SUBARU LEGACY 1999 Service Repair Manual

Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 781 of 1456

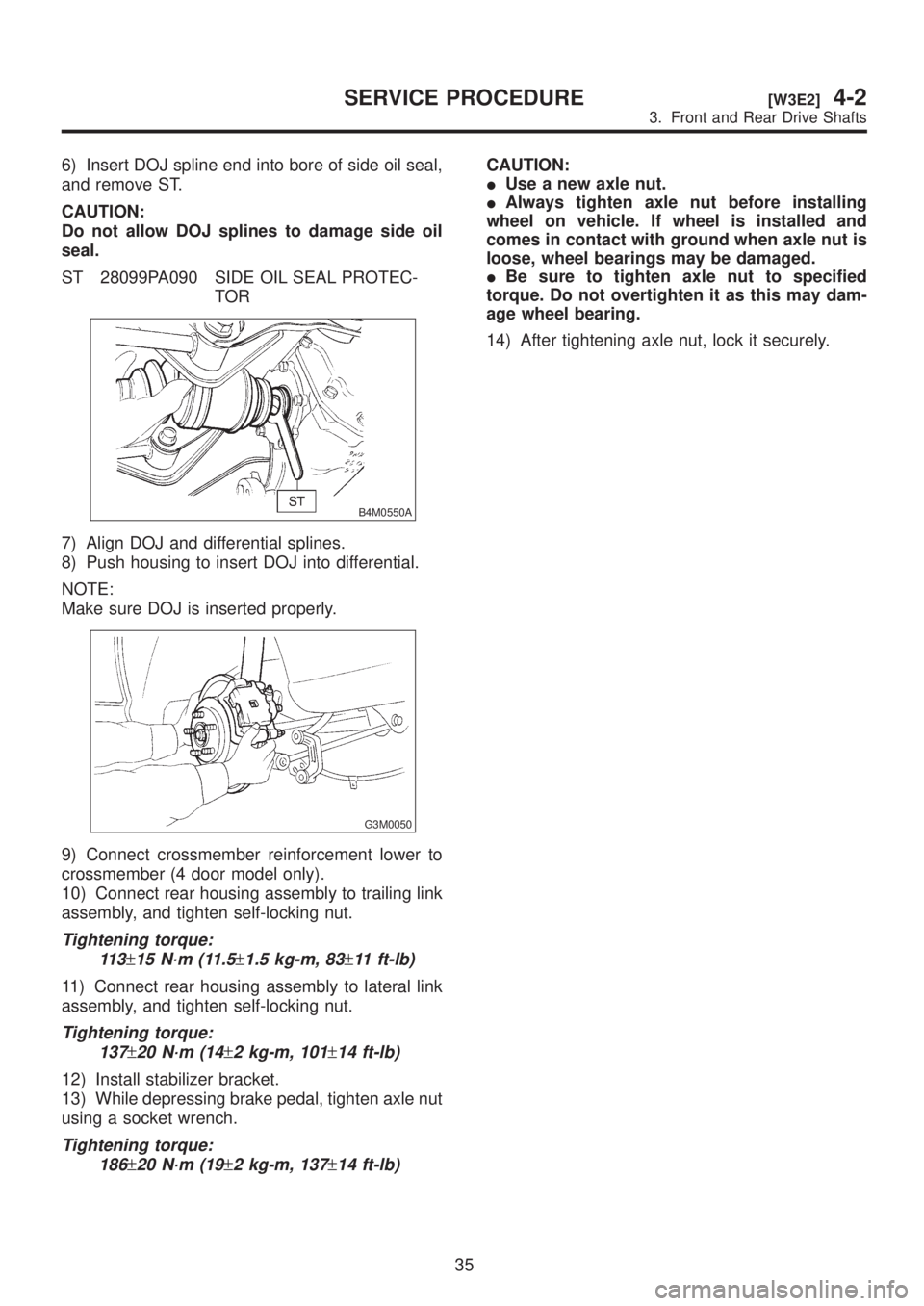

6) Insert DOJ spline end into bore of side oil seal,

and remove ST.

CAUTION:

Do not allow DOJ splines to damage side oil

seal.

ST 28099PA090 SIDE OIL SEAL PROTEC-

TOR

B4M0550A

7) Align DOJ and differential splines.

8) Push housing to insert DOJ into differential.

NOTE:

Make sure DOJ is inserted properly.

G3M0050

9) Connect crossmember reinforcement lower to

crossmember (4 door model only).

10) Connect rear housing assembly to trailing link

assembly, and tighten self-locking nut.

Tightening torque:

11 3

±15 N´m (11.5±1.5 kg-m, 83±11 ft-lb)

11) Connect rear housing assembly to lateral link

assembly, and tighten self-locking nut.

Tightening torque:

137

±20 N´m (14±2 kg-m, 101±14 ft-lb)

12) Install stabilizer bracket.

13) While depressing brake pedal, tighten axle nut

using a socket wrench.

Tightening torque:

186

±20 N´m (19±2 kg-m, 137±14 ft-lb)

CAUTION:

IUse a new axle nut.

IAlways tighten axle nut before installing

wheel on vehicle. If wheel is installed and

comes in contact with ground when axle nut is

loose, wheel bearings may be damaged.

IBe sure to tighten axle nut to specified

torque. Do not overtighten it as this may dam-

age wheel bearing.

14) After tightening axle nut, lock it securely.

35

[W3E2]4-2SERVICE PROCEDURE

3. Front and Rear Drive Shafts

Page 782 of 1456

4. Replacement of Front SFJ,

DOJ and BJ Boots

A: REMOVAL

1) Disconnect ground cable from battery.

2) Jack-up vehicle, support it with safety stands

(rigid racks), and remove front wheel cap and

wheels.

NOTE:

Do not remove axle nut.

3) Remove stabilizer link.

4) Disconnect transverse link from housing.

