SUBARU TRIBECA 2009 1.G Service Workshop Manual

Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 821 of 2453

DS-4

General Description

DRIVE SHAFT SYSTEM

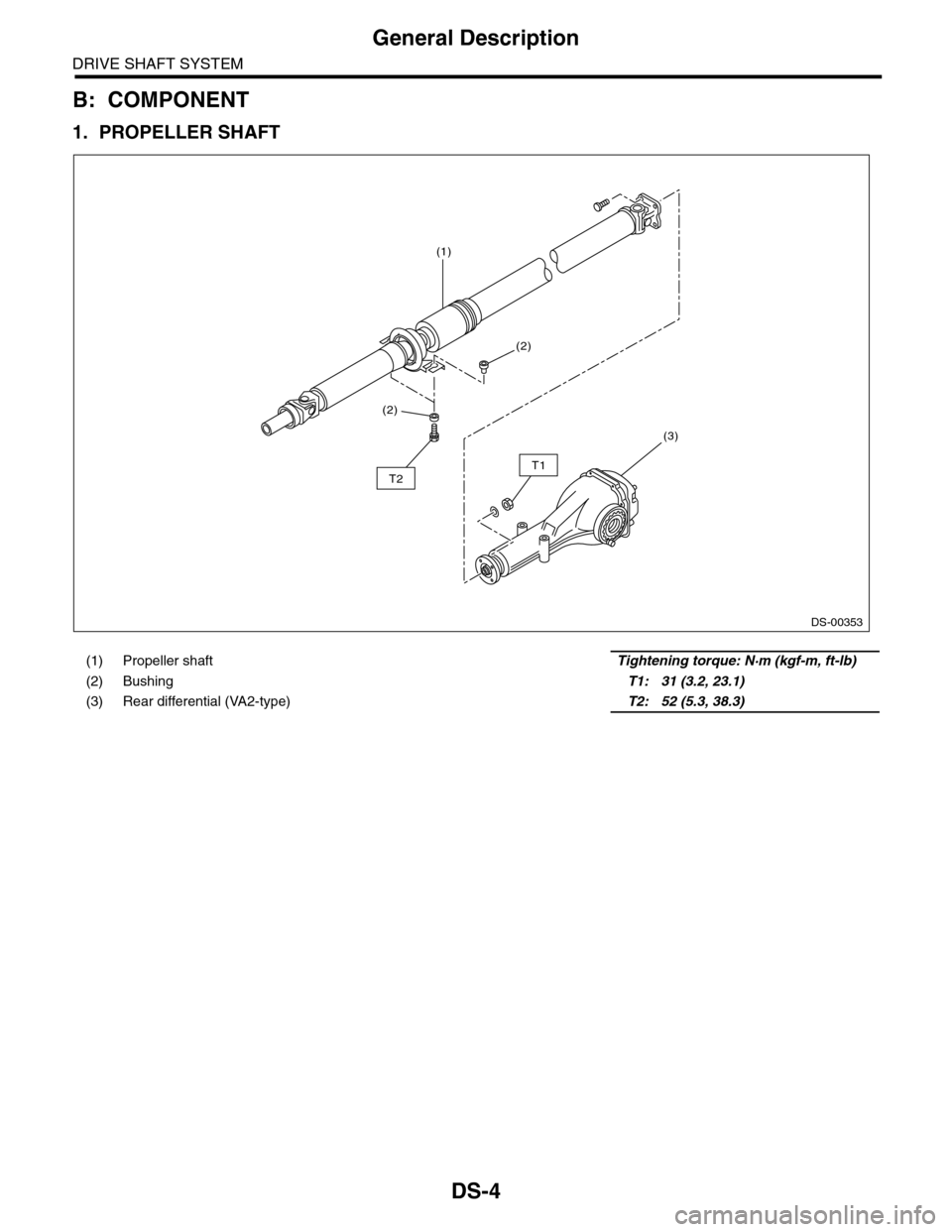

B: COMPONENT

1. PROPELLER SHAFT

(1) Propeller shaft Tightening torque: N·m (kgf-m, ft-lb)

(2) Bushing T1: 31 (3.2, 23.1)

(3) Rear differential (VA2-type) T2: 52 (5.3, 38.3)

DS-00353

(2)

(2)

T2

(1)

(3)

