sensor TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 675 of 3000

ES–3822GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

Others:

TYPICAL MALFUNCTION THRESHOLDS

P2238 and P2241 (Open circuit between AF+ and AF-):

P2238 and P2241 (Short circuit between AF+ and GND):

P2238 and P2241 (Short circuit between AF+ and AF-):

P2239 and P2242 (Short circuit between AF+ and +B):

P2252 and P2255 (Short circuit between AF- and GND):

P2253 and P2256 (Short circuit between AF- and +B):

WIRING DIAGRAM

Refer to DTC P2195 (See page ES-359).

INSPECTION PROCEDURE

HINT:

For use of the intelligent tester only:

Malfunctioning areas can be identified by performing the A/F CONTROL function provided in the ACTIVE

TEST. The A/F CONTROL function can help to determine whether the Air-Fuel Ratio (A/F) sensor, Heated

Oxygen (HO2) sensor and other potential trouble areas are malfunctioning.

The following instructions describe how to conduct the A/F CONTROL operation using the intelligent

tester.

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine and turn the tester on.

(c) Warm up the engine at an engine speed of 2500 rpm for approximately 90 seconds.

(d) Select the following menu items on the tester: DIAGNOSIS / ENHANCED OBD II / ACTIVE TEST / A/

F CONTROL.

(e) Perform the A/F CONTROL operation with the engine in an idling condition (press the RIGHT or LEFT

button to change the fuel injection volume).

Engine Running

Fuel-cut OFF

Time after fuel-cut OFF 5 seconds or more

A/F sensor heater ON

Battery voltage 11 V or more

Ignition switch ON

Time after ignition switch is OFF to ON 5 seconds or more

Battery voltage 11 V or more

Ignition switch ON

Time after ignition switch is OFF to ON 5 seconds or more

A/F sensor admittance Below 0.022 1/

AF+ terminal voltage 0.5 V or less

Difference between AF+ terminal and AF- terminal

voltage0.1 V or less

AF+ terminal voltage More than 4.5 V

AF- terminal voltage 0.5 V or less

AF- terminal voltage More than 4.5 V

Page 676 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–383

ES

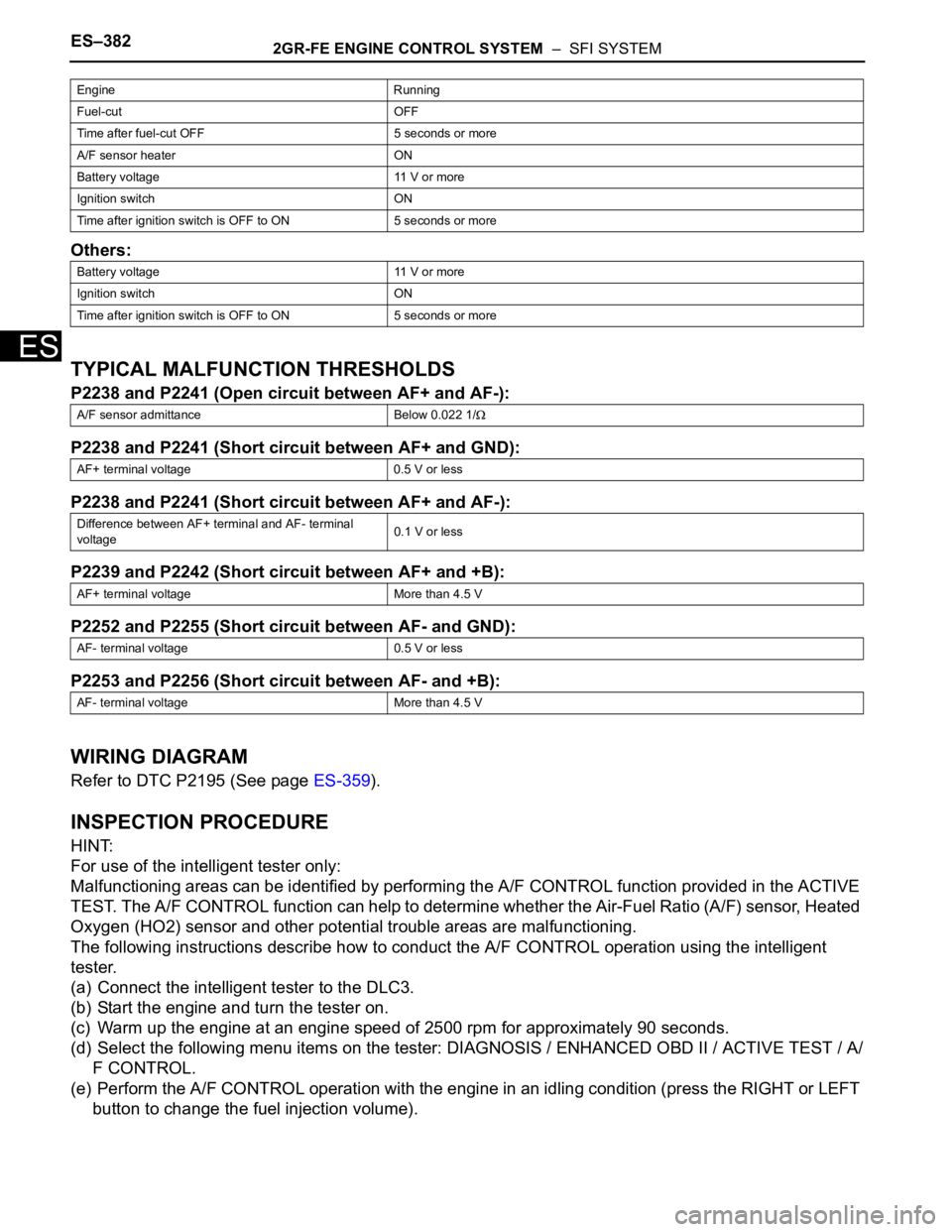

(f) Monitor the voltage outputs of the A/F and HO2 sensors (AFS B1S1 and O2S B1S2 or AFS B2S1 and

O2S B2S2) displayed on the tester.

