TOYOTA RAV4 2006 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 1661 of 2000

AIR CONDITIONING – AIR MIX CONTROL SERVO MOTOR (for Automatic Air Conditioning

System)AC–215

AC

INSTALLATION

1. INSTALL AIR MIX CONTROL SERVO MOTOR (See

page AC-196)

2. INSTALL AIR CONDITIONING UNIT

(a) Install the air conditioning radiator (see page AC-

197).

Page 1662 of 2000

AIR CONDITIONING – COMPRESSOR AND PULLEY (for 2AZ-FE)AC–217

AC

INSTALLATION

1. ADJUST ADJUST COMPRESSOR OIL

(a) When replacing the compressor and magnetic

clutch with a new one, gradually discharge the

refrigerant gas from the service valve, and drain the

following amount of oil from the new compressor

and magnetic clutch before installation.

Standard:

(Oil capacity inside the new compressor and

magnetic clutch: 130 + 15 cc (4.6 + 0.51 fl.oz.) )

-(Remaining oil amount in the removed

compressor and magnetic clutch) = (Oil

amount to be removed from the new

compressor when replacing)

NOTICE:

• When checking the compressor oil level,

observe the precautions on the cooler

removal/installation.

• If a new compressor and magnetic clutch is

installed without removing some oil

remaining in the pipes of the vehicle, the oil

amount will be too large. This prevents heat

exchange in the refrigerant cycle and causes

refrigerant failure.

• If the volume of oil remaining in the removed

compressor and magnetic clutch is too small,

check for oil leakage.

• Be sure to use ND-OIL 8 or equivalent for

compressor oil.

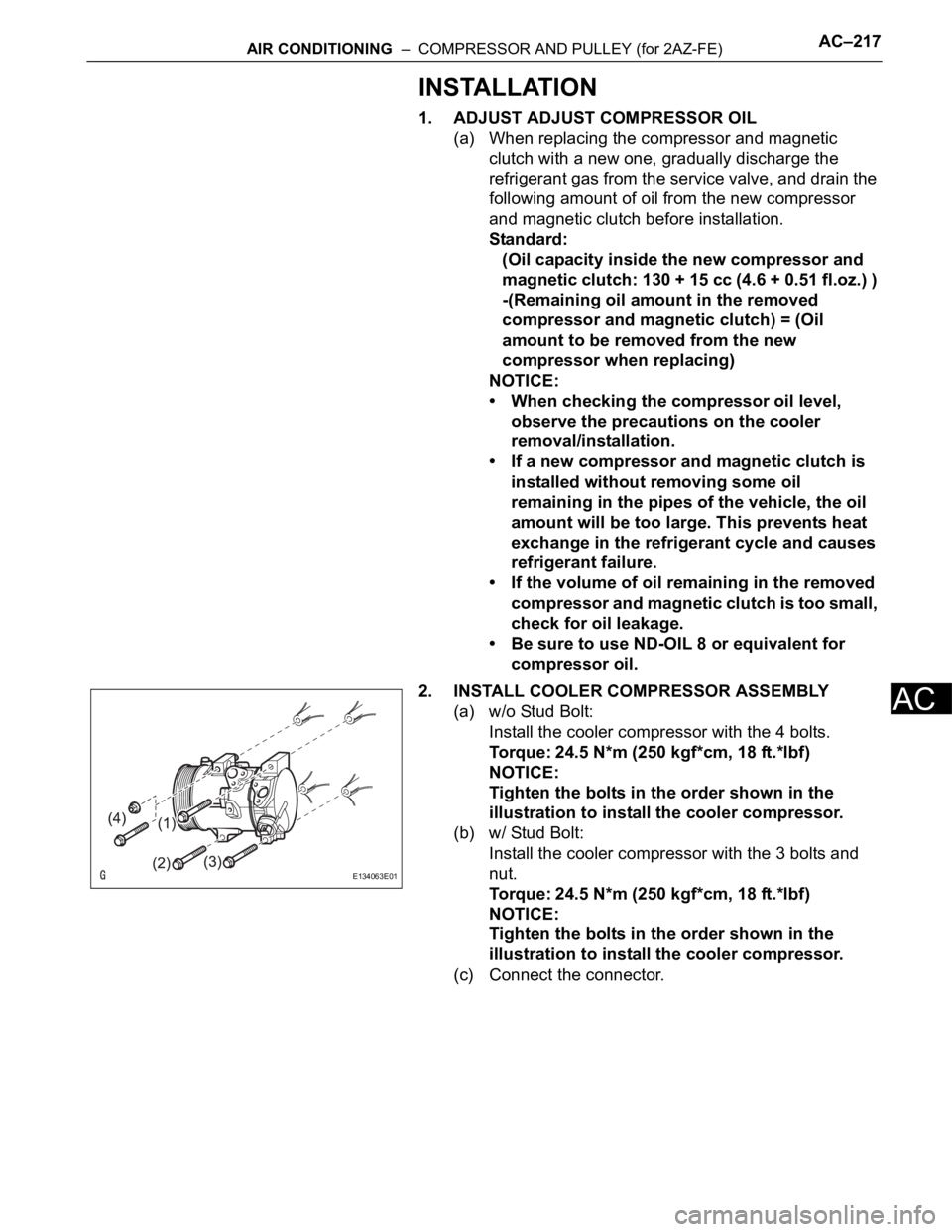

2. INSTALL COOLER COMPRESSOR ASSEMBLY

(a) w/o Stud Bolt:

Install the cooler compressor with the 4 bolts.

