TOYOTA RAV4 2006 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 1471 of 2000

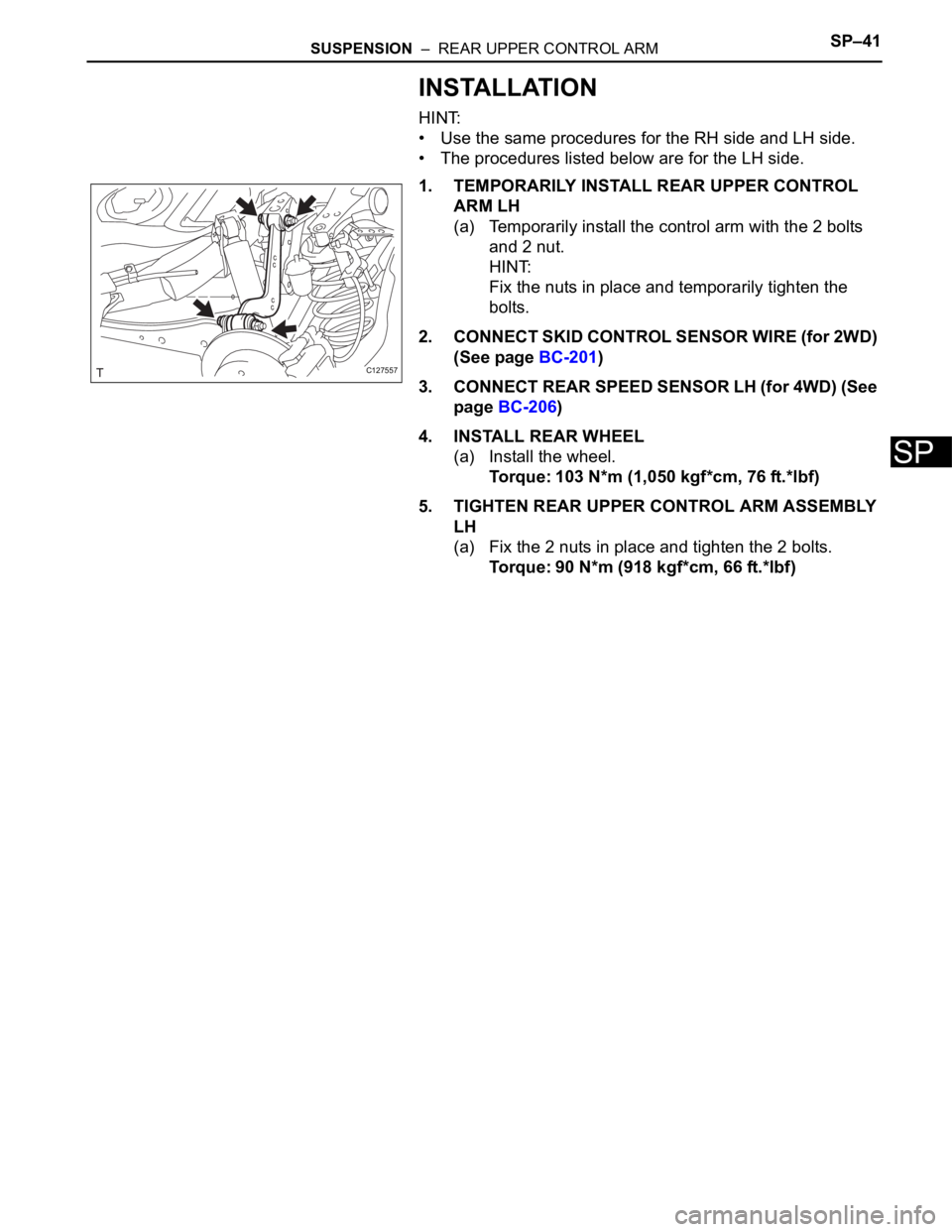

SUSPENSION – REAR UPPER CONTROL ARMSP–41

SP

INSTALLATION

HINT:

• Use the same procedures for the RH side and LH side.

• The procedures listed below are for the LH side.

1. TEMPORARILY INSTALL REAR UPPER CONTROL

ARM LH

(a) Temporarily install the control arm with the 2 bolts

and 2 nut.

HINT:

Fix the nuts in place and temporarily tighten the

bolts.

2. CONNECT SKID CONTROL SENSOR WIRE (for 2WD)

(See page BC-201)

3. CONNECT REAR SPEED SENSOR LH (for 4WD) (See

page BC-206)

4. INSTALL REAR WHEEL

(a) Install the wheel.

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

5. TIGHTEN REAR UPPER CONTROL ARM ASSEMBLY

LH

(a) Fix the 2 nuts in place and tighten the 2 bolts.

Torque: 90 N*m (918 kgf*cm, 66 ft.*lbf)

