TOYOTA RAV4 2006 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 821 of 2000

2GR-FE FUEL – FUEL TANKFU–37

FU

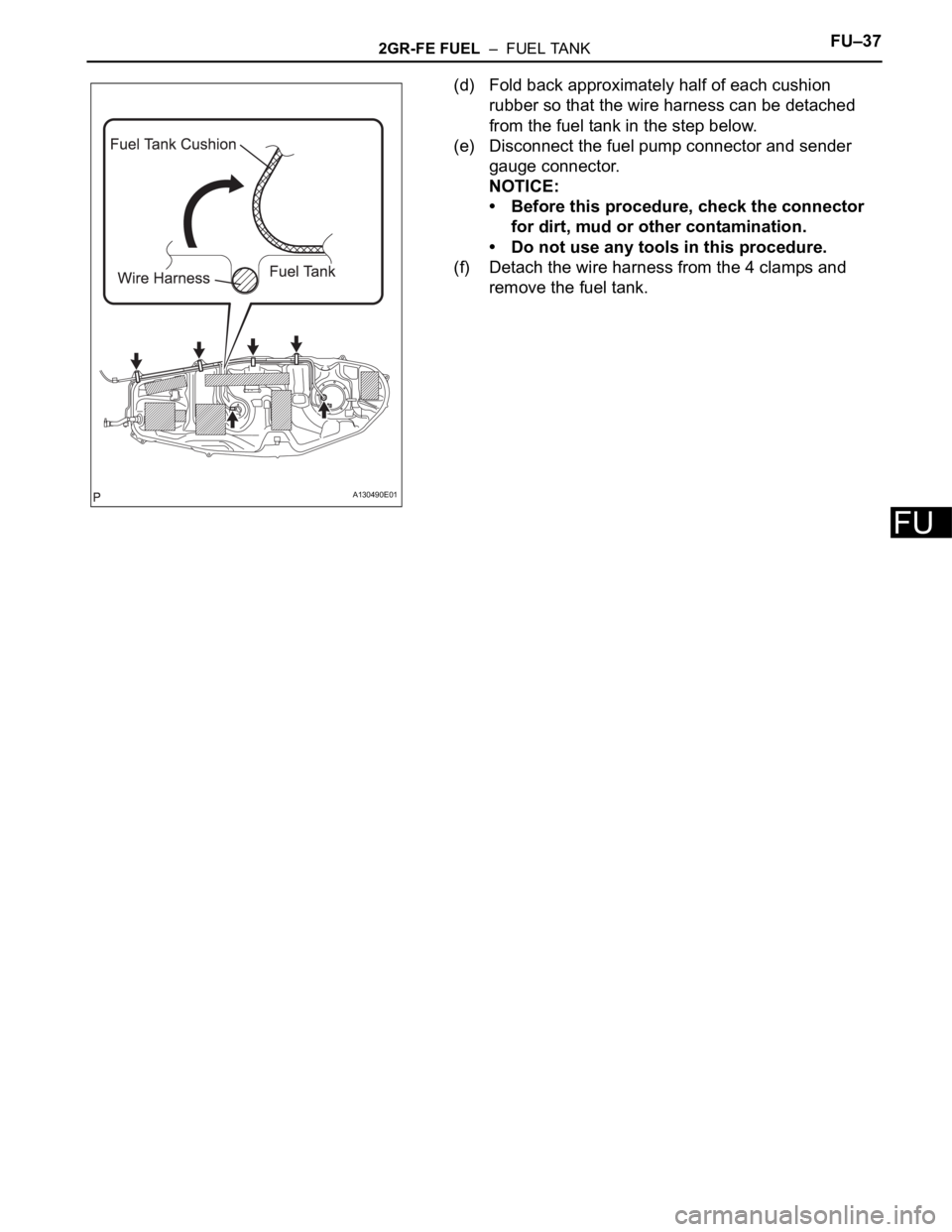

(d) Fold back approximately half of each cushion

rubber so that the wire harness can be detached

from the fuel tank in the step below.

(e) Disconnect the fuel pump connector and sender

gauge connector.

NOTICE:

• Before this procedure, check the connector

for dirt, mud or other contamination.

• Do not use any tools in this procedure.

(f) Detach the wire harness from the 4 clamps and

remove the fuel tank.

A130490E01

Page 822 of 2000

FU–382GR-FE FUEL – FUEL TANK

FU

DISASSEMBLY

1. DISCONNECT FUEL TANK MAIN TUBE SUB-

ASSEMBLY (See page FU-22)

2. REMOVE FUEL TANK VENT TUBE SET PLATE (See

page FU-22)

3. REMOVE FUEL SUCTION WITH PUMP ASSEMBLY

(See page FU-22)

