SUBARU FORESTER 2004 Service Manual PDF

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 71 of 2870

AC-15

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

Diagnostics for A/C System Malfunction

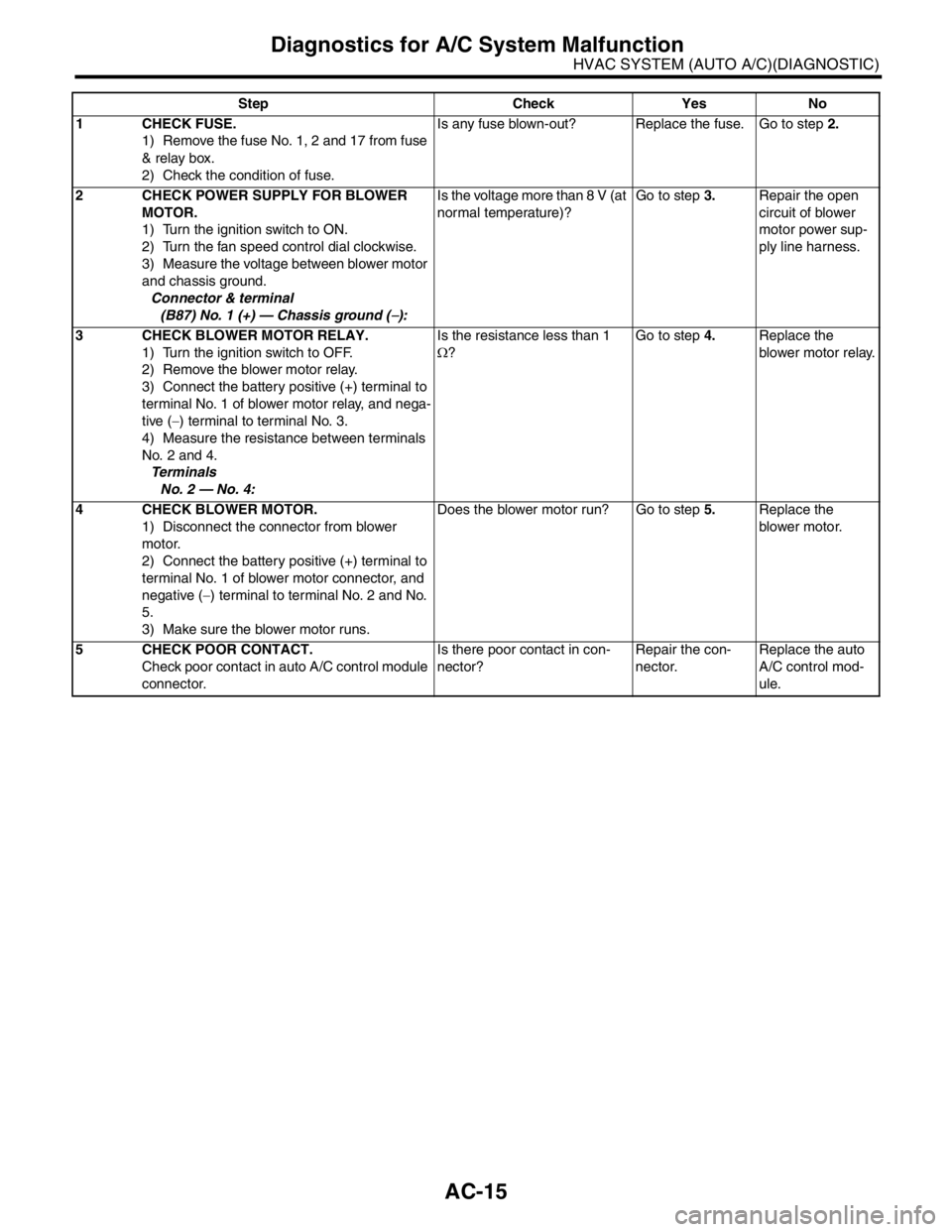

Step Check Yes No

1 CHECK FUSE.

1) Remove the fuse No. 1, 2 and 17 from fuse

& relay box.

2) Check the condition of fuse.Is any fuse blown-out? Replace the fuse. Go to step 2.

2 CHECK POWER SUPPLY FOR BLOWER

MOTOR.

1) Turn the ignition switch to ON.

2) Turn the fan speed control dial clockwise.

3) Measure the voltage between blower motor

and chassis ground.

Connector & terminal

(B87) No. 1 (+) — Chassis ground (

−):Is the voltage more than 8 V (at

normal temperature)?Go to step 3.Repair the open

circuit of blower

motor power sup-

ply line harness.

3 CHECK BLOWER MOTOR RELAY.

1) Turn the ignition switch to OFF.

2) Remove the blower motor relay.

3) Connect the battery positive (+) terminal to

terminal No. 1 of blower motor relay, and nega-

tive (−) terminal to terminal No. 3.

4) Measure the resistance between terminals

No. 2 and 4.

Te r m i n a l s

No. 2 — No. 4:Is the resistance less than 1

Ω?Go to step 4.Replace the

blower motor relay.

4 CHECK BLOWER MOTOR.

1) Disconnect the connector from blower

motor.

2) Connect the battery positive (+) terminal to

terminal No. 1 of blower motor connector, and

negative (−) terminal to terminal No. 2 and No.

5.

3) Make sure the blower motor runs.Does the blower motor run? Go to step 5.Replace the

blower motor.

5 CHECK POOR CONTACT.

Check poor contact in auto A/C control module

connector.Is there poor contact in con-

nector?Repair the con-

nector.Replace the auto

A/C control mod-

ule.

