TOYOTA RAV4 2006 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 1061 of 2000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLYAX–177

AX

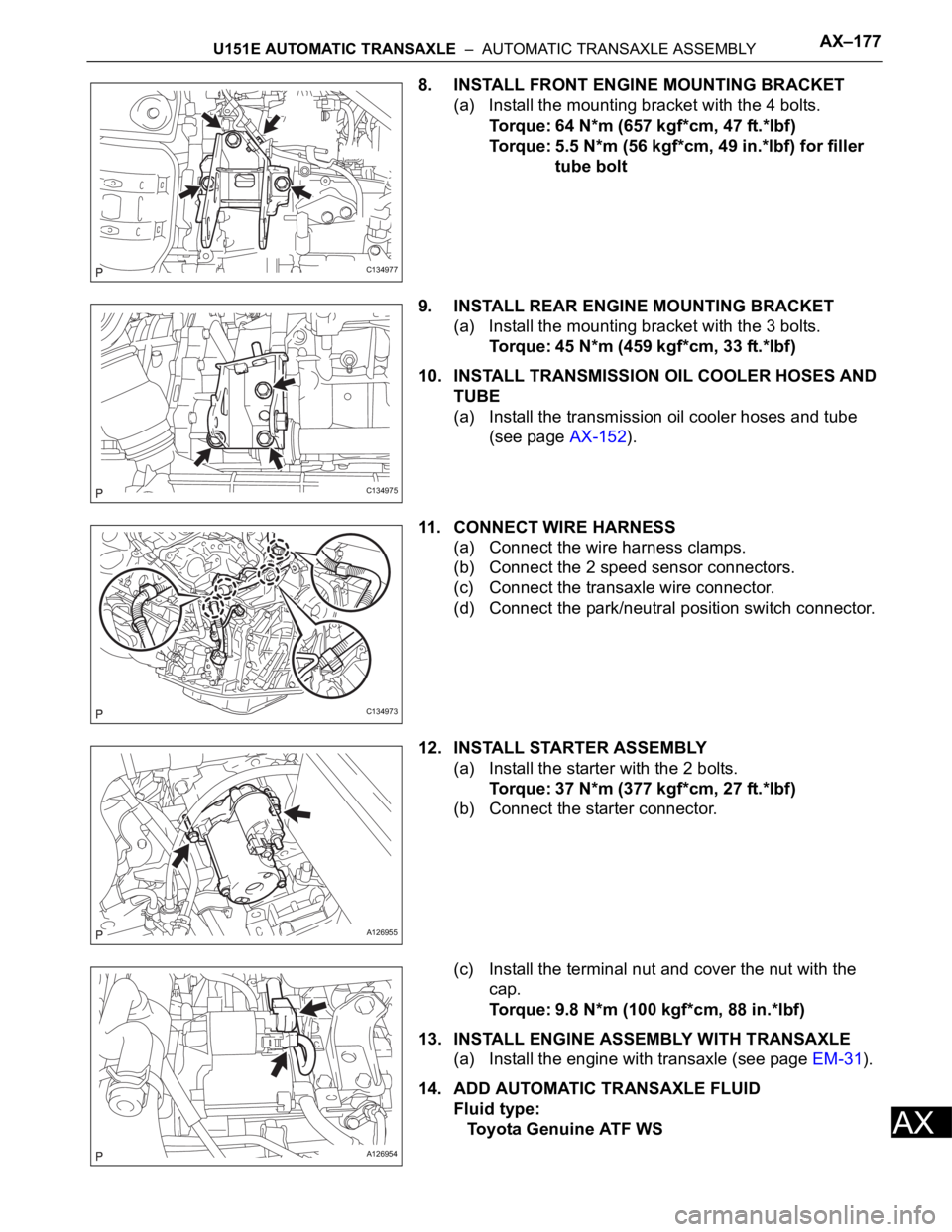

8. INSTALL FRONT ENGINE MOUNTING BRACKET

(a) Install the mounting bracket with the 4 bolts.

Torque: 64 N*m (657 kgf*cm, 47 ft.*lbf)

