TOYOTA CELICA 1987 Service Owner's Guide

Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 31 of 346

COOLING SYSTEM - Radhtor co-11

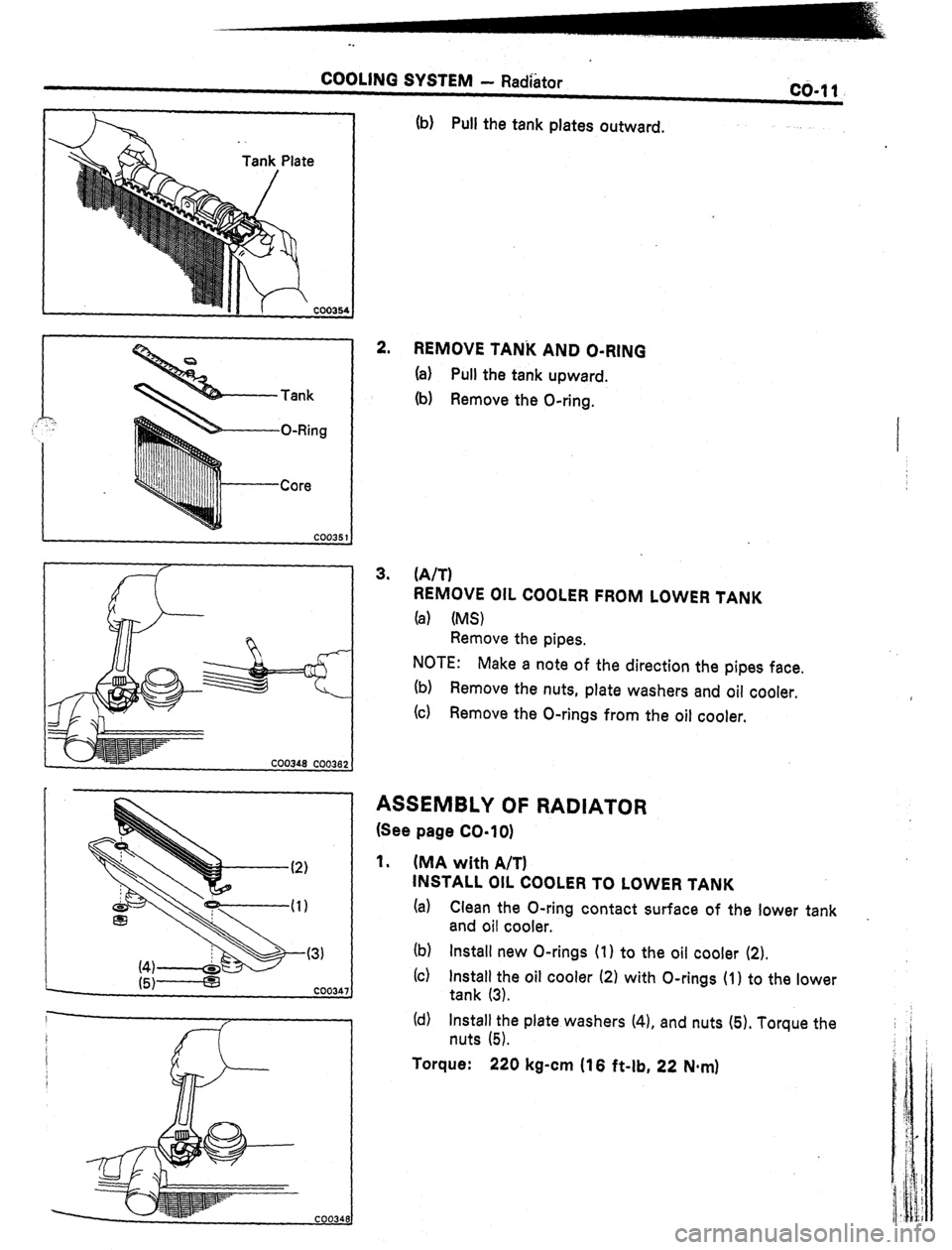

Tank

O-Ring

Core

(b) Pull the tank plates outward.

2.

REMOVE TANi( AND O-RING

(a) Pull the tank upward.

(b) Remove the O-ring.

3. (A/T)

REMOVE OIL COOLER FROM LOWER TANK

(a) (MS)

Remove the pipes.

NOTE:

Make a note of the direction the pipes face.

(b) Remove the nuts, plate washers and oil cooler.

(c) Remove the O-rings from the oil cooler.