T1

Page 822 of 2453

DS-5

General Description

DRIVE SHAFT SYSTEM

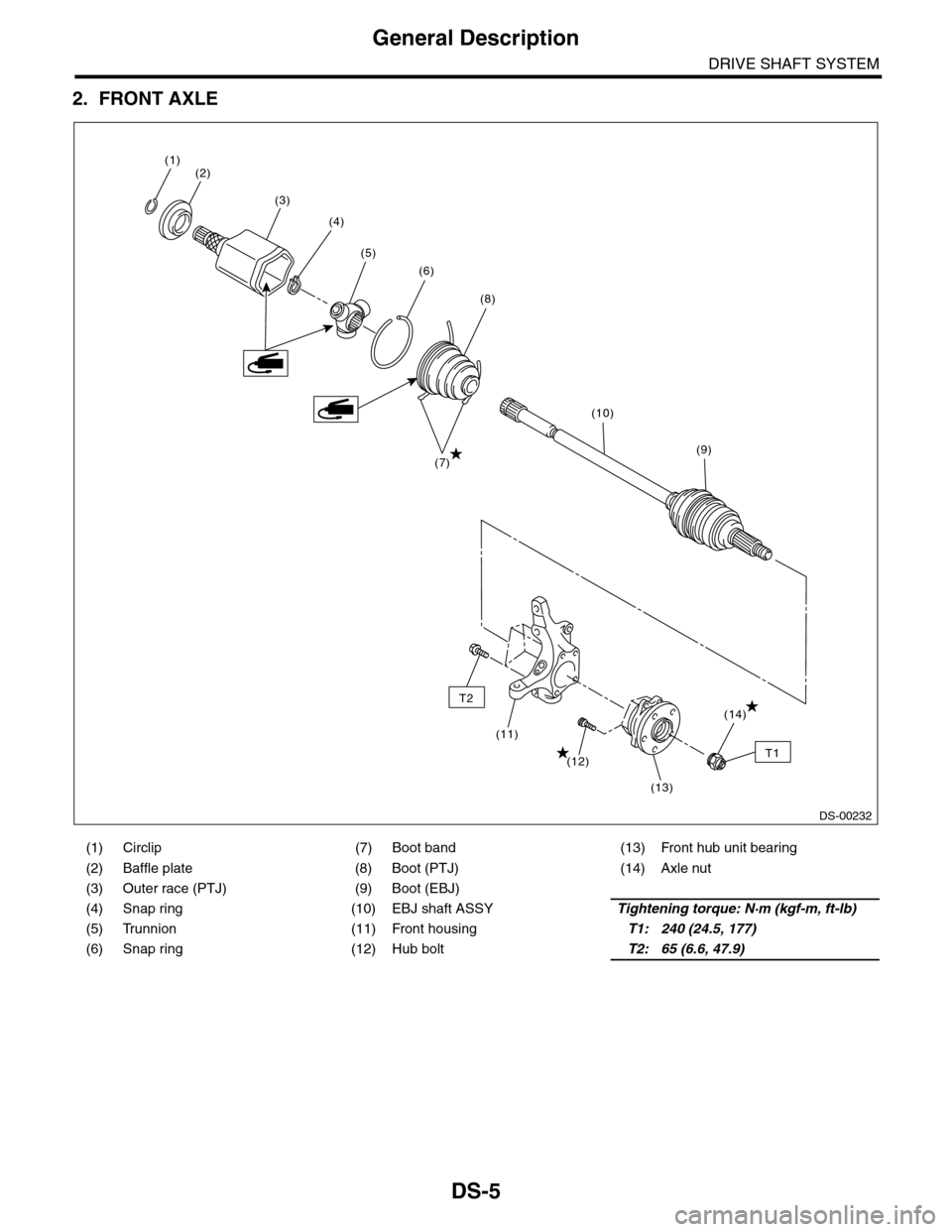

2. FRONT AXLE

(1) Circlip (7) Boot band (13) Front hub unit bearing

(2) Baffle plate (8) Boot (PTJ) (14) Axle nut

(3) Outer race (PTJ) (9) Boot (EBJ)

(4) Snap ring (10) EBJ shaft ASSYTightening torque: N·m (kgf-m, ft-lb)

(5) Trunnion (11) Front housingT1: 240 (24.5, 177)

(6) Snap ring (12) Hub boltT2: 65 (6.6, 47.9)

(3)

(2)(1)

(13)

(4)

(5)

(14)

(9)

(10)

(12)

(7)

(6)

(11)

T2

T1

(8)