Torque: 5.5 N*m (56 kgf*cm, 49 in.*lbf) for filler

tube bolt

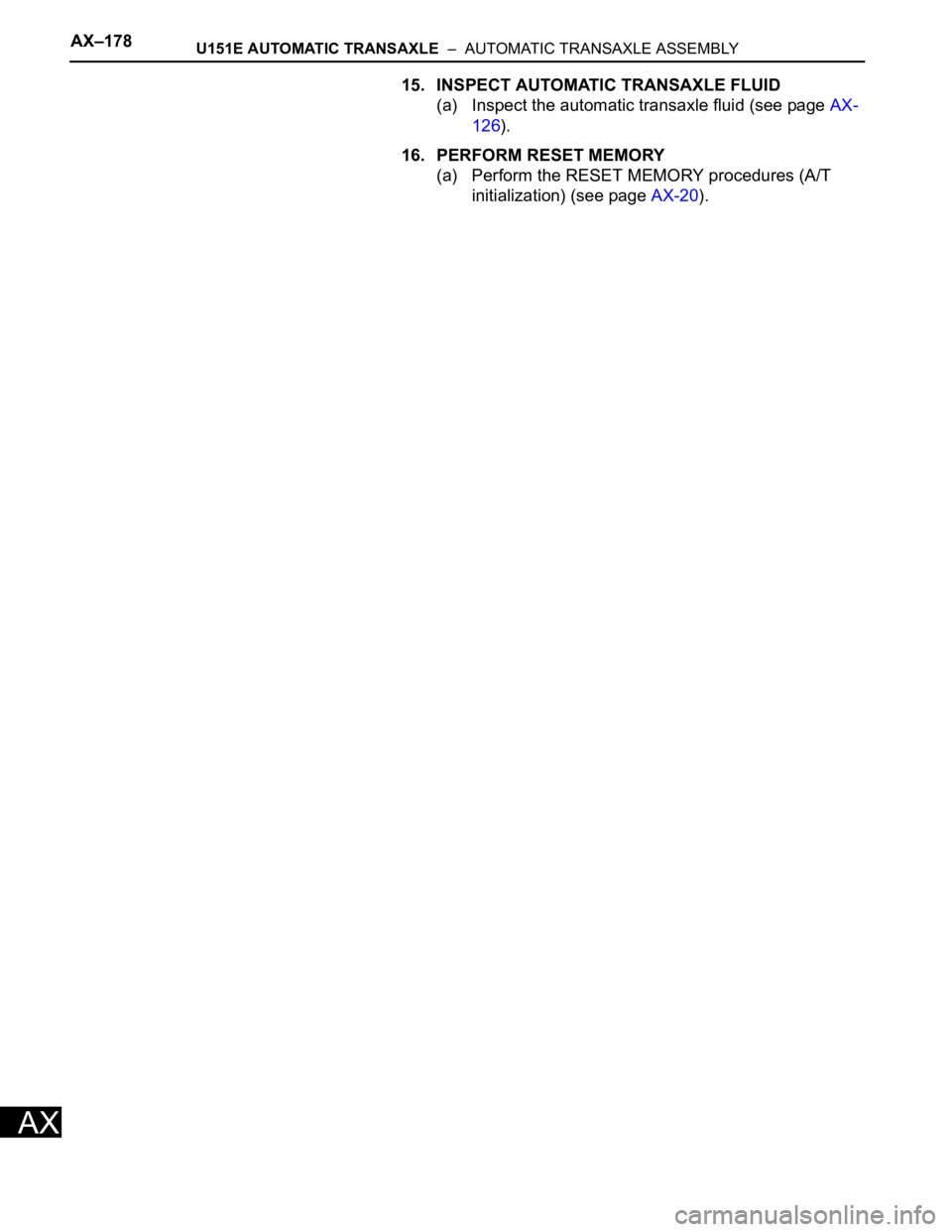

9. INSTALL REAR ENGINE MOUNTING BRACKET

(a) Install the mounting bracket with the 3 bolts.

Torque: 45 N*m (459 kgf*cm, 33 ft.*lbf)

10. INSTALL TRANSMISSION OIL COOLER HOSES AND

TUBE

(a) Install the transmission oil cooler hoses and tube

(see page AX-152).

11. CONNECT WIRE HARNESS

(a) Connect the wire harness clamps.

(b) Connect the 2 speed sensor connectors.

(c) Connect the transaxle wire connector.

(d) Connect the park/neutral position switch connector.

12. INSTALL STARTER ASSEMBLY

(a) Install the starter with the 2 bolts.

Torque: 37 N*m (377 kgf*cm, 27 ft.*lbf)

(b) Connect the starter connector.

(c) Install the terminal nut and cover the nut with the

cap.

Torque: 9.8 N*m (100 kgf*cm, 88 in.*lbf)

13. INSTALL ENGINE ASSEMBLY WITH TRANSAXLE

(a) Install the engine with transaxle (see page EM-31).

14. ADD AUTOMATIC TRANSAXLE FLUID

Fluid type:

Toyota Genuine ATF WS

C134977

C134975

C134973

A126955

A126954

Page 1062 of 2000

AX–178U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLY

AX

15. INSPECT AUTOMATIC TRANSAXLE FLUID

(a) Inspect the automatic transaxle fluid (see page AX-

126).

16. PERFORM RESET MEMORY

(a) Perform the RESET MEMORY procedures (A/T

initialization) (see page AX-20).

