SUBARU TRIBECA 2009 1.G Service Workshop Manual

Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 531 of 2453

LAN(diag)-75

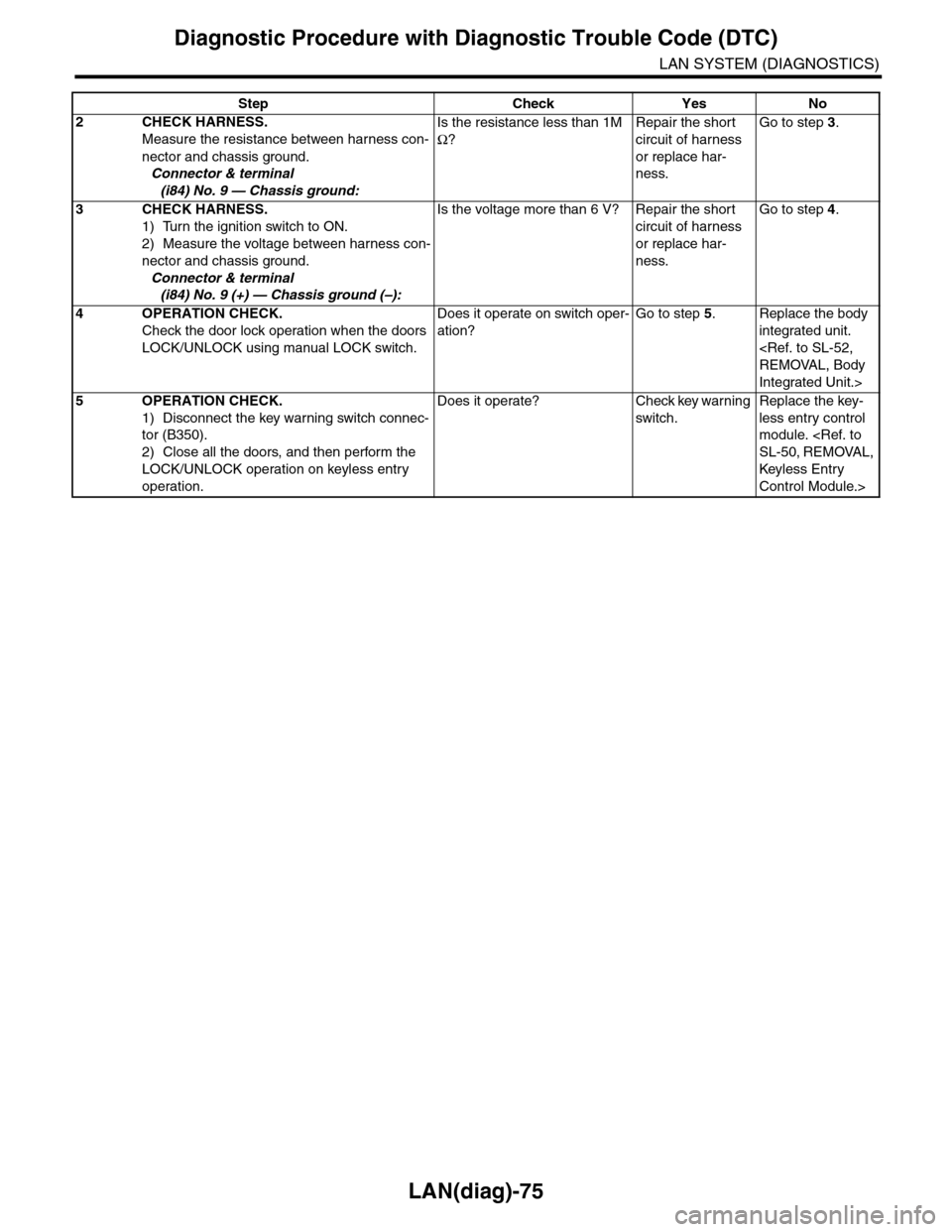

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

2CHECK HARNESS.

Measure the resistance between harness con-

nector and chassis ground.

Connector & terminal

(i84) No. 9 — Chassis ground:

Is the resistance less than 1M

Ω?

Repair the short

circuit of harness

or replace har-

ness.

Go to step 3.

3CHECK HARNESS.

1) Turn the ignition switch to ON.

2) Measure the voltage between harness con-

nector and chassis ground.

Connector & terminal

(i84) No. 9 (+) — Chassis ground (–):

Is the voltage more than 6 V? Repair the short

circuit of harness

or replace har-

ness.

Go to step 4.

4OPERATION CHECK.

Check the door lock operation when the doors

LOCK/UNLOCK using manual LOCK switch.

Does it operate on switch oper-

ation?

Go to step 5.Replace the body

integrated unit.

Integrated Unit.>

5OPERATION CHECK.

1) Disconnect the key warning switch connec-

tor (B350).

2) Close all the doors, and then perform the

LOCK/UNLOCK operation on keyless entry

operation.

Does it operate? Check key warning

switch.

Replace the key-

less entry control

module.

