torque SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1938 of 2870

FU(H4DOTC 2.5)-8

FUEL INJECTION (FUEL SYSTEM)

General Description

(1) Heat shield cover (13) Evaporation hose B (25) Evaporation hose E

(2) Fuel tank band (14) Joint pipe (26) Fuel sub level sensor gasket

(3) Protector LH (15) Evaporation hose C (27) Jet pump filter

(4) Protector RH (16) Evaporation pipe ASSY (28) Fuel sub level sensor

(5) Fuel tank (17) Evaporation pipe (29) Evaporation hose F

(6) Fuel pump gasket (18) Fuel return hose A (30) Evaporation hose G

(7) Fuel pump ASSY (19) Jet pump hose

(8) Fuel level sensor (20) RetainerTightening torque: N·m (kgf-m, ft-lb)

(9) Fuel cut valve gasket (21) Quick connectorT1: 4.4 (0.45, 3.3)

(10) Fuel cut valve (22) Evaporation hose DT2: 7.4 (0.75, 5.4)

(11) Evaporation hose A (23) Fuel pipe ASSYT3: 33 (3.4, 24.3)

(12) Clip (24) Fuel return hose B

Page 1940 of 2870

FU(H4DOTC 2.5)-10

FUEL INJECTION (FUEL SYSTEM)

General Description

(1) Clip (11) Fuel pipe ASSY (21) Two-way valve drain hose A

(2) Fuel delivery hose A (12) Grommet (22) Connector

(3) Fuel filter bracket (13) Canister hose A (23) Two-way valve drain hose B

(4) Fuel filter holder (14) Canister (24) Clamp

(5) Fuel filter cup (15) Canister bracket plate (25) Front canister bracket

(6) Fuel filter (16) Cushion

(7) Evaporation hose (17) Canister bracket spacerTightening torque: N·m (kgf-m, ft-lb)

(8) Fuel damper (18) Rear canister bracketT: 23 (2.3, 17.0)

