TOYOTA SIENNA 2007 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 2581 of 3000

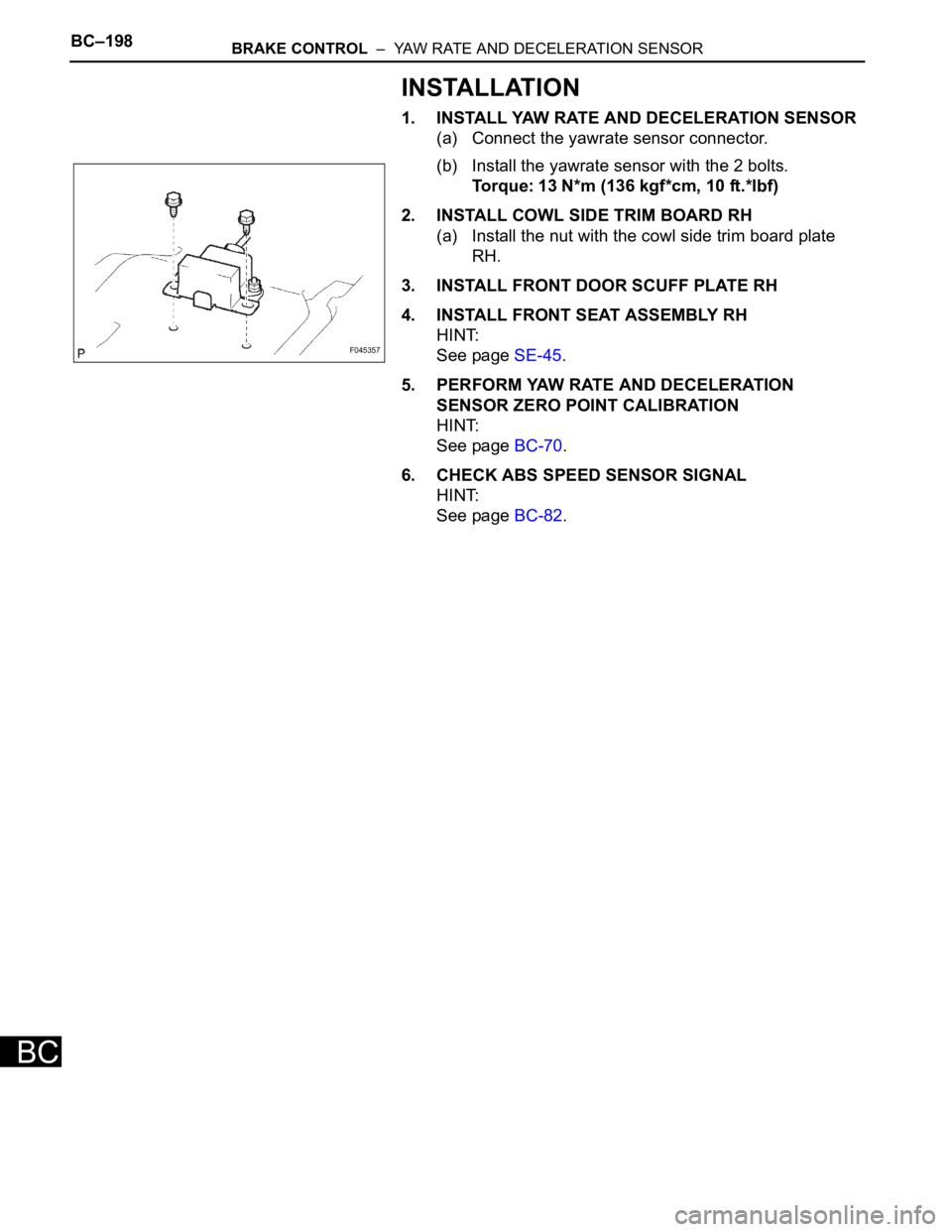

BC–198BRAKE CONTROL – YAW RATE AND DECELERATION SENSOR

BC

INSTALLATION

1. INSTALL YAW RATE AND DECELERATION SENSOR

(a) Connect the yawrate sensor connector.

(b) Install the yawrate sensor with the 2 bolts.

Torque: 13 N*m (136 kgf*cm, 10 ft.*lbf)

2. INSTALL COWL SIDE TRIM BOARD RH

(a) Install the nut with the cowl side trim board plate

RH.

3. INSTALL FRONT DOOR SCUFF PLATE RH

4. INSTALL FRONT SEAT ASSEMBLY RH

HINT:

See page SE-45.

5. PERFORM YAW RATE AND DECELERATION

SENSOR ZERO POINT CALIBRATION

HINT:

See page BC-70.

6. CHECK ABS SPEED SENSOR SIGNAL

HINT:

See page BC-82.