Keyless Entr y

Control Module.>

Step Check Yes No

Page 532 of 2453

LAN(diag)-76

General Diagnostic Table

LAN SYSTEM (DIAGNOSTICS)

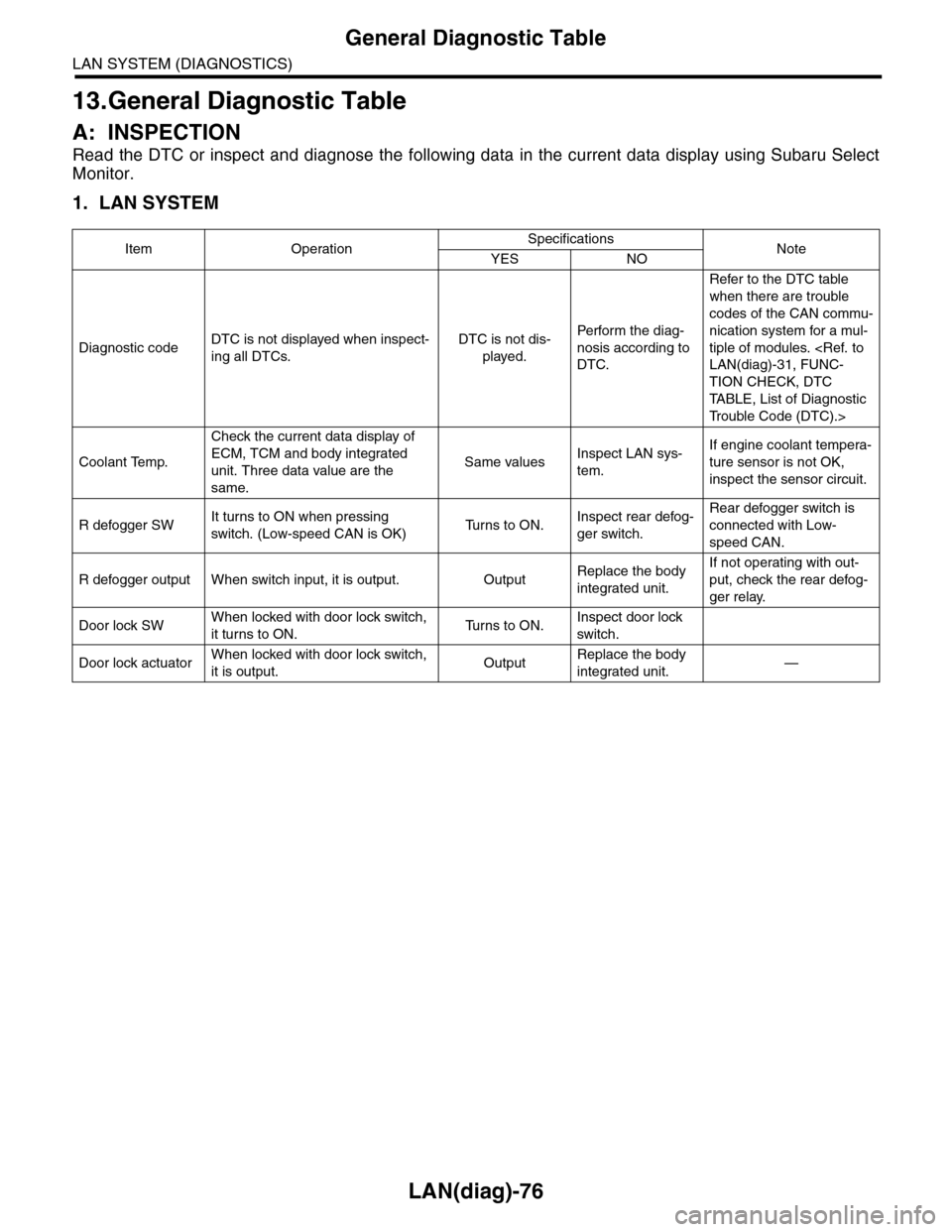

13.General Diagnostic Table

A: INSPECTION

Read the DTC or inspect and diagnose the following data in the current data display using Subaru Select

Monitor.

1. LAN SYSTEM

Item OperationSpecificationsNoteYES NO

Diagnostic codeDTC is not displayed when inspect-

ing all DTCs.

DTC is not dis-

played.

Perfor m the diag-

nosis according to

DTC.

Refer to the DTC table

when there are trouble

codes of the CAN commu-

nication system for a mul-

tiple of modules.

TION CHECK, DTC

TA B L E , L i s t o f D i a g n o s t i c

Tr o u b l e C o d e ( D T C ) . >

Coolant Temp.

Check the current data display of

ECM, TCM and body integrated

unit. Three data value are the

same.

Same valuesInspect LAN sys-

tem.

If engine coolant tempera-

ture sensor is not OK,

inspect the sensor circuit.

R defogger SWIt turns to ON when pressing

switch. (Low-speed CAN is OK)Tu r n s t o O N .Inspect rear defog-

ger switch.

Rear defogger switch is

connected with Low-

speed CAN.

R defogger output When switch input, it is output. OutputReplace the body

integrated unit.

If not operating with out-

put, check the rear defog-

ger relay.

Door lock SWWhen locked with door lock switch,

it turns to ON.Tu r n s t o O N .Inspect door lock

switch.

Door lock actuatorWhen locked with door lock switch,

it is output.OutputReplace the body

integrated unit.—

Page 533 of 2453

LAN(diag)-77

General Diagnostic Table

LAN SYSTEM (DIAGNOSTICS)