DS-00232

Page 823 of 2453

DS-6

General Description

DRIVE SHAFT SYSTEM

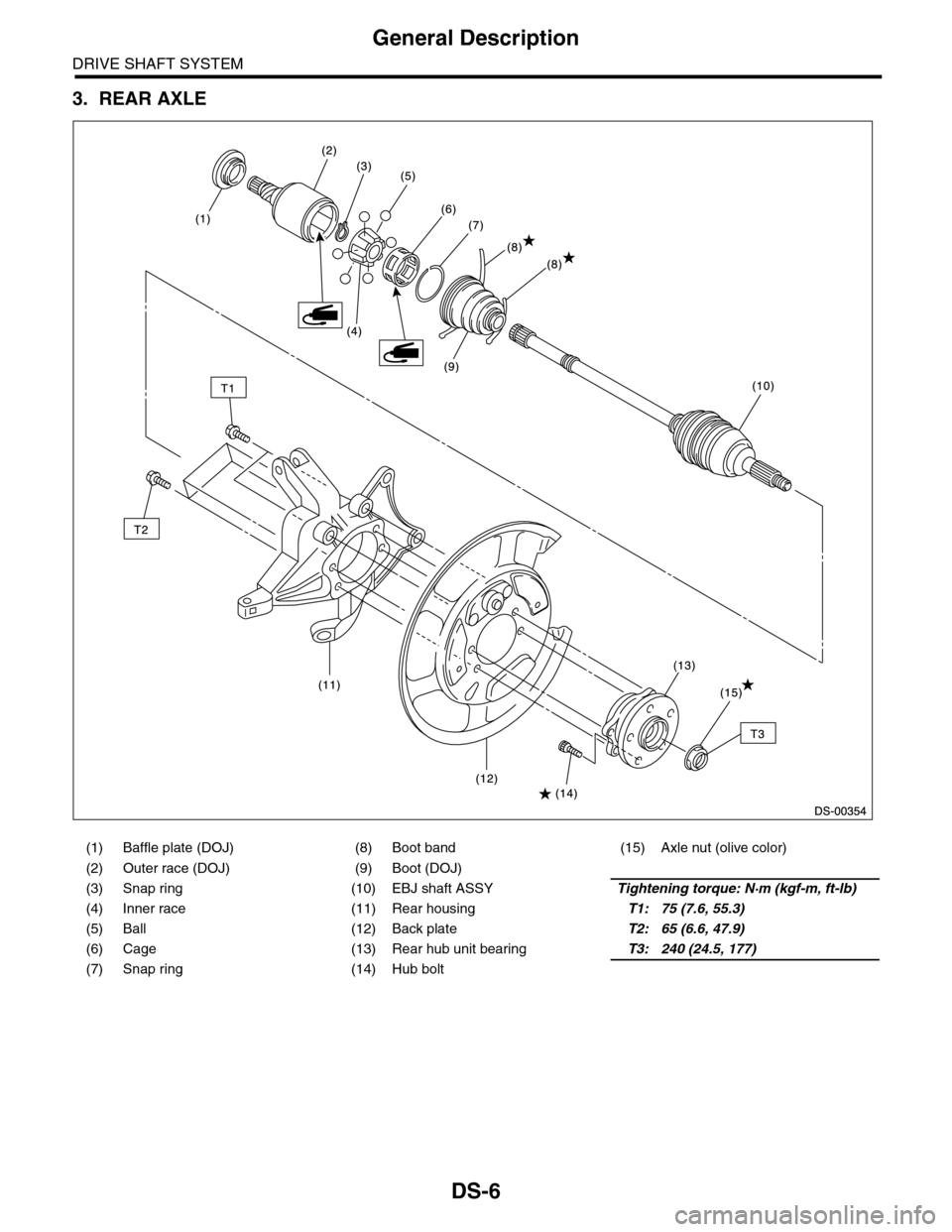

3. REAR AXLE

(1) Baffle plate (DOJ) (8) Boot band (15) Axle nut (olive color)

(2) Outer race (DOJ) (9) Boot (DOJ)

(3) Snap ring (10) EBJ shaft ASSYTightening torque: N·m (kgf-m, ft-lb)

(4) Inner race (11) Rear housingT1: 75 (7.6, 55.3)

(5) Ball (12) Back plateT2: 65 (6.6, 47.9)

(6) Cage (13) Rear hub unit bearingT3: 240 (24.5, 177)

(7) Snap ring (14) Hub bolt

Page 824 of 2453

DS-7

General Description

DRIVE SHAFT SYSTEM

C: CAUTION

Please clearly understand and adhere to the follow-

ing general precautions. They must be strictly fol-

lowed to avoid any injury to the person doing the

work or people in the area.

1. OPERATION

•Wear work clothing, including a cap, protective

goggles and protective shoes during operation.

•Remove contamination including dirt and corro-

sion before removal, installation or disassembly.

•Keep the disassembled parts in order and pro-

tect them from dust and dirt.

•Before removal, installation or disassembly, be

sure to clarify the failure. Avoid unnecessary re-

moval, installation, disassembly and replacement.

•Be careful not to burn yourself, because each

part on the vehicle is hot after running.

•Use SUBARU genuine grease etc. or equivalent.

Do not mix grease etc. with that of another grade or

from other manufacturers.

•Be sure to tighten fasteners including bolts and

nuts to the specified torque.

•Place shop jacks or rigid racks at the specified

points.

• Apply grease onto sliding or revolution surfaces

before installation.

•Before installing snap rings, apply sufficient

amount of grease to avoid damage and deforma-

tion.

•Before securing a part on a vise, place cushion-

ing material such as wood blocks, aluminum plate,

or shop cloth between the part and the vise.

2. OIL

When handling oil, follow the rules below to prevent

unexpected accidents.

•Prepare container and waste cloths when per-

forming work which oil could possibly spill. If oil

spills, wipe it off immediately to prevent from pene-

trating into floor or flowing outside, for environmen-

tal protection.

•Follow all government and local regulations con-

cerning waste disposal.