ASSEMBLY OF RADIATOR

(See page CO-lo)

1. (MA with A/T)

INSTALL OIL COOLER TO LOWER TANK

(a) Clean the O-ring contact surface of the lower tank

and oil cooler. _

(b) Install new O-rings (1) to the oil cooler (2).

(c) Install the oil cooler (2) with O-rings (1) to the lower

tank (3).

(d) Install the plate washers (4). and nuts (5). Torque the

nuts (5).

Torque: 220 kg-cm (16 f&lb, 22 Nqn)

Page 32 of 346

-.

COOLING SYSTEM - Radiator

.

ore

Plate

Core plate

XTwisteq

XTwistedl

- 2755:

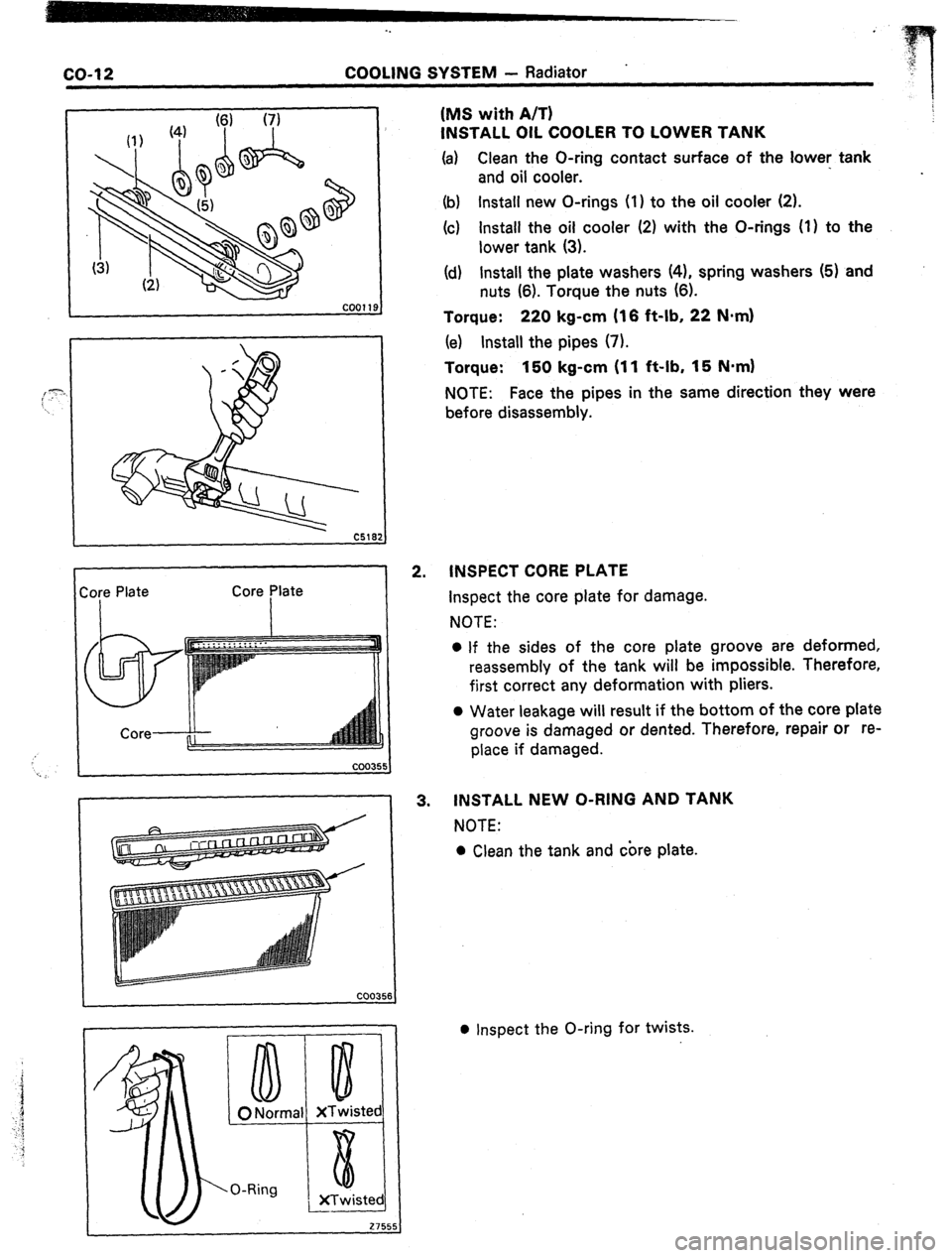

2. (MS with A/T)

INSTALL OIL COOLER TO LOWER TANK

(a)

Clean the O-ring contact surface of the

lower: tank

and oil cooler.

