TOYOTA HIGHLANDER 2001 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2001, Model line: HIGHLANDER, Model: TOYOTA HIGHLANDER 2001Pages: 2572, PDF Size: 34.8 MB

Page 321 of 2572

2005 HIGHLANDER (EWD592U)

102

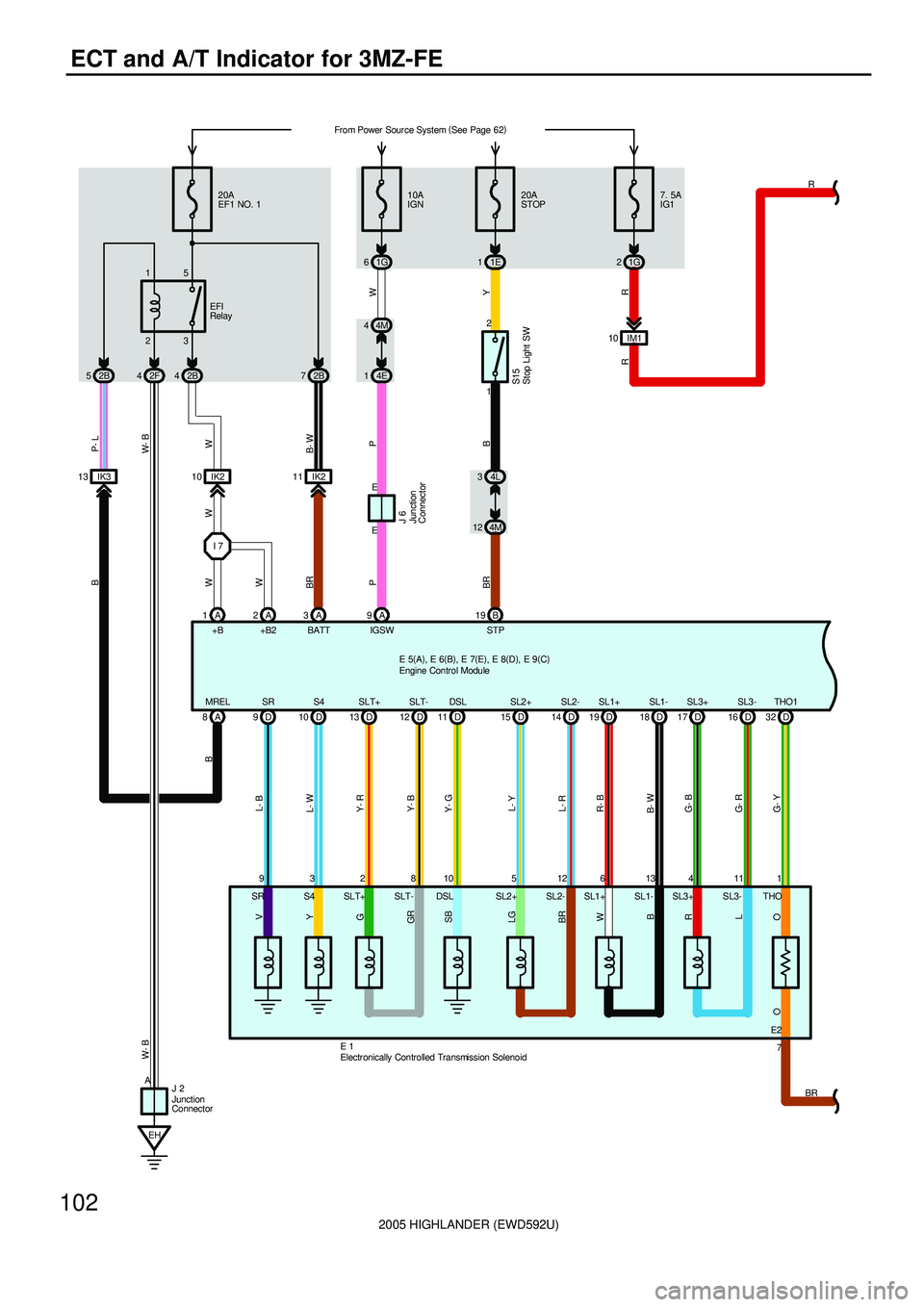

ECT and A/T Indicator for 3MZ-FE

1 11 4 12 5 10 8 2 9

G- YW P- L

+B BATT20A

EF1 NO. 1

B- W W- B

L- B

Y- R

Y- B

Y- G

L- Y

L- R

G- B

G- R

23 15

2B 4 2F 4 2B 52B7

Y

R W

IK2 10 IK21110A

IGN

1G 620A

STOP

1E 1

4E 1

B BRP

I 74M 4

EH1 2

4M 124L 3

1A A3A9B1921G7. 5A

IG1

A 8

BRW

D 9D13 D11 D15 D17 D32 D 16 D 12 D14R

E 1SL1- SL1+

18 D 19 D

B- WR- B

613 IGSW STP

A

J 2MREL SR SLT+ SLT- DSL SL2+ SL2-

W- B

SL3+ SL3- THO1

S15

EFI

Relay

IK3 13

B

B

IM1 10

R

E

E

V

G

GR

SB

LG

BR

R

OL

+B2 2A

WW

P

W

B

O

3

L- W

D 10S4

Y

THO SL3- SL3+ SL1- SL1+ SL2- SL2+ DSL SLT- SLT+ S4 SR

E2

7

BR

J 6

From Power Source System (

See Page 62)

E 5(

A)

