YAMAHA RHINO 700 2013 Owners Manual

RHINO 700 2013

YAMAHA

YAMAHA

https://www.carmanualsonline.info/img/51/51183/w960_51183-0.png

YAMAHA RHINO 700 2013 Owners Manual

Trending: low oil pressure, fuel cap release, warning light, high beam, run flat, coolant temperature, bulb

Page 131 of 188

8-18

9. Install the final gear case guard by install-ing the bolts and the collars, and then

tightening the bolts to the specified

torque.

5B410014Differential gear oil

Checking the differential gear oil level1. Park the vehicle on a level surface.

2. Remove the differential gear oil filler bolt and its gasket, and then check the oil lev-

el. It should be up to the brim of the filler

hole.

3. If the level is low, add sufficient oil of the

recommended type to raise it to the spec-

ified level. NOTICE: Be sure no foreign

material enters the differential gear

case.

Tightening torque:

Final gear case guard bolt: 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

1RB7A_EE.book Page 18 Tuesday, April 24, 2012 9:07 AM

Page 132 of 188

8-19

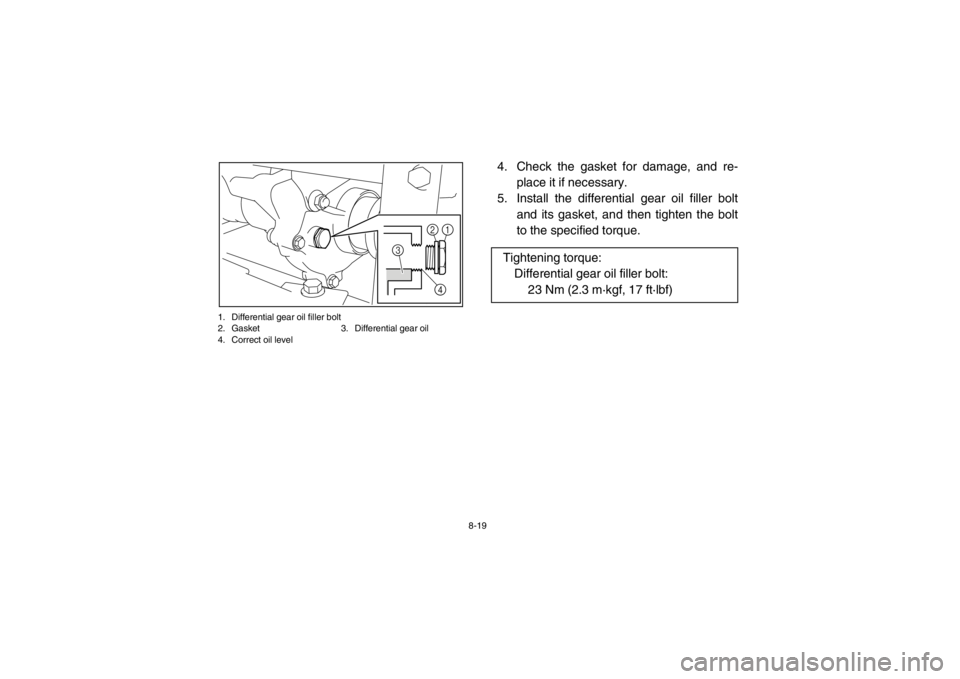

1. Differential gear oil filler bolt

2. Gasket 3. Differential gear oil

4. Correct oil level

4. Check the gasket for damage, and re-

place it if necessary.

5. Install the differential gear oil filler bolt

and its gasket, and then tighten the bolt

to the specified torque.

1

2

3

4

Tightening torque:Differential gear oil filler bolt:

23 Nm (2.3 m·kgf, 17 ft·lbf)

1RB7A_EE.book Page 19 Tuesday, April 24, 2012 9:07 AM

Page 133 of 188

8-20

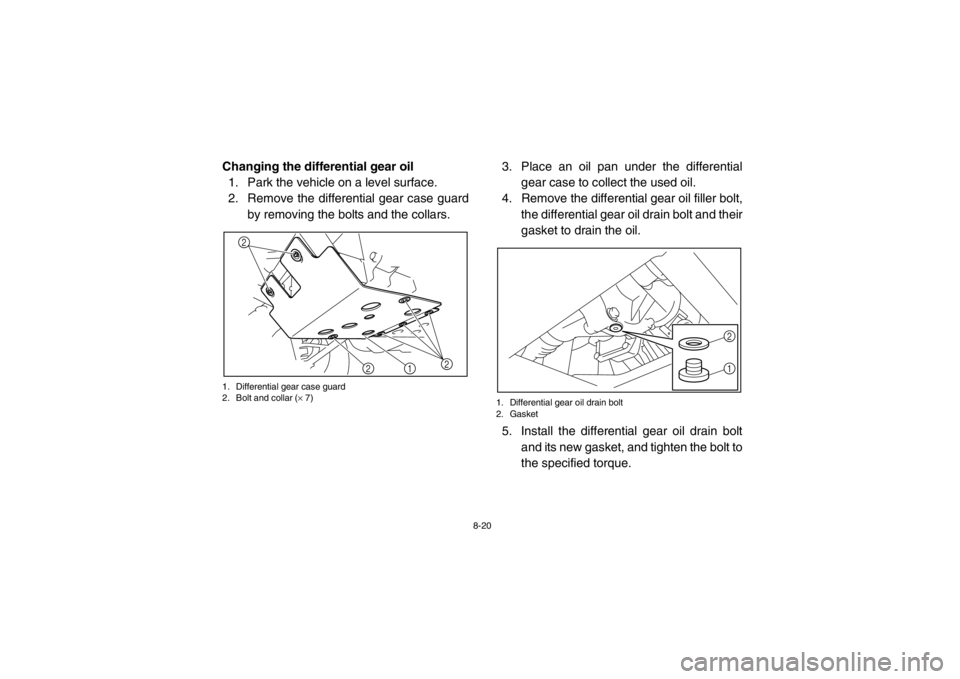

Changing the differential gear oil1. Park the vehicle on a level surface.

2. Remove the differential gear case guard by removing the bolts and the collars.1. Differential gear case guard

2. Bolt and collar ( × 7)

3. Place an oil pan under the differential

gear case to collect the used oil.

4. Remove the differential gear oil filler bolt,

the differential gear oil drain bolt and their

gasket to drain the oil.1. Differential gear oil drain bolt

2. Gasket5. Install the differential gear oil drain boltand its new gasket, and tighten the bolt to

the specified torque.

1

2

2 2

12

1RB7A_EE.book Page 20 Tuesday, April 24, 2012 9:07 AM

Page 134 of 188

8-21

6. Refill the differential gear case with therecommended oil. NOTICE: Be sure no

foreign material enters the differential

gear case.

7. Check the oil filler bolt gasket for dam- age, and replace it if necessary.

8. Install the differential gear oil filler bolt

and its gasket, and then tighten the bolt

to the specified torque. 9. Check for oil leakage. If oil leakage is

found, check for the cause.

10. Install the differential gear case guard by

installing the bolts and the collars, and

then tightening the bolts to the specified

torque.

Tightening torque:

Differential gear oil drain bolt: 9.8 Nm (0.98 m·kgf, 7.1 ft·lbf)

Recommended oil: SAE 80 API GL-4 Hypoid gear oil

Oil quantity: 0.18 L (0.19 US qt, 0.16 Imp.qt)

Tightening torque: Differential gear oil filler bolt:

23 Nm (2.3 m·kgf, 17 ft·lbf)

Tightening torque:Differential gear case guard bolt: 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