(b) Install new O-rings (1) to the oil cooler (2).

(c) Install the oil cooler (2) with the O-rings (1) to the

lower tank (3).

(d) Install the plate washers (41, spring washers (5) and

nuts (6). Torque the nuts (6).

Torque: 220 kg-cm (16 ft-lb, 22 N*m)

(e) Install the pipes (7).

Torque: 150 kg-cm (11 ft-lb, 15 N.mI

NOTE: Face the pipes in the same direction they were

before disassembly.

INSPECT CORE PLATE

Inspect the core plate for damage.

NOTE:

l If the sides of the core plate groove are deformed,

reassembly of the tank will be impossible. Therefore,

first correct any deformation with pliers.

0 Water leakage will result if the bottom of the core plate

groove is damaged or dented. Therefore, repair or re-

place if damaged.

3. INSTALL NEW O-RING AND TANK

NOTE:

l Clean the tank and core plate.

l Inspect the O-ring for twists.

Page 33 of 346

COGLING SYSTEM - Radiator’ .

__ co- 1.3::

.-

1 SST

r

i

Tank Plate

Punch I

I

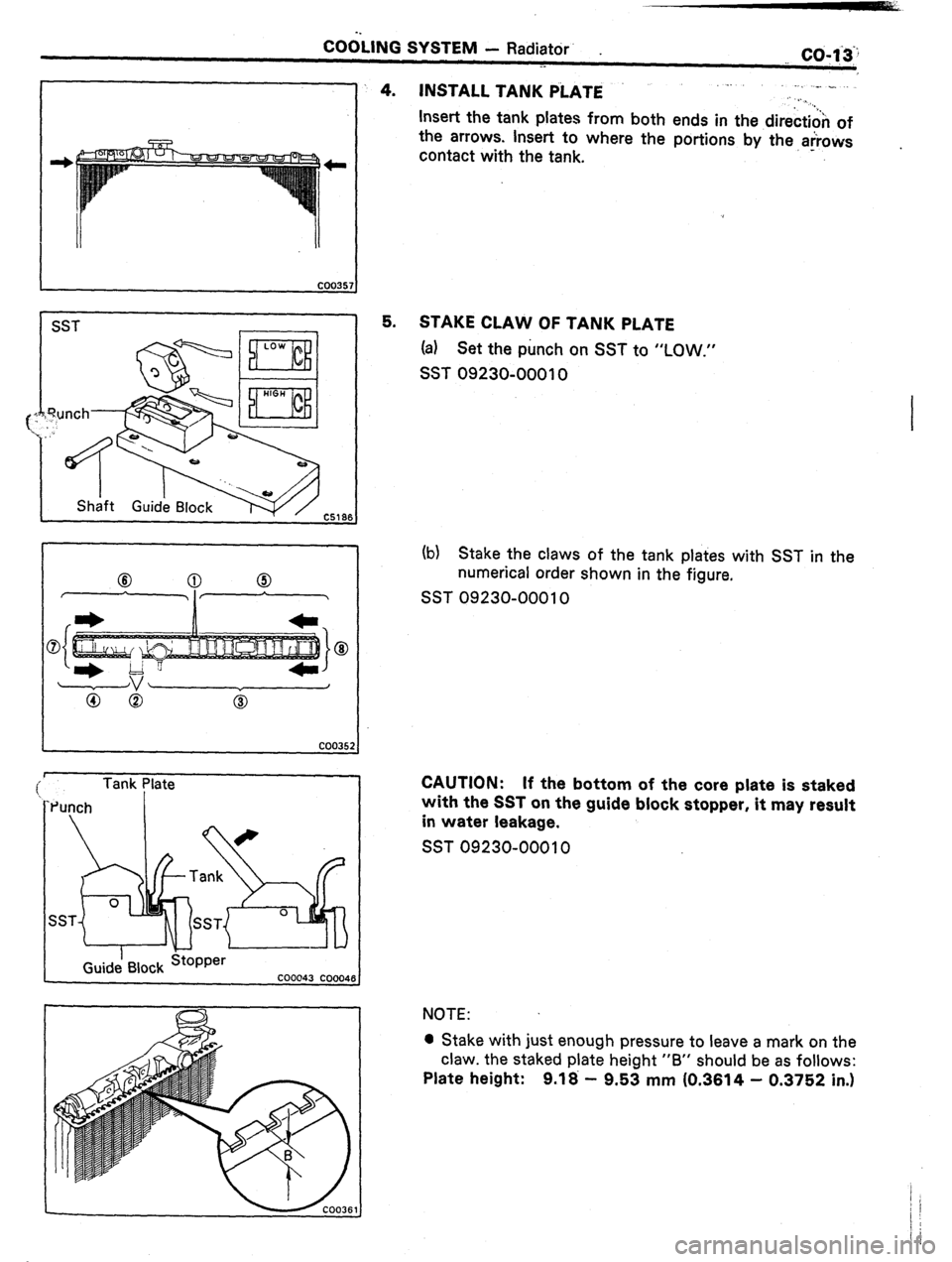

4. INSTALL TANK PiATE .

., _. .,

. ._

Insert the tank plates from both ends in the direction of

the arrows. Insert to where the portions by the arrows

contact with the tank. - .