Page 1063 of 2000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–189

AX

DISASSEMBLY

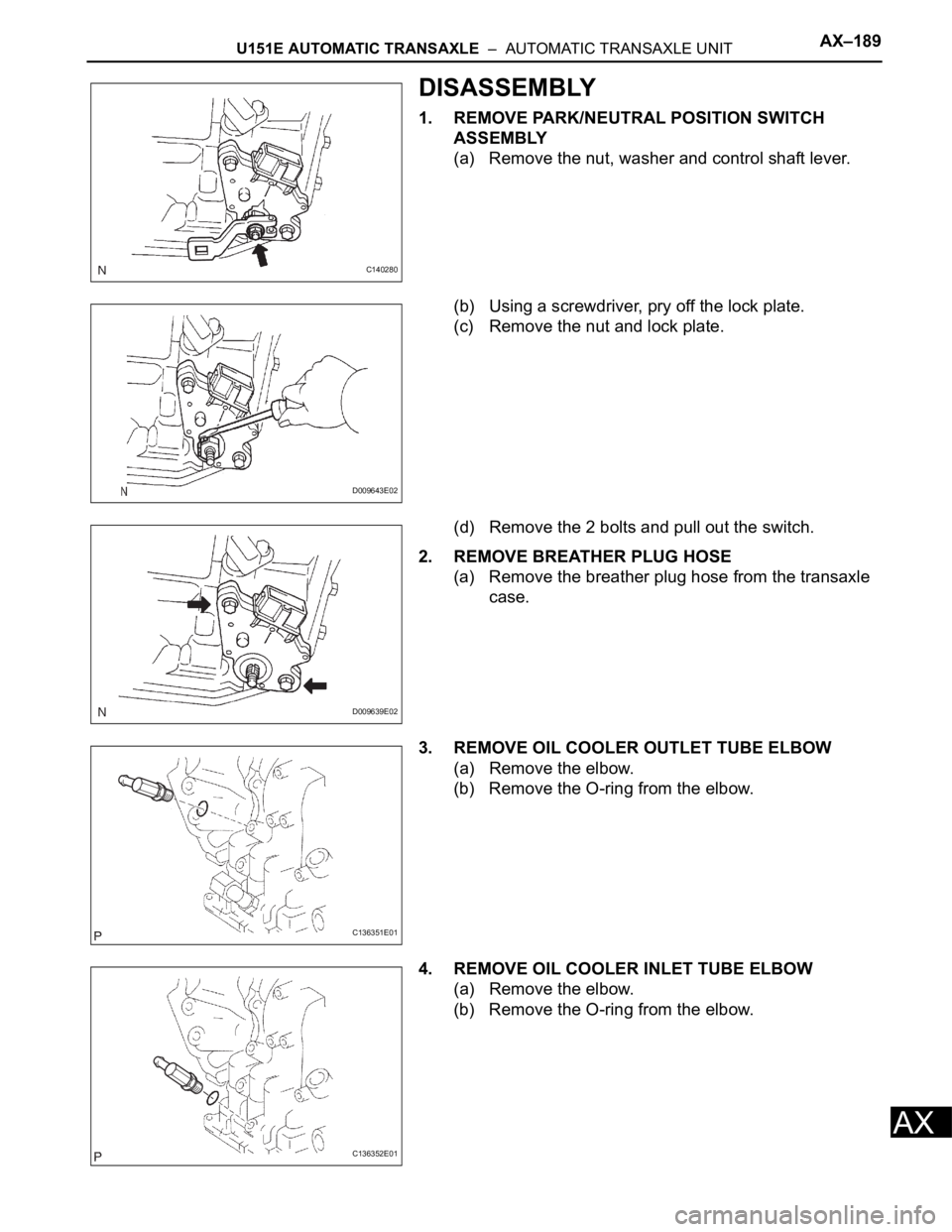

1. REMOVE PARK/NEUTRAL POSITION SWITCH

ASSEMBLY

(a) Remove the nut, washer and control shaft lever.

(b) Using a screwdriver, pry off the lock plate.

(c) Remove the nut and lock plate.

(d) Remove the 2 bolts and pull out the switch.

2. REMOVE BREATHER PLUG HOSE

(a) Remove the breather plug hose from the transaxle

case.

3. REMOVE OIL COOLER OUTLET TUBE ELBOW

(a) Remove the elbow.

(b) Remove the O-ring from the elbow.

4. REMOVE OIL COOLER INLET TUBE ELBOW

(a) Remove the elbow.

(b) Remove the O-ring from the elbow.

C140280

D009643E02

D009639E02

C136351E01

C136352E01

Page 1064 of 2000

AX–190U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

5. REMOVE SPEED SENSOR

(a) Remove the 2 bolts and the 2 speed sensors from

the transaxle.

6. REMOVE SPEEDOMETER DRIVEN HOLE COVER

SUB-ASSEMBLY

(a) Remove the bolt and cover.

(b) Remove the O-ring from the cover.

7. REMOVE NO. 1 TRANSAXLE CASE PLUG

(a) Remove the 4 plugs from the transaxle case.

(b) Remove the 4 O-rings from the 4 plugs.

8. FIX AUTOMATIC TRANSAXLE ASSEMBLY

(a) Fix the transaxle.