HINT:

• The A/F CONTROL operation lowers the fuel injection volume by 12.5% or increases the injection

volume by 25%.

• Each sensor reacts in accordance with increases and decreases in the fuel injection volume.

Standard voltage

NOTICE:

The Air-Fuel Ratio (A/F) sensor has an output delay of a few seconds and the Heated Oxygen

(HO2) sensor has a maximum output delay of approximately 20 seconds.

Tester Display (Sensor) Injection Volumes Status Voltages

AFS B1S1 or AFS B2S1 (A/F) +25% Rich Less than 3.0

AFS B1S1 or AFS B2S1 (A/F) -12.5% Lean More than 3.35

O2S B1S2 or O2S B2S2 (HO2) +25% Rich More than 0.55

O2S B1S2 or O2S B2S2 (HO2) -12.5% Lean Less than 0.4

CaseA/F Sensor (Sensor 1)

Output VoltageHO2 Sensor (Sensor 2)

Output VoltageMain Suspected

Trouble Area

1-

2•A/F sensor

•A/F sensor

heater

•A/F sensor

circuit

3•HO2 sensor

• HO2 sensor

heater

• HO2 sensor

circuit

Page 677 of 3000

ES–3842GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES– Following the A/F CONTROL procedure enables technicians to check and graph the voltage outputs of

both the A/F and HO2 sensors.

– To display the graph, select the following menu items on the tester: DIAGNOSIS / ENHANCED OBD II

/ ACTIVE TEST / A/F CONTROL / USER DATA / AFS B1S1 and O2S B1S2 or AFS B2S1 and O2S

B2S2. Press the YES button and then the ENTER button. Then press the F4 button.

HINT:

• Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame

data can be helpful in determining whether the vehicle was running or stopped, whether the engine

was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at

the time of a malfunction.

• A low A/F sensor voltage could be caused by a rich air-fuel mixture. Check for conditions that would

cause the engine to run rich.

• A high A/F sensor voltage could be caused by a lean air-fuel mixture. Check for conditions that

would cause the engine to run lean.

