TOYOTA RAV4 2006 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 1341 of 2000

GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEMTF–13

TF

TEST MODE PROCEDURE

1. DESCRIPTION

HINT:

When using a chassis dynamometer, brake tester, etc. to

perform a vehicle test, activate test mode to avoid a

"different tire diameter installed" incorrect judgment.

Test mode does not have a 4WD parameter. Test mode

is activated because it will prohibit a different tire

diameter judgment.

2. ACTIVATE TEST MODE

HINT:

Activate test mode before using a chassis dynamometer,

brake tester, etc. to perform a vehicle test.

(a) Check that the ignition switch is OFF.

(b) Use either of the following methods to change the

4WD ECU to test mode.

(1) Test mode activation through intelligent tester

(with CAM VIM).

• Connect the intelligent tester (with CAM VIM)

to the DLC3 connector and turn the ignition

switch ON. Using the test mode activation

function (mode 10), activate test mode.

(2) Test mode activation by shorting TS terminal

• With the ignition switch OFF, short-circuit the

TS and CG terminals of the DLC3 connector.

Then turn the ignition switch ON to activate

test mode.

NOTICE:

When the ignition switch is turned from

OFF to ON, the 4WD indicator light will

illuminate for 4 seconds. Then it will turn

off.

4WD Lock Mode indicator

HINT:

When the ignition switch is ON and the 4WD

lock switch is turned from OFF to ON, the

4WD lock mode indicator blinks twice and

then illuminates.

If the indicator does not illuminate, check the

bulb for burnout. Also, inspect the wire

harness between the 4WD ECU and

combination meter.

Control Status 4WD Control Status

During test mode Different tire diameter malfunction judgment (detection that tire

diameter of 4 wheels are not same) is not performed.

Other than above item, normal control is performed.

- 4WD lock switch OFF (4WD auto mode status)

- 4WD lock switch ON (4WD lock mode status)

4WD Lock Switch OFF Illuminates for 4 seconds, then turns

OFF

4WD Lock Switch ON Remains illuminated

Page 1342 of 2000

TF–14GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEM

TF

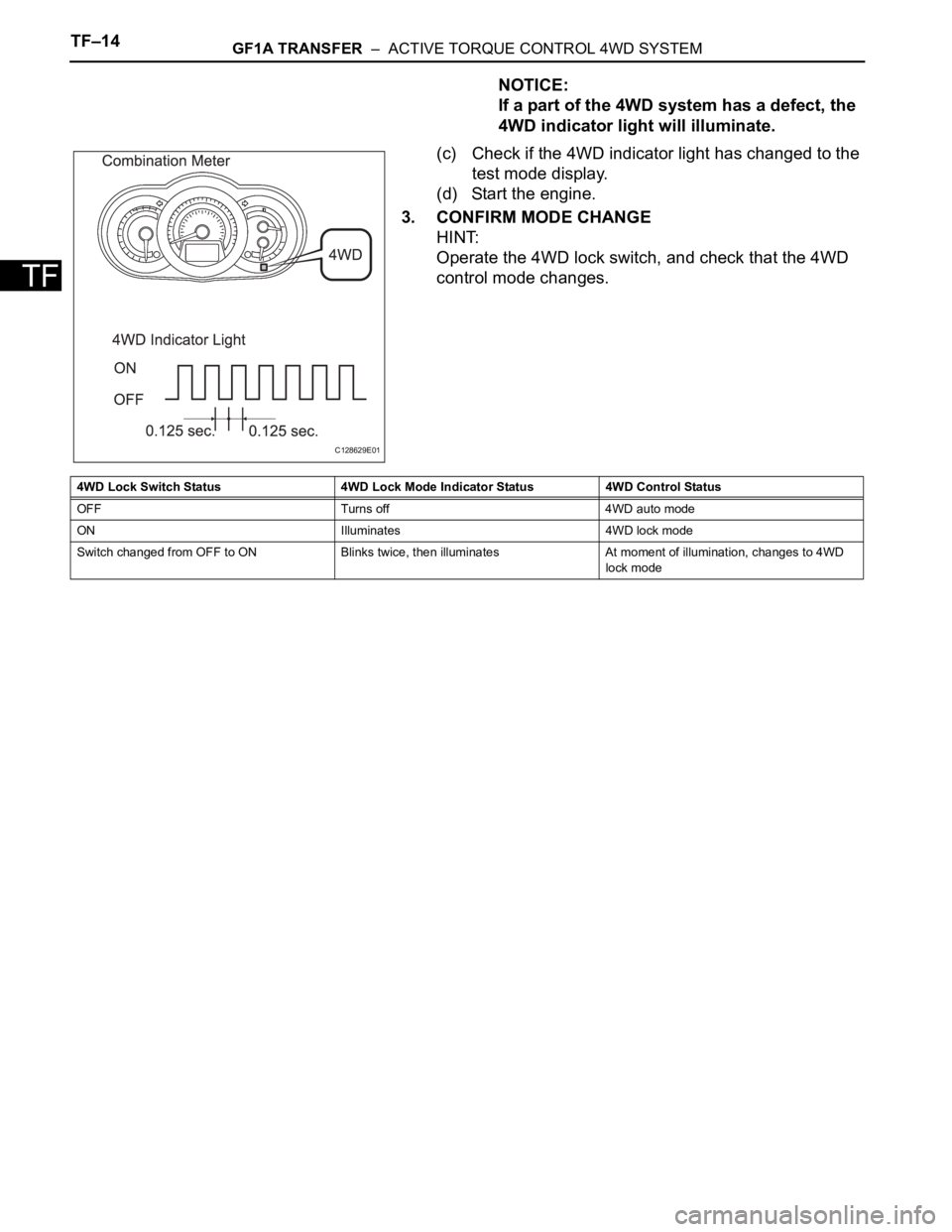

NOTICE:

If a part of the 4WD system has a defect, the

4WD indicator light will illuminate.