Torque: 24.5 N*m (250 kgf*cm, 18 ft.*lbf)

NOTICE:

Tighten the bolts in the order shown in the

illustration to install the cooler compressor.

(b) w/ Stud Bolt:

Install the cooler compressor with the 3 bolts and

nut.

Torque: 24.5 N*m (250 kgf*cm, 18 ft.*lbf)

NOTICE:

Tighten the bolts in the order shown in the

illustration to install the cooler compressor.

(c) Connect the connector.

E134063E01

Page 1663 of 2000

AC–218AIR CONDITIONING – COMPRESSOR AND PULLEY (for 2AZ-FE)

AC

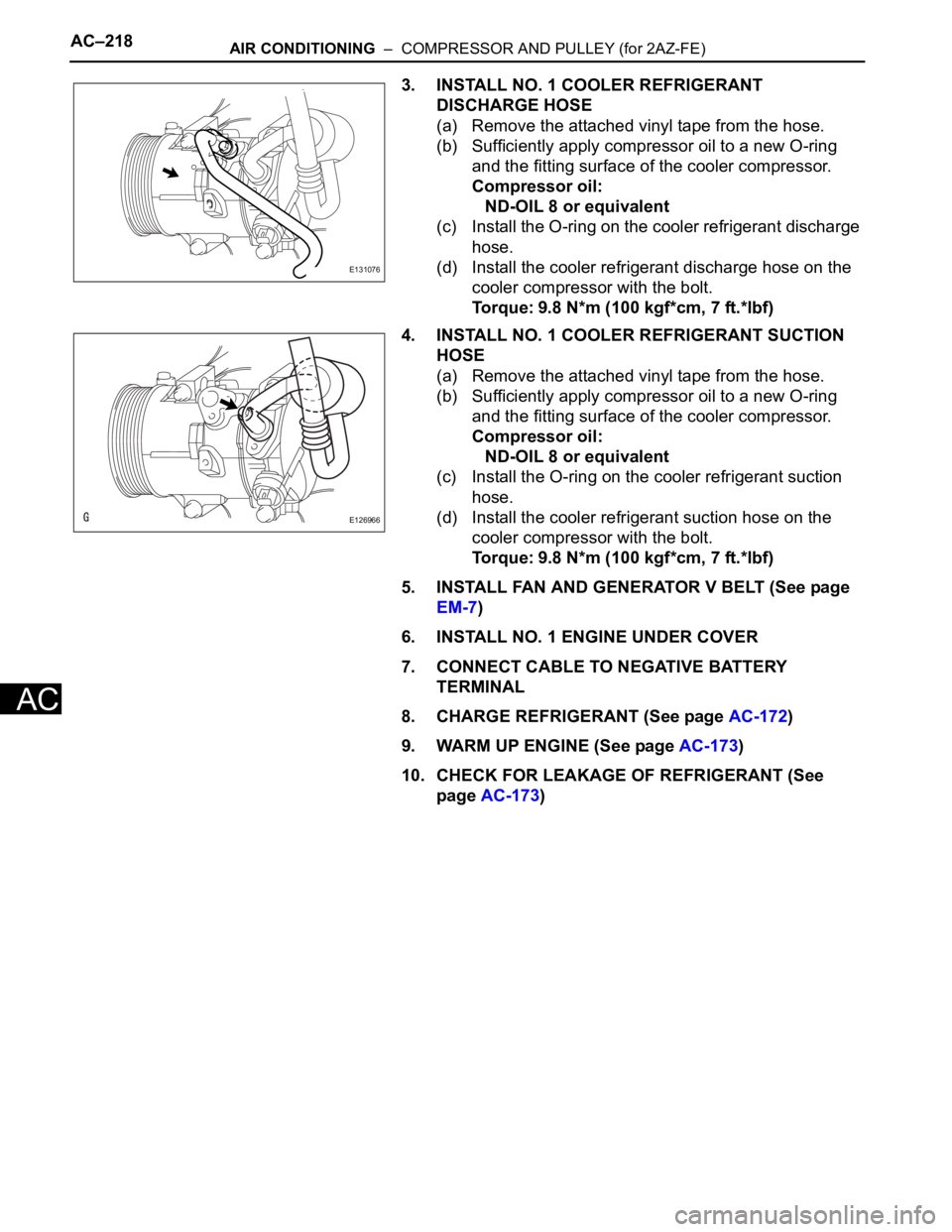

3. INSTALL NO. 1 COOLER REFRIGERANT

DISCHARGE HOSE

(a) Remove the attached vinyl tape from the hose.

(b) Sufficiently apply compressor oil to a new O-ring

and the fitting surface of the cooler compressor.

Compressor oil:

ND-OIL 8 or equivalent

(c) Install the O-ring on the cooler refrigerant discharge

hose.

(d) Install the cooler refrigerant discharge hose on the

cooler compressor with the bolt.