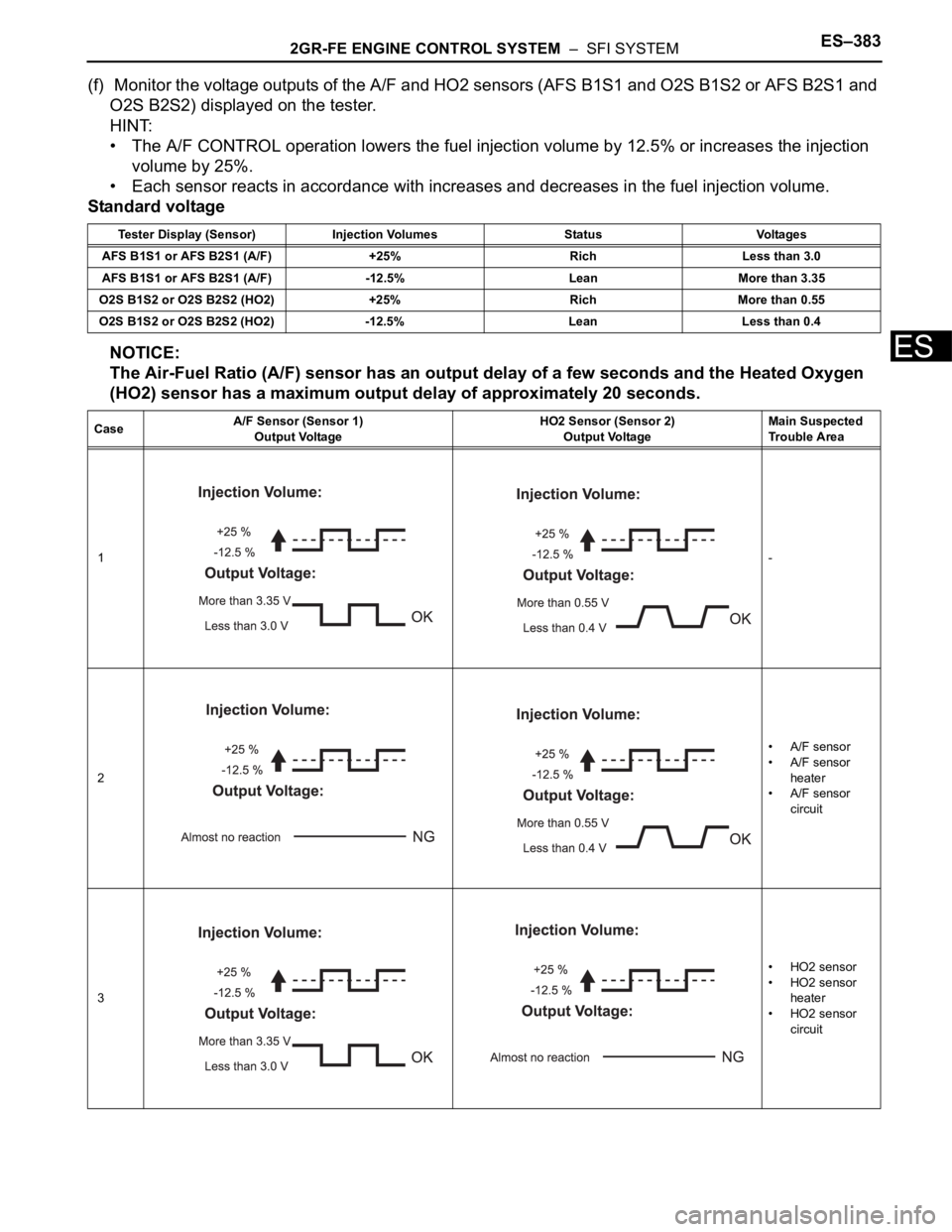

(a) Disconnect the A5 or A6 A/F sensor connector.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

Bank 1

Bank 2

(c) Reconnect the A/F sensor connector.

Result

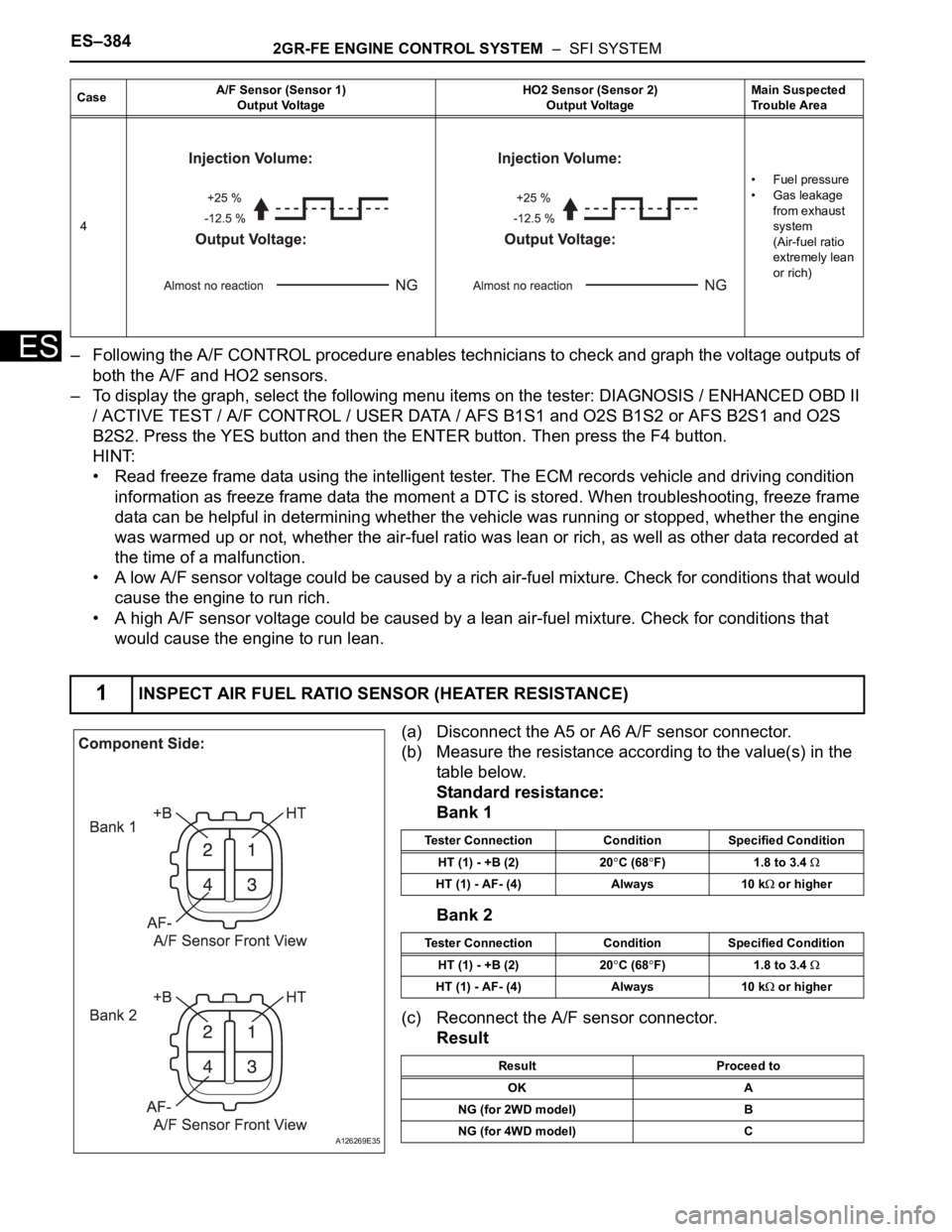

4•Fuel pressure

• Gas leakage

from exhaust

system

(Air-fuel ratio

extremely lean

or rich)

1INSPECT AIR FUEL RATIO SENSOR (HEATER RESISTANCE)

CaseA/F Sensor (Sensor 1)

Output VoltageHO2 Sensor (Sensor 2)

