SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 151 of 698

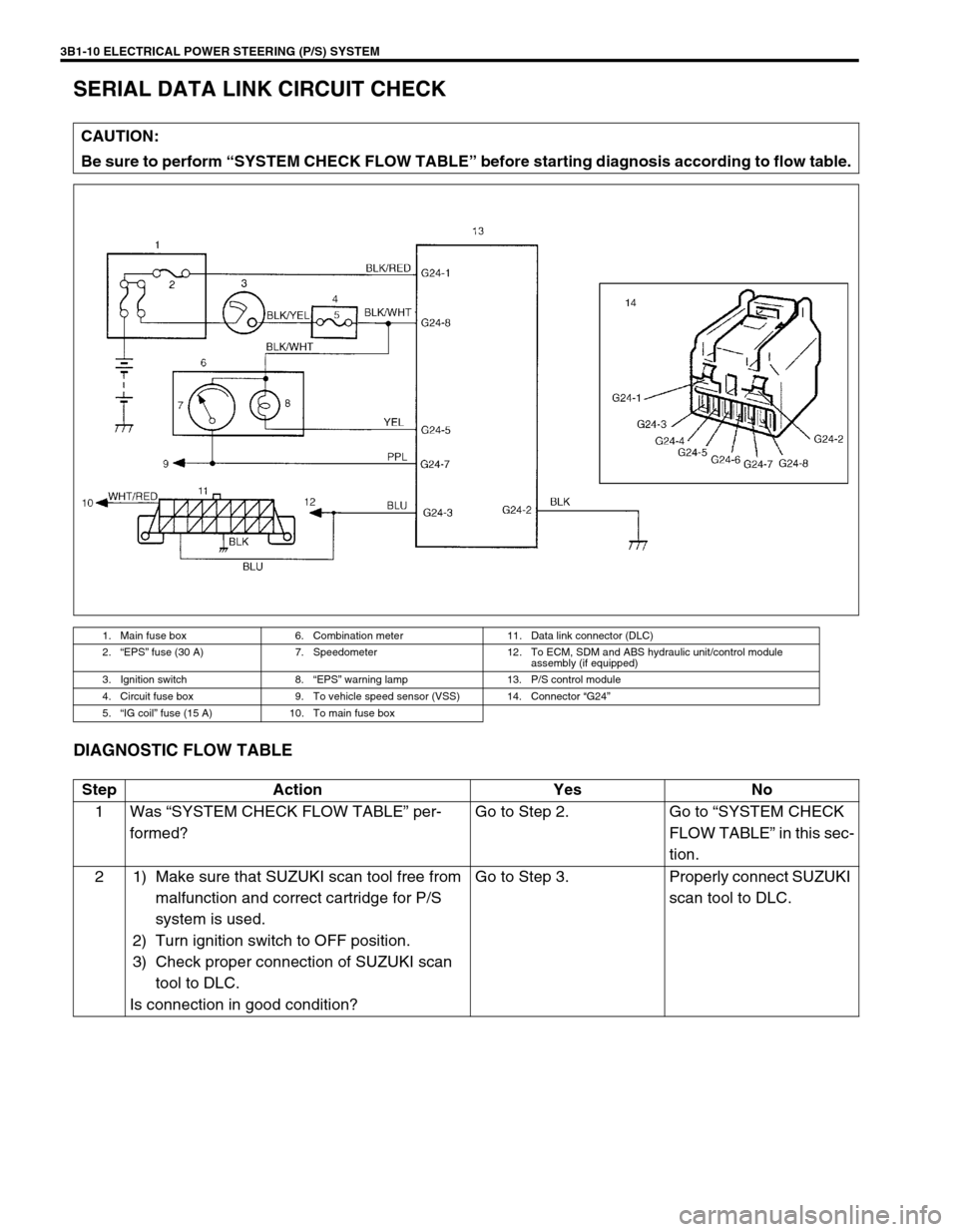

3B1-10 ELECTRICAL POWER STEERING (P/S) SYSTEM

SERIAL DATA LINK CIRCUIT CHECK

DIAGNOSTIC FLOW TABLE

CAUTION:

Be sure to perform “SYSTEM CHECK FLOW TABLE” before starting diagnosis according to flow table.

1. Main fuse box 6. Combination meter 11. Data link connector (DLC)

2.“EPS” fuse (30 A) 7. Speedometer 12. To ECM, SDM and ABS hydraulic unit/control module

assembly (if equipped)

3. Ignition switch 8.“EPS” warning lamp 13. P/S control module

4. Circuit fuse box 9. To vehicle speed sensor (VSS) 14. Connector “G24”

5.“IG coil” fuse (15 A) 10. To main fuse box

Step Action Yes No

1Was “SYSTEM CHECK FLOW TABLE” per-

formed?Go to Step 2. Go to “SYSTEM CHECK

FLOW TABLE” in this sec-

tion.

2 1) Make sure that SUZUKI scan tool free from

malfunction and correct cartridge for P/S

system is used.

2) Turn ignition switch to OFF position.

3) Check proper connection of SUZUKI scan

tool to DLC.

Is connection in good condition?Go to Step 3. Properly connect SUZUKI

scan tool to DLC.