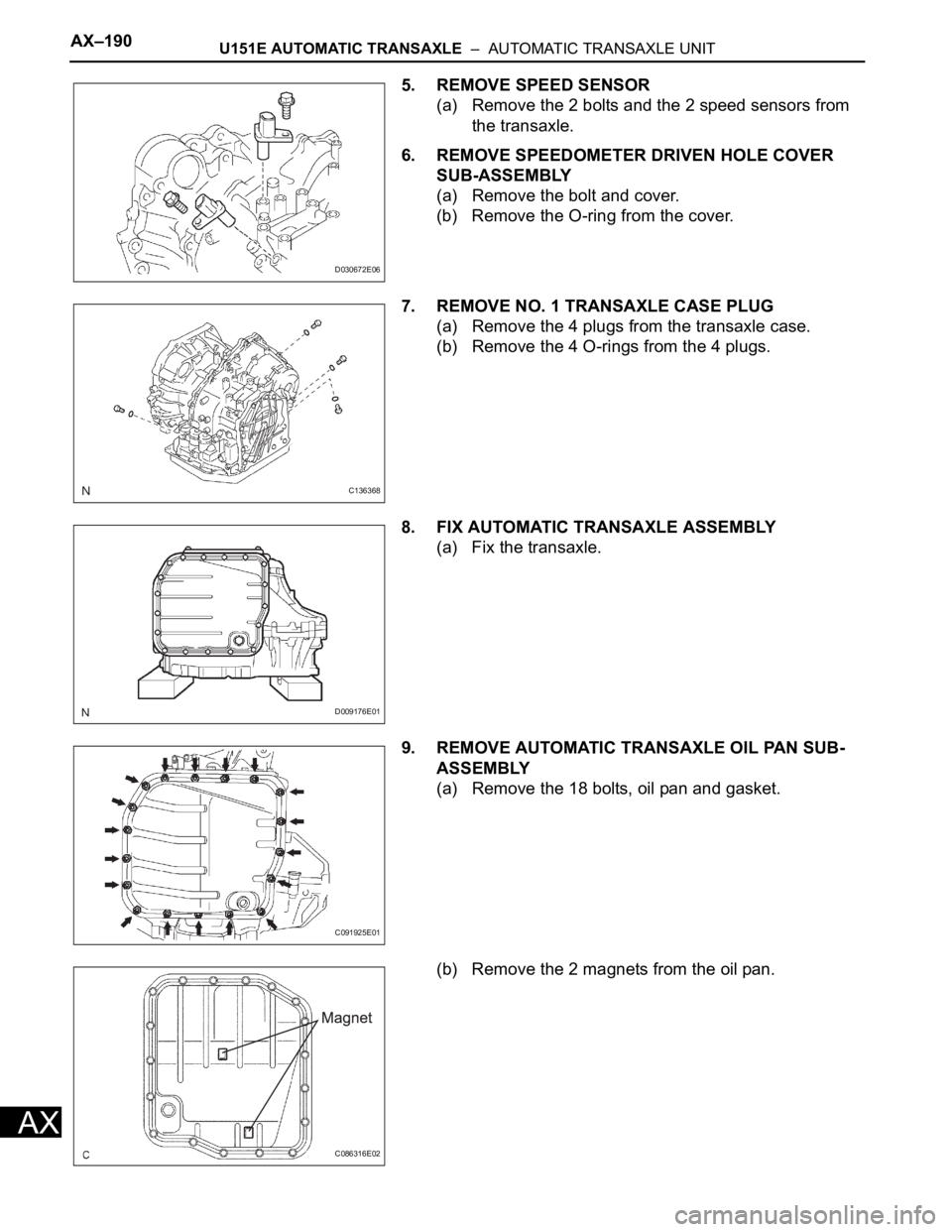

9. REMOVE AUTOMATIC TRANSAXLE OIL PAN SUB-

ASSEMBLY

(a) Remove the 18 bolts, oil pan and gasket.

(b) Remove the 2 magnets from the oil pan.

D030672E06

C136368

D009176E01

C091925E01

C086316E02

Page 1065 of 2000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–191

AX

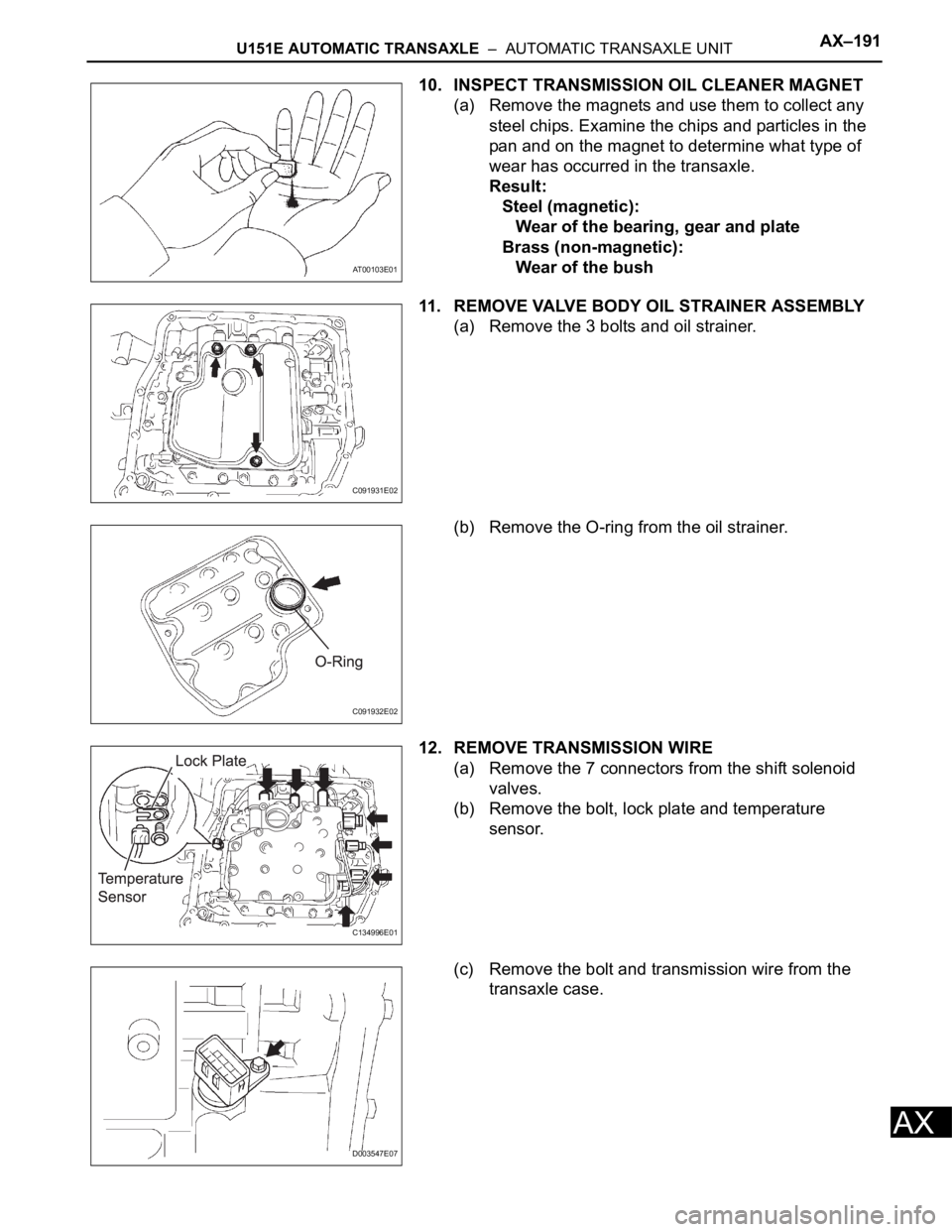

10. INSPECT TRANSMISSION OIL CLEANER MAGNET

(a) Remove the magnets and use them to collect any

steel chips. Examine the chips and particles in the

pan and on the magnet to determine what type of

wear has occurred in the transaxle.

