lock TOYOTA SUPRA 2022 Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2022, Model line: SUPRA, Model: TOYOTA SUPRA 2022Pages: 498, PDF Size: 104.06 MB

Page 293 of 498

291

5

5-1. MOBILITY

MOBILITY

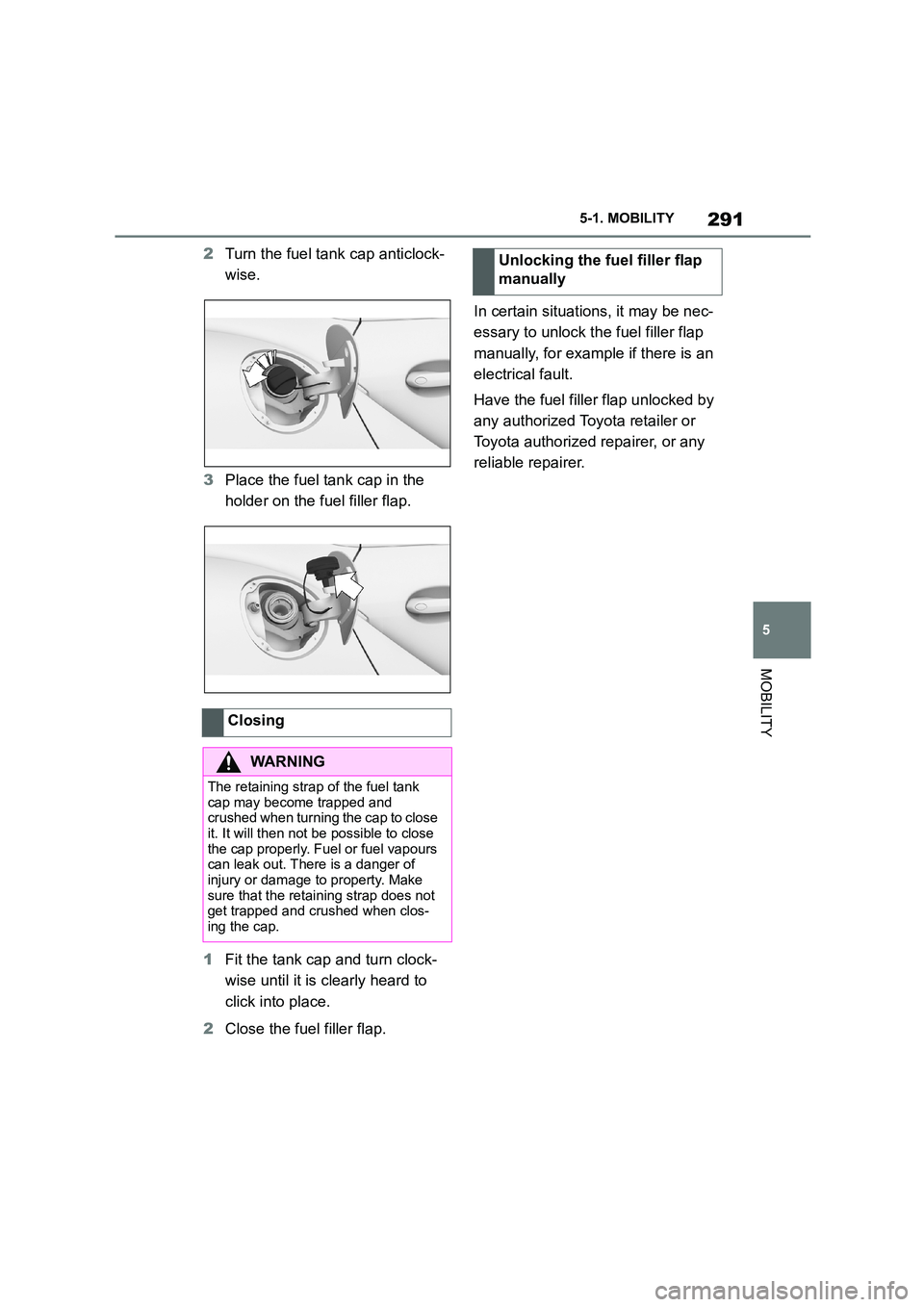

2 Turn the fuel tank cap anticlock-

wise.

3 Place the fuel tank cap in the

holder on the fuel filler flap.

1 Fit the tank cap and turn clock-

wise until it is clearly heard to

click into place.

2 Close the fuel filler flap.

In certain situations, it may be nec-

essary to unlock th e fuel filler flap

manually, for example if there is an

electrical fault.

Have the fuel filler flap unlocked by

any authorized Toyota retailer or

Toyota authorized repairer, or any

reliable repairer.

Closing

WA R N I N G

The retaining strap of the fuel tank

cap may become trapped and crushed when turning the cap to close

it. It will then not be possible to close

the cap properly. Fuel or fuel vapours can leak out. There is a danger of

injury or damage to property. Make

sure that the retaining strap does not get trapped and crushed when clos-

ing the cap.

Unlocking the fuel filler flap

manually

Page 298 of 498

2965-1. MOBILITY

The date of manufacture of the tyre

is indicated on the tyre sidewall.

Have the wheel fitted and balanced

by any authorized Toyota retailer or

Toyota authorized repairer, or any

reliable repairer.

The following properties are recom-

mended and approved by the man-

ufacturer of the vehicle for the

approved wheels and tyres per

vehicle type and special equipment:

• Wheel and tyre combinations.

•Rim designs.

• Tyre sizes.

• Tyre makes.

You can ask any authorized Toyota

retailer or Toyota authorized

repairer, or any reliable repairer

about the approved wheels and

tyres for the vehicle and the special

equipment.