(9) Fuel deliver y hose B (19) Two-way valve return hose

(10) Fuel return hose (20) Two-way valve

Page 1941 of 2870

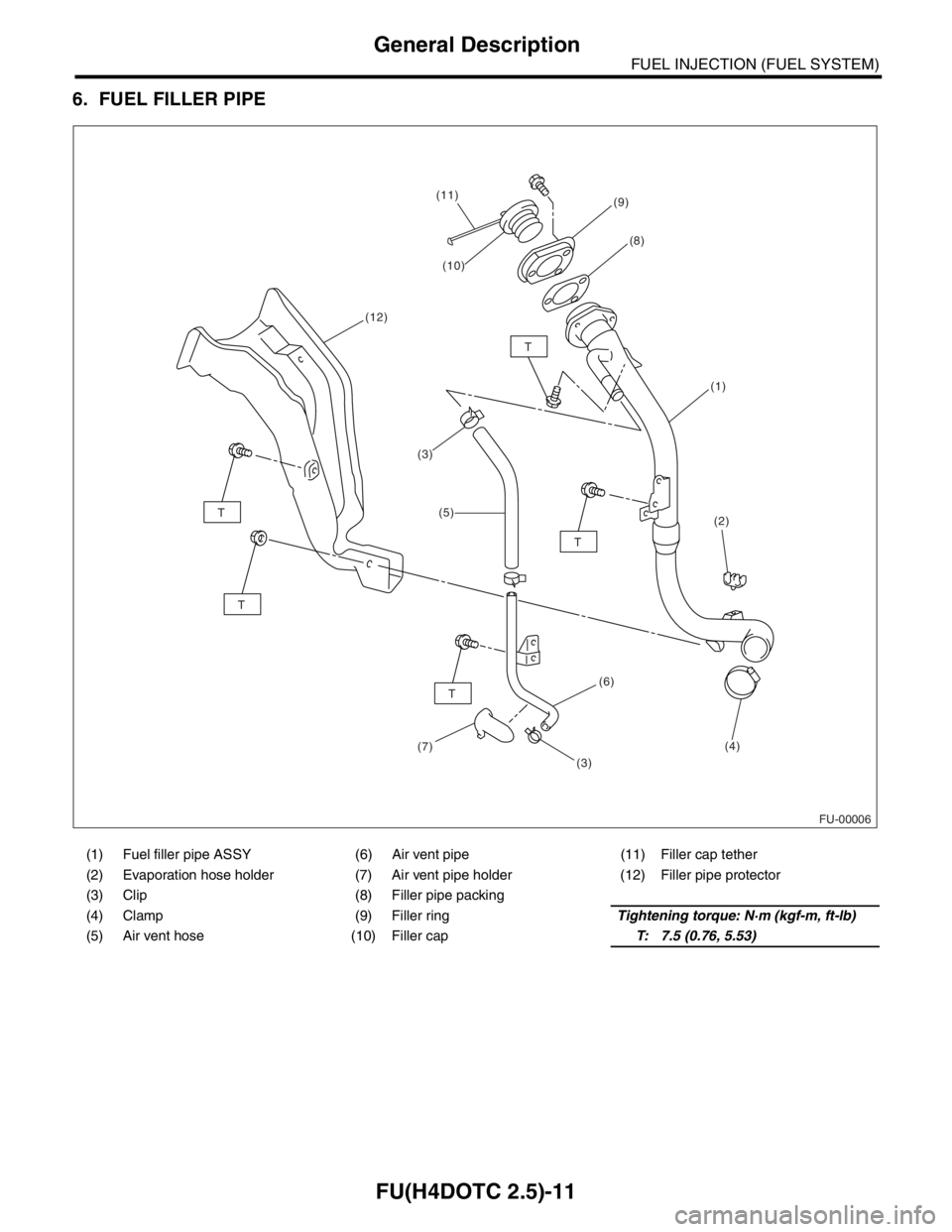

FU(H4DOTC 2.5)-11

FUEL INJECTION (FUEL SYSTEM)

General Description

6. FUEL FILLER PIPE

(1) Fuel filler pipe ASSY (6) Air vent pipe (11) Filler cap tether

(2) Evaporation hose holder (7) Air vent pipe holder (12) Filler pipe protector

(3) Clip (8) Filler pipe packing

(4) Clamp (9) Filler ringTightening torque: N·m (kgf-m, ft-lb)

(5) Air vent hose (10) Filler capT: 7.5 (0.76, 5.53)

FU-00006

(4)

(2)

(8)

(1)

(12)(11)

(6)

(7)

(9)

(10)

(5)

(3)

(3)

T

T

T

T

T

Page 1942 of 2870

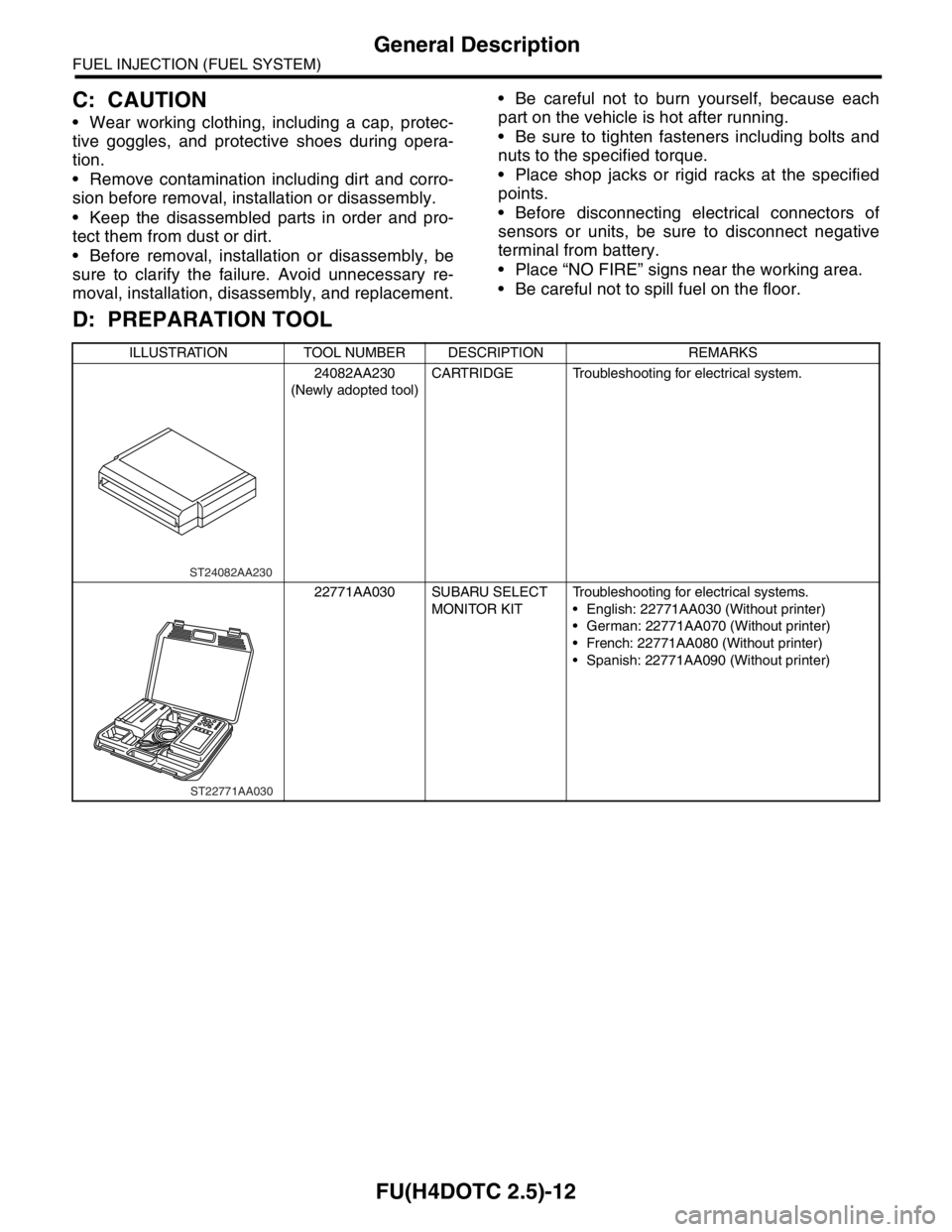

FU(H4DOTC 2.5)-12

FUEL INJECTION (FUEL SYSTEM)

General Description

C: CAUTION

Wear working clothing, including a cap, protec-

tive goggles, and protective shoes during opera-

tion.

