sensor TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 689 of 3000

ES–3962GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

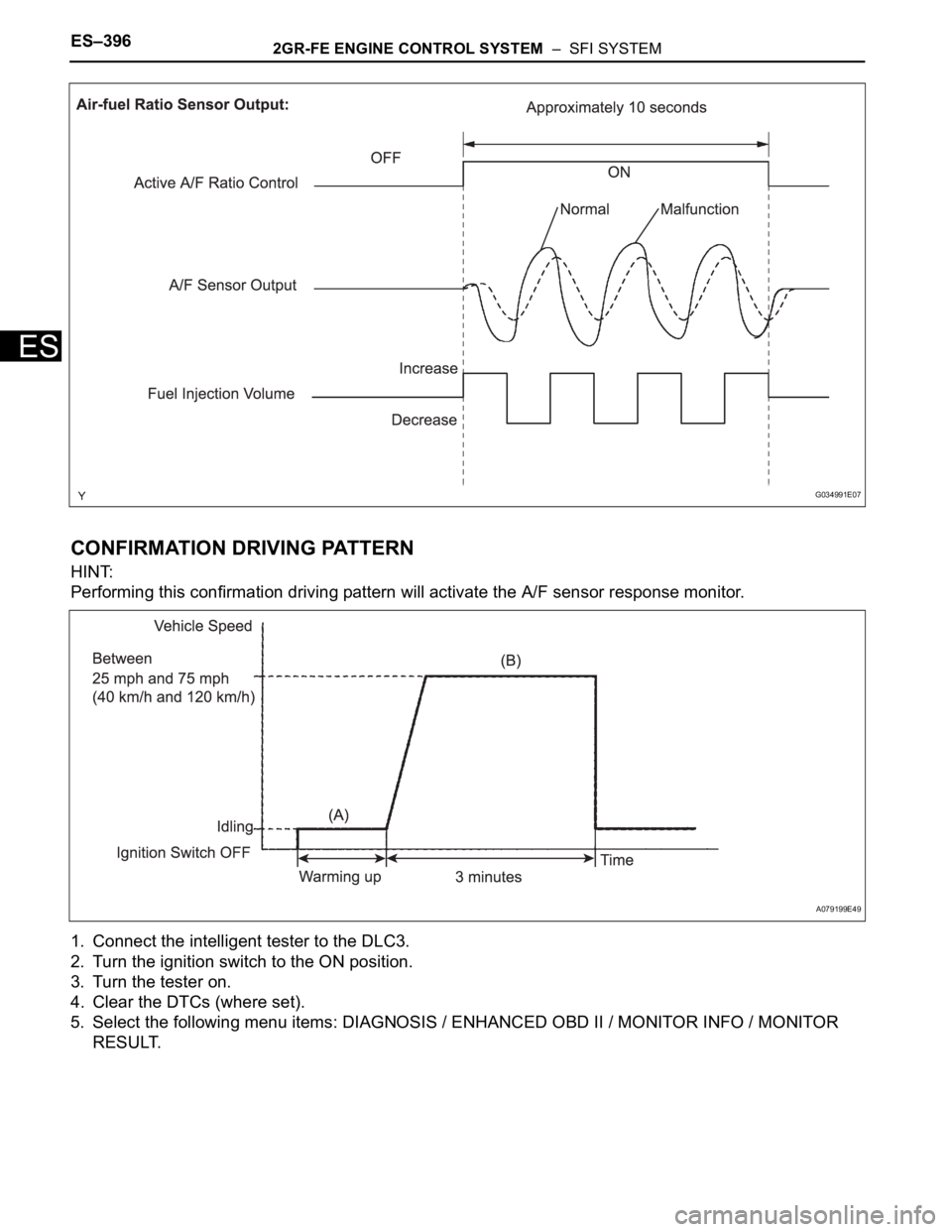

CONFIRMATION DRIVING PATTERN

HINT:

Performing this confirmation driving pattern will activate the A/F sensor response monitor.

1. Connect the intelligent tester to the DLC3.

2. Turn the ignition switch to the ON position.

3. Turn the tester on.

4. Clear the DTCs (where set).

5. Select the following menu items: DIAGNOSIS / ENHANCED OBD II / MONITOR INFO / MONITOR

RESULT.