1RB7A_EE.book Page 21 Tuesday, April 24, 2012 9:07 AM

Page 135 of 188

8-22

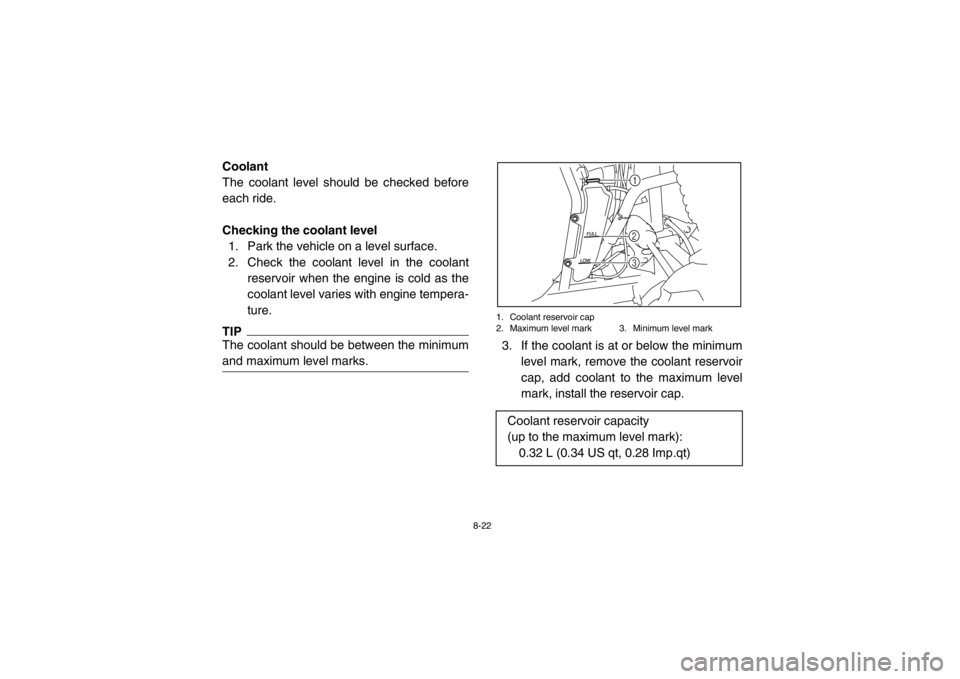

5B410015Coolant

The coolant level should be checked before

each ride.

Checking the coolant level1. Park the vehicle on a level surface.

2. Check the coolant level in the coolant

reservoir when the engine is cold as the

coolant level varies with engine tempera-

ture. TIPThe coolant should be between the minimum

and maximum level marks.

1. Coolant reservoir cap

2. Maximum level mark 3. Minimum level mark3. If the coolant is at or below the minimum level mark, remove the coolant reservoir

cap, add coolant to the maximum level

mark, install the reservoir cap.

Coolant reservoir capacity

(up to the maximum level mark): 0.32 L (0.34 US qt, 0.28 Imp.qt)

1

2

3

1RB7A_EE.book Page 22 Tuesday, April 24, 2012 9:07 AM

Page 136 of 188

8-23

Changing the coolant

The coolant must be changed by a Yamaha

dealer at the intervals specified in the periodic

maintenance and lubrication chart.

Adding water instead of coolant lowers the

antifreeze content of the coolant. If water is

used instead of coolant, have a Yamaha deal-

er check the antifreeze content of the coolant

as soon as possible.

The radiator fan is automatically switched on

or off according to the coolant temperature in

the radiator.NOTICEMix antifreeze with distilled water only.

However, if distilled water is not available,

soft water may be used for refilling.If your vehicle overheats, see page 8-63 for

instructions.