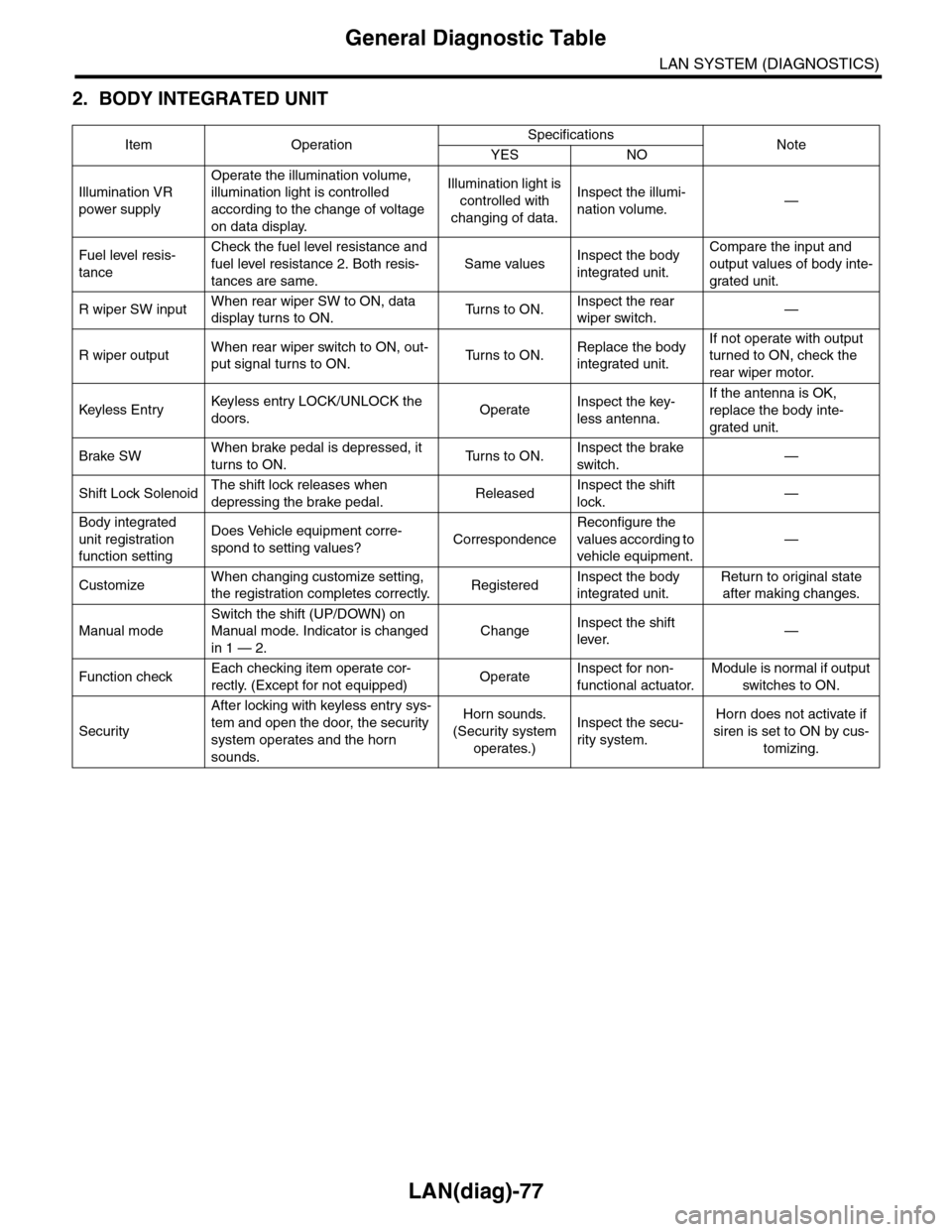

2. BODY INTEGRATED UNIT

Item OperationSpecificationsNoteYES NO

Illumination VR

power supply

Operate the illumination volume,

illumination light is controlled

according to the change of voltage

on data display.

Illumination light is

controlled with

changing of data.

Inspect the illumi-

nation volume.—

Fuel level resis-

tance

Check the fuel level resistance and

fuel level resistance 2. Both resis-

tances are same.

Same valuesInspect the body

integrated unit.

Compare the input and

output values of body inte-

grated unit.

R wiper SW inputWhen rear wiper SW to ON, data

display turns to ON.Tu r n s t o O N .Inspect the rear

wiper switch.—

R wiper outputWhen rear wiper switch to ON, out-

put signal turns to ON.Tu r n s t o O N .Replace the body

integrated unit.

If not operate with output

turned to ON, check the

rear wiper motor.

Keyless Entr yKeyless entr y LOCK/UNLOCK the

doors.OperateInspect the key-

less antenna.

If the antenna is OK,

replace the body inte-

grated unit.

Brake SWWhen brake pedal is depressed, it

turns to ON.Tu r n s t o O N .Inspect the brake

switch.—

Shift Lock SolenoidThe shift lock releases when

depressing the brake pedal.ReleasedInspect the shift

lock.—

Body integrated

unit registration

function setting

Does Vehicle equipment corre-

spond to setting values?Correspondence

Reconfigure the

values according to

vehicle equipment.

—

CustomizeWhen changing customize setting,

the registration completes correctly.RegisteredInspect the body

integrated unit.

Return to original state

after making changes.

Manual mode

Switch the shift (UP/DOWN) on

Manual mode. Indicator is changed

in 1 — 2.

ChangeInspect the shift

lever.—

Function checkEach checking item operate cor-

rectly. (Except for not equipped)OperateInspect for non-

functional actuator.

Module is normal if output

switches to ON.

Security

After locking with keyless entry sys-

tem and open the door, the security

system operates and the horn

sounds.

Horn sounds.

(Security system

operates.)

Inspect the secu-

rity system.

Horn does not activate if

siren is set to ON by cus-

tomizing.