F045357

Page 2582 of 3000

BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEMBC–39

BC

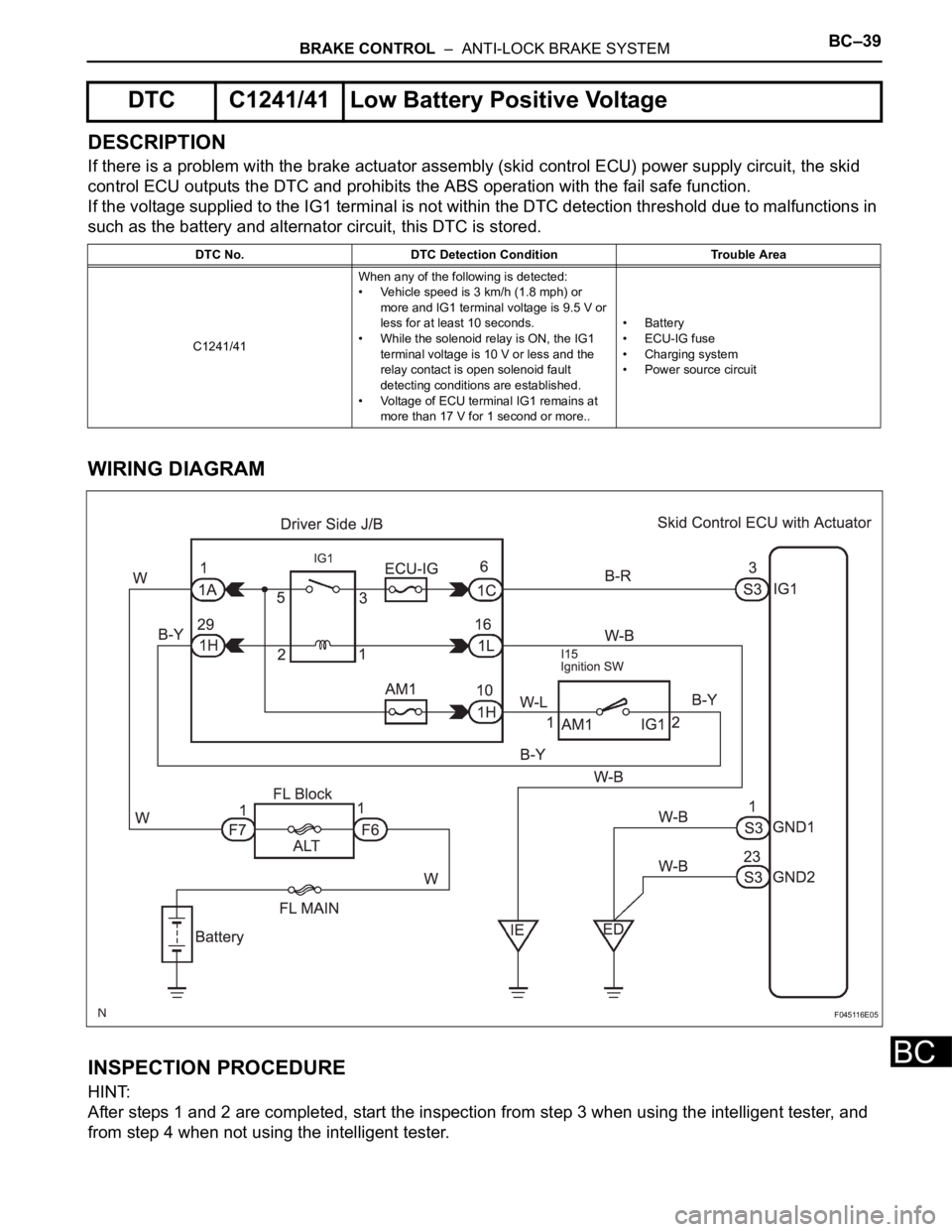

DESCRIPTION

If there is a problem with the brake actuator assembly (skid control ECU) power supply circuit, the skid

control ECU outputs the DTC and prohibits the ABS operation with the fail safe function.

If the voltage supplied to the IG1 terminal is not within the DTC detection threshold due to malfunctions in

such as the battery and alternator circuit, this DTC is stored.

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT:

After steps 1 and 2 are completed, start the inspection from step 3 when using the intelligent tester, and

from step 4 when not using the intelligent tester.

DTC C1241/41 Low Battery Positive Voltage

DTC No. DTC Detection Condition Trouble Area

C1241/41When any of the following is detected:

• Vehicle speed is 3 km/h (1.8 mph) or

more and IG1 terminal voltage is 9.5 V or

less for at least 10 seconds.

• While the solenoid relay is ON, the IG1

terminal voltage is 10 V or less and the

relay contact is open solenoid fault

detecting conditions are established.

• Voltage of ECU terminal IG1 remains at

more than 17 V for 1 second or more..• Battery

•ECU-IG fuse

• Charging system

• Power source circuit

F045116E05

Page 2583 of 3000

BC–40BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEM

BC

(a) Check the battery voltage.

Standard voltage:

11 to 14 V

NG

OK

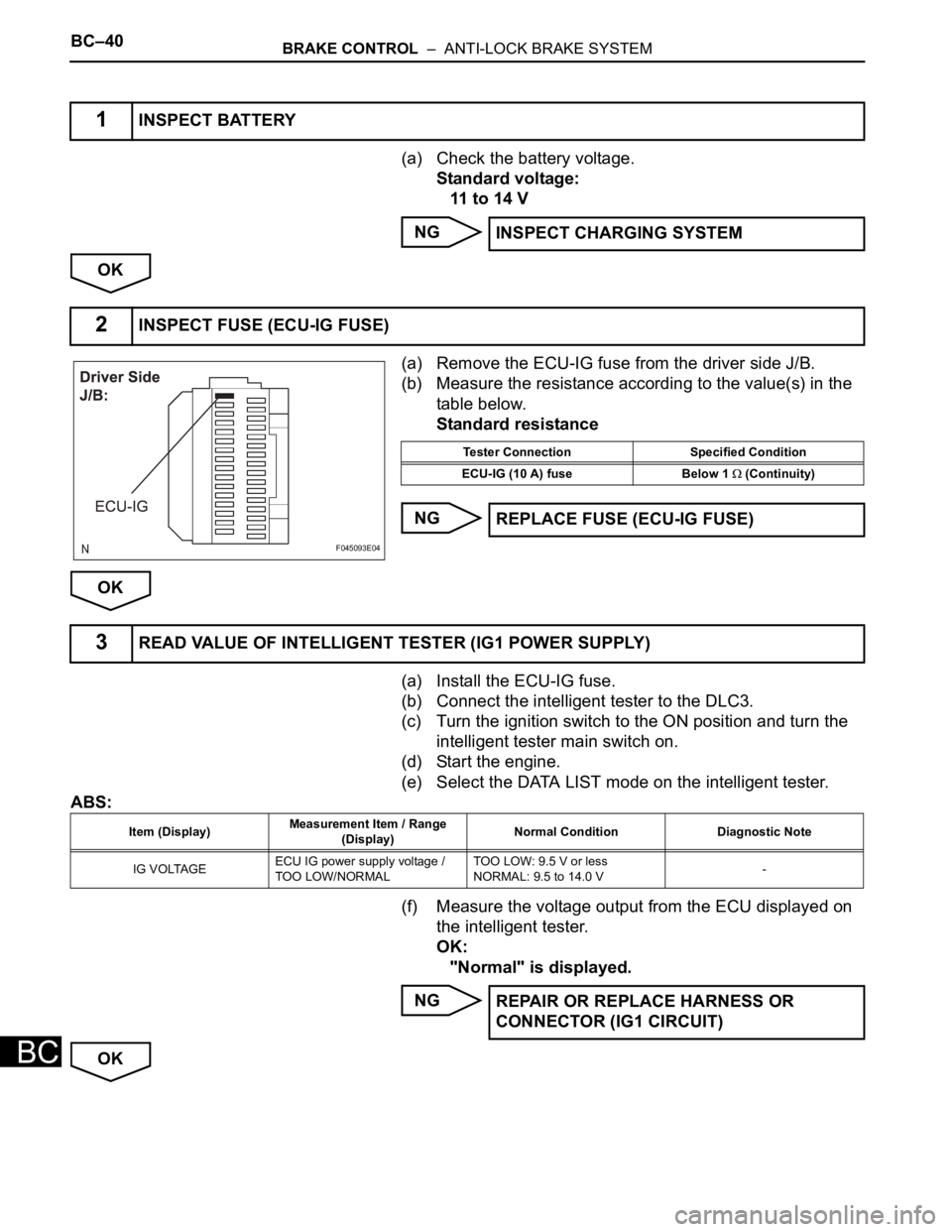

(a) Remove the ECU-IG fuse from the driver side J/B.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

NG

OK

(a) Install the ECU-IG fuse.

(b) Connect the intelligent tester to the DLC3.

(c) Turn the ignition switch to the ON position and turn the

intelligent tester main switch on.

(d) Start the engine.

(e) Select the DATA LIST mode on the intelligent tester.

ABS:

(f) Measure the voltage output from the ECU displayed on

the intelligent tester.

OK:

"Normal" is displayed.

NG

OK

1INSPECT BATTERY

INSPECT CHARGING SYSTEM

2INSPECT FUSE (ECU-IG FUSE)

F045093E04

Tester Connection Specified Condition

ECU-IG (10 A) fuse Below 1

(Continuity)

REPLACE FUSE (ECU-IG FUSE)

3READ VALUE OF INTELLIGENT TESTER (IG1 POWER SUPPLY)

Item (Display)Measurement Item / Range

(Display)Normal Condition Diagnostic Note

IG VOLTAGEECU IG power supply voltage /

TOO LOW/NORMALTOO LOW: 9.5 V or less

NORMAL: 9.5 to 14.0 V-

REPAIR OR REPLACE HARNESS OR

CONNECTOR (IG1 CIRCUIT)