Remove contamination including dirt and corro-

sion before removal, installation or disassembly.

Keep the disassembled parts in order and pro-

tect them from dust or dirt.

Before removal, installation or disassembly, be

sure to clarify the failure. Avoid unnecessary re-

moval, installation, disassembly, and replacement. Be careful not to burn yourself, because each

part on the vehicle is hot after running.

Be sure to tighten fasteners including bolts and

nuts to the specified torque.

Place shop jacks or rigid racks at the specified

points.

Before disconnecting electrical connectors of

sensors or units, be sure to disconnect negative

terminal from battery.

Place “NO FIRE” signs near the working area.

Be careful not to spill fuel on the floor.

D: PREPARATION TOOL

ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

24082AA230

(Newly adopted tool)CARTRIDGE Troubleshooting for electrical system.

22771AA030 SUBARU SELECT

MONITOR KITTroubleshooting for electrical systems.

English: 22771AA030 (Without printer)

German: 22771AA070 (Without printer)

French: 22771AA080 (Without printer)

Spanish: 22771AA090 (Without printer)

ST24082AA230

ST22771AA030

Page 1943 of 2870

FU(H4DOTC 2.5)-13

FUEL INJECTION (FUEL SYSTEM)

Throttle Body

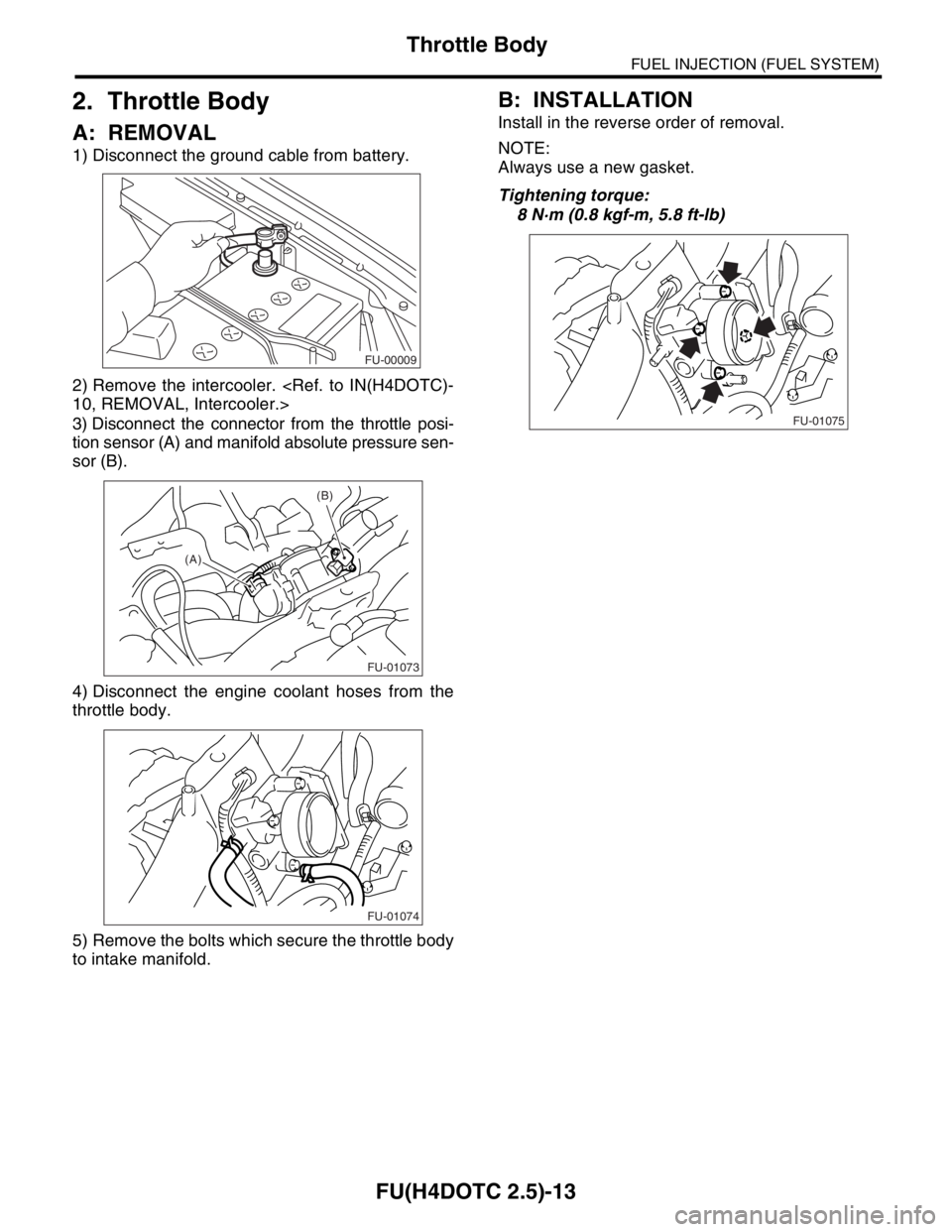

2. Throttle Body

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the intercooler.