Page 534 of 2453

LAN(diag)-78

General Diagnostic Table

LAN SYSTEM (DIAGNOSTICS)

Page 535 of 2453

LI-2

General Description

LIGHTING SYSTEM

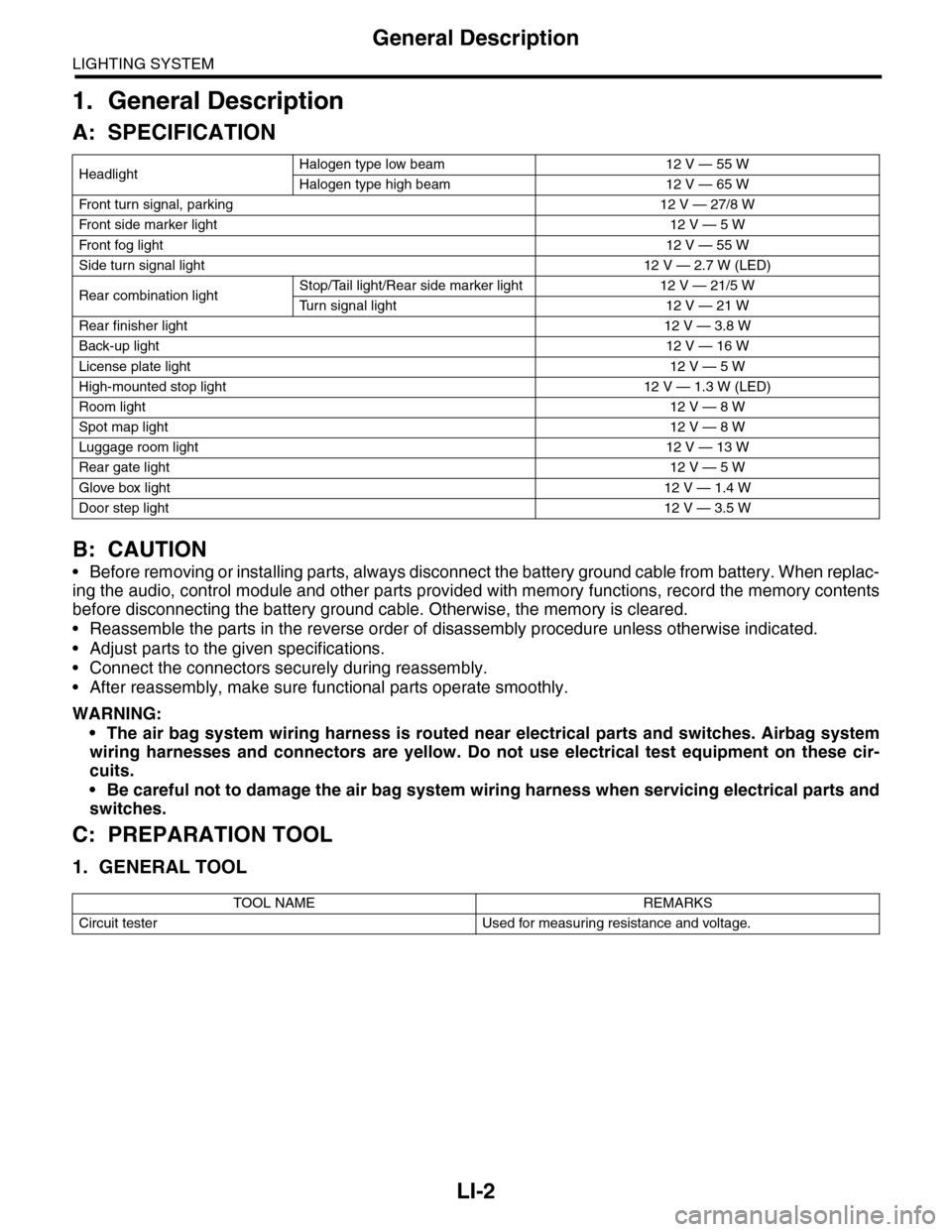

1. General Description

A: SPECIFICATION

B: CAUTION

•Before removing or installing parts, always disconnect the battery ground cable from battery. When replac-

ing the audio, control module and other parts provided with memory functions, record the memory contents

before disconnecting the battery ground cable. Otherwise, the memory is cleared.

•Reassemble the parts in the reverse order of disassembly procedure unless otherwise indicated.

•Adjust parts to the given specifications.

•Connect the connectors securely during reassembly.

•After reassembly, make sure functional parts operate smoothly.

WARNING:

•The air bag system wiring harness is routed near electrical parts and switches. Airbag system

wiring harnesses and connectors are yellow. Do not use electrical test equipment on these cir-

cuits.

•Be careful not to damage the air bag system wiring harness when servicing electrical parts and

switches.

C: PREPARATION TOOL

1. GENERAL TOOL

HeadlightHalogen type low beam 12 V — 55 W

Halogen type high beam 12 V — 65 W

Fr o nt t ur n si gn a l, p ar k in g 1 2 V — 27 / 8 W

Fr o nt si d e m ar ke r li gh t12 V — 5 W

Fr o nt fog li g ht12 V — 55 W

Side turn signal light 12 V — 2.7 W (LED)

Rear combination lightStop/Tail light/Rear side marker light 12 V — 21/5 W

Tu r n s i g n a l l i g h t 1 2 V — 2 1 W

Rear finisher light12 V — 3.8 W

Back-up light12 V — 16 W

License plate light12 V — 5 W

High-mounted stop light 12 V — 1.3 W (LED)

Room light12 V — 8 W

Spot map light12 V — 8 W

Luggage room light12 V — 13 W

Rear gate light12 V — 5 W

Glove box light12 V — 1.4 W

Door step light12 V — 3.5 W

TOOL NAME REMARKS

Circuit tester Used for measuring resistance and voltage.