G034991E07

A079199E49

Page 690 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–397

ES

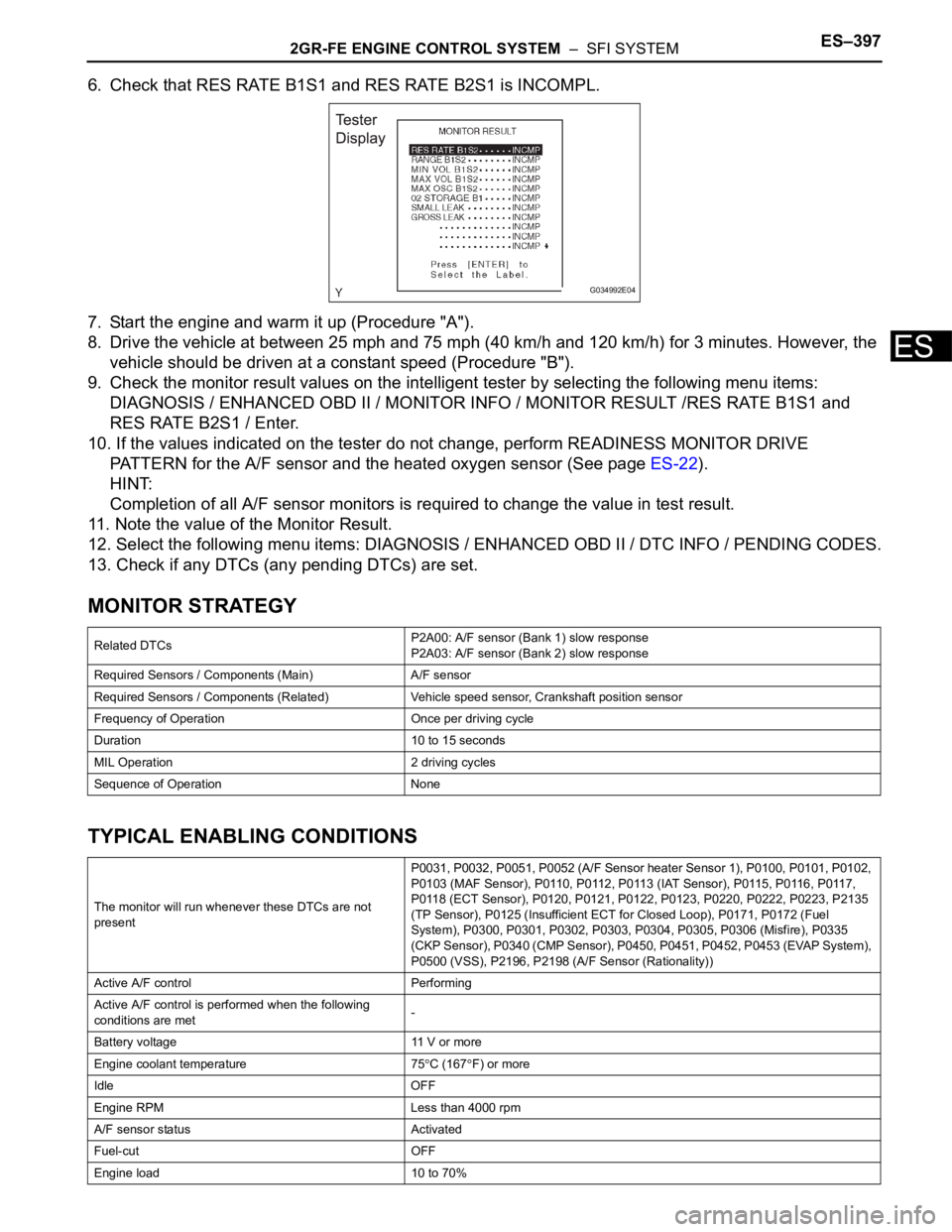

6. Check that RES RATE B1S1 and RES RATE B2S1 is INCOMPL.

7. Start the engine and warm it up (Procedure "A").

8. Drive the vehicle at between 25 mph and 75 mph (40 km/h and 120 km/h) for 3 minutes. However, the

vehicle should be driven at a constant speed (Procedure "B").

9. Check the monitor result values on the intelligent tester by selecting the following menu items:

DIAGNOSIS / ENHANCED OBD II / MONITOR INFO / MONITOR RESULT /RES RATE B1S1 and

RES RATE B2S1 / Enter.

10. If the values indicated on the tester do not change, perform READINESS MONITOR DRIVE

PATTERN for the A/F sensor and the heated oxygen sensor (See page ES-22).

HINT:

Completion of all A/F sensor monitors is required to change the value in test result.

11. Note the value of the Monitor Result.

12. Select the following menu items: DIAGNOSIS / ENHANCED OBD II / DTC INFO / PENDING CODES.

13. Check if any DTCs (any pending DTCs) are set.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

Related DTCsP2A00: A/F sensor (Bank 1) slow response

P2A03: A/F sensor (Bank 2) slow response

Required Sensors / Components (Main) A/F sensor

Required Sensors / Components (Related) Vehicle speed sensor, Crankshaft position sensor

Frequency of Operation Once per driving cycle

Duration 10 to 15 seconds

MIL Operation 2 driving cycles

Sequence of Operation None

The monitor will run whenever these DTCs are not

presentP0031, P0032, P0051, P0052 (A/F Sensor heater Sensor 1), P0100, P0101, P0102,

P0103 (MAF Sensor), P0110, P0112, P0113 (IAT Sensor), P0115, P0116, P0117,

P0118 (ECT Sensor), P0120, P0121, P0122, P0123, P0220, P0222, P0223, P2135

(TP Sensor), P0125 (Insufficient ECT for Closed Loop), P0171, P0172 (Fuel

System), P0300, P0301, P0302, P0303, P0304, P0305, P0306 (Misfire), P0335

(CKP Sensor), P0340 (CMP Sensor), P0450, P0451, P0452, P0453 (EVAP System),

P0500 (VSS), P2196, P2198 (A/F Sensor (Rationality))

Active A/F control Performing

Active A/F control is performed when the following

conditions are met-

Battery voltage 11 V or more

Engine coolant temperature 75

C (167F) or more

Idle OFF

Engine RPM Less than 4000 rpm

A/F sensor status Activated

Fuel-cut OFF

Engine load 10 to 70%

G034992E04

Page 691 of 3000

ES–3982GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

TYPICAL MALFUNCTION THRESHOLDS

MONITOR RESULT

Refer to CHECKING MONITOR STATUS (See page ES-19).

WIRING DIAGRAM

Refer to DTC P2195 (See page ES-359).

INSPECTION PROCEDURE

HINT:

Malfunctioning areas can be identified by performing the A/F CONTROL function provided in the ACTIVE

TEST. The A/F CONTROL function can help to determine whether the Air-Fuel Ratio (A/F) sensor, Heated

Oxygen (HO2) sensor and other potential trouble areas are malfunctioning.

The following instructions describe how to conduct the A/F CONTROL operation using an intelligent

tester.

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine and turn the tester on.

(c) Warm up the engine at an engine speed of 2500 rpm for approximately 90 seconds.

(d) Select the following menu items on the tester: DIAGNOSIS / ENHANCED OBD II / ACTIVE TEST / A/

F CONTROL.

(e) Perform the A/F CONTROL operation with the engine in an idling condition (press the RIGHT or LEFT

button to change the fuel injection volume).

(f) Monitor the voltage outputs of the A/F and HO2 sensors (AFS B1S1 and O2S B1S2 or AFS B2S1 and

O2S B2S2) displayed on the tester.

HINT:

• The A/F CONTROL operation lowers the fuel injection volume by 12.5% or increases the injection

volume by 25%.