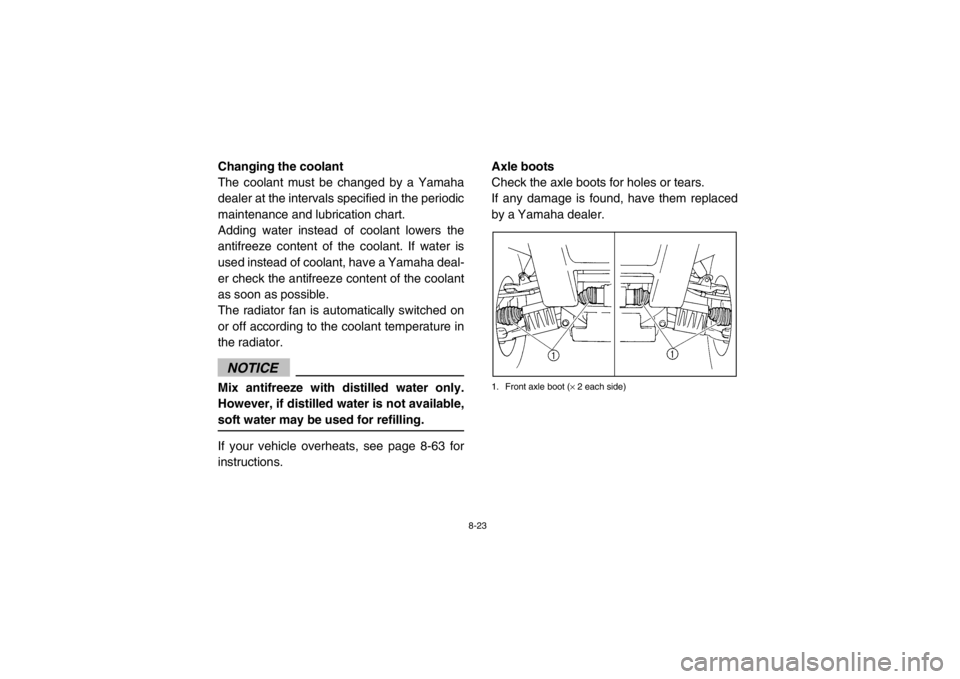

EVU00740Axle boots

Check the axle boots for holes or tears.

If any damage is found, have them replaced

by a Yamaha dealer.1. Front axle boot (× 2 each side)

1RB7A_EE.book Page 23 Tuesday, April 24, 2012 9:07 AM

Page 137 of 188

8-24

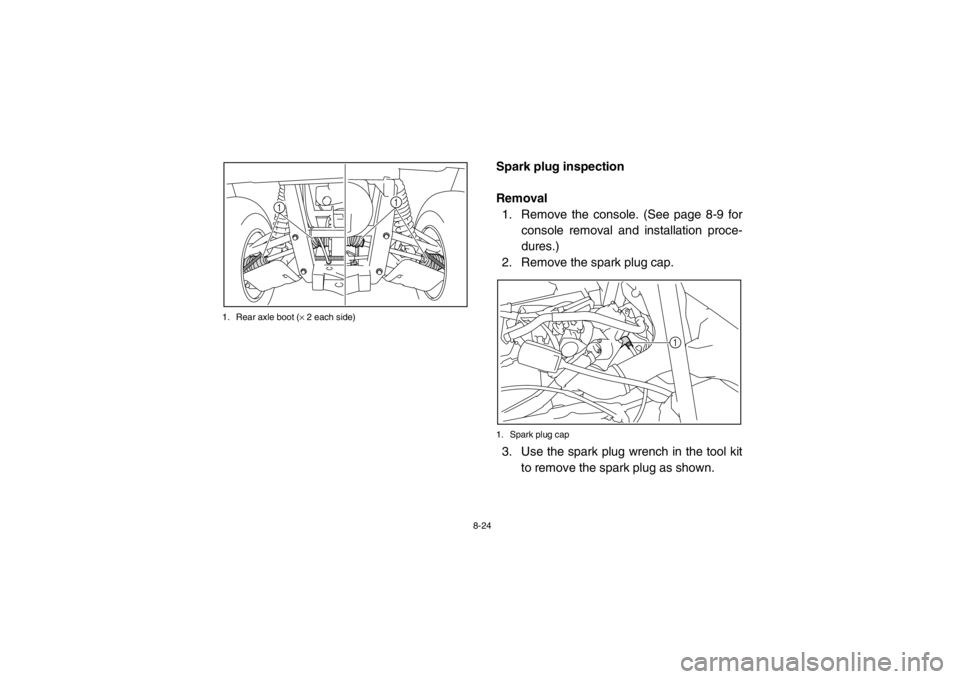

1. Rear axle boot (

× 2 each side)

EVU00750Spark plug inspection

Removal

1. Remove the console. (See page 8-9 for console removal and installation proce-

dures.)

2. Remove the spark plug cap.1. Spark plug cap3. Use the spark plug wrench in the tool kit to remove the spark plug as shown.