Torque: 9.8 N*m (100 kgf*cm, 7 ft.*lbf)

4. INSTALL NO. 1 COOLER REFRIGERANT SUCTION

HOSE

(a) Remove the attached vinyl tape from the hose.

(b) Sufficiently apply compressor oil to a new O-ring

and the fitting surface of the cooler compressor.

Compressor oil:

ND-OIL 8 or equivalent

(c) Install the O-ring on the cooler refrigerant suction

hose.

(d) Install the cooler refrigerant suction hose on the

cooler compressor with the bolt.

Torque: 9.8 N*m (100 kgf*cm, 7 ft.*lbf)

5. INSTALL FAN AND GENERATOR V BELT (See page

EM-7)

6. INSTALL NO. 1 ENGINE UNDER COVER

7. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

8. CHARGE REFRIGERANT (See page AC-172)

9. WARM UP ENGINE (See page AC-173)

10. CHECK FOR LEAKAGE OF REFRIGERANT (See

page AC-173)

E131076

E126966

Page 1664 of 2000

AIR CONDITIONING – COMPRESSOR AND PULLEY (for 2GR-FE)AC–221

AC

INSTALLATION

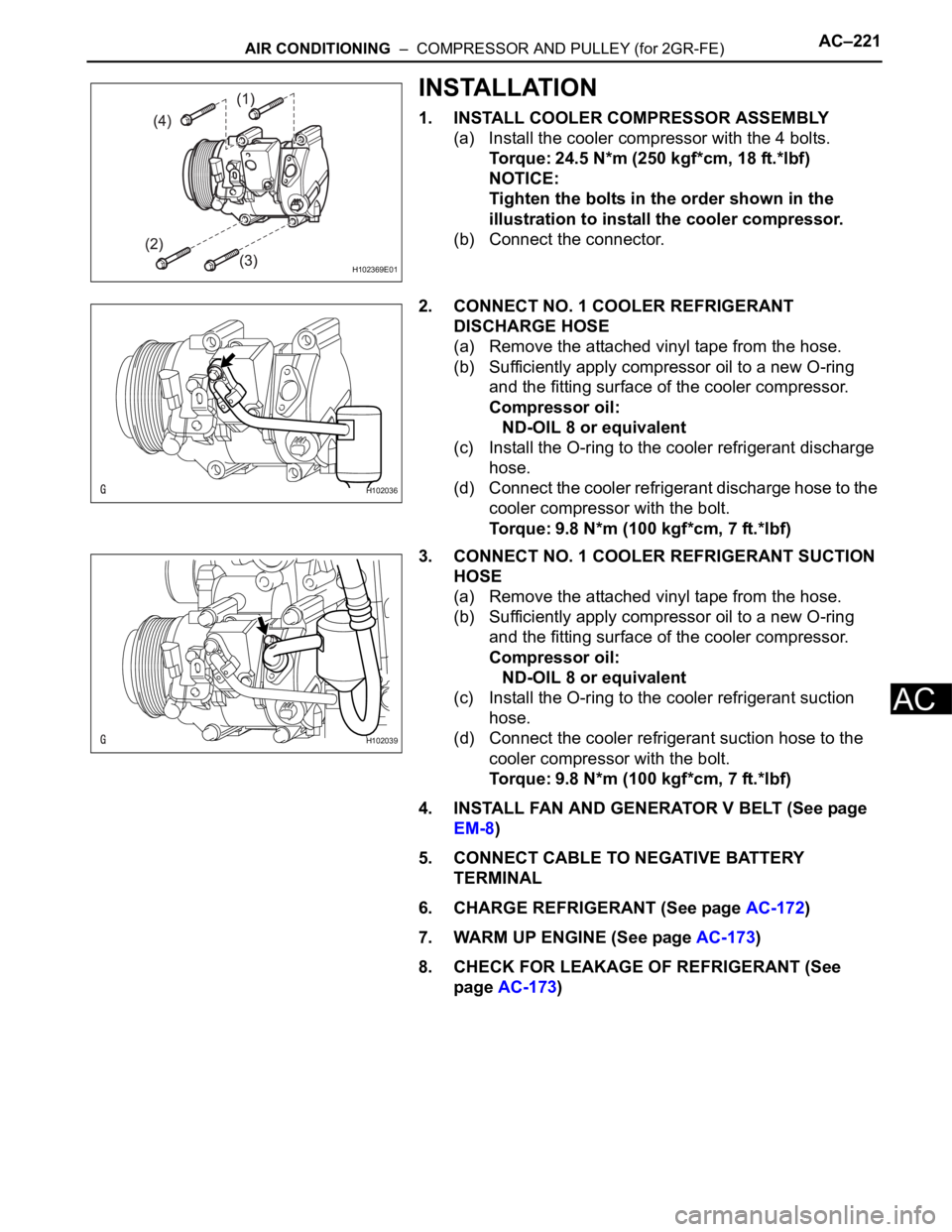

1. INSTALL COOLER COMPRESSOR ASSEMBLY

(a) Install the cooler compressor with the 4 bolts.

Torque: 24.5 N*m (250 kgf*cm, 18 ft.*lbf)

NOTICE:

Tighten the bolts in the order shown in the

illustration to install the cooler compressor.