• Each sensor reacts in accordance with increases and decreases in the fuel injection volume.

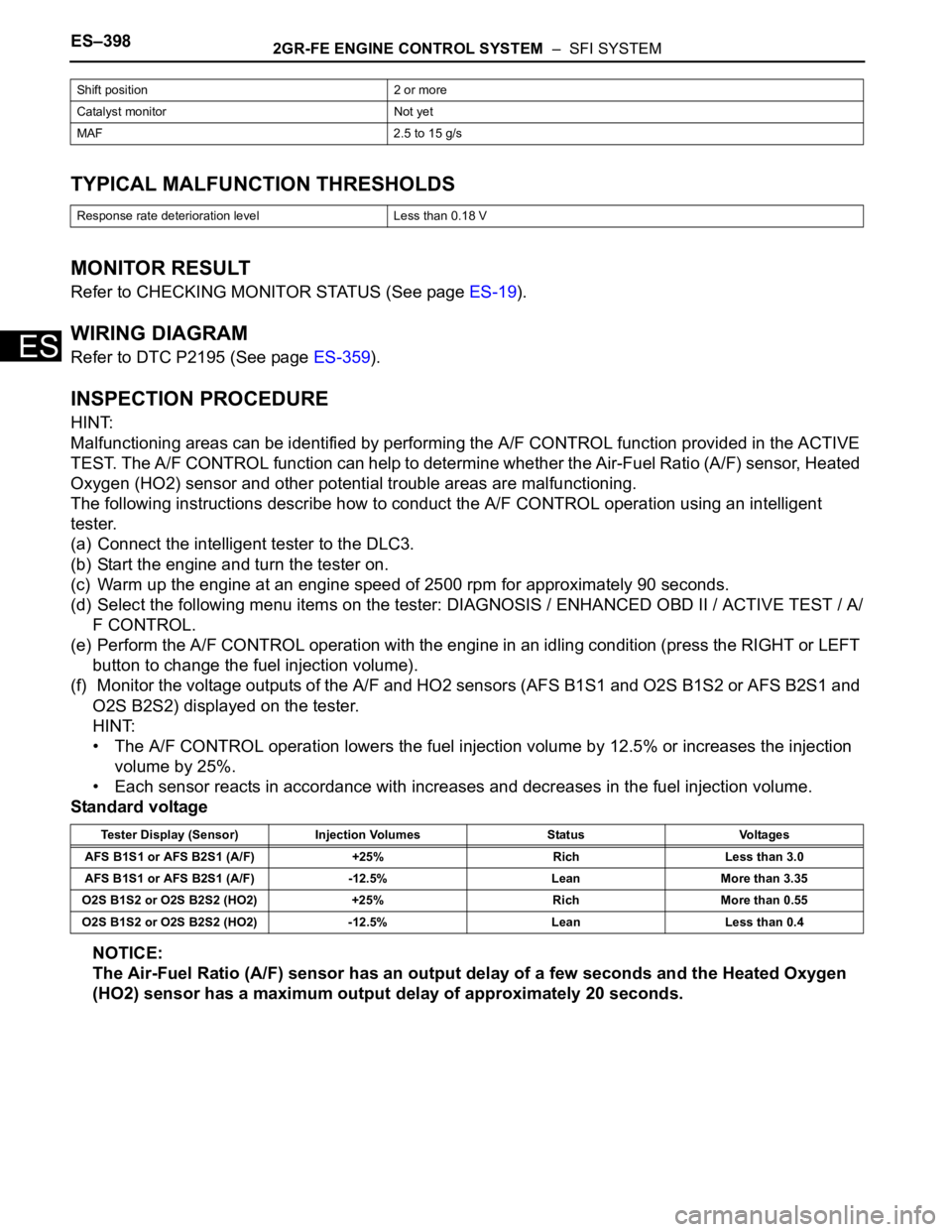

Standard voltage

NOTICE:

The Air-Fuel Ratio (A/F) sensor has an output delay of a few seconds and the Heated Oxygen

(HO2) sensor has a maximum output delay of approximately 20 seconds.

Shift position 2 or more

Catalyst monitor Not yet

MAF 2.5 to 15 g/s

Response rate deterioration level Less than 0.18 V

Tester Display (Sensor) Injection Volumes Status Voltages

AFS B1S1 or AFS B2S1 (A/F) +25% Rich Less than 3.0

AFS B1S1 or AFS B2S1 (A/F) -12.5% Lean More than 3.35

O2S B1S2 or O2S B2S2 (HO2) +25% Rich More than 0.55

O2S B1S2 or O2S B2S2 (HO2) -12.5% Lean Less than 0.4

Page 692 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–399

ES

– Following the A/F CONTROL procedure enables technicians to check and graph the voltage outputs of

both the A/F and HO2 sensors.

– To display the graph, select the following menu items on the tester: DIAGNOSIS / ENHANCED OBD II

/ ACTIVE TEST / A/F CONTROL / USER DATA / AFS B1S1 and O2S B1S2 or AFS B2S1 and O2S

B2S2. Press the YES button and then the ENTER button. Then press the F4 button.

HINT:

• DTC P2A00 or P2A03 may be also set when the air-fuel ratio is stuck rich or lean.

CaseA/F Sensor (Sensor 1)

Output VoltageHO2 Sensor (Sensor 2)

Output VoltageMain Suspected

Trouble Area

1-

2•A/F sensor

•A/F sensor

heater

•A/F sensor

circuit

3•HO2 sensor

• HO2 sensor

heater

• HO2 sensor

circuit

4• Fuel pressure

• Gas leakage

from exhaust

system

(Air-fuel ratio

extremely lean

or rich)

Page 693 of 3000

ES–4002GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

• A low A/F sensor voltage could be caused by a rich air-fuel mixture. Check for conditions that would

cause the engine to run rich.

• A high A/F sensor voltage could be caused by a lean air-fuel mixture. Check for conditions that

would cause the engine to run lean.

• Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame

data can be helpful in determining whether the vehicle was running or stopped, whether the engine

was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at

the time of a malfunction.

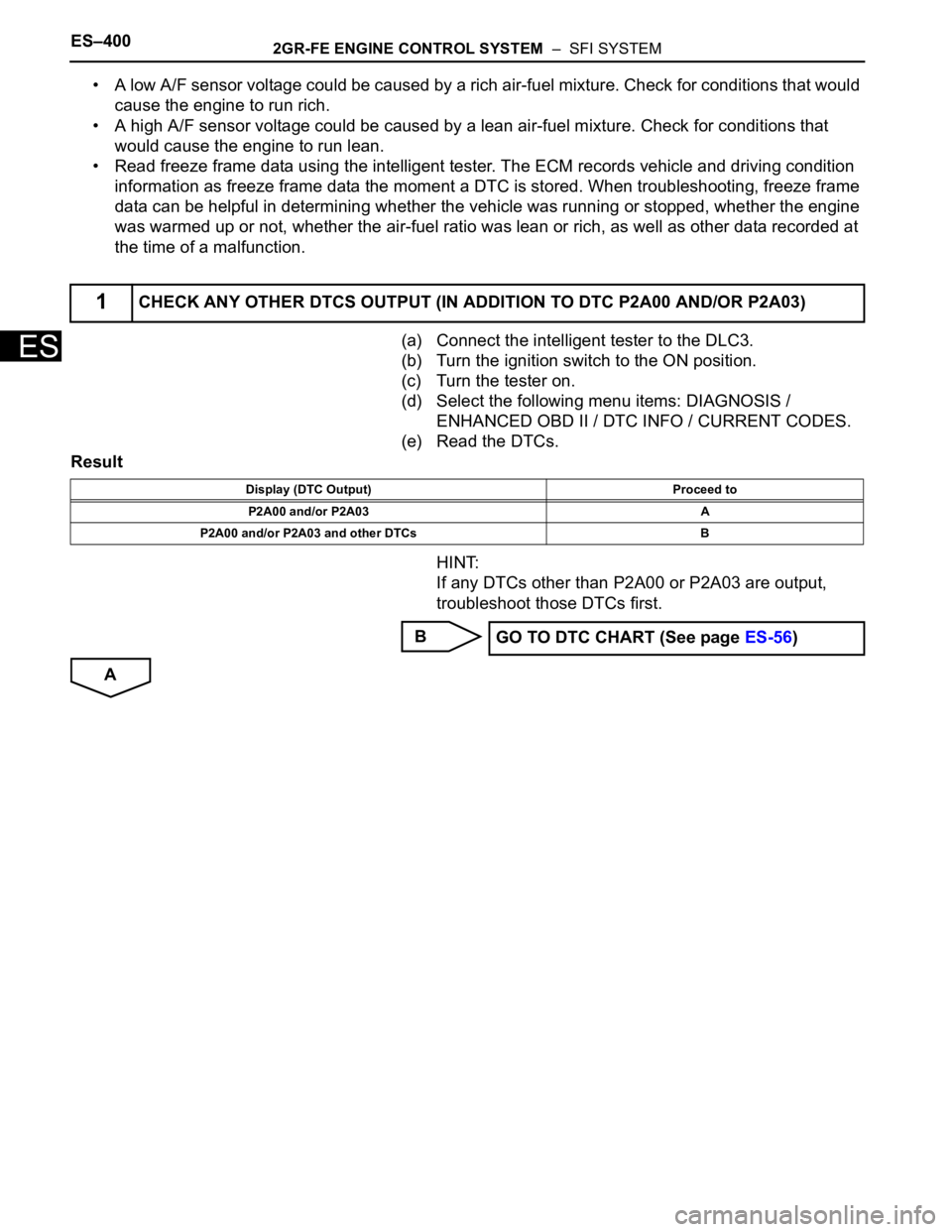

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the tester on.

(d) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT CODES.

(e) Read the DTCs.

Result

HINT:

If any DTCs other than P2A00 or P2A03 are output,

troubleshoot those DTCs first.

B

A

1CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P2A00 AND/OR P2A03)

Display (DTC Output) Proceed to

P2A00 and/or P2A03 A

P2A00 and/or P2A03 and other DTCs B

GO TO DTC CHART (See page ES-56)