C127557

Page 1472 of 2000

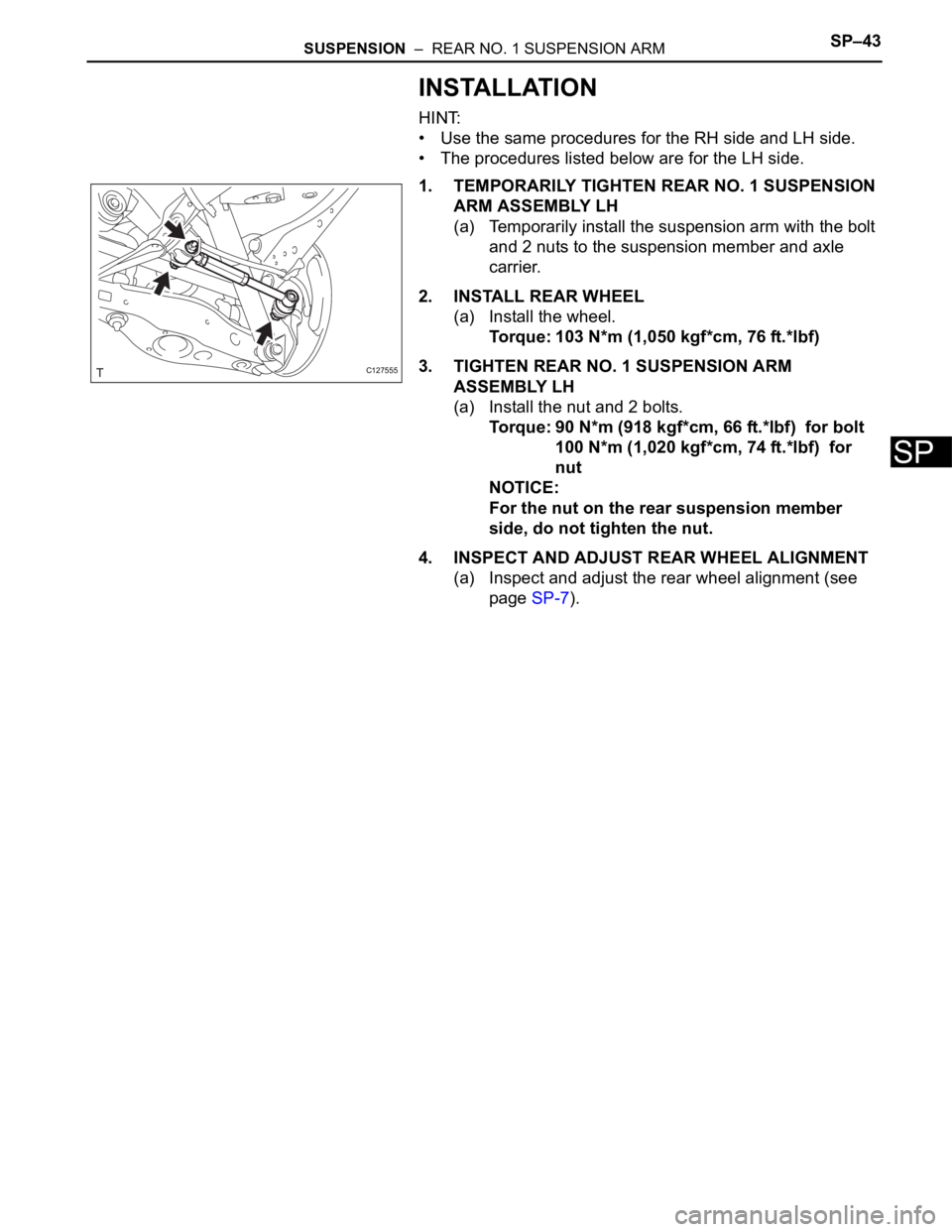

SUSPENSION – REAR NO. 1 SUSPENSION ARMSP–43

SP

INSTALLATION

HINT:

• Use the same procedures for the RH side and LH side.

• The procedures listed below are for the LH side.

1. TEMPORARILY TIGHTEN REAR NO. 1 SUSPENSION

ARM ASSEMBLY LH

(a) Temporarily install the suspension arm with the bolt

and 2 nuts to the suspension member and axle

carrier.

2. INSTALL REAR WHEEL

(a) Install the wheel.

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

3. TIGHTEN REAR NO. 1 SUSPENSION ARM

ASSEMBLY LH

(a) Install the nut and 2 bolts.

Torque: 90 N*m (918 kgf*cm, 66 ft.*lbf) for bolt

100 N*m (1,020 kgf*cm, 74 ft.*lbf) for

nut

NOTICE:

For the nut on the rear suspension member

side, do not tighten the nut.

4. INSPECT AND ADJUST REAR WHEEL ALIGNMENT

(a) Inspect and adjust the rear wheel alignment (see

page SP-7).