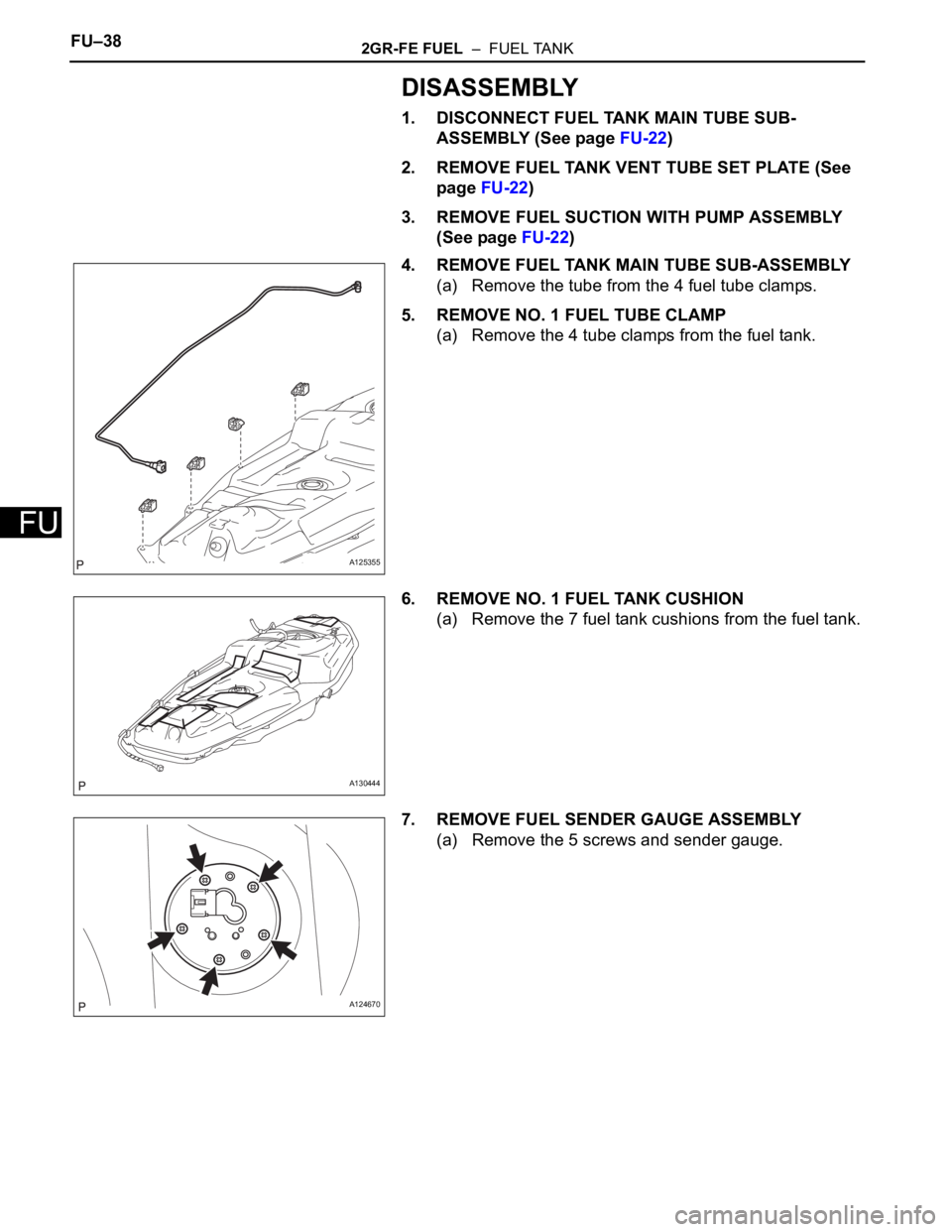

4. REMOVE FUEL TANK MAIN TUBE SUB-ASSEMBLY

(a) Remove the tube from the 4 fuel tube clamps.

5. REMOVE NO. 1 FUEL TUBE CLAMP

(a) Remove the 4 tube clamps from the fuel tank.

6. REMOVE NO. 1 FUEL TANK CUSHION

(a) Remove the 7 fuel tank cushions from the fuel tank.

7. REMOVE FUEL SENDER GAUGE ASSEMBLY

(a) Remove the 5 screws and sender gauge.