Page 694 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–401

ES

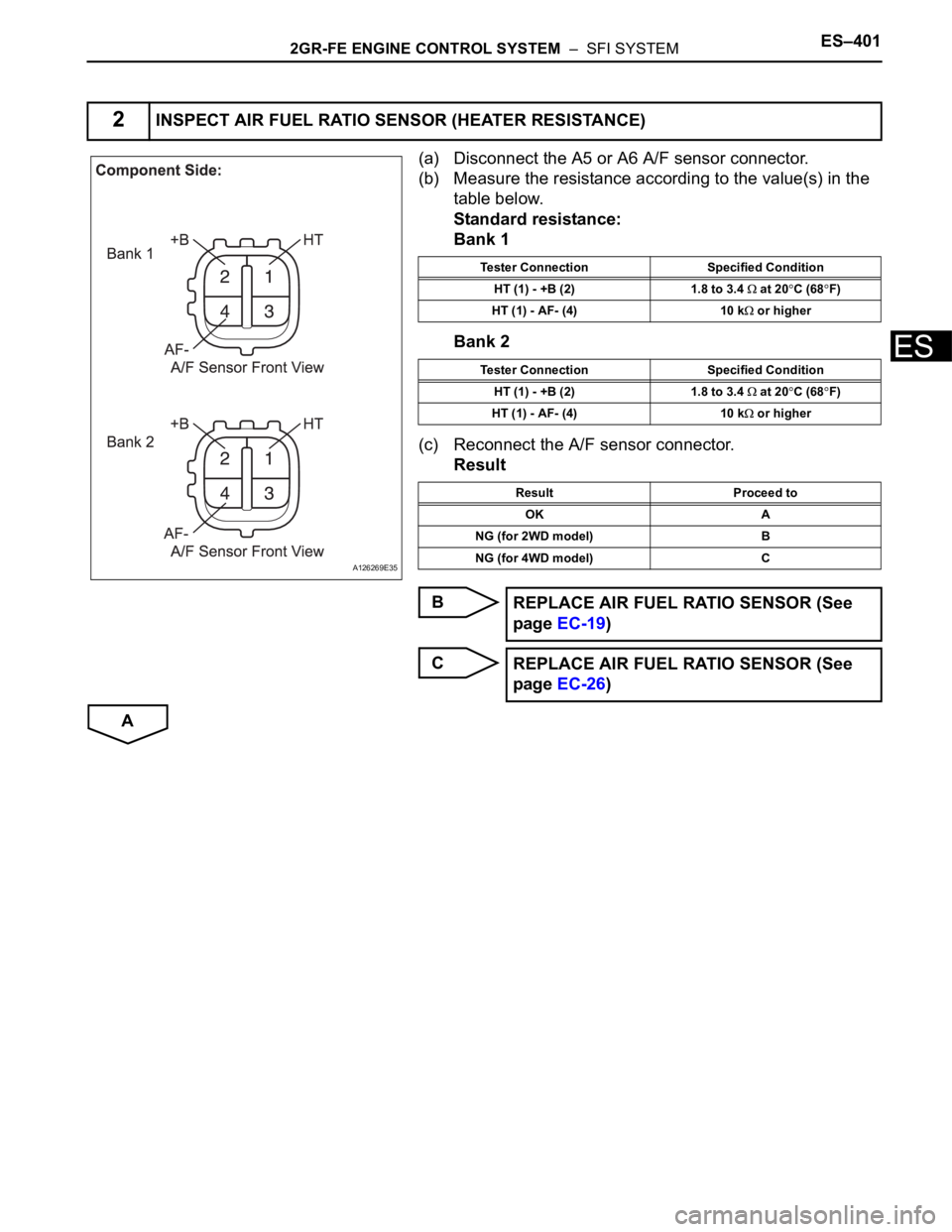

(a) Disconnect the A5 or A6 A/F sensor connector.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

Bank 1

Bank 2

(c) Reconnect the A/F sensor connector.

Result

B

C

A

2INSPECT AIR FUEL RATIO SENSOR (HEATER RESISTANCE)

A126269E35

Tester Connection Specified Condition

HT (1) - +B (2) 1.8 to 3.4

at 20C (68F)

HT (1) - AF- (4) 10 k

or higher

Tester Connection Specified Condition

HT (1) - +B (2) 1.8 to 3.4

at 20C (68F)

HT (1) - AF- (4) 10 k

or higher

Result Proceed to

OK A

NG (for 2WD model) B

NG (for 4WD model) C

REPLACE AIR FUEL RATIO SENSOR (See

page EC-19)

REPLACE AIR FUEL RATIO SENSOR (See

page EC-26)

Page 695 of 3000

ES–4022GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

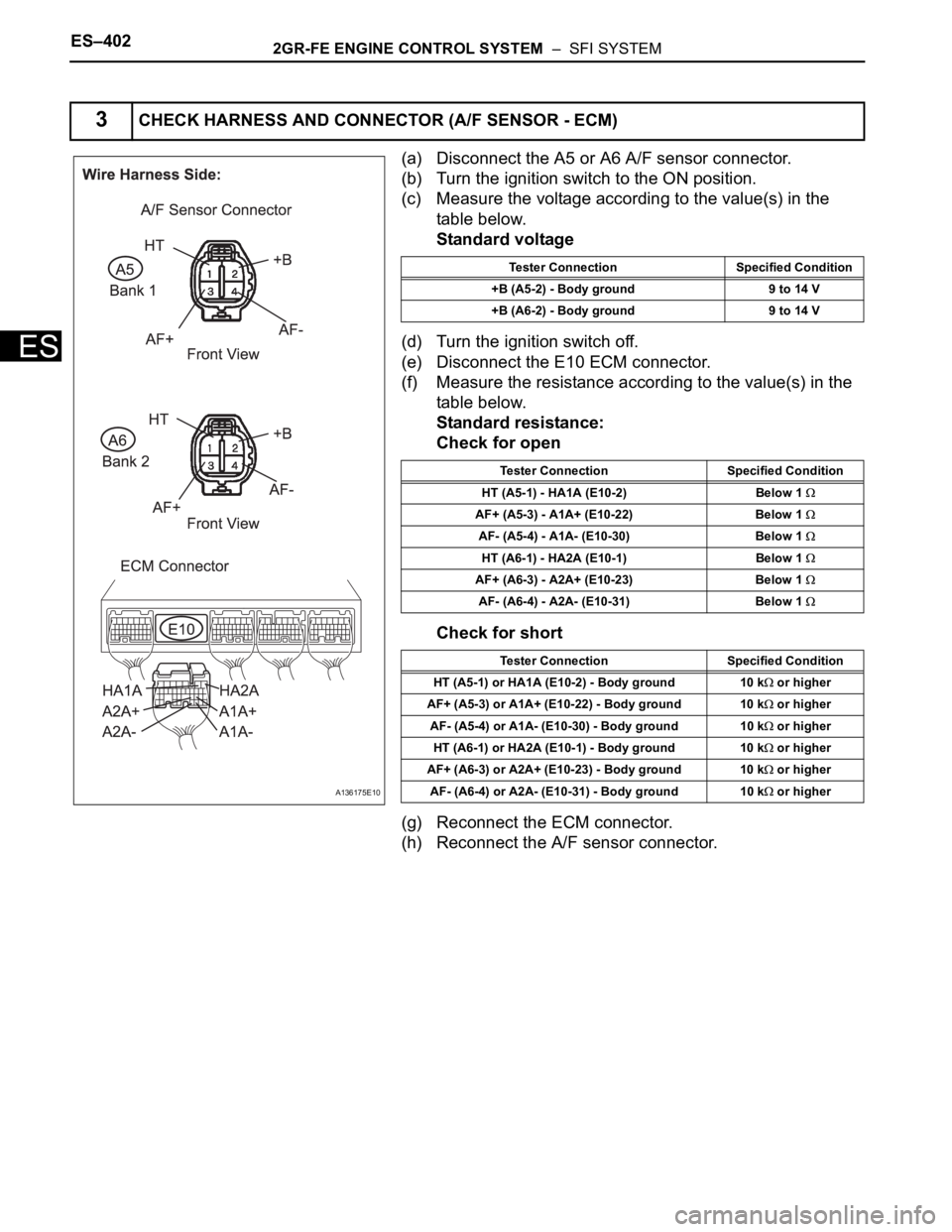

(a) Disconnect the A5 or A6 A/F sensor connector.