C127555

Page 1473 of 2000

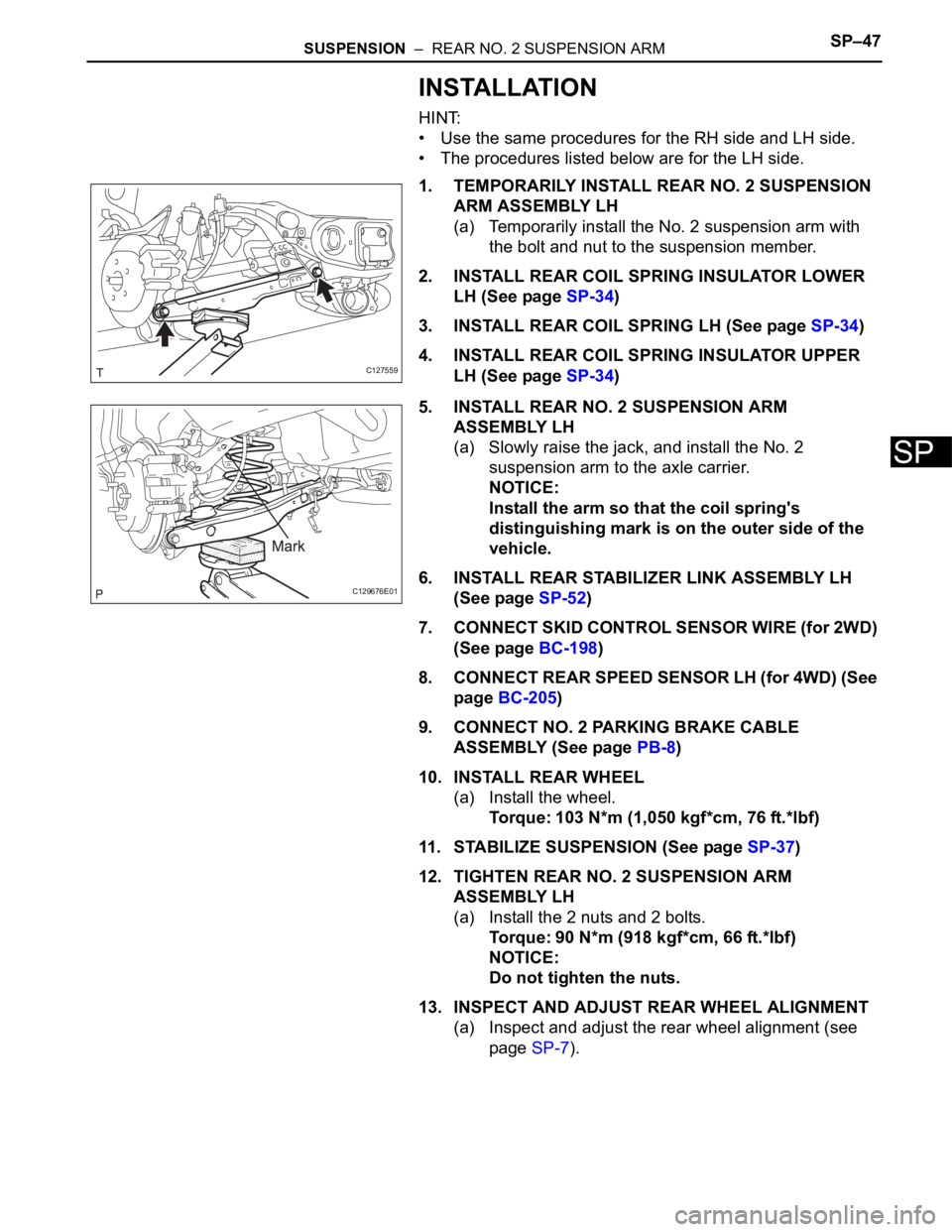

SUSPENSION – REAR NO. 2 SUSPENSION ARMSP–47

SP

INSTALLATION

HINT:

• Use the same procedures for the RH side and LH side.

• The procedures listed below are for the LH side.

1. TEMPORARILY INSTALL REAR NO. 2 SUSPENSION

ARM ASSEMBLY LH

(a) Temporarily install the No. 2 suspension arm with

the bolt and nut to the suspension member.

2. INSTALL REAR COIL SPRING INSULATOR LOWER

LH (See page SP-34)

3. INSTALL REAR COIL SPRING LH (See page SP-34)

4. INSTALL REAR COIL SPRING INSULATOR UPPER

LH (See page SP-34)

5. INSTALL REAR NO. 2 SUSPENSION ARM

ASSEMBLY LH

(a) Slowly raise the jack, and install the No. 2

suspension arm to the axle carrier.

NOTICE:

Install the arm so that the coil spring's

distinguishing mark is on the outer side of the

vehicle.

6. INSTALL REAR STABILIZER LINK ASSEMBLY LH

(See page SP-52)

7. CONNECT SKID CONTROL SENSOR WIRE (for 2WD)

(See page BC-198)

8. CONNECT REAR SPEED SENSOR LH (for 4WD) (See

page BC-205)

9. CONNECT NO. 2 PARKING BRAKE CABLE

ASSEMBLY (See page PB-8)

10. INSTALL REAR WHEEL

(a) Install the wheel.

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

11. STABILIZE SUSPENSION (See page SP-37)

12. TIGHTEN REAR NO. 2 SUSPENSION ARM

ASSEMBLY LH

(a) Install the 2 nuts and 2 bolts.

Torque: 90 N*m (918 kgf*cm, 66 ft.*lbf)

NOTICE:

Do not tighten the nuts.

13. INSPECT AND ADJUST REAR WHEEL ALIGNMENT

(a) Inspect and adjust the rear wheel alignment (see

page SP-7).

C127559

C129676E01

Page 1474 of 2000

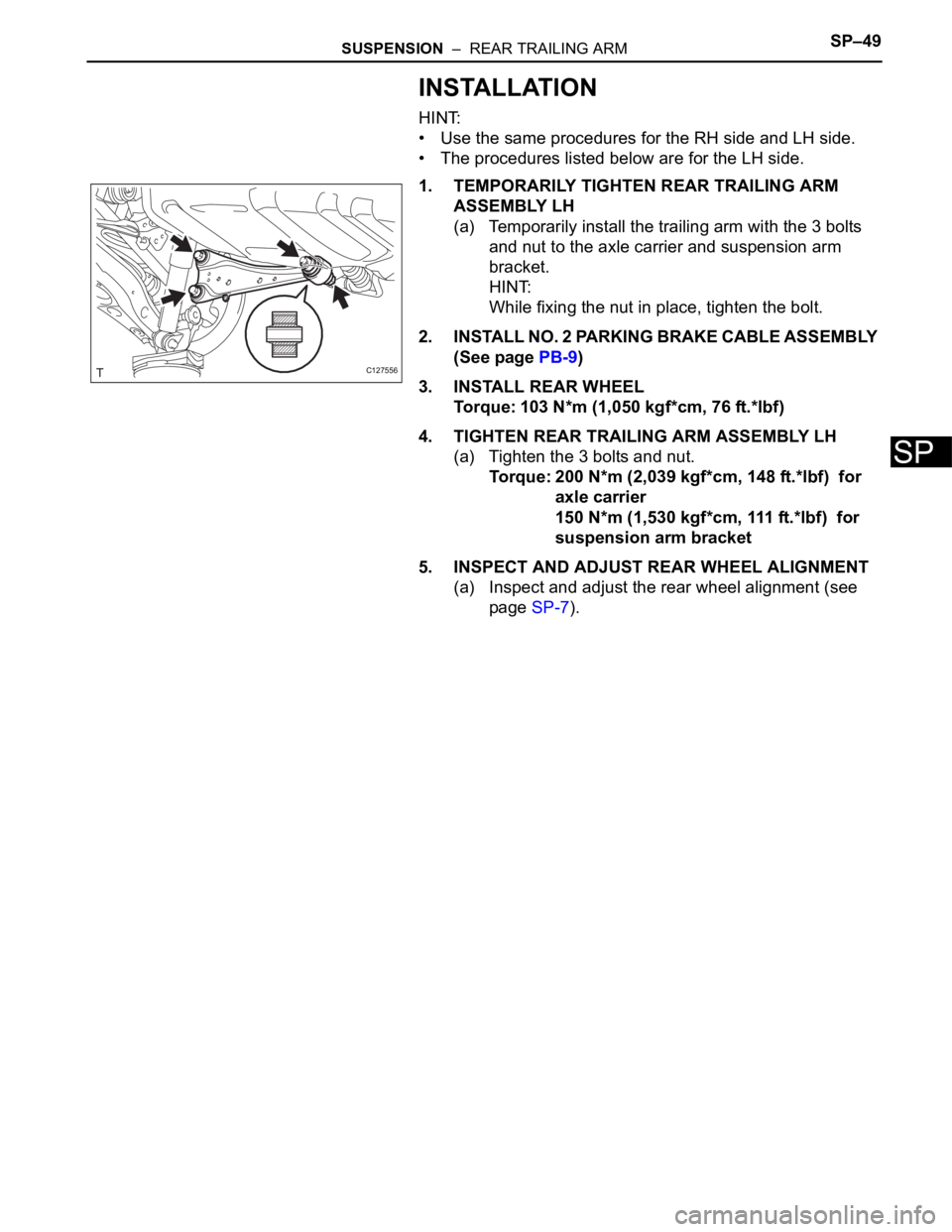

SUSPENSION – REAR TRAILING ARMSP–49

SP

INSTALLATION

HINT:

• Use the same procedures for the RH side and LH side.