3) Disconnect the connector from the throttle posi-

tion sensor (A) and manifold absolute pressure sen-

sor (B).

4) Disconnect the engine coolant hoses from the

throttle body.

5) Remove the bolts which secure the throttle body

to intake manifold.

B: INSTALLATION

Install in the reverse order of removal.

NOTE:

Always use a new gasket.

Tightening torque:

8 N·m (0.8 kgf-m, 5.8 ft-lb)

FU-00009

FU-01073

(A)

(B)

FU-01074

FU-01075

Page 1947 of 2870

FU(H4DOTC 2.5)-17

FUEL INJECTION (FUEL SYSTEM)

Intake Manifold

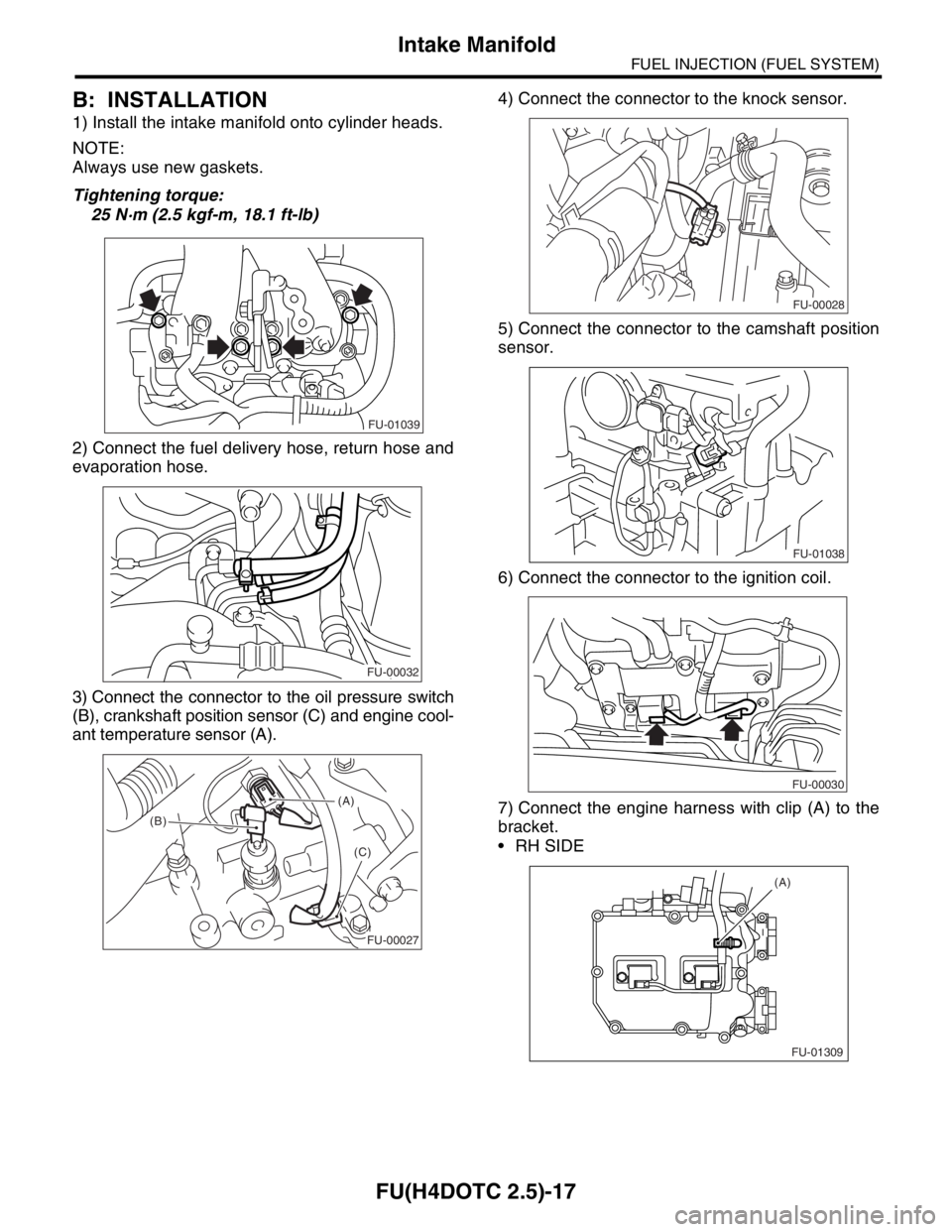

B: INSTALLATION

1) Install the intake manifold onto cylinder heads.