Page 536 of 2453

LI-3

Headlight and Tail Light System

LIGHTING SYSTEM

2. Headlight and Tail Light Sys-

tem

A: WIRING DIAGRAM

1. HALOGEN TYPE HEADLIGHT

2. CLEARANCE LIGHT AND ILLUMINA-

TION LIGHT

B: INSPECTION

1. HEADLIGHT SWITCH

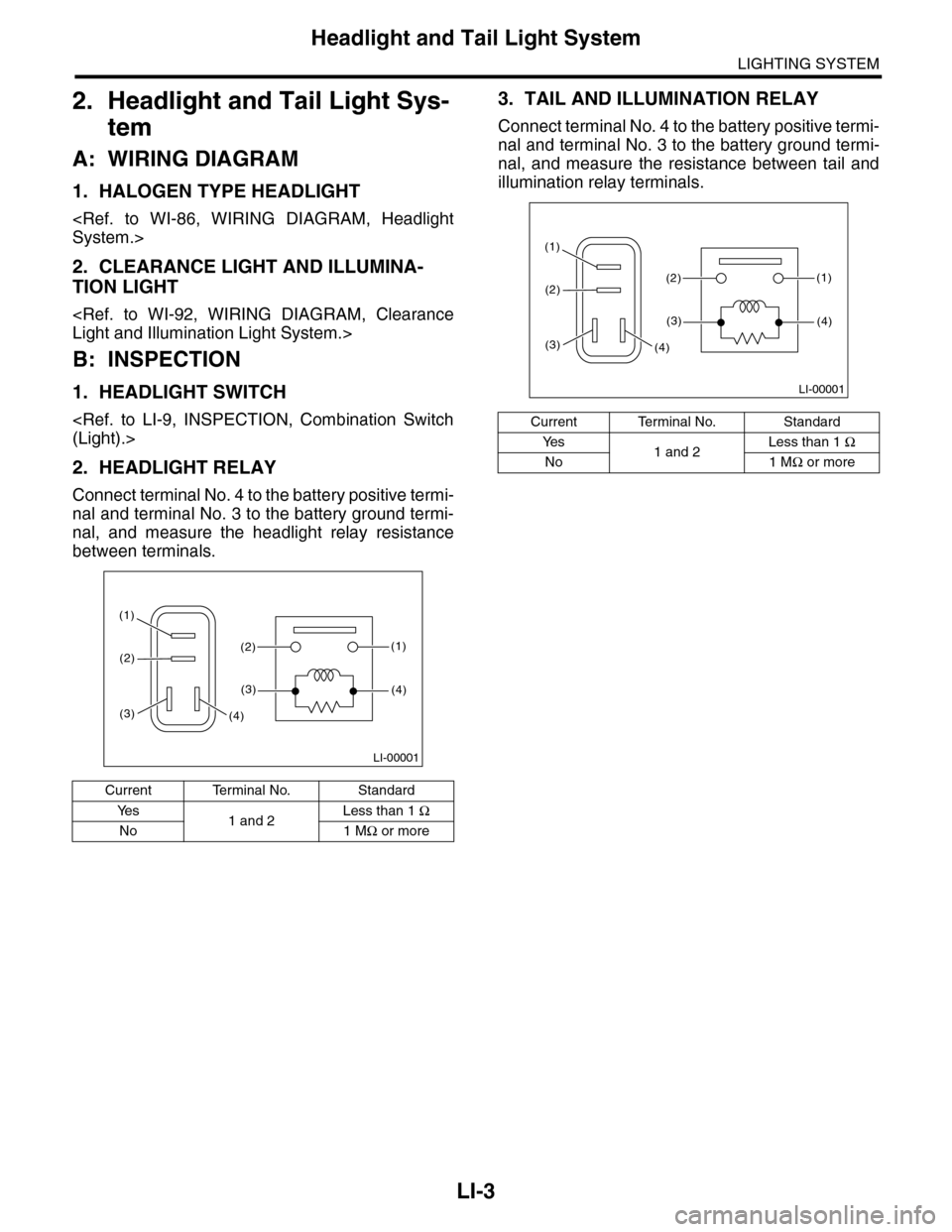

2. HEADLIGHT RELAY

Connect terminal No. 4 to the battery positive termi-

nal and terminal No. 3 to the battery ground termi-

nal, and measure the headlight relay resistance

between terminals.

3. TAIL AND ILLUMINATION RELAY

Connect terminal No. 4 to the battery positive termi-

nal and terminal No. 3 to the battery ground termi-

nal, and measure the resistance between tail and

illumination relay terminals.

Current Terminal No. Standard

Ye s1 and 2Less than 1 Ω

No 1 MΩ or more

LI-00001

(1)(2)

(1)

(4)

(2)

(3)

(3)(4)

Current Terminal No. Standard

Ye s1 and 2Less than 1 Ω

No 1 MΩ or more

LI-00001

(1)(2)

(1)

(4)

(2)

(3)

(3)(4)