Page 152 of 698

ELECTRICAL POWER STEERING (P/S) SYSTEM 3B1-11

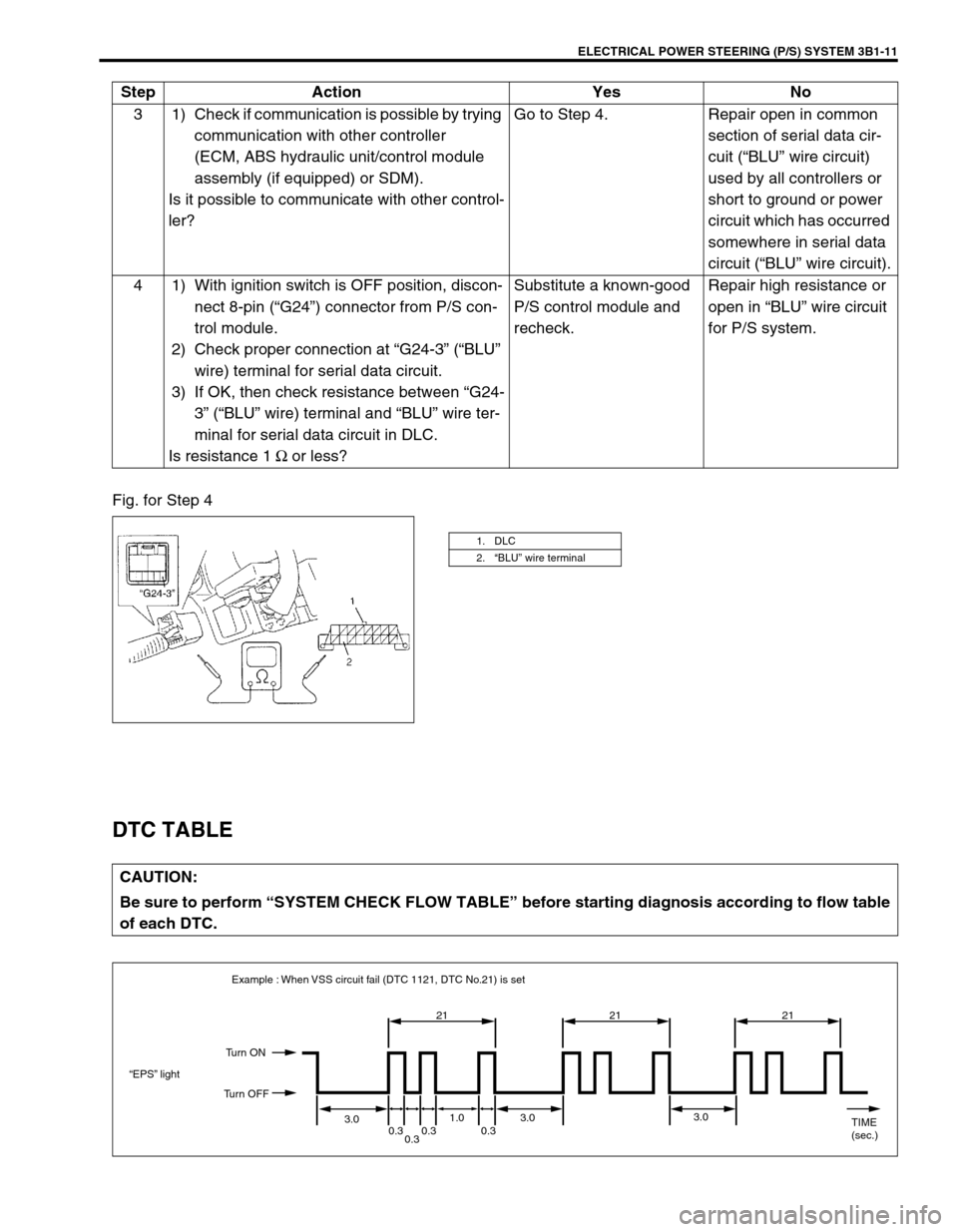

Fig. for Step 4

DTC TABLE

3 1) Check if communication is possible by trying

communication with other controller

(ECM, ABS hydraulic unit/control module

assembly (if equipped) or SDM).

Is it possible to communicate with other control-

ler?Go to Step 4. Repair open in common

section of serial data cir-

cuit (“BLU” wire circuit)

used by all controllers or

short to ground or power

circuit which has occurred

somewhere in serial data

circuit (“BLU” wire circuit).

4 1) With ignition switch is OFF position, discon-

nect 8-pin (“G24”) connector from P/S con-

trol module.

2) Check proper connection at “G24-3” (“BLU”

wire) terminal for serial data circuit.

3) If OK, then check resistance between “G24-

3” (“BLU” wire) terminal and “BLU” wire ter-

minal for serial data circuit in DLC.