, E 6(

B)

, E 7(

E)

, E 8(

D)

, E 9(

C)

Electr onically Controlled Transmission SolenoidEngine Control Module

Junction

Connector

Junction

Connector

Stop Light SW

Page 322 of 2572

2005 HIGHLANDER (EWD592U)

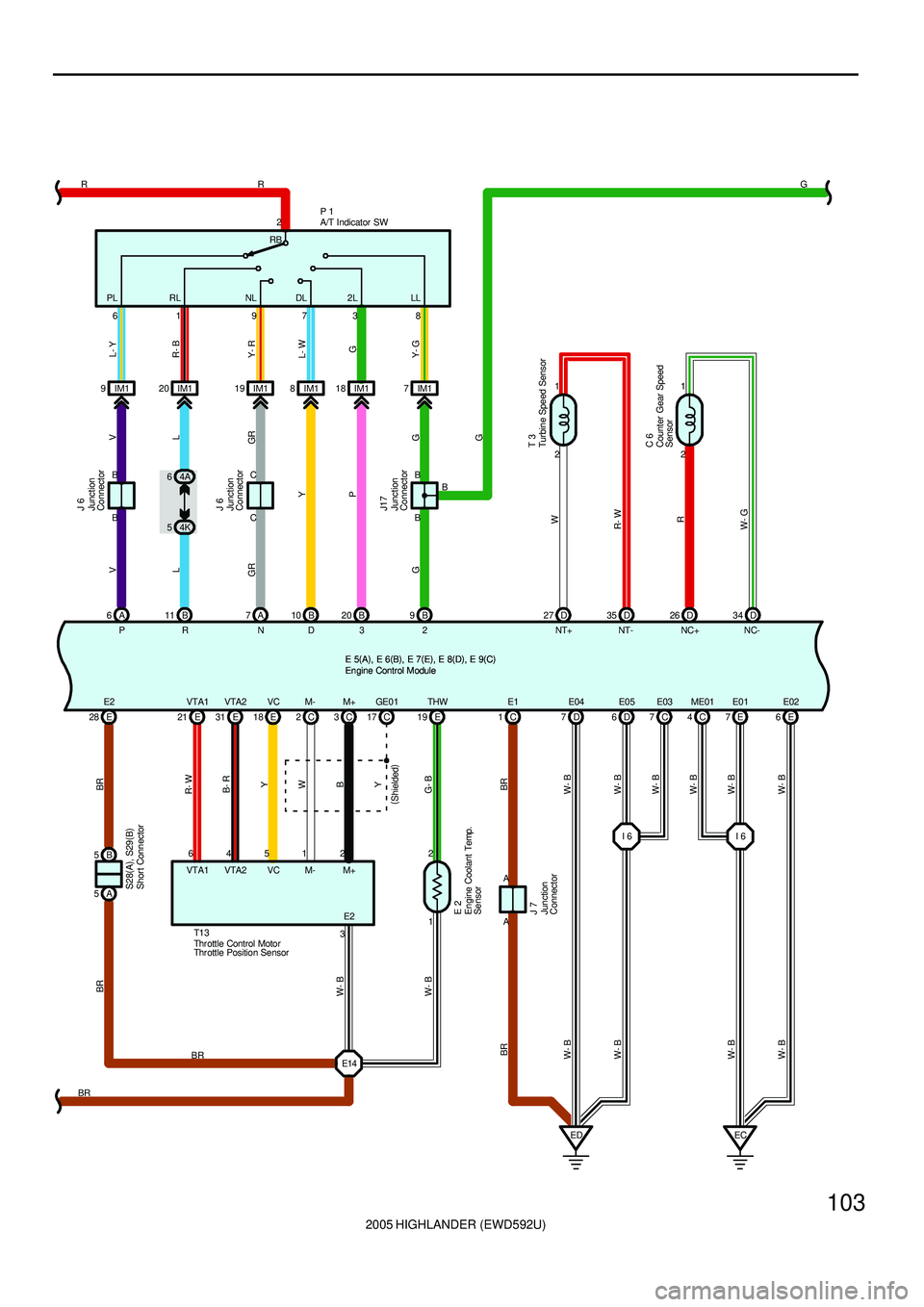

103

20 IM1

W- B W- B

W- B

W- B W- B W- BBR G- BY BR

L- W

GP

Y- GG Y- R R- BL- Y

9

J 6

IM1

7C

EC ED6E 7E PL RL NL DL 2L LL

61 97382

6D 1C D7E03

W- B

W- B J 7

9B B 20 B 10 7A B 11 A 6

A

A R

BR

B- R

VC

3 5

VTA2 R

1 2

E14 E 28 E18 E19

VTA1

BR

T1 3

E 2

4 64AP 1

54K

PR ND3 2

E2 VC THW E04E1 E05 E01 E02 B

B C

C B

B7IM1 18 IM1 8IM1 19 IM1

I 6

J 6

J17Y GRL VV

L

GR

G

E 31VTA2

R- W

6E 21VTA1G

NC- NC+ NT- NT+

W- GR R- WWT 3

C 6

D 261

2

D 34 35 D 2 1

27 D B

BR

A 5B 5

E2

W- BW- B W- BG

RB

BR4CME01

W- B

I 6

W

M- 1C 2M- M+

3C

2

M+

B

GE0 1

C 17

Y

(

Shielded)

E 5(

A)

, E 6(

B)

, E 7(

E)

, E 8(

D)

, E 9(

C)

E 5(

A)

, E 6(

B)

, E 7(

E)

, E 8(

D)

, E 9(

C)

S28(

A)

, S29(

B)

Counter Gear Speed

Sensor Engine Coolant Temp.

