TOYOTA RAV4 2006 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2006,

Model line: RAV4,

Model: TOYOTA RAV4 2006

Pages: 2000, PDF Size: 45.84 MB

TOYOTA RAV4 2006 Service Repair Manual

RAV4 2006

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57463/w960_57463-0.png

TOYOTA RAV4 2006 Service Repair Manual

Trending: Bearing, overdrive, ECO mode, suspension, power steering fluid, fuel pressure, check engine light

Page 1021 of 2000

U140F AUTOMATIC TRANSAXLE – DIFFERENTIAL CASEAX–261

AX

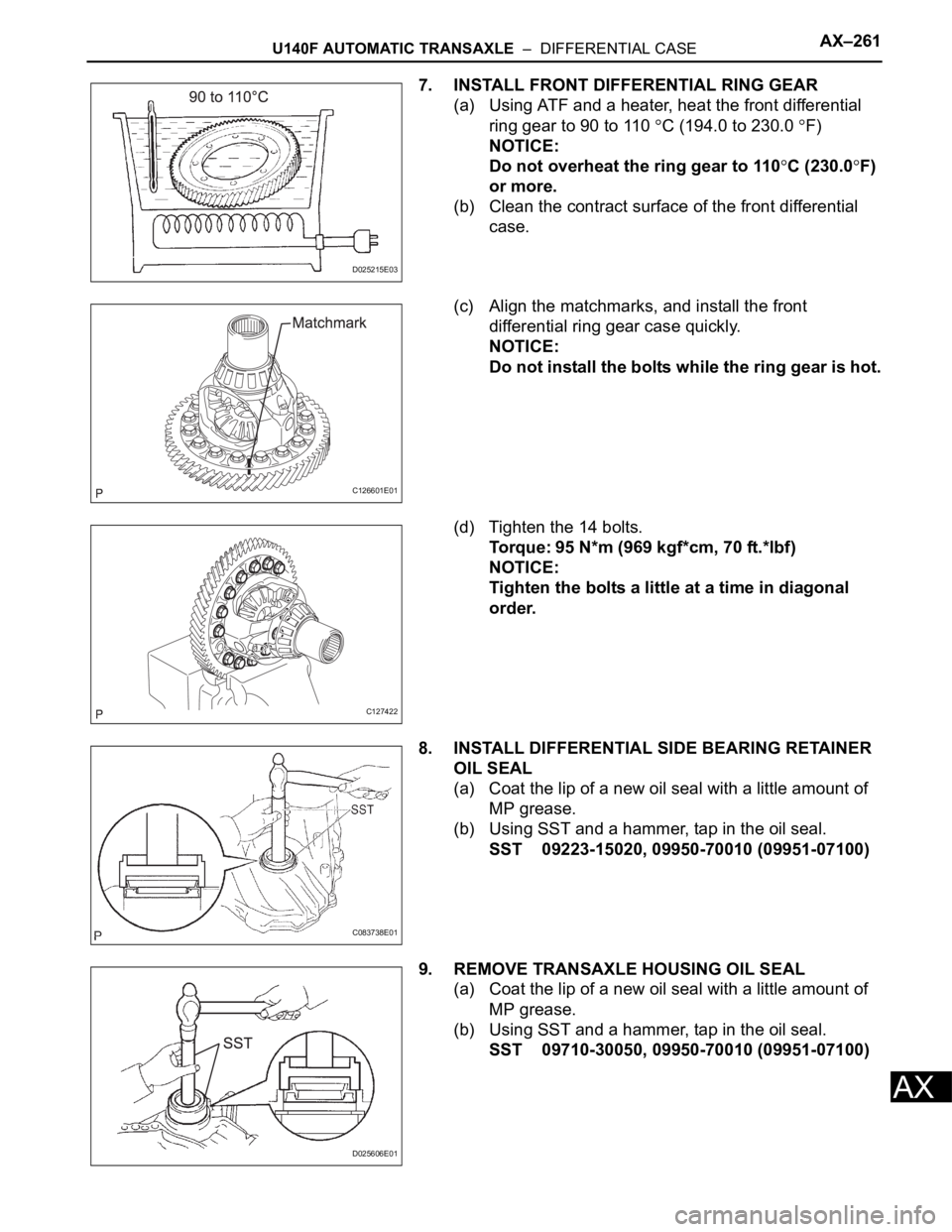

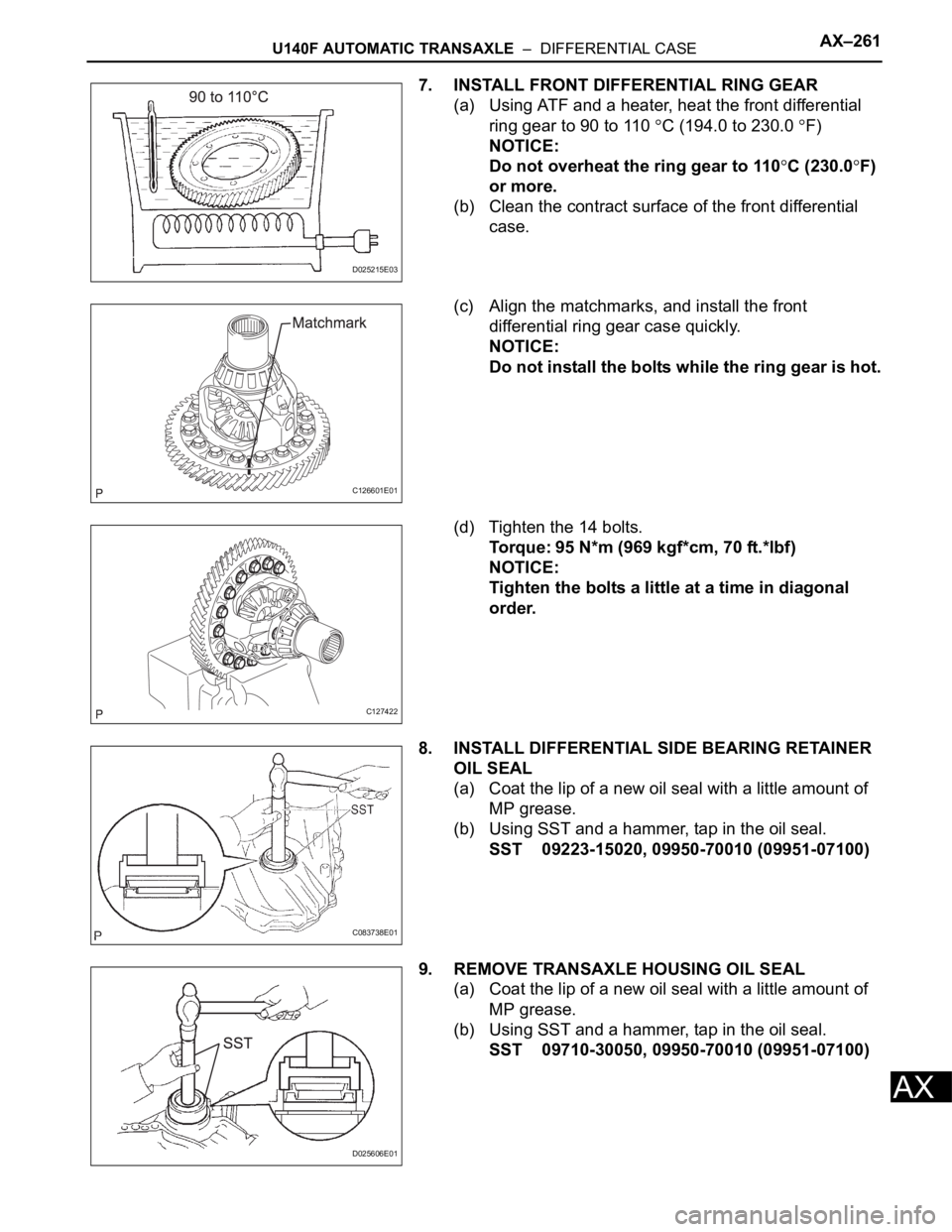

7. INSTALL FRONT DIFFERENTIAL RING GEAR

(a) Using ATF and a heater, heat the front differential

ring gear to 90 to 110

C (194.0 to 230.0 F)

NOTICE:

Do not overheat the ring gear to 110

C (230.0F)

or more.

(b) Clean the contract surface of the front differential

case.

(c) Align the matchmarks, and install the front

differential ring gear case quickly.

NOTICE:

Do not install the bolts while the ring gear is hot.

(d) Tighten the 14 bolts.

Torque: 95 N*m (969 kgf*cm, 70 ft.*lbf)

NOTICE:

Tighten the bolts a little at a time in diagonal

order.

8. INSTALL DIFFERENTIAL SIDE BEARING RETAINER

OIL SEAL

(a) Coat the lip of a new oil seal with a little amount of

MP grease.

(b) Using SST and a hammer, tap in the oil seal.

SST 09223-15020, 09950-70010 (09951-07100)

9. REMOVE TRANSAXLE HOUSING OIL SEAL

(a) Coat the lip of a new oil seal with a little amount of

MP grease.

(b) Using SST and a hammer, tap in the oil seal.

SST 09710-30050, 09950-70010 (09951-07100)