NOTE:

Always use new gaskets.

Tightening torque:

25 N·m (2.5 kgf-m, 18.1 ft-lb)

2) Connect the fuel delivery hose, return hose and

evaporation hose.

3) Connect the connector to the oil pressure switch

(B), crankshaft position sensor (C) and engine cool-

ant temperature sensor (A).4) Connect the connector to the knock sensor.

5) Connect the connector to the camshaft position

sensor.

6) Connect the connector to the ignition coil.

7) Connect the engine harness with clip (A) to the

bracket.

RH SIDE

FU-01039

FU-00032

(A)

(B)

(C)

FU-00027

FU-00028

FU-01038

FU-00030

FU-01309 (A)

Page 1949 of 2870

FU(H4DOTC 2.5)-19

FUEL INJECTION (FUEL SYSTEM)

Intake Manifold

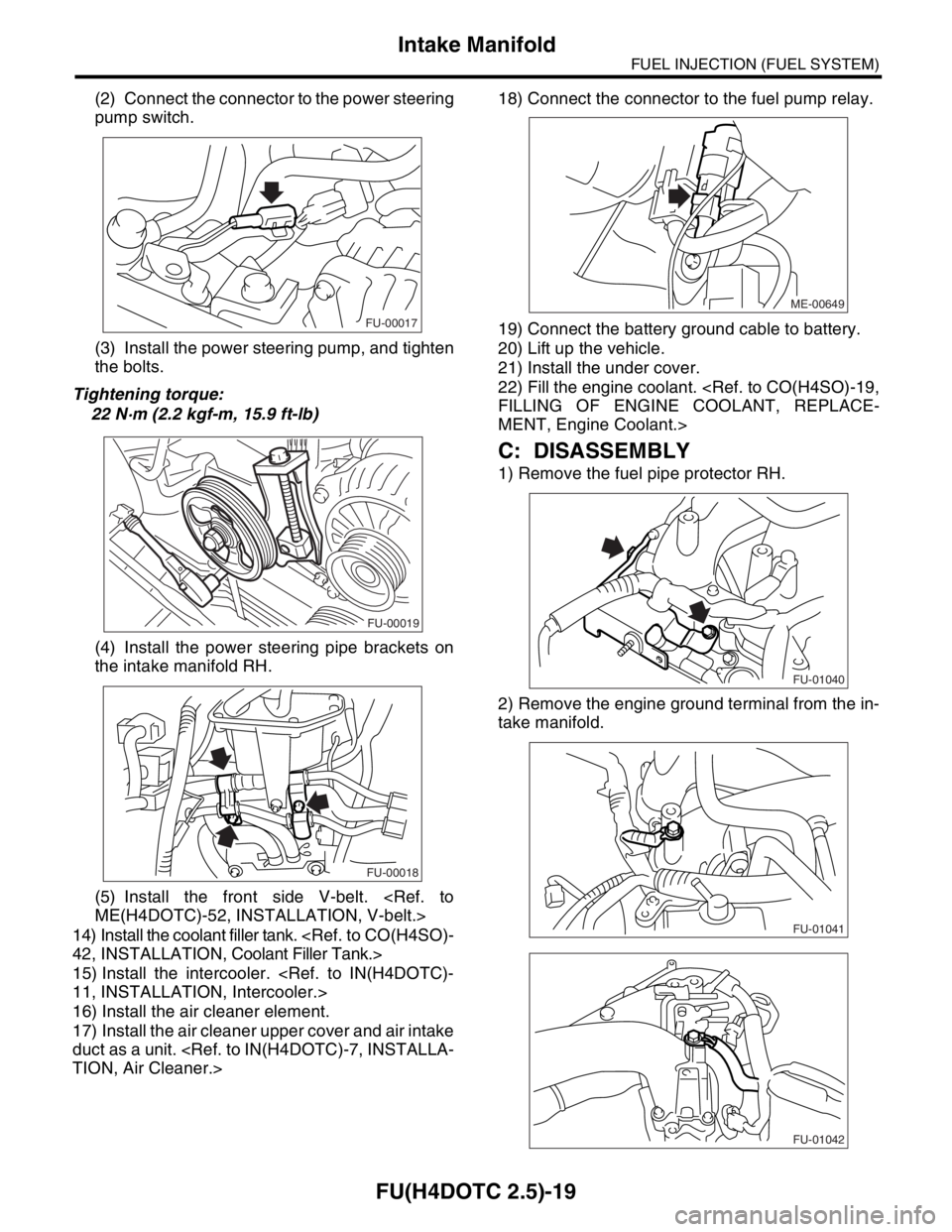

(2) Connect the connector to the power steering

pump switch.

(3) Install the power steering pump, and tighten

the bolts.

Tightening torque:

22 N·m (2.2 kgf-m, 15.9 ft-lb)

(4) Install the power steering pipe brackets on

the intake manifold RH.

(5) Install the front side V-belt.

