Using the refrigerant recovery system, discharge

refrigerant.

2) Disconnect the ground cable from battery.

3) Disconnect the pressure hose and pipe from

condenser.

4) Remove the radiator bracket (A).

5) Remove the two bolts. While lifting the condens-

er, pull it out through the space between radiator

and radiator panel.

CAUTION:

Be careful not to damage the radiator fins and

condenser fins. If a damaged fin is found, repair

it using a thin screwdriver.

If the condenser is replaced, add appropriate

amount of compressor oil to the compressor.

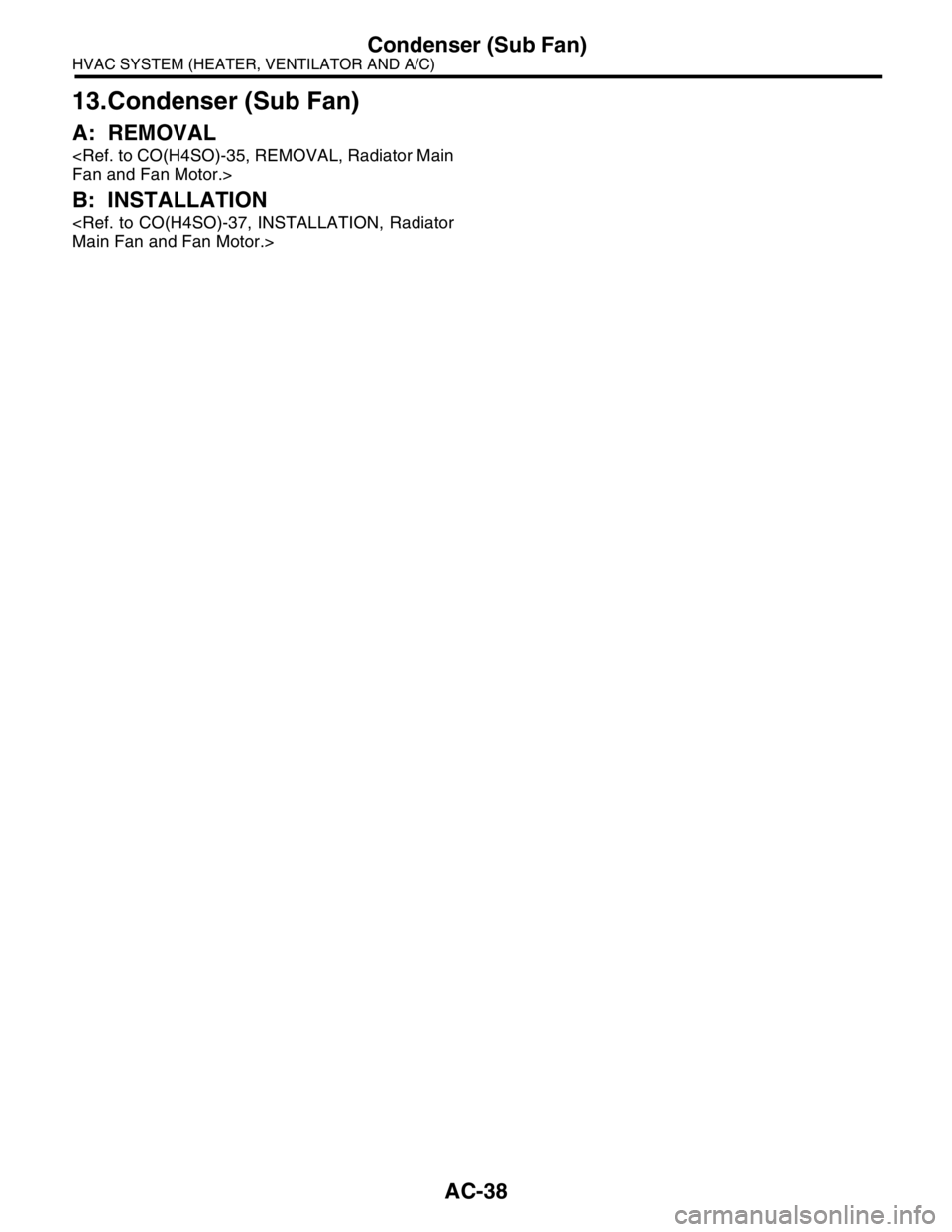

B: INSTALLATION

1) Install in the reverse order of removal.

CAUTION:

Replace the O-rings on hoses or pipes with new

ones, and then apply compressor oil. Confirm

that lower guide of condenser has been fitted

into holes on radiator panel.

2) Charge refrigerant.

Tightening torque:

Refer to COMPONENT in General Descrip-

tion.

tion.>

C: INSPECTION

1) Check that no dust or insects are found on the

condenser fins. Air-blow or flush fins with water as

needed.

2) Check that no oil leaks from condenser. If a fail-

ure is found, replace the condenser with a new one.

AC-00246

AC-00053(A)

AC-00091

AC-00092

Page 40 of 2870

AC-38

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

Condenser (Sub Fan)

13.Condenser (Sub Fan)

A: REMOVAL

B: INSTALLATION