D025215E03

C126601E01

C127422

C083738E01

D025606E01

Page 1022 of 2000

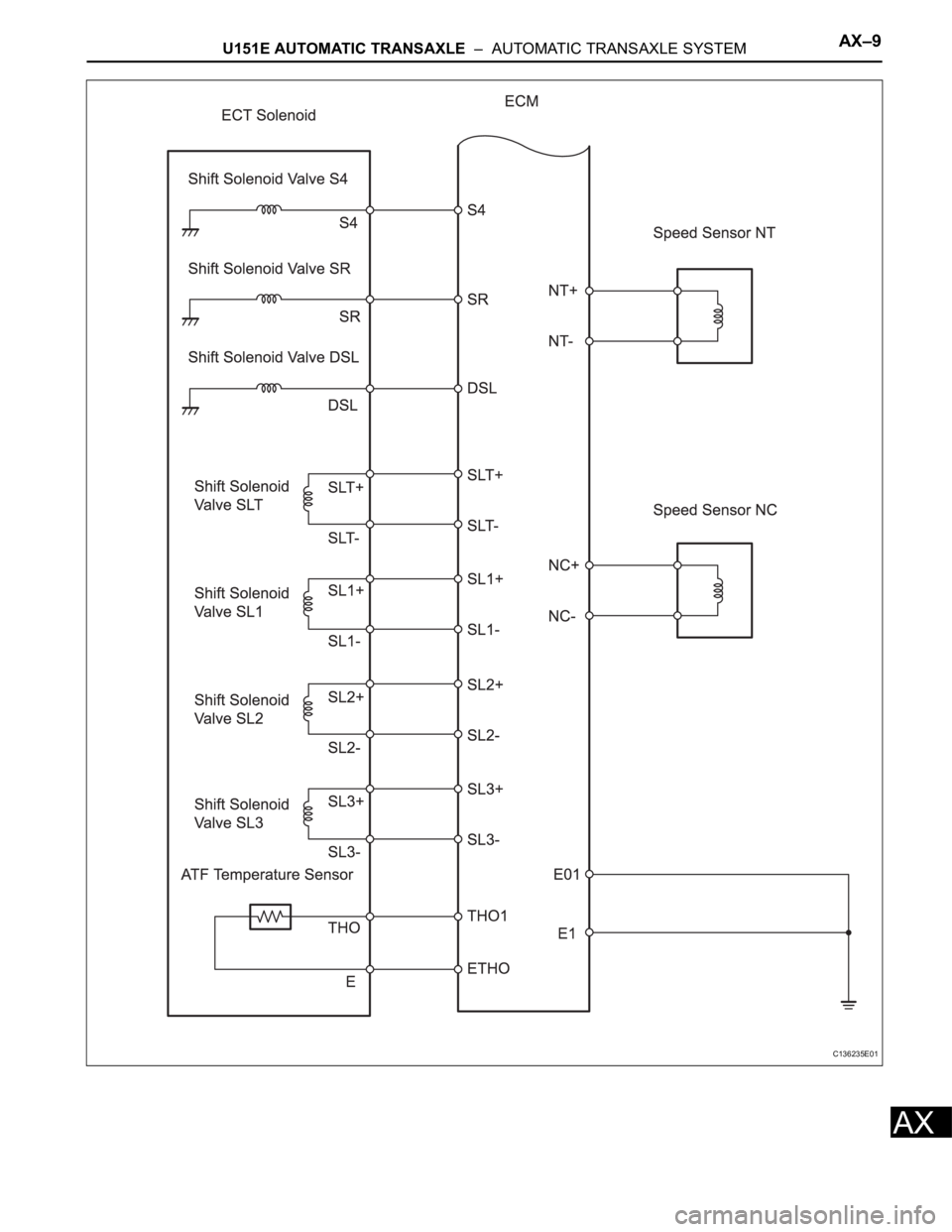

AX–6U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

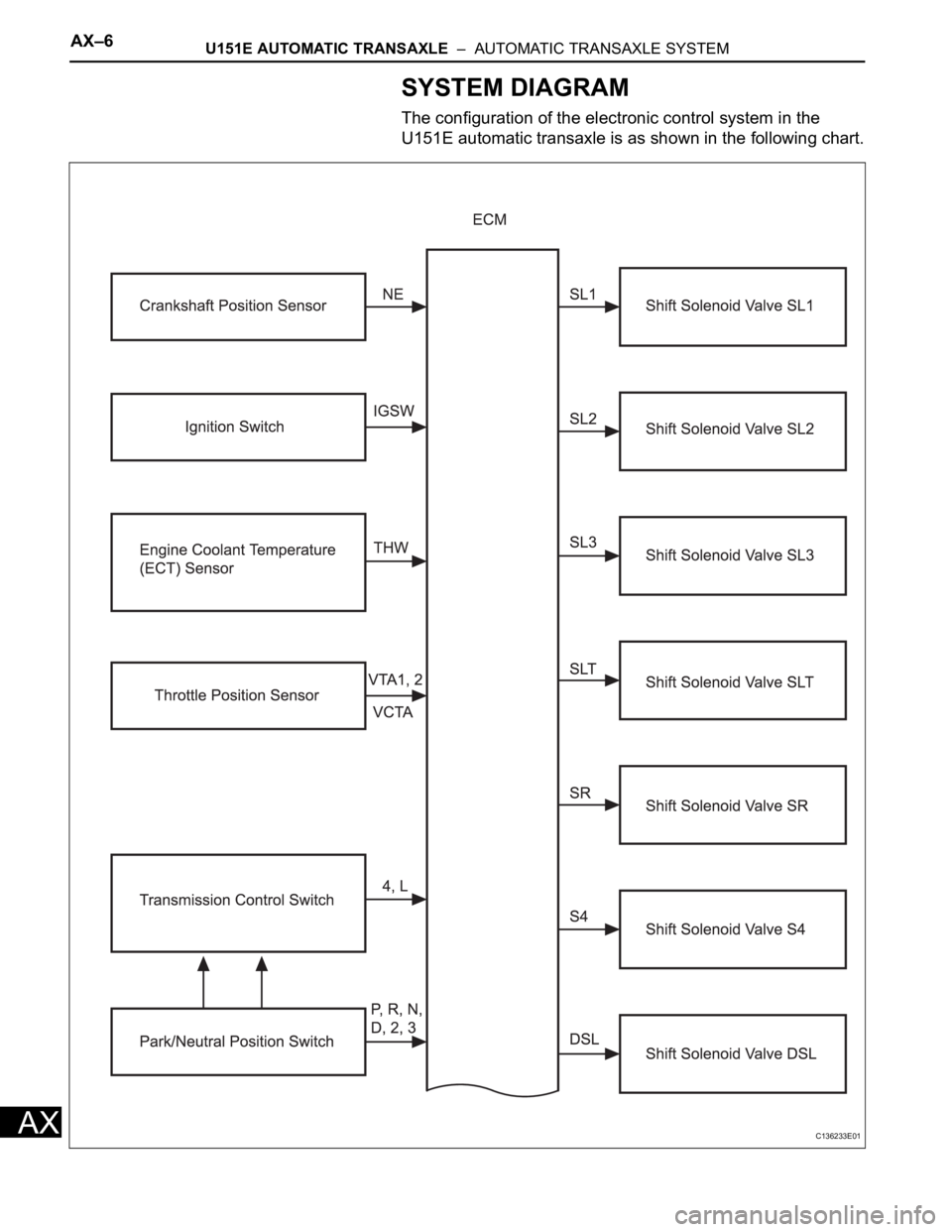

SYSTEM DIAGRAM

The configuration of the electronic control system in the

U151E automatic transaxle is as shown in the following chart.