Output VoltageMain Suspected

Trouble Area

A126269E35

Tester Connection Condition Specified Condition

HT (1) - +B (2) 20

C (68F) 1.8 to 3.4

HT (1) - AF- (4) Always 10 k or higher

Tester Connection Condition Specified Condition

HT (1) - +B (2) 20

C (68F) 1.8 to 3.4

HT (1) - AF- (4) Always 10 k or higher

Result Proceed to

OK A

NG (for 2WD model) B

NG (for 4WD model) C

Page 678 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–385

ES

B

C

A

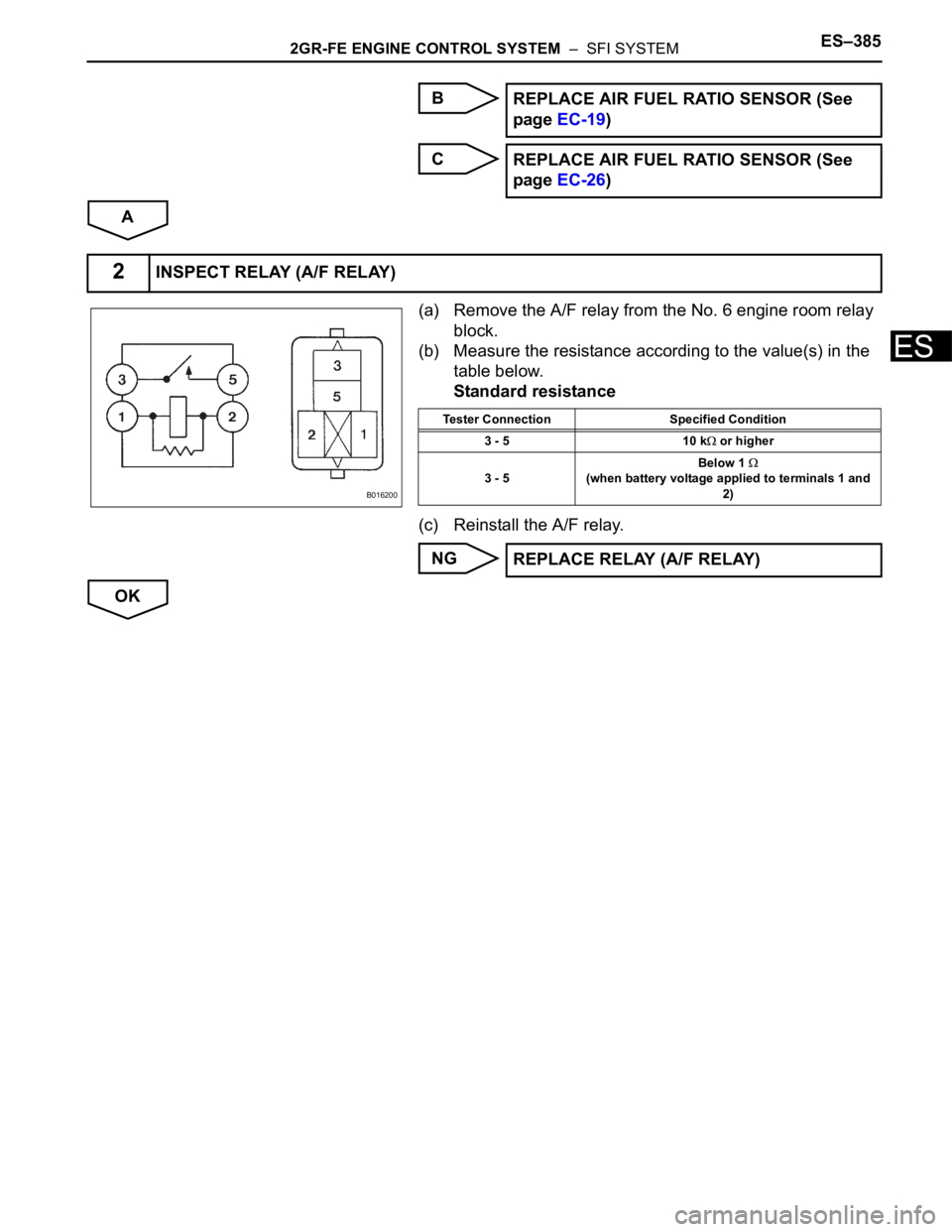

(a) Remove the A/F relay from the No. 6 engine room relay

block.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

(c) Reinstall the A/F relay.

NG

OKREPLACE AIR FUEL RATIO SENSOR (See

page EC-19)

REPLACE AIR FUEL RATIO SENSOR (See

page EC-26)

2INSPECT RELAY (A/F RELAY)

B016200

Tester Connection Specified Condition

3 - 5 10 k

or higher

3 - 5Below 1

(when battery voltage applied to terminals 1 and

2)

REPLACE RELAY (A/F RELAY)