(b) Turn the ignition switch to the ON position.

(c) Measure the voltage according to the value(s) in the

table below.

Standard voltage

(d) Turn the ignition switch off.

(e) Disconnect the E10 ECM connector.

(f) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

Check for open

Check for short

(g) Reconnect the ECM connector.

(h) Reconnect the A/F sensor connector.

3CHECK HARNESS AND CONNECTOR (A/F SENSOR - ECM)

A136175E10

Tester Connection Specified Condition

+B (A5-2) - Body ground 9 to 14 V

+B (A6-2) - Body ground 9 to 14 V

Tester Connection Specified Condition

HT (A5-1) - HA1A (E10-2) Below 1

AF+ (A5-3) - A1A+ (E10-22) Below 1

AF- (A5-4) - A1A- (E10-30) Below 1

HT (A6-1) - HA2A (E10-1) Below 1

AF+ (A6-3) - A2A+ (E10-23) Below 1

AF- (A6-4) - A2A- (E10-31) Below 1

Tester Connection Specified Condition

HT (A5-1) or HA1A (E10-2) - Body ground 10 k

or higher

AF+ (A5-3) or A1A+ (E10-22) - Body ground 10 k

or higher

AF- (A5-4) or A1A- (E10-30) - Body ground 10 k

or higher

HT (A6-1) or HA2A (E10-1) - Body ground 10 k

or higher

AF+ (A6-3) or A2A+ (E10-23) - Body ground 10 k

or higher

AF- (A6-4) or A2A- (E10-31) - Body ground 10 k

or higher

Page 696 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–403

ES

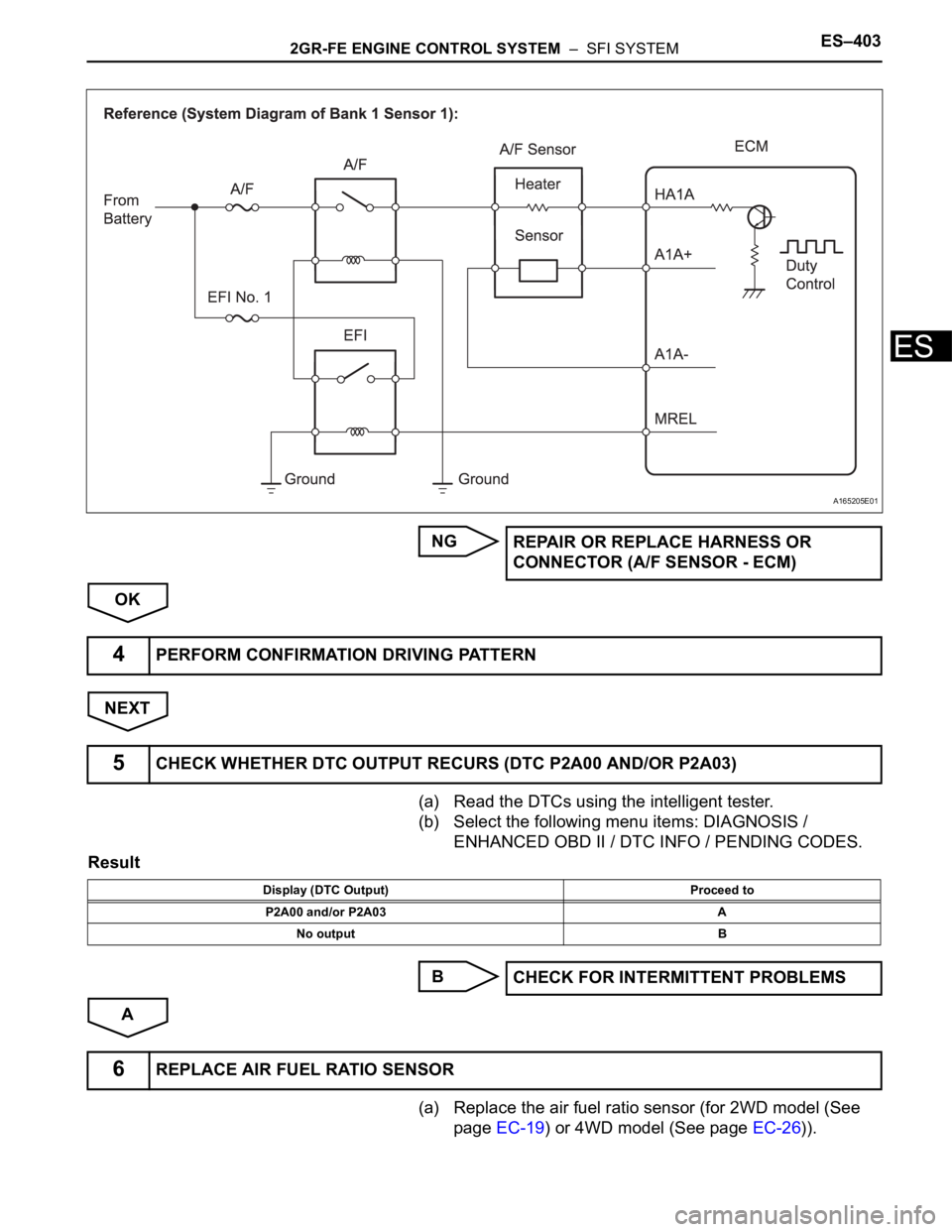

NG

OK

NEXT

(a) Read the DTCs using the intelligent tester.