Page 537 of 2453

LI-4

Front Fog Light System

LIGHTING SYSTEM

3. Front Fog Light System

A: WIRING DIAGRAM

1. FRONT FOG LIGHT

B: INSPECTION

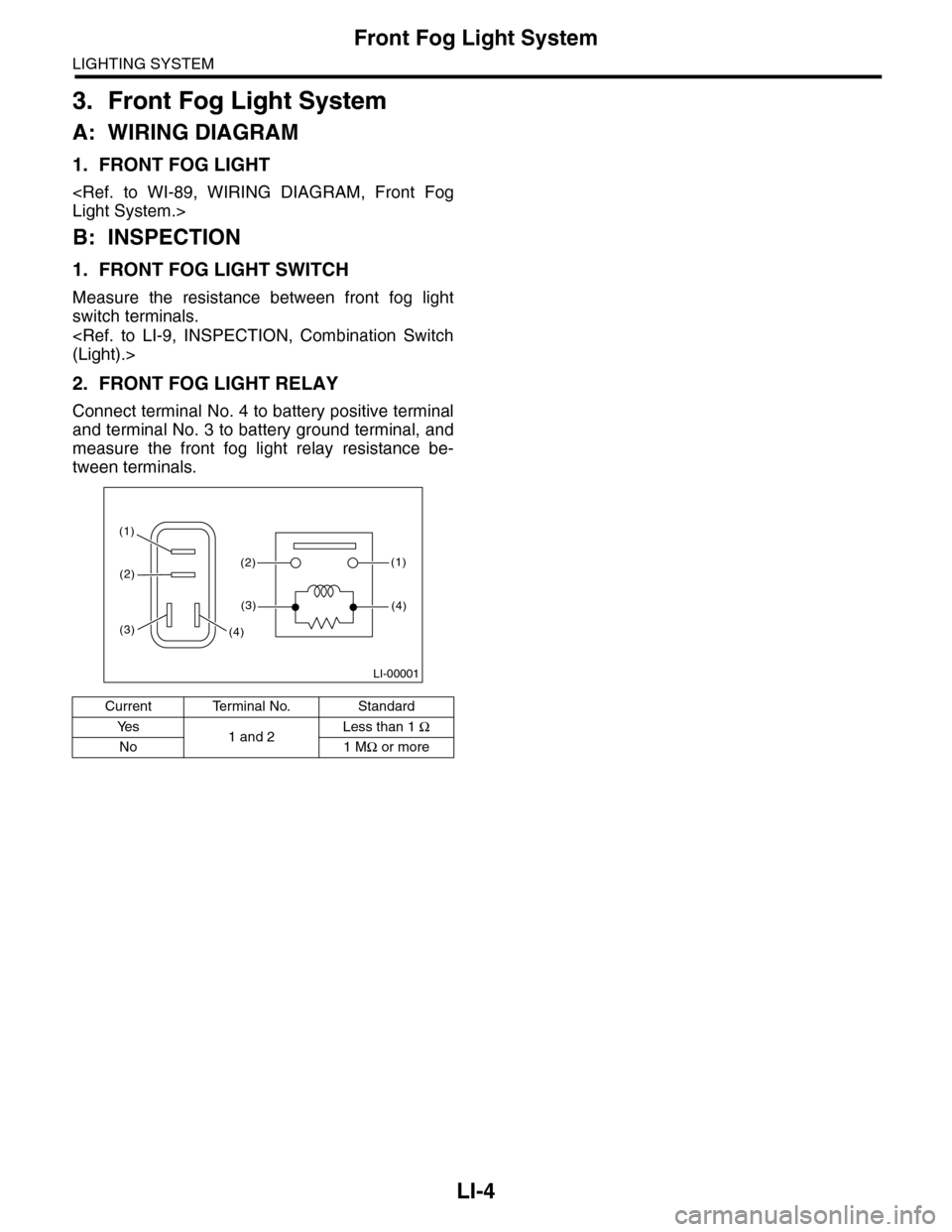

1. FRONT FOG LIGHT SWITCH

Measure the resistance between front fog light

switch terminals.

2. FRONT FOG LIGHT RELAY

Connect terminal No. 4 to battery positive terminal

and terminal No. 3 to battery ground terminal, and

measure the front fog light relay resistance be-

tween terminals.

Current Terminal No. Standard

Ye s1 and 2Less than 1 Ω

No 1 MΩ or more

LI-00001

(1)(2)

(1)

(4)

(2)

(3)

(3)(4)