14) Install the coolant filler tank.

15) Install the intercooler.

16) Install the air cleaner element.

17) Install the air cleaner upper cover and air intake

duct as a unit.

19) Connect the battery ground cable to battery.

20) Lift up the vehicle.

21) Install the under cover.

22) Fill the engine coolant.

MENT, Engine Coolant.>

C: DISASSEMBLY

1) Remove the fuel pipe protector RH.

2) Remove the engine ground terminal from the in-

take manifold.

FU-00017

FU-00019

FU-00018

ME-00649

FU-01040

FU-01041

FU-01042

Page 1952 of 2870

FU(H4DOTC 2.5)-22

FUEL INJECTION (FUEL SYSTEM)

Intake Manifold

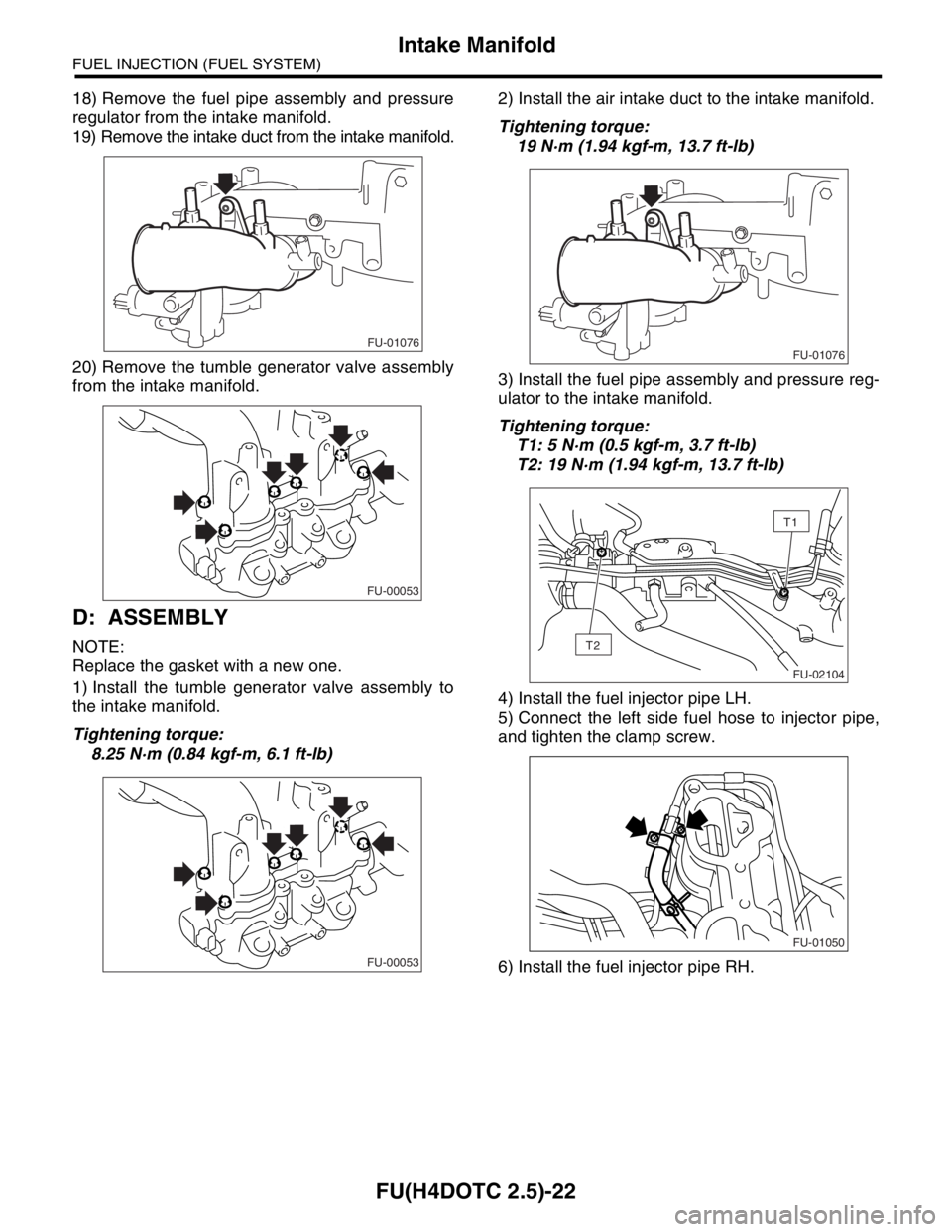

18) Remove the fuel pipe assembly and pressure

regulator from the intake manifold.

19) Remove the intake duct from the intake manifold.

20) Remove the tumble generator valve assembly

from the intake manifold.

D: ASSEMBLY

NOTE:

Replace the gasket with a new one.

1) Install the tumble generator valve assembly to

the intake manifold.

Tightening torque:

8.25 N·m (0.84 kgf-m, 6.1 ft-lb)2) Install the air intake duct to the intake manifold.

Tightening torque:

19 N·m (1.94 kgf-m, 13.7 ft-lb)

3) Install the fuel pipe assembly and pressure reg-

ulator to the intake manifold.