Sensor

Engine Control Module Engine Control Module

Junction

Connector

Junction

Connector

Junction

ConnectorJunction

Connector

A/T Indicator SW

Shor t Connector

Turbine Speed Sensor

Thr ottle Position Sensor Throttle Control Motor

Page 323 of 2572

2005 HIGHLANDER (EWD592U)

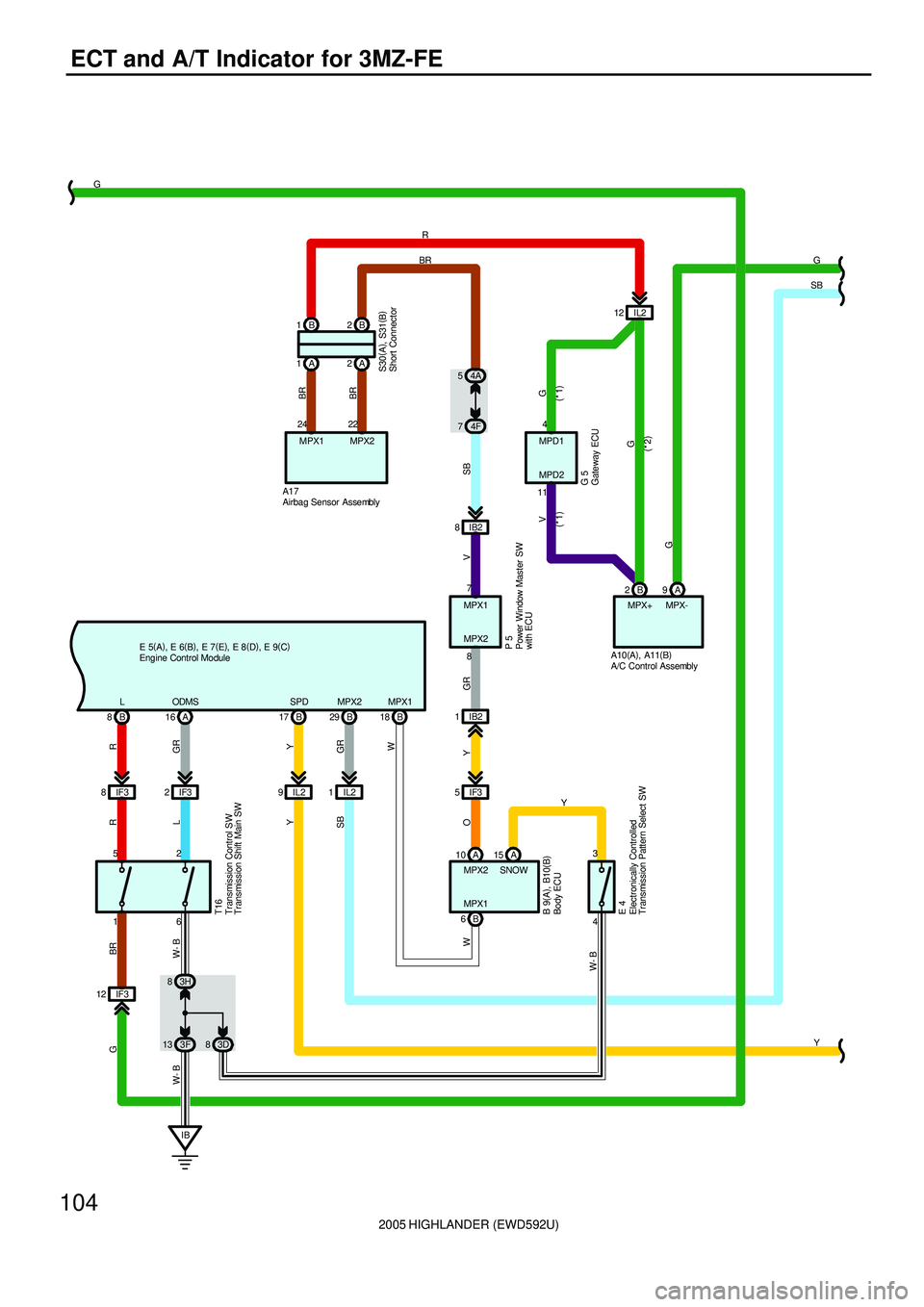

104

ECT and A/T Indicator for 3MZ-FE

BMPX-

A

1MPX1

W

2IF3R

SNOW MPX1

A 16

10

GR

ODMS9

MPX2

L

GR W- B

L

W- BW- BR

MPX2

V GR Y

E 4

29 BBR

R

8B

6

IB 13 3F6

83H3

4 A17

IF3 82B A IB2 8

IB2 1

IF3 5

15

O

7

8 MPX1

MPX2

A

P 5

MPX+

W

18 B

52

BR G

B

Y

SPD

17 B

IL2 9

Y

G

83D2 B 1

A 1A2

BR

24

MPX1

BR

22

MPX2

G V

4

11MPD1

MPD2

G 5

IL2 12

SB

74F 54AG

SB

Y IL2 1

SB

IF3 12

(

*1) (

*1)

G

(

*2)

G

Y

T16

S30(

A)

, S31(

B)

A10(

A)

, A11(

B)

B 9(

A)

, B10(

B)

E 5(

A)

, E 6(

B)