• The procedures listed below are for the LH side.

1. TEMPORARILY TIGHTEN REAR TRAILING ARM

ASSEMBLY LH

(a) Temporarily install the trailing arm with the 3 bolts

and nut to the axle carrier and suspension arm

bracket.

HINT:

While fixing the nut in place, tighten the bolt.

2. INSTALL NO. 2 PARKING BRAKE CABLE ASSEMBLY

(See page PB-9)

3. INSTALL REAR WHEEL

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

4. TIGHTEN REAR TRAILING ARM ASSEMBLY LH

(a) Tighten the 3 bolts and nut.

Torque: 200 N*m (2,039 kgf*cm, 148 ft.*lbf) for

axle carrier

150 N*m (1,530 kgf*cm, 111 ft.*lbf) for

suspension arm bracket

5. INSPECT AND ADJUST REAR WHEEL ALIGNMENT

(a) Inspect and adjust the rear wheel alignment (see

page SP-7).

C127556

Page 1475 of 2000

SUSPENSION – REAR STABILIZER BARSP–51

SP

INSPECTION

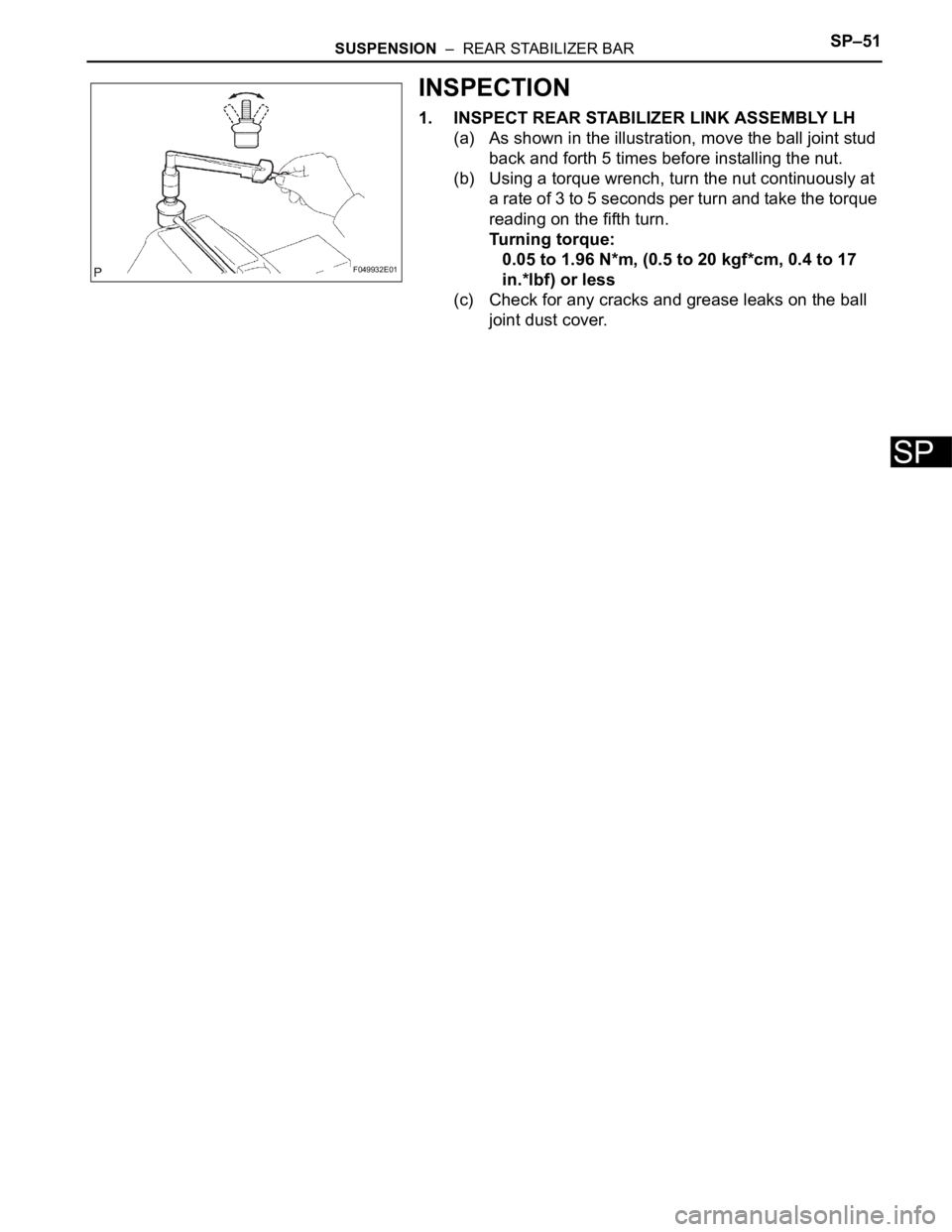

1. INSPECT REAR STABILIZER LINK ASSEMBLY LH

(a) As shown in the illustration, move the ball joint stud

back and forth 5 times before installing the nut.

(b) Using a torque wrench, turn the nut continuously at

a rate of 3 to 5 seconds per turn and take the torque

reading on the fifth turn.

Turning torque:

0.05 to 1.96 N*m, (0.5 to 20 kgf*cm, 0.4 to 17

in.*lbf) or less

(c) Check for any cracks and grease leaks on the ball

joint dust cover.

F049932E01

Page 1476 of 2000

SP–52SUSPENSION – REAR STABILIZER BAR

SP

INSTALLATION

HINT:

• Use the same procedures for the RH side and LH side.

• The procedures listed below are for the LH side.