Result:

Steel (magnetic):

Wear of the bearing, gear and plate

Brass (non-magnetic):

Wear of the bush

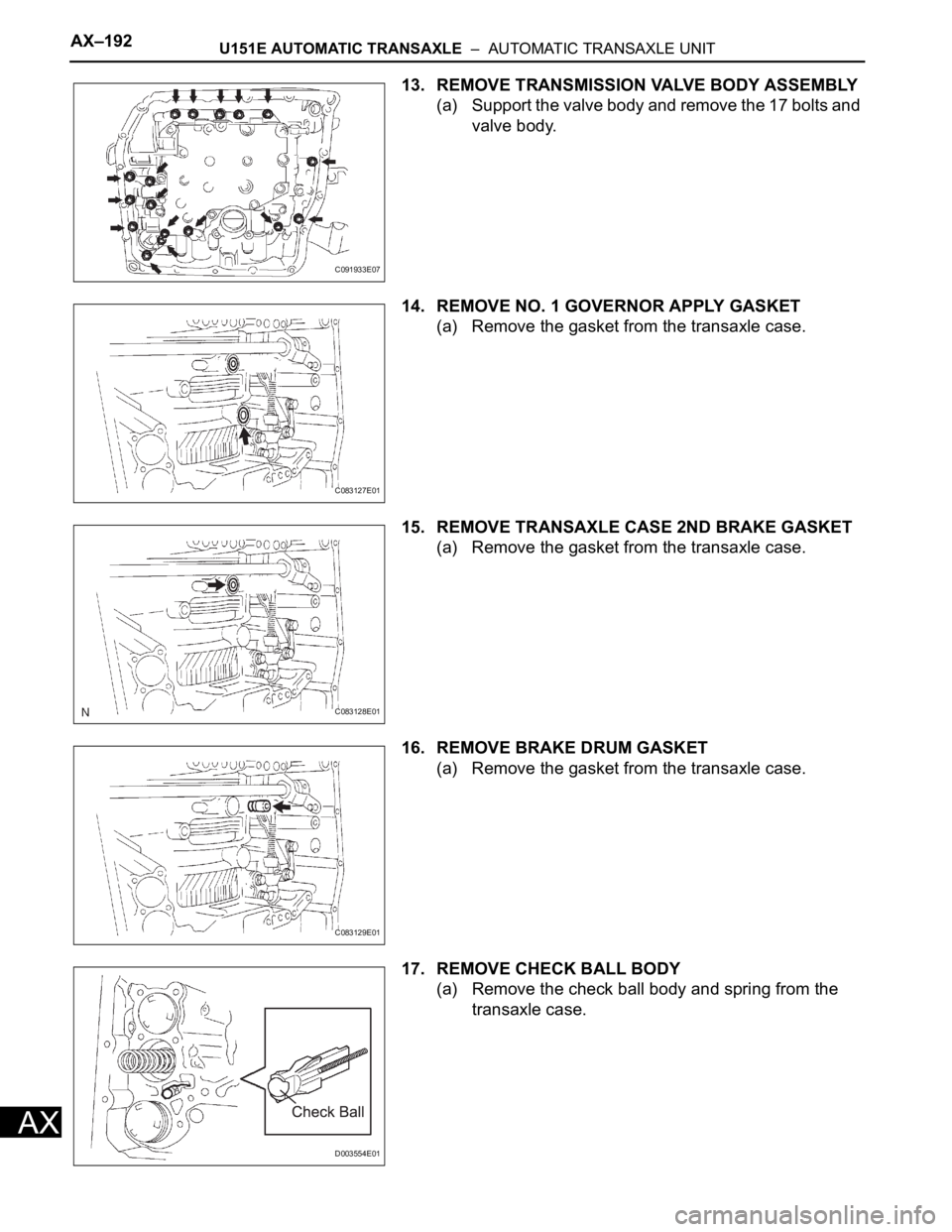

11. REMOVE VALVE BODY OIL STRAINER ASSEMBLY

(a) Remove the 3 bolts and oil strainer.

(b) Remove the O-ring from the oil strainer.

12. REMOVE TRANSMISSION WIRE

(a) Remove the 7 connectors from the shift solenoid

valves.

(b) Remove the bolt, lock plate and temperature

sensor.

(c) Remove the bolt and transmission wire from the

transaxle case.