Page 679 of 3000

ES–3862GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

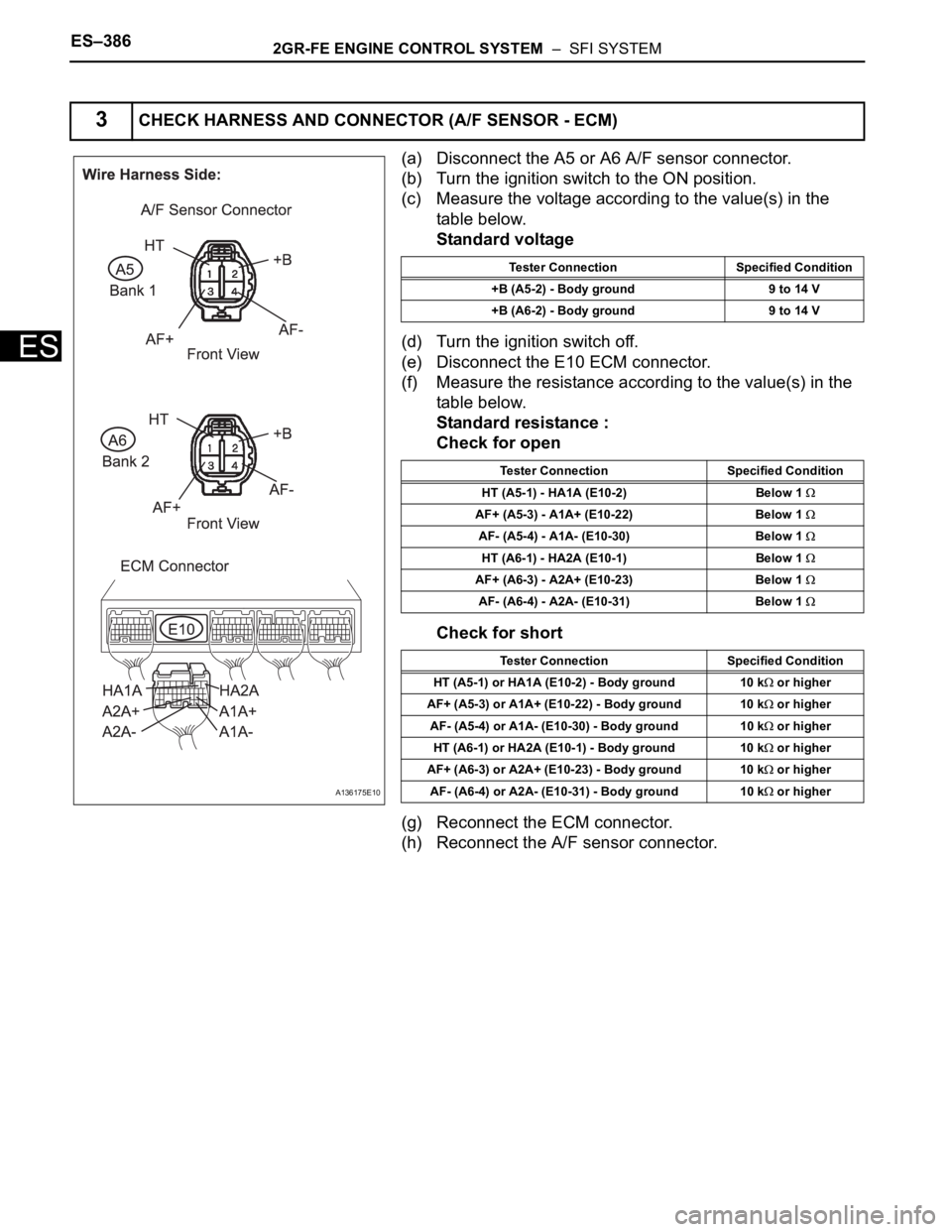

(a) Disconnect the A5 or A6 A/F sensor connector.

(b) Turn the ignition switch to the ON position.

(c) Measure the voltage according to the value(s) in the

table below.

Standard voltage

(d) Turn the ignition switch off.

(e) Disconnect the E10 ECM connector.

(f) Measure the resistance according to the value(s) in the

table below.

Standard resistance :

Check for open

Check for short

(g) Reconnect the ECM connector.

(h) Reconnect the A/F sensor connector.

3CHECK HARNESS AND CONNECTOR (A/F SENSOR - ECM)