Page 72 of 2870

AC-16

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

Diagnostics for A/C System Malfunction

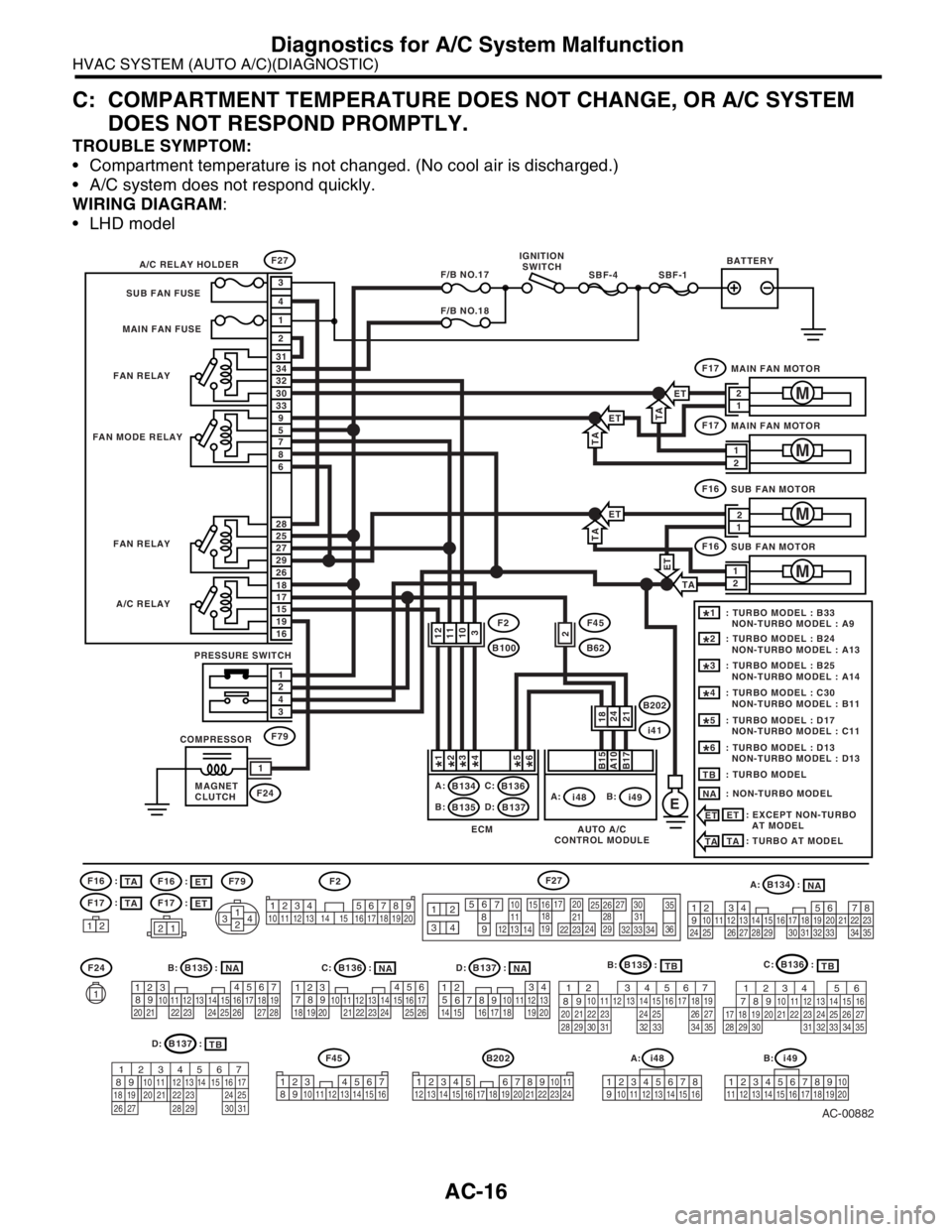

C: COMPARTMENT TEMPERATURE DOES NOT CHANGE, OR A/C SYSTEM

DOES NOT RESPOND PROMPTLY.

TROUBLE SYMPTOM:

Compartment temperature is not changed. (No cool air is discharged.)

A/C system does not respond quickly.

WIRING DIAGRAM:

LHD model

AC-00882

A: B134 :

B: B135 :

B202

D: B137 :C: B136 :

F2F27

EA:

i48

F27

F17

F79

F45

B62

B202

i41

F24

F24

F16F79

F45

F17

B:

i49A:

B134 B136

B135 B137C:

B:D:IGNITION

SWITCHBATTERY

A/C RELAY HOLDER

FAN RELAY

FAN RELAY

A/C RELAY

PRESSURE SWITCH

COMPRESSOR

MAGNET

CLUTCH FAN MODE RELAYSUB FAN FUSE

MAIN FAN FUSE

MAIN FAN MOTOR

1

M

SBF-1SBF-4F/B NO.17

F/B NO.18

1

2

3

2

1

4

3033

32 31

34

86

7 9

5

2926

27 28

25

1916

15 18

17

43

21

B15A10B17

F17

MAIN FAN MOTOR

M

F16

SUB FAN MOTOR

M

F16

SUB FAN MOTOR

M

1

2112 1314

15 16171819

20

10

1121222324

2526272829

3031323334

35

36

12

93456

7

82 314

567

82 1

94

310

24 22 23 251112131415

26 27

281617181920 21

4

1

53

2618 15 167891011

17 19

20121314

1234567891011121314151617181920212223242526272829303132333435

AUTO A/C

CONTROL MODULE ECM

2421

1234 5678910 11 12 13 14 15 16 17 18 19 20

123 4567

8910 11 12 13 14 15 16

56

78 2 1

94

310

24 22 23 251112131415

261617181920 21

34 12 8910 11

12 13 14 15 16 17 18 19 20 21 22 23 24567

D: B137 :

B: B135 :C: B136 :

A: i48

12345678

910 11 12 13 14 15 16

B: i49

12345678910

11 12 13 14 15 1617 18 19 20

: TURBO MODEL : B33

NON-TURBO MODEL : A91*

: TURBO MODEL : B24

NON-TURBO MODEL : A132*

: TURBO MODEL : B25

NON-TURBO MODEL : A143*

: TURBO MODEL : C30

NON-TURBO MODEL : B114*

: TURBO MODEL : D17

NON-TURBO MODEL : C115*

: TURBO MODEL : D13

NON-TURBO MODEL : D136*

: TURBO MODELTB

: NON-TURBO MODEL

NA

: EXCEPT NON-TURBO

AT MODEL

ET

ETNA

TB

TBNANANATB

1112

10

3

18 1

*2*3*4*5*6*

2F2

B100

ET

ETTA

TA

ET

TA

ET

: TURBO AT MODEL

TATA

TA

ET

:

ET :

F16

F17

TA :

TA :