A125355

A130444

A124670

Page 823 of 2000

2GR-FE FUEL – FUEL TANKFU–39

FU

REASSEMBLY

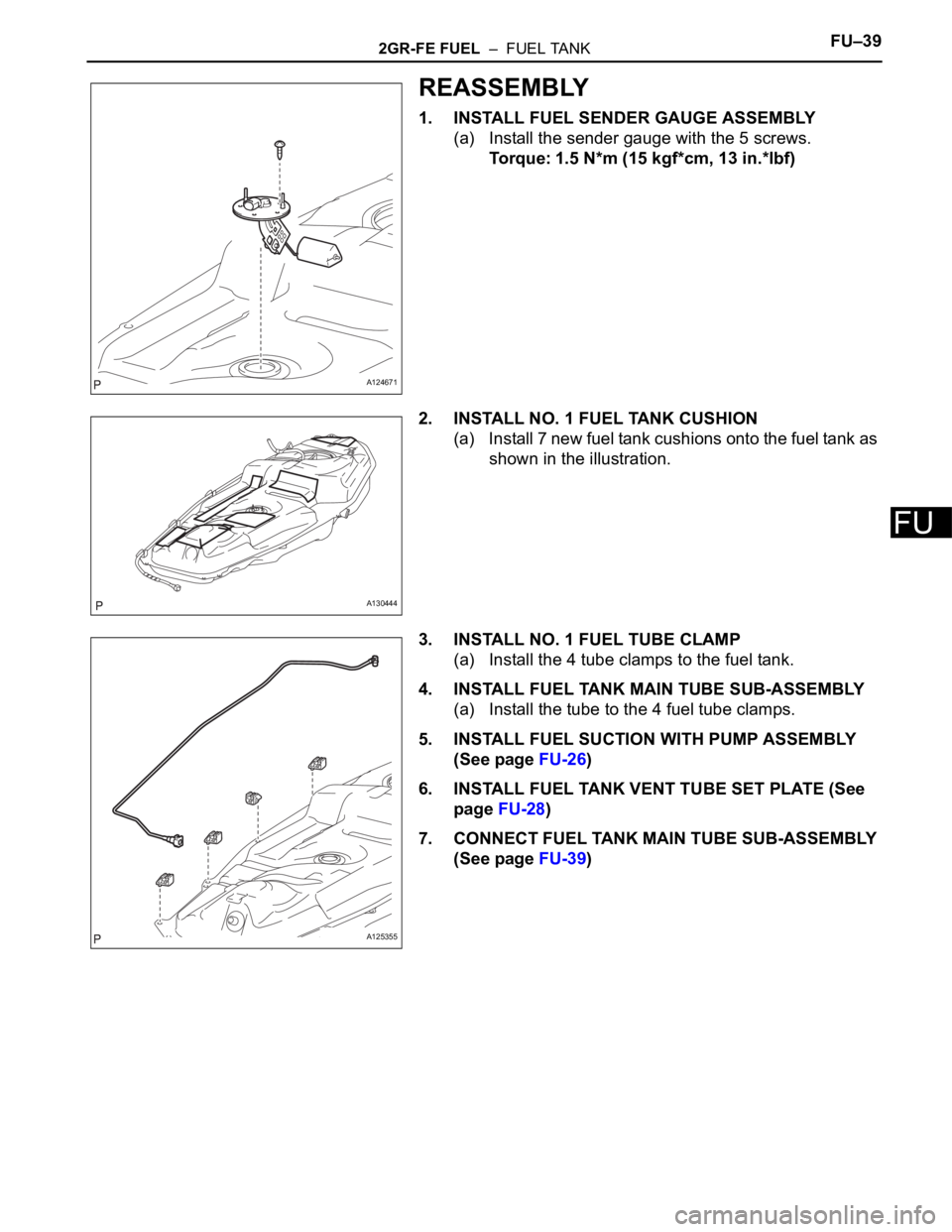

1. INSTALL FUEL SENDER GAUGE ASSEMBLY

(a) Install the sender gauge with the 5 screws.

Torque: 1.5 N*m (15 kgf*cm, 13 in.*lbf)

2. INSTALL NO. 1 FUEL TANK CUSHION

(a) Install 7 new fuel tank cushions onto the fuel tank as

shown in the illustration.

3. INSTALL NO. 1 FUEL TUBE CLAMP

(a) Install the 4 tube clamps to the fuel tank.

4. INSTALL FUEL TANK MAIN TUBE SUB-ASSEMBLY

(a) Install the tube to the 4 fuel tube clamps.

5. INSTALL FUEL SUCTION WITH PUMP ASSEMBLY

(See page FU-26)

6. INSTALL FUEL TANK VENT TUBE SET PLATE (See

page FU-28)

7. CONNECT FUEL TANK MAIN TUBE SUB-ASSEMBLY

(See page FU-39)

A124671

A130444

A125355

Page 824 of 2000

FU–402GR-FE FUEL – FUEL TANK

FU

INSTALLATION

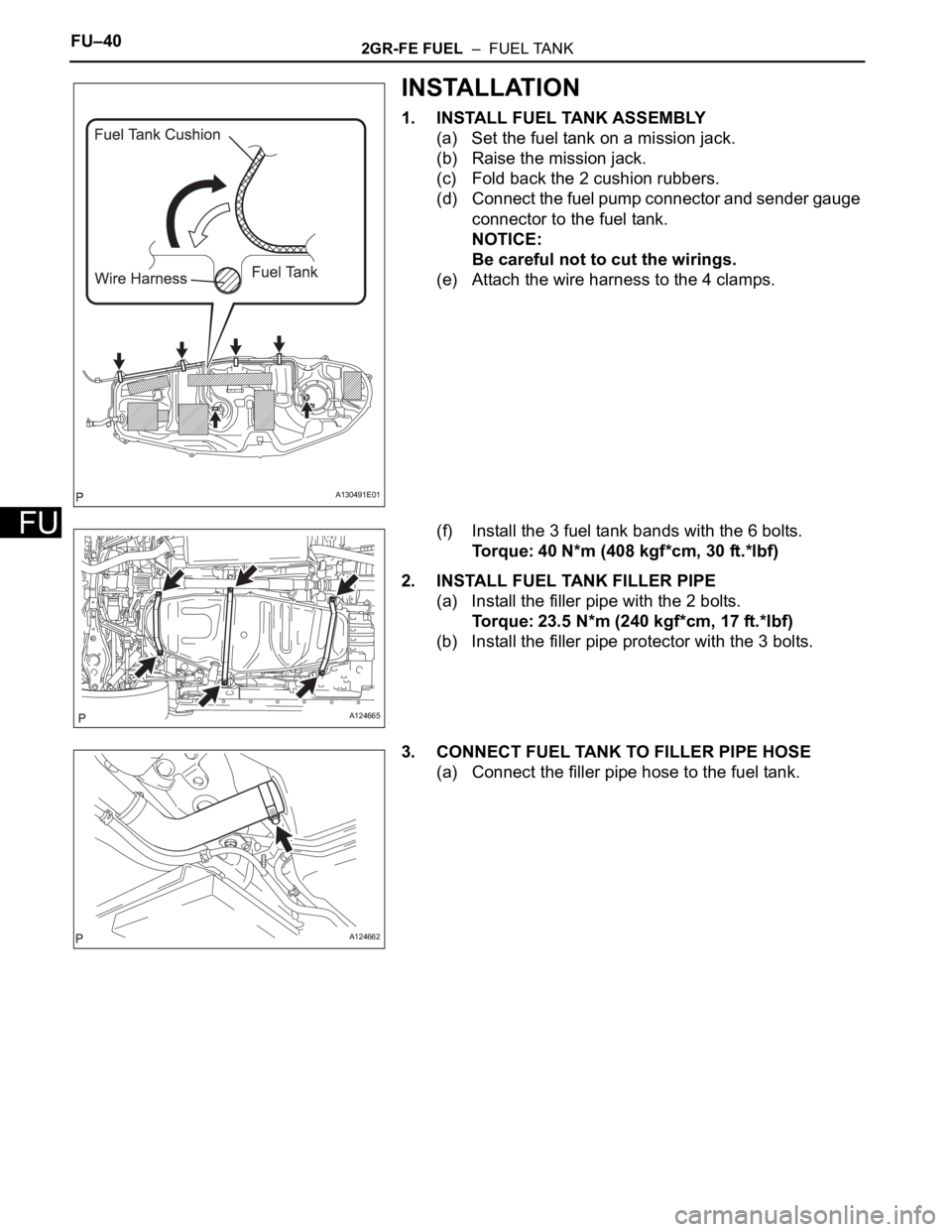

1. INSTALL FUEL TANK ASSEMBLY

(a) Set the fuel tank on a mission jack.