Date of manufacture

DesignationDate of manufac-

ture

DOT … 382038th week of 2020

Replacement of wheels and

tyres

Fitting and balancing

Permissible wheels and tyres

General

Safety notes

WA R N I N G

Wheels and tyres that are not suitable

for your vehicle can damage parts of the vehicle. For example they could

come into contact with the bodywork

on account of their dimensional toler- ances, despite having the same nomi-

nal size. There is a danger of

accidents. The manufacturer of the

vehicle recommends using wheels and tyres that have been categorised

as suitable for the respective vehicle

type.

WA R N I N G

Mounted steel wheels can lead to

technical problems, for example wheel studs may work loose and

brake discs may be damaged. There

is a risk of accident. Do not install steel wheels.

WA R N I N G

Incorrect wheel/tyre combinations

impair the vehicle's handling charac- teristics and interfere with the proper

functioning of various systems, such

as the Anti-lock Brake System or Vehicle Stability Control. There is a

danger of accidents. To maintain good

vehicle handling, always fit tyres of the same make and tread pattern to

all wheels. The manufacturer of the

vehicle recommends using wheels and tyres that have been categorised

as suitable for the respective vehicle

type. After a tyre has been damaged, refit the same wheel/tyre combination

as the original.

Page 301 of 498

299

5

5-1. MOBILITY

MOBILITY

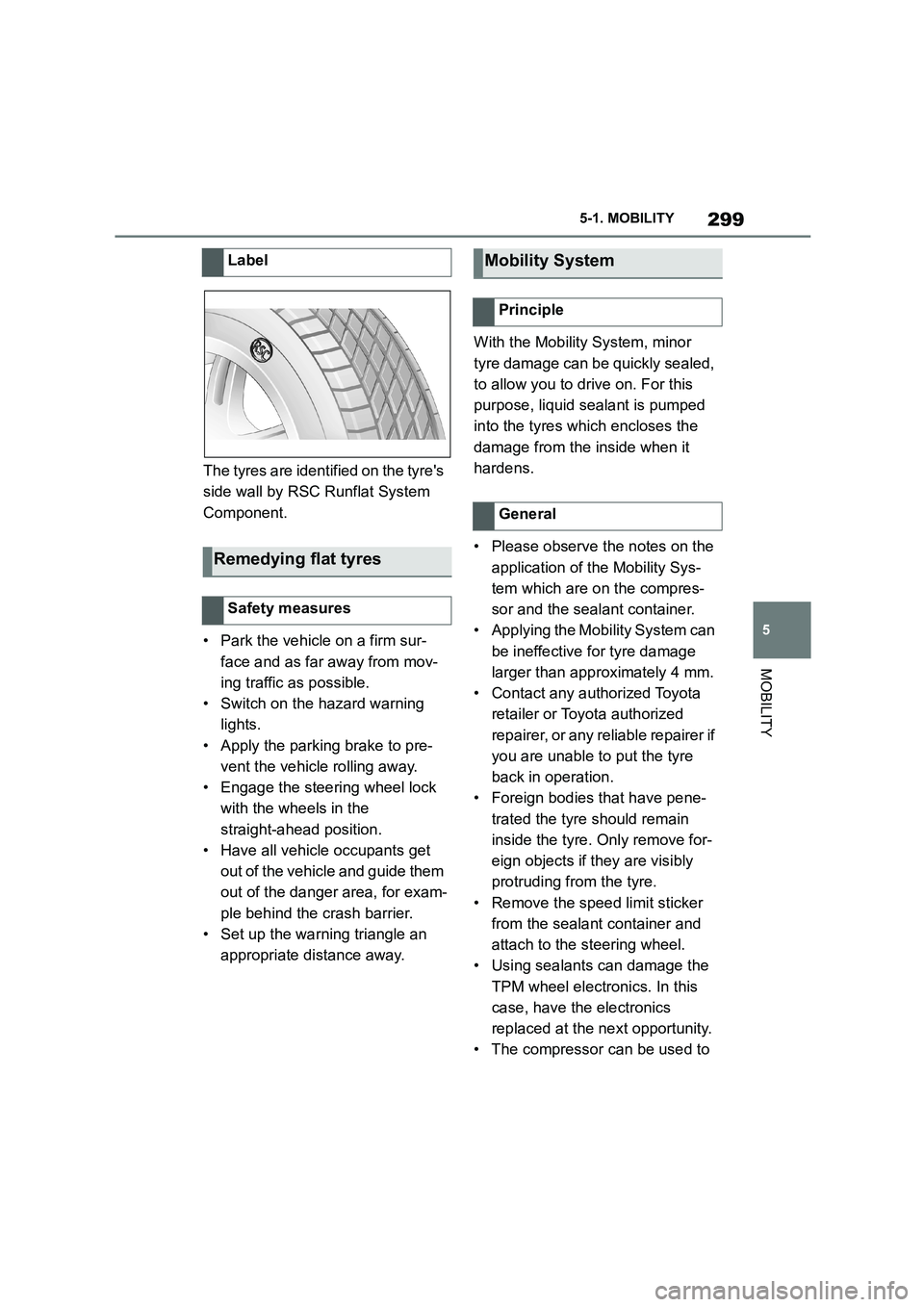

The tyres are identified on the tyre's

side wall by RSC Runflat System

Component.

• Park the vehicle on a firm sur-

face and as far away from mov-

ing traffic as possible.

• Switch on the hazard warning

lights.

• Apply the parking brake to pre-

vent the vehicle rolling away.

• Engage the steering wheel lock

with the wheels in the

straight-ahead position.