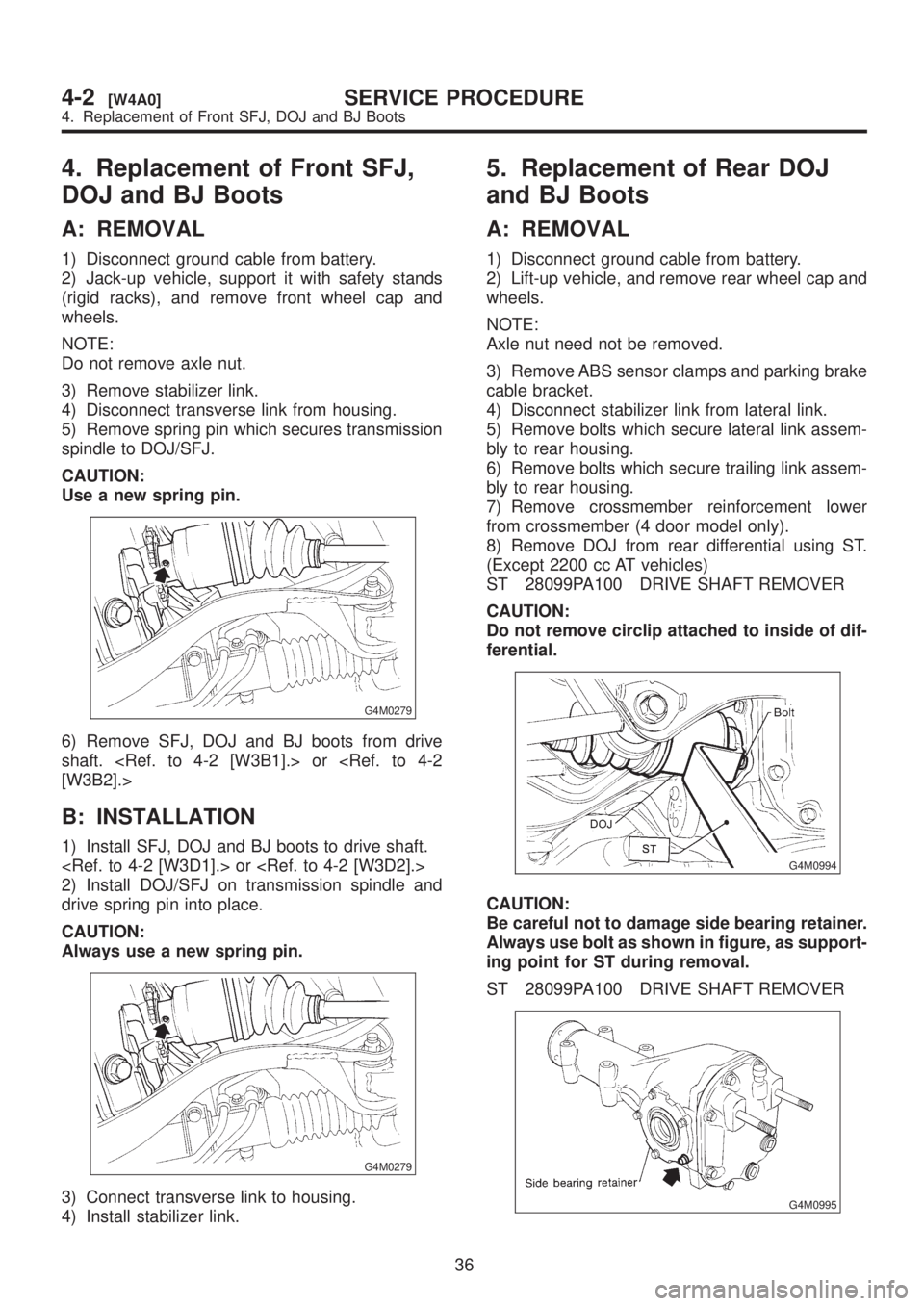

5) Remove spring pin which secures transmission

spindle to DOJ/SFJ.

CAUTION:

Use a new spring pin.

G4M0279

6) Remove SFJ, DOJ and BJ boots from drive

shaft.

B: INSTALLATION

1) Install SFJ, DOJ and BJ boots to drive shaft.

2) Install DOJ/SFJ on transmission spindle and

drive spring pin into place.

CAUTION:

Always use a new spring pin.

G4M0279

3) Connect transverse link to housing.

4) Install stabilizer link.

5. Replacement of Rear DOJ

and BJ Boots

A: REMOVAL

1) Disconnect ground cable from battery.

2) Lift-up vehicle, and remove rear wheel cap and

wheels.

NOTE:

Axle nut need not be removed.

3) Remove ABS sensor clamps and parking brake

cable bracket.

4) Disconnect stabilizer link from lateral link.

5) Remove bolts which secure lateral link assem-

bly to rear housing.

6) Remove bolts which secure trailing link assem-

bly to rear housing.

7) Remove crossmember reinforcement lower

from crossmember (4 door model only).