5. STAKE CLAW OF TANK PLATE

(a) Set the punch on SST to “LOW.”

SST 09230-00010

(b) Stake the claws of the tank plates with SST in the

numerical order shown in the figure.

SST 09230-00010

CAUTION: If the bottom of the core plate is staked

with the SST on the guide block stopper, it may result

in water leakage.

SST 09230-00010

NOTE:

l Stake with just enough pressure to leave a mark on the

claw. the staked plate height “B” should be as follows:

Plate height: 9.18 - 9.53 mm (0.3614 - 0.3752 in.)

Page 34 of 346

co-14

-.

COOLINQ SYSTEM. - Radiator

Tank Plate

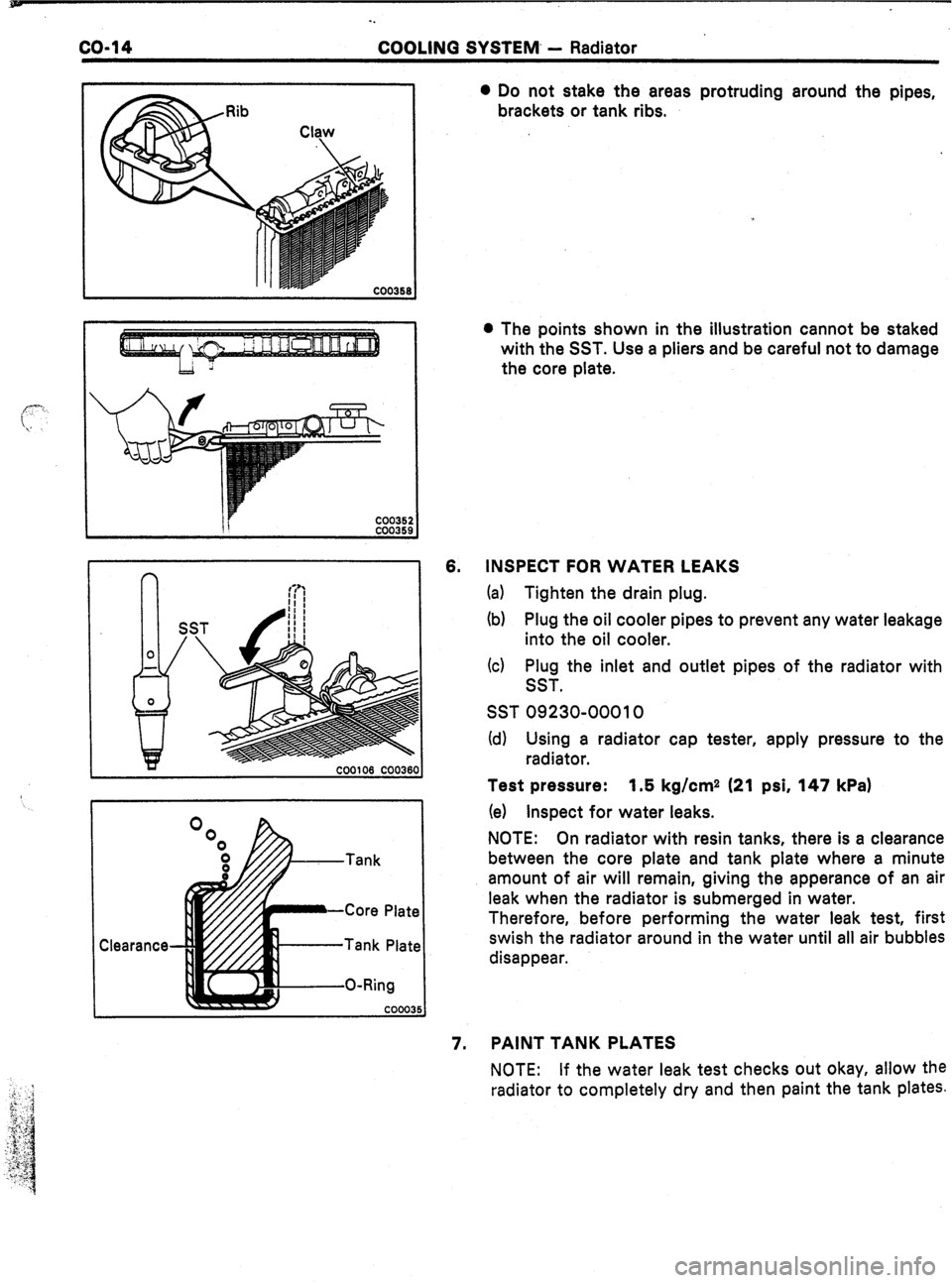

O-Ring 6. 0 Do not stake the areas protruding around the pipes,

brackets or tank ribs.

l The points shown in the illustration cannot be staked

with the SST. Use a pliers and be careful not to damage

the core plate.

INSPECT FOR WATER LEAKS

(a) Tighten the drain plug.

(b) Plug the oil cooler pipes to prevent any water leakage

into the oil cooler.

(c) Plug the inlet and outlet pipes of the radiator with

SST.

SST 09230-00010

(d) Using a radiator cap tester, apply pressure to the

radiator.

Test pressure: 1.5 kg/cm2 (21 psi, 147 kPa)

(e) Inspect for water leaks.

NOTE: On radiator with resin tanks, there is a clearance

between the core plate and tank plate where a minute

amount of air will remain, giving the apperance of an air

leak when the radiator is submerged in water.

Therefore, before performing the water leak test, first

swish the radiator around in the water until all air bubbles

disappear.

7. PAINT TANK PLATES

NOTE: If the water leak test checks out okay, allow the

radiator to completely dry and then paint the tank plates.

Page 35 of 346

FI-1

i’.. ;

-EFI SYSTEM

i

‘x

. .

Page

SYSTEM DESCRIPTION

....................... Fl-i.&.

PRECAUTIONS

;;:“, F,-, ;a”“- .............................. . ....

INSPECTION PRECAUTIONS

FI-7 . ....................

TROUBLESHOOTING

.......................... FI-12

DIAGNOSIS SYSTEM

.................... .

.... FI-25

TROUBLESHOOTING WITH

VOLT/OHMMETER (MA)