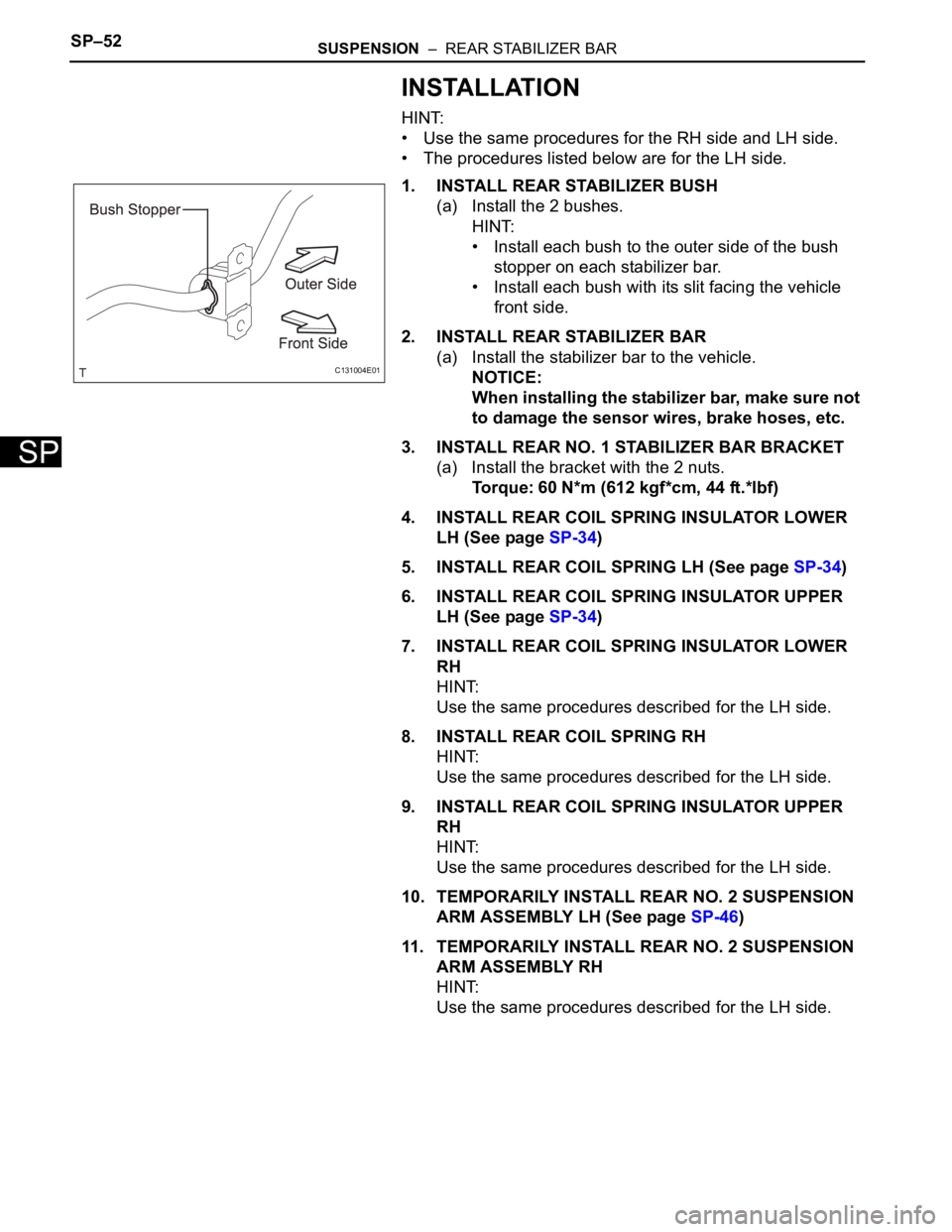

1. INSTALL REAR STABILIZER BUSH

(a) Install the 2 bushes.

HINT:

• Install each bush to the outer side of the bush

stopper on each stabilizer bar.

• Install each bush with its slit facing the vehicle

front side.

2. INSTALL REAR STABILIZER BAR

(a) Install the stabilizer bar to the vehicle.

NOTICE:

When installing the stabilizer bar, make sure not

to damage the sensor wires, brake hoses, etc.

3. INSTALL REAR NO. 1 STABILIZER BAR BRACKET

(a) Install the bracket with the 2 nuts.

Torque: 60 N*m (612 kgf*cm, 44 ft.*lbf)

4. INSTALL REAR COIL SPRING INSULATOR LOWER

LH (See page SP-34)

5. INSTALL REAR COIL SPRING LH (See page SP-34)

6. INSTALL REAR COIL SPRING INSULATOR UPPER

LH (See page SP-34)

7. INSTALL REAR COIL SPRING INSULATOR LOWER

RH

HINT:

Use the same procedures described for the LH side.

8. INSTALL REAR COIL SPRING RH

HINT:

Use the same procedures described for the LH side.

9. INSTALL REAR COIL SPRING INSULATOR UPPER

RH

HINT:

Use the same procedures described for the LH side.

10. TEMPORARILY INSTALL REAR NO. 2 SUSPENSION

ARM ASSEMBLY LH (See page SP-46)