(b) Raise the mission jack.

(c) Fold back the 2 cushion rubbers.

(d) Connect the fuel pump connector and sender gauge

connector to the fuel tank.

NOTICE:

Be careful not to cut the wirings.

(e) Attach the wire harness to the 4 clamps.

(f) Install the 3 fuel tank bands with the 6 bolts.

Torque: 40 N*m (408 kgf*cm, 30 ft.*lbf)

2. INSTALL FUEL TANK FILLER PIPE

(a) Install the filler pipe with the 2 bolts.

Torque: 23.5 N*m (240 kgf*cm, 17 ft.*lbf)

(b) Install the filler pipe protector with the 3 bolts.

3. CONNECT FUEL TANK TO FILLER PIPE HOSE

(a) Connect the filler pipe hose to the fuel tank.

A130491E01

A124665

A124662

Page 825 of 2000

2GR-FE FUEL – FUEL TANKFU–41

FU

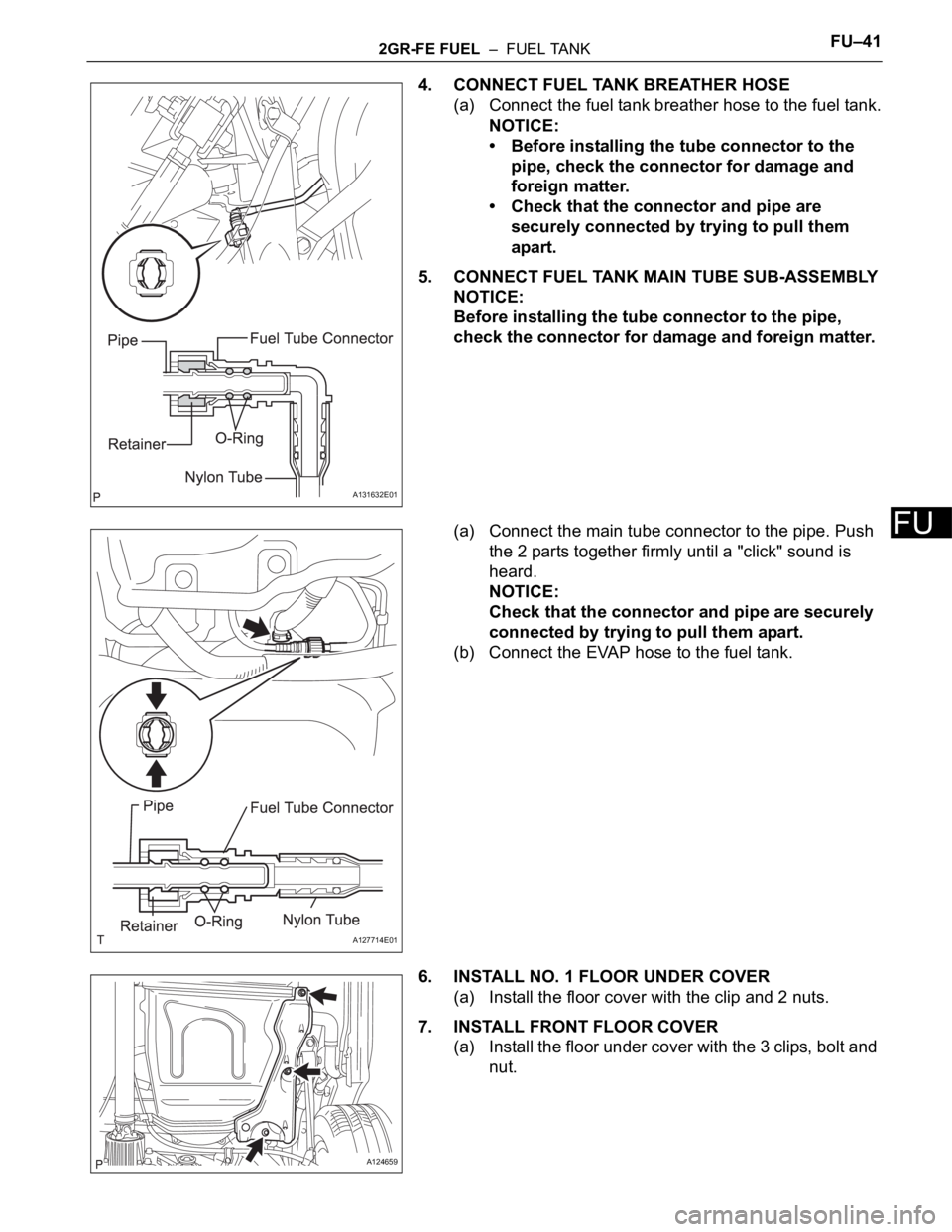

4. CONNECT FUEL TANK BREATHER HOSE

(a) Connect the fuel tank breather hose to the fuel tank.

NOTICE:

• Before installing the tube connector to the

pipe, check the connector for damage and

foreign matter.

• Check that the connector and pipe are

securely connected by trying to pull them

apart.