C136233E01

Page 1023 of 2000

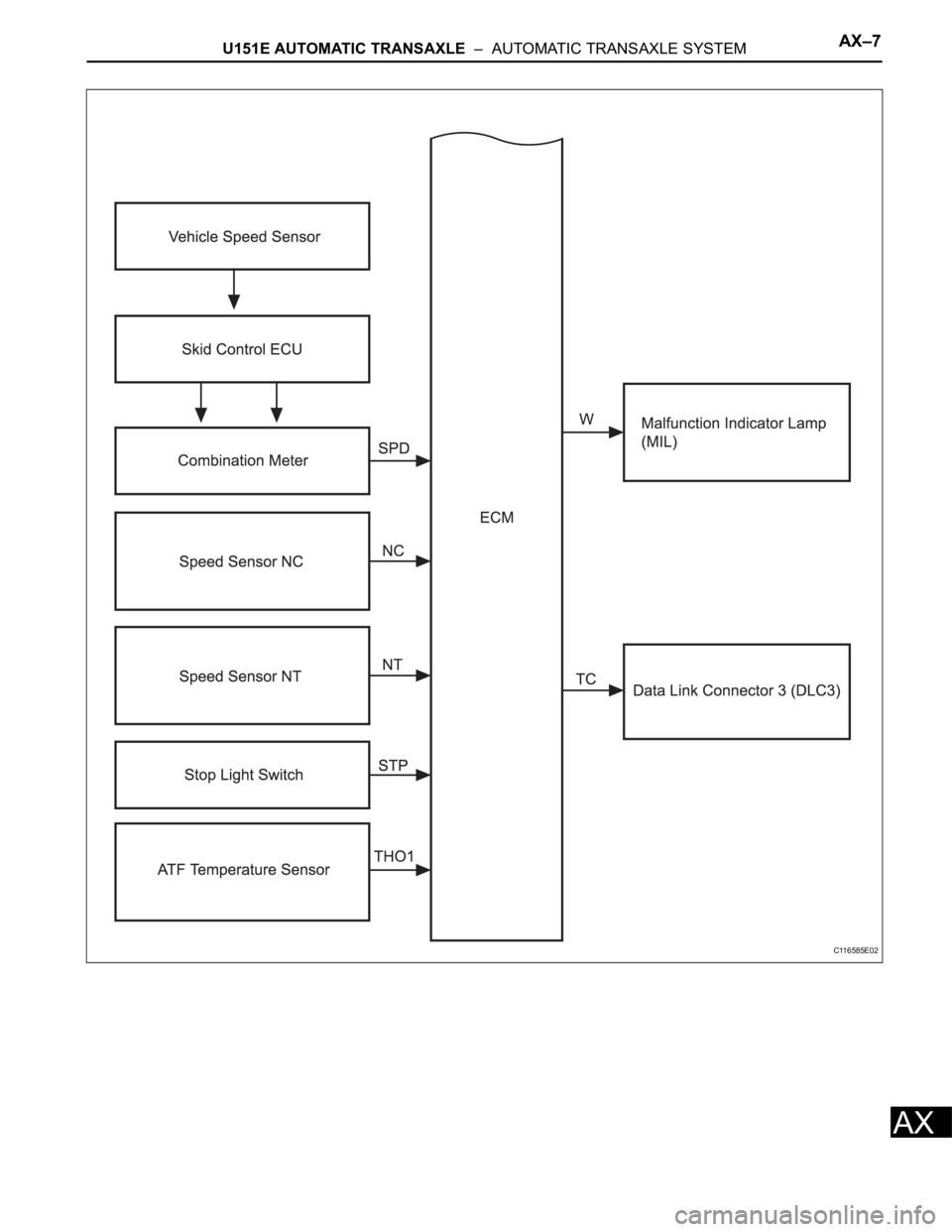

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–7

AX

C116585E02

Page 1024 of 2000

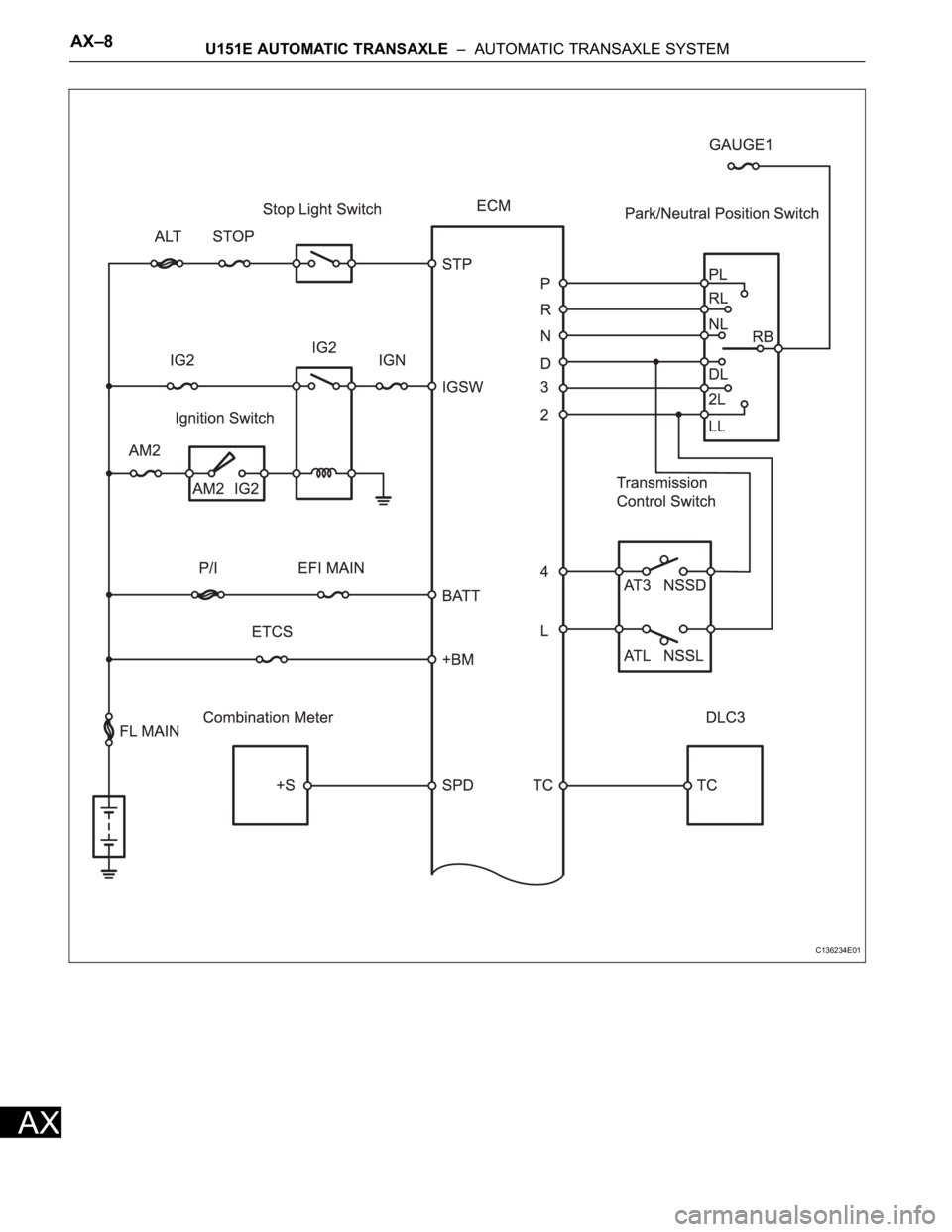

AX–8U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

C136234E01

Page 1025 of 2000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–9

AX

C136235E01

Page 1026 of 2000

AX–10U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

SYSTEM DESCRIPTION

1. SYSTEM DESCRIPTION

(a) The Electronic Controlled Automatic Transaxle

(ECT) is an automatic transaxle that electronically

controls shift timing using the Engine Control

Module (ECM). The ECM detects electrical signals

that indicate engine and driving conditions, and

controls the shift point based on driver habits and

road conditions. As a result, fuel efficiency and

power transaxle performance are improved.