, E 7(

E)

, E 8(

D)

, E 9(

C)

A/C Control Assembly Airbag Sensor Assembly

Body ECU

Electronically Controlled

Transmission Pattern Select SW

Engine Control Module

Gateway ECU Power Window Master SW

with ECUShort Connector Transmission Control SW

Transmission Shift Main SW

Page 324 of 2572

2005 HIGHLANDER (EWD592U)

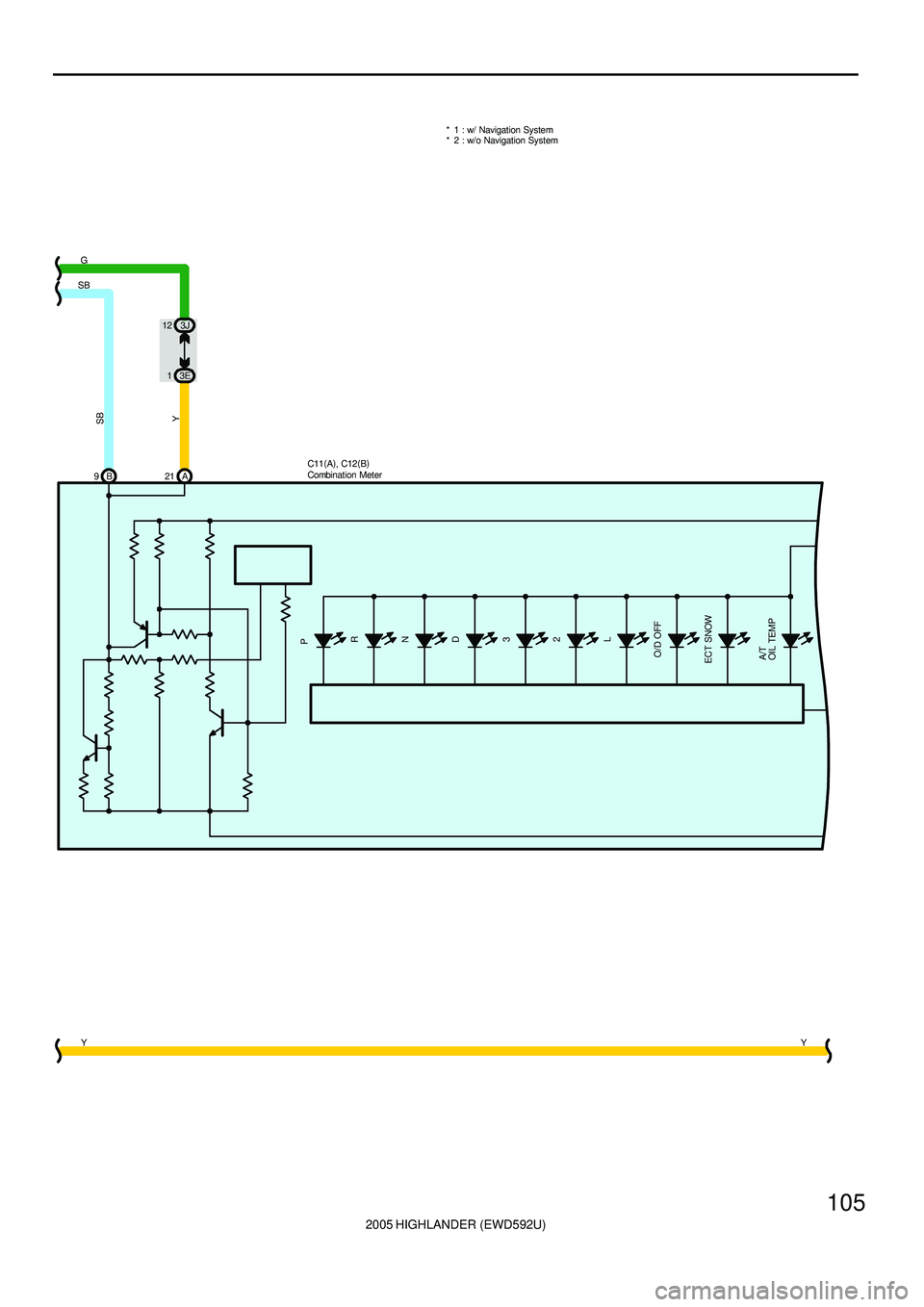

105

SB

Y

13E 12 3J SBG* 1 : w/ Navigation System

* 2 : w/o Navigation System

Y21 A 9B

A/T

OI L TEM PP

ECT SNOWO/D OFFL 2 3 D N R

Y C11(

A)

, C12(

B)