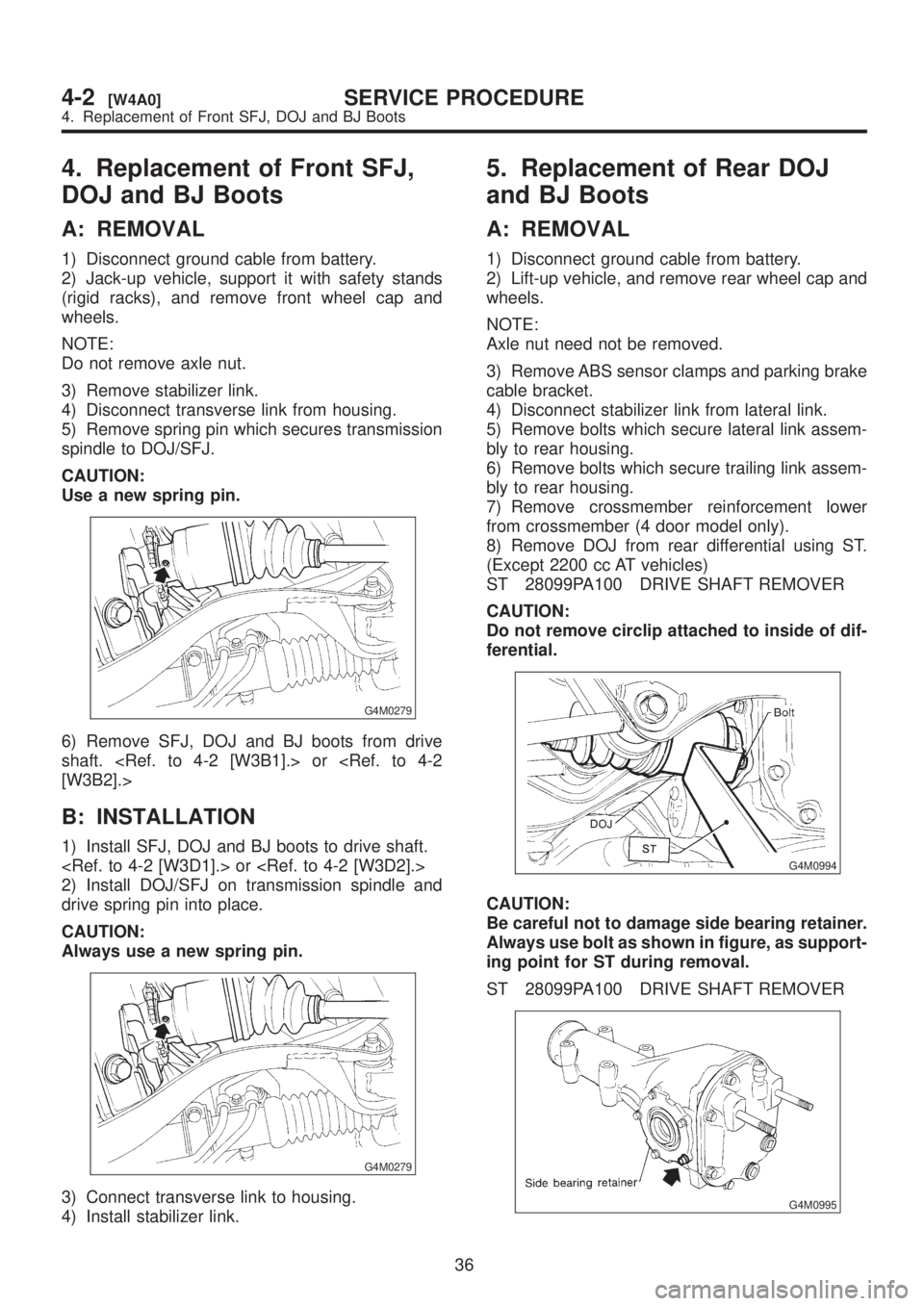

8) Remove DOJ from rear differential using ST.

(Except 2200 cc AT vehicles)

ST 28099PA100 DRIVE SHAFT REMOVER

CAUTION:

Do not remove circlip attached to inside of dif-

ferential.

G4M0994

CAUTION:

Be careful not to damage side bearing retainer.

Always use bolt as shown in figure, as support-

ing point for ST during removal.

ST 28099PA100 DRIVE SHAFT REMOVER

G4M0995

36

4-2[W4A0]SERVICE PROCEDURE

4. Replacement of Front SFJ, DOJ and BJ Boots

Page 783 of 1456

4. Replacement of Front SFJ,

DOJ and BJ Boots

A: REMOVAL

1) Disconnect ground cable from battery.

2) Jack-up vehicle, support it with safety stands

(rigid racks), and remove front wheel cap and

wheels.

NOTE:

Do not remove axle nut.

3) Remove stabilizer link.

4) Disconnect transverse link from housing.

5) Remove spring pin which secures transmission

spindle to DOJ/SFJ.

CAUTION:

Use a new spring pin.

G4M0279

6) Remove SFJ, DOJ and BJ boots from drive

shaft.

B: INSTALLATION

1) Install SFJ, DOJ and BJ boots to drive shaft.

2) Install DOJ/SFJ on transmission spindle and

drive spring pin into place.

CAUTION:

Always use a new spring pin.

G4M0279

3) Connect transverse link to housing.

4) Install stabilizer link.

5. Replacement of Rear DOJ

and BJ Boots

A: REMOVAL

1) Disconnect ground cable from battery.

2) Lift-up vehicle, and remove rear wheel cap and

wheels.

NOTE:

Axle nut need not be removed.

3) Remove ABS sensor clamps and parking brake

cable bracket.

4) Disconnect stabilizer link from lateral link.

5) Remove bolts which secure lateral link assem-

bly to rear housing.

6) Remove bolts which secure trailing link assem-

bly to rear housing.

7) Remove crossmember reinforcement lower

from crossmember (4 door model only).

8) Remove DOJ from rear differential using ST.

(Except 2200 cc AT vehicles)

ST 28099PA100 DRIVE SHAFT REMOVER

CAUTION:

Do not remove circlip attached to inside of dif-

ferential.

G4M0994

CAUTION:

Be careful not to damage side bearing retainer.

Always use bolt as shown in figure, as support-

ing point for ST during removal.