.................... FI-34

m

.:

TROUBLESHOOTING WITH

VOLT/OHMMETER (MS)

.................... FI-57

FUEL SYSTEM

................................ FI-73,

Fuel Pump ..................................

FI-73

Cold Start Injector ...........................

Fl-80

Pressure Regulator

.......................... FI’i84 ..

Injectors

.............................. ..i ..

FI-86

AIR INDUCTION SYSTEM

..................... FI-96

Air Flow Meter (7M-GE)

..................... FI-96

Air Flow Meter (7M-GTE)

................... FI-98

Throttle Body

.............................. FI-102

Idle Speed Control (ISC) Valve

............... FI-108

ELECTRONIC CONTROL SYSTEM .............. FI-110

Location of Electronic Control Parts .......... FI-110

l EFI Main Relay

............................. Fl-112

. Circuit Opening Relay ....................... FI-113

Solenoid Resistor

........................... Fl-114

Cold Start Injector Time Switch ...............

FI-115

Water Temperature Sensor ..................

FI-116

Fuel Pump Relay and Resistor ............... FI-117

High Temperature Line Pressure -

Up System ............................... FIi119

High Altitude Compensation (HACK

System (7M-GTE)

........................ FI-121

Oxygen Sensor .............................

FI-122

Electronic Controlled Unit (ECU) .............

FI-125

Fuel Cut RPM

.............................. FI-128

Page 36 of 346

Circuit

Opening

Fuel Pump Relay

I

Warning 1

I :..I-, -7-I ECU

P 1

L-

VSV (FPU)

Electronic

Load

di!=

Check C&tnector

A/C Compressc

I-=-

Szeed Sensor

IIIII:IIlI Igniter w/coil

l---it-

Start‘lnjector Time Switch

Water Te&p. Sensor

TWC

Neutral Start

Switch (A/T)

Page 37 of 346

![TOYOTA CELICA 1987 Service Owners Guide Circuit

Opening

Relay Fuel Pump Relay

“CHECK 1 f-- 1 ] : :

llll II :

: :

ENGINE”

Warning

Light ECU

I iIll

+-,llllllllllll

Electronic

Load Air Temp. Sensor

Check Connector 1 1 1 / 1 TOYOTA CELICA 1987 Service Owners Guide Circuit

Opening

Relay Fuel Pump Relay

“CHECK 1 f-- 1 ] : :

llll II :