Shift shock is reduced by controlling the engine and

transaxle simultaneously.

In addition, the ECT has the following features:

• Diagnostic function.

• Fail-safe function when a malfunction occurs.

Page 1027 of 2000

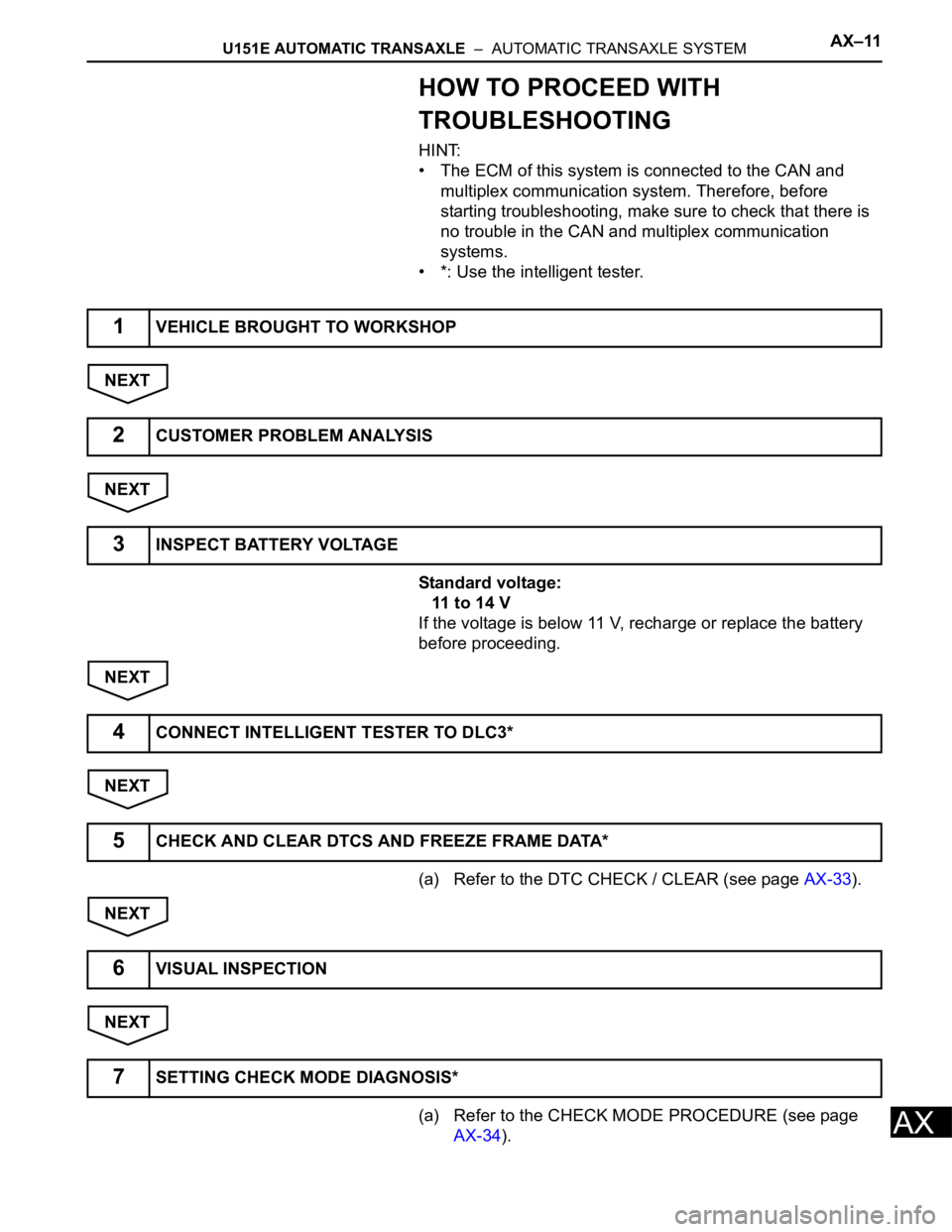

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–11

AX

HOW TO PROCEED WITH

TROUBLESHOOTING

HINT:

• The ECM of this system is connected to the CAN and

multiplex communication system. Therefore, before

starting troubleshooting, make sure to check that there is

no trouble in the CAN and multiplex communication

systems.

• *: Use the intelligent tester.

NEXT

NEXT

Standard voltage:

11 to 14 V

If the voltage is below 11 V, recharge or replace the battery

before proceeding.

NEXT

NEXT

(a) Refer to the DTC CHECK / CLEAR (see page AX-33).

NEXT

NEXT

(a) Refer to the CHECK MODE PROCEDURE (see page

AX-34).