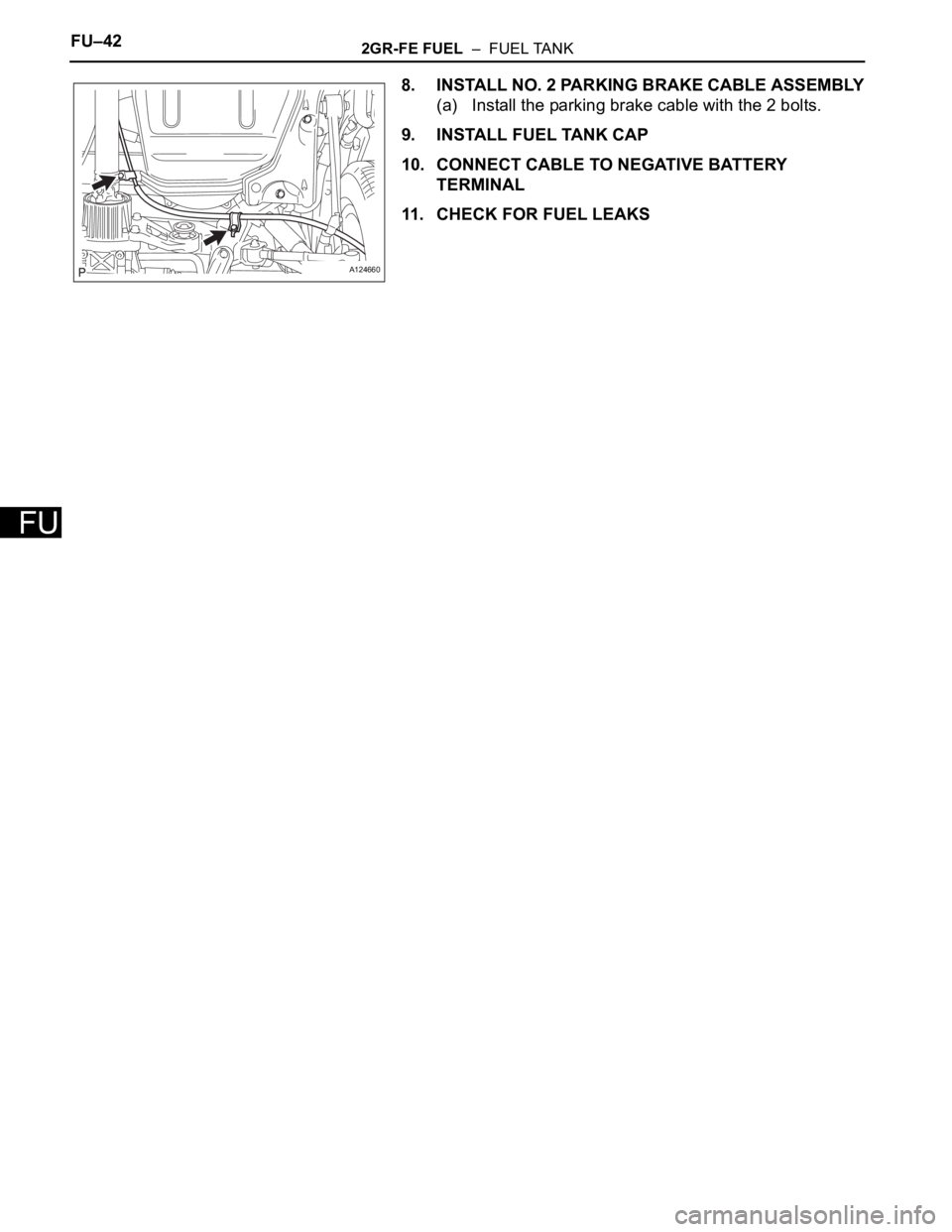

5. CONNECT FUEL TANK MAIN TUBE SUB-ASSEMBLY

NOTICE:

Before installing the tube connector to the pipe,

check the connector for damage and foreign matter.

(a) Connect the main tube connector to the pipe. Push

the 2 parts together firmly until a "click" sound is

heard.

NOTICE:

Check that the connector and pipe are securely

connected by trying to pull them apart.

(b) Connect the EVAP hose to the fuel tank.