Page 2584 of 3000

BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEMBC–41

BC

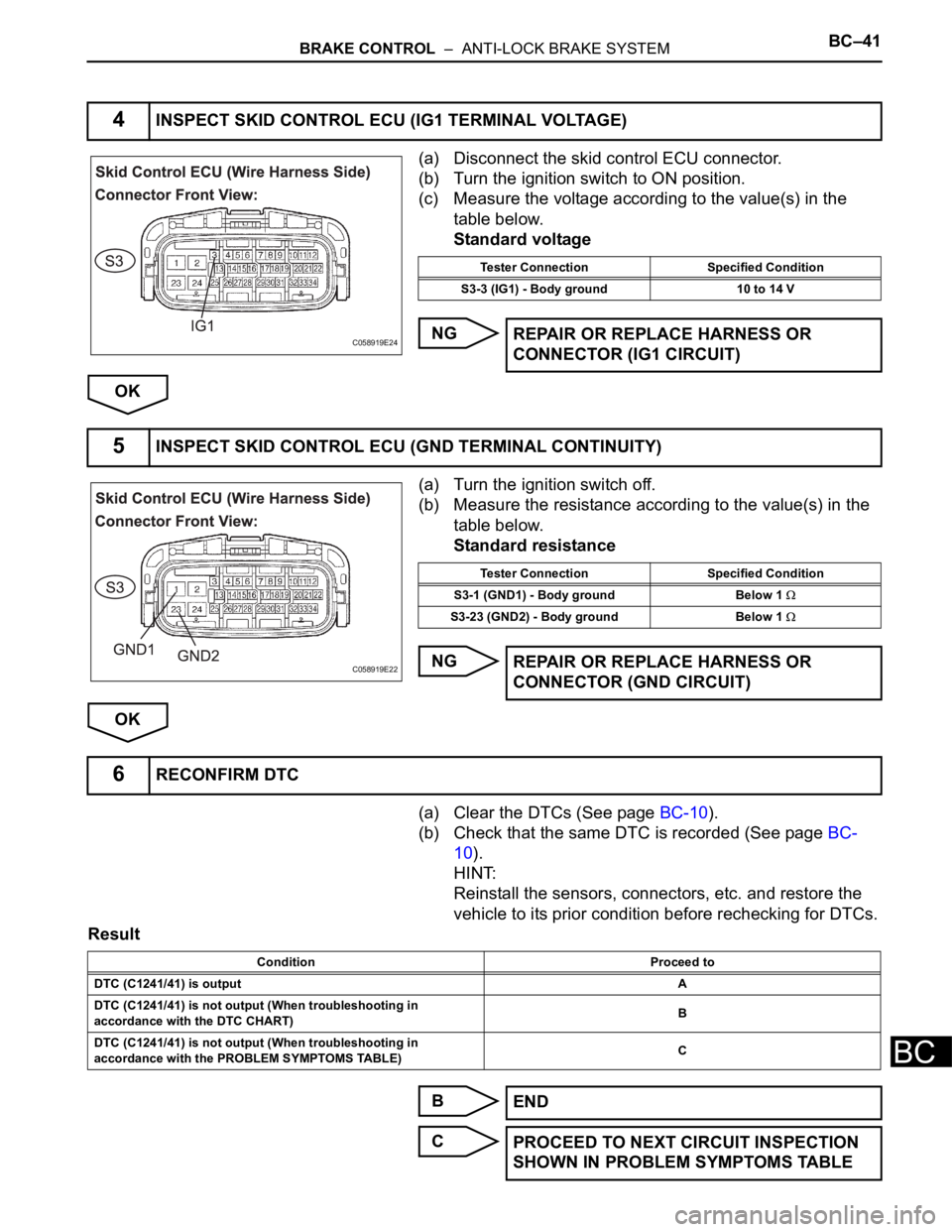

(a) Disconnect the skid control ECU connector.

(b) Turn the ignition switch to ON position.

(c) Measure the voltage according to the value(s) in the

table below.

Standard voltage

NG

OK

(a) Turn the ignition switch off.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

NG

OK

(a) Clear the DTCs (See page BC-10).

(b) Check that the same DTC is recorded (See page BC-

10).

HINT:

Reinstall the sensors, connectors, etc. and restore the

vehicle to its prior condition before rechecking for DTCs.

Result

B

C

4INSPECT SKID CONTROL ECU (IG1 TERMINAL VOLTAGE)

C058919E24

Tester Connection Specified Condition

S3-3 (IG1) - Body ground 10 to 14 V

REPAIR OR REPLACE HARNESS OR

CONNECTOR (IG1 CIRCUIT)

5INSPECT SKID CONTROL ECU (GND TERMINAL CONTINUITY)

C058919E22

Tester Connection Specified Condition

S3-1 (GND1) - Body ground Below 1

S3-23 (GND2) - Body ground Below 1

REPAIR OR REPLACE HARNESS OR

CONNECTOR (GND CIRCUIT)