Page 538 of 2453

LI-5

Turn Signal Light and Hazard Light System

LIGHTING SYSTEM

4. Turn Signal Light and Hazard

Light System

A: WIRING DIAGRAM

1. TURN SIGNAL LIGHT AND HAZARD

LIGHT

B: INSPECTION

1. TURN SIGNAL SWITCH

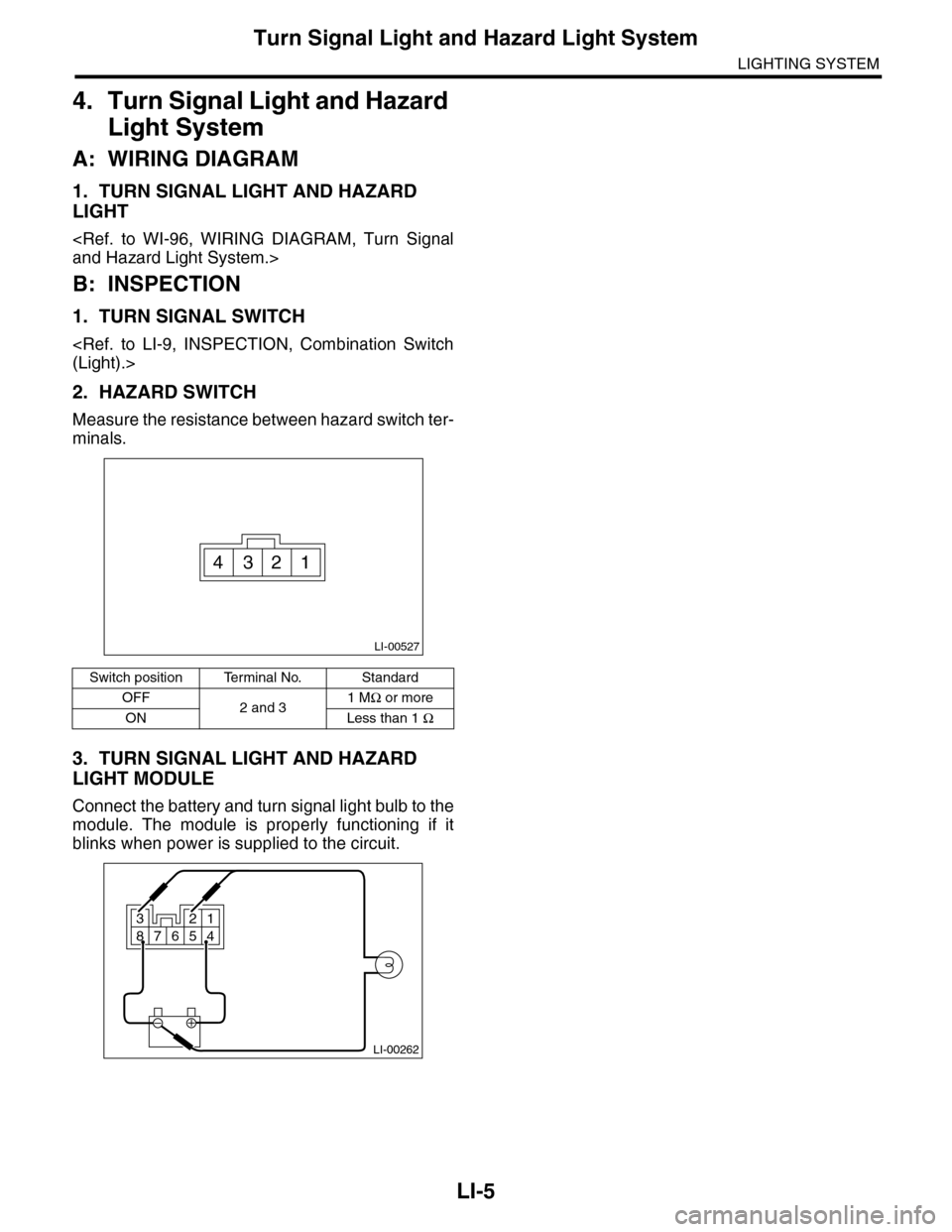

2. HAZARD SWITCH

Measure the resistance between hazard switch ter-

minals.

3. TURN SIGNAL LIGHT AND HAZARD

LIGHT MODULE

Connect the battery and turn signal light bulb to the

module. The module is properly functioning if it

blinks when power is supplied to the circuit.