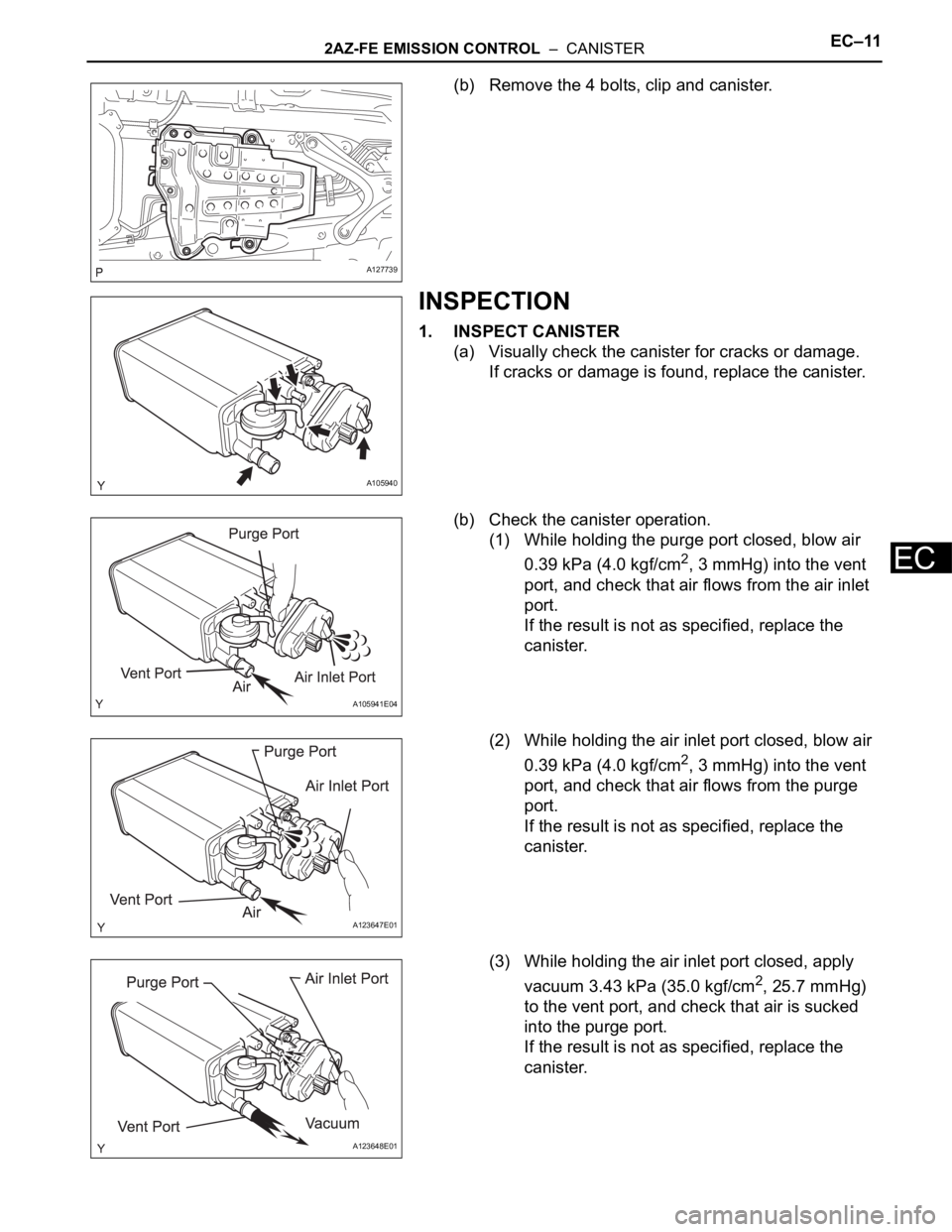

6. INSTALL NO. 1 FLOOR UNDER COVER

(a) Install the floor cover with the clip and 2 nuts.

7. INSTALL FRONT FLOOR COVER

(a) Install the floor under cover with the 3 clips, bolt and

nut.

A131632E01

A127714E01

A124659

Page 826 of 2000

FU–422GR-FE FUEL – FUEL TANK

FU

8. INSTALL NO. 2 PARKING BRAKE CABLE ASSEMBLY

(a) Install the parking brake cable with the 2 bolts.

9. INSTALL FUEL TANK CAP

10. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

11. CHECK FOR FUEL LEAKS

A124660

Page 827 of 2000

2AZ-FE EMISSION CONTROL – CANISTEREC–11

EC

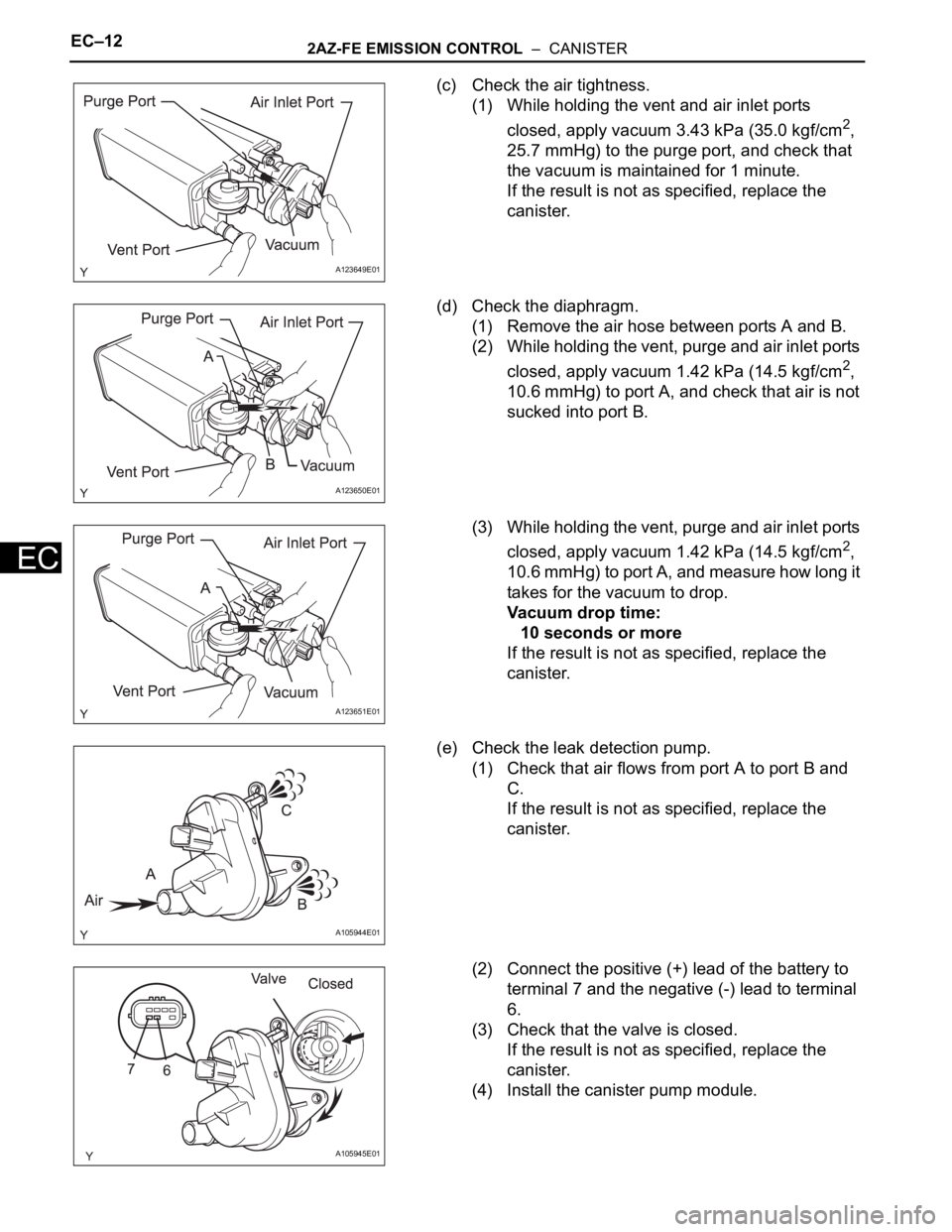

(b) Remove the 4 bolts, clip and canister.