Is resistance 1 Ω or less?Substitute a known-good

P/S control module and

recheck.Repair high resistance or

open in “BLU” wire circuit

for P/S system. Step Action Yes No

1. DLC

2.“BLU” wire terminal

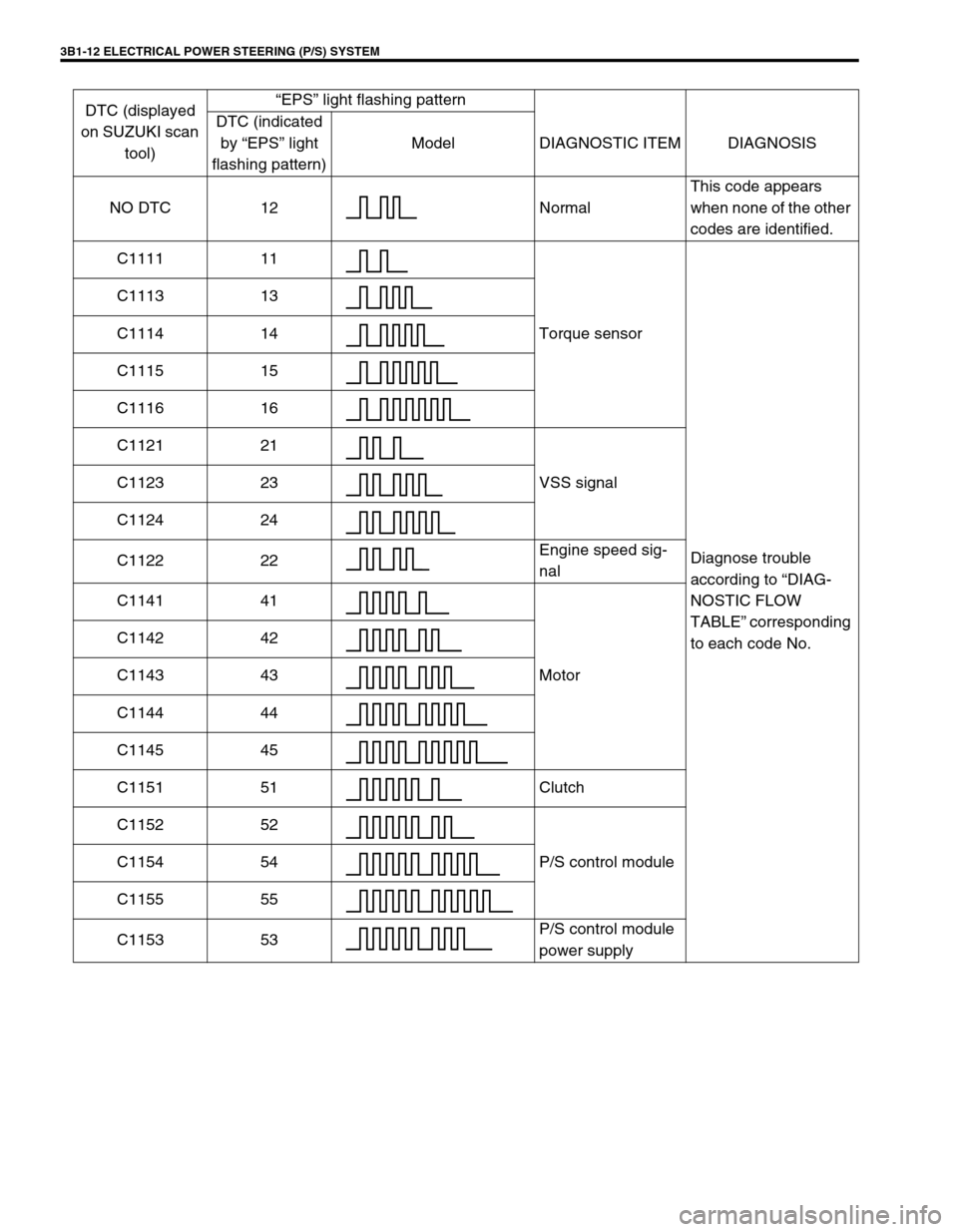

CAUTION:

Be sure to perform “SYSTEM CHECK FLOW TABLE” before starting diagnosis according to flow table

of each DTC.

21

3.0

0.3

0.30.3 0.31.0 3.03.0 21 21

Example : When VSS circuit fail (DTC 1121, DTC No.21) is set

“EPS” lightTurn ON

Turn OFF

TIME

(sec.)

Page 153 of 698

3B1-12 ELECTRICAL POWER STEERING (P/S) SYSTEM

DTC (displayed

on SUZUKI scan

tool)“EPS” light flashing pattern

DTC (indicated

by “EPS” light

flashing pattern)Model DIAGNOSTIC ITEM DIAGNOSIS

NO DTC 12 NormalThis code appears

when none of the other

codes are identified.

C1111 11

Torque sensor

Diagnose trouble

according to “DIAG-

NOSTIC FLOW

TABLE” corresponding

to each code No. C1113 13

C1114 14

C1115 15

C1116 16

C1121 21

VSS signal C1123 23

C1124 24

C1122 22Engine speed sig-

nal

C1141 41

Motor C1142 42

C1143 43

C1144 44

C1145 45

C1151 51 Clutch

C1152 52

P/S control module C1154 54

C1155 55

C1153 53P/S control module

power supply

Page 154 of 698

ELECTRICAL POWER STEERING (P/S) SYSTEM 3B1-13

TABLE A - MALFUNCTION INDICATOR LAMP DOES NOT COME ON AT IGNI-

TION SWITCH ON BUT LEAVING ENGINE OFF

CIRCUIT

1. To main fuse 5.“EPS” warning lamp 9. Ground terminal

2. Ignition switch 6. Combination meter 10. P/S control module

3.“P/S” fuse (30A) in fuse box 7. Monitor coupler 11. Connector “G24”