(b) Connect the connector.

2. CONNECT NO. 1 COOLER REFRIGERANT

DISCHARGE HOSE

(a) Remove the attached vinyl tape from the hose.

(b) Sufficiently apply compressor oil to a new O-ring

and the fitting surface of the cooler compressor.

Compressor oil:

ND-OIL 8 or equivalent

(c) Install the O-ring to the cooler refrigerant discharge

hose.

(d) Connect the cooler refrigerant discharge hose to the

cooler compressor with the bolt.

Torque: 9.8 N*m (100 kgf*cm, 7 ft.*lbf)

3. CONNECT NO. 1 COOLER REFRIGERANT SUCTION

HOSE

(a) Remove the attached vinyl tape from the hose.

(b) Sufficiently apply compressor oil to a new O-ring

and the fitting surface of the cooler compressor.

Compressor oil:

ND-OIL 8 or equivalent

(c) Install the O-ring to the cooler refrigerant suction

hose.

(d) Connect the cooler refrigerant suction hose to the

cooler compressor with the bolt.

Torque: 9.8 N*m (100 kgf*cm, 7 ft.*lbf)

4. INSTALL FAN AND GENERATOR V BELT (See page

EM-8)

5. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

6. CHARGE REFRIGERANT (See page AC-172)

7. WARM UP ENGINE (See page AC-173)

8. CHECK FOR LEAKAGE OF REFRIGERANT (See

page AC-173)

H102369E01

H102036

H102039

Page 1665 of 2000

AC–224AIR CONDITIONING – CONDENSER

AC

ON-VEHICLE INSPECTION

1. INSPECT COOLER CONDENSER ASSEMBLY

(a) If the fins of the cooler condenser are dirty, clean

them with water. Dry the fins with compressed air.

NOTICE:

Do not damage the fins of the condenser.

(b) If a fin of the cooler condenser is bent, straighten it

using a screwdriver or pliers.

2. CHECK CONDENSER FOR LEAKAGE OF

REFRIGERANT

(a) Using a halogen leak detector, check the pipe joints

for gas leakage.

(b) If gas leakage is detected in a joint, check the

torque of the joint.

Page 1666 of 2000

AIR CONDITIONING – CONDENSERAC–225

AC

REMOVAL

1. DISCHARGE REFRIGERANT FROM

REFRIGERATION SYSTEM (See page AC-172)

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

3. REMOVE FRONT BUMPER COVER

(a) Remove front bumper cover (see page ET-4).