A136175E10

Tester Connection Specified Condition

+B (A5-2) - Body ground 9 to 14 V

+B (A6-2) - Body ground 9 to 14 V

Tester Connection Specified Condition

HT (A5-1) - HA1A (E10-2) Below 1

AF+ (A5-3) - A1A+ (E10-22) Below 1

AF- (A5-4) - A1A- (E10-30) Below 1

HT (A6-1) - HA2A (E10-1) Below 1

AF+ (A6-3) - A2A+ (E10-23) Below 1

AF- (A6-4) - A2A- (E10-31) Below 1

Tester Connection Specified Condition

HT (A5-1) or HA1A (E10-2) - Body ground 10 k

or higher

AF+ (A5-3) or A1A+ (E10-22) - Body ground 10 k

or higher

AF- (A5-4) or A1A- (E10-30) - Body ground 10 k

or higher

HT (A6-1) or HA2A (E10-1) - Body ground 10 k

or higher

AF+ (A6-3) or A2A+ (E10-23) - Body ground 10 k

or higher

AF- (A6-4) or A2A- (E10-31) - Body ground 10 k

or higher

Page 680 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–387

ES

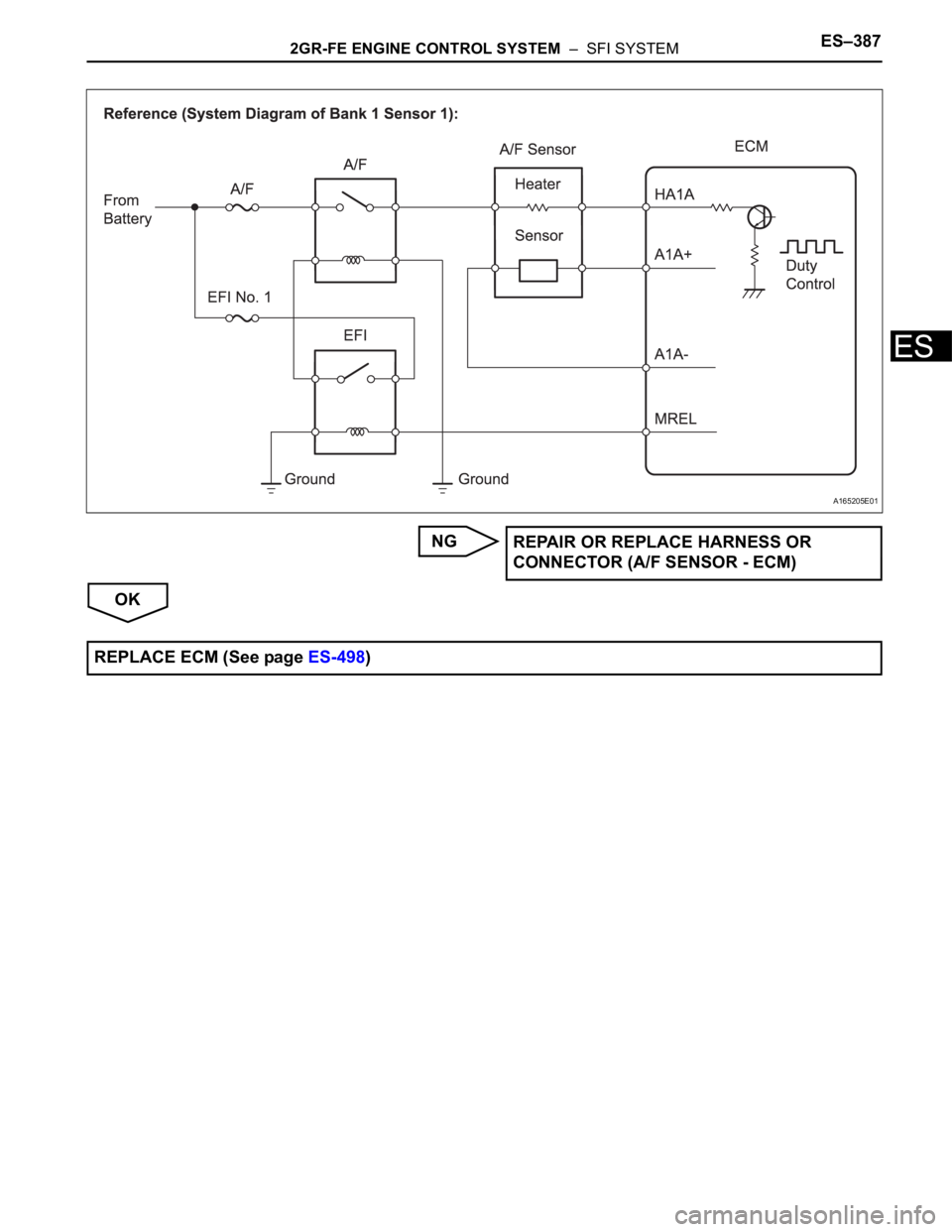

NG

OK

A165205E01

REPAIR OR REPLACE HARNESS OR

CONNECTOR (A/F SENSOR - ECM)

REPLACE ECM (See page ES-498)