(c) Check if the 4WD indicator light has changed to the

test mode display.

(d) Start the engine.

3. CONFIRM MODE CHANGE

HINT:

Operate the 4WD lock switch, and check that the 4WD

control mode changes.

C128629E01

4WD Lock Switch Status 4WD Lock Mode Indicator Status 4WD Control Status

OFF Turns off 4WD auto mode

ON Illuminates 4WD lock mode

Switch changed from OFF to ON Blinks twice, then illuminates At moment of illumination, changes to 4WD

lock mode

Page 1343 of 2000

GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEMTF–15

TF

PROBLEM SYMPTOMS TABLE

HINT:

• Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms

are listed in order of probability in the "Suspected area"

column of the table. Check each symptom by checking the

suspected areas in the order they are listed. Replace parts

as necessary.

• Inspect the fuses and relays related to this system before

inspecting the suspected areas below.

Active torque control 4WD system

HINT:

*:When driving 4WD mode, the vehicle is hard to turn, as if

the brakes were applied, due to the rotational difference

between the front and rear tires while turning.

Symptom Suspected area See page

Phenomenon of tight-corner braking*1.Steering angle sensor circuitTF-27

2.Linear solenoid circuitTF-30

3.4WD control ECU

4WD indicator light remains ON 4WD indicator light circuitTF-36

4WD indicator light does not come ON 4WD indicator light circuitTF-40

The system is in the DTC output mode although

terminals TC and CG of the DLC3 are not short

circuited1.TC and CG terminal circuitTF-42

2.4WD indicator light circuit

The system is not in the DTC output mode although

terminals TC and CG of the DLC3 are not short

circuited1.TC and CG terminal circuitTF-42

2.4WD indicator light circuit

Page 1344 of 2000

TF–16GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEM

TF

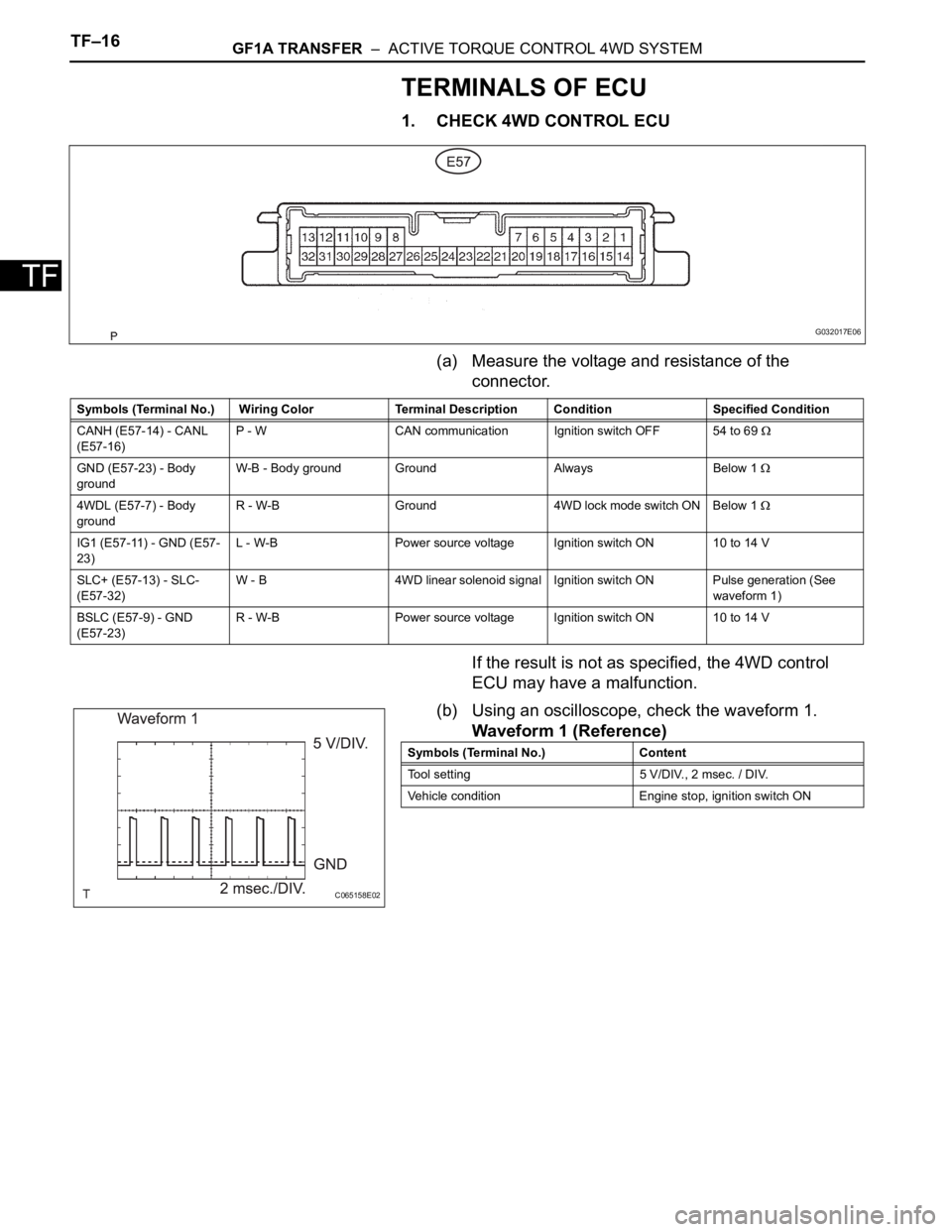

TERMINALS OF ECU

1. CHECK 4WD CONTROL ECU

(a) Measure the voltage and resistance of the

connector.