ST 28099PA100 DRIVE SHAFT REMOVER

G4M0995

36

4-2[W4A0]SERVICE PROCEDURE

4. Replacement of Front SFJ, DOJ and BJ Boots

Page 784 of 1456

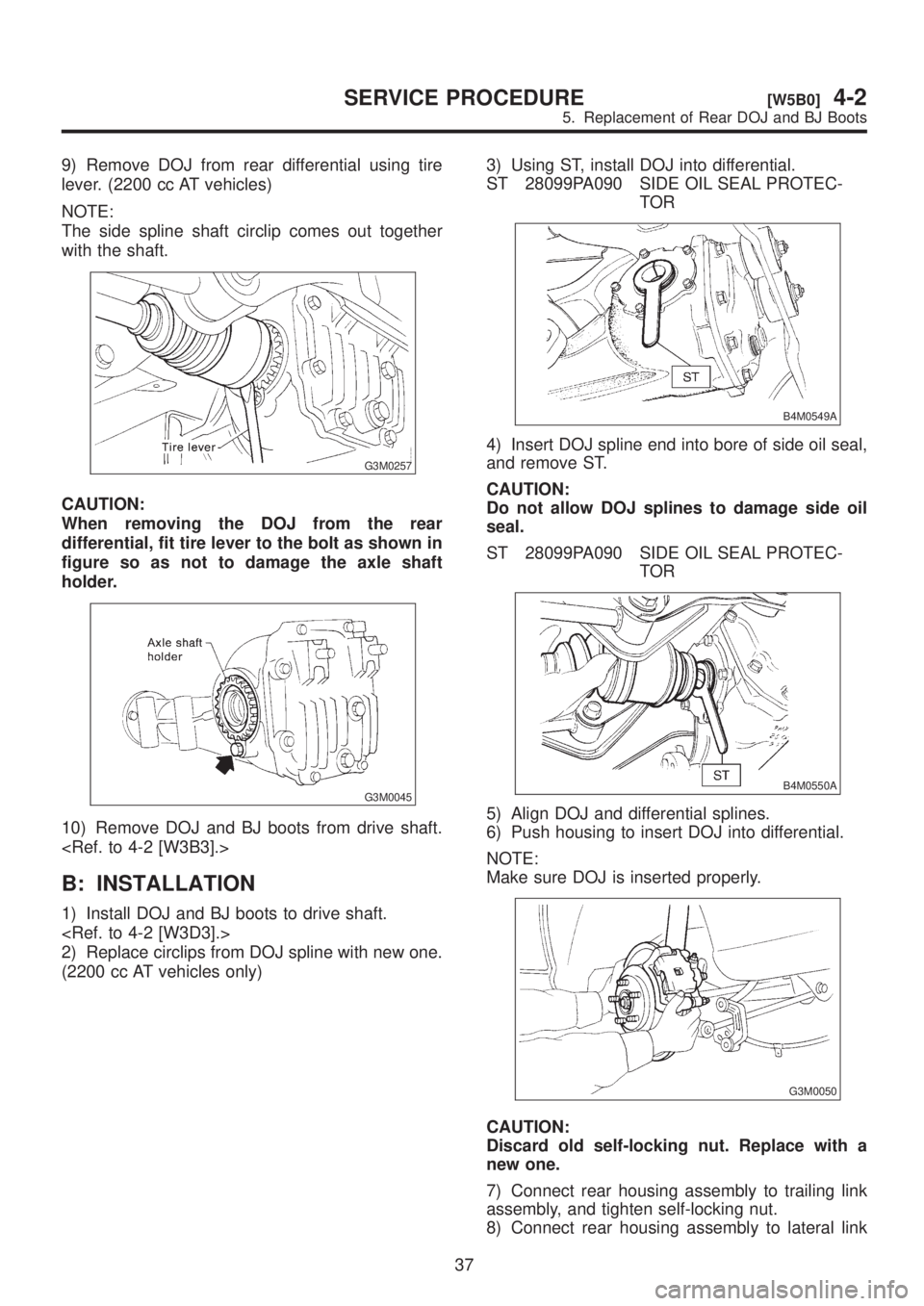

9) Remove DOJ from rear differential using tire

lever. (2200 cc AT vehicles)

NOTE:

The side spline shaft circlip comes out together

with the shaft.

G3M0257

CAUTION:

When removing the DOJ from the rear

differential, fit tire lever to the bolt as shown in

figure so as not to damage the axle shaft

holder.

G3M0045

10) Remove DOJ and BJ boots from drive shaft.

B: INSTALLATION

1) Install DOJ and BJ boots to drive shaft.

2) Replace circlips from DOJ spline with new one.

(2200 cc AT vehicles only)3) Using ST, install DOJ into differential.

ST 28099PA090 SIDE OIL SEAL PROTEC-

TOR

B4M0549A

4) Insert DOJ spline end into bore of side oil seal,

and remove ST.

CAUTION:

Do not allow DOJ splines to damage side oil

seal.

ST 28099PA090 SIDE OIL SEAL PROTEC-

TOR

B4M0550A

5) Align DOJ and differential splines.

6) Push housing to insert DOJ into differential.

NOTE:

Make sure DOJ is inserted properly.

G3M0050

CAUTION:

Discard old self-locking nut. Replace with a

new one.

7) Connect rear housing assembly to trailing link

assembly, and tighten self-locking nut.

8) Connect rear housing assembly to lateral link

37

[W5B0]4-2SERVICE PROCEDURE

5. Replacement of Rear DOJ and BJ Boots

Page 785 of 1456

assembly, and tighten self-locking nut.

9) Connect stabilizer link to lateral link.

10) Install crossmember reinforcement lower to

crossmember (4 door model only).

11) Install ABS sensor clamps and parking brake

cable bracket.6. Full Wheel Cap

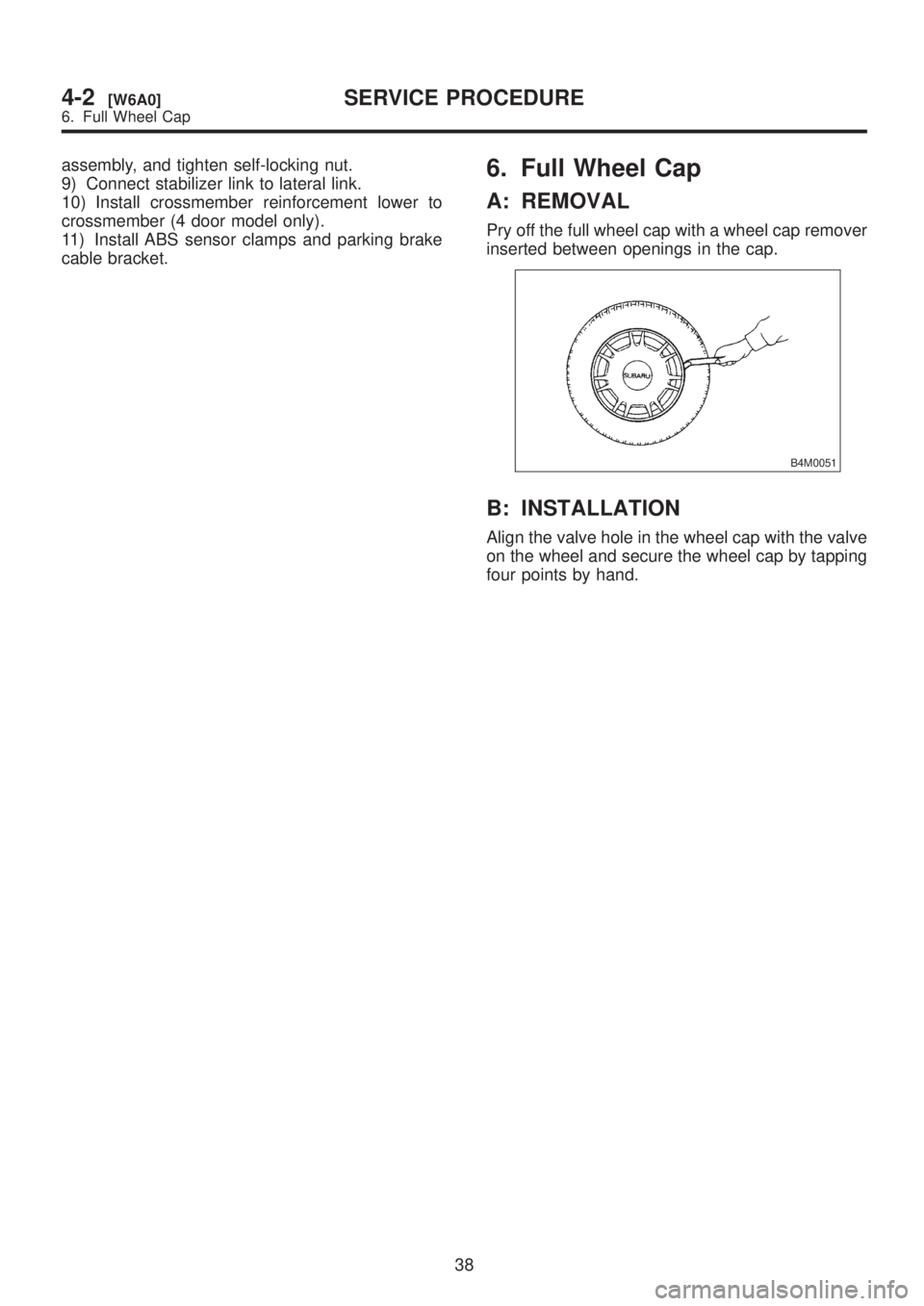

A: REMOVAL

Pry off the full wheel cap with a wheel cap remover

inserted between openings in the cap.