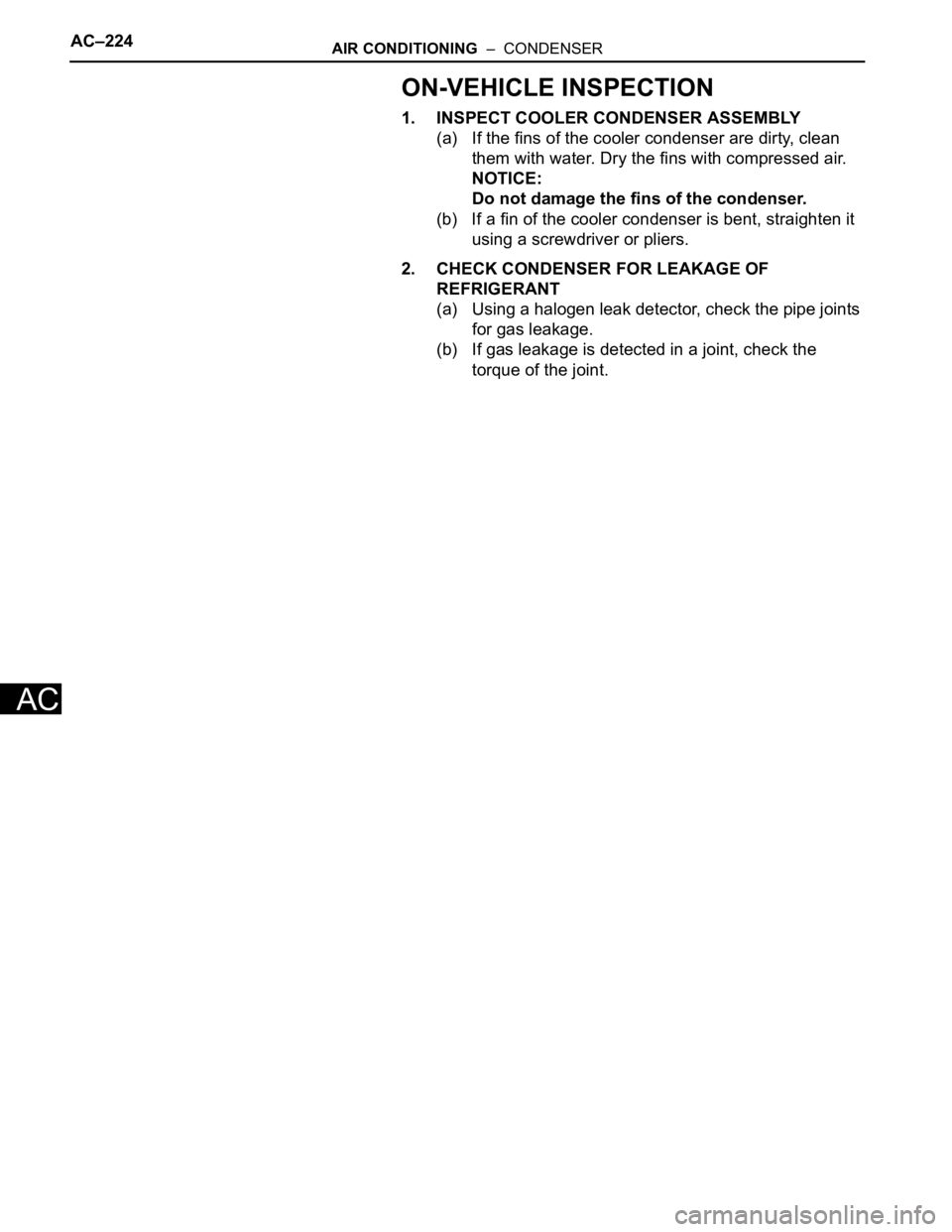

4. DISCONNECT NO. 1 COOLER REFRIGERANT

DISCHARGE HOSE

(a) Remove the bolt and disconnect the cooler

refrigerant discharge hose from the cooler

condenser.

(b) Remove the O-ring from the cooler refrigerant

discharge hose.

NOTICE:

Seal the openings of the disconnected parts

using vinyl tape to prevent moisture and foreign

matter from entering them.

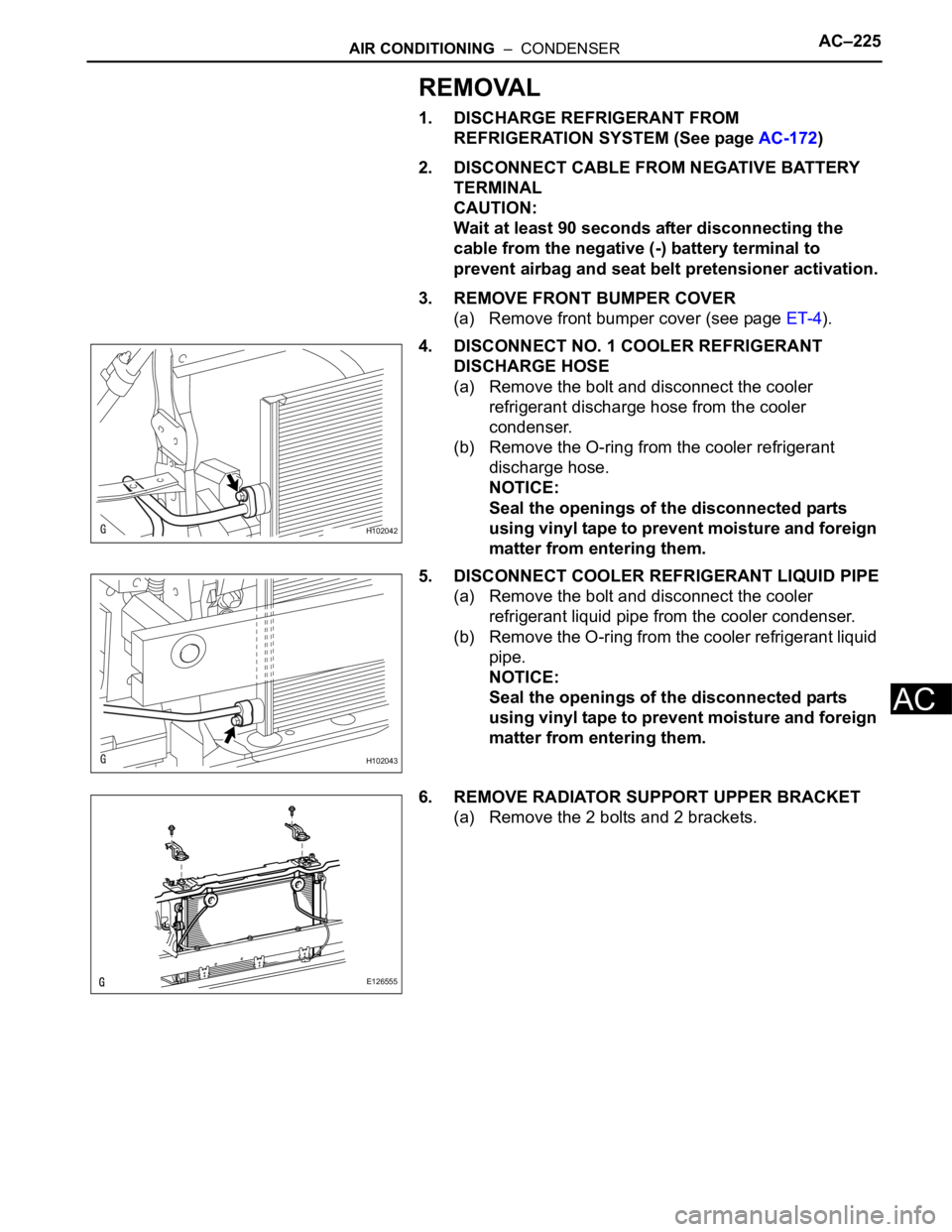

5. DISCONNECT COOLER REFRIGERANT LIQUID PIPE

(a) Remove the bolt and disconnect the cooler

refrigerant liquid pipe from the cooler condenser.