4.“IG METER” fuse (15A) in fuse box 8. Diagnosis switch terminal

G24-1

G24-8

G24-5

G24-4

G24-2 1

23

4

5 6

7

8

910

BLK/WHT

BLK/WHTBLK/RED

YEL

PPL/WHT

BLKBLK

87 7

6

G24-1

G24-4

G24-5

G24-8G24-2

11

Page 155 of 698

3B1-14 ELECTRICAL POWER STEERING (P/S) SYSTEM

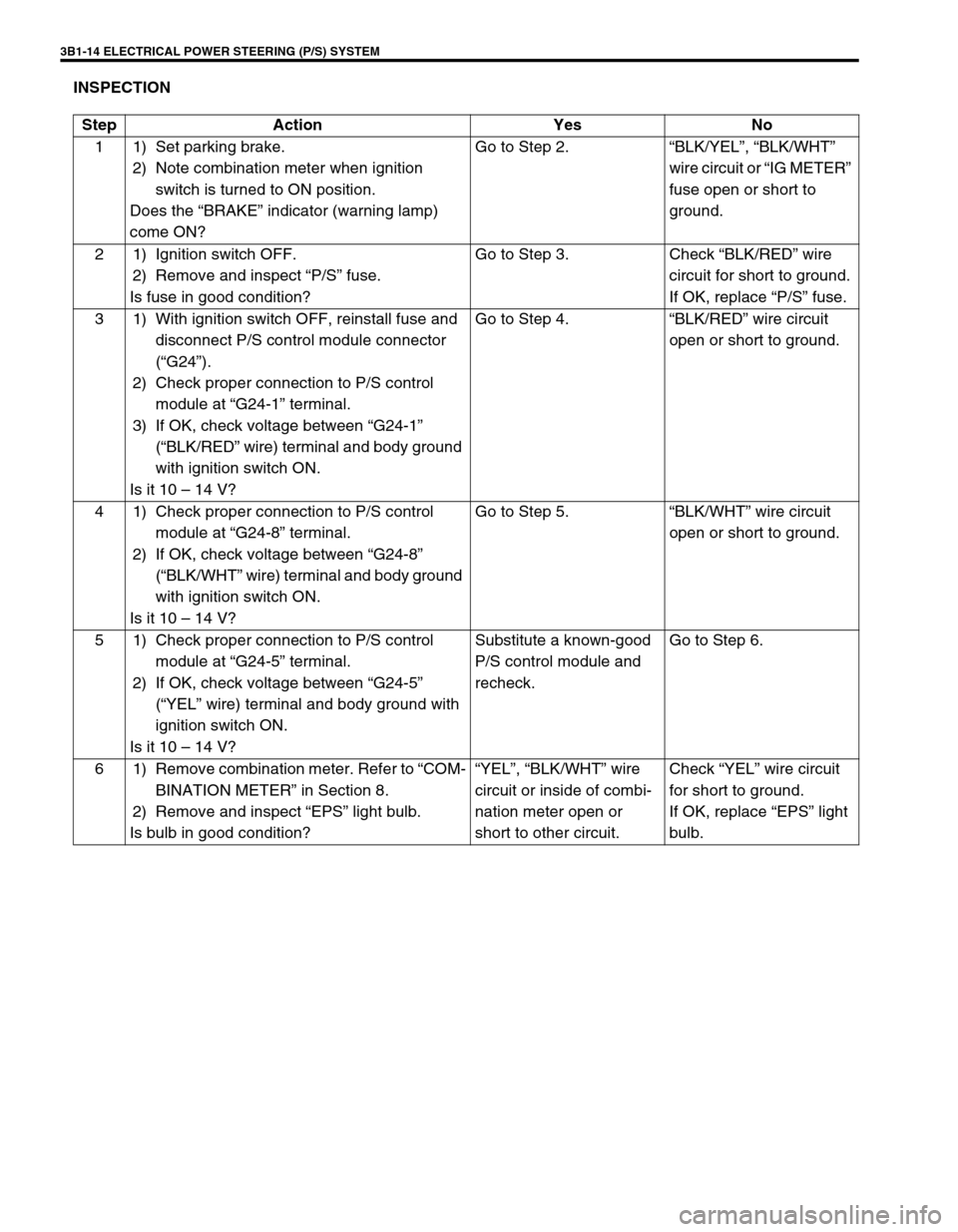

INSPECTION

Step Action Yes No

1 1) Set parking brake.

2) Note combination meter when ignition

switch is turned to ON position.

Does the “BRAKE” indicator (warning lamp)

come ON?Go to Step 2.“BLK/YEL”, “BLK/WHT”

wire circuit or “IG METER”

fuse open or short to

ground.

2 1) Ignition switch OFF.

2) Remove and inspect “P/S” fuse.

Is fuse in good condition?Go to Step 3. Check “BLK/RED” wire

circuit for short to ground.

If OK, replace “P/S” fuse.

3 1) With ignition switch OFF, reinstall fuse and

disconnect P/S control module connector

(“G24”).

2) Check proper connection to P/S control

module at “G24-1” terminal.

3) If OK, check voltage between “G24-1”

(“BLK/RED” wire) terminal and body ground

with ignition switch ON.

Is it 10 – 14 V?Go to Step 4.“BLK/RED” wire circuit

open or short to ground.

4 1) Check proper connection to P/S control

module at “G24-8” terminal.

2) If OK, check voltage between “G24-8”

(“BLK/WHT” wire) terminal and body ground

with ignition switch ON.

Is it 10 – 14 V?Go to Step 5.“BLK/WHT” wire circuit

open or short to ground.

5 1) Check proper connection to P/S control

module at “G24-5” terminal.

2) If OK, check voltage between “G24-5”

(“YEL” wire) terminal and body ground with

ignition switch ON.

Is it 10 – 14 V?Substitute a known-good

P/S control module and

recheck.Go to Step 6.

6 1) Remove combination meter. Refer to “COM-

BINATION METER” in Section 8.

2) Remove and inspect “EPS” light bulb.

Is bulb in good condition?“YEL”, “BLK/WHT” wire

circuit or inside of combi-

nation meter open or

short to other circuit.Check “YEL” wire circuit

for short to ground.

If OK, replace “EPS” light

bulb.

Page 156 of 698

ELECTRICAL POWER STEERING (P/S) SYSTEM 3B1-15

TABLE B - MALFUNCTION INDICATOR LAMP FLASHES AT IGNITION SWITCH

ON

CIRCUIT

Refer to TABLE-A for System Circuit Diagram.

TABLE C - MALFUNCTION INDICATOR LAMP DOES NOT FLASH, JUST

REMAINS ON OR JUST REMAINS OFF EVEN WITH DIAGNOSIS SWITCH TER-

MINAL GROUNDED

CIRCUIT

Refer to TABLE-A for System Circuit Diagram.Step Action Yes No

1 1) Check monitor coupler.

Is it connected diagnosis switch terminal (“8”)

and ground terminal (“9”) in monitor connector

by jumper wire?Disconnect jumper wire

from monitor coupler.Go to Step 2.

2 1) Check voltage between diagnosis switch

terminal of monitor coupler and body

ground with ignition switch ON.

Is it 10 – 14 V?Substitute a known-good

P/S control module and

recheck.“PPL/WHT” wire circuit

short to ground.

Step Action Yes No

1 1) Inspect connection between diagnosis

switch and ground terminals on monitor

coupler by jumper wire.

Is it securely connected between them by

jumper wire?Go to Step 2. Properly connection diag-

nosis switch and ground

terminals on monitor cou-

pler by jumper wire.