Tightening torque:

T1: 5 N·m (0.5 kgf-m, 3.7 ft-lb)

T2: 19 N·m (1.94 kgf-m, 13.7 ft-lb)

4) Install the fuel injector pipe LH.

5) Connect the left side fuel hose to injector pipe,

and tighten the clamp screw.

6) Install the fuel injector pipe RH.

FU-01076

FU-00053

FU-00053

FU-01076

FU-02104

T1

T2

FU-01050

Page 1953 of 2870

FU(H4DOTC 2.5)-23

FUEL INJECTION (FUEL SYSTEM)

Intake Manifold

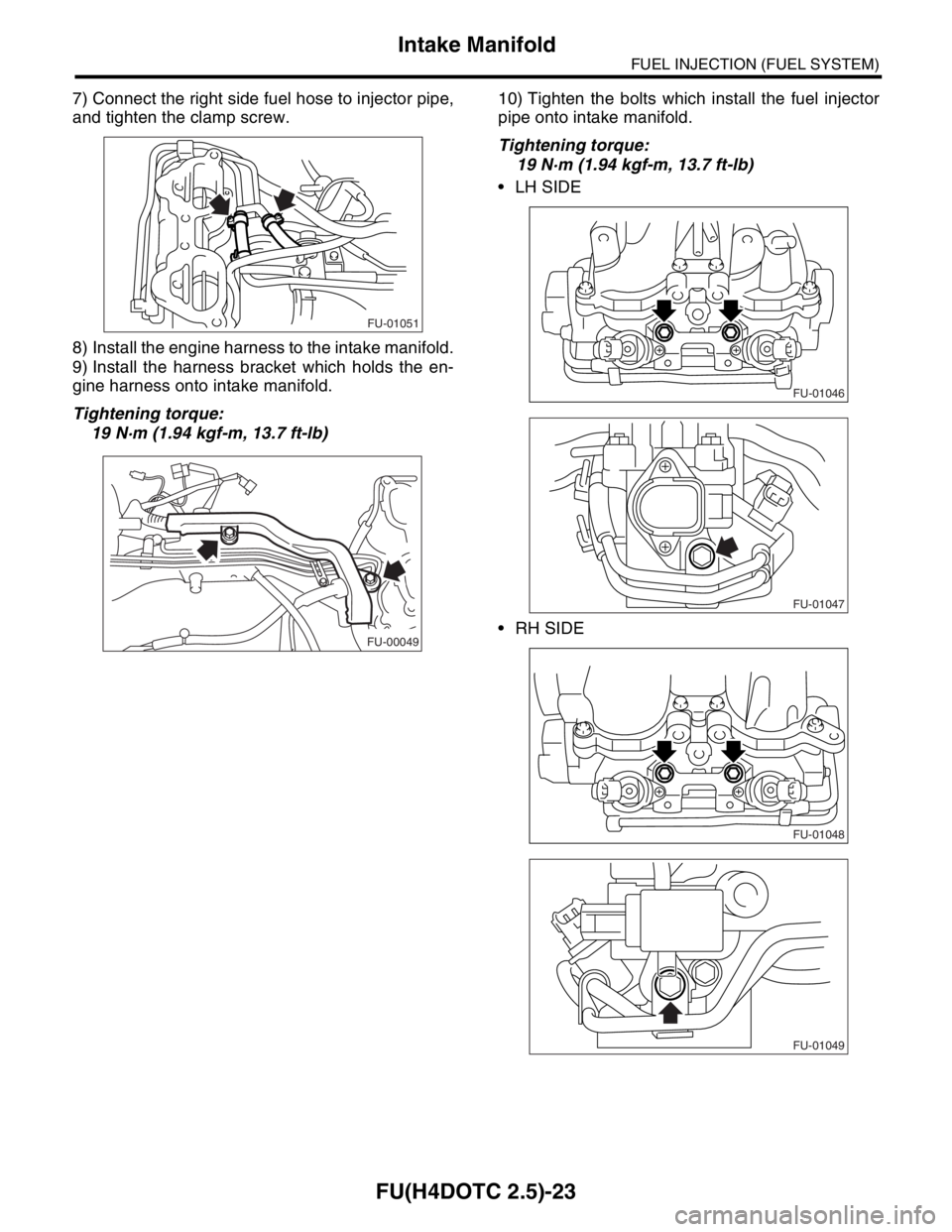

7) Connect the right side fuel hose to injector pipe,

and tighten the clamp screw.

8) Install the engine harness to the intake manifold.

9) Install the harness bracket which holds the en-

gine harness onto intake manifold.

Tightening torque:

19 N·m (1.94 kgf-m, 13.7 ft-lb)10) Tighten the bolts which install the fuel injector

pipe onto intake manifold.