1VEHICLE BROUGHT TO WORKSHOP

2CUSTOMER PROBLEM ANALYSIS

3INSPECT BATTERY VOLTAGE

4CONNECT INTELLIGENT TESTER TO DLC3*

5CHECK AND CLEAR DTCS AND FREEZE FRAME DATA*

6VISUAL INSPECTION

7SETTING CHECK MODE DIAGNOSIS*

Page 1028 of 2000

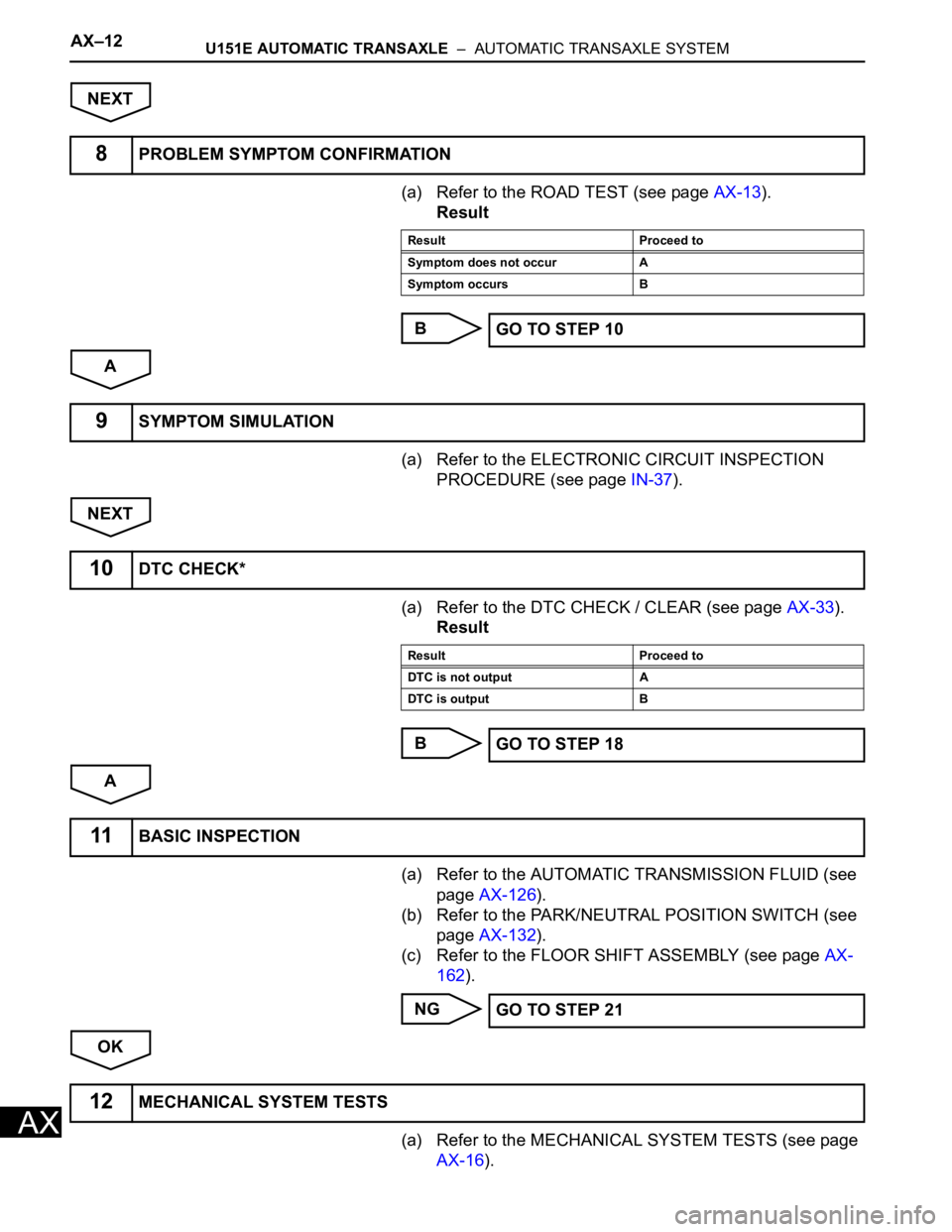

AX–12U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

NEXT

(a) Refer to the ROAD TEST (see page AX-13).

Result

B

A

(a) Refer to the ELECTRONIC CIRCUIT INSPECTION

PROCEDURE (see page IN-37).

NEXT

(a) Refer to the DTC CHECK / CLEAR (see page AX-33).

Result

B

A

(a) Refer to the AUTOMATIC TRANSMISSION FLUID (see

page AX-126).

(b) Refer to the PARK/NEUTRAL POSITION SWITCH (see

page AX-132).

(c) Refer to the FLOOR SHIFT ASSEMBLY (see page AX-

162).

NG

OK

(a) Refer to the MECHANICAL SYSTEM TESTS (see page

AX-16).