• Have all vehicle occupants get

out of the vehicle and guide them

out of the danger area, for exam-

ple behind the crash barrier.

• Set up the warning triangle an

appropriate distance away.

With the Mobility System, minor

tyre damage can be quickly sealed,

to allow you to drive on. For this

purpose, liquid sealant is pumped

into the tyres which encloses the

damage from the inside when it

hardens.

• Please observe the notes on the

application of the Mobility Sys-

tem which are on the compres-

sor and the sealant container.

• Applying the Mobility System can

be ineffective for tyre damage

larger than approximately 4 mm.

• Contact any authorized Toyota

retailer or Toyota authorized

repairer, or any reliable repairer if

you are unable to put the tyre

back in operation.

• Foreign bodies that have pene-

trated the tyre should remain

inside the tyre. Only remove for-

eign objects if they are visibly

protruding from the tyre.

• Remove the speed limit sticker

from the sealant container and

attach to the steering wheel.

• Using sealants can damage the

TPM wheel electronics. In this

case, have the electronics

replaced at the next opportunity.

• The compressor can be used to

Label

Remedying flat tyres

Safety measures

Mobility System

Principle

General

Page 302 of 498

3005-1. MOBILITY

check the tyre inflation pressure.

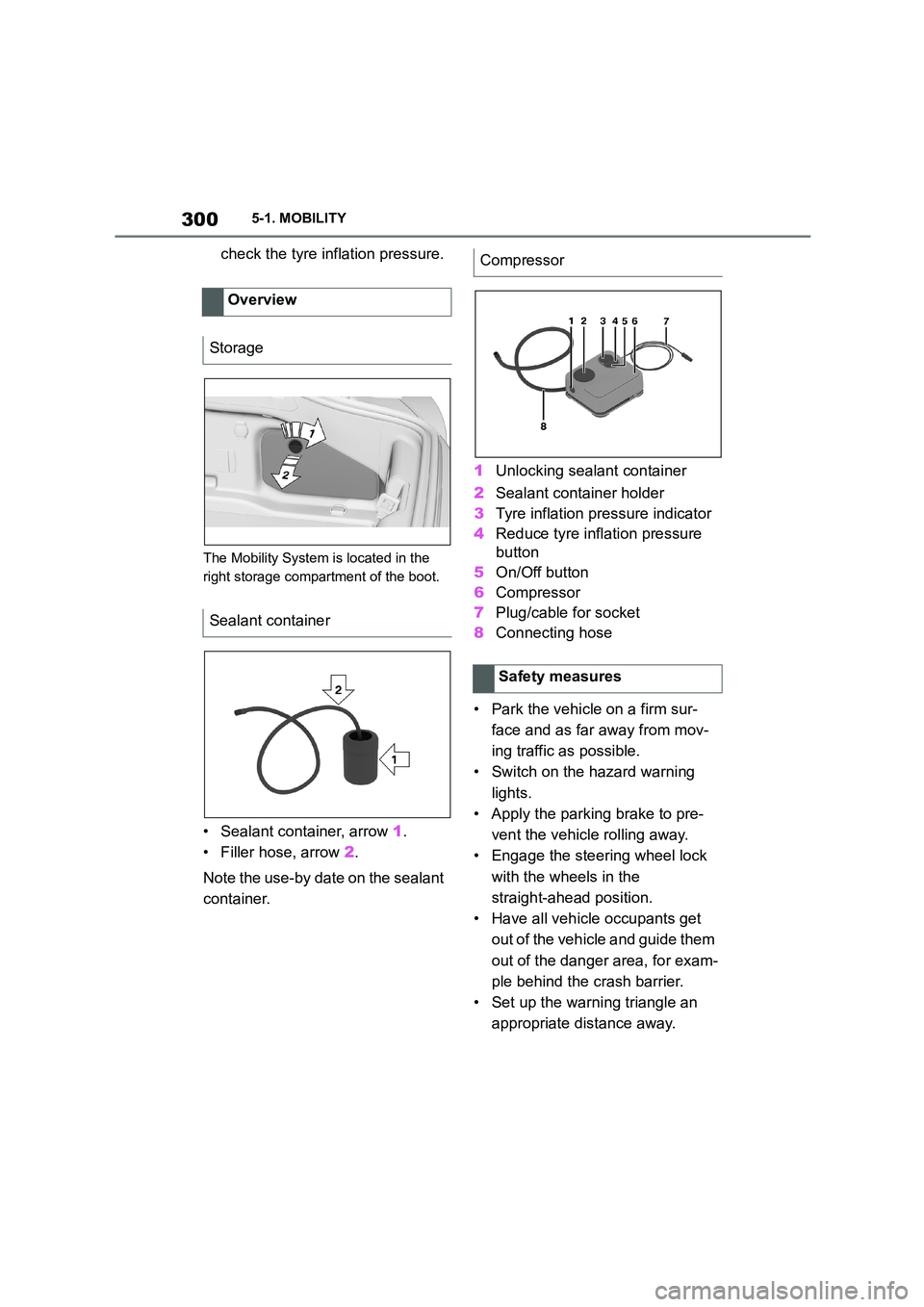

The Mobility System is located in the

right storage compartment of the boot.

• Sealant container, arrow 1.

• Filler hose, arrow 2.

Note the use-by date on the sealant

container.

1 Unlocking sealant container

2 Sealant container holder

3 Tyre inflation pressure indicator

4 Reduce tyre inflation pressure

button

5 On/Off button

6 Compressor

7 Plug/cable for socket

8 Connecting hose

• Park the vehicle on a firm sur-

face and as far away from mov-

ing traffic as possible.