(b) Remove the O-ring from the cooler refrigerant liquid

pipe.

NOTICE:

Seal the openings of the disconnected parts

using vinyl tape to prevent moisture and foreign

matter from entering them.

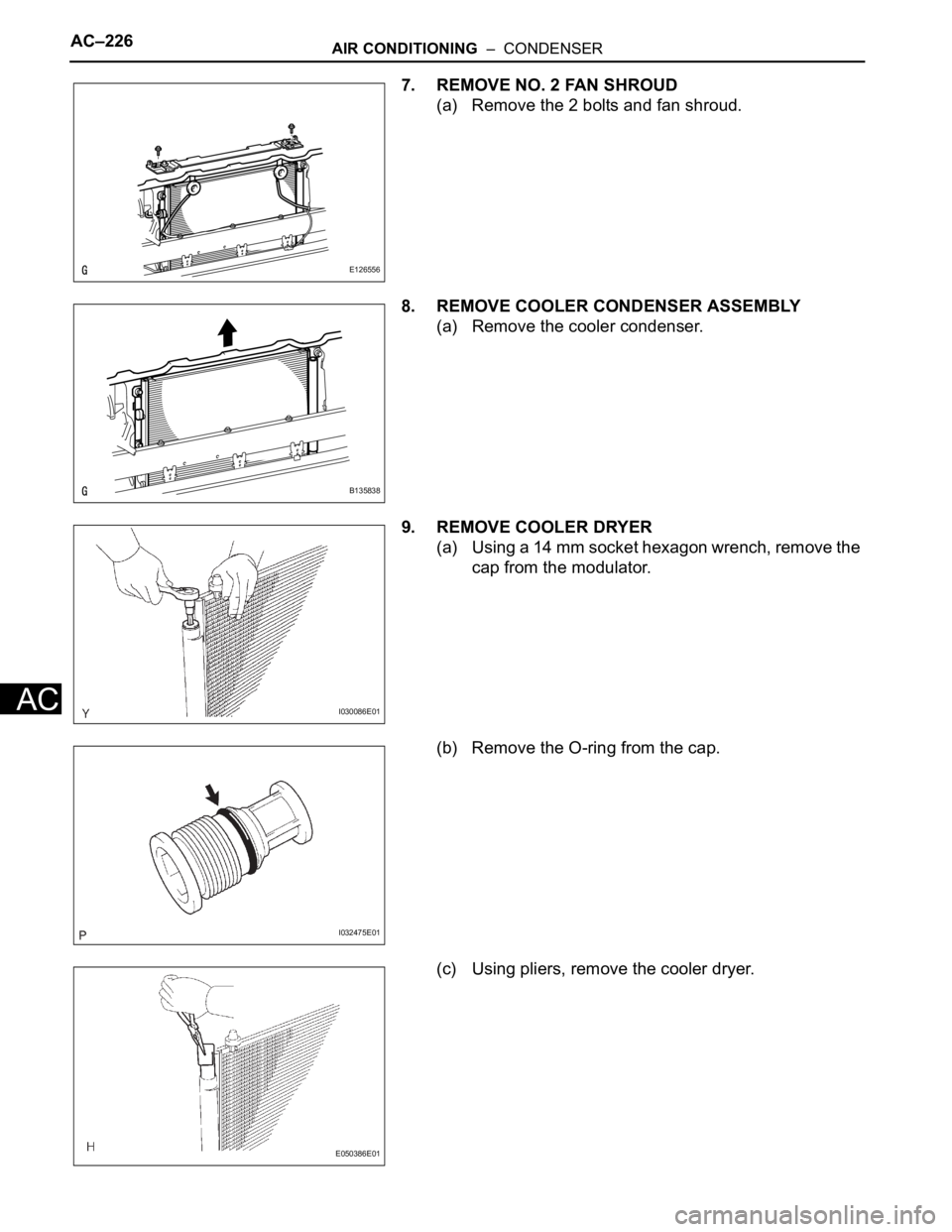

6. REMOVE RADIATOR SUPPORT UPPER BRACKET

(a) Remove the 2 bolts and 2 brackets.

H102042

H102043

E126555

Page 1667 of 2000

AC–226AIR CONDITIONING – CONDENSER

AC

7. REMOVE NO. 2 FAN SHROUD

(a) Remove the 2 bolts and fan shroud.

8. REMOVE COOLER CONDENSER ASSEMBLY

(a) Remove the cooler condenser.

9. REMOVE COOLER DRYER

(a) Using a 14 mm socket hexagon wrench, remove the

cap from the modulator.

(b) Remove the O-ring from the cap.

(c) Using pliers, remove the cooler dryer.

E126556

B135838

I030086E01

I032475E01

E050386E01

Page 1668 of 2000

AIR CONDITIONING – CONDENSERAC–227

AC

INSTALLATION

1. INSTALL COOLER DRYER

(a) Using pliers, install the cooler dryer.

(b) Apply a sufficient amount of compressor oil to the

contact surfaces of a new O-ring and the cap.

Compressor oil:

ND-OIL 8 or equivalent

(c) Install the O-ring to the cap.