(b) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / PENDING CODES.

Result

B

A

(a) Replace the air fuel ratio sensor (for 2WD model (See

page EC-19) or 4WD model (See page EC-26)).

A165205E01

REPAIR OR REPLACE HARNESS OR

CONNECTOR (A/F SENSOR - ECM)

4PERFORM CONFIRMATION DRIVING PATTERN

5CHECK WHETHER DTC OUTPUT RECURS (DTC P2A00 AND/OR P2A03)

Display (DTC Output) Proceed to

P2A00 and/or P2A03 A

No output B

CHECK FOR INTERMITTENT PROBLEMS

6REPLACE AIR FUEL RATIO SENSOR

Page 698 of 3000

ES–4122GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

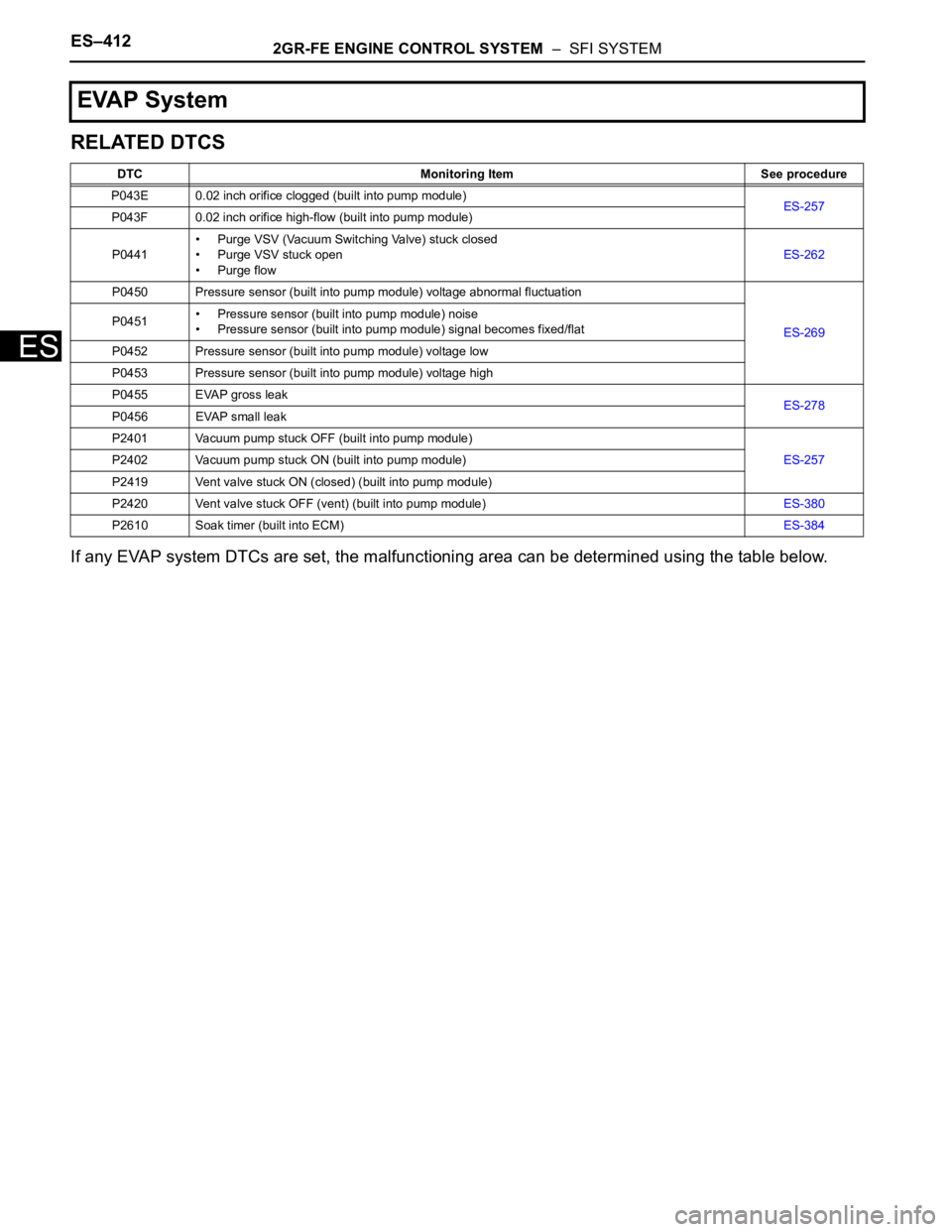

RELATED DTCS

If any EVAP system DTCs are set, the malfunctioning area can be determined using the table below.

EVAP System

DTC Monitoring Item See procedure

P043E 0.02 inch orifice clogged (built into pump module)

ES-257

P043F 0.02 inch orifice high-flow (built into pump module)

P0441• Purge VSV (Vacuum Switching Valve) stuck closed

• Purge VSV stuck open

• Purge flowES-262

P0450 Pressure sensor (built into pump module) voltage abnormal fluctuation

ES-269 P0451• Pressure sensor (built into pump module) noise

• Pressure sensor (built into pump module) signal becomes fixed/flat

P0452 Pressure sensor (built into pump module) voltage low

P0453 Pressure sensor (built into pump module) voltage high

P0455 EVAP gross leak

ES-278

P0456 EVAP small leak

P2401 Vacuum pump stuck OFF (built into pump module)

ES-257 P2402 Vacuum pump stuck ON (built into pump module)

P2419 Vent valve stuck ON (closed) (built into pump module)