Page 825 of 2453

DS-8

General Description

DRIVE SHAFT SYSTEM

D: PREPARATION TOOL

1. SPECIAL TOOL

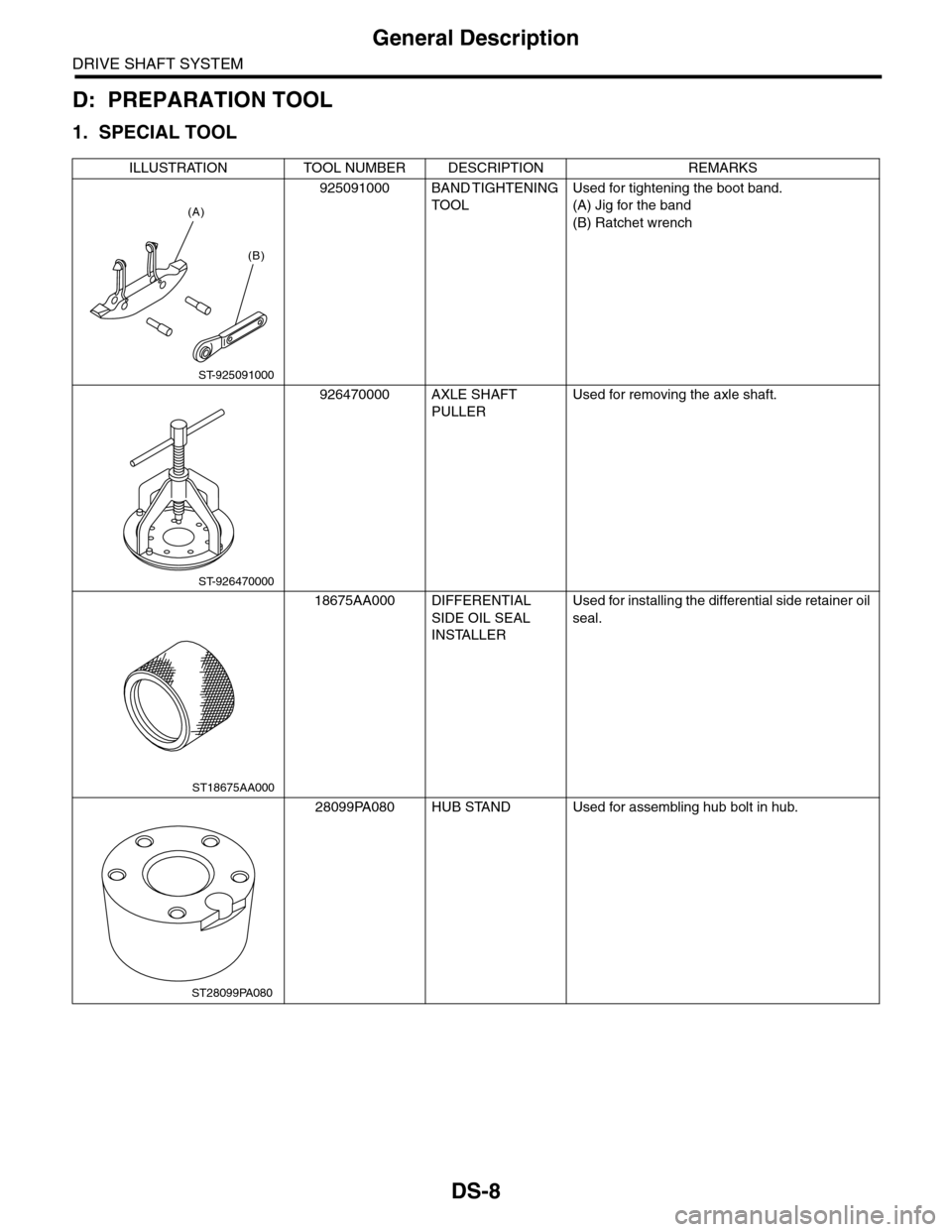

ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

925091000 BAND TIGHTENING

TOOL

Used for tightening the boot band.

(A) Jig for the band

(B) Ratchet wrench

926470000 AXLE SHAFT

PULLER

Used for removing the axle shaft.

18675AA000 DIFFERENTIAL

SIDE OIL SEAL

INSTALLER

Used for installing the differential side retainer oil

seal.

28099PA080 HUB STAND Used for assembling hub bolt in hub.

ST-925091000

(A)

(B)