• Switch on the hazard warning

lights.

• Apply the parking brake to pre-

vent the vehicle rolling away.

• Engage the steering wheel lock

with the wheels in the

straight-ahead position.

• Have all vehicle occupants get

out of the vehicle and guide them

out of the danger area, for exam-

ple behind the crash barrier.

• Set up the warning triangle an

appropriate distance away.

Overview

Storage

Sealant container

Compressor

Safety measures

Page 303 of 498

301

5

5-1. MOBILITY

MOBILITY

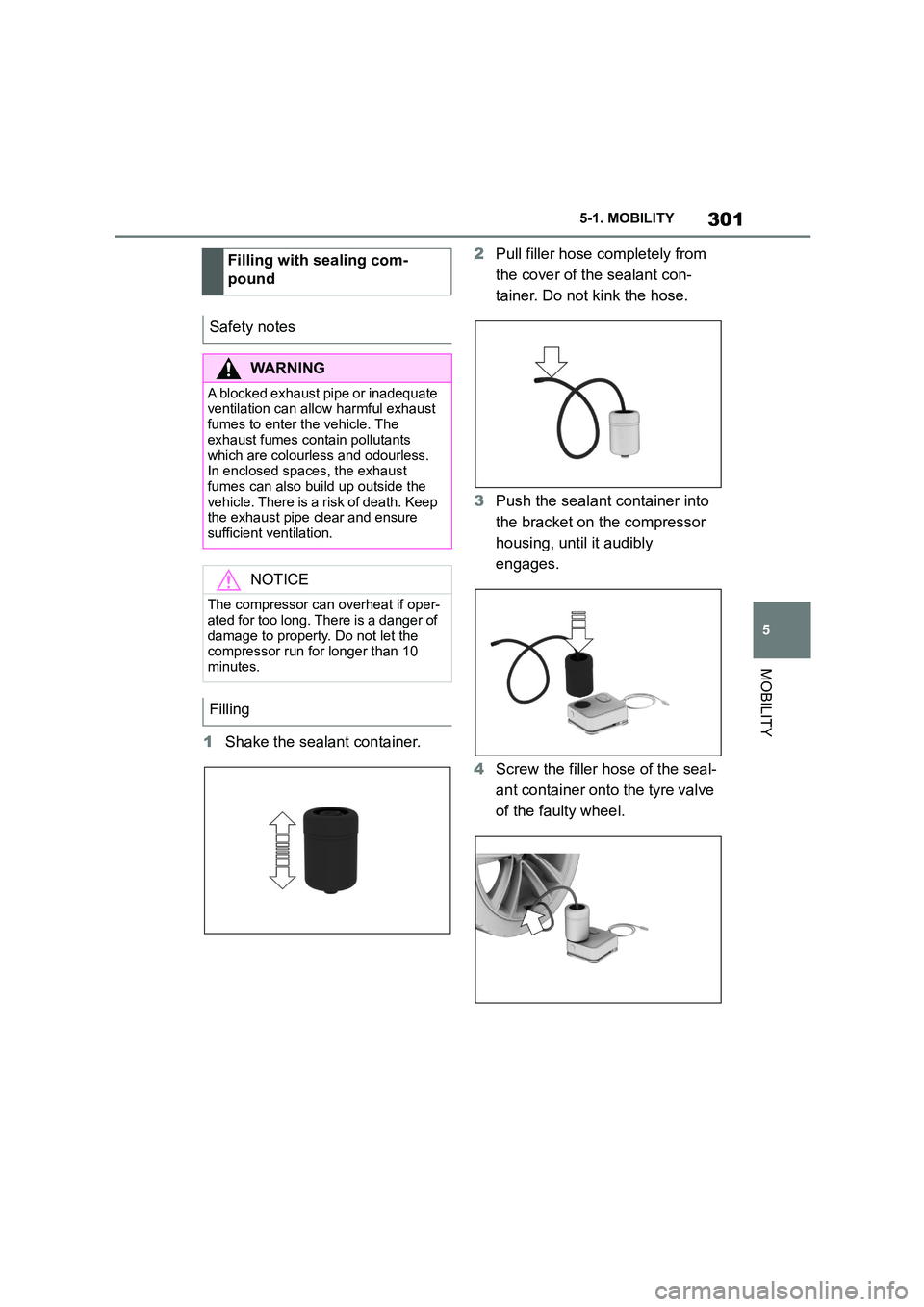

1 Shake the sealant container.

2 Pull filler hose completely from

the cover of the sealant con-

tainer. Do not kink the hose.

3 Push the sealant container into

the bracket on the compressor

housing, until it audibly

engages.

4 Screw the filler hose of the seal-

ant container onto the tyre valve

of the faulty wheel.

Filling with sealing com-

pound

Safety notes

WA R N I N G

A blocked exhaust pipe or inadequate ventilation can allow harmful exhaust

fumes to enter the vehicle. The

exhaust fumes contain pollutants

which are colourless and odourless. In enclosed spaces, the exhaust

fumes can also build up outside the

vehicle. There is a risk of death. Keep the exhaust pipe clear and ensure

sufficient ventilation.

NOTICE

The compressor can overheat if oper-

ated for too long. There is a danger of

damage to property. Do not let the compressor run for longer than 10

minutes.