If the result is not as specified, the 4WD control

ECU may have a malfunction.

(b) Using an oscilloscope, check the waveform 1.

Waveform 1 (Reference)

G032017E06

Symbols (Terminal No.) Wiring Color Terminal Description Condition Specified Condition

CANH (E57-14) - CANL

(E57-16)P - W CAN communication Ignition switch OFF 54 to 69

GND (E57-23) - Body

groundW-B - Body ground Ground Always Below 1

4WDL (E57-7) - Body

groundR - W-B Ground 4WD lock mode switch ON Below 1

IG1 (E57-11) - GND (E57-

23)L - W-B Power source voltage Ignition switch ON 10 to 14 V

SLC+ (E57-13) - SLC-

(E57-32)W - B 4WD linear solenoid signal Ignition switch ON Pulse generation (See

waveform 1)

BSLC (E57-9) - GND

(E57-23)R - W-B Power source voltage Ignition switch ON 10 to 14 V

C065158E02

Symbols (Terminal No.) Content

Tool setting 5 V/DIV., 2 msec. / DIV.

Vehicle condition Engine stop, ignition switch ON

Page 1345 of 2000

GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEMTF–17

TF

DIAGNOSIS SYSTEM

1. DESCRIPTION

Active torque control 4WD system data can be read in

the Data Link Connector 3 (DLC3) of the vehicle. When

the system seems to be malfunctioning, use the

intelligent tester (with CAN VIM) to check for

malfunctions and perform repairs. Therefore when there

seems to be a problem with the active torque control

4WD, use the intelligent tester (with CAN VIM) or SST to

check and troubleshoot it.

SST 09843-18040

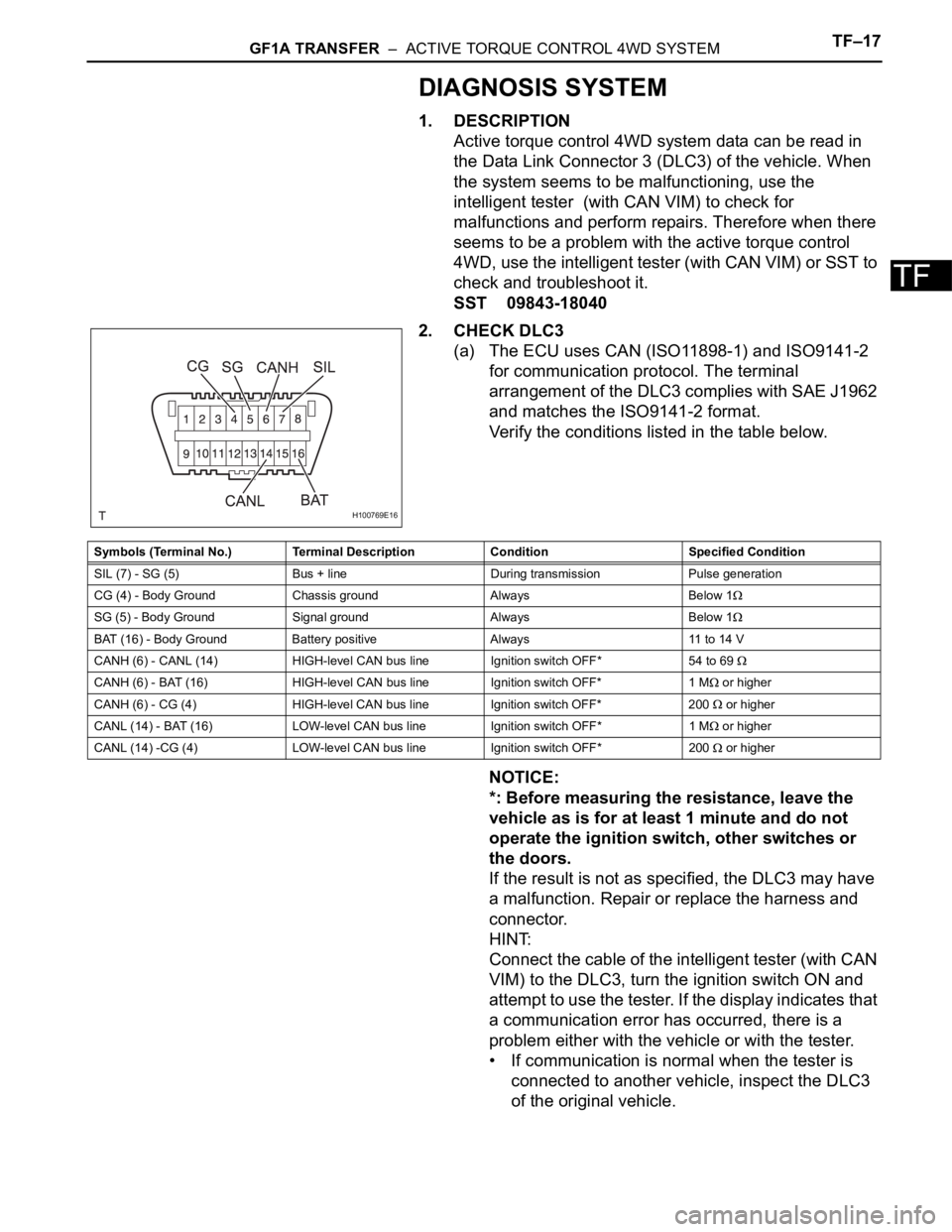

2. CHECK DLC3

(a) The ECU uses CAN (ISO11898-1) and ISO9141-2

for communication protocol. The terminal

arrangement of the DLC3 complies with SAE J1962

and matches the ISO9141-2 format.