B4M0051

B: INSTALLATION

Align the valve hole in the wheel cap with the valve

on the wheel and secure the wheel cap by tapping

four points by hand.

38

4-2[W6A0]SERVICE PROCEDURE

6. Full Wheel Cap

Page 786 of 1456

assembly, and tighten self-locking nut.

9) Connect stabilizer link to lateral link.

10) Install crossmember reinforcement lower to

crossmember (4 door model only).

11) Install ABS sensor clamps and parking brake

cable bracket.6. Full Wheel Cap

A: REMOVAL

Pry off the full wheel cap with a wheel cap remover

inserted between openings in the cap.

B4M0051

B: INSTALLATION

Align the valve hole in the wheel cap with the valve

on the wheel and secure the wheel cap by tapping

four points by hand.

38

4-2[W6A0]SERVICE PROCEDURE

6. Full Wheel Cap

Page 787 of 1456

7. Steel Wheel and Tire

A: INSPECTION

1) Deformation or damage on the rim can cause

air leakage. Check the rim flange for deformation,

crack, or damage, and repair or replace as neces-

sary.

2) Take stone, glass, nail etc. off the tread groove.

3) Replace tire:

CAUTION:

IWhen replacing a tire, make sure to use only

the same size, construction and load range as

originally installed.

IAvoid mixing radial, belted bias or bias tires

on the vehicle.

(1) when large crack on side wall, damage or

crack on tread is found.

(2) when the ªtread wear indicatorº appears as

a solid band across the tread.

G4M0297

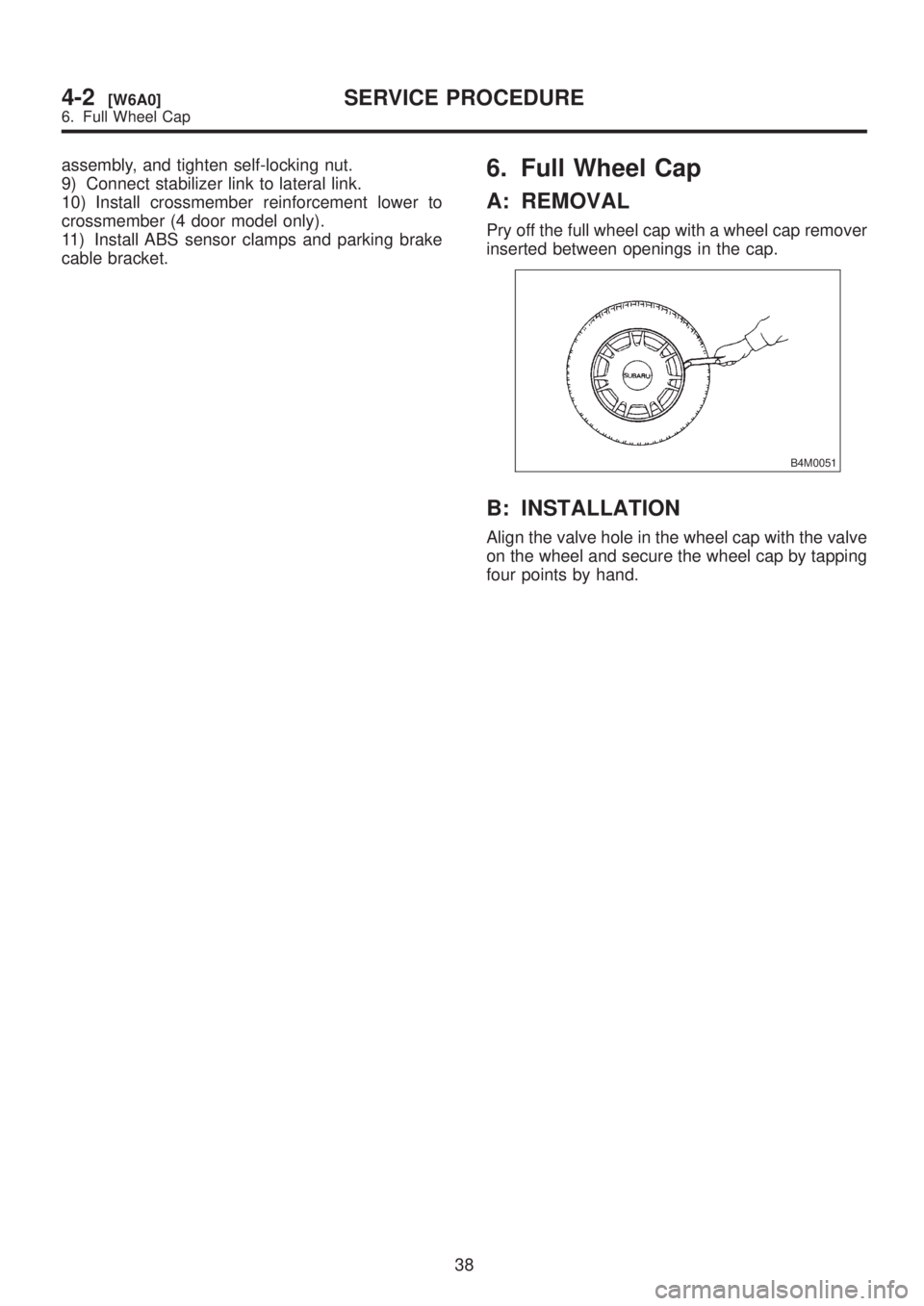

1. INSPECTION OF WHEEL RUNOUT

1) Jack-up vehicle until wheels clear the floor.

2) Slowly rotate wheel to check rim ªrunoutº using

a dial gauge.

G4M0298

Axial runout limit Radial runout limit

Steel wheel 1.5 mm (0.059 in)

Aluminum wheel 1.0 mm (0.039 in)

G4M0299

3) If rim runout exceeds specifications, remove

tire from rim and check runout while attaching dial

gauge to positions shown in figure.

4) If measured runout still exceeds specifications,

replace the wheel.