(d) Using a 14 mm socket hexagon wrench, install the

cap to the modulator.

Torque: 2.9 N*m (29 kgf*cm, 25 in.*lbf)

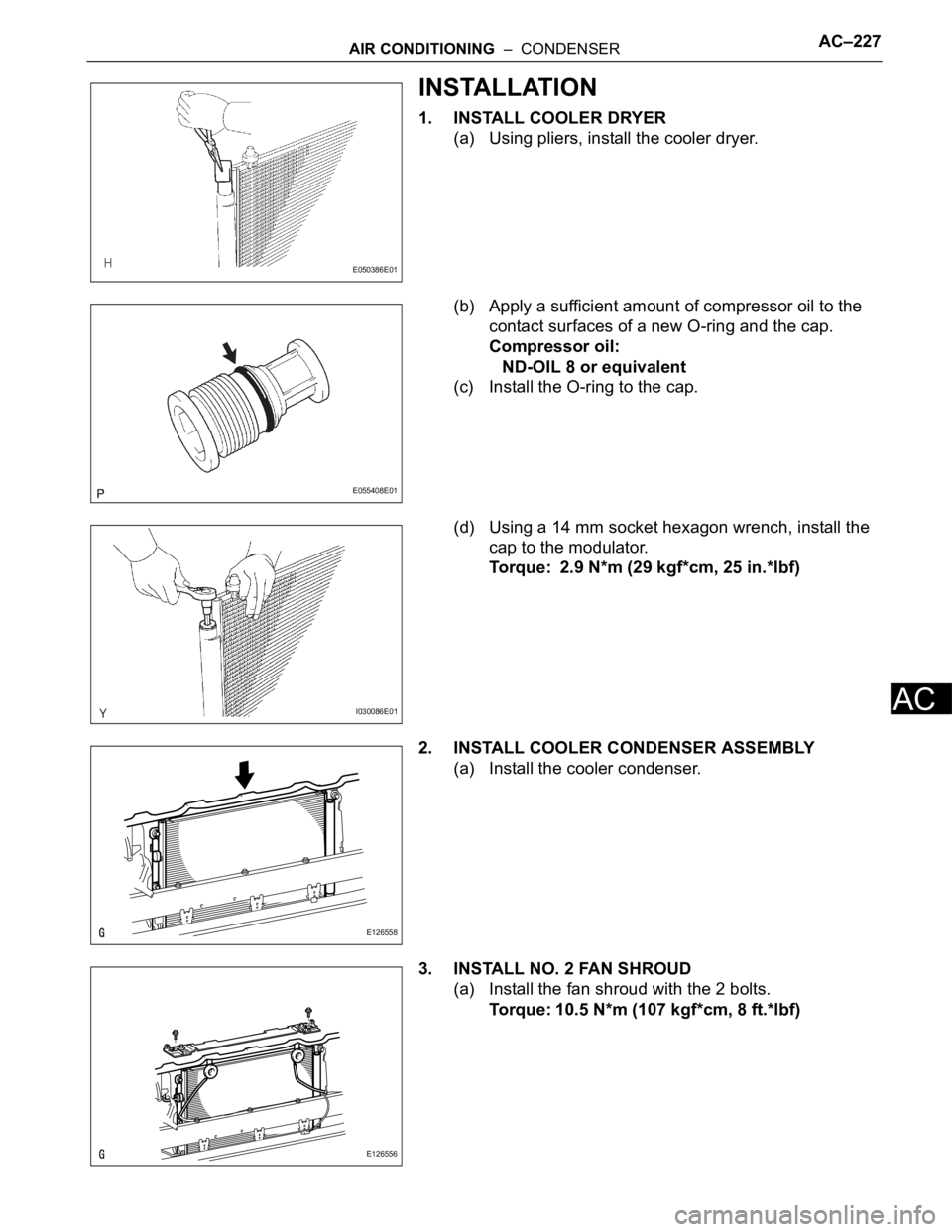

2. INSTALL COOLER CONDENSER ASSEMBLY

(a) Install the cooler condenser.

3. INSTALL NO. 2 FAN SHROUD

(a) Install the fan shroud with the 2 bolts.

Torque: 10.5 N*m (107 kgf*cm, 8 ft.*lbf)