Verify the conditions listed in the table below.

NOTICE:

*: Before measuring the resistance, leave the

vehicle as is for at least 1 minute and do not

operate the ignition switch, other switches or

the doors.

If the result is not as specified, the DLC3 may have

a malfunction. Repair or replace the harness and

connector.

HINT:

Connect the cable of the intelligent tester (with CAN

VIM) to the DLC3, turn the ignition switch ON and

attempt to use the tester. If the display indicates that

a communication error has occurred, there is a

problem either with the vehicle or with the tester.

• If communication is normal when the tester is

connected to another vehicle, inspect the DLC3

of the original vehicle.

H100769E16

Symbols (Terminal No.) Terminal Description Condition Specified Condition

SIL (7) - SG (5) Bus + line During transmission Pulse generation

CG (4) - Body Ground Chassis ground Always Below 1

SG (5) - Body Ground Signal ground Always Below 1

BAT (16) - Body Ground Battery positive Always 11 to 14 V

CANH (6) - CANL (14) HIGH-level CAN bus line Ignition switch OFF* 54 to 69

CANH (6) - BAT (16) HIGH-level CAN bus line Ignition switch OFF* 1 M or higher

CANH (6) - CG (4) HIGH-level CAN bus line Ignition switch OFF* 200

or higher

CANL (14) - BAT (16) LOW-level CAN bus line Ignition switch OFF* 1 M

or higher

CANL (14) -CG (4) LOW-level CAN bus line Ignition switch OFF* 200

or higher

Page 1346 of 2000

TF–18GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEM

TF

• If communication is still not possible when the

tester is connected to another vehicle, the

problem may be in the tester itself. Consult the

Service Department listed in the tester's

instruction manual.

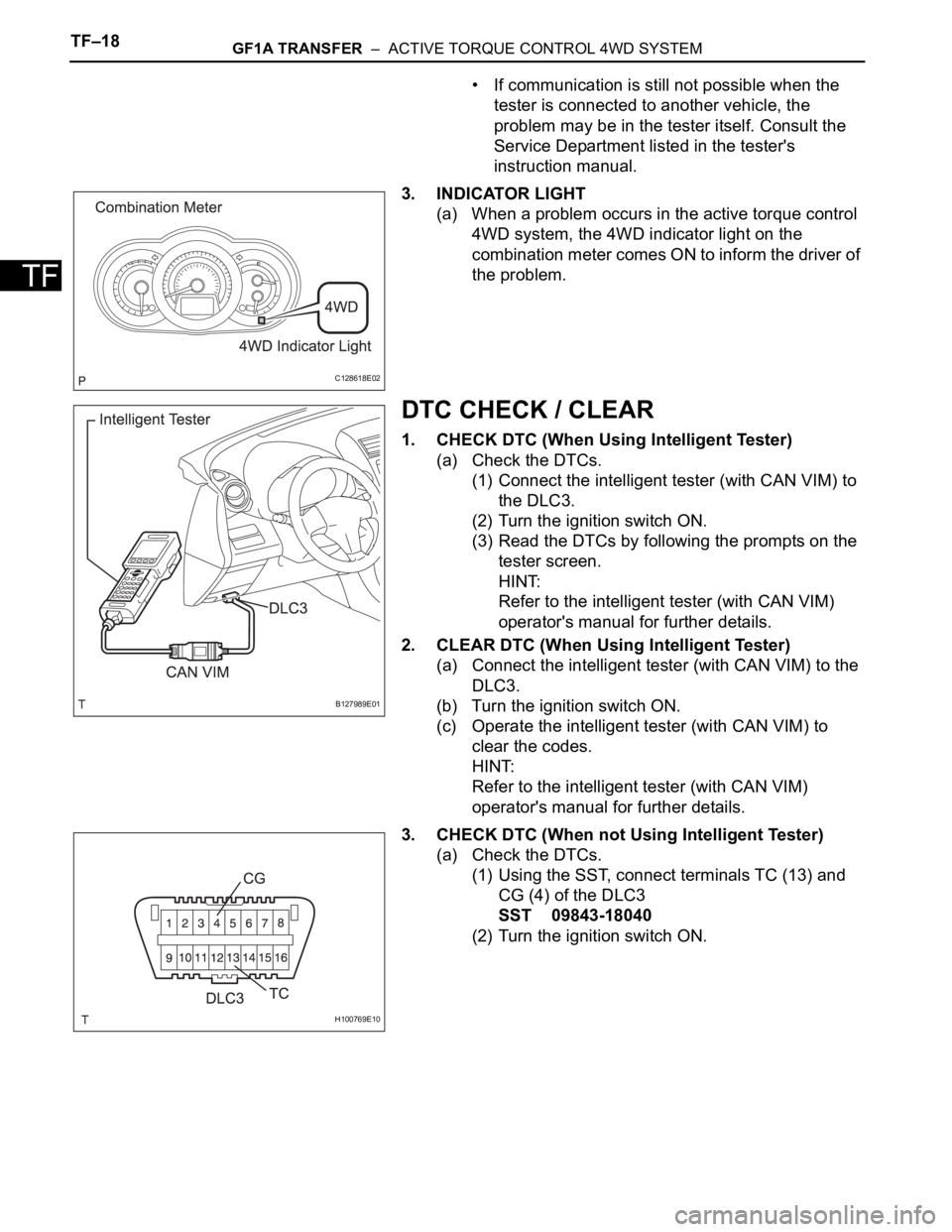

3. INDICATOR LIGHT

(a) When a problem occurs in the active torque control

4WD system, the 4WD indicator light on the

combination meter comes ON to inform the driver of

the problem.