567

82 1

94 310

24 22 23 2511 12 13 14 15

26 27

2816 17 18 19

20 21

29 30 31 32 33 34 3556

782 1

94 310

24 22 23 2511 12 13

1415

26 27

2816

17 18 19 20 21

33 34 29

32 30

31 35

567

82 1

94 310

22 23 11 12 13 14 15

24 25

2616 17

18 19 20 21

27 28 29 30 31

12

1

2

2 1

12

Page 73 of 2870

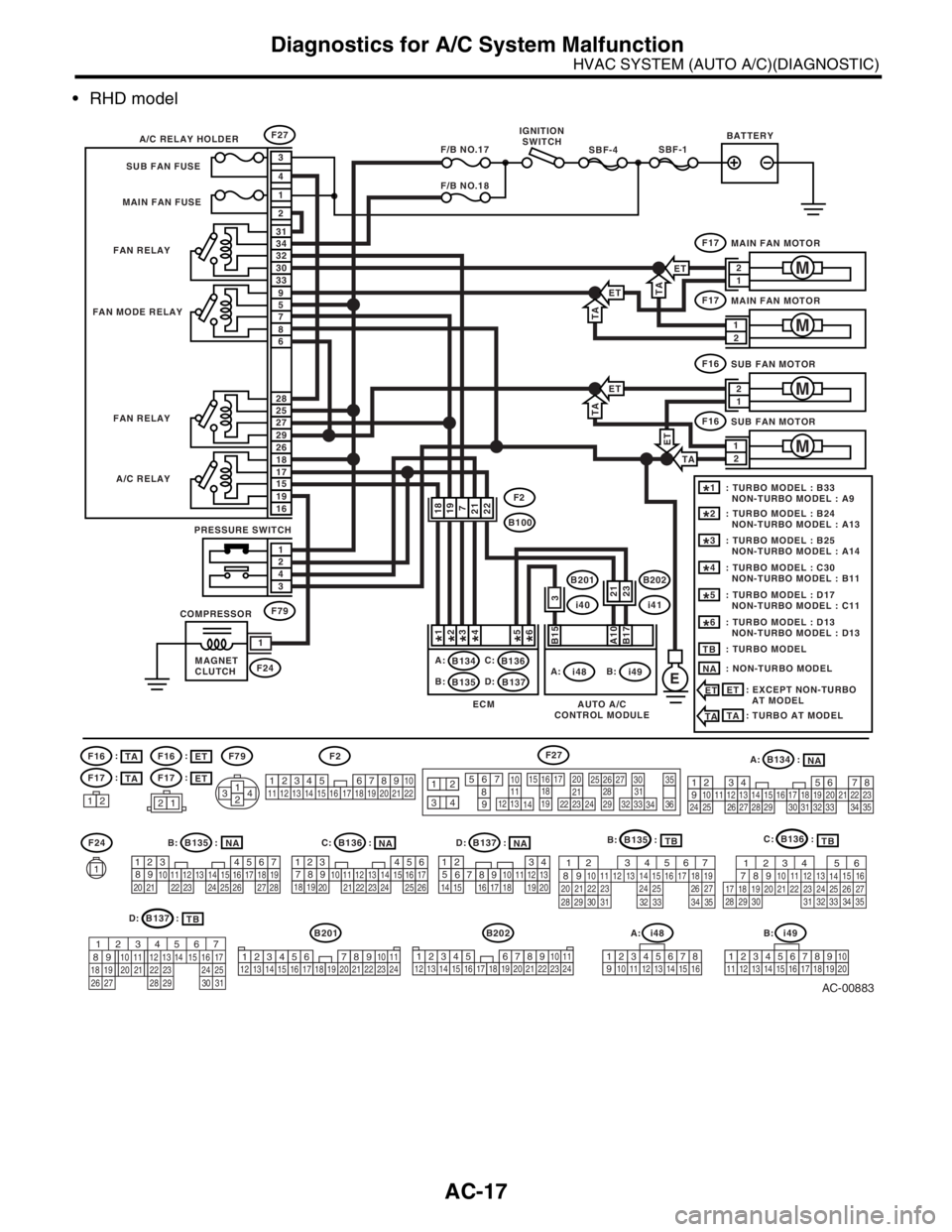

AC-17

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

Diagnostics for A/C System Malfunction

RHD model

AC-00883

A: B134 :

B: B135 :

B202

D: B137 :C: B136 :

F2F27

EA:

i48

F27

F17

F79

B202

i41

B201

i40

F24

F16F79

B201

F17

B:

i49A:

B134 B136

B135 B137C:

B:D:IGNITION

SWITCHBATTERY

A/C RELAY HOLDER

FAN RELAY

FAN RELAY

A/C RELAY

PRESSURE SWITCH

COMPRESSOR

MAGNET

CLUTCH FAN MODE RELAYSUB FAN FUSE

MAIN FAN FUSE

MAIN FAN MOTOR

1

M

SBF-1SBF-4F/B NO.17

F/B NO.18

1

2

3

2

1

4

3033

32 31

34

86

7 9

5

2926

27 28

25

1916

15 18

17

43

21

B15A10B17

F17

MAIN FAN MOTOR

M

F16

SUB FAN MOTOR

M2

1

F16

SUB FAN MOTOR

M

2112 1314

15 16171819

20

10

1121222324

2526272829

3031323334

35

36

12

93456

7

82 314

567

82 1

94

310

24 22 23 251112131415

26 27

281617181920 21

4

1

53

2618 15 167891011

17 19

20121314

1234567891011121314151617181920212223242526272829303132333435

AUTO A/C

CONTROL MODULE ECM

2123

56

78 2 1

94

310

24 22 23 251112131415

261617181920 21

34 12 8910 11

12 13 14 15 16 17 18 19 20 21 22 23 24567

D: B137 :

B: B135 :C: B136 :

A: i48

12345678

910 11 12 13 14 15 16

B: i49

12345678910

11 12 13 14 15 1617 18 19 20

: TURBO MODEL : B33

NON-TURBO MODEL : A91*

: TURBO MODEL : B24

NON-TURBO MODEL : A132*

: TURBO MODEL : B25

NON-TURBO MODEL : A143*

: TURBO MODEL : C30

NON-TURBO MODEL : B114*

: TURBO MODEL : D17

NON-TURBO MODEL : C115*

: TURBO MODEL : D13

NON-TURBO MODEL : D136*

: TURBO MODELTB

: NON-TURBO MODEL

NA

: EXCEPT NON-TURBO

AT MODEL

ET

ETNA

TB

TBNANANATB

1918

7

2122

3 1

*2*3*4*5*6*

F2

B100

ET

ETTA

TA

ET

TA

ET

: TURBO AT MODEL

TATA

TA

ET

:

ET :

567

82 1

94 310

24 22 23 2511 12 13 14 15

26 27

2816 17 18 19

20 21

29 30 31 32 33 34 3556

782 1

94 310

24 22 23 2511 12 13

1415

26 27

2816

17 18 19 20 21

33 34 29

32 30

31 35

567

82 1

94 310

22 23 11 12 13 14 15

24 25

2616 17

18 19 20 21

27 28 29 30 31

12345 678910

11

1219 20 21

13 14 151617

18 22

34 12 8910 11

12 13 14 15 16 17 18 19 20 21 22 23 2456 7

F24

1

F16

F17

TA :

TA :

12

2 1

2 1

Page 74 of 2870

AC-18

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

Diagnostics for A/C System Malfunction

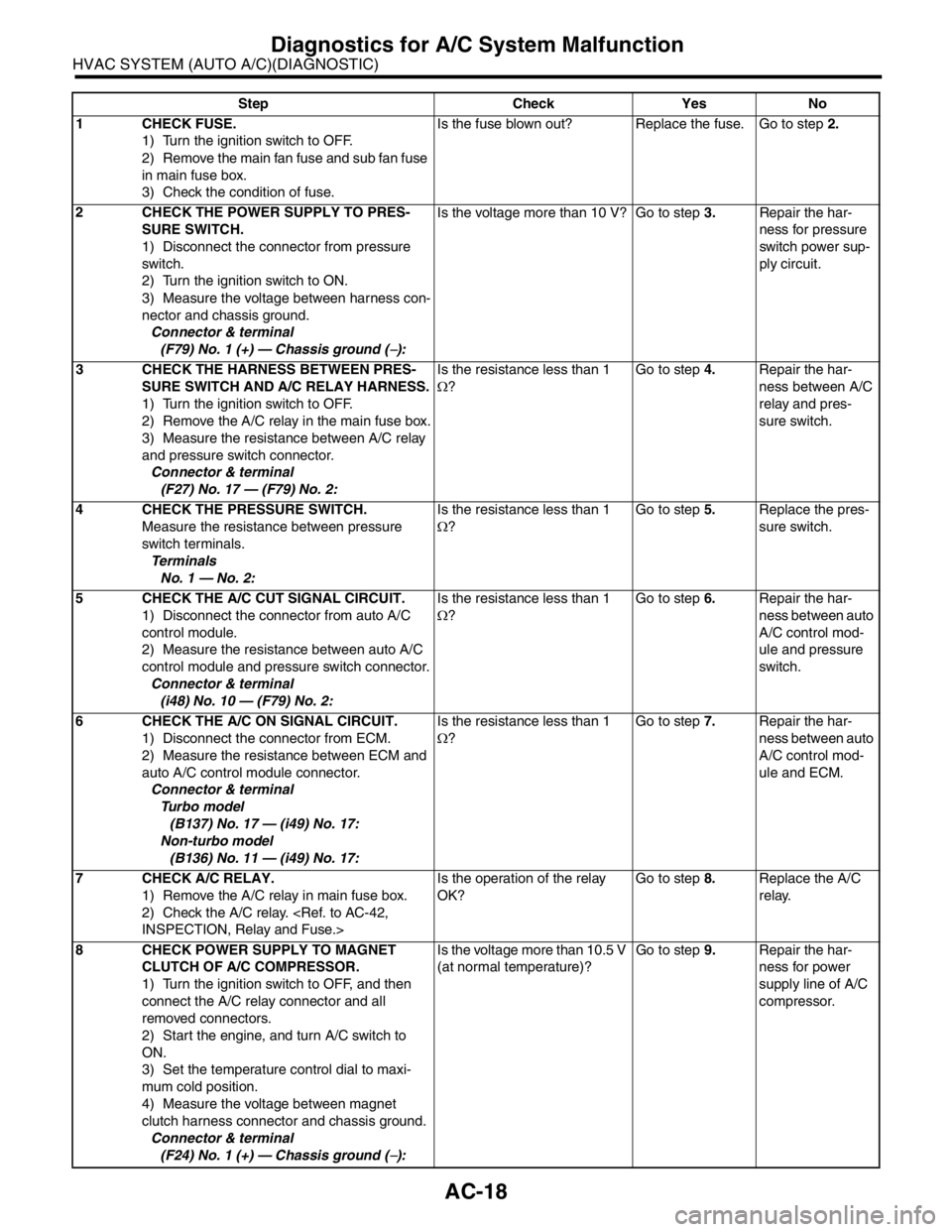

Step Check Yes No

1 CHECK FUSE.

1) Turn the ignition switch to OFF.