2 1) With ignition switch OFF, disconnect P/S

control module connector (“G24”).

2) Check proper connection to P/S control

module at “G24-4” terminal.

3) If OK, check resistance between “G24-4”

(“PPL/WHT” wire) terminal and diagnosis

switch terminal of monitor coupler.

Is there continuity?Go to Step 3.“PPL/WHT” wire circuit

open.

3 1) Check proper connection to P/S control

module at “G24-2” terminal.

2) If OK, check resistance between “G24-2”

(“BLK” wire) terminal and body ground.

Is there continuity?Go to Step 4.“BLK” wire circuit open.

4 1) Check proper connection to P/S control

module at “G24-5” terminal.

2) If OK, check voltage between “G24-5”

(“YEL” wire) terminal and body ground with

ignition switch ON.

Is it 10 – 14 V?Substitute a known-good

P/S control module and

recheck.“YEL” wire circuit or inside

of combination meter

short to other circuit or

ground.

Page 157 of 698

3B1-16 ELECTRICAL POWER STEERING (P/S) SYSTEM

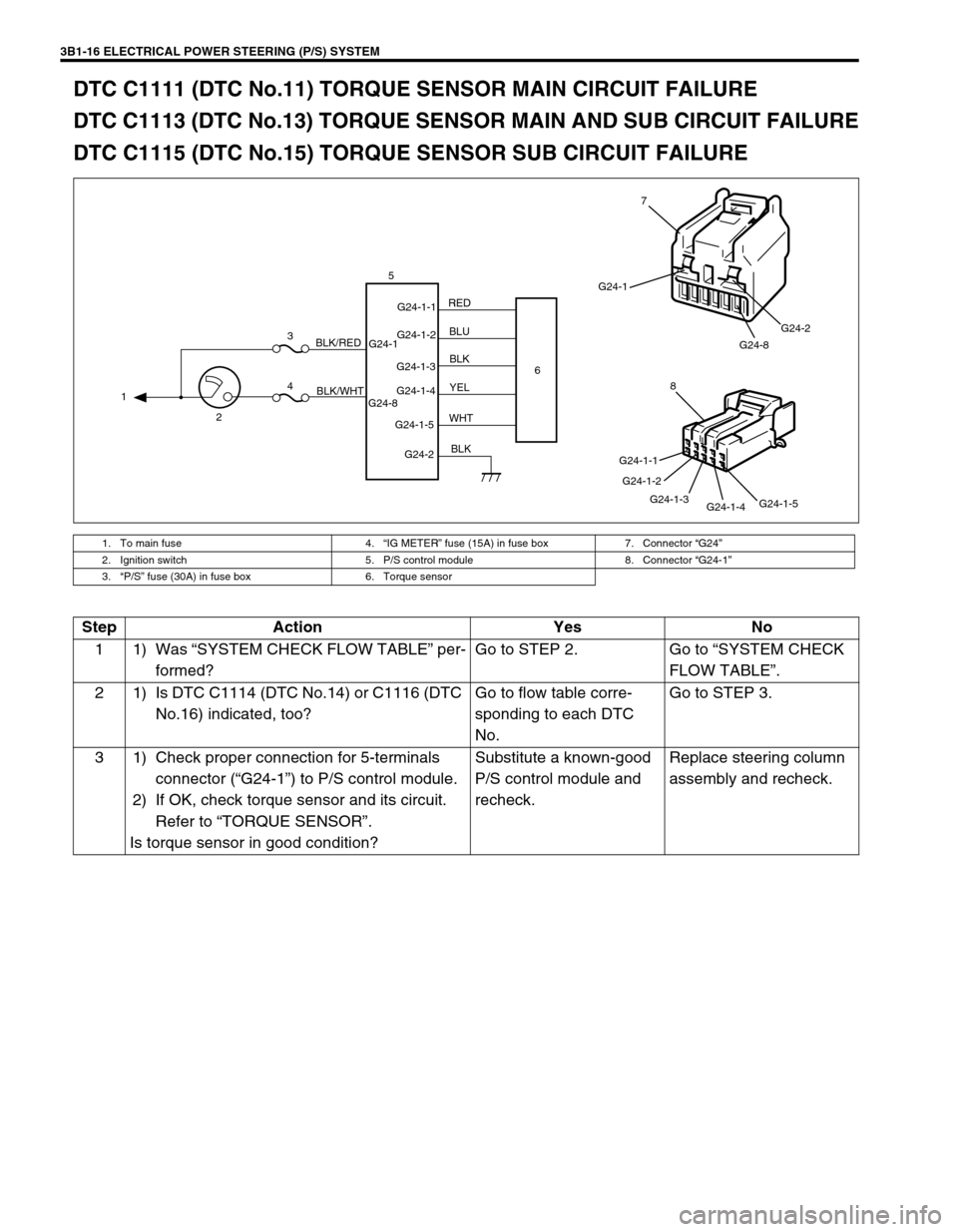

DTC C1111 (DTC No.11) TORQUE SENSOR MAIN CIRCUIT FAILURE

DTC C1113 (DTC No.13) TORQUE SENSOR MAIN AND SUB CIRCUIT FAILURE

DTC C1115 (DTC No.15) TORQUE SENSOR SUB CIRCUIT FAILURE

1. To main fuse 4.“IG METER” fuse (15A) in fuse box 7. Connector “G24”

2. Ignition switch 5. P/S control module 8. Connector “G24-1”

3.“P/S” fuse (30A) in fuse box 6. Torque sensor

G24-2 G24-1

G24-8G24-1-4 G24-1-3

G24-1-5G24-1-2G24-1-1

1

23

45

6

BLK/WHT BLK/RED

BLK WHTYEL BLK BLU RED

G24-1

G24-8G24-2

7

G24-1-5

G24-1-4 G24-1-3 G24-1-2 G24-1-18

Step Action Yes No

11)Was “SYSTEM CHECK FLOW TABLE” per-

formed?Go to STEP 2. Go to “SYSTEM CHECK

FLOW TABLE”.