ST-926470000

ST18675AA000

ST28099PA080

Page 826 of 2453

DS-9

General Description

DRIVE SHAFT SYSTEM

2. GENERAL TOOL

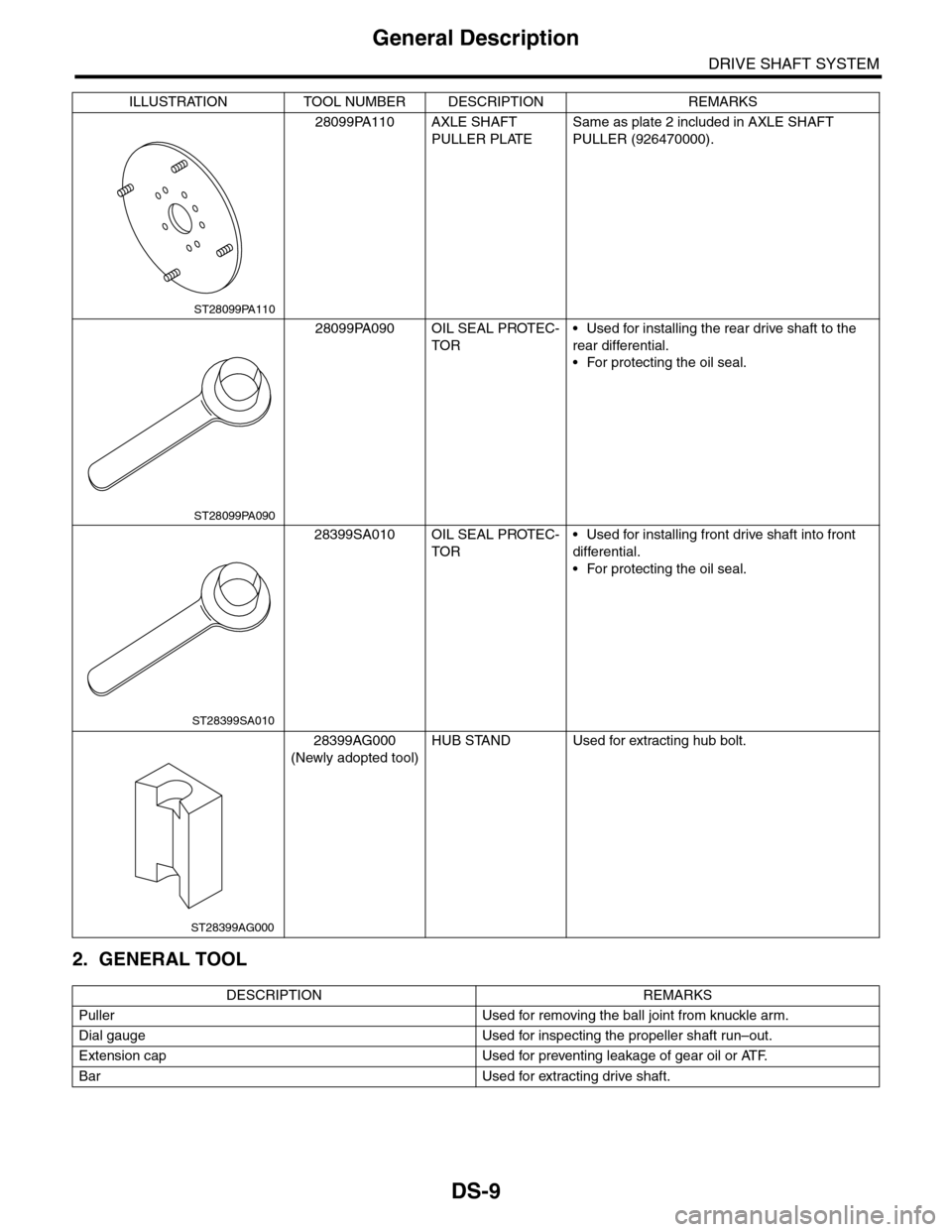

28099PA110 AXLE SHAFT

PULLER PLATE

Same as plate 2 included in AXLE SHAFT

PULLER (926470000).

28099PA090 OIL SEAL PROTEC-

TOR

•Used for installing the rear drive shaft to the

rear differential.

•For protecting the oil seal.

28399SA010 OIL SEAL PROTEC-

TOR

•Used for installing front drive shaft into front

differential.

•For protecting the oil seal.

28399AG000

(Newly adopted tool)

HUB STAND Used for extracting hub bolt.

DESCRIPTION REMARKS

Puller Used for removing the ball joint from knuckle arm.

Dial gauge Used for inspecting the propeller shaft run–out.

Extension cap Used for preventing leakage of gear oil or ATF.

Bar Used for extracting drive shaft.

ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

ST28099PA110

ST28099PA090

ST28399SA010

ST28399AG000

Page 827 of 2453

DS-10

Propeller Shaft

DRIVE SHAFT SYSTEM

2. Propeller Shaft

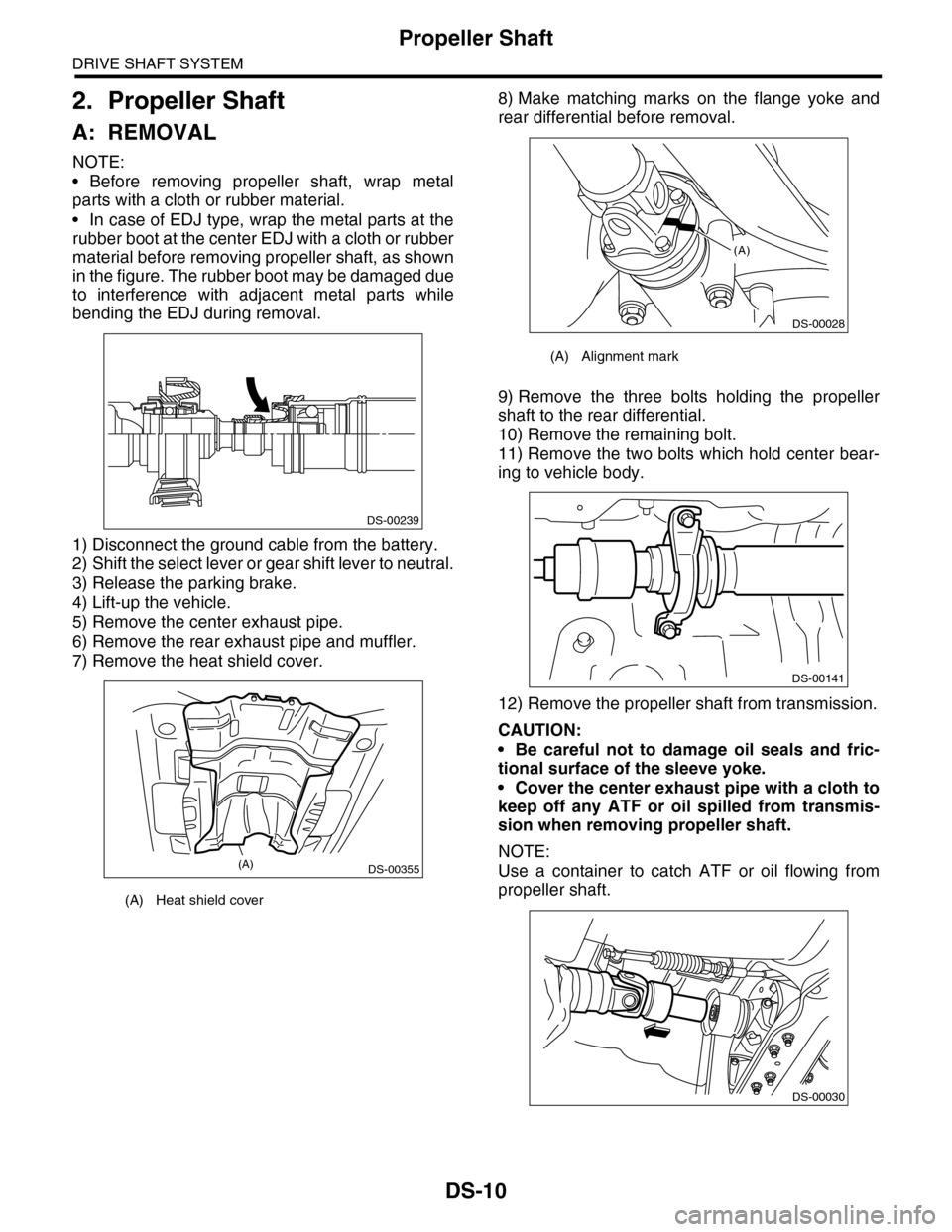

A: REMOVAL

NOTE:

•Before removing propeller shaft, wrap metal

parts with a cloth or rubber material.