Tightening torque:

19 N·m (1.94 kgf-m, 13.7 ft-lb)

LH SIDE

RH SIDE

FU-01051

FU-00049

FU-01046

FU-01047

FU-01048

FU-01049

Page 1954 of 2870

FU(H4DOTC 2.5)-24

FUEL INJECTION (FUEL SYSTEM)

Intake Manifold

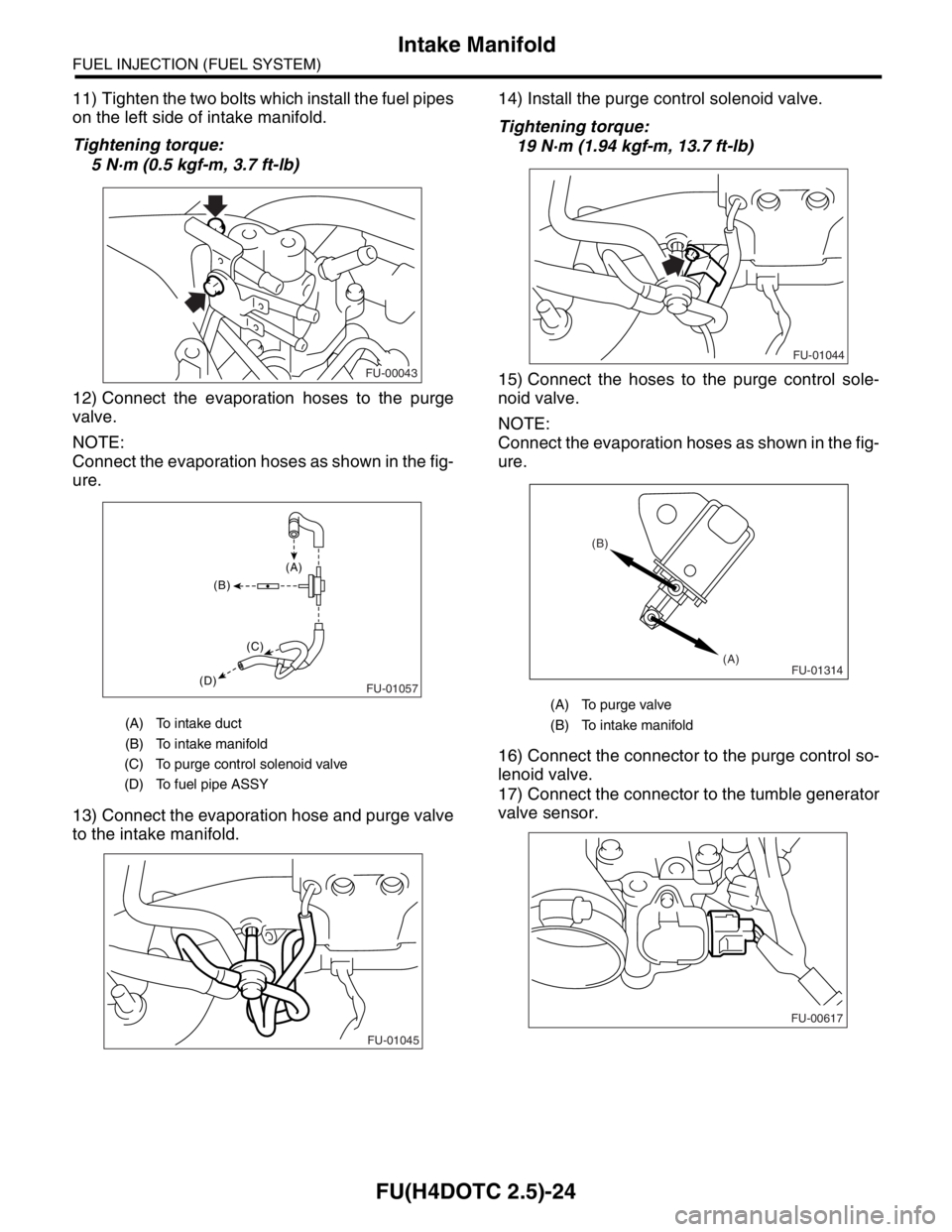

11) Tighten the two bolts which install the fuel pipes

on the left side of intake manifold.

Tightening torque:

5 N·m (0.5 kgf-m, 3.7 ft-lb)

12) Connect the evaporation hoses to the purge

valve.

NOTE:

Connect the evaporation hoses as shown in the fig-

ure.

13) Connect the evaporation hose and purge valve

to the intake manifold.14) Install the purge control solenoid valve.

Tightening torque:

19 N·m (1.94 kgf-m, 13.7 ft-lb)

15) Connect the hoses to the purge control sole-

noid valve.

NOTE:

Connect the evaporation hoses as shown in the fig-

ure.

16) Connect the connector to the purge control so-

lenoid valve.

17) Connect the connector to the tumble generator

valve sensor.

(A) To intake duct

(B) To intake manifold

(C) To purge control solenoid valve

(D) To fuel pipe ASSY

FU-00043

FU-01057

(A)

(B)

(D)(C)

FU-01045

(A) To purge valve

(B) To intake manifold

FU-01044

FU-01314(A)

(B)

FU-00617