1

1

1

1RB7A_EE.book Page 24 Tuesday, April 24, 2012 9:07 AM

Page 138 of 188

8-25

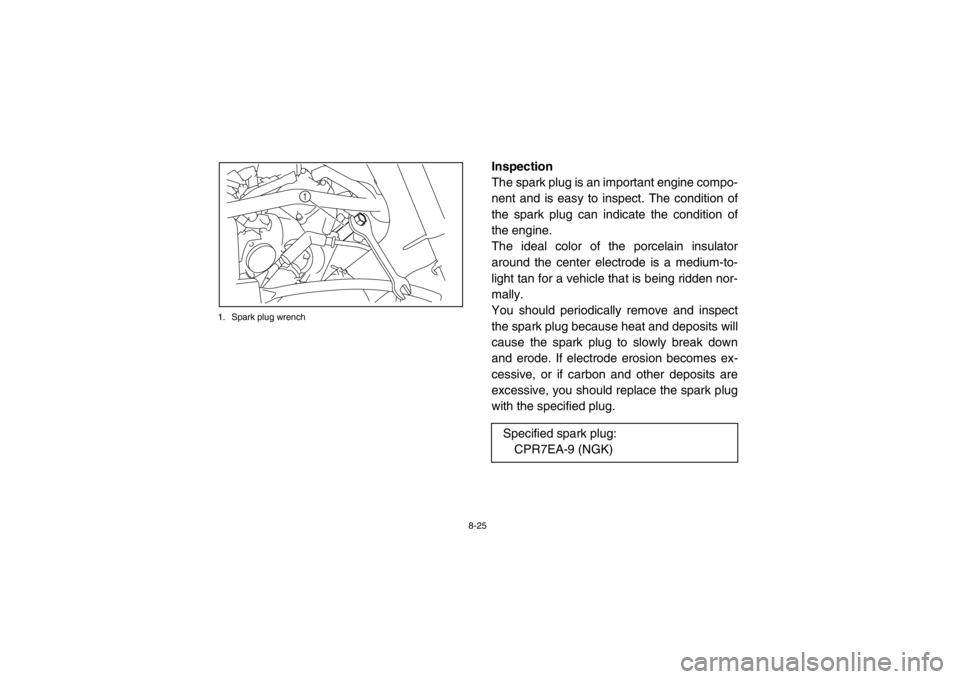

1. Spark plug wrench

Inspection

The spark plug is an important engine compo-

nent and is easy to inspect. The condition of

the spark plug can indicate the condition of

the engine.

The ideal color of the porcelain insulator

around the center electrode is a medium-to-

light tan for a vehicle that is being ridden nor-

mally.

You should periodically remove and inspect

the spark plug because heat and deposits will

cause the spark plug to slowly break down

and erode. If electrode erosion becomes ex-

cessive, or if carbon and other deposits are

excessive, you should replace the spark plug

with the specified plug.

1

Specified spark plug:

CPR7EA-9 (NGK)