2) Remove the main fan fuse and sub fan fuse

in main fuse box.

3) Check the condition of fuse.Is the fuse blown out? Replace the fuse. Go to step 2.

2 CHECK THE POWER SUPPLY TO PRES-

SURE SWITCH.

1) Disconnect the connector from pressure

switch.

2) Turn the ignition switch to ON.

3) Measure the voltage between harness con-

nector and chassis ground.

Connector & terminal

(F79) No. 1 (+) — Chassis ground (

−):Is the voltage more than 10 V? Go to step 3.Repair the har-

ness for pressure

switch power sup-

ply circuit.

3 CHECK THE HARNESS BETWEEN PRES-

SURE SWITCH AND A/C RELAY HARNESS.

1) Turn the ignition switch to OFF.

2) Remove the A/C relay in the main fuse box.

3) Measure the resistance between A/C relay

and pressure switch connector.

Connector & terminal

(F27) No. 17 — (F79) No. 2:Is the resistance less than 1

Ω?Go to step 4.Repair the har-

ness between A/C

relay and pres-

sure switch.

4 CHECK THE PRESSURE SWITCH.

Measure the resistance between pressure

switch terminals.

Te r m i n a l s

No. 1 — No. 2:Is the resistance less than 1

Ω?Go to step 5.Replace the pres-

sure switch.

5 CHECK THE A/C CUT SIGNAL CIRCUIT.

1) Disconnect the connector from auto A/C

control module.

2) Measure the resistance between auto A/C

control module and pressure switch connector.

Connector & terminal

(i48) No. 10 — (F79) No. 2:Is the resistance less than 1

Ω?Go to step 6.Repair the har-

ness between auto

A/C control mod-

ule and pressure

switch.

6 CHECK THE A/C ON SIGNAL CIRCUIT.

1) Disconnect the connector from ECM.

2) Measure the resistance between ECM and

auto A/C control module connector.

Connector & terminal

Turbo model

(B137) No. 17 — (i49) No. 17:

Non-turbo model

(B136) No. 11 — (i49) No. 17:Is the resistance less than 1

Ω?Go to step 7.Repair the har-

ness between auto

A/C control mod-

ule and ECM.

7 CHECK A/C RELAY.

1) Remove the A/C relay in main fuse box.

2) Check the A/C relay.

OK?Go to step 8.Replace the A/C

relay.

8 CHECK POWER SUPPLY TO MAGNET

CLUTCH OF A/C COMPRESSOR.

1) Turn the ignition switch to OFF, and then

connect the A/C relay connector and all

removed connectors.

2) Start the engine, and turn A/C switch to

ON.

3) Set the temperature control dial to maxi-

mum cold position.

4) Measure the voltage between magnet

clutch harness connector and chassis ground.

Connector & terminal

(F24) No. 1 (+) — Chassis ground (

−):Is the voltage more than 10.5 V

(at normal temperature)?Go to step 9.Repair the har-

ness for power

supply line of A/C

compressor.

Page 75 of 2870

AC-19

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

Diagnostics for A/C System Malfunction

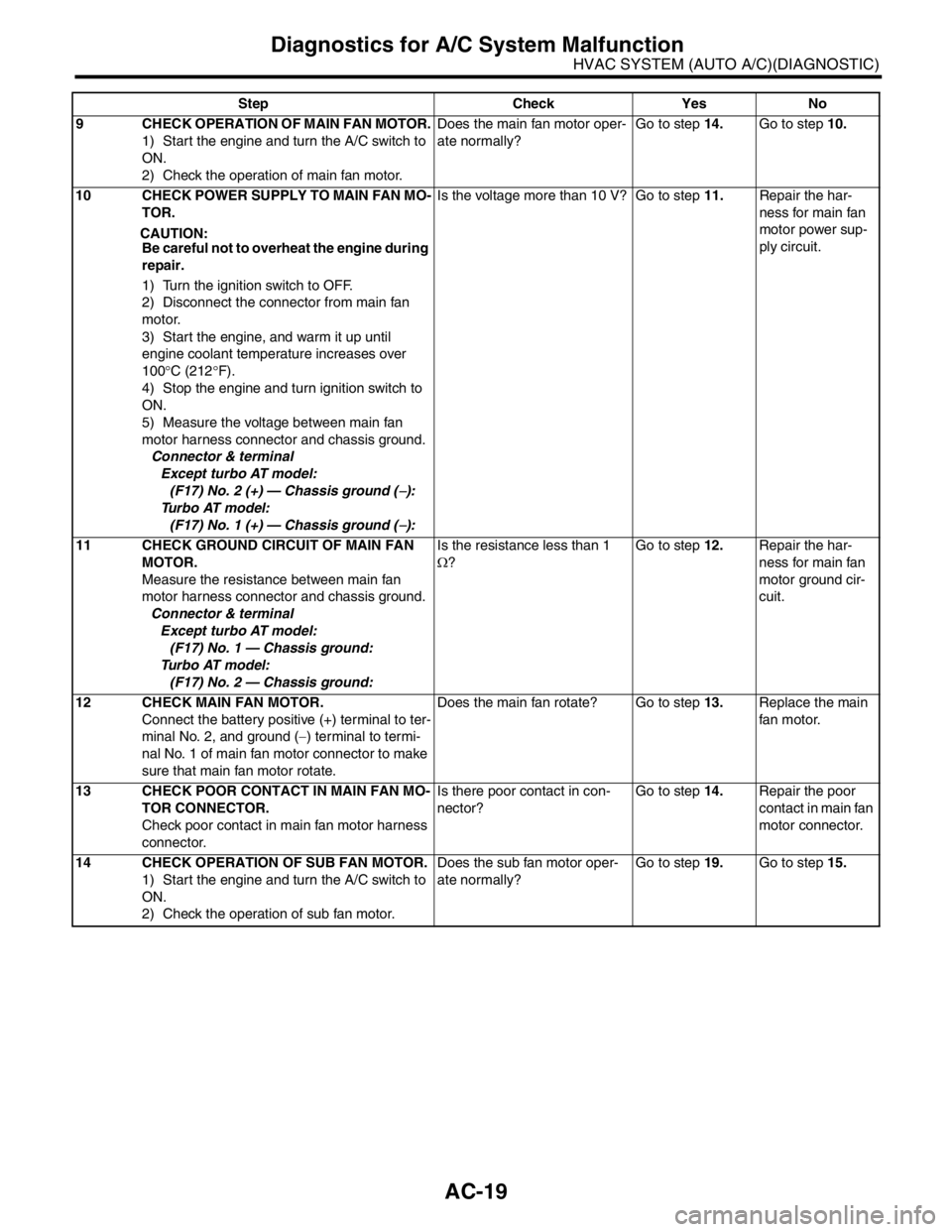

9 CHECK OPERATION OF MAIN FAN MOTOR.

1) Start the engine and turn the A/C switch to

ON.