2 1) Is DTC C1114 (DTC No.14) or C1116 (DTC

No.16) indicated, too?Go to flow table corre-

sponding to each DTC

No.Go to STEP 3.

3 1) Check proper connection for 5-terminals

connector (“G24-1”) to P/S control module.

2) If OK, check torque sensor and its circuit.

Refer to “TORQUE SENSOR”.

Is torque sensor in good condition?Substitute a known-good

P/S control module and

recheck.Replace steering column

assembly and recheck.

Page 158 of 698

ELECTRICAL POWER STEERING (P/S) SYSTEM 3B1-17

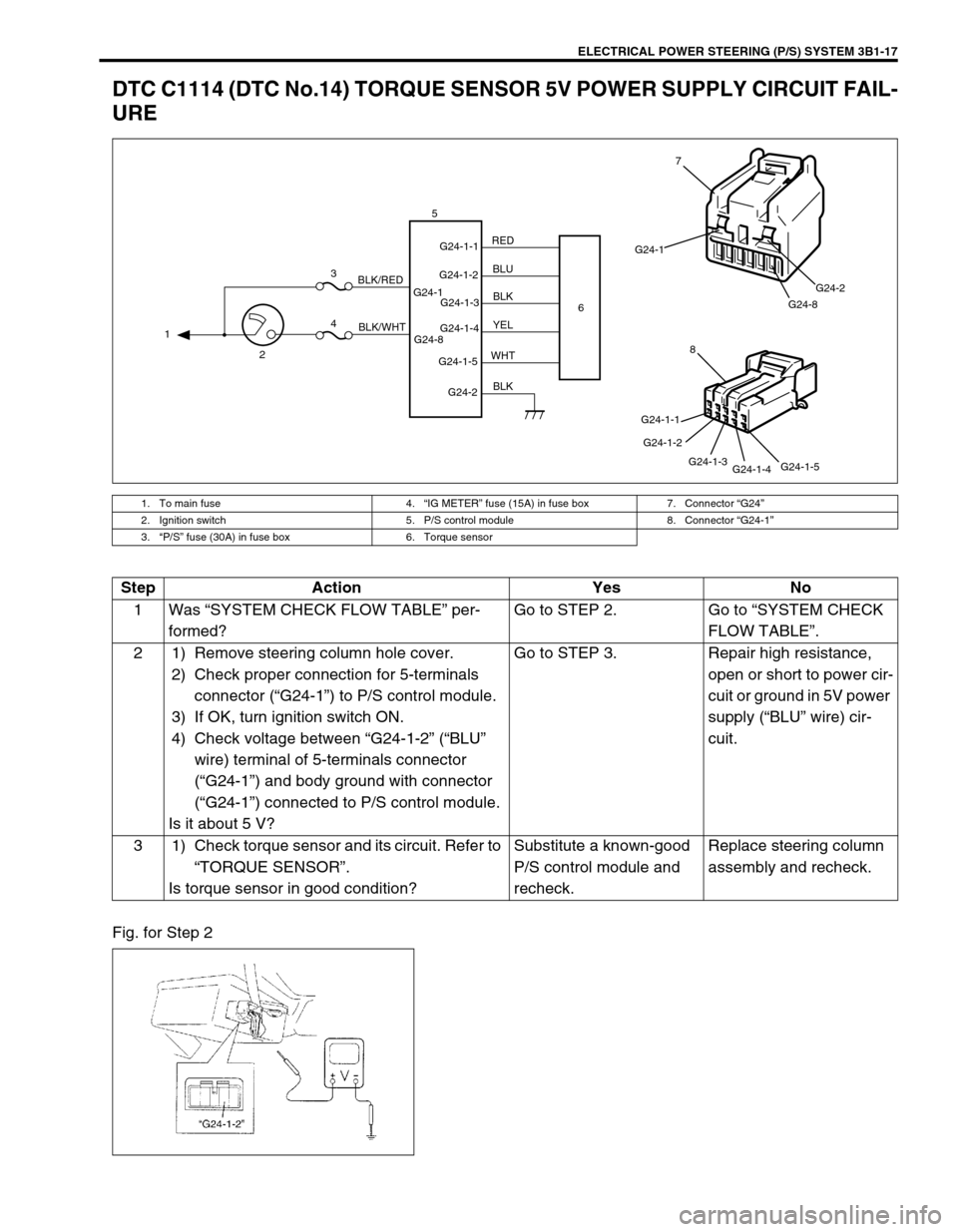

DTC C1114 (DTC No.14) TORQUE SENSOR 5V POWER SUPPLY CIRCUIT FAIL-

URE

Fig. for Step 2

1. To main fuse 4.“IG METER” fuse (15A) in fuse box 7. Connector “G24”

2. Ignition switch 5. P/S control module 8. Connector “G24-1”

3.“P/S” fuse (30A) in fuse box 6. Torque sensor

G24-1

G24-8G24-2

7

G24-1-5

G24-1-4 G24-1-3 G24-1-2 G24-1-18

G24-2 G24-1

G24-8G24-1-4G24-1-3

G24-1-5G24-1-2G24-1-1

1

23

45

6

BLK/WHT BLK/RED

BLK WHTYEL BLK BLU RED

Step Action Yes No

1Was “SYSTEM CHECK FLOW TABLE” per-

formed?Go to STEP 2. Go to “SYSTEM CHECK

FLOW TABLE”.

2 1) Remove steering column hole cover.

2) Check proper connection for 5-terminals

connector (“G24-1”) to P/S control module.

3) If OK, turn ignition switch ON.

4) Check voltage between “G24-1-2” (“BLU”

wire) terminal of 5-terminals connector

(“G24-1”) and body ground with connector

(“G24-1”) connected to P/S control module.