: :

ENGINE”

Warning

Light ECU

I iIll

+-,llllllllllll

Electronic

Load Air Temp. Sensor

Check Connector 1 1 1 / 1](/img/14/57451/w960_57451-36.png)

Circuit

Opening

Relay Fuel Pump Relay

“CHECK 1 f-- 1 ] : :

llll II :

: :

ENGINE”

Warning

Light ECU

I iIll

+-,llllllllllll

Electronic

Load Air Temp. Sensor

Check Connector 1 1 1 / 1 1 1 1 1 1 1 1

:uator

Igniter w/r-:’ ’

A/C Compressor

& 1 wTwy 1 To Charcoal Canister

Neutral Start

Switch (A/T)

Page 38 of 346

EFI SYSTEM - STystem Description

;SYSTEM DESCRIPTION (Cont’d)

5 (Others)

,

.

I

I I I

I .5:

a

J I

Page 39 of 346

EFI SYSTEM

- System Description

’

FI-5

FM-GTE -.

SYSTEM DESCRIPTION (Cont’d)

._

1

Page 40 of 346

1-6 EFI SYSTEM - System Description

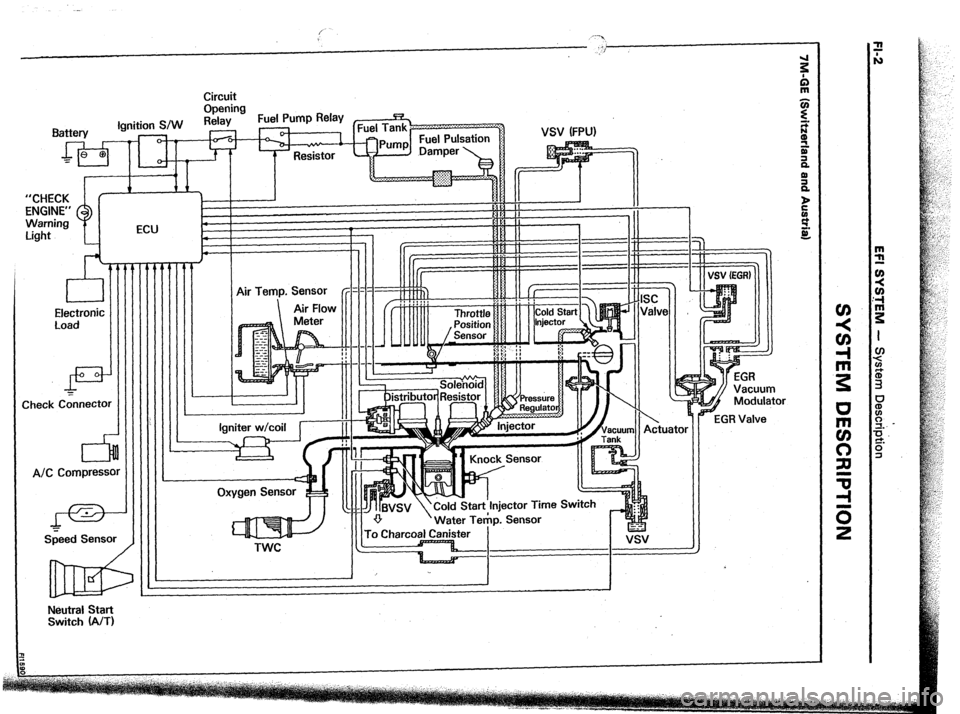

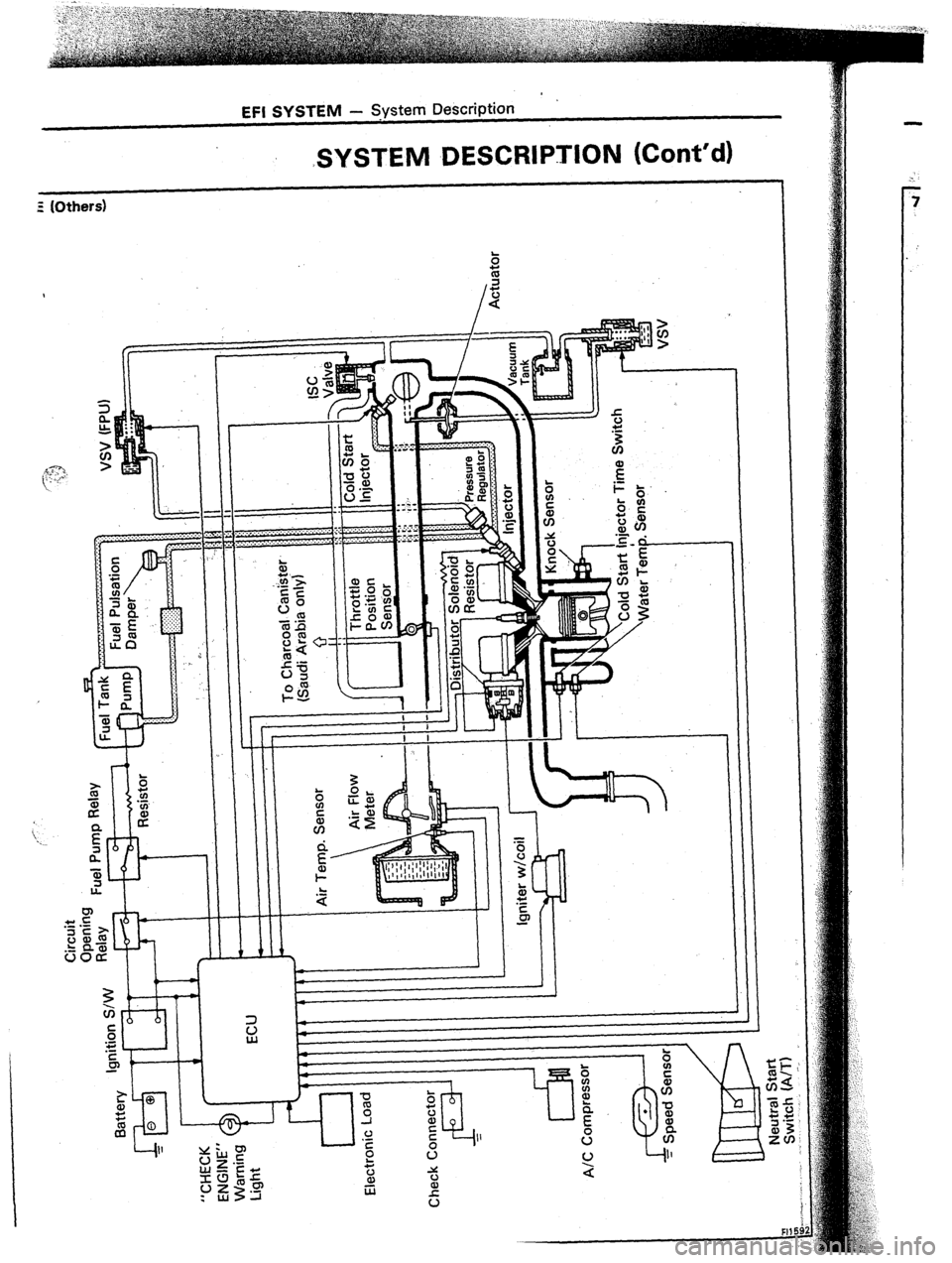

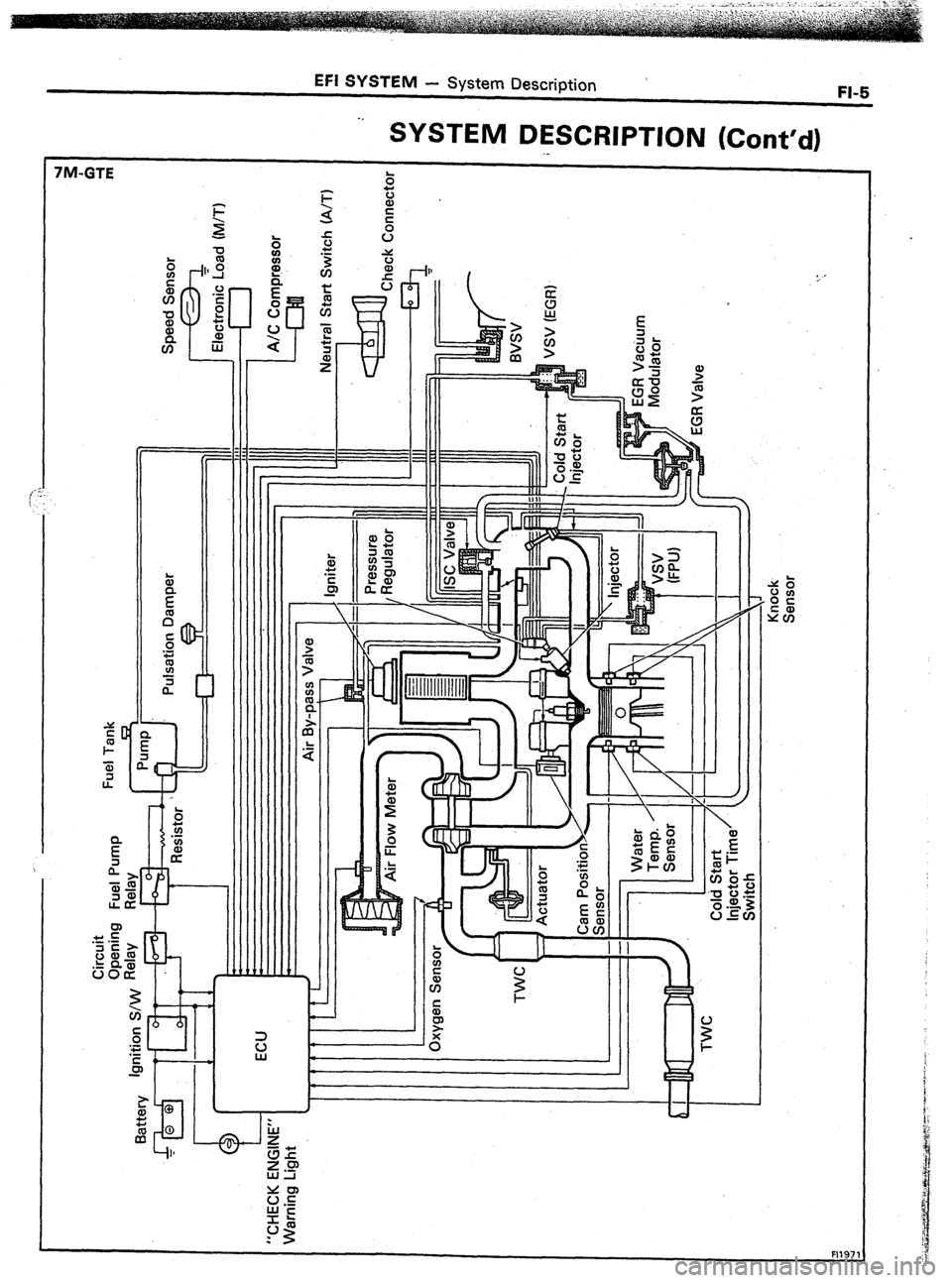

‘he .EFI system is composed of 3 basic sub

;ystems; Fuel Induction, Air Induction and

Ziectronic Control.

FUEL SYSTEM

An electric fuel pump supplies sufficient fuel,

under a constant pressure, to the injectors. These