•In case of EDJ type, wrap the metal parts at the

rubber boot at the center EDJ with a cloth or rubber

material before removing propeller shaft, as shown

in the figure. The rubber boot may be damaged due

to interference with adjacent metal parts while

bending the EDJ during removal.

1) Disconnect the ground cable from the battery.

2) Shift the select lever or gear shift lever to neutral.

3) Release the parking brake.

4) Lift-up the vehicle.

5) Remove the center exhaust pipe.

6) Remove the rear exhaust pipe and muffler.

7) Remove the heat shield cover.

8) Make matching marks on the flange yoke and

rear differential before removal.

9) Remove the three bolts holding the propeller

shaft to the rear differential.

10) Remove the remaining bolt.

11) Remove the two bolts which hold center bear-

ing to vehicle body.

12) Remove the propeller shaft from transmission.

CAUTION:

•Be careful not to damage oil seals and fric-

tional surface of the sleeve yoke.

•Cover the center exhaust pipe with a cloth to

keep off any ATF or oil spilled from transmis-

sion when removing propeller shaft.

NOTE:

Use a container to catch ATF or oil flowing from

propeller shaft.(A) Heat shield cover

DS-00239

DS-00355(A)

(A) Alignment mark

DS-00028

(A)

DS-00141

DS-00030

Page 828 of 2453

DS-11

Propeller Shaft

DRIVE SHAFT SYSTEM

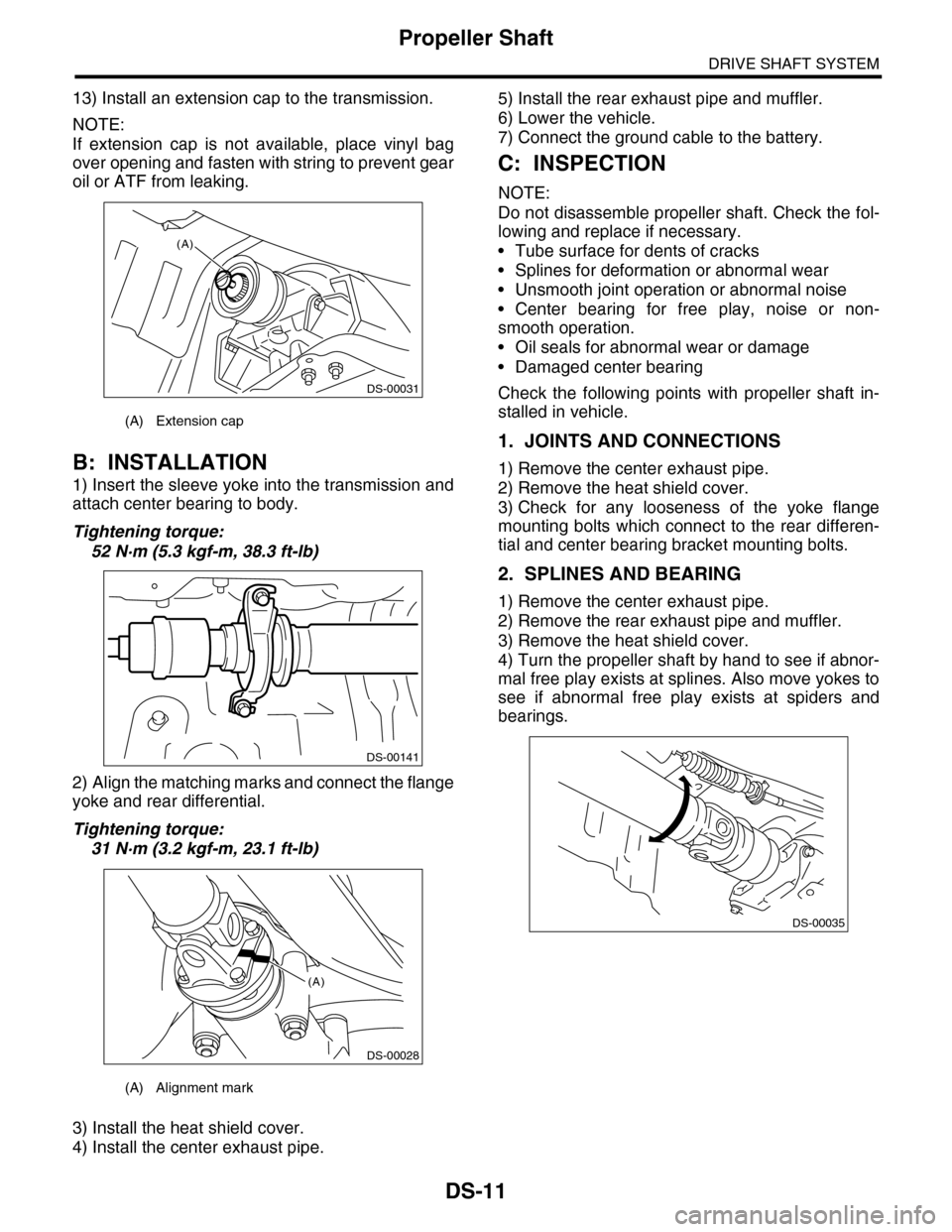

13) Install an extension cap to the transmission.

NOTE:

If extension cap is not available, place vinyl bag

over opening and fasten with string to prevent gear

oil or ATF from leaking.

B: INSTALLATION

1) Insert the sleeve yoke into the transmission and

attach center bearing to body.

Tightening torque:

52 N·m (5.3 kgf-m, 38.3 ft-lb)

2) Align the matching marks and connect the flange

yoke and rear differential.