DTC CHECK / CLEAR

1. CHECK DTC (When Using Intelligent Tester)

(a) Check the DTCs.

(1) Connect the intelligent tester (with CAN VIM) to

the DLC3.

(2) Turn the ignition switch ON.

(3) Read the DTCs by following the prompts on the

tester screen.

HINT:

Refer to the intelligent tester (with CAN VIM)

operator's manual for further details.

2. CLEAR DTC (When Using Intelligent Tester)

(a) Connect the intelligent tester (with CAN VIM) to the

DLC3.

(b) Turn the ignition switch ON.

(c) Operate the intelligent tester (with CAN VIM) to

clear the codes.

HINT:

Refer to the intelligent tester (with CAN VIM)

operator's manual for further details.

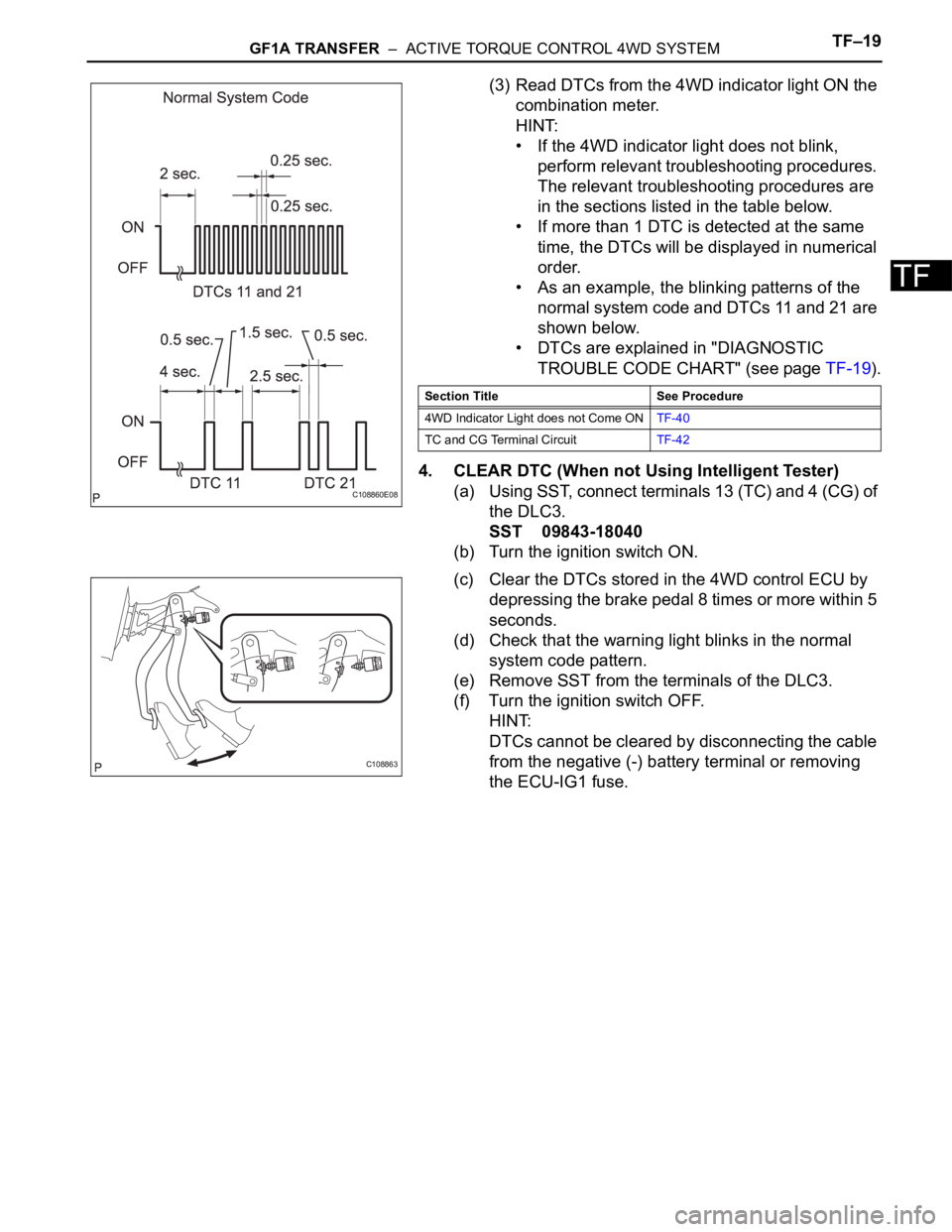

3. CHECK DTC (When not Using Intelligent Tester)

(a) Check the DTCs.

(1) Using the SST, connect terminals TC (13) and

CG (4) of the DLC3

SST 09843-18040

(2) Turn the ignition switch ON.