injectors inject a metered quantity of fuel into the

intake manifold in accordance with signals from

the ECU (Electronic Control Unit).

AIR INDUCTION SYSTEM

The air induction system provides sufficient air for

engine operation.

[3: ‘I

i&TRONIC CONTROL SYSTEM

The 7M-GE, 7M-GTE engines are equipped wifh a

Toyota Computer Control System (TCCS) which

centrally controls the EFI, ESA, Diagnosis systems,

etc. by means of an Electronic Control Unit (ECU -

for-merly EFI computer) employing a microcom-

puter.

By means of the ECU, the TCCS controls the

following functions:

1. Electronic Fuel injection (EFI)

The ECU receivers signals from,various sen-

sors indicating changing engine operating

conditions such as:

Exhaust oxygen content (w/ TWC)

Intake air volume

i Intake air temperature

Coolant temperature

Engine rpm

Vehicle speed

Acceleration/deceleration etc.

These signals are utilized by the ECU to

determine the injection duration necessary for

an optimum air-fuel ratio.

2. Electronic Spark Advance (ESA)

The ECU is programmed with data for

optimum ignition timing under any and all

operating conditions. Using data provided by

sensors which monitor various engine func-

tions (rpm, A/C signal, coolant temperature,

etc.), the microcomputer (ECU) triggers the

spark at precisely the right instant. (See IG

section) 3. Idle Speed Control (IX)

The ECU is programmed with, target idling

speed values to respond to different engine

conditions (coolant temperature, air condi-

tioner on/off, etc.). Sensors transmit signals

to the ECU which control the flow of air

through the bypass of the throttle valve and

adjust idle speed to the target value.

(See pages FI-53, 7 1, 108) ’

4. Diagnosis

The ECU detects any malfunctions or abnor-

malities in the sensor network and tights the

“CHECK ENGINE” warning light on the instru-

ment panel. At the same time, the trouble is

identified and a diagnostic code is recorded

by the ECU.

5. Fail-Safe Function ’

In the event of computer malfunction, a back-

up circuit will take over to provide minimal

drivability. Simultaneously, the “CHECK

ENGINE” warning light will come on.