AT00103E01

C091931E02

C091932E02

C134996E01

D003547E07

Page 1066 of 2000

AX–192U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

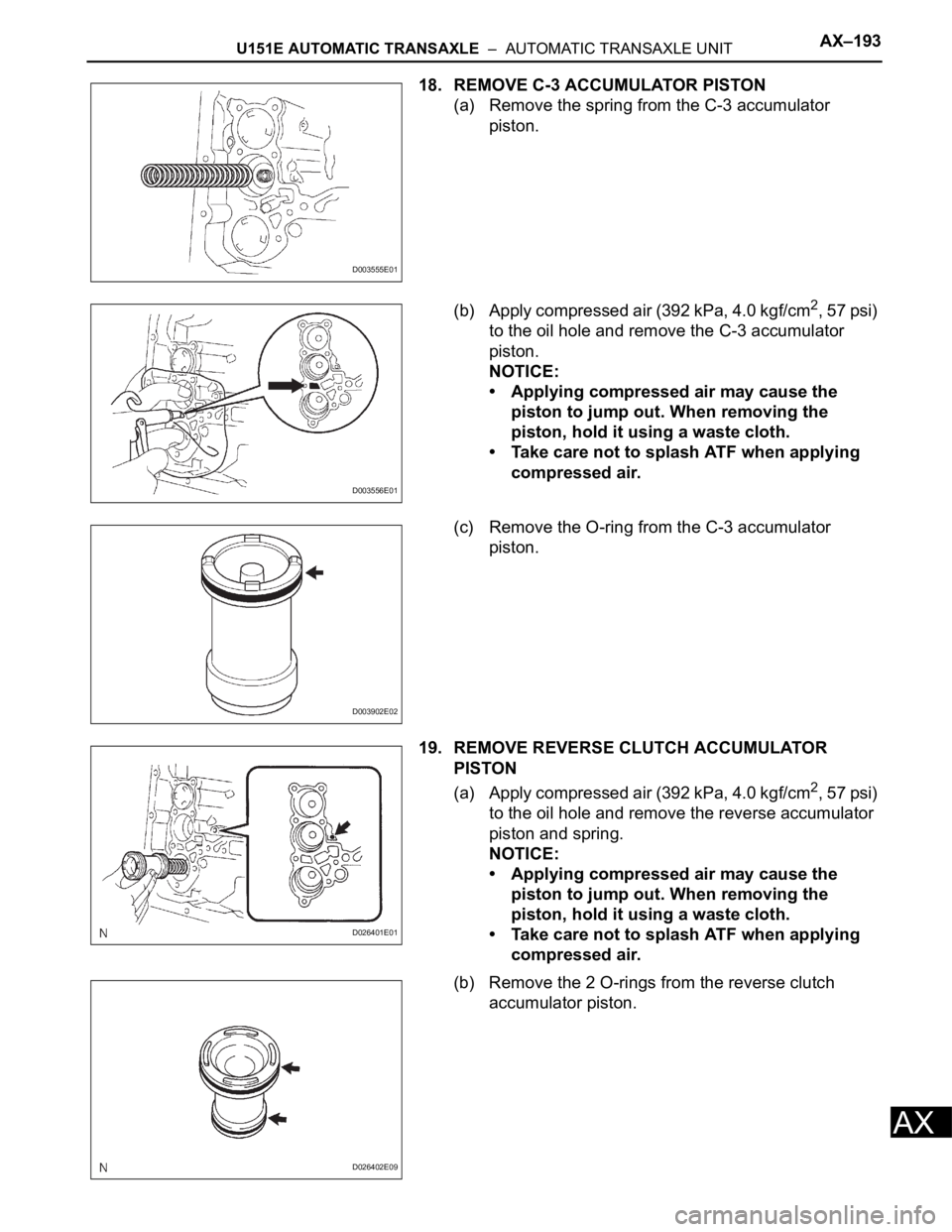

13. REMOVE TRANSMISSION VALVE BODY ASSEMBLY

(a) Support the valve body and remove the 17 bolts and

valve body.

14. REMOVE NO. 1 GOVERNOR APPLY GASKET

(a) Remove the gasket from the transaxle case.

15. REMOVE TRANSAXLE CASE 2ND BRAKE GASKET

(a) Remove the gasket from the transaxle case.

16. REMOVE BRAKE DRUM GASKET

(a) Remove the gasket from the transaxle case.

17. REMOVE CHECK BALL BODY

(a) Remove the check ball body and spring from the

transaxle case.

C091933E07

C083127E01

C083128E01

C083129E01

D003554E01

Page 1067 of 2000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–193

AX

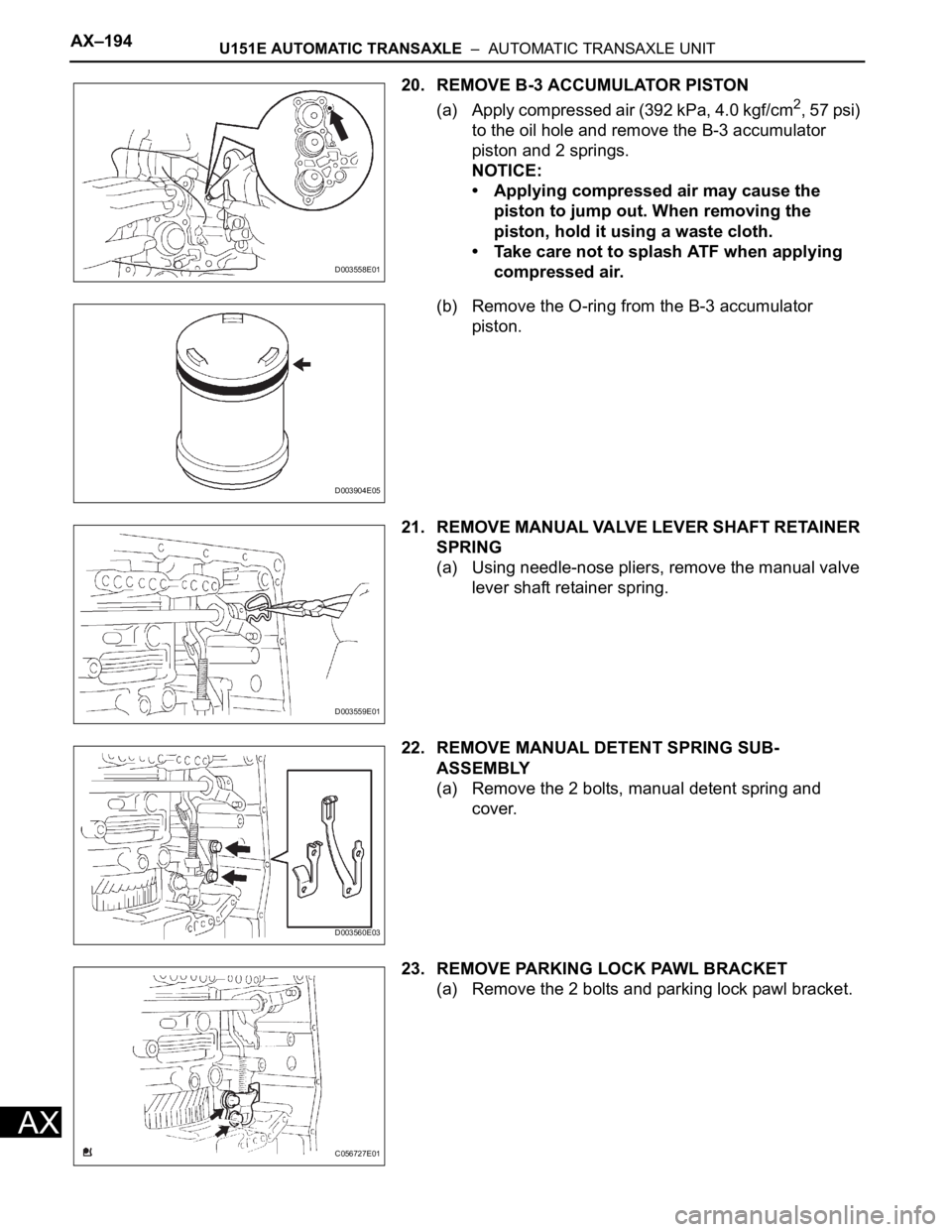

18. REMOVE C-3 ACCUMULATOR PISTON

(a) Remove the spring from the C-3 accumulator

piston.