Filling

Page 304 of 498

3025-1. MOBILITY

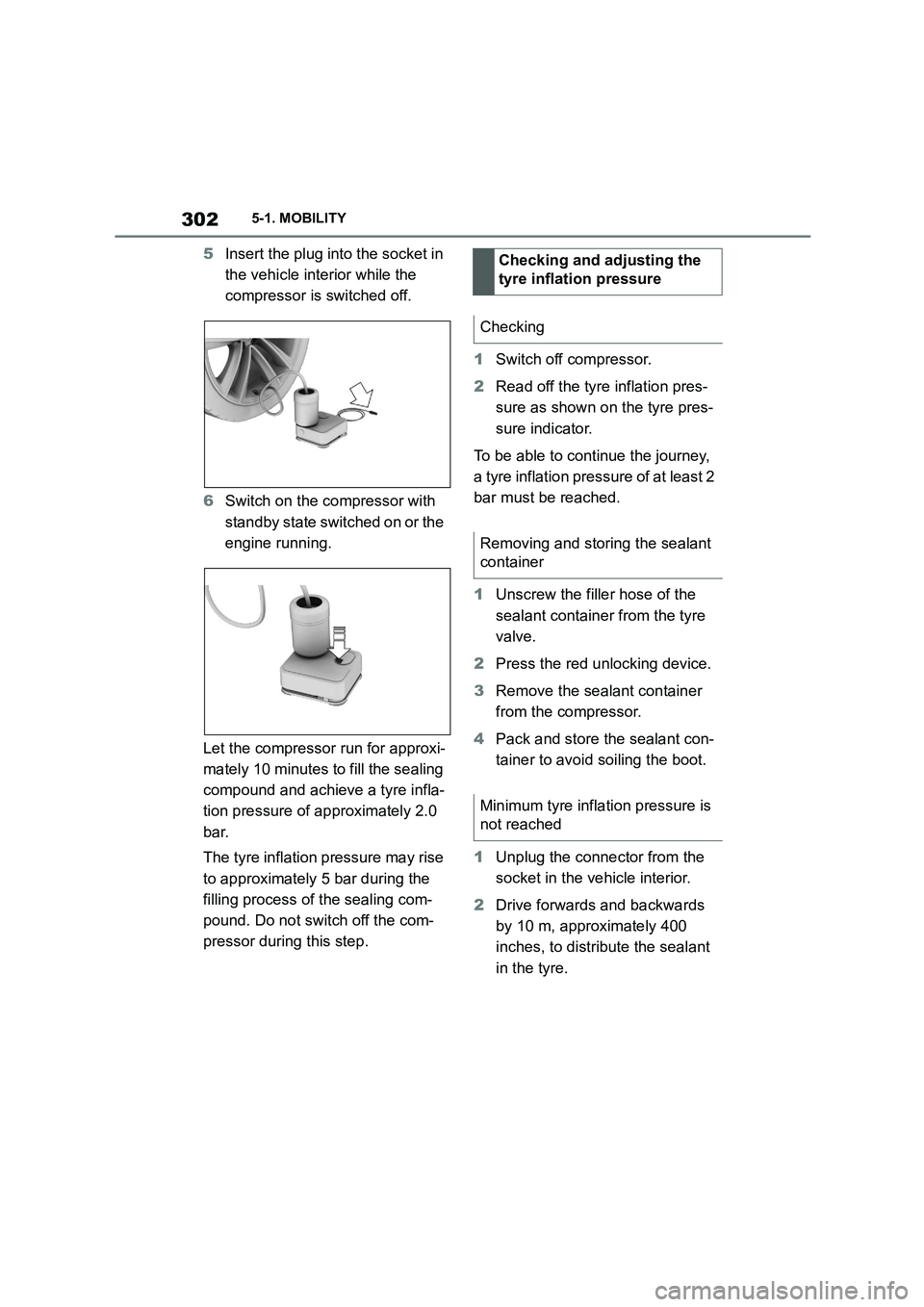

5Insert the plug into the socket in

the vehicle interior while the

compressor is switched off.

6 Switch on the compressor with

standby state switched on or the

engine running.

Let the compressor run for approxi-

mately 10 minutes to fill the sealing

compound and achieve a tyre infla-

tion pressure of approximately 2.0

bar.

The tyre inflation pressure may rise

to approximately 5 bar during the

filling process of the sealing com-

pound. Do not switch off the com-

pressor during this step.

1 Switch off compressor.

2 Read off the tyre inflation pres-

sure as shown on the tyre pres-

sure indicator.

To be able to continue the journey,

a tyre inflation pressure of at least 2

bar must be reached.

1 Unscrew the filler hose of the

sealant container from the tyre

valve.

2 Press the red unlocking device.

3 Remove the sealant container

from the compressor.

4 Pack and store the sealant con-

tainer to avoid soiling the boot.

1 Unplug the connector from the

socket in the vehicle interior.

2 Drive forwards and backwards

by 10 m, approximately 400

inches, to distribute the sealant

in the tyre.

Checking and adjusting the

tyre inflation pressure

Checking

Removing and storing the sealant

container

Minimum tyre inflation pressure is

not reached

Page 315 of 498

313

5

5-1. MOBILITY

MOBILITY

any reliable repairer.

For run-flat tyres or when using a

flat tyre kit, it is not always neces-

sary to change a wheel immedi-

ately if tyre inflatio n pressure is lost

due to a flat tyre.

If required, the tools for changing

wheels are available as special

accessories from any authorized

Toyota retailer or Toyota authorized

repairer, or any reliable repairer.

Wheel change

General

Safety notes

WA R N I N G

The jack is only intended for raising

the vehicle briefly during a wheel

change. Even if the safety measures are complied with, there is a risk of

the raised vehicle falling over due to

the jack slipping. There is a danger of injury or even death. If the vehicle is

raised with the jack, do not lie under-

neath the vehicle and do not start the engine.