Page 682 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–389

ES

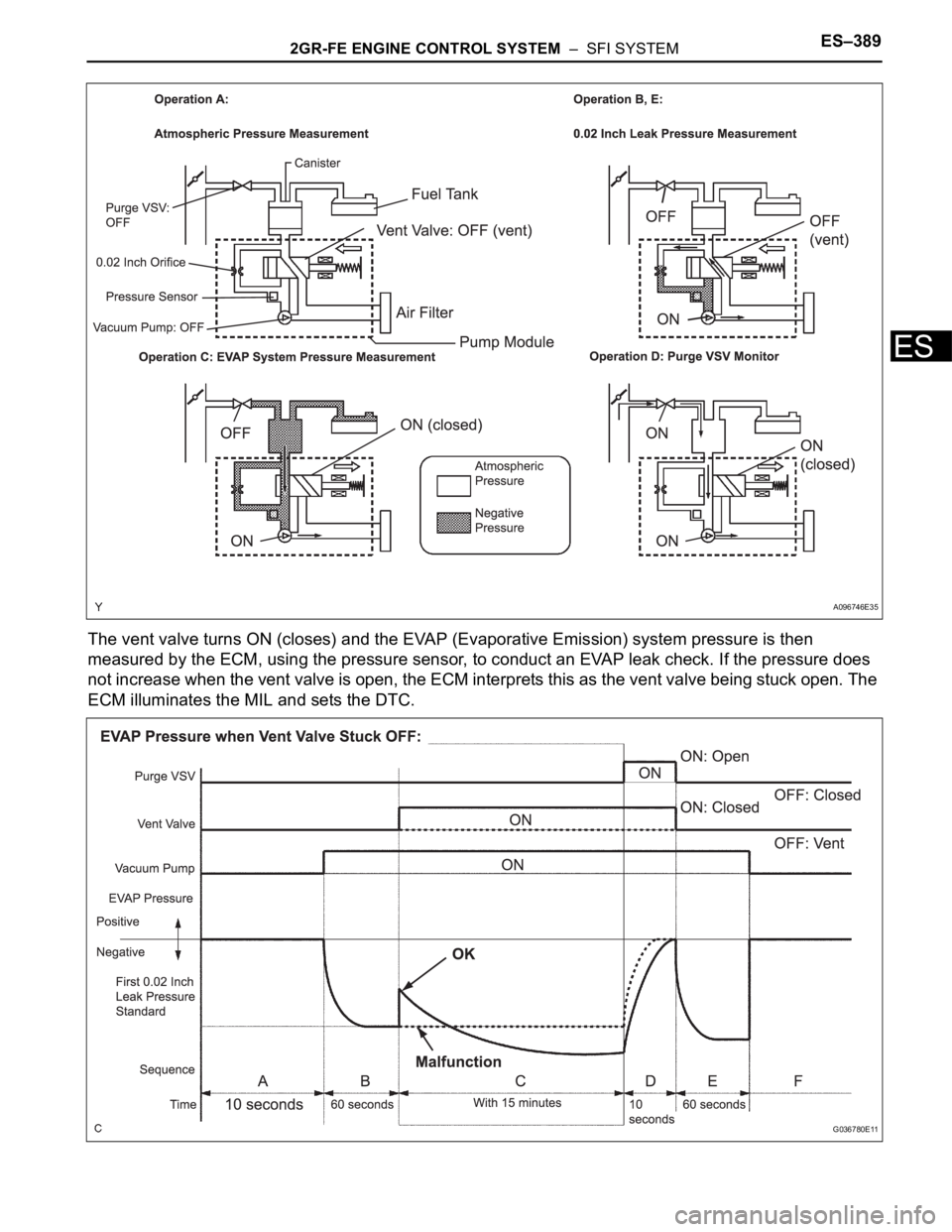

The vent valve turns ON (closes) and the EVAP (Evaporative Emission) system pressure is then

measured by the ECM, using the pressure sensor, to conduct an EVAP leak check. If the pressure does

not increase when the vent valve is open, the ECM interprets this as the vent valve being stuck open. The

ECM illuminates the MIL and sets the DTC.

A096746E35

G036780E11

Page 683 of 3000

ES–3902GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

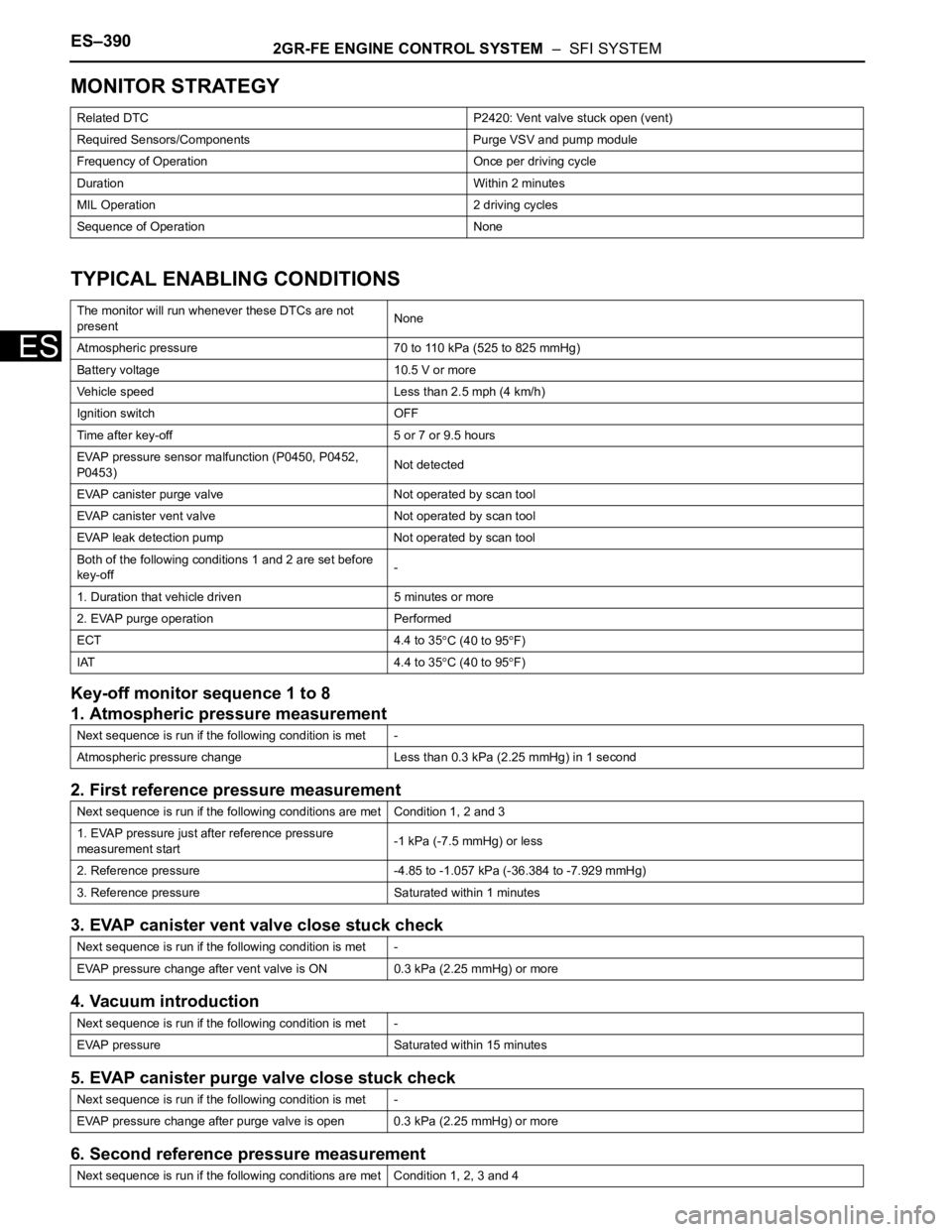

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

Key-off monitor sequence 1 to 8

1. Atmospheric pressure measurement

2. First reference pressure measurement

3. EVAP canister vent valve close stuck check

4. Vacuum introduction

5. EVAP canister purge valve close stuck check

6. Second reference pressure measurement

Related DTC P2420: Vent valve stuck open (vent)