Combination Meter

Page 325 of 2572

2005 HIGHLANDER (EWD592U)

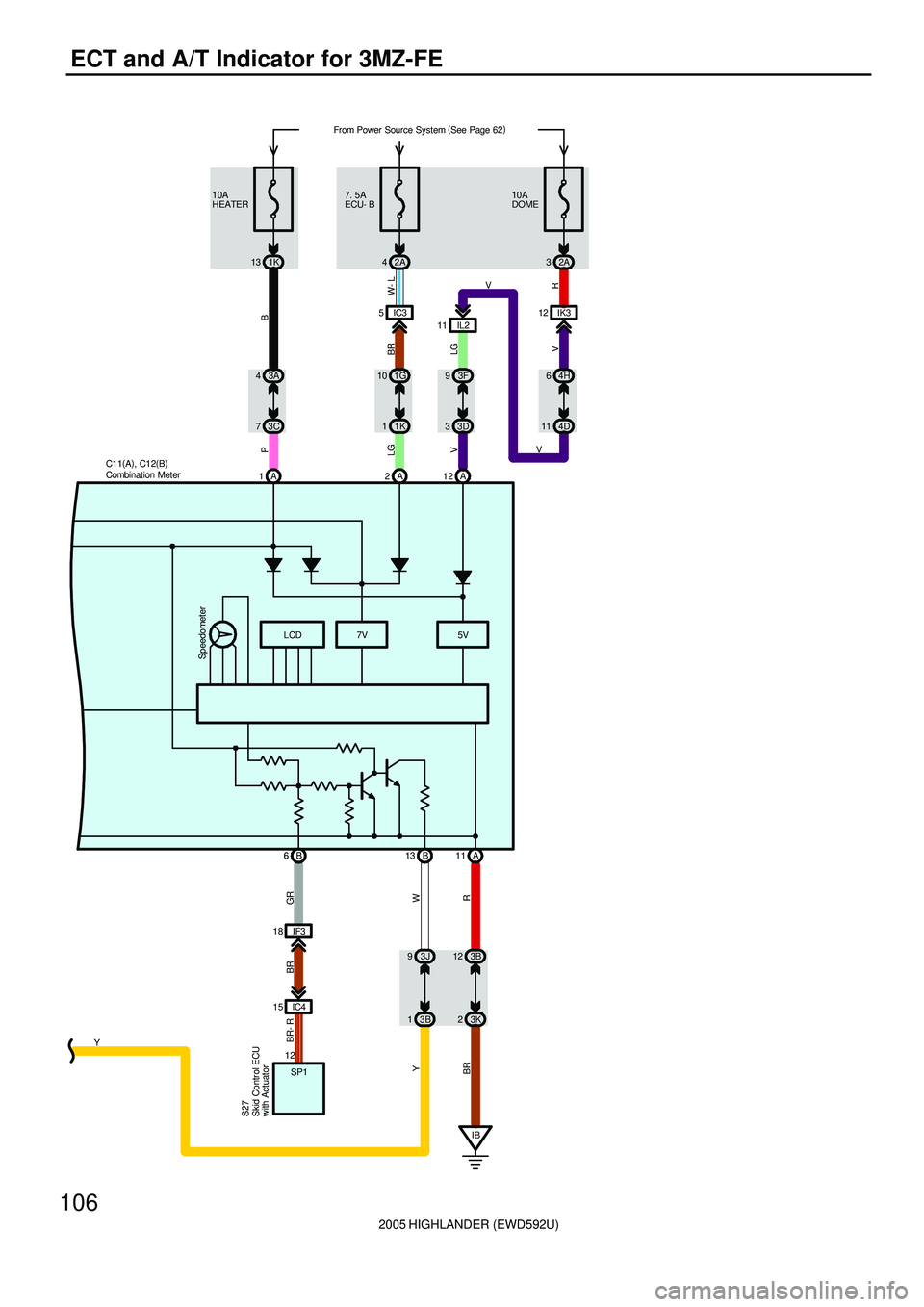

106

ECT and A/T Indicator for 3MZ-FE

LCD

W Y

93J

13B IF3 18

IC4 15

GR BR BR- R

12

SP1

S27

6B

IB A 12 A 2 A

5V 7V

Speedometer

B 13 1

B 6

R

11 A

3B 12

3K 2 11 IL2IK3 12

V V

VR

32A 10A

DOME

11 4D64H

LG V

33D 93F

BR W- L LGPB

73C 43A

11K 10 1G5IC3 7. 5A

ECU- B

2A 4 13 1K 10A

HEATER

BR

YFrom Power Source System (

See Page 62)

C11(

A)

, C12(

B)