WA R N I N G

Supports such as wooden blocks

under the vehicle jack can prevent it from achieving its load capacity due

to the restricted height. The load

capacity of the wooden blocks may be exceeded, causing the vehicle to tip

over. There is a danger of injury or

even death. Do not place supports under the vehicle jack.

WA R N I N G

The jack, issued by the vehicle manu-

facturer, is provided in order to per-

form a wheel change in the event of a breakdown. The jack is not designed

for frequent use; for example, chang-

ing from summer to winter tyres. Using the jack frequently may cause it

to become jammed or damaged.

There is a danger of injury and dam-

age to property. Only use the jack to change an emergency wheel or a

spare wheel in the event of a flat tyre.

WA R N I N G

On soft, uneven or slippery ground,

for example, snow, ice, tiles or similar,

the jack may slip. There is a danger of injury. Perform the wheel change on a

level, firm and non-slip surface if at all

possible.

WA R N I N G

The jack is only optimised for raising

the vehicle and for use with the jack-

ing points on the vehicle. There is a danger of injury. Do not lift another

vehicle or other items with the jack.

WA R N I N G

If the jack has not been guided into the jacking point provided, the vehicle

might be damaged when the jack is

extended, or the jack could slip. There is a danger of injury or damage to

property. When extending, make sure

that the jack is guided into the jacking point adjacent to the wheelhouse.

Page 316 of 498

3145-1. MOBILITY

The vehicle manufacturer recom-

mends that the vehicle should addi-

tionally be protec ted against rolling

away during a wheel change.

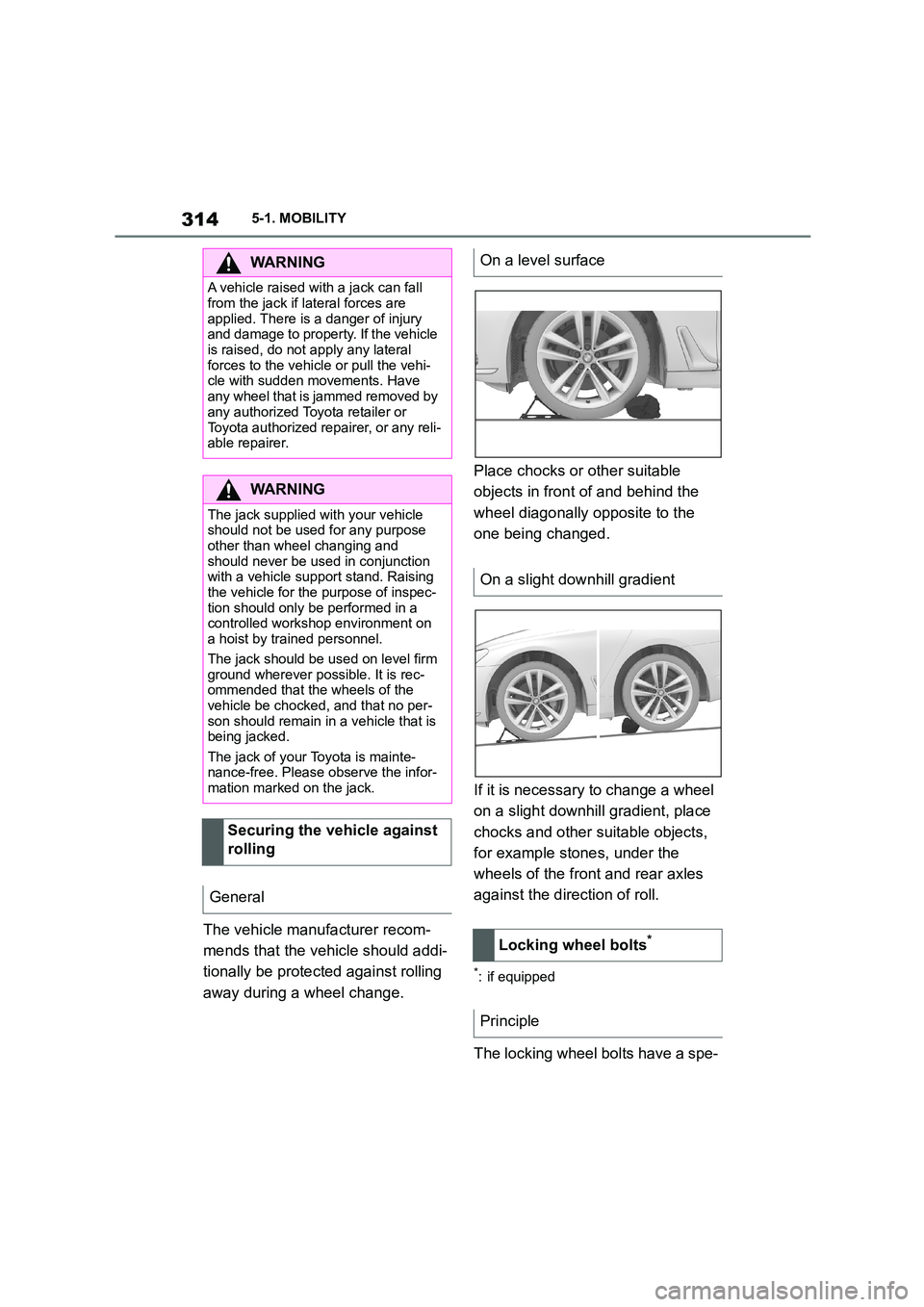

Place chocks or other suitable

objects in front of and behind the

wheel diagonally opposite to the

one being changed.

If it is necessary to change a wheel

on a slight downh ill gradient, place

chocks and other suitable objects,

for example stones, under the

wheels of the front and rear axles

against the direction of roll.