Tightening torque:

31 N·m (3.2 kgf-m, 23.1 ft-lb)

3) Install the heat shield cover.

4) Install the center exhaust pipe.

5) Install the rear exhaust pipe and muffler.

6) Lower the vehicle.

7) Connect the ground cable to the battery.

C: INSPECTION

NOTE:

Do not disassemble propeller shaft. Check the fol-

lowing and replace if necessary.

•Tube surface for dents of cracks

•Splines for deformation or abnormal wear

•Unsmooth joint operation or abnormal noise

•Center bearing for free play, noise or non-

smooth operation.

•Oil seals for abnormal wear or damage

•Damaged center bearing

Check the following points with propeller shaft in-

stalled in vehicle.

1. JOINTS AND CONNECTIONS

1) Remove the center exhaust pipe.

2) Remove the heat shield cover.

3) Check for any looseness of the yoke flange

mounting bolts which connect to the rear differen-

tial and center bearing bracket mounting bolts.

2. SPLINES AND BEARING

1) Remove the center exhaust pipe.

2) Remove the rear exhaust pipe and muffler.

3) Remove the heat shield cover.

4) Turn the propeller shaft by hand to see if abnor-

mal free play exists at splines. Also move yokes to

see if abnormal free play exists at spiders and

bearings.

(A) Extension cap

(A) Alignment mark

DS-00031

(A)

DS-00141

DS-00028

(A)

DS-00035

Page 829 of 2453

DS-12

Propeller Shaft

DRIVE SHAFT SYSTEM

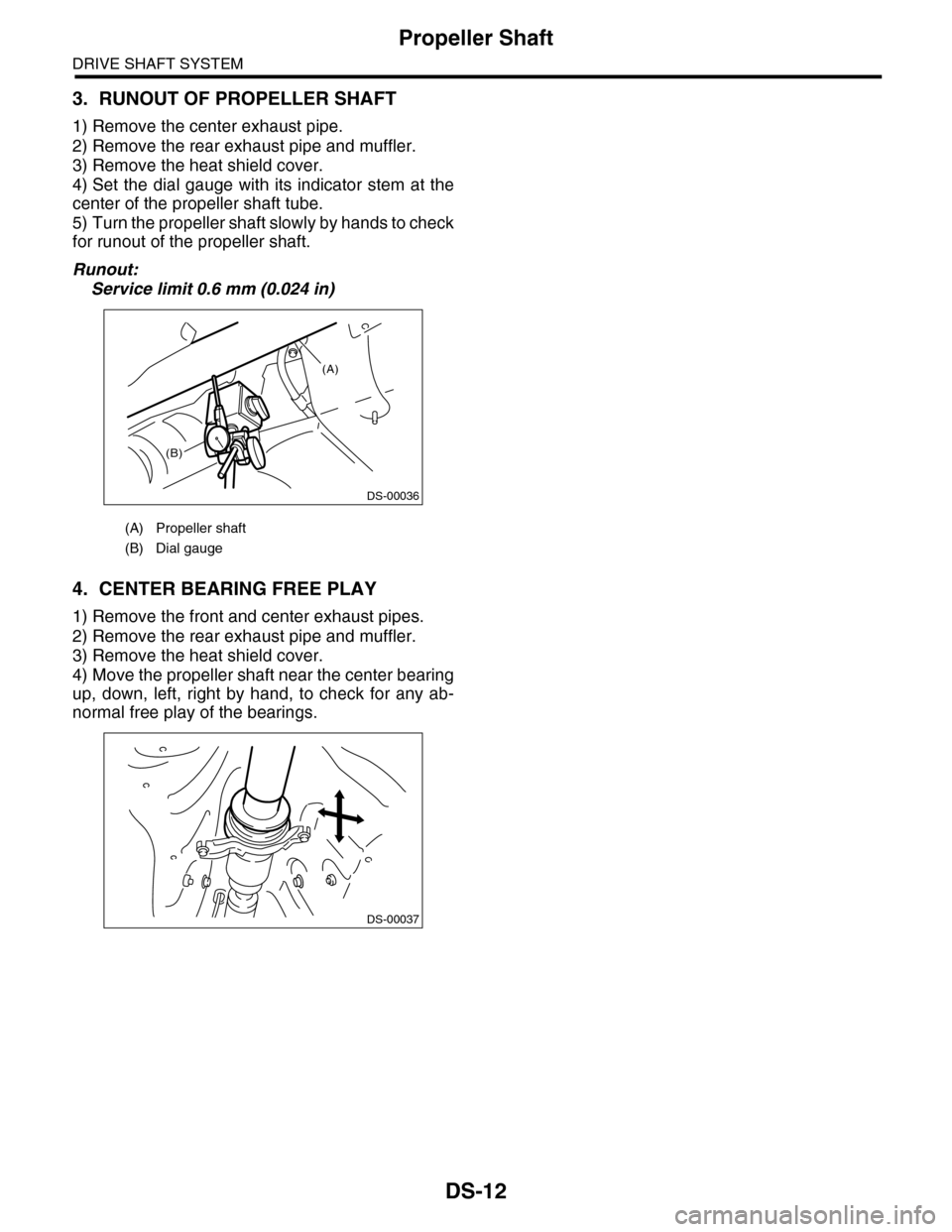

3. RUNOUT OF PROPELLER SHAFT

1) Remove the center exhaust pipe.

2) Remove the rear exhaust pipe and muffler.

3) Remove the heat shield cover.

4) Set the dial gauge with its indicator stem at the

center of the propeller shaft tube.