E050386E01

E055408E01

I030086E01

E126558

E126556

Page 1669 of 2000

AC–228AIR CONDITIONING – CONDENSER

AC

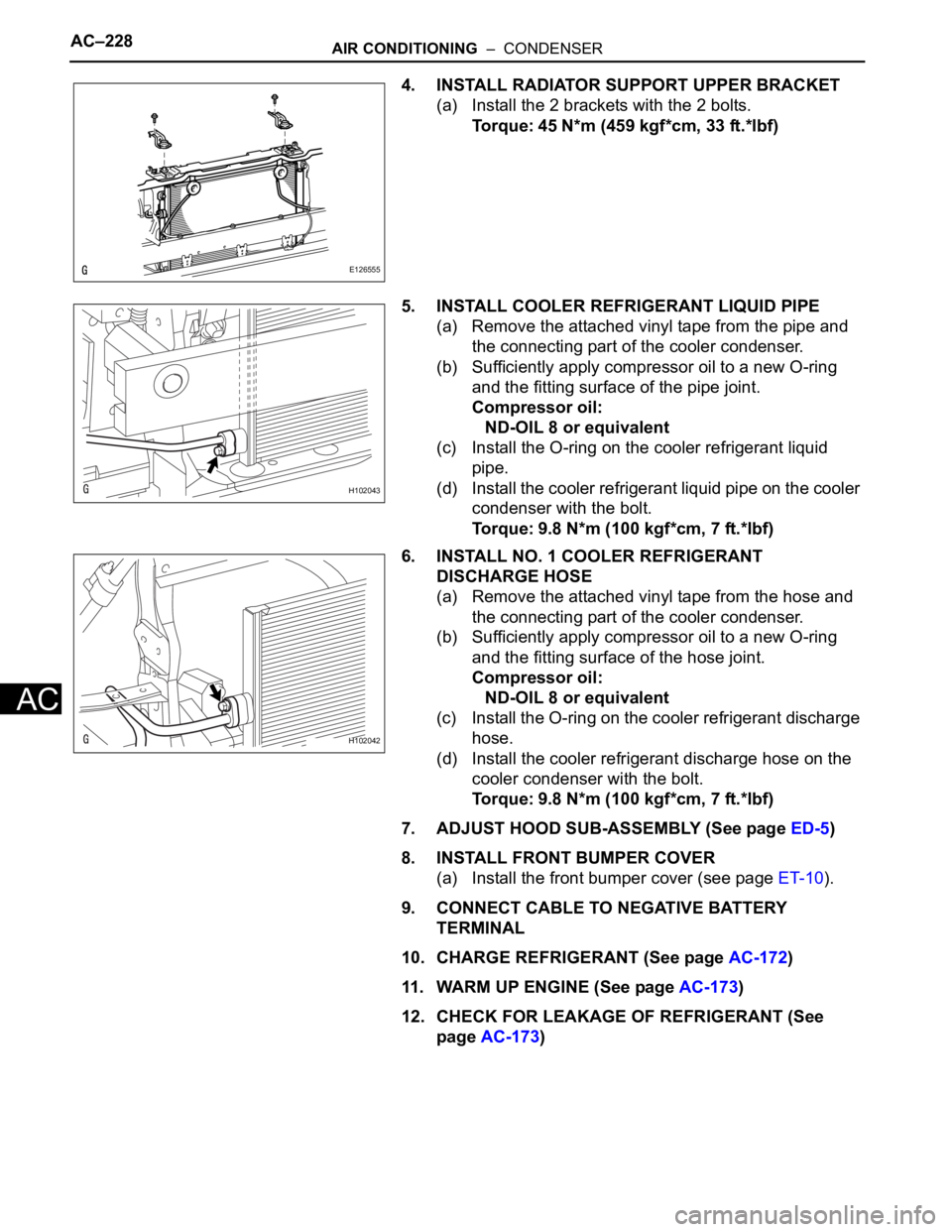

4. INSTALL RADIATOR SUPPORT UPPER BRACKET

(a) Install the 2 brackets with the 2 bolts.

Torque: 45 N*m (459 kgf*cm, 33 ft.*lbf)

5. INSTALL COOLER REFRIGERANT LIQUID PIPE

(a) Remove the attached vinyl tape from the pipe and

the connecting part of the cooler condenser.

(b) Sufficiently apply compressor oil to a new O-ring

and the fitting surface of the pipe joint.

Compressor oil:

ND-OIL 8 or equivalent

(c) Install the O-ring on the cooler refrigerant liquid

pipe.

(d) Install the cooler refrigerant liquid pipe on the cooler

condenser with the bolt.

Torque: 9.8 N*m (100 kgf*cm, 7 ft.*lbf)

6. INSTALL NO. 1 COOLER REFRIGERANT

DISCHARGE HOSE

(a) Remove the attached vinyl tape from the hose and

the connecting part of the cooler condenser.

(b) Sufficiently apply compressor oil to a new O-ring

and the fitting surface of the hose joint.

Compressor oil:

ND-OIL 8 or equivalent

(c) Install the O-ring on the cooler refrigerant discharge

hose.

(d) Install the cooler refrigerant discharge hose on the

cooler condenser with the bolt.

Torque: 9.8 N*m (100 kgf*cm, 7 ft.*lbf)

7. ADJUST HOOD SUB-ASSEMBLY (See page ED-5)

8. INSTALL FRONT BUMPER COVER

(a) Install the front bumper cover (see page ET-10).

9. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

10. CHARGE REFRIGERANT (See page AC-172)

11. WARM UP ENGINE (See page AC-173)

12. CHECK FOR LEAKAGE OF REFRIGERANT (See

page AC-173)

E126555

H102043

H102042

Page 1670 of 2000

AIR CONDITIONING – ROOM TEMPERATURE SENSOR (for Automatic Air Conditioning

System)AC–231

AC

INSTALLATION

1. INSTALL ROOM TEMPERATURE SENSOR

(a) Attach the claws to install the sensor.

(b) Connect the connector.

(c) Connect the duct.

2. INSTALL LOWER INSTRUMENT PANEL

(a) Install the lower instrument panel (see page IP-23).