11. TEMPORARILY INSTALL REAR NO. 2 SUSPENSION

ARM ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

C131004E01

Page 1477 of 2000

SUSPENSION – REAR STABILIZER BARSP–53

SP

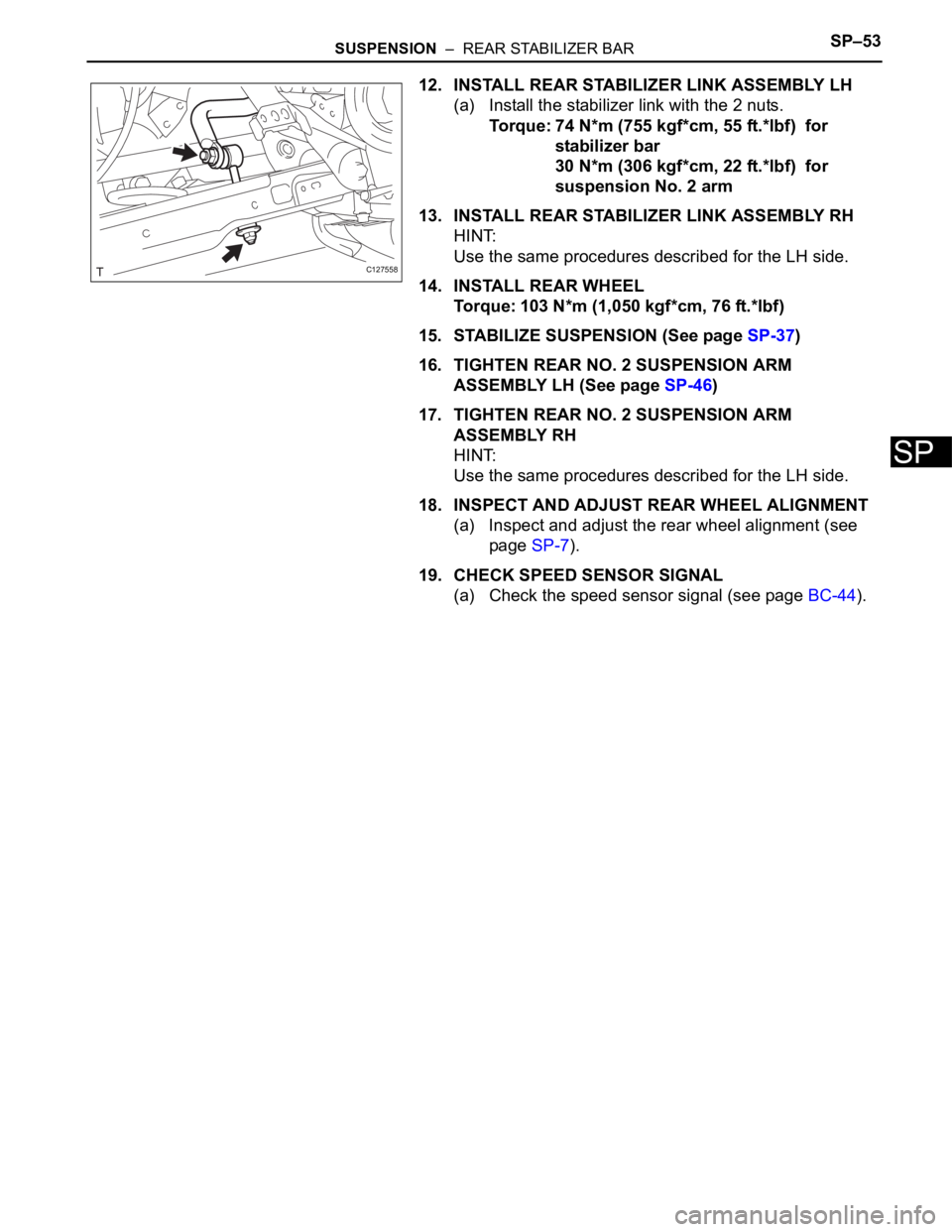

12. INSTALL REAR STABILIZER LINK ASSEMBLY LH

(a) Install the stabilizer link with the 2 nuts.

Torque: 74 N*m (755 kgf*cm, 55 ft.*lbf) for

stabilizer bar

30 N*m (306 kgf*cm, 22 ft.*lbf) for

suspension No. 2 arm

13. INSTALL REAR STABILIZER LINK ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

14. INSTALL REAR WHEEL

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

15. STABILIZE SUSPENSION (See page SP-37)

16. TIGHTEN REAR NO. 2 SUSPENSION ARM

ASSEMBLY LH (See page SP-46)

17. TIGHTEN REAR NO. 2 SUSPENSION ARM

ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

18. INSPECT AND ADJUST REAR WHEEL ALIGNMENT

(a) Inspect and adjust the rear wheel alignment (see

page SP-7).

19. CHECK SPEED SENSOR SIGNAL

(a) Check the speed sensor signal (see page BC-44).