1RB7A_EE.book Page 25 Tuesday, April 24, 2012 9:07 AM

Page 139 of 188

8-26

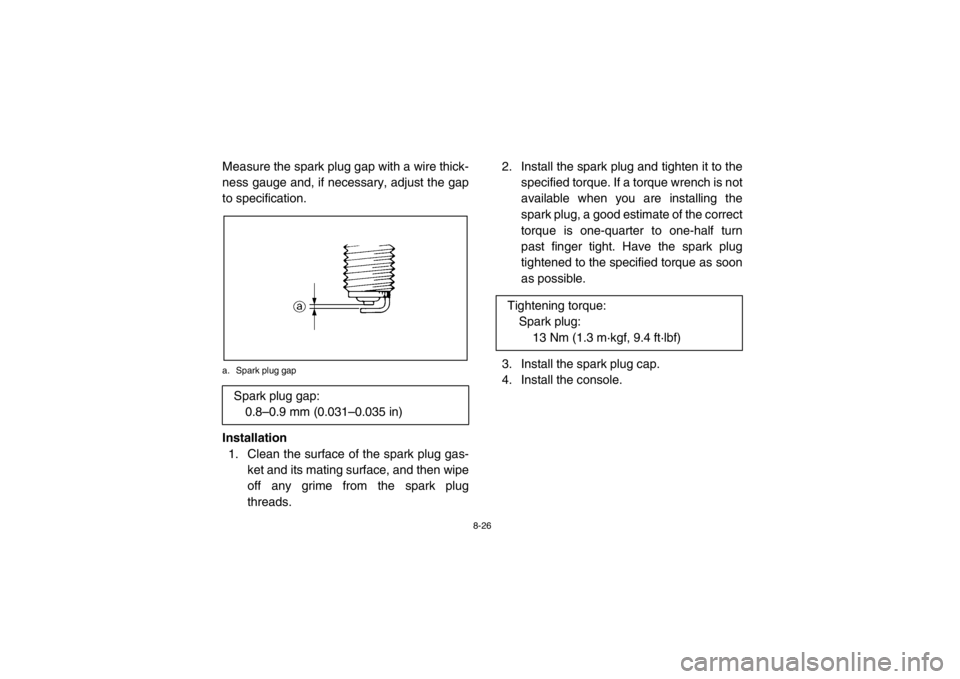

Measure the spark plug gap with a wire thick-

ness gauge and, if necessary, adjust the gap

to specification.a. Spark plug gapInstallation1. Clean the surface of the spark plug gas- ket and its mating surface, and then wipe

off any grime from the spark plug

threads. 2. Install the spark plug and tighten it to the

specified torque. If a torque wrench is not

available when you are installing the

spark plug, a good estimate of the correct

torque is one-quarter to one-half turn

past finger tight. Have the spark plug

tightened to the specified torque as soon

as possible.

3. Install the spark plug cap.

4. Install the console.

Spark plug gap: 0.8–0.9 mm (0.031–0.035 in)

Tightening torque:Spark plug:

13 Nm (1.3 m·kgf, 9.4 ft·lbf)

1RB7A_EE.book Page 26 Tuesday, April 24, 2012 9:07 AM

Page 140 of 188

8-27

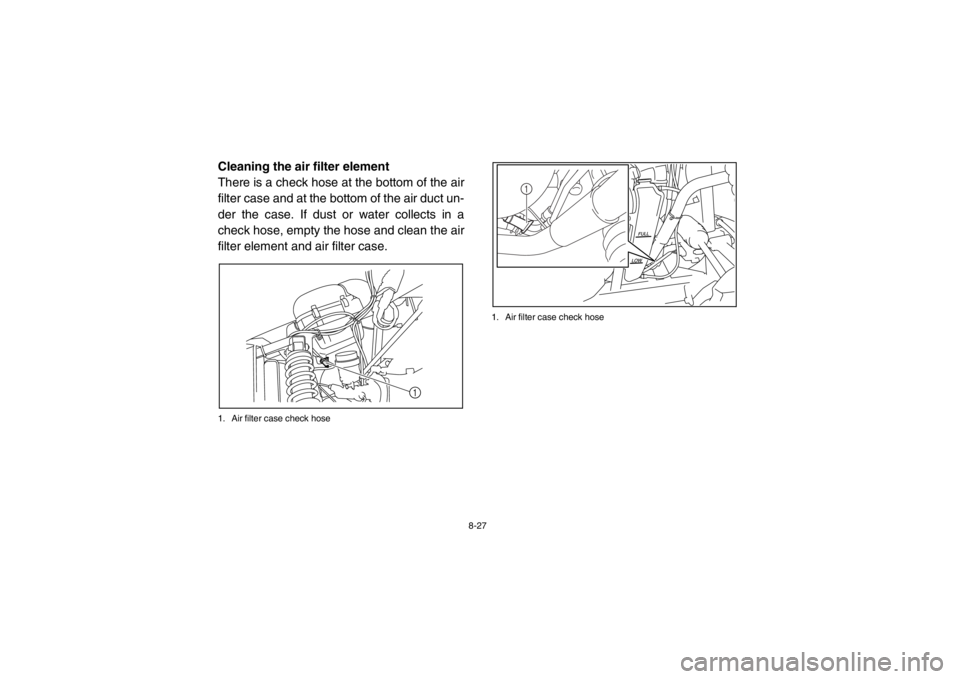

5B410016Cleaning the air filter element

There is a check hose at the bottom of the air

filter case and at the bottom of the air duct un-

der the case. If dust or water collects in a

check hose, empty the hose and clean the air

filter element and air filter case.1. Air filter case check hose1. Air filter case check hose

1

1

1RB7A_EE.book Page 27 Tuesday, April 24, 2012 9:07 AM

Trending: brake pads replacement, key battery, belt, fuel tank capacity, warning lights, spare wheel, fuel cap release