*: if equipped

The locking wheel bolts have a spe-

WA R N I N G

A vehicle raised with a jack can fall

from the jack if lateral forces are

applied. There is a danger of injury and damage to property. If the vehicle

is raised, do not apply any lateral

forces to the vehicle or pull the vehi- cle with sudden movements. Have

any wheel that is jammed removed by

any authorized Toyota retailer or

Toyota authorized repairer, or any reli- able repairer.

WA R N I N G

The jack supplied with your vehicle should not be used for any purpose

other than wheel changing and

should never be used in conjunction with a vehicle support stand. Raising

the vehicle for the purpose of inspec-

tion should only be performed in a controlled workshop environment on

a hoist by trained personnel.

The jack should be used on level firm ground wherever possible. It is rec-

ommended that the wheels of the

vehicle be chocked, and that no per-

son should remain in a vehicle that is being jacked.

The jack of your Toyota is mainte-

nance-free. Please observe the infor- mation marked on the jack.

Securing the vehicle against

rolling

General

On a level surface

On a slight downhill gradient

Locking wheel bolts*

Principle

Page 317 of 498

315

5

5-1. MOBILITY

MOBILITY

cial coding. The bolts can only be

released with the adapter that

matches the coding.

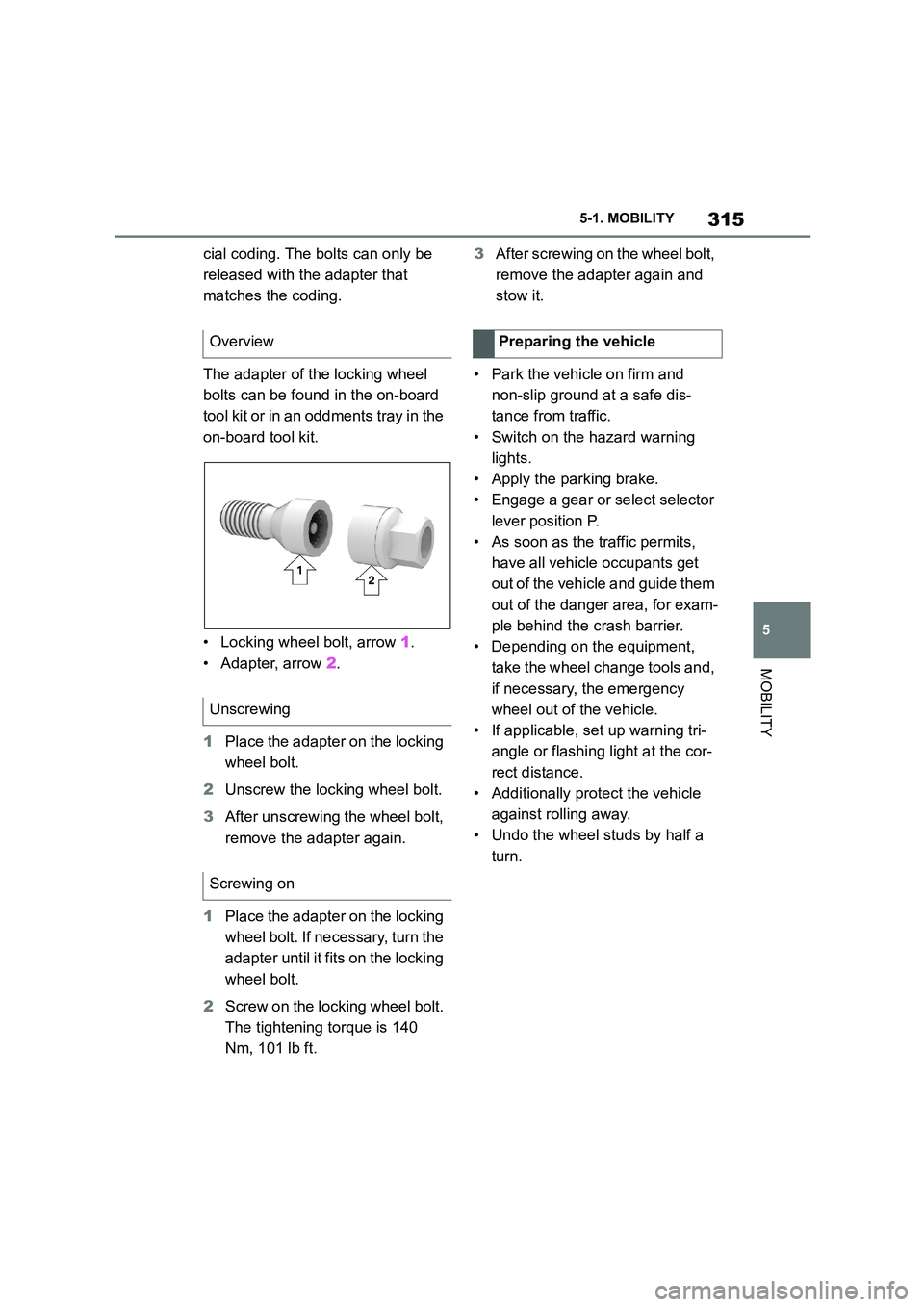

The adapter of the locking wheel

bolts can be found in the on-board

tool kit or in an oddments tray in the

on-board tool kit.

• Locking wheel bolt, arrow 1.

• Adapter, arrow 2.

1 Place the adapter on the locking

wheel bolt.

2 Unscrew the locking wheel bolt.

3 After unscrewing the wheel bolt,

remove the adapter again.