Combination Meter

Skid Contr ol ECU

with Actuator

Page 326 of 2572

2005 HIGHLANDER (EWD592U)

107

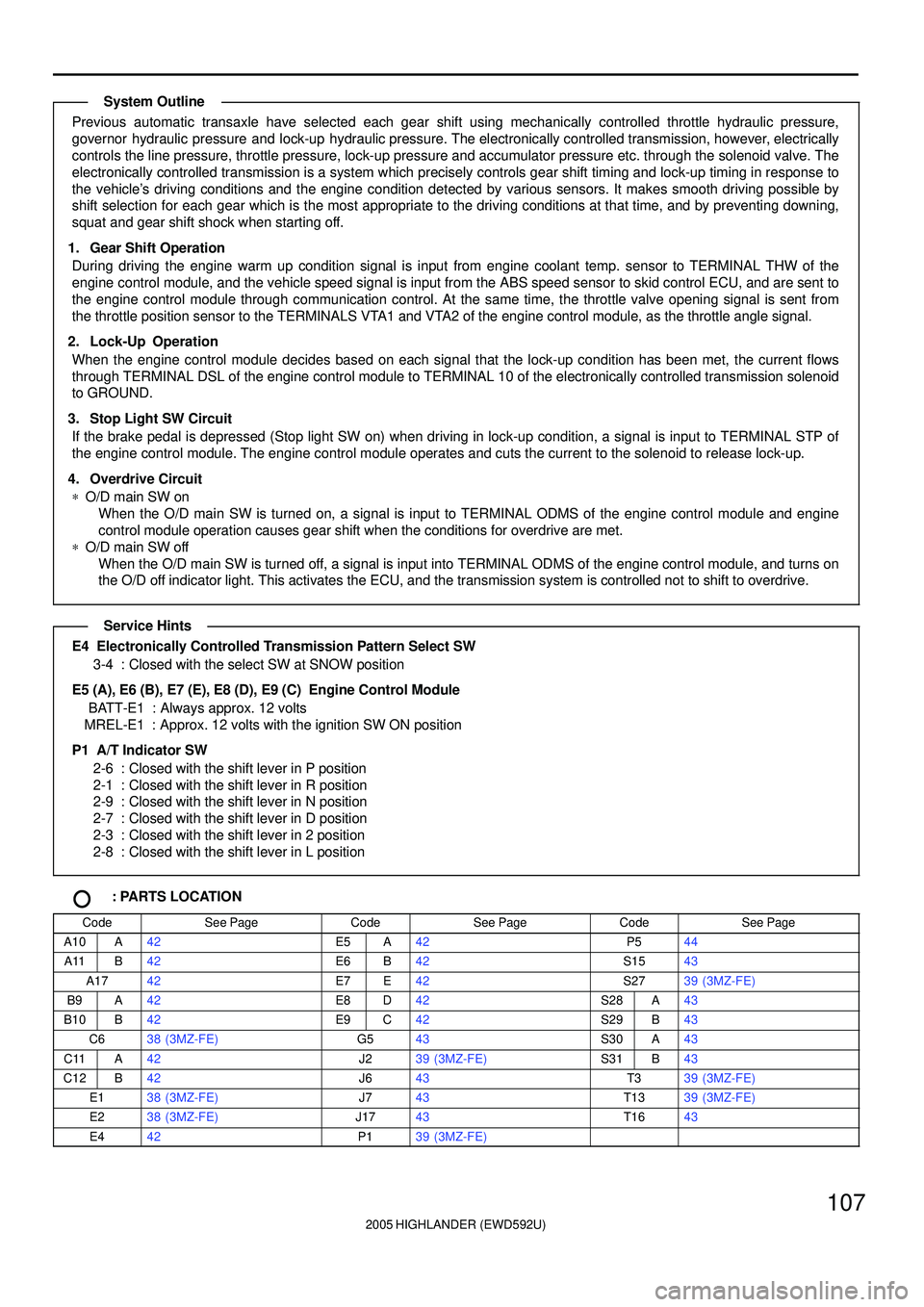

Previous automatic transaxle have selected each gear shift using mechanically controlled throttle hydraulic pressure,

governor hydraulic pressure and lock-up hydraulic pressure. The electronically controlled transmission, however, electrically

controls the line pressure, throttle pressure, lock-up pressure and accumulator pressure etc. through the solenoid valve. The

electronically controlled transmission is a system which precisely controls gear shift timing and lock-up timing in response to

the vehicle's driving conditions and the engine condition detected by various sensors. It makes smooth driving possible by

shift selection for each gear which is the most appropriate to the driving conditions at that time, and by preventing downing,

squat and gear shift shock when starting off.

1. Gear Shift Operation

During driving the engine warm up condition signal is input from engine coolant temp. sensor to TERMINAL THW of the

engine control module, and the vehicle speed signal is input from the ABS speed sensor to skid control ECU, and are sent to

the engine control module through communication control. At the same time, the throttle valve opening signal is sent from

the throttle position sensor to the TERMINALS VTA1 and VTA2 of the engine control module, as the throttle angle signal.

2. Lock-Up Operation

When the engine control module decides based on each signal that the lock-up condition has been met, the current flows

through TERMINAL DSL of the engine control module to TERMINAL 10 of the electronically controlled transmission solenoid

to GROUND.

3. Stop Light SW Circuit

If the brake pedal is depressed (Stop light SW on) when driving in lock-up condition, a signal is input to TERMINAL STP of

the engine control module. The engine control module operates and cuts the current to the solenoid to release lock-up.

4. Overdrive Circuit

*O/D main SW on

When the O/D main SW is turned on, a signal is input to TERMINAL ODMS of the engine control module and engine

control module operation causes gear shift when the conditions for overdrive are met.

*O/D main SW off

When the O/D main SW is turned off, a signal is input into TERMINAL ODMS of the engine control module, and turns on

the O/D off indicator light. This activates the ECU, and the transmission system is controlled not to shift to overdrive.

E4 Electronically Controlled Transmission Pattern Select SW

3-4 : Closed with the select SW at SNOW position

E5 (A), E6 (B), E7 (E), E8 (D), E9 (C) Engine Control Module

BATT-E1 : Always approx. 12 volts

MREL-E1 : Approx. 12 volts with the ignition SW ON position

P1 A/T Indicator SW

2-6 : Closed with the shift lever in P position

2-1 : Closed with the shift lever in R position

2-9 : Closed with the shift lever in N position

2-7 : Closed with the shift lever in D position

2-3 : Closed with the shift lever in 2 position

2-8 : Closed with the shift lever in L position

: PARTS LOCATION

CodeSee PageCodeSee PageCodeSee Page

A10A42E5A42P544

A11B42E6B42S1543

A1742E7E42S2739 (3MZ-FE)

B9A42E8D42S28A43

B10B42E9C42S29B43

C638 (3MZ-FE)G543S30A43

C11A42J239 (3MZ-FE)S31B43

C12B42J643T339 (3MZ-FE)

E138 (3MZ-FE)J743T1339 (3MZ-FE)

E238 (3MZ-FE)J1743T1643

E442P139 (3MZ-FE)