C128618E02

B127989E01

H100769E10

Page 1347 of 2000

GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEMTF–19

TF

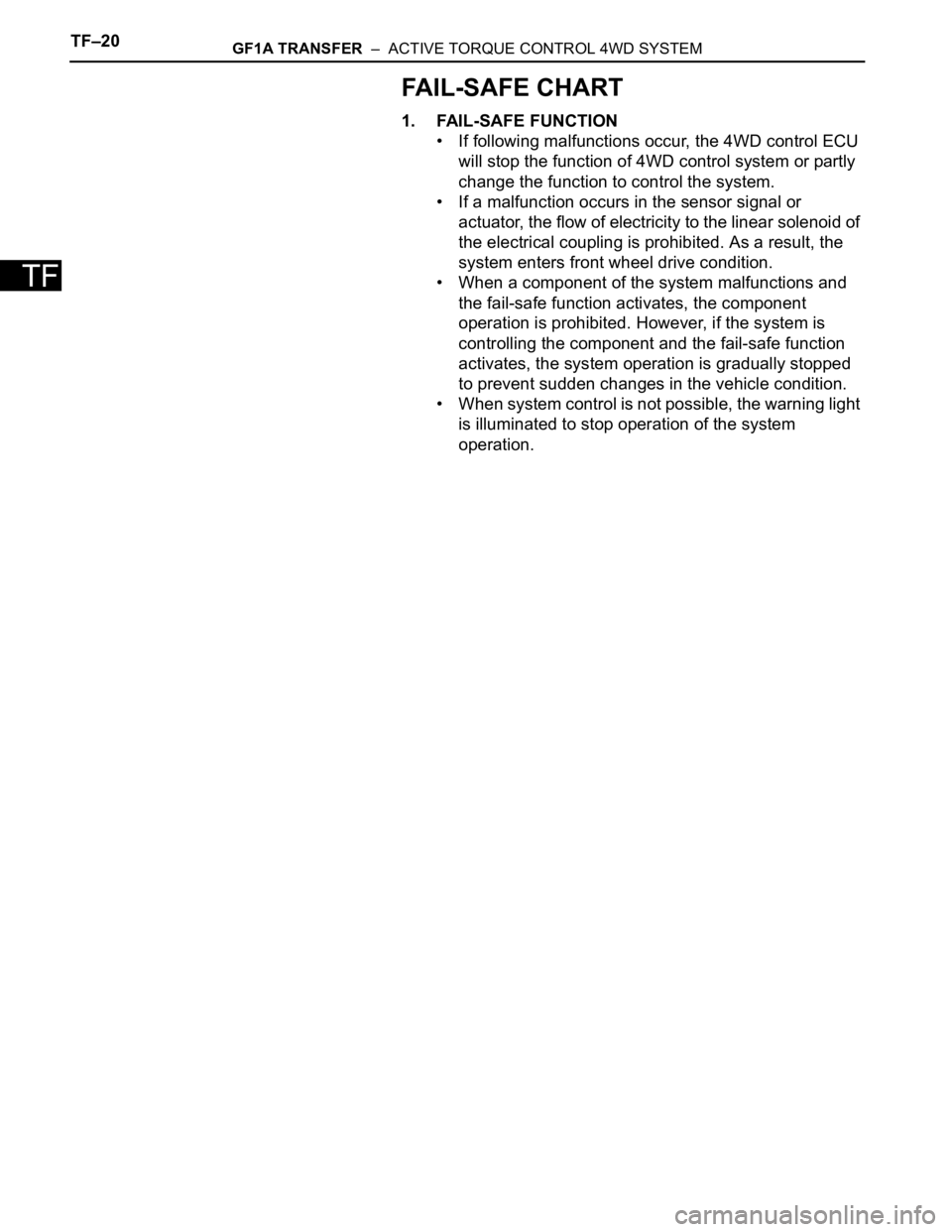

(3) Read DTCs from the 4WD indicator light ON the

combination meter.

HINT:

• If the 4WD indicator light does not blink,

perform relevant troubleshooting procedures.

The relevant troubleshooting procedures are

in the sections listed in the table below.

• If more than 1 DTC is detected at the same

time, the DTCs will be displayed in numerical

order.

• As an example, the blinking patterns of the

normal system code and DTCs 11 and 21 are

shown below.

• DTCs are explained in "DIAGNOSTIC

TROUBLE CODE CHART" (see page TF-19).

4. CLEAR DTC (When not Using Intelligent Tester)

(a) Using SST, connect terminals 13 (TC) and 4 (CG) of

the DLC3.

SST 09843-18040

(b) Turn the ignition switch ON.

(c) Clear the DTCs stored in the 4WD control ECU by

depressing the brake pedal 8 times or more within 5

seconds.

(d) Check that the warning light blinks in the normal

system code pattern.

(e) Remove SST from the terminals of the DLC3.

(f) Turn the ignition switch OFF.

HINT:

DTCs cannot be cleared by disconnecting the cable

from the negative (-) battery terminal or removing

the ECU-IG1 fuse.

C108860E08

Section Title See Procedure

4WD Indicator Light does not Come ONTF-40

TC and CG Terminal CircuitTF-42

C108863

Page 1348 of 2000

TF–20GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEM

TF

FAIL-SAFE CHART

1. FAIL-SAFE FUNCTION

• If following malfunctions occur, the 4WD control ECU

will stop the function of 4WD control system or partly

change the function to control the system.

• If a malfunction occurs in the sensor signal or

actuator, the flow of electricity to the linear solenoid of

the electrical coupling is prohibited. As a result, the

system enters front wheel drive condition.

• When a component of the system malfunctions and

the fail-safe function activates, the component

operation is prohibited. However, if the system is

controlling the component and the fail-safe function

activates, the system operation is gradually stopped

to prevent sudden changes in the vehicle condition.

• When system control is not possible, the warning light

is illuminated to stop operation of the system

operation.