1 Place the adapter on the locking

wheel bolt. If necessary, turn the

adapter until it fi ts on the locking

wheel bolt.

2 Screw on the locking wheel bolt.

The tightening torque is 140

Nm, 101 lb ft.

3 After screwing on the wheel bolt,

remove the adapter again and

stow it.

• Park the vehicle on firm and

non-slip ground at a safe dis-

tance from traffic.

• Switch on the hazard warning

lights.

• Apply the parking brake.

• Engage a gear or select selector

lever position P.

• As soon as the traffic permits,

have all vehicle occupants get

out of the vehicle and guide them

out of the danger area, for exam-

ple behind the crash barrier.

• Depending on the equipment,

take the wheel change tools and,

if necessary, the emergency

wheel out of the vehicle.

• If applicable, set up warning tri-

angle or flashing light at the cor-

rect distance.

• Additionally protect the vehicle

against rolling away.

• Undo the wheel studs by half a

turn.

Overview

Unscrewing

Screwing on

Preparing the vehicle

Page 318 of 498

3165-1. MOBILITY

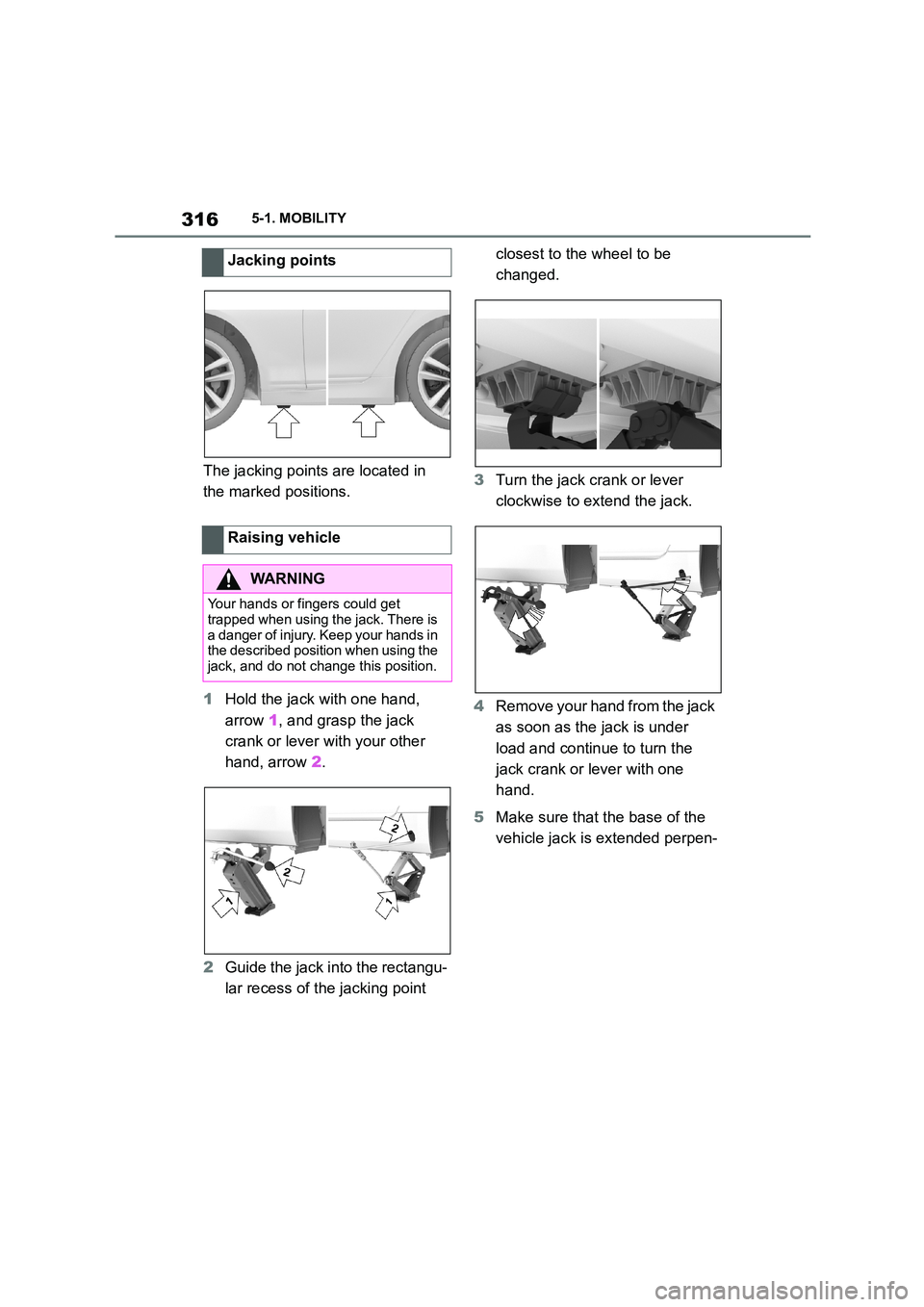

The jacking points are located in

the marked positions.

1 Hold the jack with one hand,

arrow 1, and grasp the jack

crank or lever with your other

hand, arrow 2.

2 Guide the jack into the rectangu-

lar recess of the jacking point

closest to the wheel to be

changed.

3 Turn the jack crank or lever

clockwise to extend the jack.

4 Remove your hand from the jack

as soon as the jack is under

load and continue to turn the

jack crank or lever with one

hand.

5 Make sure that the base of the

vehicle jack is extended perpen-

Jacking points

Raising vehicle

WA R N I N G

Your hands or fingers could get

trapped when using the jack. There is a danger of injury. Keep your hands in

the described position when using the

jack, and do not change this position.