C127558

Page 1478 of 2000

TW–6TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

TW

SYSTEM DESCRIPTION

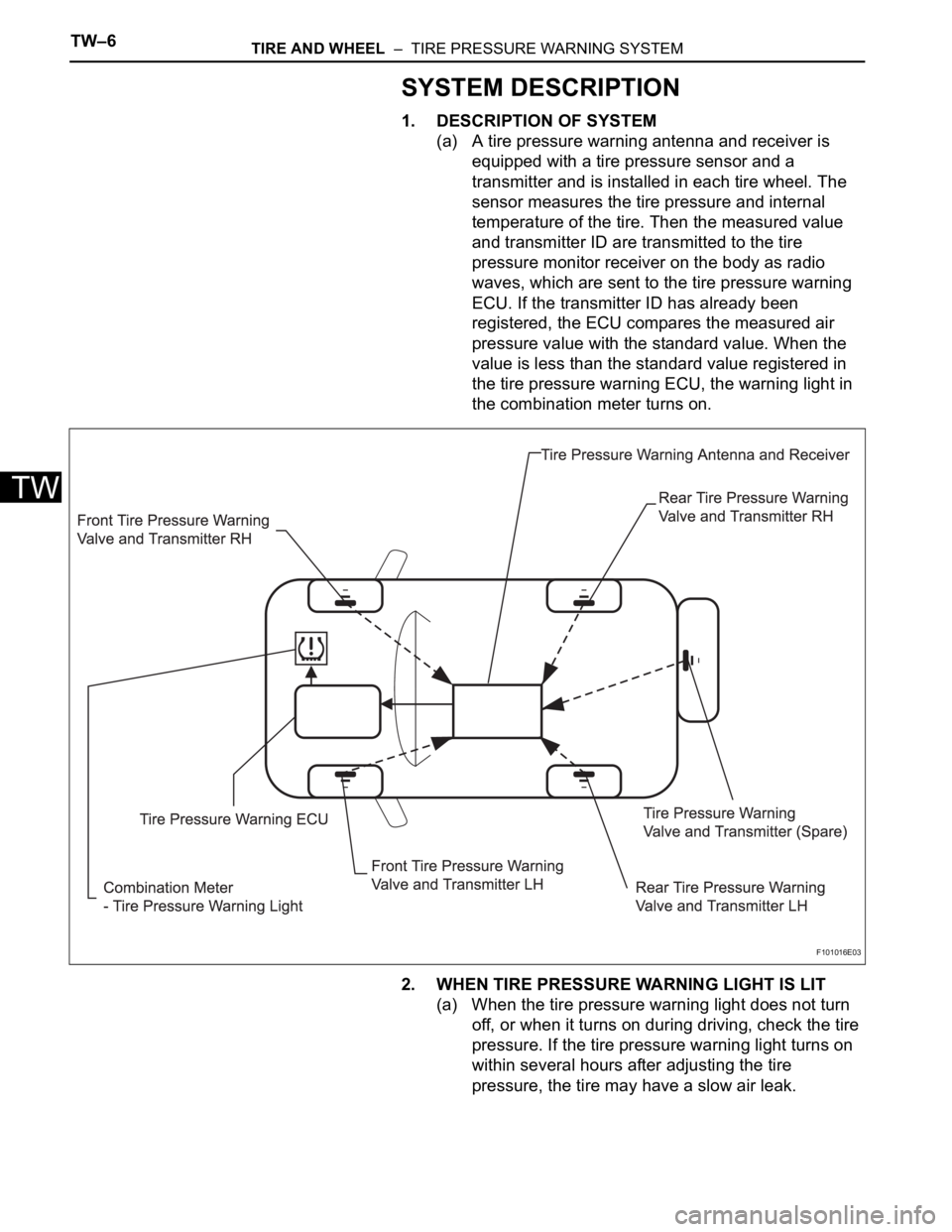

1. DESCRIPTION OF SYSTEM

(a) A tire pressure warning antenna and receiver is

equipped with a tire pressure sensor and a

transmitter and is installed in each tire wheel. The

sensor measures the tire pressure and internal

temperature of the tire. Then the measured value

and transmitter ID are transmitted to the tire

pressure monitor receiver on the body as radio

waves, which are sent to the tire pressure warning

ECU. If the transmitter ID has already been

registered, the ECU compares the measured air

pressure value with the standard value. When the

value is less than the standard value registered in

the tire pressure warning ECU, the warning light in

the combination meter turns on.

2. WHEN TIRE PRESSURE WARNING LIGHT IS LIT

(a) When the tire pressure warning light does not turn

off, or when it turns on during driving, check the tire

pressure. If the tire pressure warning light turns on

within several hours after adjusting the tire

pressure, the tire may have a slow air leak.

F101016E03

Page 1479 of 2000

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEMTW–7

TW

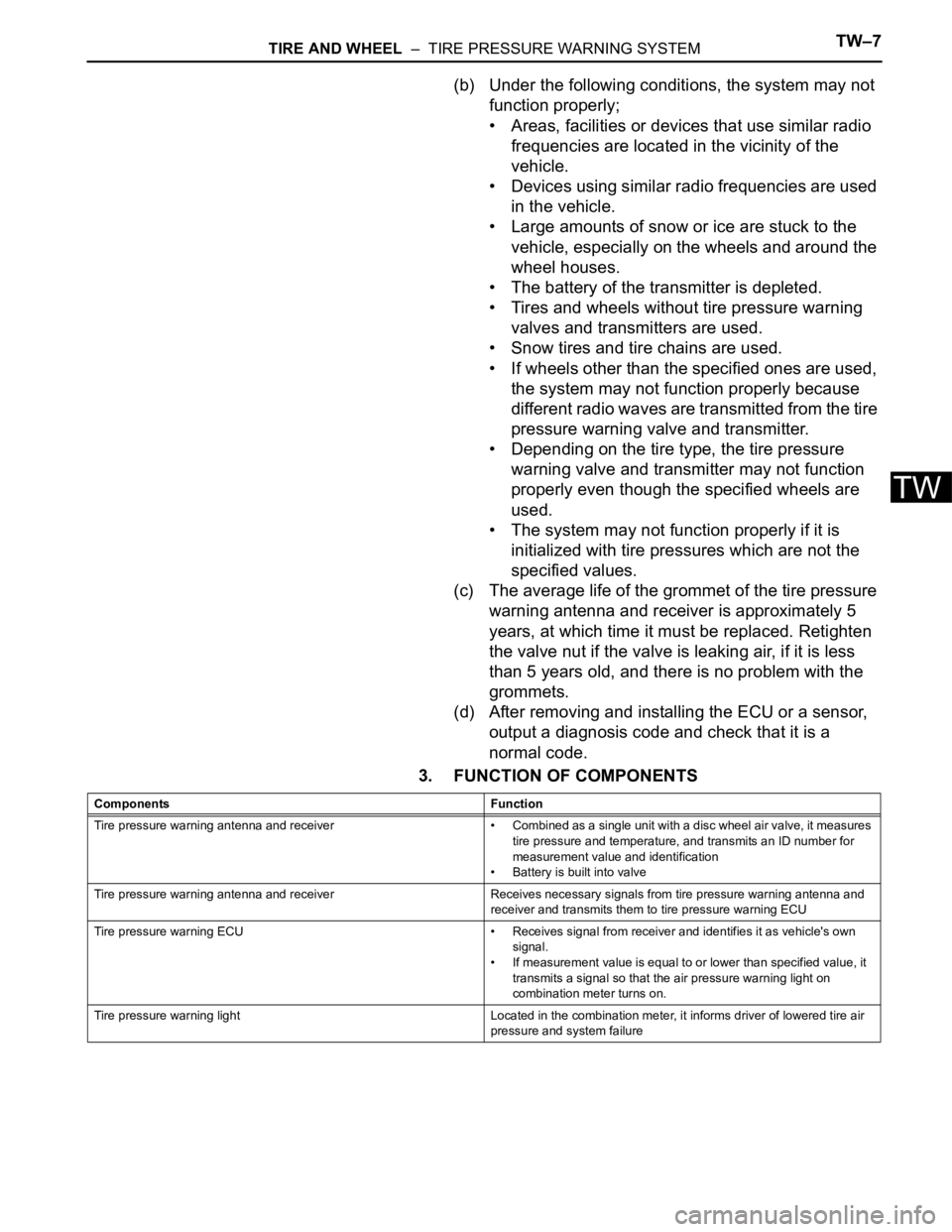

(b) Under the following conditions, the system may not

function properly;

• Areas, facilities or devices that use similar radio

frequencies are located in the vicinity of the

vehicle.

• Devices using similar radio frequencies are used

in the vehicle.

• Large amounts of snow or ice are stuck to the

vehicle, especially on the wheels and around the

wheel houses.