INSPECTION

1. INSPECT CANISTER

(a) Visually check the canister for cracks or damage.

If cracks or damage is found, replace the canister.

(b) Check the canister operation.

(1) While holding the purge port closed, blow air

0.39 kPa (4.0 kgf/cm

2, 3 mmHg) into the vent

port, and check that air flows from the air inlet

port.

If the result is not as specified, replace the

canister.

(2) While holding the air inlet port closed, blow air

0.39 kPa (4.0 kgf/cm

2, 3 mmHg) into the vent

port, and check that air flows from the purge

port.

If the result is not as specified, replace the

canister.

(3) While holding the air inlet port closed, apply

vacuum 3.43 kPa (35.0 kgf/cm

2, 25.7 mmHg)

to the vent port, and check that air is sucked

into the purge port.

If the result is not as specified, replace the

canister.

A127739

A105940

A105941E04

A123647E01

A123648E01

Page 828 of 2000

EC–122AZ-FE EMISSION CONTROL – CANISTER

EC

(c) Check the air tightness.

(1) While holding the vent and air inlet ports

closed, apply vacuum 3.43 kPa (35.0 kgf/cm

2,

25.7 mmHg) to the purge port, and check that

the vacuum is maintained for 1 minute.

If the result is not as specified, replace the

canister.

(d) Check the diaphragm.

(1) Remove the air hose between ports A and B.

(2) While holding the vent, purge and air inlet ports

closed, apply vacuum 1.42 kPa (14.5 kgf/cm

2,

10.6 mmHg) to port A, and check that air is not

sucked into port B.

(3) While holding the vent, purge and air inlet ports

closed, apply vacuum 1.42 kPa (14.5 kgf/cm

2,

10.6 mmHg) to port A, and measure how long it

takes for the vacuum to drop.

Vacuum drop time:

10 seconds or more

If the result is not as specified, replace the

canister.

(e) Check the leak detection pump.

(1) Check that air flows from port A to port B and

C.

If the result is not as specified, replace the

canister.

(2) Connect the positive (+) lead of the battery to

terminal 7 and the negative (-) lead to terminal

6.

(3) Check that the valve is closed.

If the result is not as specified, replace the

canister.

(4) Install the canister pump module.

A123649E01

A123650E01

A123651E01

A105944E01

A105945E01

Page 829 of 2000

2AZ-FE EMISSION CONTROL – CANISTEREC–13

EC

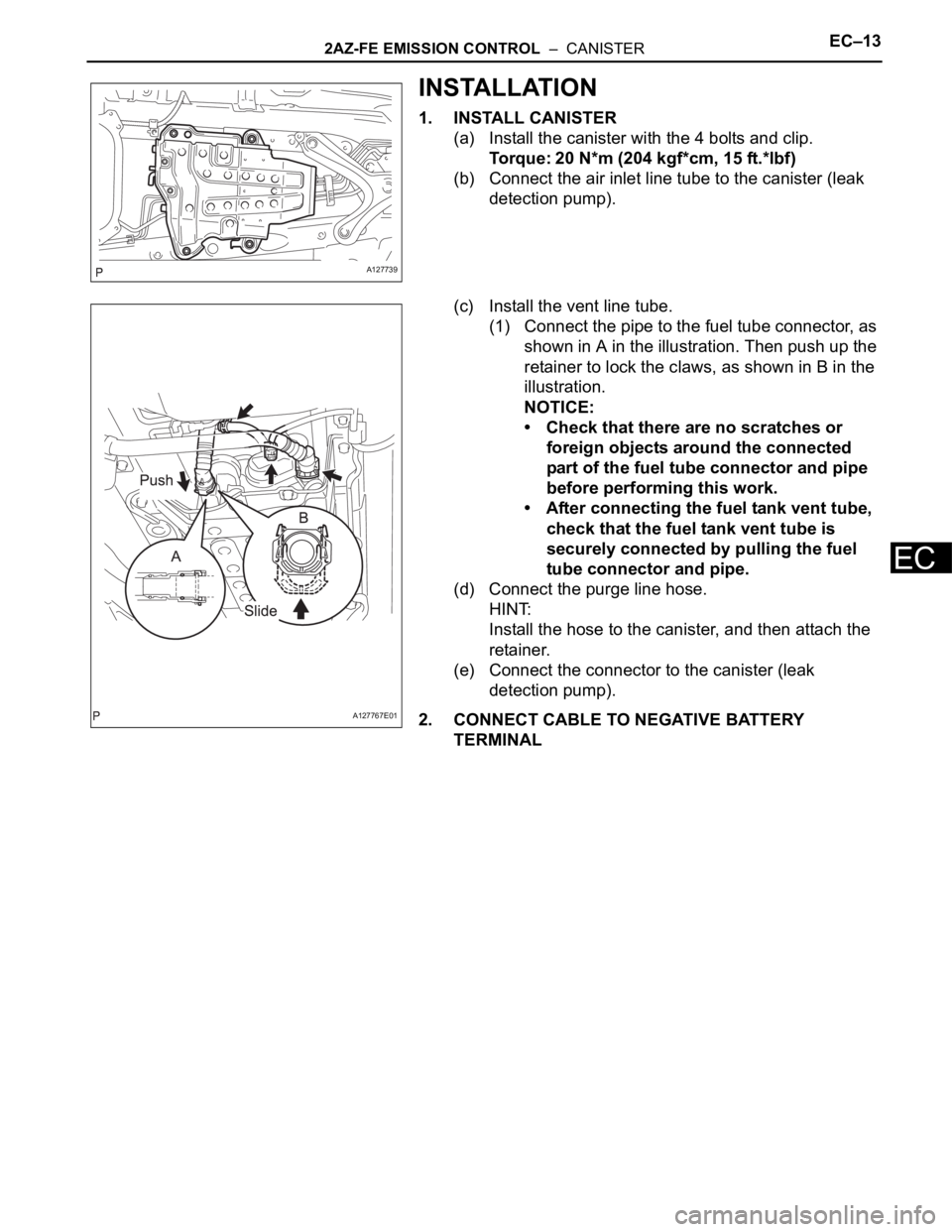

INSTALLATION

1. INSTALL CANISTER

(a) Install the canister with the 4 bolts and clip.