(b) Apply compressed air (392 kPa, 4.0 kgf/cm

2, 57 psi)

to the oil hole and remove the C-3 accumulator

piston.

NOTICE:

• Applying compressed air may cause the

piston to jump out. When removing the

piston, hold it using a waste cloth.

• Take care not to splash ATF when applying

compressed air.

(c) Remove the O-ring from the C-3 accumulator

piston.

19. REMOVE REVERSE CLUTCH ACCUMULATOR

PISTON

(a) Apply compressed air (392 kPa, 4.0 kgf/cm

2, 57 psi)

to the oil hole and remove the reverse accumulator

piston and spring.

NOTICE:

• Applying compressed air may cause the

piston to jump out. When removing the

piston, hold it using a waste cloth.

• Take care not to splash ATF when applying

compressed air.

(b) Remove the 2 O-rings from the reverse clutch

accumulator piston.

D003555E01

D003556E01

D003902E02

D026401E01

D026402E09

Page 1068 of 2000

AX–194U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

20. REMOVE B-3 ACCUMULATOR PISTON

(a) Apply compressed air (392 kPa, 4.0 kgf/cm

2, 57 psi)

to the oil hole and remove the B-3 accumulator

piston and 2 springs.

NOTICE:

• Applying compressed air may cause the

piston to jump out. When removing the

piston, hold it using a waste cloth.

• Take care not to splash ATF when applying

compressed air.

(b) Remove the O-ring from the B-3 accumulator

piston.

21. REMOVE MANUAL VALVE LEVER SHAFT RETAINER

SPRING

(a) Using needle-nose pliers, remove the manual valve

lever shaft retainer spring.

22. REMOVE MANUAL DETENT SPRING SUB-

ASSEMBLY

(a) Remove the 2 bolts, manual detent spring and

cover.

23. REMOVE PARKING LOCK PAWL BRACKET

(a) Remove the 2 bolts and parking lock pawl bracket.

D003558E01

D003904E05

D003559E01

D003560E03

C056727E01

Page 1069 of 2000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–195

AX

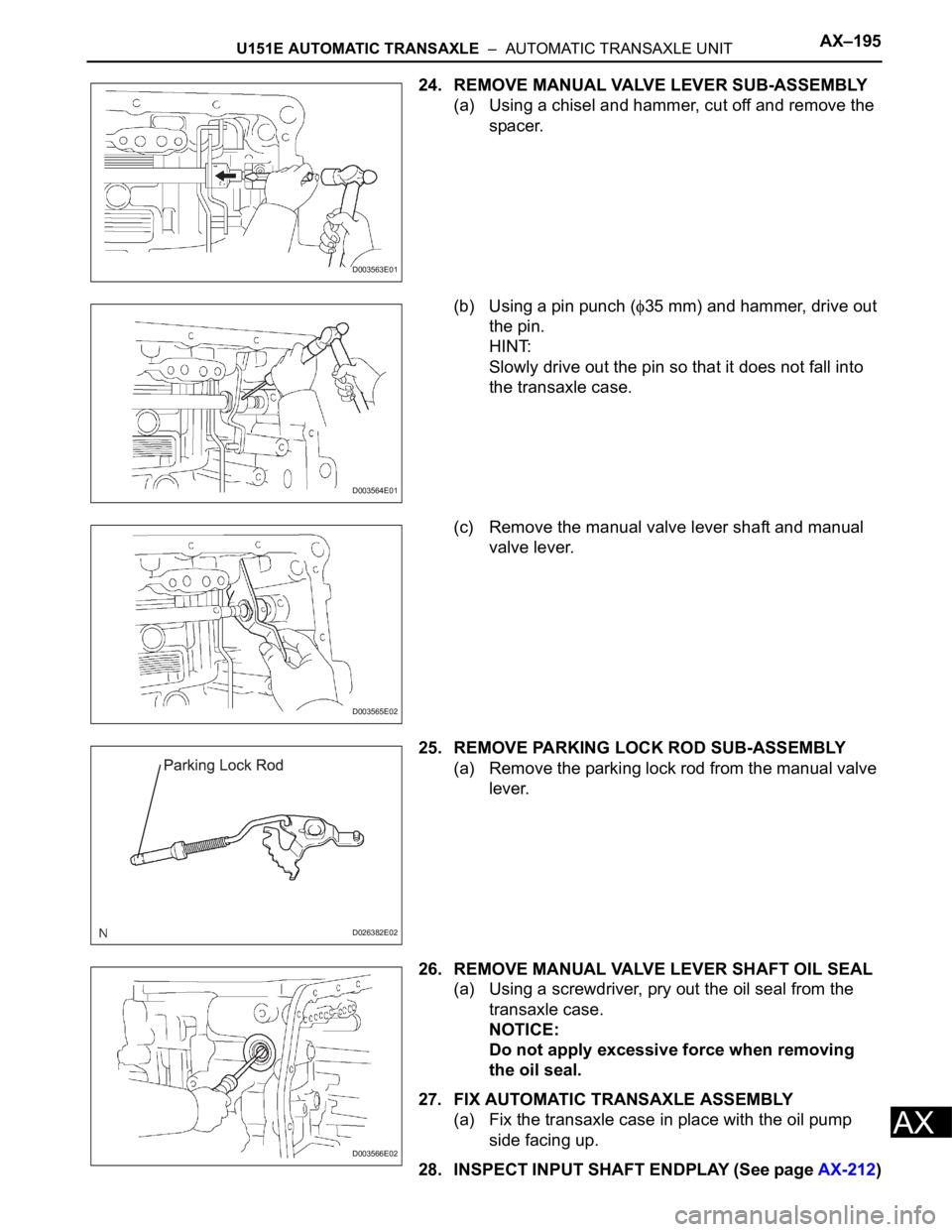

24. REMOVE MANUAL VALVE LEVER SUB-ASSEMBLY

(a) Using a chisel and hammer, cut off and remove the

spacer.