39

[W7A1]4-2SERVICE PROCEDURE

7. Steel Wheel and Tire

Page 788 of 1456

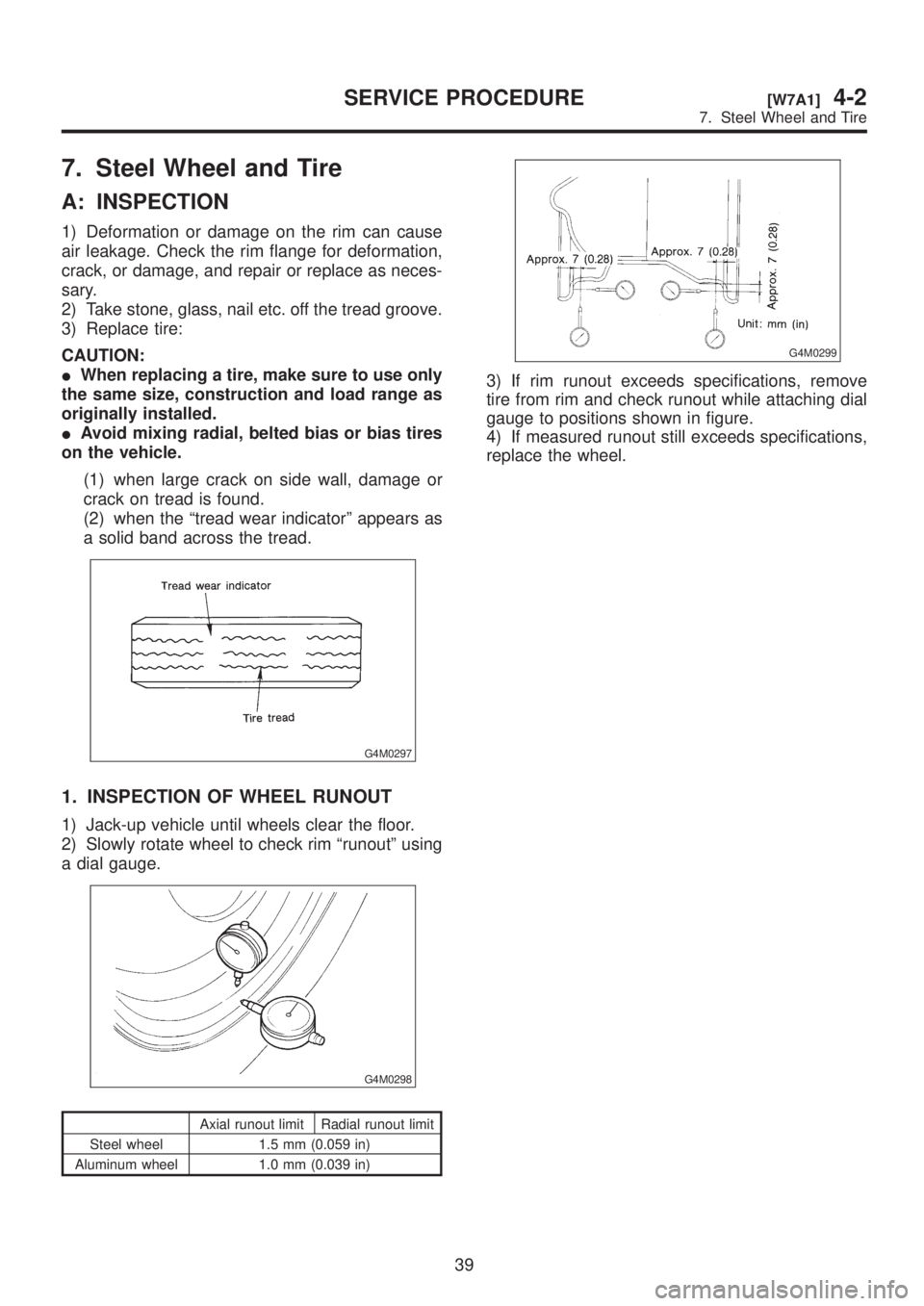

8. Aluminum Wheel

A: INSPECTION

Inspection for aluminum wheels is basically the

same as the one for steel wheels. However, check

the rim flange for cracks or damage, and replace

(not repair) aluminum wheel if air leakage is found.

B: PRECAUTIONS

Aluminum wheels are easily scratched. To main-

tain their appearance and safety, do the following:

1) Do not damage aluminum wheels during

removal, disassembly, installation, wheel

balancing, etc. After removing aluminum wheels,

place them on a rubber mat, etc.

2) While vehicle is being driven, be careful not to

ride over sharp obstacles or allow aluminum

wheels to contact the shoulder of the road.

3) When installing tire chain, be sure to install it

properly not to have a slack; otherwise it may hit

wheel while driving.

4) When washing aluminum wheel, use neutral

synthetic detergent and water. Avoid using the

cleanser including abrasive, hard brushes or an

automatic car washer.