2) Check the operation of main fan motor.Does the main fan motor oper-

ate normally?Go to step 14.Go to step 10.

10 CHECK POWER SUPPLY TO MAIN FAN MO-

TOR.

CAUTION:

Be careful not to overheat the engine during

repair.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from main fan

motor.

3) Start the engine, and warm it up until

engine coolant temperature increases over

100°C (212°F).

4) Stop the engine and turn ignition switch to

ON.

5) Measure the voltage between main fan

motor harness connector and chassis ground.

Connector & terminal

Except turbo AT model:

(F17) No. 2 (+) — Chassis ground (

−):

Turbo AT model:

(F17) No. 1 (+) — Chassis ground (

−):Is the voltage more than 10 V? Go to step 11.Repair the har-

ness for main fan

motor power sup-

ply circuit.

11 CHECK GROUND CIRCUIT OF MAIN FAN

MOTOR.

Measure the resistance between main fan

motor harness connector and chassis ground.

Connector & terminal

Except turbo AT model:

(F17) No. 1 — Chassis ground:

Turbo AT model:

(F17) No. 2 — Chassis ground:Is the resistance less than 1

Ω?Go to step 12.Repair the har-

ness for main fan

motor ground cir-

cuit.

12 CHECK MAIN FAN MOTOR.

Connect the battery positive (+) terminal to ter-

minal No. 2, and ground (−) terminal to termi-

nal No. 1 of main fan motor connector to make

sure that main fan motor rotate.Does the main fan rotate? Go to step 13.Replace the main

fan motor.

13 CHECK POOR CONTACT IN MAIN FAN MO-

TOR CONNECTOR.

Check poor contact in main fan motor harness

connector.Is there poor contact in con-

nector?Go to step 14.Repair the poor

contact in main fan

motor connector.

14 CHECK OPERATION OF SUB FAN MOTOR.

1) Start the engine and turn the A/C switch to

ON.

2) Check the operation of sub fan motor.Does the sub fan motor oper-

ate normally?Go to step 19.Go to step 15. Step Check Yes No

Page 76 of 2870

AC-20

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

Diagnostics for A/C System Malfunction

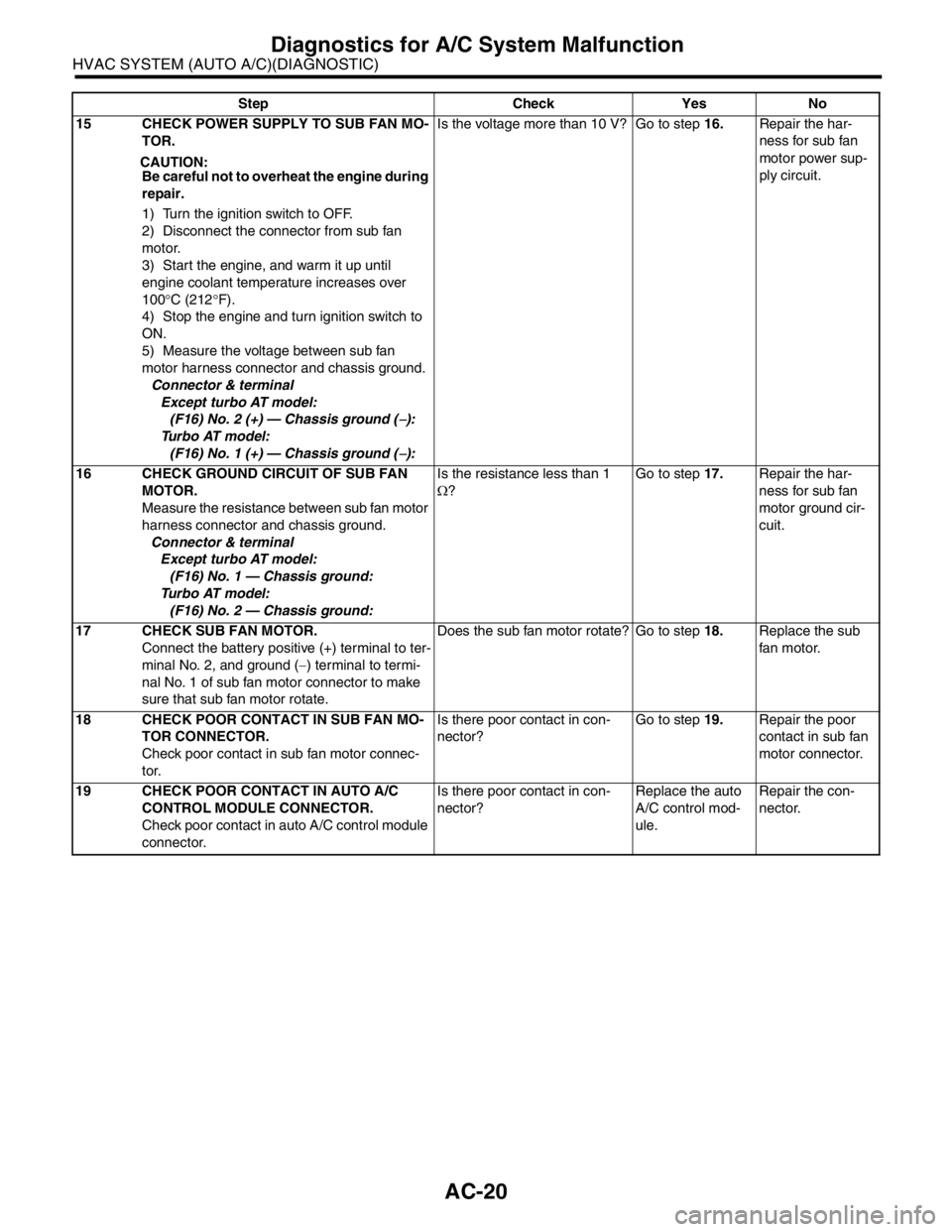

15 CHECK POWER SUPPLY TO SUB FAN MO-

TOR.

CAUTION:

Be careful not to overheat the engine during

repair.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from sub fan

motor.

3) Start the engine, and warm it up until

engine coolant temperature increases over

100°C (212°F).

4) Stop the engine and turn ignition switch to

ON.

5) Measure the voltage between sub fan

motor harness connector and chassis ground.

Connector & terminal

Except turbo AT model:

(F16) No. 2 (+) — Chassis ground (

−):

Turbo AT model:

(F16) No. 1 (+) — Chassis ground (

−):Is the voltage more than 10 V? Go to step 16.Repair the har-

ness for sub fan

motor power sup-

ply circuit.

16 CHECK GROUND CIRCUIT OF SUB FAN

MOTOR.

Measure the resistance between sub fan motor

harness connector and chassis ground.

Connector & terminal

Except turbo AT model:

(F16) No. 1 — Chassis ground:

Turbo AT model:

(F16) No. 2 — Chassis ground:Is the resistance less than 1

Ω?Go to step 17.Repair the har-

ness for sub fan

motor ground cir-

cuit.