Is it about 5 V?Go to STEP 3. Repair high resistance,

open or short to power cir-

cuit or ground in 5V power

supply (“BLU” wire) cir-

cuit.

3 1) Check torque sensor and its circuit. Refer to

“TORQUE SENSOR”.

Is torque sensor in good condition?Substitute a known-good

P/S control module and

recheck.Replace steering column

assembly and recheck.

Page 159 of 698

3B1-18 ELECTRICAL POWER STEERING (P/S) SYSTEM

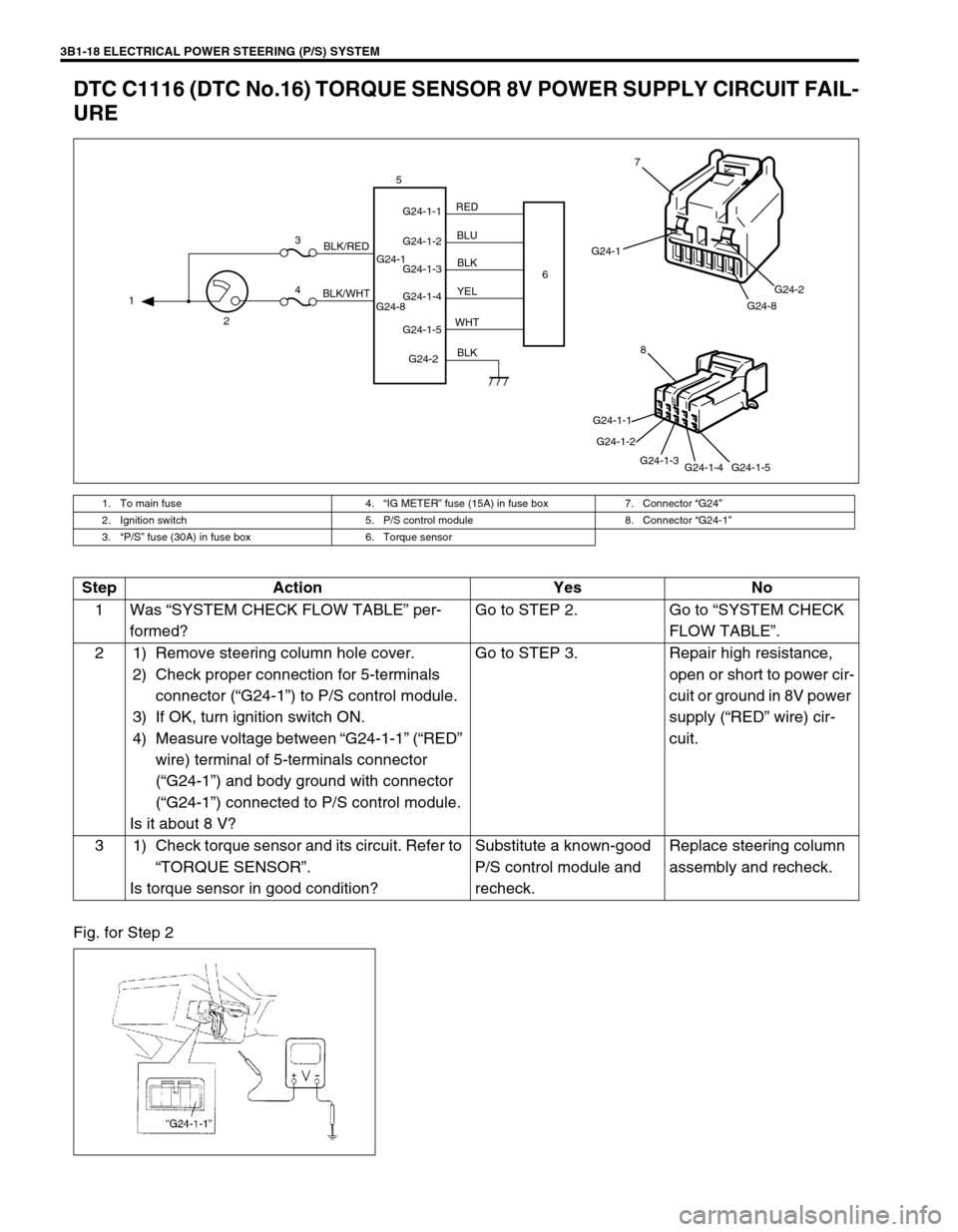

DTC C1116 (DTC No.16) TORQUE SENSOR 8V POWER SUPPLY CIRCUIT FAIL-

URE

Fig. for Step 2

1. To main fuse 4.“IG METER” fuse (15A) in fuse box 7. Connector “G24”

2. Ignition switch 5. P/S control module 8. Connector “G24-1”

3.“P/S” fuse (30A) in fuse box 6. Torque sensor

G24-1

G24-8G24-2

7

G24-1-5

G24-1-4 G24-1-3 G24-1-2 G24-1-18

G24-2 G24-1

G24-8G24-1-4 G24-1-3

G24-1-5 G24-1-2 G24-1-1

1

23

45

6

BLK/WHTBLK/RED

BLK WHTYEL BLK BLU RED

Step Action Yes No

1Was “SYSTEM CHECK FLOW TABLE” per-

formed?Go to STEP 2. Go to “SYSTEM CHECK

FLOW TABLE”.

2 1) Remove steering column hole cover.

2) Check proper connection for 5-terminals

connector (“G24-1”) to P/S control module.

3) If OK, turn ignition switch ON.

4) Measure voltage between “G24-1-1” (“RED”

wire) terminal of 5-terminals connector

(“G24-1”) and body ground with connector

(“G24-1”) connected to P/S control module.

Is it about 8 V?Go to STEP 3. Repair high resistance,

open or short to power cir-

cuit or ground in 8V power

supply (“RED” wire) cir-

cuit.