Torque: 20 N*m (204 kgf*cm, 15 ft.*lbf)

(b) Connect the air inlet line tube to the canister (leak

detection pump).

(c) Install the vent line tube.

(1) Connect the pipe to the fuel tube connector, as

shown in A in the illustration. Then push up the

retainer to lock the claws, as shown in B in the

illustration.

NOTICE:

• Check that there are no scratches or

foreign objects around the connected

part of the fuel tube connector and pipe

before performing this work.

• After connecting the fuel tank vent tube,

check that the fuel tank vent tube is

securely connected by pulling the fuel

tube connector and pipe.

(d) Connect the purge line hose.

HINT:

Install the hose to the canister, and then attach the

retainer.

(e) Connect the connector to the canister (leak

detection pump).

2. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

A127739

A127767E01

Page 830 of 2000

2AZ-FE EMISSION CONTROL – VENTILATION VALVEEC–19

EC

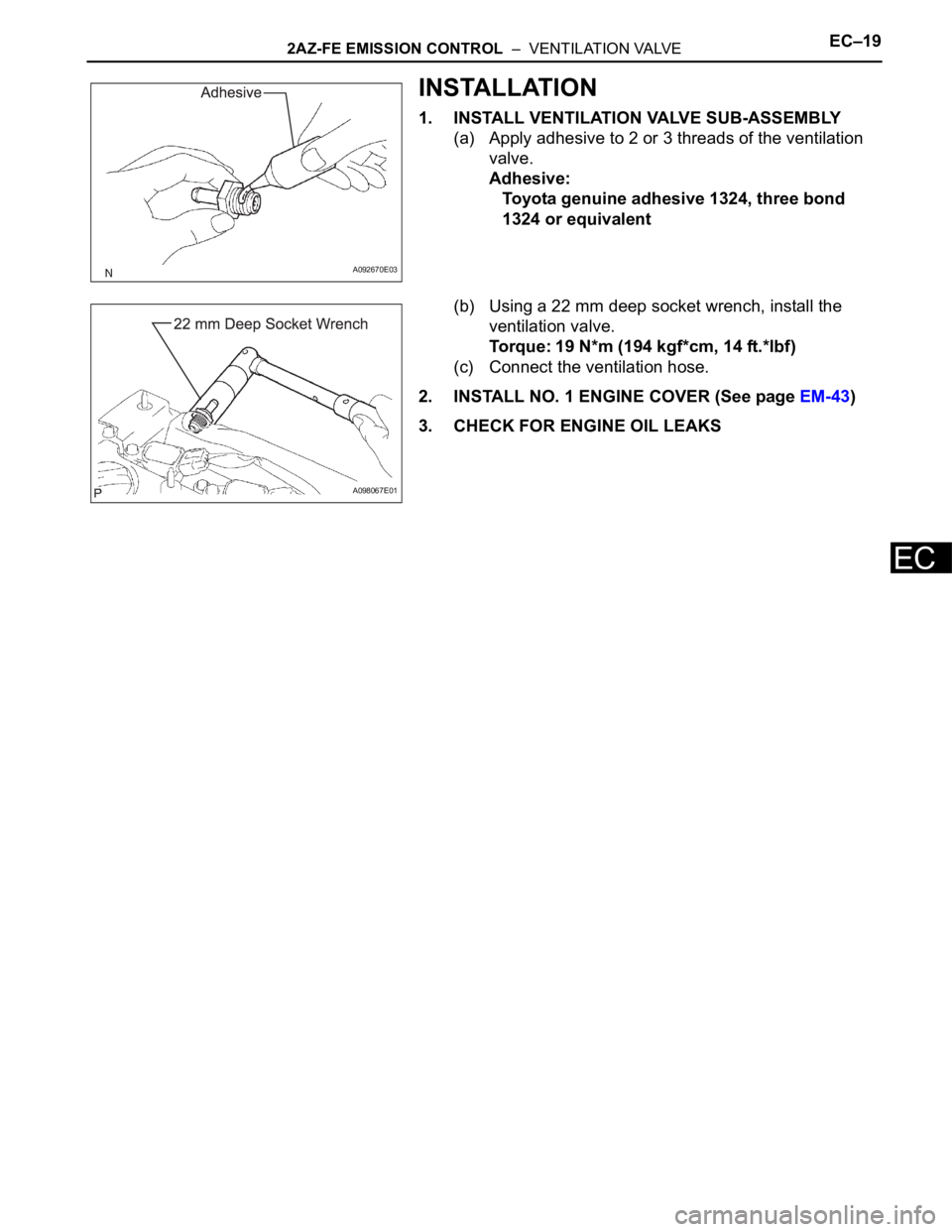

INSTALLATION

1. INSTALL VENTILATION VALVE SUB-ASSEMBLY

(a) Apply adhesive to 2 or 3 threads of the ventilation

valve.

Adhesive:

Toyota genuine adhesive 1324, three bond

1324 or equivalent

(b) Using a 22 mm deep socket wrench, install the

ventilation valve.

Torque: 19 N*m (194 kgf*cm, 14 ft.*lbf)

(c) Connect the ventilation hose.

2. INSTALL NO. 1 ENGINE COVER (See page EM-43)

3. CHECK FOR ENGINE OIL LEAKS

A092670E03

A098067E01