6RECONFIRM DTC

Condition Proceed to

DTC (C1241/41) is outputA

DTC (C1241/41) is not output (When troubleshooting in

accordance with the DTC CHART)B

DTC (C1241/41) is not output (When troubleshooting in

accordance with the PROBLEM SYMPTOMS TABLE)C

END

PROCEED TO NEXT CIRCUIT INSPECTION

SHOWN IN PROBLEM SYMPTOMS TABLE

Page 2585 of 3000

BC–42BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEM

BC

A

REPLACE BRAKE ACTUATOR ASSEMBLY

Page 2586 of 3000

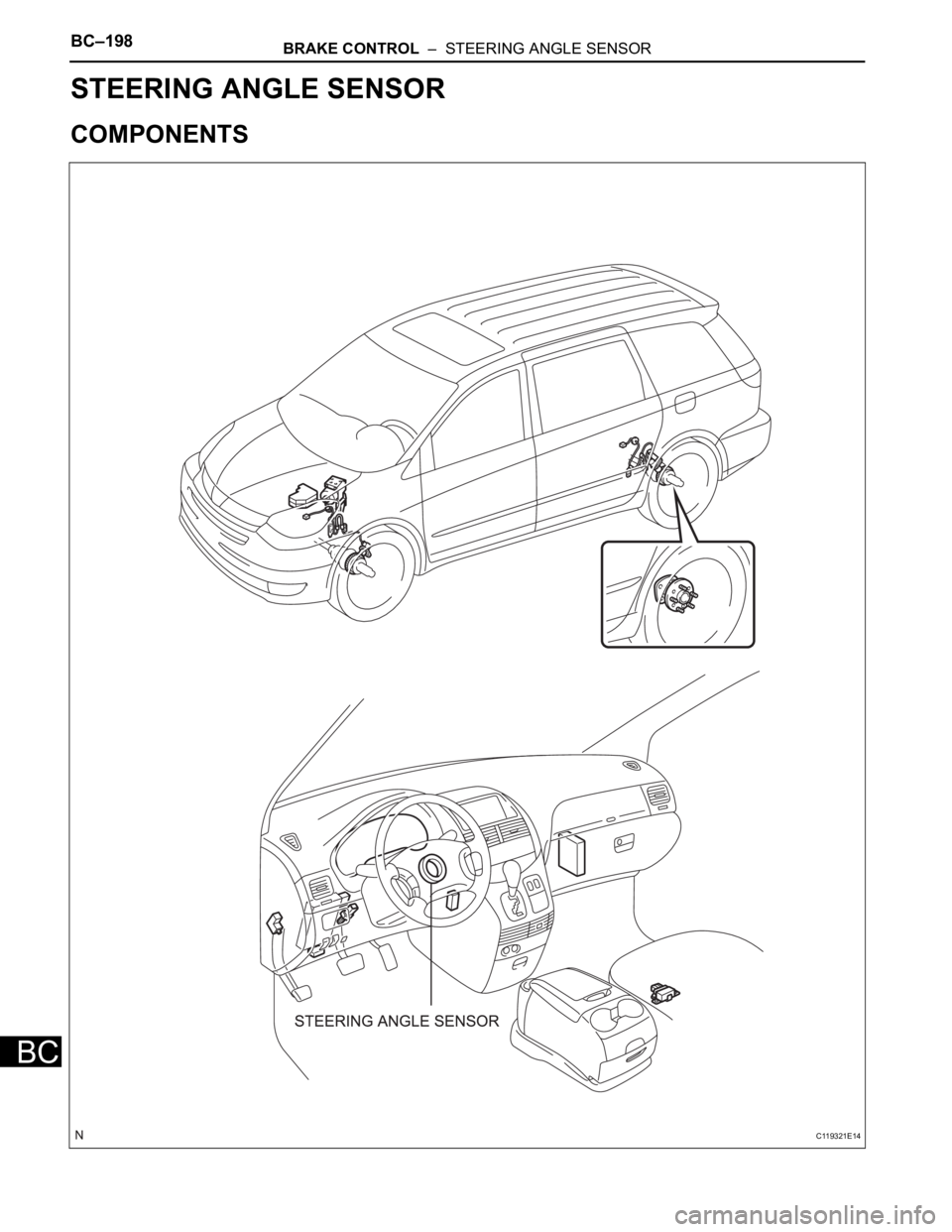

BC–198BRAKE CONTROL – STEERING ANGLE SENSOR

BC

BRAKE

BRAKE CONTROL

STEERING ANGLE SENSOR

COMPONENTS

C119321E14

Page 2587 of 3000

BRAKE CONTROL – STEERING ANGLE SENSORBC–199

BC

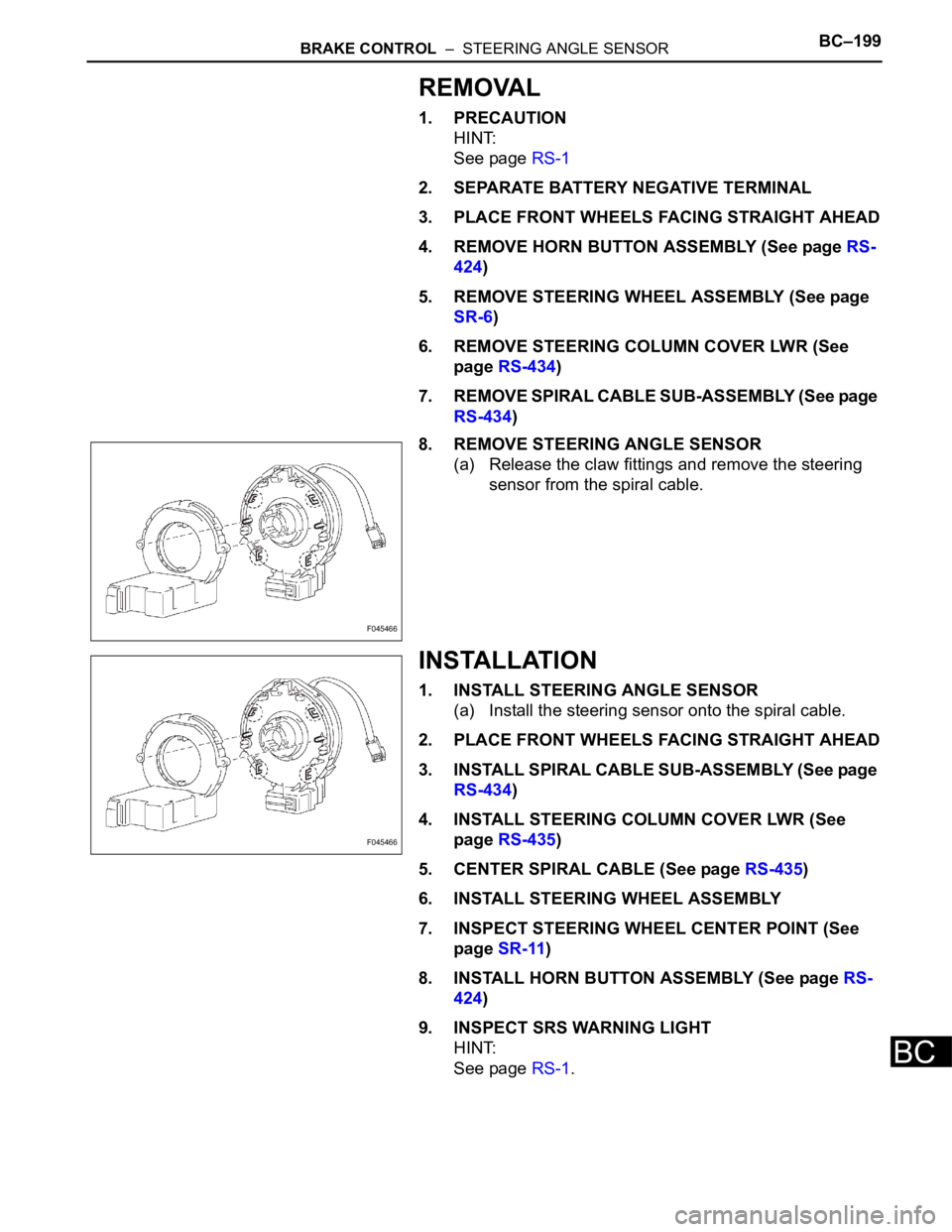

REMOVAL

1. PRECAUTION

HINT:

See page RS-1

2. SEPARATE BATTERY NEGATIVE TERMINAL

3. PLACE FRONT WHEELS FACING STRAIGHT AHEAD

4. REMOVE HORN BUTTON ASSEMBLY (See page RS-

424)

5. REMOVE STEERING WHEEL ASSEMBLY (See page

SR-6)

6. REMOVE STEERING COLUMN COVER LWR (See

page RS-434)

7. REMOVE SPIRAL CABLE SUB-ASSEMBLY (See page

RS-434)

8. REMOVE STEERING ANGLE SENSOR

(a) Release the claw fittings and remove the steering

sensor from the spiral cable.

INSTALLATION

1. INSTALL STEERING ANGLE SENSOR

(a) Install the steering sensor onto the spiral cable.

2. PLACE FRONT WHEELS FACING STRAIGHT AHEAD

3. INSTALL SPIRAL CABLE SUB-ASSEMBLY (See page

RS-434)

4. INSTALL STEERING COLUMN COVER LWR (See

page RS-435)

5. CENTER SPIRAL CABLE (See page RS-435)

6. INSTALL STEERING WHEEL ASSEMBLY

7. INSPECT STEERING WHEEL CENTER POINT (See

page SR-11)

8. INSTALL HORN BUTTON ASSEMBLY (See page RS-

424)

9. INSPECT SRS WARNING LIGHT

HINT:

See page RS-1.

F045466

F045466

Page 2588 of 3000