3 1) Check torque sensor and its circuit. Refer to

“TORQUE SENSOR”.

Is torque sensor in good condition?Substitute a known-good

P/S control module and

recheck.Replace steering column

assembly and recheck.

Page 160 of 698

ELECTRICAL POWER STEERING (P/S) SYSTEM 3B1-19

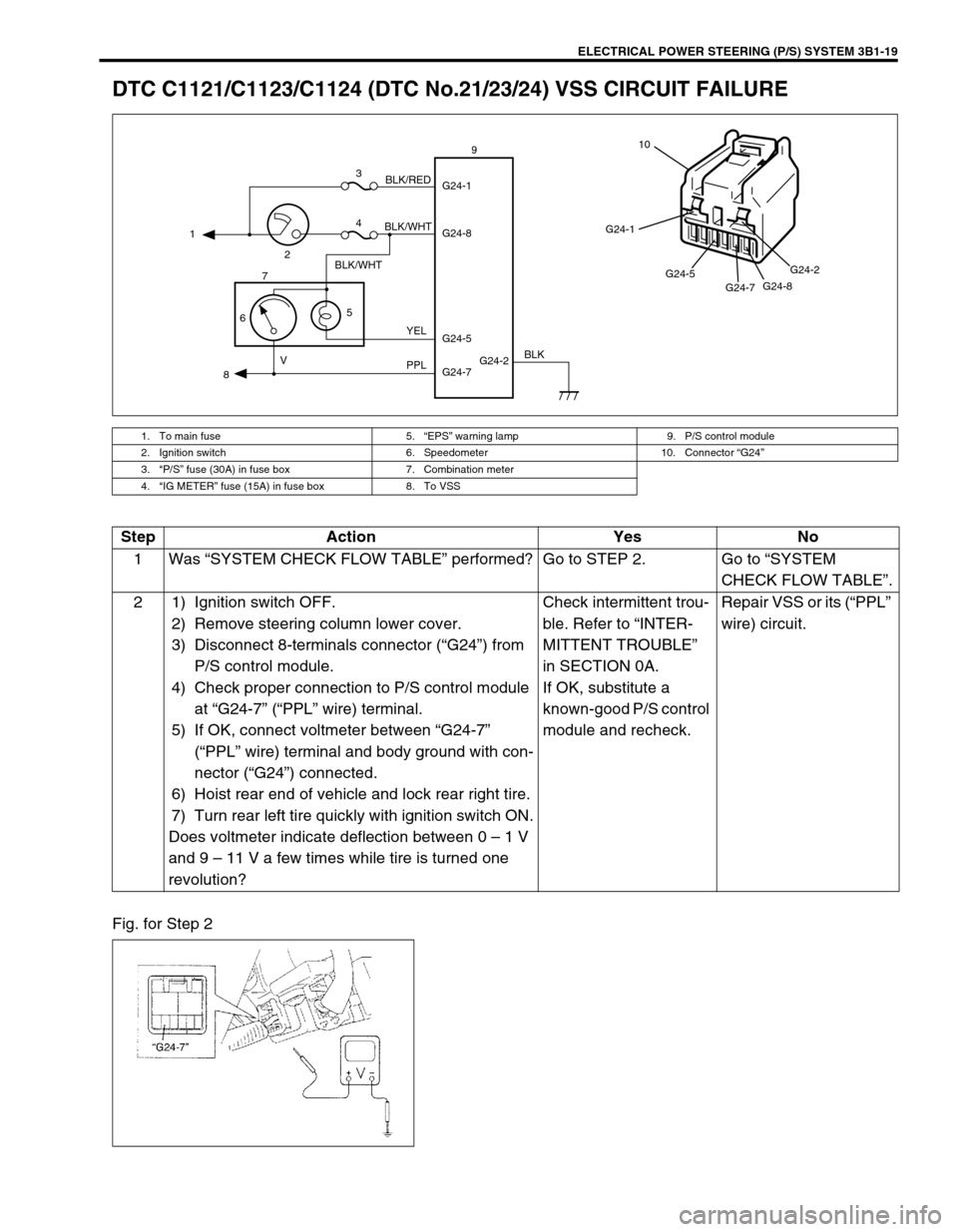

DTC C1121/C1123/C1124 (DTC No.21/23/24) VSS CIRCUIT FAILURE

Fig. for Step 2

1. To main fuse 5.“EPS” warning lamp 9. P/S control module

2. Ignition switch 6. Speedometer 10. Connector “G24”

3.“P/S” fuse (30A) in fuse box 7. Combination meter

4.“IG METER” fuse (15A) in fuse box 8. To VSS

G24-2 G24-1

G24-8

G24-7 G24-5 1

23

4

5

67

89

BLK/WHT

BLK/WHTBLK/RED

YEL

PPL VBLK

G24-1

G24-5

G24-7G24-8G24-2

10

Step Action Yes No

1Was “SYSTEM CHECK FLOW TABLE” performed? Go to STEP 2. Go to “SYSTEM

CHECK FLOW TABLE”.

2 1) Ignition switch OFF.

2) Remove steering column lower cover.

3) Disconnect 8-terminals connector (“G24”) from

P/S control module.

4) Check proper connection to P/S control module

at “G24-7” (“PPL” wire) terminal.

5) If OK, connect voltmeter between “G24-7”

(“PPL” wire) terminal and body ground with con-

nector (“G24”) connected.

6) Hoist rear end of vehicle and lock rear right tire.

7) Turn rear left tire quickly with ignition switch ON.

Does voltmeter indicate deflection between 0 – 1 V

and 9 – 11 V a few times while tire is turned one

revolution?Check intermittent trou-

ble. Refer to “INTER-

MITTENT TROUBLE”

in SECTION 0A.

If OK, substitute a

known-good P/S control

module and recheck.Repair VSS or its (“PPL”

wire) circuit.