Required Sensors/Components Purge VSV and pump module

Frequency of Operation Once per driving cycle

Duration Within 2 minutes

MIL Operation 2 driving cycles

Sequence of Operation None

The monitor will run whenever these DTCs are not

presentNone

Atmospheric pressure 70 to 110 kPa (525 to 825 mmHg)

Battery voltage 10.5 V or more

Vehicle speed Less than 2.5 mph (4 km/h)

Ignition switch OFF

Time after key-off 5 or 7 or 9.5 hours

EVAP pressure sensor malfunction (P0450, P0452,

P0453)Not detected

EVAP canister purge valve Not operated by scan tool

EVAP canister vent valve Not operated by scan tool

EVAP leak detection pump Not operated by scan tool

Both of the following conditions 1 and 2 are set before

key-off-

1. Duration that vehicle driven 5 minutes or more

2. EVAP purge operation Performed

ECT 4.4 to 35

C (40 to 95F)

IAT 4.4 to 35

C (40 to 95F)

Next sequence is run if the following condition is met -

Atmospheric pressure change Less than 0.3 kPa (2.25 mmHg) in 1 second

Next sequence is run if the following conditions are met Condition 1, 2 and 3

1. EVAP pressure just after reference pressure

measurement start-1 kPa (-7.5 mmHg) or less

2. Reference pressure -4.85 to -1.057 kPa (-36.384 to -7.929 mmHg)

3. Reference pressure Saturated within 1 minutes

Next sequence is run if the following condition is met -

EVAP pressure change after vent valve is ON 0.3 kPa (2.25 mmHg) or more

Next sequence is run if the following condition is met -

EVAP pressure Saturated within 15 minutes

Next sequence is run if the following condition is met -

EVAP pressure change after purge valve is open 0.3 kPa (2.25 mmHg) or more

Next sequence is run if the following conditions are met Condition 1, 2, 3 and 4

Page 686 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–393

ES

MONITOR DESCRIPTION

5 hours after the ignition switch is turned off, the soak timer activates the ECM to begin the EVAP system

monitor. While the engine is running, the ECM monitors the synchronization of the soak timer and the

CPU clock. If these two are not synchronized, the ECM interprets this as a malfunction, illuminates the

MIL and sets the DTC (2 trip detection logic).

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

INSPECTION PROCEDURE

HINT:

• DTC P2610 is set if an internal ECM problem is detected. Diagnostic procedures are not required.

ECM replacement is required.

• Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame

data can be helpful in determining whether the vehicle was running or stopped, whether the engine

was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the

time of a malfunction.

(a) Replace the ECM (See page ES-498).

NEXT

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Clear the DTCs (See page ES-39).

(d) Start the engine and wait for 10 minutes or more.

Required Sensors / Components ECM

Frequency of Operation Once per driving cycle

Duration 10 minutes

MIL Operation 2 driving cycles

Sequence of Operation None

The monitor will run whenever these DTCs are not

presentNone

Ignition switch ON

Engine Running

Battery voltage 8 V or more

Sta r t e r OF F

Soak timer measurement when ECM CPU clock counts

10 minutesLess than 7 minutes or more than 13 minutes

1REPLACE ECM

2CHECK WHETHER DTC OUTPUT RECURS

Page 688 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–395

ES

HINT:

• DTC P2A00 indicates malfunctions related to the bank 1 A/F sensor.

• DTC P2A03 indicates malfunctions related to the bank 2 A/F sensor.

• Bank 1 refers to the bank that includes cylinder No. 1.

• Bank 2 refers to the bank that includes cylinder No. 2.

• Sensor 1 refers to the sensor mounted in front of the Three-Way Catalytic Converter (TWC) and

located near the engine assembly.

DESCRIPTION

Refer to DTC P2195 (See page ES-355).

MONITOR DESCRIPTION

After the engine is warmed up, the ECM performs air-fuel ratio feedback control to maintain the air-fuel

ratio at the stoichiometric level. In addition, active A/F ratio control is performed for approximately 10

seconds after preconditions are met in order to measure the A/F sensor response rate. During active A/F

ratio control, the ECM forcibly increases and decreases the injection volume to a certain amount, based

on the stoichiometric air-fuel ratio learned during normal air-fuel ratio control, and measures the A/F

sensor response rate. The ECM receives a signal from the A/F sensor while performing active A/F ratio

control and uses it to calculate the A/F sensor response rate deterioration level.

If the value for A/F sensor response rate deterioration level is less than the threshold, the ECM interprets

this as a malfunction and sets the DTC.

DTC P2A00A/F Sensor Circuit Slow Response (Bank 1

Sensor 1)

DTC P2A03A/F Sensor Circuit Slow Response (Bank 2

Sensor 1)

DTC No. DTC Detection Condition Trouble Area

P2A00

P2A03Calculated value for air-fuel ratio (A/F) sensor response

rate deterioration level is less than threshold• Open or short in A/F sensor circuit

• A/F sensor

•ECM