BRAKE – BRAKE PEDALBR–13

BR

REASSEMBLY

1. INSTALL BRAKE PEDAL PAD

(a) Install the brake pedal pad to the brake pedal sub-

assembly.

2. INSTALL PUSH ROD PIN

(a) Apply lithium soap base glycol grease to inside

surface of 2 new push rod bushes.

(b) Install the 2 new push rod bushes.

(c) Install the 2 push rod pins with the 2 plate to the

brake pedal.

(d) Using needle-nose pliers, install the 2 new E-rings

to the 2 push rod pins.

NOTICE:

Install the E-ring securely to the grooves of the

push rod pin.

3. INSTALL BRAKE PEDAL BUSH

(a) Apply lithium soap base glycol grease to inside

surface of 4 new brake pedal bushes.

(b) Install the 4 brake pedal bushes to the brake pedal.

4. INSTALL BRAKE PEDAL SHAFT COLLAR

(a) Apply the lithium soap base glycol grease to inside

surface of 2 brake pedal shaft collars.

(b) Install the 2 brake pedal shaft collars to the brake

pedal.

5. INSTALL BRAKE PEDAL

(a) Install the 2 brake pedal shafts, 2 nuts, brake pedal

and brake pedal bracket No. 3 to the brake pedal

support sub-assembly.

6. INSTALL STOP LIGHT SWITCH CUSHION

(a) Install the stop light switch cushion to the brake

pedal sub-assembly.

7. INSTALL STOP LIGHT SWITCH ASSEMBLY

(a) Install the stop light switch mounting adjuster to the

brake pedal support sub-assembly.

(b) Install the stop light switch assembly until the body

hits the cushion.

(c) Make a quarter turn clockwise to install the stop light

switch assembly.

NOTICE:

The turning torque for installing the stop light

switch assembly.

Torque: 1.5 N*m (15 kgf*cm, 13 in.*lbf) or less

HINT:

Due to the inverse screw structure, if the stop light

switch assembly is turned clockwise, the stop light

switch assembly moves in the direction to be pulled

out.