8PROBLEM SYMPTOM CONFIRMATION

Result Proceed to

Symptom does not occur A

Symptom occurs B

GO TO STEP 10

9SYMPTOM SIMULATION

10DTC CHECK*

Result Proceed to

DTC is not output A

DTC is output B

GO TO STEP 18

11BASIC INSPECTION

GO TO STEP 21

12MECHANICAL SYSTEM TESTS

Page 1029 of 2000

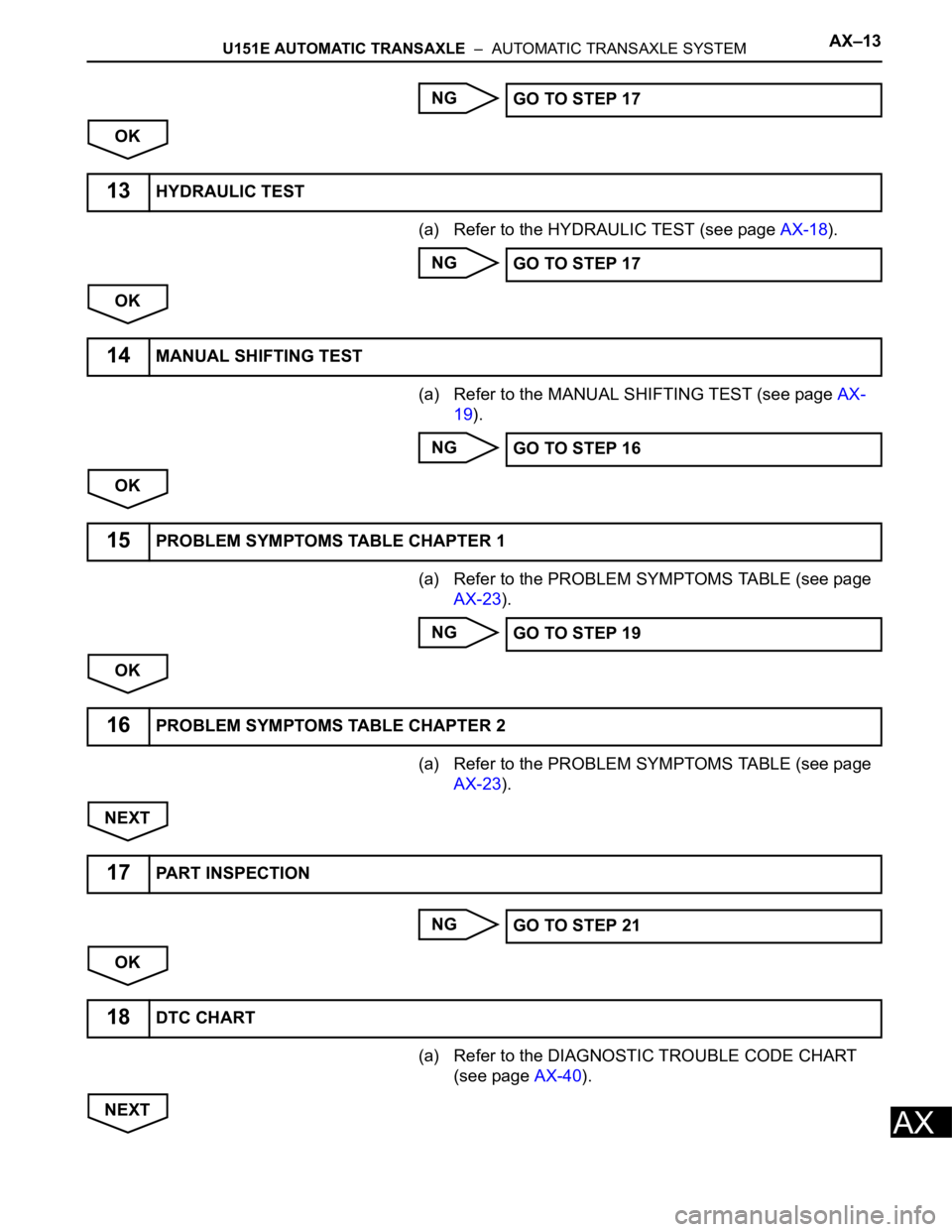

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–13

AX

NG

OK

(a) Refer to the HYDRAULIC TEST (see page AX-18).

NG

OK

(a) Refer to the MANUAL SHIFTING TEST (see page AX-

19).

NG

OK

(a) Refer to the PROBLEM SYMPTOMS TABLE (see page

AX-23).

NG

OK

(a) Refer to the PROBLEM SYMPTOMS TABLE (see page

AX-23).

NEXT

NG

OK

(a) Refer to the DIAGNOSTIC TROUBLE CODE CHART

(see page AX-40).

NEXTGO TO STEP 17

13HYDRAULIC TEST

GO TO STEP 17

14MANUAL SHIFTING TEST

GO TO STEP 16

15PROBLEM SYMPTOMS TABLE CHAPTER 1

GO TO STEP 19

16PROBLEM SYMPTOMS TABLE CHAPTER 2

17PART INSPECTION

GO TO STEP 21

18DTC CHART

Page 1030 of 2000

AX–14U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

NEXT

NEXT

NEXT

NEXT

19CIRCUIT INSPECTION

20IDENTIFICATION OF PROBLEM

21REPAIR OR REPLACE

22CONFIRMATION TEST

END

Trending: Install air manifold, Front bar, Engine cover, steering column, jacking, radiator cap, electrical diagram