Switch position Terminal No. Standard

OFF2 and 31 MΩ or more

ON Less than 1 Ω

LI-00527

4321

LI-00262

321

87654

Page 539 of 2453

LI-6

Back-up Light System

LIGHTING SYSTEM

5. Back-up Light System

A: WIRING DIAGRAM

1. BACK-UP LIGHT

B: INSPECTION

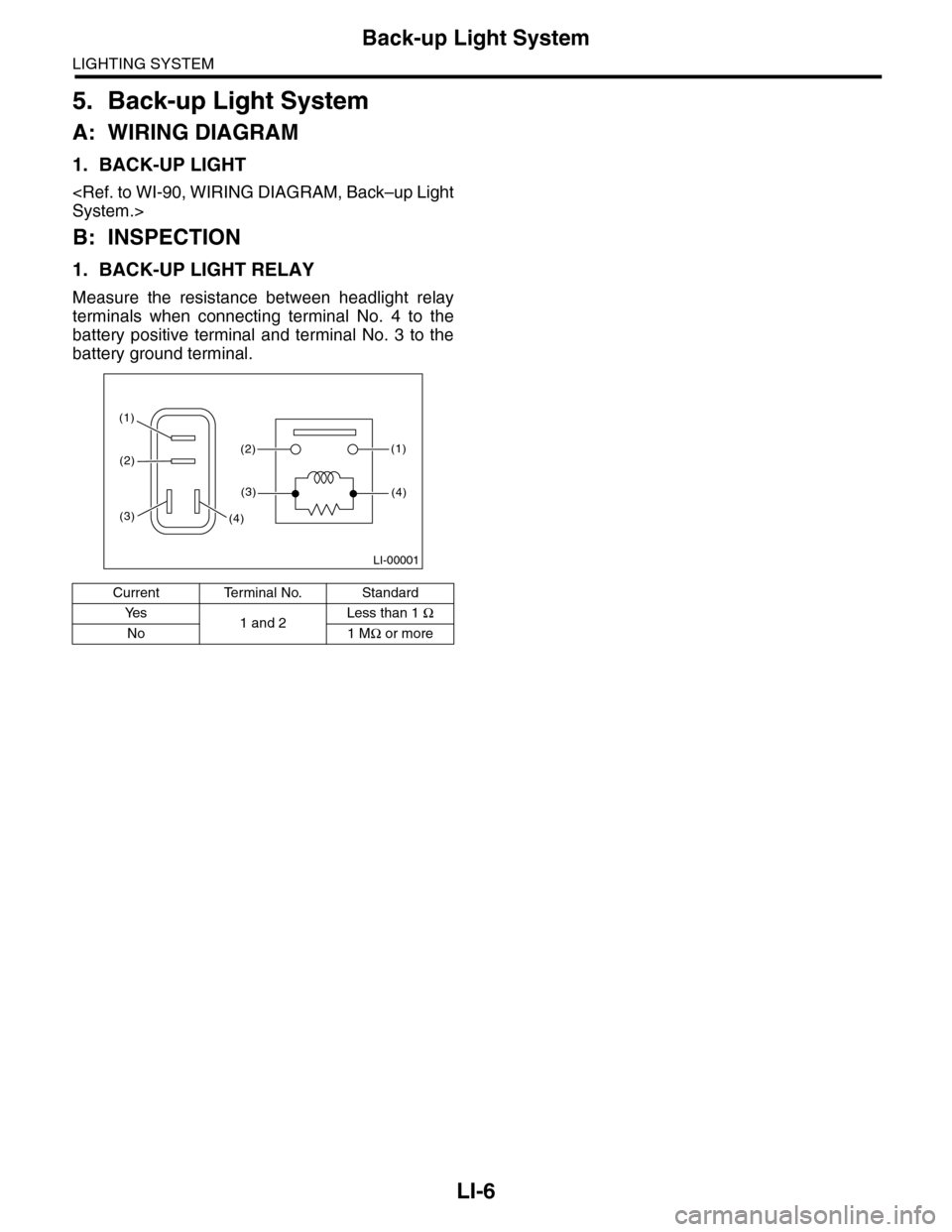

1. BACK-UP LIGHT RELAY

Measure the resistance between headlight relay

terminals when connecting terminal No. 4 to the

battery positive terminal and terminal No. 3 to the

battery ground terminal.

Current Terminal No. Standard

Ye s1 and 2Less than 1 Ω

No 1 MΩ or more

LI-00001

(1)(2)

(1)

(4)

(2)

(3)

(3)(4)

Page 540 of 2453

LI-7

Stop Light System

LIGHTING SYSTEM

6. Stop Light System

A: WIRING DIAGRAM

1. STOP LIGHT

B: INSPECTION

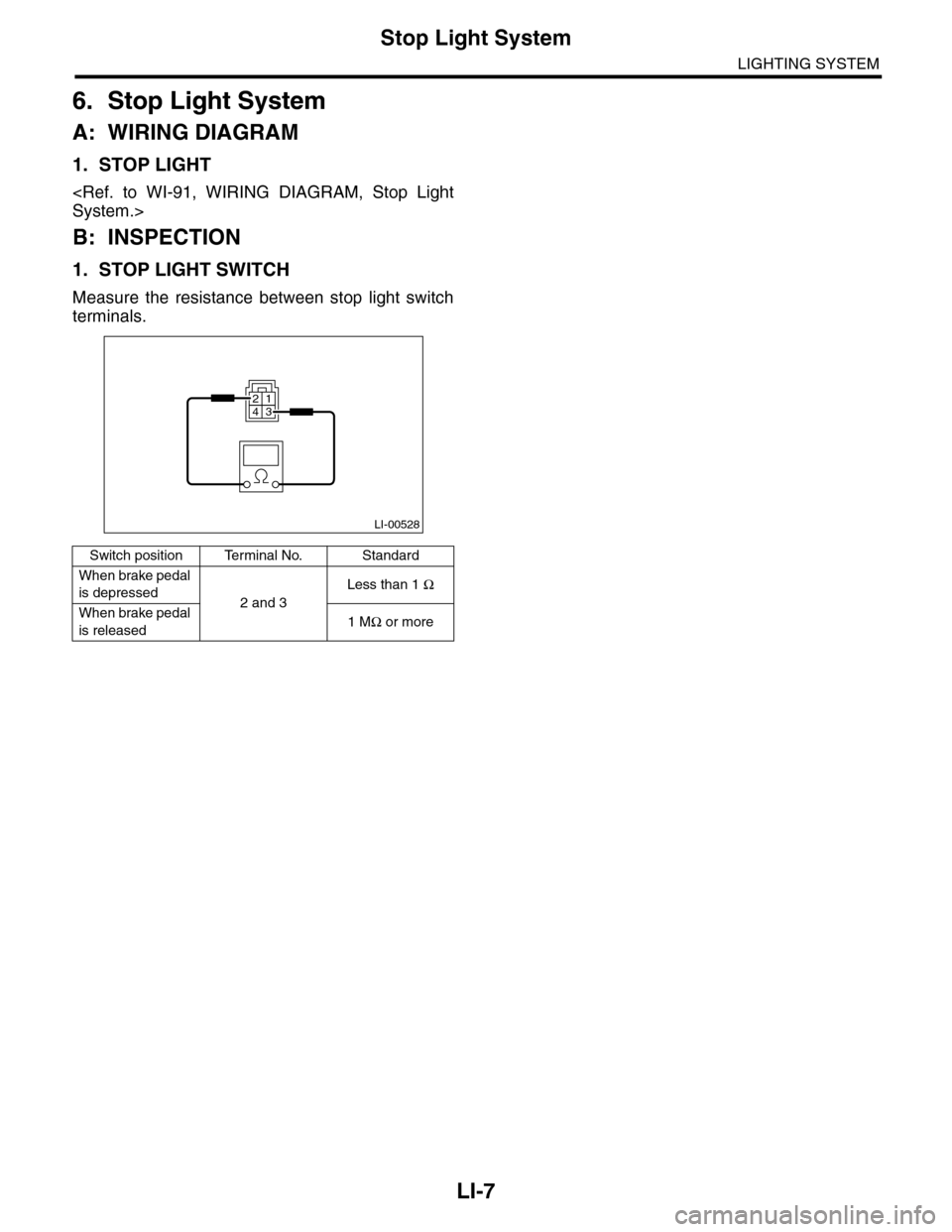

1. STOP LIGHT SWITCH

Measure the resistance between stop light switch

terminals.

Switch position Terminal No. Standard

When brake pedal

is depressed2 and 3

Less than 1 Ω

When brake pedal

is released1 MΩ or more

LI-00528

3412