Page 2589 of 3000

BR–14BRAKE – BRAKE PEDAL

BR

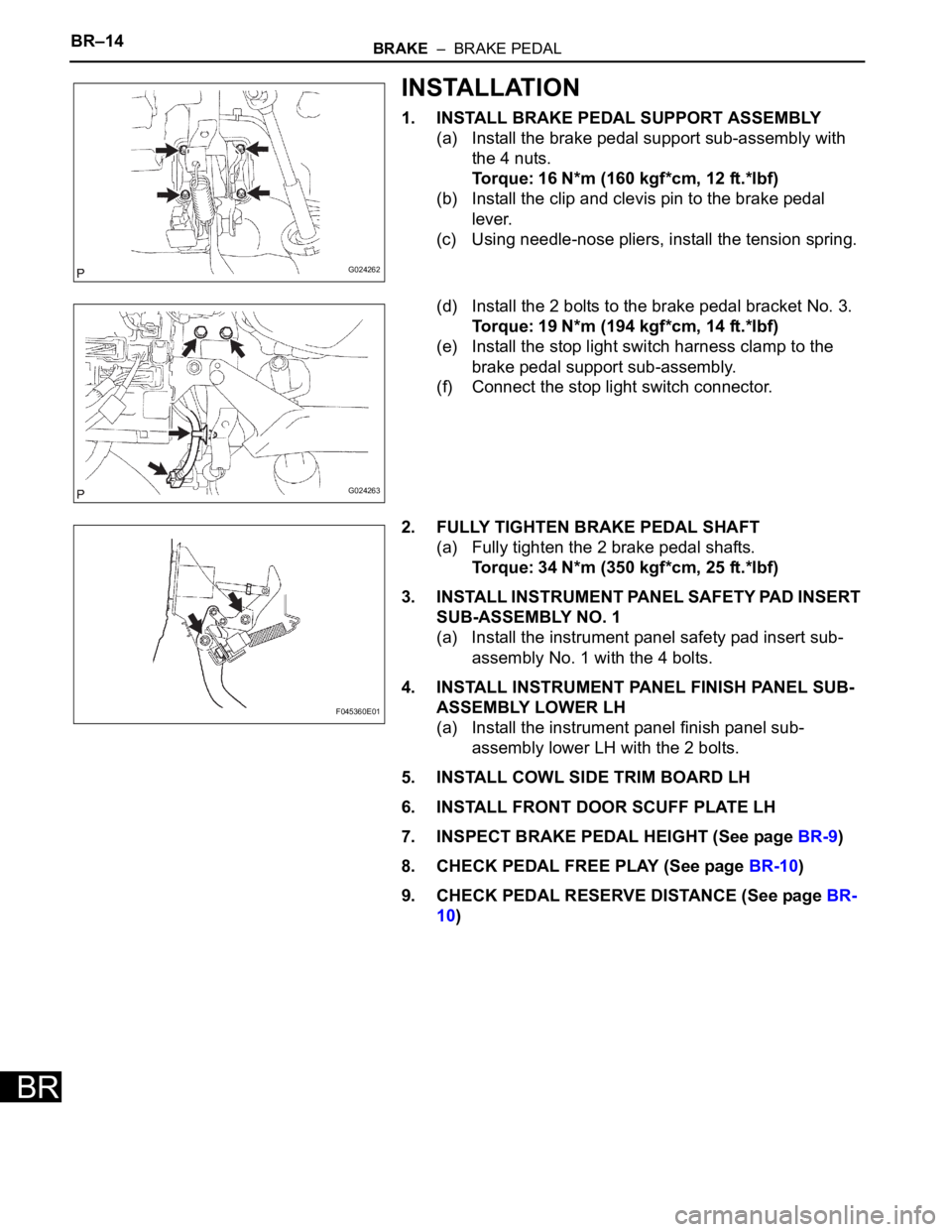

INSTALLATION

1. INSTALL BRAKE PEDAL SUPPORT ASSEMBLY

(a) Install the brake pedal support sub-assembly with

the 4 nuts.

Torque: 16 N*m (160 kgf*cm, 12 ft.*lbf)

(b) Install the clip and clevis pin to the brake pedal

lever.

(c) Using needle-nose pliers, install the tension spring.

(d) Install the 2 bolts to the brake pedal bracket No. 3.

Torque: 19 N*m (194 kgf*cm, 14 ft.*lbf)

(e) Install the stop light switch harness clamp to the

brake pedal support sub-assembly.

(f) Connect the stop light switch connector.

2. FULLY TIGHTEN BRAKE PEDAL SHAFT

(a) Fully tighten the 2 brake pedal shafts.

Torque: 34 N*m (350 kgf*cm, 25 ft.*lbf)

3. INSTALL INSTRUMENT PANEL SAFETY PAD INSERT

SUB-ASSEMBLY NO. 1

(a) Install the instrument panel safety pad insert sub-

assembly No. 1 with the 4 bolts.

4. INSTALL INSTRUMENT PANEL FINISH PANEL SUB-

ASSEMBLY LOWER LH

(a) Install the instrument panel finish panel sub-

assembly lower LH with the 2 bolts.