Page 1349 of 2000

GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEMTF–21

TF

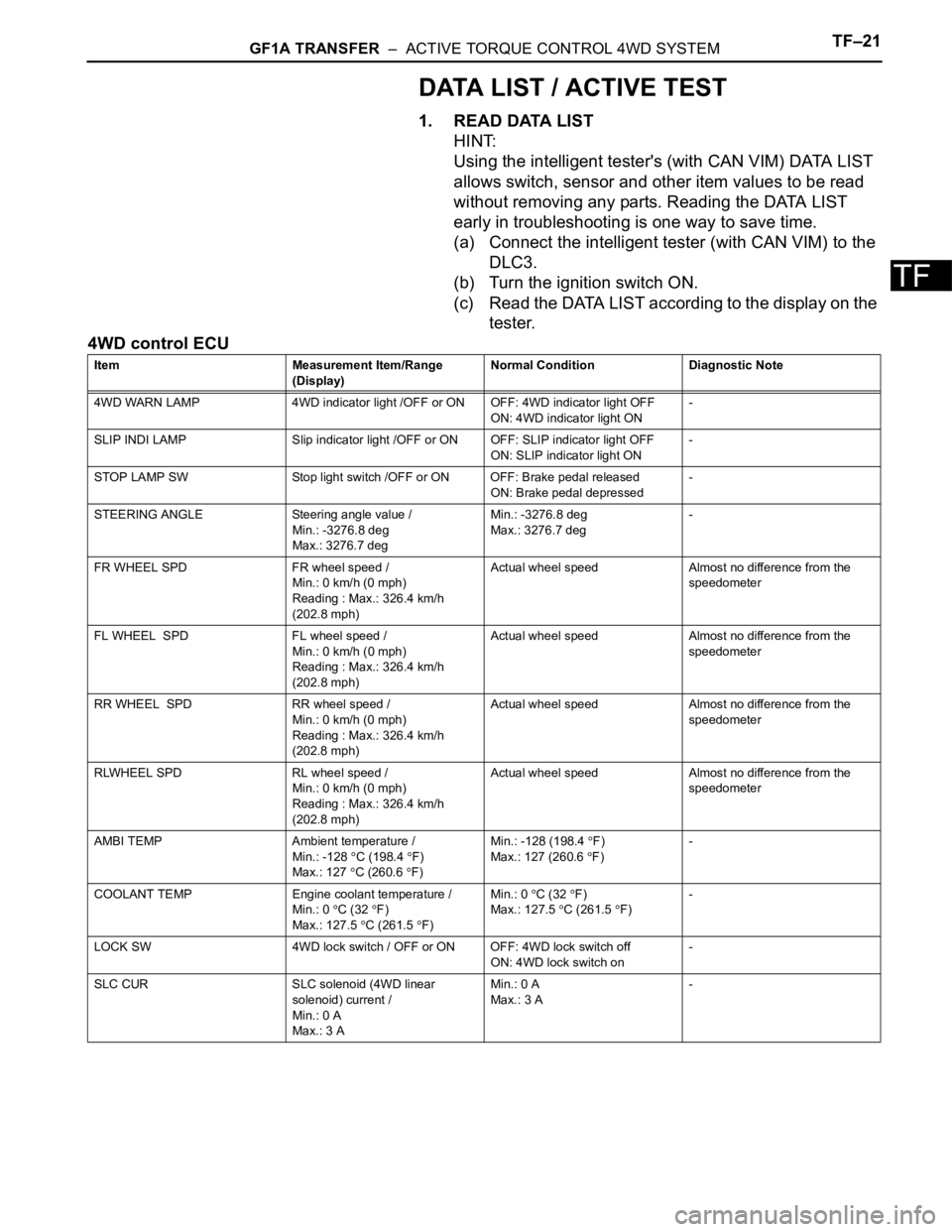

DATA LIST / ACTIVE TEST

1. READ DATA LIST

HINT:

Using the intelligent tester's (with CAN VIM) DATA LIST

allows switch, sensor and other item values to be read

without removing any parts. Reading the DATA LIST

early in troubleshooting is one way to save time.

(a) Connect the intelligent tester (with CAN VIM) to the

DLC3.

(b) Turn the ignition switch ON.

(c) Read the DATA LIST according to the display on the

tester.

4WD control ECU

Item Measurement Item/Range

(Display)Normal Condition Diagnostic Note

4WD WARN LAMP 4WD indicator light /OFF or ON OFF: 4WD indicator light OFF

ON: 4WD indicator light ON-

SLIP INDI LAMP Slip indicator light /OFF or ON OFF: SLIP indicator light OFF

ON: SLIP indicator light ON-

STOP LAMP SW Stop light switch /OFF or ON OFF: Brake pedal released

ON: Brake pedal depressed-

STEERING ANGLE Steering angle value /

Min.: -3276.8 deg

Max.: 3276.7 degMin.: -3276.8 deg

Max.: 3276.7 deg-

FR WHEEL SPD FR wheel speed /

Min.: 0 km/h (0 mph)

Reading : Max.: 326.4 km/h

(202.8 mph)Actual wheel speed Almost no difference from the

speedometer

FL WHEEL SPD FL wheel speed /

Min.: 0 km/h (0 mph)

Reading : Max.: 326.4 km/h

(202.8 mph)Actual wheel speed Almost no difference from the

speedometer

RR WHEEL SPD RR wheel speed /

Min.: 0 km/h (0 mph)

Reading : Max.: 326.4 km/h

(202.8 mph)Actual wheel speed Almost no difference from the

speedometer

RLWHEEL SPD RL wheel speed /

Min.: 0 km/h (0 mph)

Reading : Max.: 326.4 km/h

(202.8 mph)Actual wheel speed Almost no difference from the

speedometer

AMBI TEMP Ambient temperature /

Min.: -128

C (198.4 F)