P2420 Vent valve stuck OFF (vent) (built into pump module)ES-380

P2610 Soak timer (built into ECM)ES-384

Page 705 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–419

ES

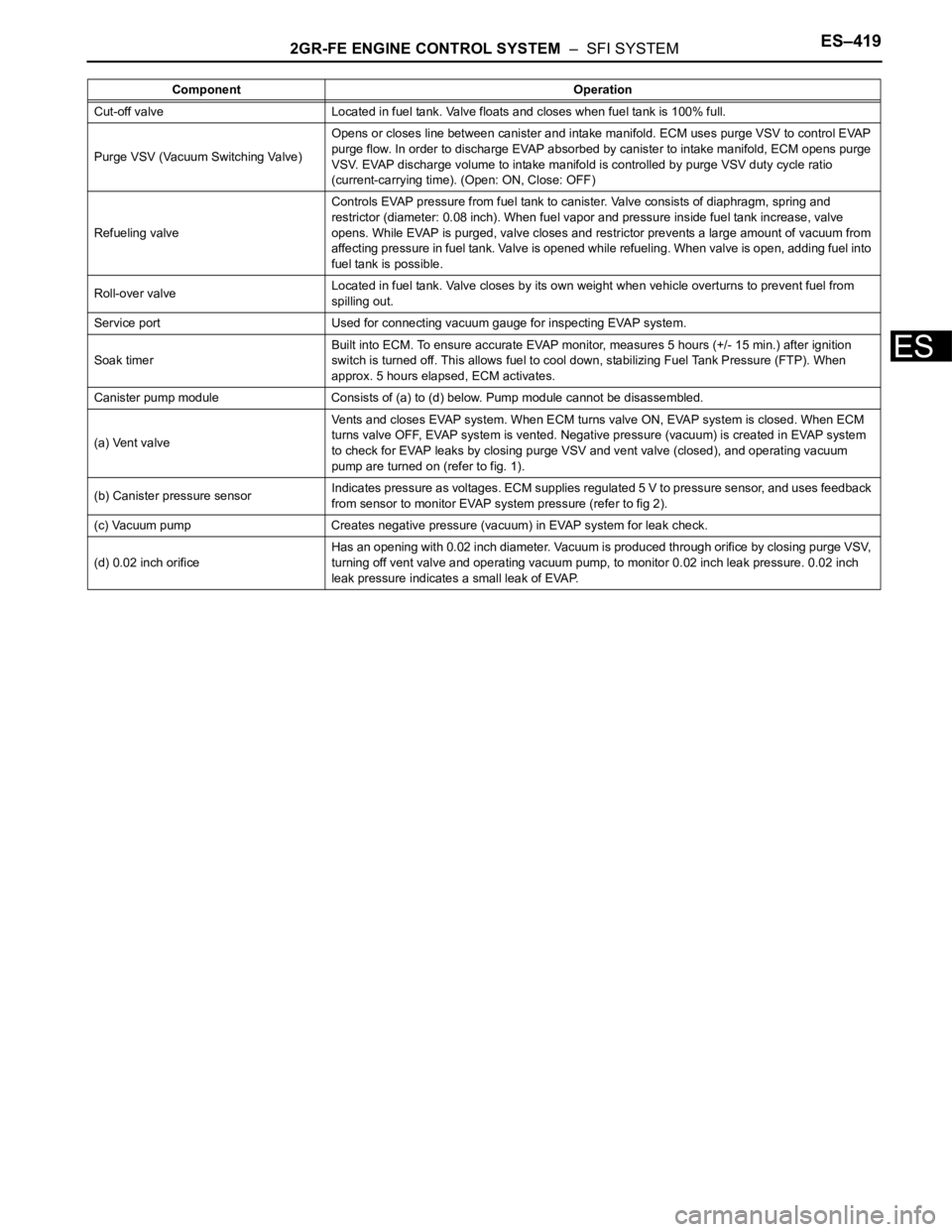

Cut-off valve Located in fuel tank. Valve floats and closes when fuel tank is 100% full.

Purge VSV (Vacuum Switching Valve)Opens or closes line between canister and intake manifold. ECM uses purge VSV to control EVAP

purge flow. In order to discharge EVAP absorbed by canister to intake manifold, ECM opens purge

VSV. EVAP discharge volume to intake manifold is controlled by purge VSV duty cycle ratio

(current-carrying time). (Open: ON, Close: OFF)

Refueling valveControls EVAP pressure from fuel tank to canister. Valve consists of diaphragm, spring and

restrictor (diameter: 0.08 inch). When fuel vapor and pressure inside fuel tank increase, valve

opens. While EVAP is purged, valve closes and restrictor prevents a large amount of vacuum from

affecting pressure in fuel tank. Valve is opened while refueling. When valve is open, adding fuel into

fuel tank is possible.

Roll-over valveLocated in fuel tank. Valve closes by its own weight when vehicle overturns to prevent fuel from

spilling out.

Service port Used for connecting vacuum gauge for inspecting EVAP system.

Soak timerBuilt into ECM. To ensure accurate EVAP monitor, measures 5 hours (+/- 15 min.) after ignition

switch is turned off. This allows fuel to cool down, stabilizing Fuel Tank Pressure (FTP). When

approx. 5 hours elapsed, ECM activates.

Canister pump module Consists of (a) to (d) below. Pump module cannot be disassembled.

(a) Vent valveVents and closes EVAP system. When ECM turns valve ON, EVAP system is closed. When ECM

turns valve OFF, EVAP system is vented. Negative pressure (vacuum) is created in EVAP system

to check for EVAP leaks by closing purge VSV and vent valve (closed), and operating vacuum

pump are turned on (refer to fig. 1).

(b) Canister pressure sensorIndicates pressure as voltages. ECM supplies regulated 5 V to pressure sensor, and uses feedback

from sensor to monitor EVAP system pressure (refer to fig 2).

(c) Vacuum pump Creates negative pressure (vacuum) in EVAP system for leak check.

(d) 0.02 inch orificeHas an opening with 0.02 inch diameter. Vacuum is produced through orifice by closing purge VSV,

turning off vent valve and operating vacuum pump, to monitor 0.02 inch leak pressure. 0.02 inch

leak pressure indicates a small leak of EVAP. Component Operation