5) Turn the propeller shaft slowly by hands to check

for runout of the propeller shaft.

Runout:

Service limit 0.6 mm (0.024 in)

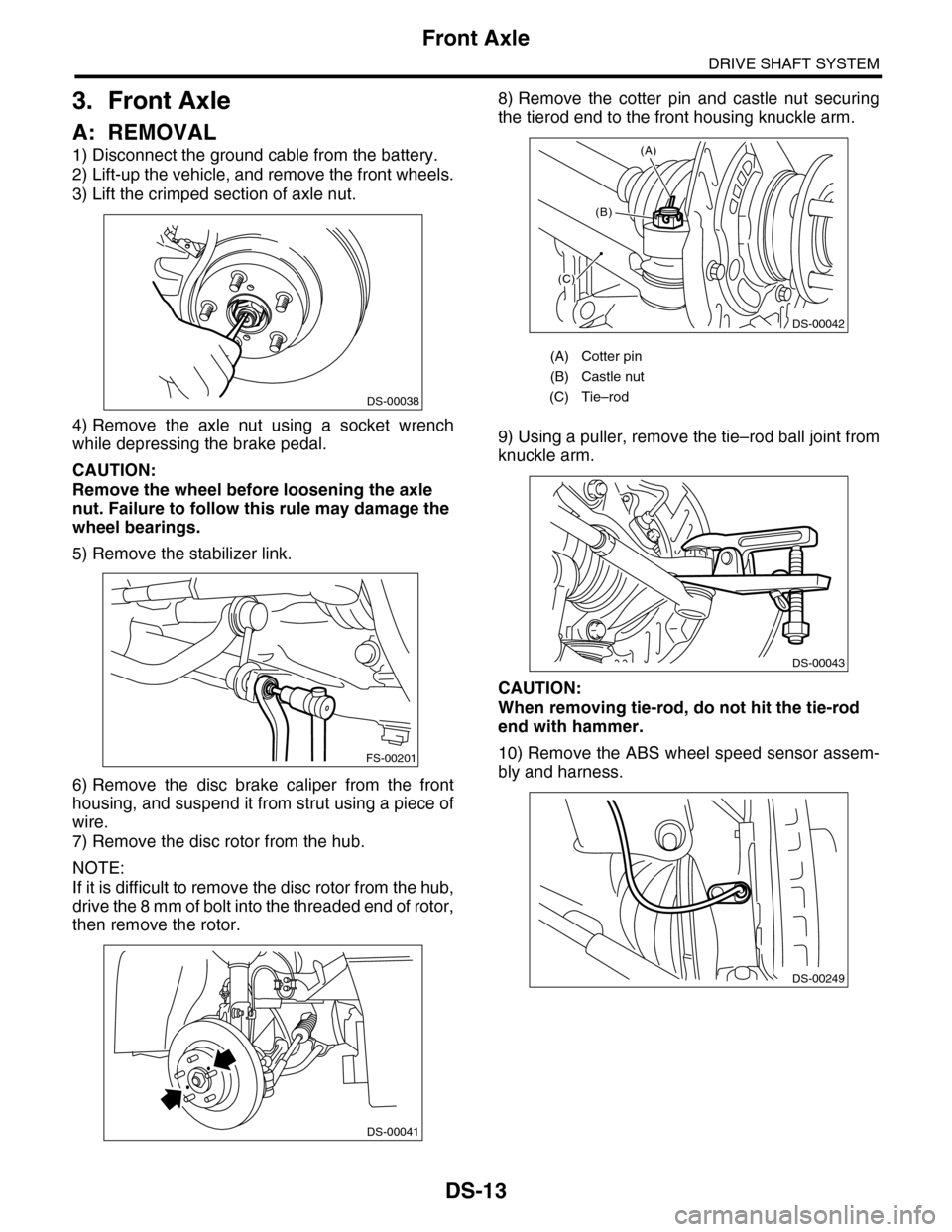

4. CENTER BEARING FREE PLAY

1) Remove the front and center exhaust pipes.

2) Remove the rear exhaust pipe and muffler.

3) Remove the heat shield cover.

4) Move the propeller shaft near the center bearing

up, down, left, right by hand, to check for any ab-

normal free play of the bearings.

(A) Propeller shaft

(B) Dial gauge

DS-00036

(B)

(A)

DS-00037

Page 830 of 2453

DS-13

Front Axle

DRIVE SHAFT SYSTEM

3. Front Axle

A: REMOVAL

1) Disconnect the ground cable from the battery.

2) Lift-up the vehicle, and remove the front wheels.

3) Lift the crimped section of axle nut.

4) Remove the axle nut using a socket wrench

while depressing the brake pedal.

CAUTION:

Remove the wheel before loosening the axle

nut. Failure to follow this rule may damage the

wheel bearings.

5) Remove the stabilizer link.

6) Remove the disc brake caliper from the front

housing, and suspend it from strut using a piece of

wire.

7) Remove the disc rotor from the hub.

NOTE:

If it is difficult to remove the disc rotor from the hub,

drive the 8 mm of bolt into the threaded end of rotor,

then remove the rotor.

8) Remove the cotter pin and castle nut securing

the tierod end to the front housing knuckle arm.

9) Using a puller, remove the tie–rod ball joint from

knuckle arm.

CAUTION:

When removing tie-rod, do not hit the tie-rod

end with hammer.

10) Remove the ABS wheel speed sensor assem-

bly and harness.

DS-00038

FS-00201

DS-00041

(A) Cotter pin

(B) Castle nut

(C) Tie–rod

DS-00042

(C)

(B)

(A)

DS-00043

DS-00249