(b) Using a pin punch (

35 mm) and hammer, drive out

the pin.

HINT:

Slowly drive out the pin so that it does not fall into

the transaxle case.

(c) Remove the manual valve lever shaft and manual

valve lever.

25. REMOVE PARKING LOCK ROD SUB-ASSEMBLY

(a) Remove the parking lock rod from the manual valve

lever.

26. REMOVE MANUAL VALVE LEVER SHAFT OIL SEAL

(a) Using a screwdriver, pry out the oil seal from the

transaxle case.

NOTICE:

Do not apply excessive force when removing

the oil seal.

27. FIX AUTOMATIC TRANSAXLE ASSEMBLY

(a) Fix the transaxle case in place with the oil pump

side facing up.

28. INSPECT INPUT SHAFT ENDPLAY (See page AX-212)

D003563E01

D003564E01

D003565E02

D026382E02

D003566E02

Page 1070 of 2000

AX–196U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

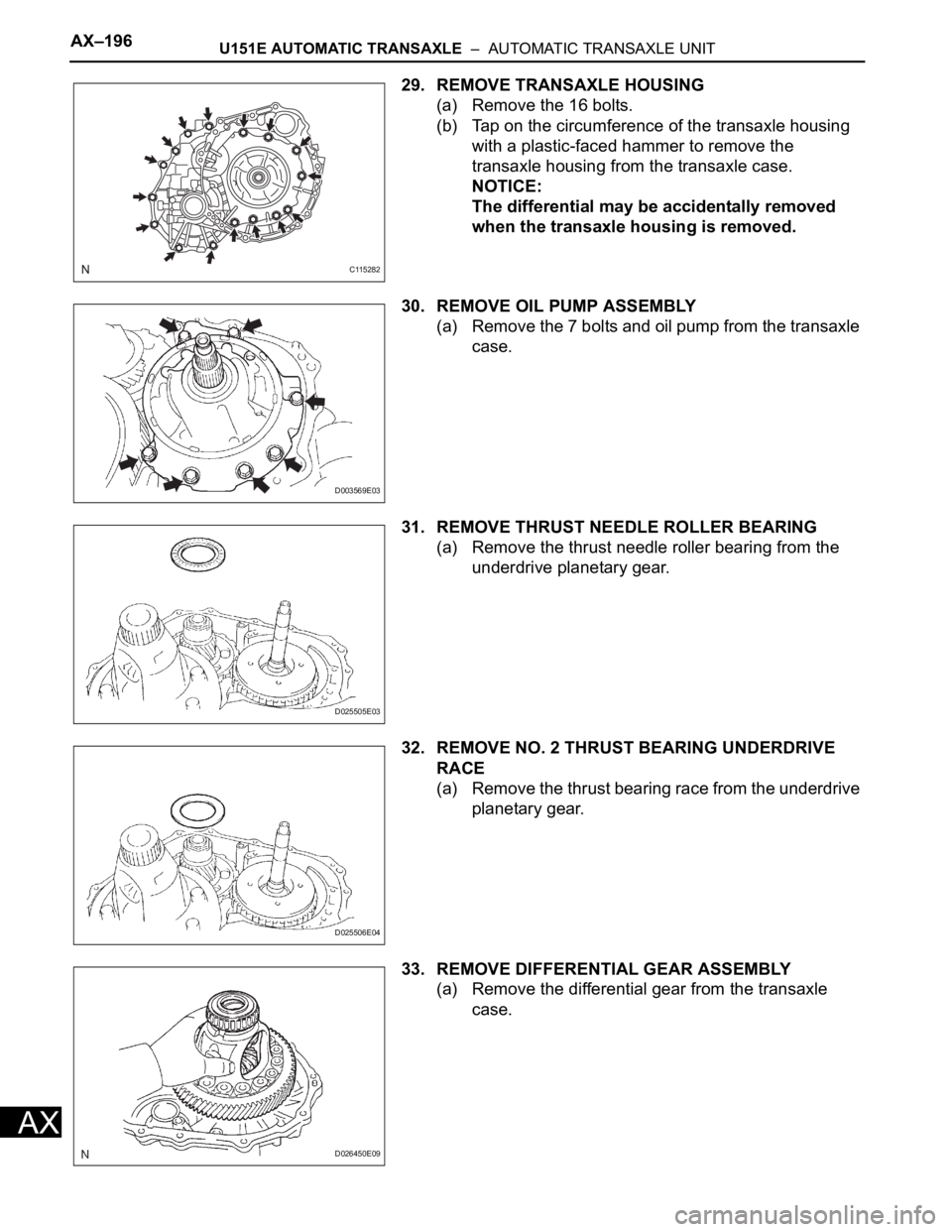

29. REMOVE TRANSAXLE HOUSING

(a) Remove the 16 bolts.

(b) Tap on the circumference of the transaxle housing

with a plastic-faced hammer to remove the

transaxle housing from the transaxle case.

NOTICE:

The differential may be accidentally removed

when the transaxle housing is removed.

30. REMOVE OIL PUMP ASSEMBLY

(a) Remove the 7 bolts and oil pump from the transaxle

case.

31. REMOVE THRUST NEEDLE ROLLER BEARING

(a) Remove the thrust needle roller bearing from the

underdrive planetary gear.

32. REMOVE NO. 2 THRUST BEARING UNDERDRIVE

RACE

(a) Remove the thrust bearing race from the underdrive

planetary gear.

33. REMOVE DIFFERENTIAL GEAR ASSEMBLY

(a) Remove the differential gear from the transaxle

case.

C115282

D003569E03

D025505E03

D025506E04

D026450E09