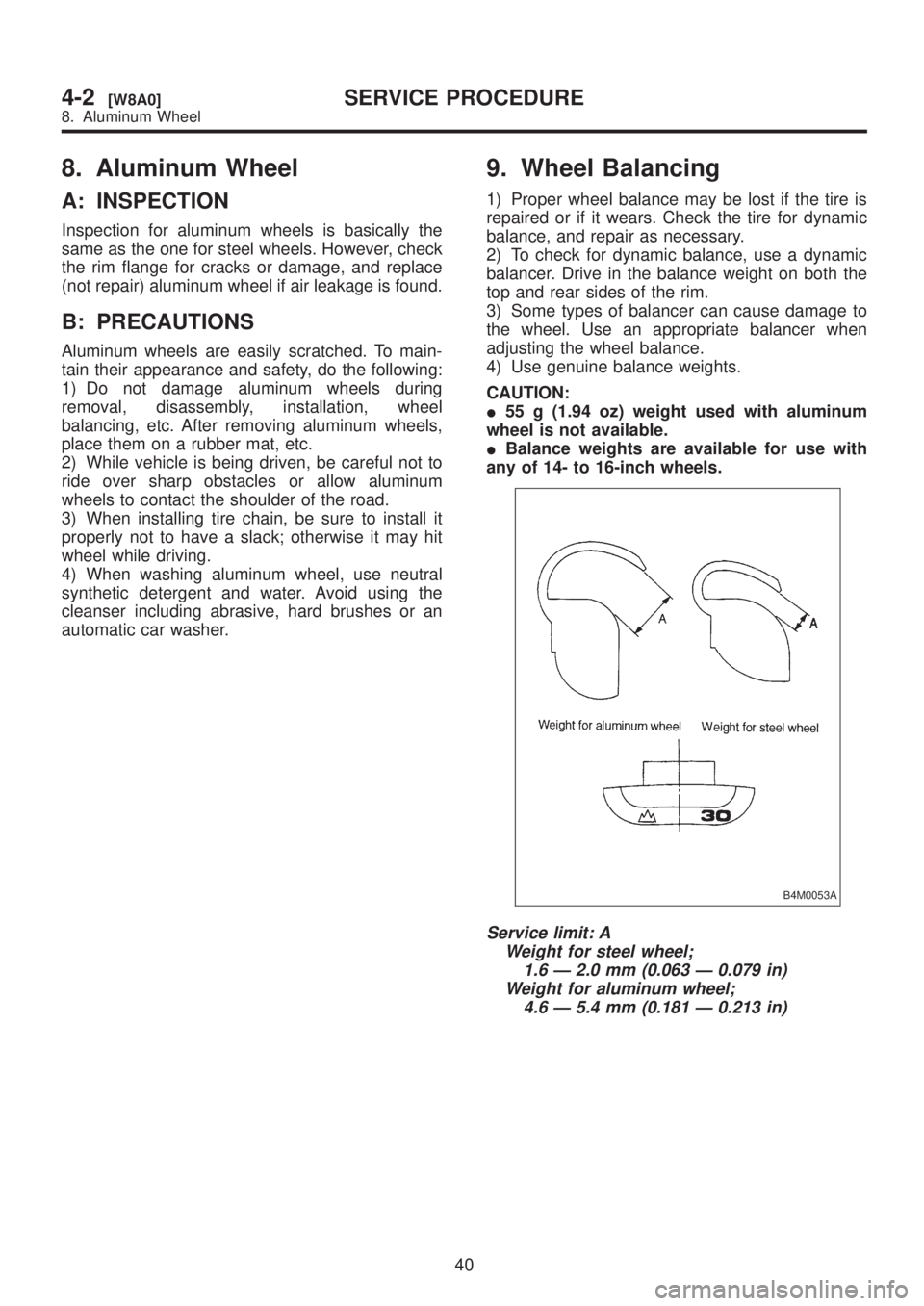

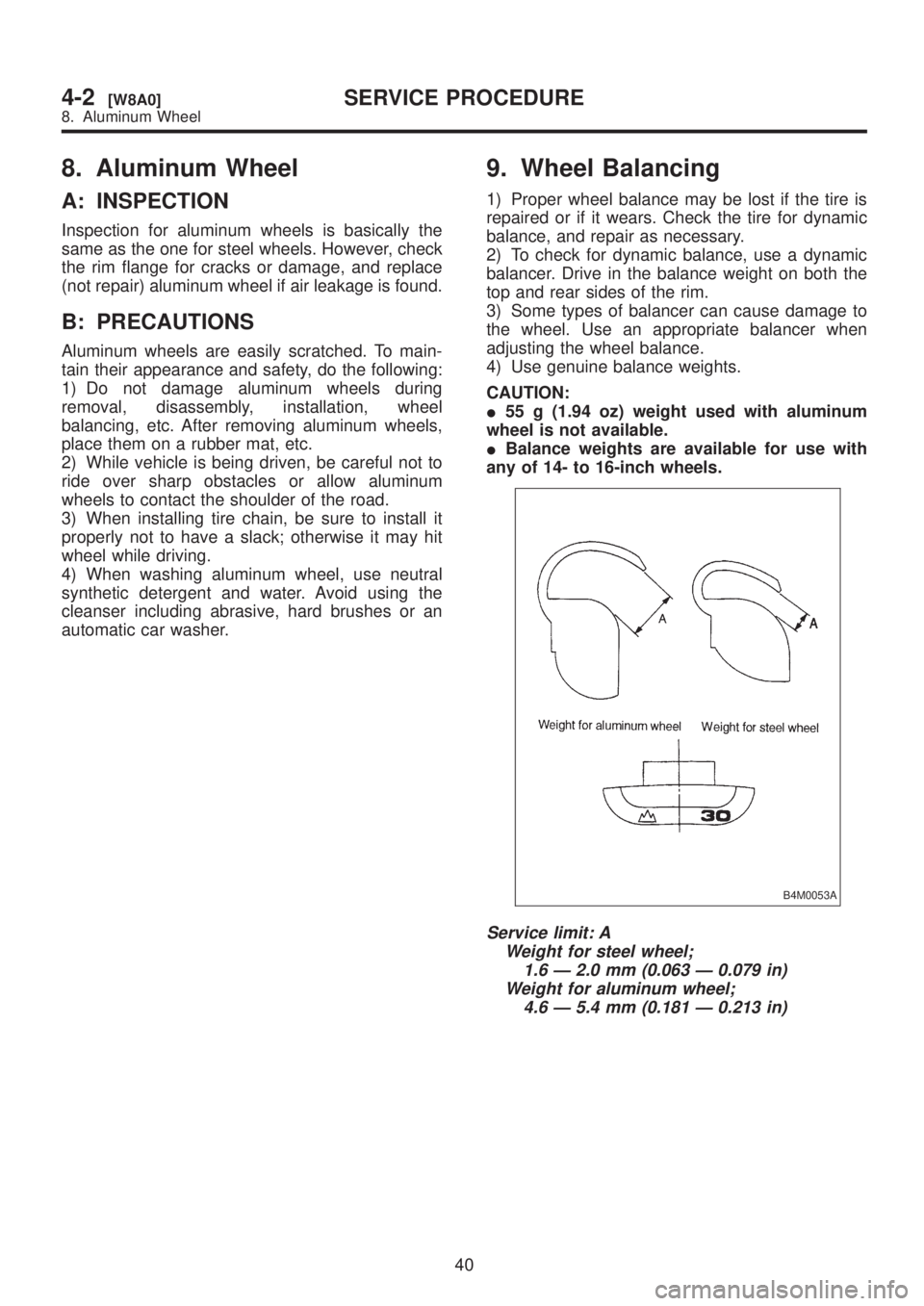

9. Wheel Balancing

1) Proper wheel balance may be lost if the tire is

repaired or if it wears. Check the tire for dynamic

balance, and repair as necessary.

2) To check for dynamic balance, use a dynamic

balancer. Drive in the balance weight on both the

top and rear sides of the rim.

3) Some types of balancer can cause damage to

the wheel. Use an appropriate balancer when

adjusting the wheel balance.

4) Use genuine balance weights.

CAUTION:

I55 g (1.94 oz) weight used with aluminum

wheel is not available.

IBalance weights are available for use with

any of 14- to 16-inch wheels.

B4M0053A

Service limit: A

Weight for steel wheel;

1.6 Ð 2.0 mm (0.063 Ð 0.079 in)

Weight for aluminum wheel;

4.6 Ð 5.4 mm (0.181 Ð 0.213 in)

40

4-2[W8A0]SERVICE PROCEDURE

8. Aluminum Wheel

Page 789 of 1456

8. Aluminum Wheel

A: INSPECTION

Inspection for aluminum wheels is basically the

same as the one for steel wheels. However, check

the rim flange for cracks or damage, and replace

(not repair) aluminum wheel if air leakage is found.

B: PRECAUTIONS

Aluminum wheels are easily scratched. To main-

tain their appearance and safety, do the following:

1) Do not damage aluminum wheels during

removal, disassembly, installation, wheel

balancing, etc. After removing aluminum wheels,

place them on a rubber mat, etc.