17 CHECK SUB FAN MOTOR.

Connect the battery positive (+) terminal to ter-

minal No. 2, and ground (−) terminal to termi-

nal No. 1 of sub fan motor connector to make

sure that sub fan motor rotate.Does the sub fan motor rotate? Go to step 18.Replace the sub

fan motor.

18 CHECK POOR CONTACT IN SUB FAN MO-

TOR CONNECTOR.

Check poor contact in sub fan motor connec-

tor.Is there poor contact in con-

nector?Go to step 19.Repair the poor

contact in sub fan

motor connector.

19 CHECK POOR CONTACT IN AUTO A/C

CONTROL MODULE CONNECTOR.

Check poor contact in auto A/C control module

connector.Is there poor contact in con-

nector?Replace the auto

A/C control mod-

ule.Repair the con-

nector. Step Check Yes No

Page 77 of 2870

AC-21

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

Diagnostic Procedure for Actuators

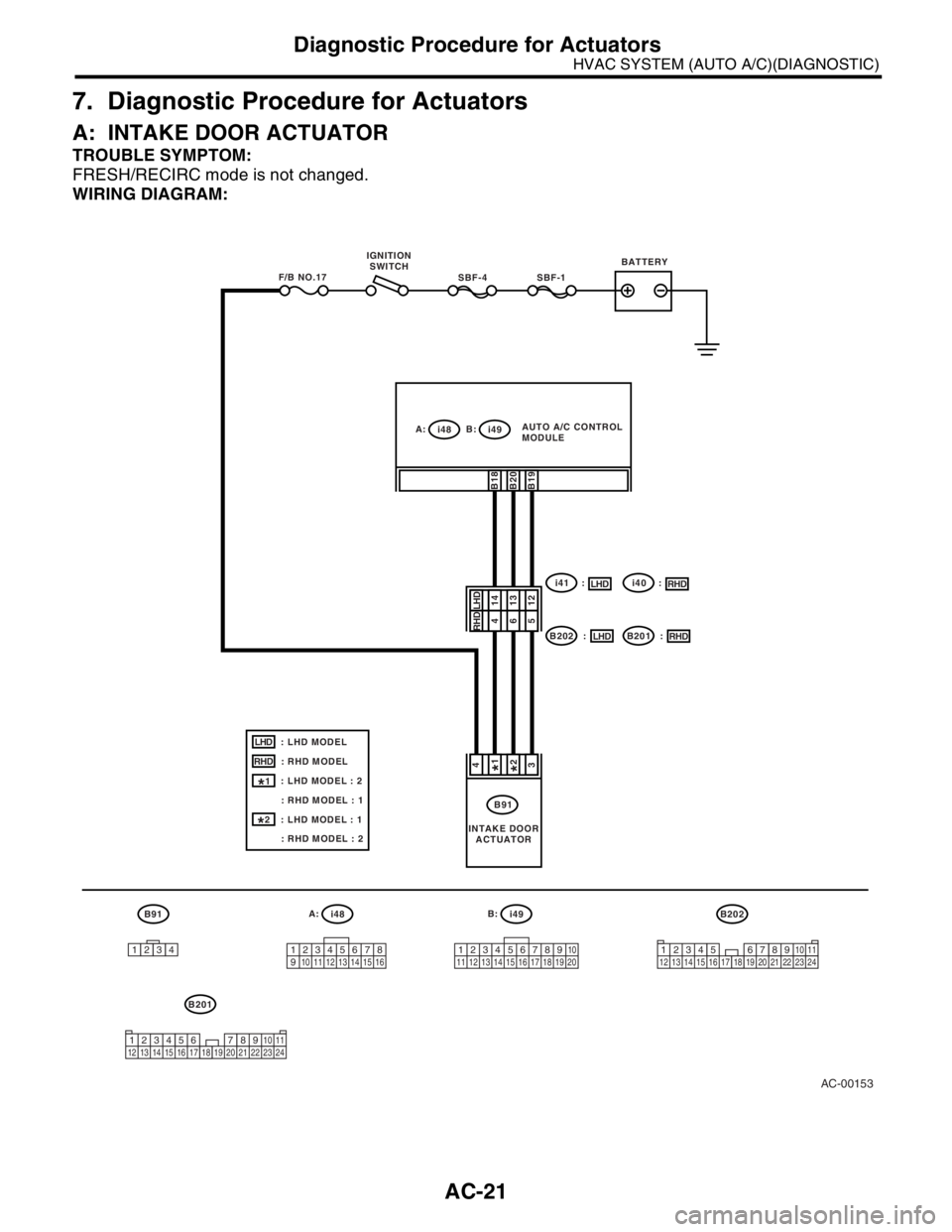

7. Diagnostic Procedure for Actuators

A: INTAKE DOOR ACTUATOR

TROUBLE SYMPTOM:

FRESH/RECIRC mode is not changed.

WIRING DIAGRAM:

AC-00153

B91A:

i48B:

i49

12345678

910 11 12 13 14 15 1612345678910

11 12 13 14 15 16 17 18 19 20

B91

i41 :

B202 : IGNITION

SWITCHBATTERY

SBF-1SBF-4F/B NO.17

43

141312

B18B20B19

1234

B202

34 12 8910 11

12 13 14 15 16 17 18 19 20 21 22 23 24567

A:

i48B:

i49AUTO A/C CONTROL

MODULE

INTAKE DOOR

ACTUATOR

B201

34 12 8910 11

12 13 14 15 16 17 18 19 20 21 22 23 2456 7

: LHD MODEL

: RHD MODELLHD

RHD

: LHD MODEL : 2

: RHD MODEL : 1

: LHD MODEL : 1

: RHD MODEL : 2

1*

2*

LHD465RHD

i40 :

B201 :