System Outline

Service Hints

Page 327 of 2572

2005 HIGHLANDER (EWD592U)

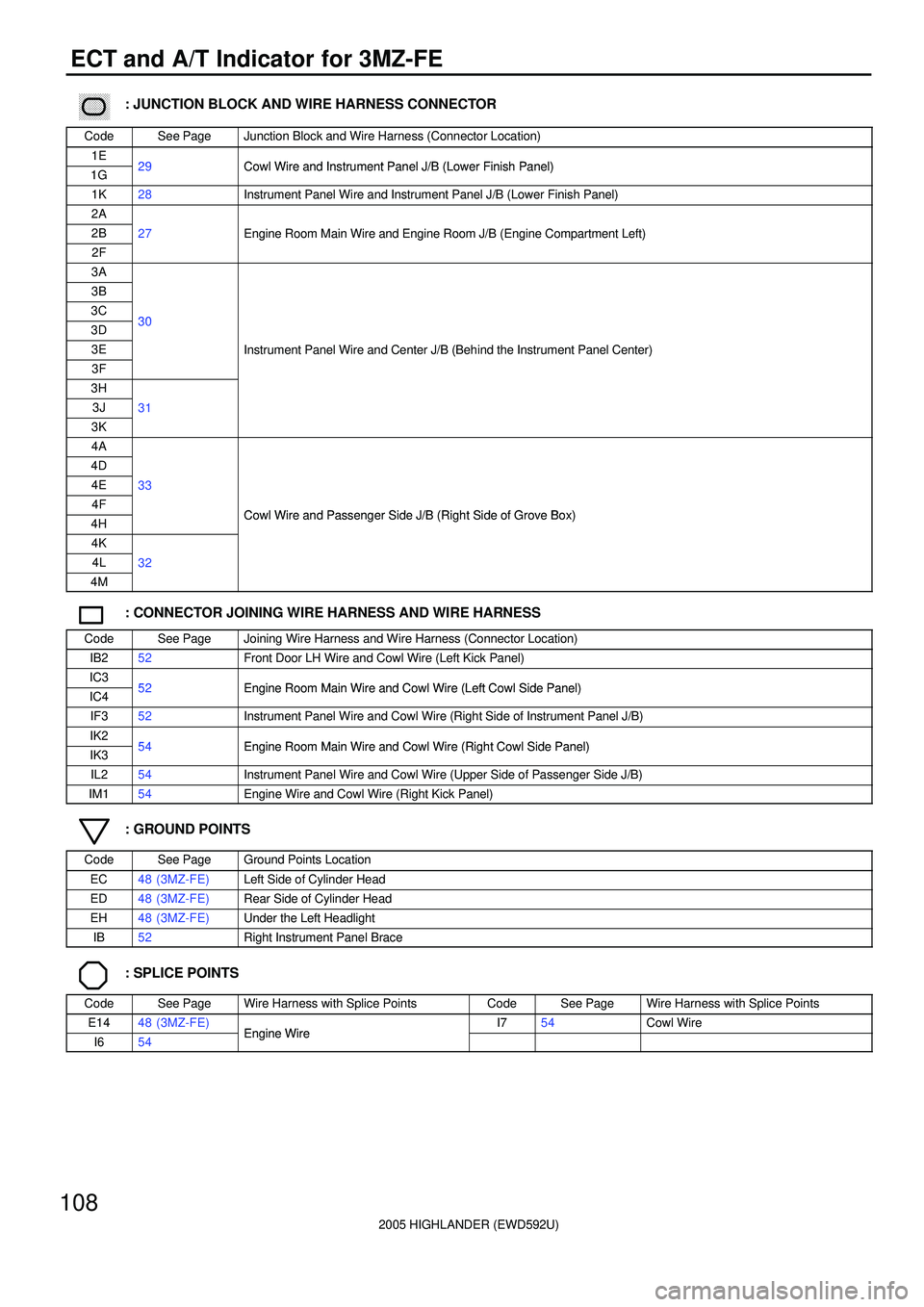

108

ECT and A/T Indicator for 3MZ-FE

������ ���: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CodeSee PageJunction Block and Wire Harness (Connector Location)

1E29Cowl Wire and Instrument Panel J/B (Lower Finish Panel)1G29Cowl Wire and Instrument Panel J/B (Lower Finish Panel)

1K28Instrument Panel Wire and Instrument Panel J/B (Lower Finish Panel)

2A

2B27Engine Room Main Wire and Engine Room J/B (Engine Compartment Left)

2F

gg(g)

3A

3B

3C303D30

3EInstrument Panel Wire and Center J/B (Behind the Instrument Panel Center)

3F

()

3H

3J31

3K

4A

4D

4E33

4FCowl Wire and Passenger Side J/B (Right Side of Grove Box)4HCowl Wire and Passenger Side J/B (Right Side of Grove Box)

4K

4L32

4M

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CodeSee PageJoining Wire Harness and Wire Harness (Connector Location)

IB252Front Door LH Wire and Cowl Wire (Left Kick Panel)

IC352Engine Room Main Wire and Cowl Wire (Left Cowl Side Panel)IC452Engine Room Main Wire and Cowl Wire (Left Cowl Side Panel)

IF352Instrument Panel Wire and Cowl Wire (Right Side of Instrument Panel J/B)

IK254Engine Room Main Wire and Cowl Wire (Right Cowl Side Panel)IK354Engine Room Main Wire and Cowl Wire (Right Cowl Side Panel)