Max.: 127 C (260.6 F)Min.: -128 (198.4

F)

Max.: 127 (260.6

F)-

COOLANT TEMP Engine coolant temperature /

Min.: 0

C (32 F)

Max.: 127.5

C (261.5 F)Min.: 0

C (32 F)

Max.: 127.5 C (261.5 F)-

LOCK SW 4WD lock switch / OFF or ON OFF: 4WD lock switch off

ON: 4WD lock switch on-

SLC CUR SLC solenoid (4WD linear

solenoid) current /

Min.: 0 A

Max.: 3 AMin.: 0 A

Max.: 3 A-

Page 1350 of 2000

TF–22GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEM

TF

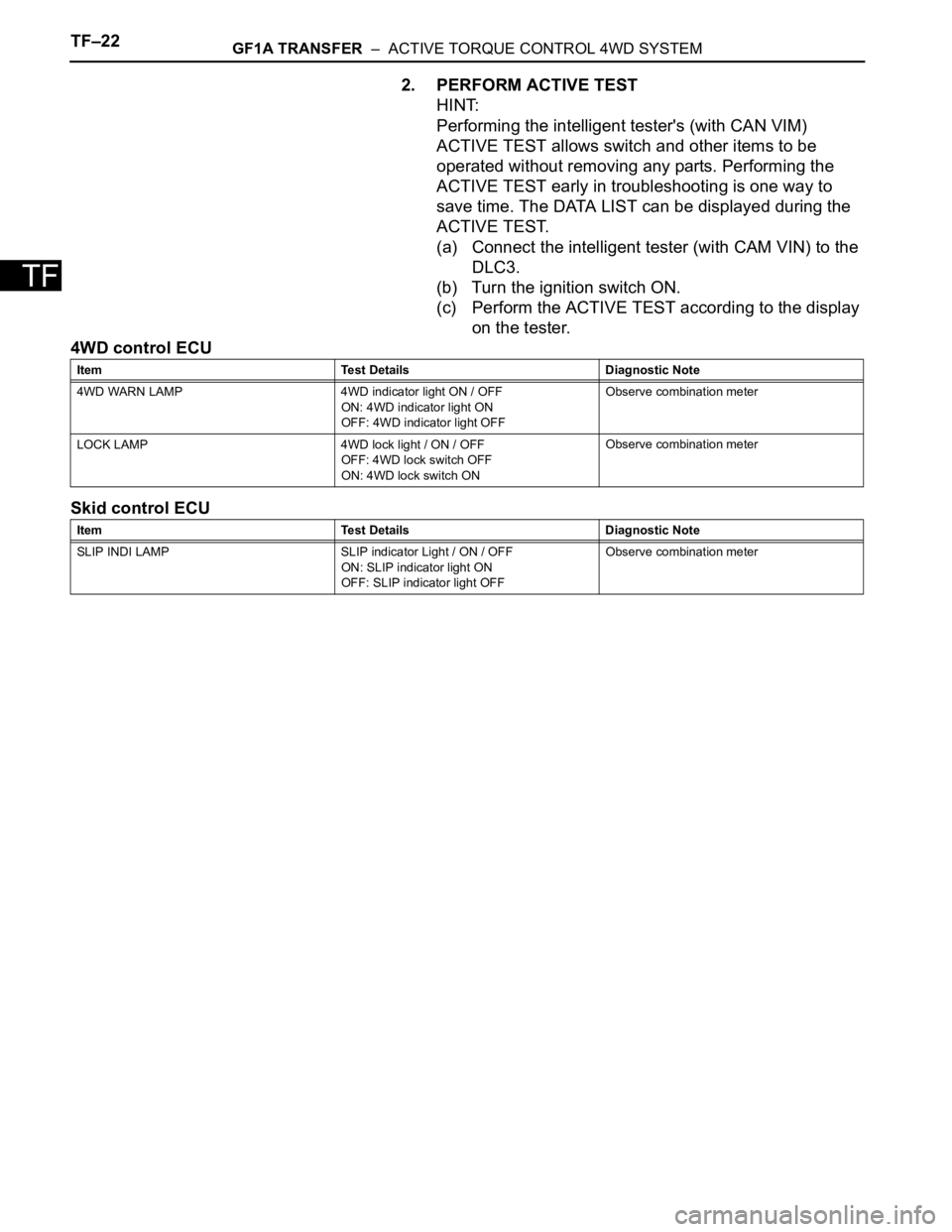

2. PERFORM ACTIVE TEST

HINT:

Performing the intelligent tester's (with CAN VIM)

ACTIVE TEST allows switch and other items to be

operated without removing any parts. Performing the

ACTIVE TEST early in troubleshooting is one way to

save time. The DATA LIST can be displayed during the

ACTIVE TEST.

(a) Connect the intelligent tester (with CAM VIN) to the

DLC3.

(b) Turn the ignition switch ON.

(c) Perform the ACTIVE TEST according to the display

on the tester.

4WD control ECU

Skid control ECU

Item Test Details Diagnostic Note

4WD WARN LAMP 4WD indicator light ON / OFF

ON: 4WD indicator light ON

OFF: 4WD indicator light OFFObserve combination meter

LOCK LAMP 4WD lock light / ON / OFF

OFF: 4WD lock switch OFF

ON: 4WD lock switch ONObserve combination meter

Item Test Details Diagnostic Note

SLIP INDI LAMP SLIP indicator Light / ON / OFF

ON: SLIP indicator light ON

OFF: SLIP indicator light OFFObserve combination meter