LHDRHD

LHDRHD

1*2*

Page 78 of 2870

AC-22

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

Diagnostic Procedure for Actuators

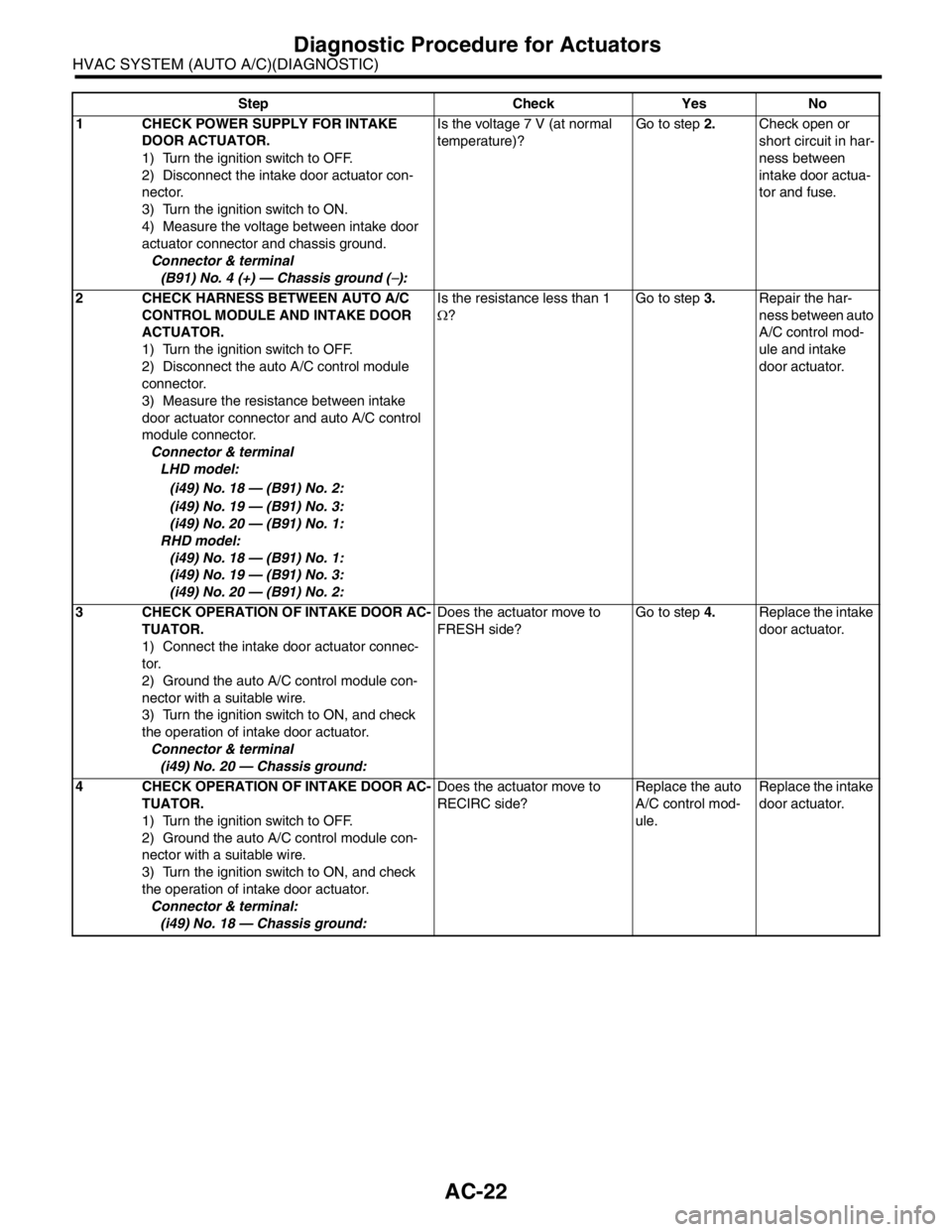

Step Check Yes No

1 CHECK POWER SUPPLY FOR INTAKE

DOOR ACTUATOR.

1) Turn the ignition switch to OFF.

2) Disconnect the intake door actuator con-

nector.

3) Turn the ignition switch to ON.

4) Measure the voltage between intake door

actuator connector and chassis ground.

Connector & terminal

(B91) No. 4 (+) — Chassis ground (

−):Is the voltage 7 V (at normal

temperature)?Go to step 2.Check open or

short circuit in har-

ness between

intake door actua-

tor and fuse.

2 CHECK HARNESS BETWEEN AUTO A/C

CONTROL MODULE AND INTAKE DOOR

ACTUATOR.

1) Turn the ignition switch to OFF.

2) Disconnect the auto A/C control module

connector.

3) Measure the resistance between intake

door actuator connector and auto A/C control

module connector.

Connector & terminal

LHD model:

(i49) No. 18 — (B91) No. 2:

(i49) No. 19 — (B91) No. 3:

(i49) No. 20 — (B91) No. 1:

RHD model:

(i49) No. 18 — (B91) No. 1:

(i49) No. 19 — (B91) No. 3:

(i49) No. 20 — (B91) No. 2:Is the resistance less than 1

Ω?Go to step 3.Repair the har-

ness between auto

A/C control mod-

ule and intake

door actuator.

3 CHECK OPERATION OF INTAKE DOOR AC-

TUATOR.

1) Connect the intake door actuator connec-

tor.

2) Ground the auto A/C control module con-

nector with a suitable wire.

3) Turn the ignition switch to ON, and check

the operation of intake door actuator.

Connector & terminal

(i49) No. 20 — Chassis ground:Does the actuator move to

FRESH side?Go to step 4.Replace the intake

door actuator.

4 CHECK OPERATION OF INTAKE DOOR AC-

TUATOR.

1) Turn the ignition switch to OFF.

2) Ground the auto A/C control module con-

nector with a suitable wire.

3) Turn the ignition switch to ON, and check

the operation of intake door actuator.

Connector & terminal:

(i49) No. 18 — Chassis ground:Does the actuator move to

RECIRC side?Replace the auto

A/C control mod-

ule.Replace the intake

door actuator.

Page 79 of 2870

AC-23

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

Diagnostic Procedure for Actuators

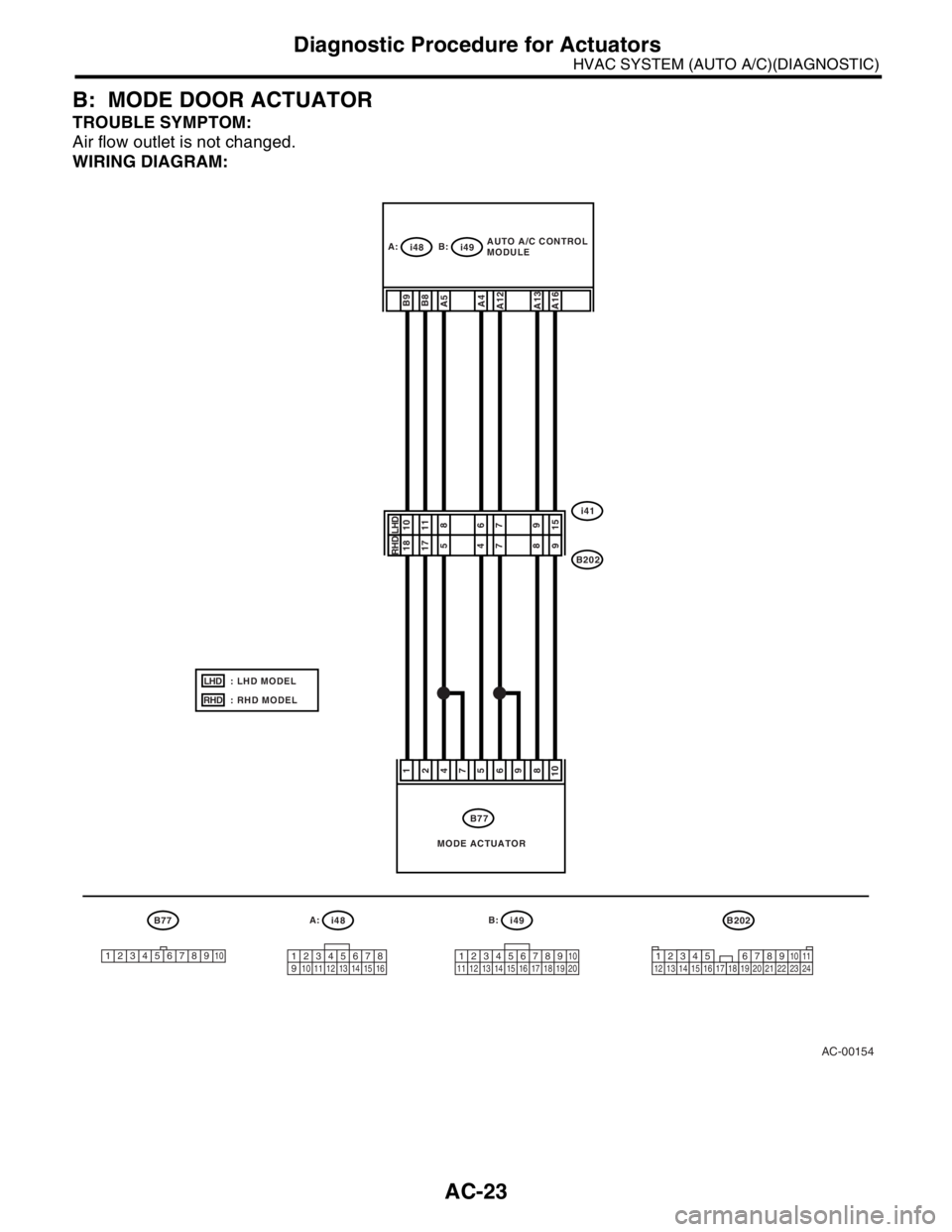

B: MODE DOOR ACTUATOR

TROUBLE SYMPTOM:

Air flow outlet is not changed.