IL254Instrument Panel Wire and Cowl Wire (Upper Side of Passenger Side J/B)

IM154Engine Wire and Cowl Wire (Right Kick Panel)

: GROUND POINTS

CodeSee PageGround Points Location

EC48 (3MZ-FE)Left Side of Cylinder Head

ED48 (3MZ-FE)Rear Side of Cylinder Head

EH48 (3MZ-FE)Under the Left Headlight

IB52Right Instrument Panel Brace

: SPLICE POINTS

CodeSee PageWire Harness with Splice PointsCodeSee PageWire Harness with Splice Points

E1448 (3MZ-FE)Engine WireI754Cowl Wire

I654Engine Wire

Page 328 of 2572

2005 HIGHLANDER (EWD592U)

109

MEMO

Page 329 of 2572

'05 HIGHLANDER_U (L/O 0409)

169

2005 HIGHLANDER from Nov. '04 Prod. (OM48570U)

OPERATION OF INSTRUMENTS AND

CONTROLS

Audio system

Reference170 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using your audio system170 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Audio remote controls186 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear seat entertainment system189 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Audio/video system operating hints240 . . . . . . . . . . . . . . . . . . . . . . . . . . .

For vehicle equipped with Navigation system, please refer to the

separate Navigation System Owner's Manualº.

SECTION 1- 8

Page 330 of 2572

'05 HIGHLANDER_U (L/O 0409)

170

2005 HIGHLANDER from Nov. '04 Prod. (OM48570U)

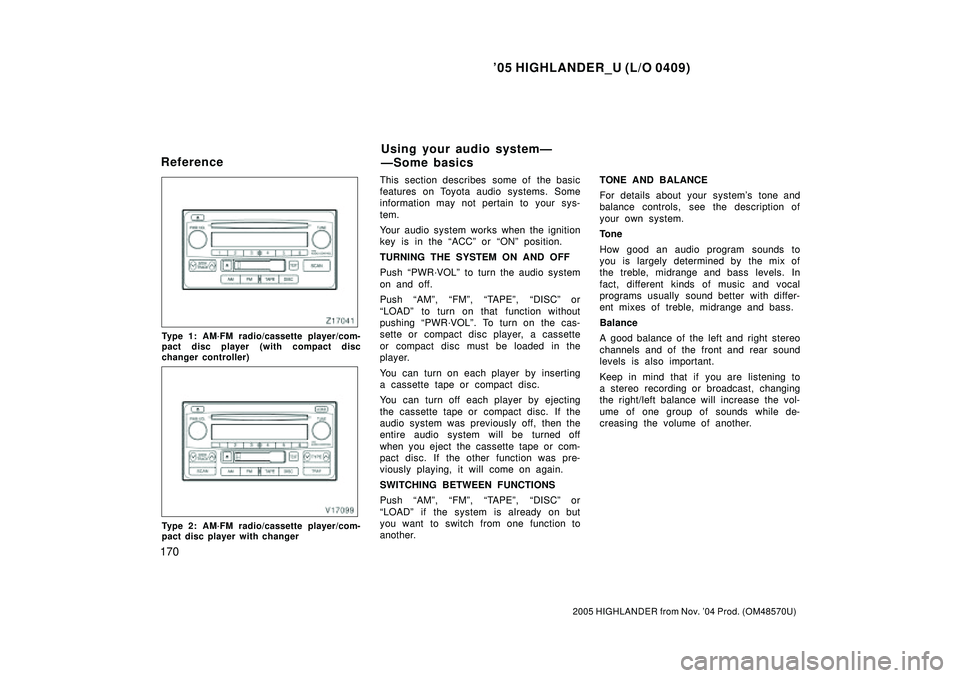

Type 1: AM´FM radio/cassette player/com-

pact disc player (with compact disc

changer controller)

Type 2: AM´FM radio/cassette player/com-

pact disc player with changer

This section describes some of the basic

features on Toyota audio systems. Some

information may not pertain to your sys-

tem.

Your audio system works when the ignition

key is in the ACCº or ONº position.

TURNING THE SYSTEM ON AND OFF

Push PWR´VOLº to turn the audio system

on and off.

Push AMº, FMº, TAPEº, DISCº or

LOADº to turn on that function without

pushing PWR´VOLº. To turn on the cas-

sette or compact disc player, a cassette

or compact disc must be loaded in the

player.

You can turn on each player by inserting

a cassette tape or compact disc.

You can turn off each player by ejecting

the cassette tape or compact disc. If the

audio system was previously off, then the

entire audio system will be turned off

when you eject the cassette tape or com-

pact disc. If the other function was pre-

viously playing, it will come on again.

SWITCHING BETWEEN FUNCTIONS

Push AMº, FMº, TAPEº, DISCº or

LOADº if the system is already on but

you want to switch from one function to

another.TONE AND BALANCE

For details about your system's tone and

balance controls, see the description of

your own system.

Tone

How good an audio program sounds to

you is largely determined by the mix of

the treble, midrange and bass levels. In

fact, different kinds of music and vocal

programs usually sound better with differ-

ent mixes of treble, midrange and bass.

Balance

A good balance of the left and right stereo

channels and of the front and rear sound

levels is also important.

Keep in mind that if you are listening to

a stereo recording or broadcast, changing

the right/left balance will increase the vol-

ume of one group of sounds while de-

creasing the volume of another.

ReferenceUsing your audio systemÐ

ÐSome basics