• The battery of the transmitter is depleted.

• Tires and wheels without tire pressure warning

valves and transmitters are used.

• Snow tires and tire chains are used.

• If wheels other than the specified ones are used,

the system may not function properly because

different radio waves are transmitted from the tire

pressure warning valve and transmitter.

• Depending on the tire type, the tire pressure

warning valve and transmitter may not function

properly even though the specified wheels are

used.

• The system may not function properly if it is

initialized with tire pressures which are not the

specified values.

(c) The average life of the grommet of the tire pressure

warning antenna and receiver is approximately 5

years, at which time it must be replaced. Retighten

the valve nut if the valve is leaking air, if it is less

than 5 years old, and there is no problem with the

grommets.

(d) After removing and installing the ECU or a sensor,

output a diagnosis code and check that it is a

normal code.

3. FUNCTION OF COMPONENTS

Components Function

Tire pressure warning antenna and receiver • Combined as a single unit with a disc wheel air valve, it measures

tire pressure and temperature, and transmits an ID number for

measurement value and identification

• Battery is built into valve

Tire pressure warning antenna and receiver Receives necessary signals from tire pressure warning antenna and

receiver and transmits them to tire pressure warning ECU

Tire pressure warning ECU • Receives signal from receiver and identifies it as vehicle's own

signal.

• If measurement value is equal to or lower than specified value, it

transmits a signal so that the air pressure warning light on

combination meter turns on.

Tire pressure warning light Located in the combination meter, it informs driver of lowered tire air

pressure and system failure

Page 1480 of 2000

TW–8TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

TW

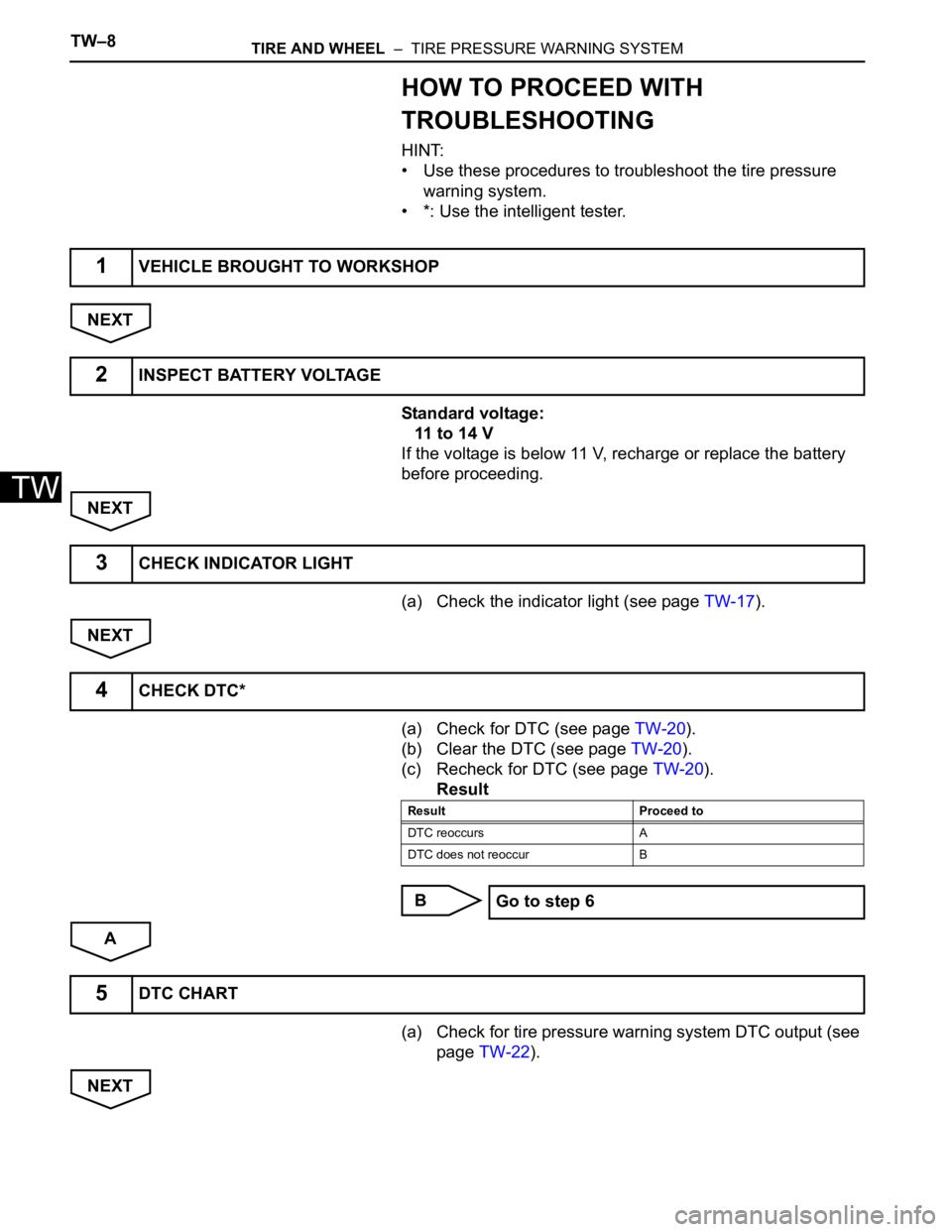

HOW TO PROCEED WITH

TROUBLESHOOTING

HINT:

• Use these procedures to troubleshoot the tire pressure

warning system.

• *: Use the intelligent tester.

NEXT

Standard voltage:

11 to 14 V

If the voltage is below 11 V, recharge or replace the battery

before proceeding.

NEXT

(a) Check the indicator light (see page TW-17).

NEXT

(a) Check for DTC (see page TW-20).

(b) Clear the DTC (see page TW-20).

(c) Recheck for DTC (see page TW-20).

Result

B

A

(a) Check for tire pressure warning system DTC output (see

page TW-22).

NEXT

1VEHICLE BROUGHT TO WORKSHOP

2INSPECT BATTERY VOLTAGE

3CHECK INDICATOR LIGHT

4CHECK DTC*

Result Proceed to

DTC reoccurs A

DTC does not reoccur B

Go to step 6

5DTC CHART