WIRING DIAGRAM:

AC-00154

B77A:

i48B:

i49B202

12345678

910 11 12 13 14 15 1612345678910

11 12 13 14 15 16 17 18 19 203

4 128910 11

12 13 14 15 16 17 18 19 20 21 22 23 24567

B77

i41

B202

471210895

6

1110867915

B8B9A5

A4A12

A13

A16

12345678910

A:

i48B:

i49AUTO A/C CONTROL

MODULE

MODE ACTUATOR : LHD MODEL

: RHD MODEL

LHD

RHD

171854789LHD RHD

Page 80 of 2870

AC-24

HVAC SYSTEM (AUTO A/C)(DIAGNOSTIC)

Diagnostic Procedure for Actuators

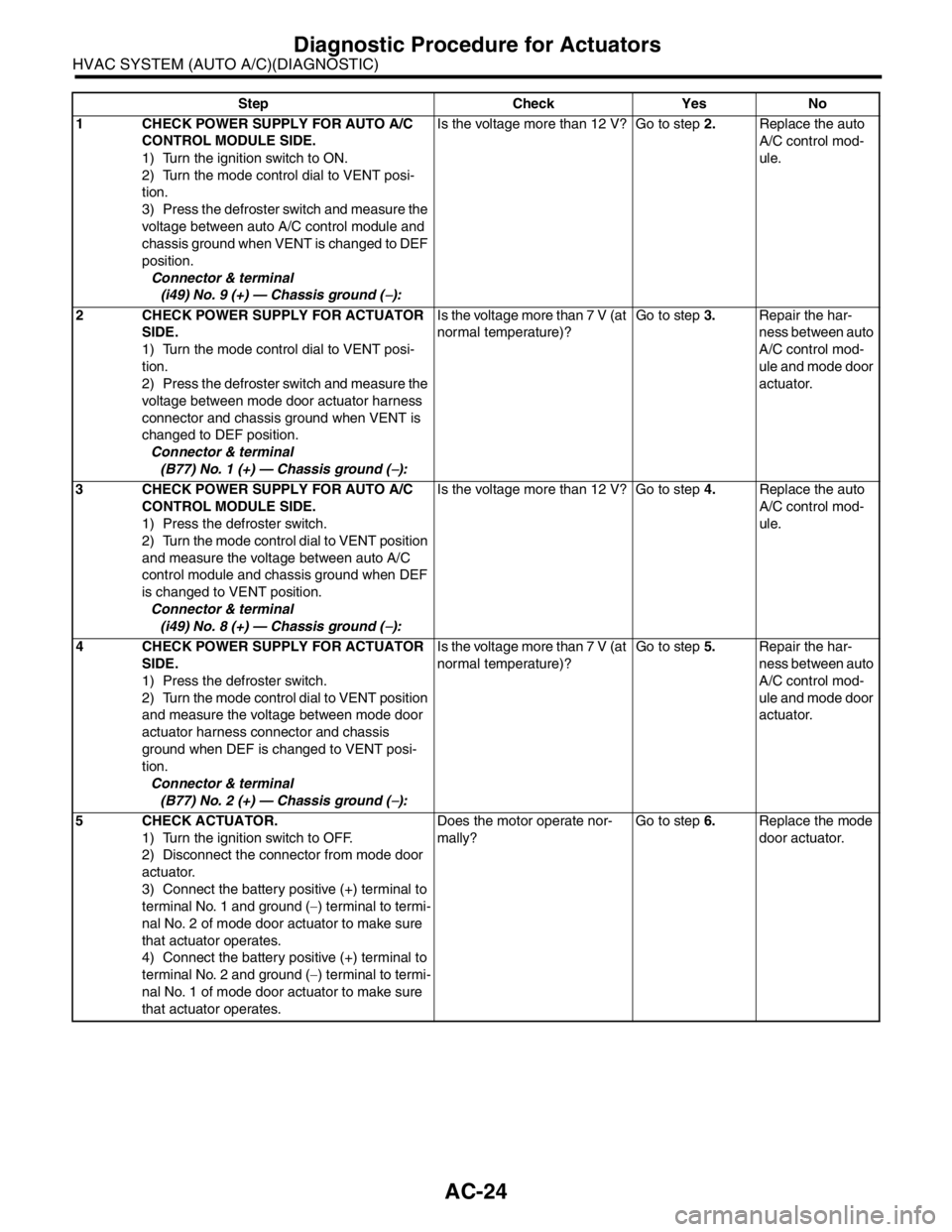

Step Check Yes No

1 CHECK POWER SUPPLY FOR AUTO A/C

CONTROL MODULE SIDE.

1) Turn the ignition switch to ON.

2) Turn the mode control dial to VENT posi-

tion.

3) Press the defroster switch and measure the

voltage between auto A/C control module and

chassis ground when VENT is changed to DEF

position.

Connector & terminal

(i49) No. 9 (+) — Chassis ground (

−):Is the voltage more than 12 V? Go to step 2.Replace the auto

A/C control mod-

ule.

2 CHECK POWER SUPPLY FOR ACTUATOR

SIDE.

1) Turn the mode control dial to VENT posi-

tion.

2) Press the defroster switch and measure the

voltage between mode door actuator harness

connector and chassis ground when VENT is

changed to DEF position.

Connector & terminal

(B77) No. 1 (+) — Chassis ground (

−):Is the voltage more than 7 V (at

normal temperature)?Go to step 3.Repair the har-

ness between auto

A/C control mod-

ule and mode door

actuator.

3 CHECK POWER SUPPLY FOR AUTO A/C

CONTROL MODULE SIDE.

1) Press the defroster switch.

2) Turn the mode control dial to VENT position

and measure the voltage between auto A/C

control module and chassis ground when DEF

is changed to VENT position.

Connector & terminal

(i49) No. 8 (+) — Chassis ground (

−):Is the voltage more than 12 V? Go to step 4.Replace the auto

A/C control mod-

ule.

4 CHECK POWER SUPPLY FOR ACTUATOR

SIDE.

1) Press the defroster switch.

2) Turn the mode control dial to VENT position

and measure the voltage between mode door

actuator harness connector and chassis

ground when DEF is changed to VENT posi-

tion.

Connector & terminal

(B77) No. 2 (+) — Chassis ground (

−):Is the voltage more than 7 V (at

normal temperature)?Go to step 5.Repair the har-

ness between auto

A/C control mod-

ule and mode door

actuator.

5 CHECK ACTUATOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from mode door

actuator.

3) Connect the battery positive (+) terminal to

terminal No. 1 and ground (−) terminal to termi-

nal No. 2 of mode door actuator to make sure

that actuator operates.

4) Connect the battery positive (+) terminal to

terminal No. 2 and ground (−) terminal to termi-

nal No. 1 of mode door actuator to make sure

that actuator operates.Does the motor operate nor-

mally?Go to step 6.Replace the mode

door actuator.