YAMAHA RHINO 700 2013 Workshop Manual

Manufacturer: YAMAHA, Model Year: 2013, Model line: RHINO 700, Model: YAMAHA RHINO 700 2013Pages: 188, PDF Size: 4.9 MB

Page 51 of 188

4-21

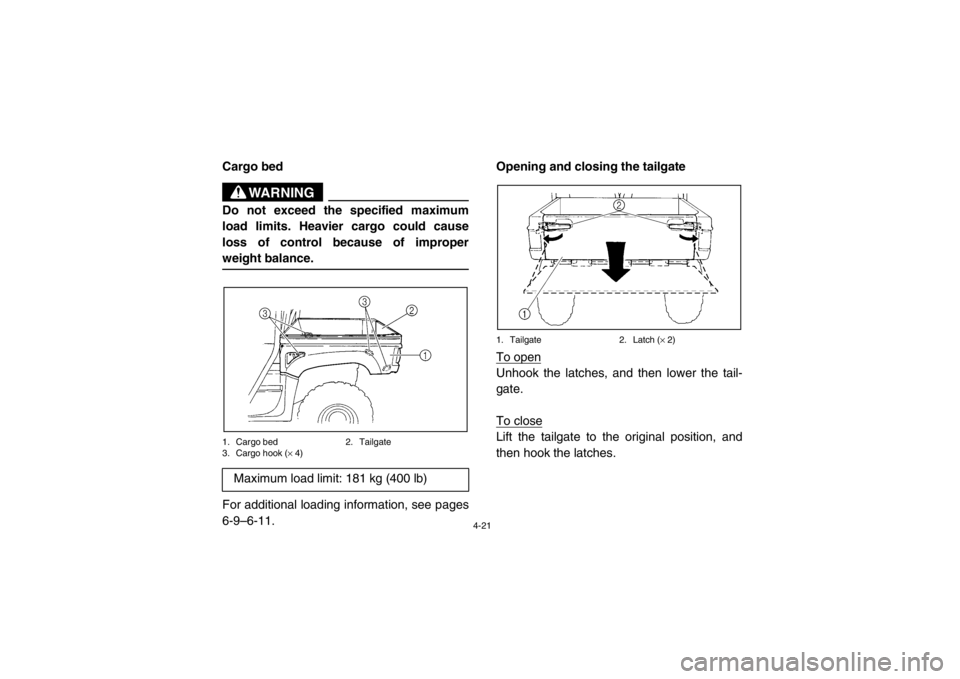

EVU00351Cargo bed

WARNING

Do not exceed the specified maximum

load limits. Heavier cargo could cause

loss of control because of improper

weight balance.1. Cargo bed2. Tailgate

3. Cargo hook ( × 4)For additional loading information, see pages

6-9–6-11. Opening and closing the tailgate

1. Tailgate

2. Latch (× 2)To openUnhook the latches, and then lower the tail-

gate.

To closeLift the tailgate to the original position, and

then hook the latches.

Maximum load limit: 181 kg (400 lb)