2) While vehicle is being driven, be careful not to

ride over sharp obstacles or allow aluminum

wheels to contact the shoulder of the road.

3) When installing tire chain, be sure to install it

properly not to have a slack; otherwise it may hit

wheel while driving.

4) When washing aluminum wheel, use neutral

synthetic detergent and water. Avoid using the

cleanser including abrasive, hard brushes or an

automatic car washer.

9. Wheel Balancing

1) Proper wheel balance may be lost if the tire is

repaired or if it wears. Check the tire for dynamic

balance, and repair as necessary.

2) To check for dynamic balance, use a dynamic

balancer. Drive in the balance weight on both the

top and rear sides of the rim.

3) Some types of balancer can cause damage to

the wheel. Use an appropriate balancer when

adjusting the wheel balance.

4) Use genuine balance weights.

CAUTION:

I55 g (1.94 oz) weight used with aluminum

wheel is not available.

IBalance weights are available for use with

any of 14- to 16-inch wheels.

B4M0053A

Service limit: A

Weight for steel wheel;

1.6 Ð 2.0 mm (0.063 Ð 0.079 in)

Weight for aluminum wheel;

4.6 Ð 5.4 mm (0.181 Ð 0.213 in)

40

4-2[W8A0]SERVICE PROCEDURE

8. Aluminum Wheel

Page 790 of 1456

10. Installation of Wheel

Assembly to Vehicle

1) Attach the wheel to the hub by aligning the

wheel bolt hole with the hub bolt.

2) Temporarily attach the wheel nuts to the hub

bolts. (In the case of aluminum wheel, use

SUBARU genuine wheel nut for aluminum wheel.)

3) Manually tighten the nuts making sure the

wheel hub hole is aligned correctly to the guide

portion of hub.

4) Tighten the wheel nuts in a diagonal selection

to the specified torque. Use a wheel nut wrench.

Wheel nut tightening torque:

88

±10 N´m (9±1 kg-m, 65±7 ft-lb)

CAUTION:

ITighten the wheel nuts in two or three steps

by gradually increasing the torque and working

diagonally, until the specified torque is

reached. For drum brake models, excess tight-

ening of wheel nuts may cause wheels to ªjud-

derº.

IDo not depress the wrench with a foot;

Always use both hands when tightening.

IMake sure the bolt, nut and the nut seating

surface of the wheel are free from oils.

5) If a wheel is removed for replacement or for

repair of a puncture, retighten the wheel nuts to the

specified torque after running 1,000 km (600

miles).

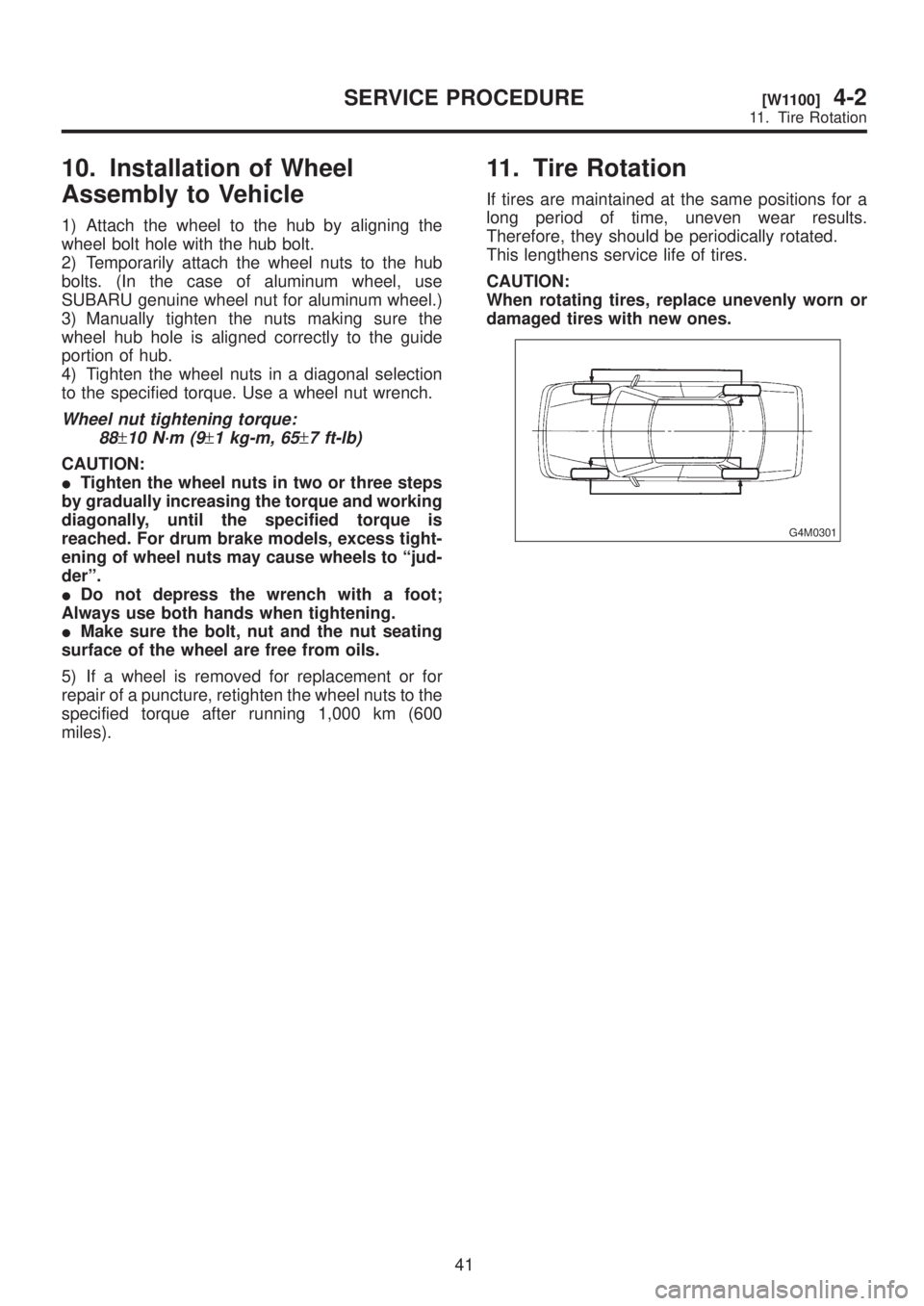

11. Tire Rotation

If tires are maintained at the same positions for a

long period of time, uneven wear results.

Therefore, they should be periodically rotated.

This lengthens service life of tires.

CAUTION:

When rotating tires, replace unevenly worn or

damaged tires with new ones.

G4M0301

41

[W1100]4-2SERVICE PROCEDURE

11. Tire Rotation