5. INSTALL COWL SIDE TRIM BOARD LH

6. INSTALL FRONT DOOR SCUFF PLATE LH

7. INSPECT BRAKE PEDAL HEIGHT (See page BR-9)

8. CHECK PEDAL FREE PLAY (See page BR-10)

9. CHECK PEDAL RESERVE DISTANCE (See page BR-

10)

G024262

G024263

F045360E01

Page 2590 of 3000

BR–16BRAKE – BRAKE MASTER CYLINDER

BR

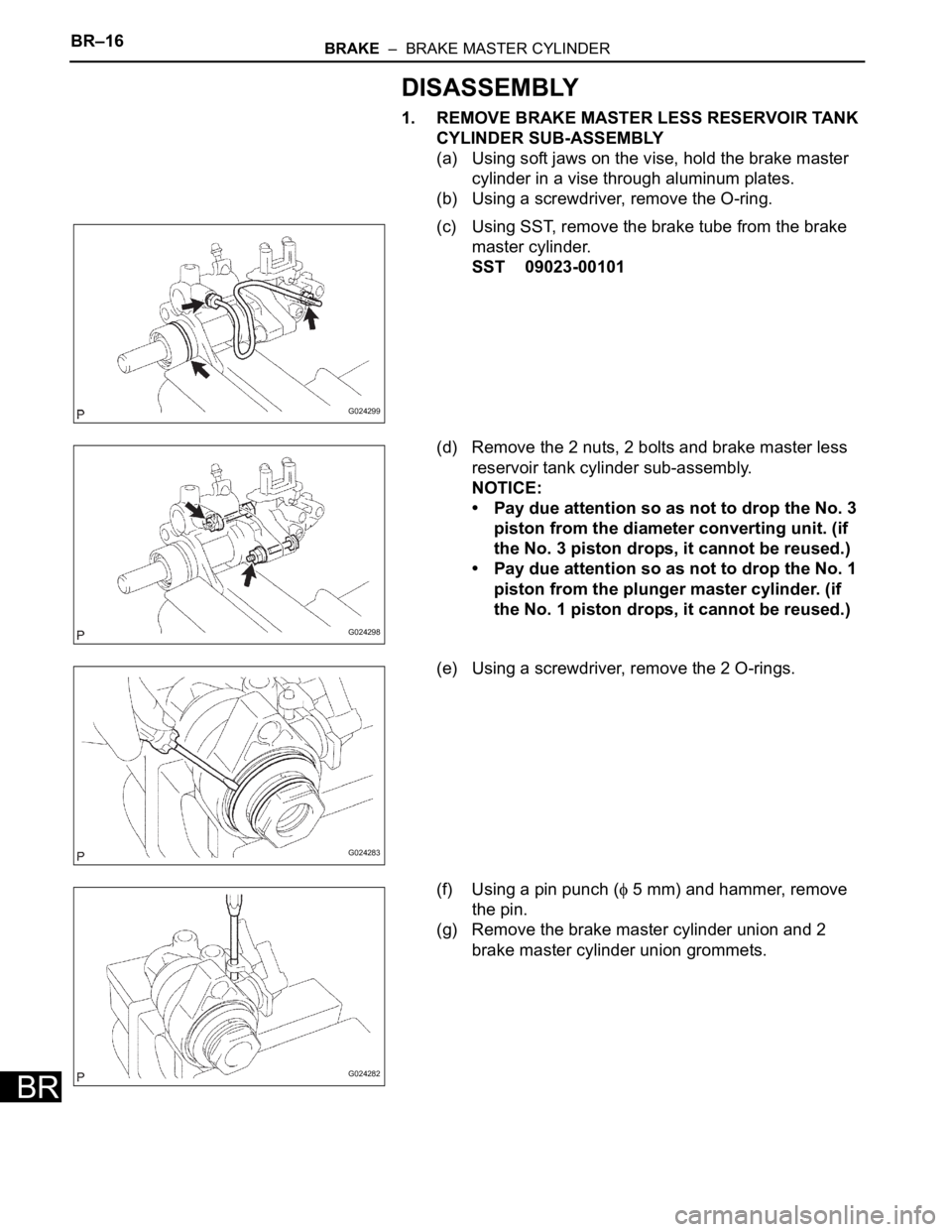

DISASSEMBLY

1. REMOVE BRAKE MASTER LESS RESERVOIR TANK

CYLINDER SUB-ASSEMBLY

(a) Using soft jaws on the vise, hold the brake master

cylinder in a vise through aluminum plates.

(b) Using a screwdriver, remove the O-ring.

(c) Using SST, remove the brake tube from the brake

master cylinder.

SST 09023-00101

(d) Remove the 2 nuts, 2 bolts and brake master less

reservoir tank cylinder sub-assembly.

NOTICE:

• Pay due attention so as not to drop the No. 3

piston from the diameter converting unit. (if

the No. 3 piston drops, it cannot be reused.)

• Pay due attention so as not to drop the No. 1

piston from the plunger master cylinder. (if

the No. 1 piston drops, it cannot be reused.)

(e) Using a screwdriver, remove the 2 O-rings.

(f) Using a pin punch (

5 mm) and hammer, remove

the pin.

(g) Remove the brake master cylinder union and 2

brake master cylinder union grommets.

G024299

G024298

G024283

G024282