1RB7A_EE.book Page 21 Tuesday, April 24, 2012 9:07 AM

Page 52 of 188

4-22

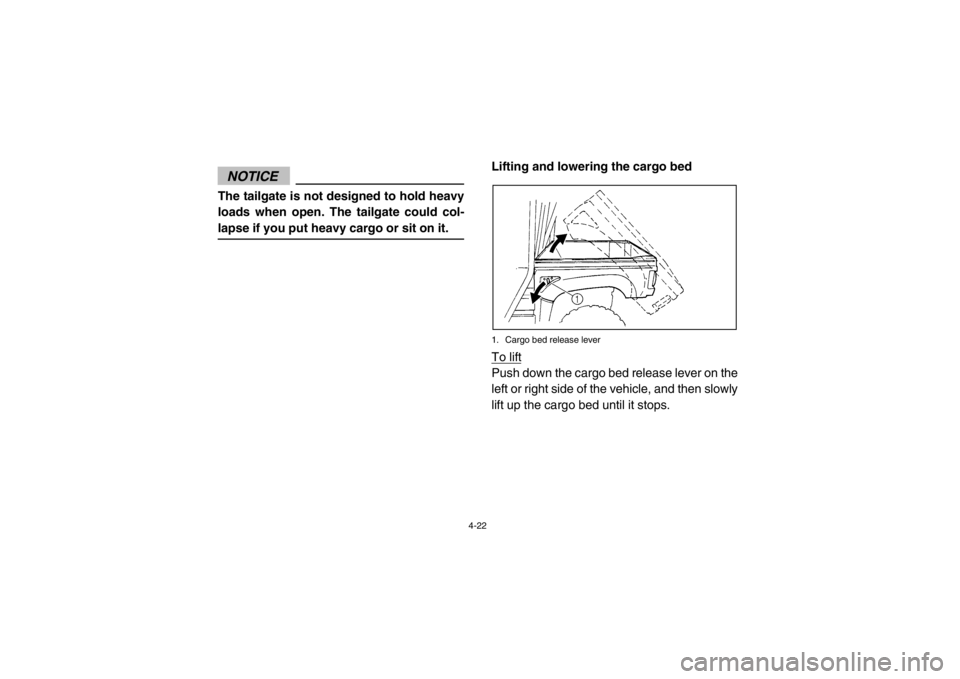

NOTICEThe tailgate is not designed to hold heavy

loads when open. The tailgate could col-

lapse if you put heavy cargo or sit on it.

Lifting and lowering the cargo bed1. Cargo bed release leverTo liftPush down the cargo bed release lever on the

left or right side of the vehicle, and then slowly

lift up the cargo bed until it stops.

1RB7A_EE.book Page 22 Tuesday, April 24, 2012 9:07 AM

Page 53 of 188

4-23

To lowerWith hands and fingers clear of pinch points,

lower the cargo bed slowly to its original posi-

tion and be sure it is locked into place.

WARNING! Keep hands, body, and other

people away from pinch points when low-

ering bed. Do not hold onto the cage/frame

while closing the bed.

5B410006Adjusting the front and rear shock

absorber assemblies

(YXR7FD/YXR700FAD)

WARNING

Always adjust the shock absorbers on the

left and right sides to the same setting. Un-

even adjustment can cause poor handling

and loss of stability, which could lead to

an accident.The spring preload can be adjusted to suit the

operating conditions. You can reduce preload

for a softer ride, or increase preload if frequent

bottoming occurs or when carrying loads.NOTICEFrequent or severe bottoming can cause

increased wear or damage to the vehicle.

1RB7A_EE.book Page 23 Tuesday, April 24, 2012 9:07 AM

Page 54 of 188

4-24

The rear wheels need to be removed to adjust

the rear shock absorber assemblies. (See

pages 8-44–8-46 for wheel removal and in-

stallation procedures.)

Adjust the spring preload as follows:

To increase the spring preload, turn the spring

preload adjusting ring in direction a.

To decrease the spring preload, turn the

spring preload adjusting ring in direction b.

Align the appropriate notch in the adjusting

ring with the position indicator on the shock

absorber.1. Spring preload adjusting ring 2. Position indicator

TIPA special wrench can be obtained at a

Yamaha dealer to make this adjustment.1. Special wrench

Standard position: B A- Minimum (soft)

E- Maximum (hard)

1RB7A_EE.book Page 24 Tuesday, April 24, 2012 9:07 AM

Page 55 of 188

4-25

5UG1B001 Adjusting the front shock absorber

assemblies (YXR7FSPD)

WARNING

These shock absorber assemblies contain

highly pressurized nitrogen gas. Read and

understand the following information be-

fore handling the shock absorber assem-

blies.●

Do not tamper with or attempt to open

the cylinder assemblies.

●

Do not subject the shock absorber as-

semblies to an open flame or other

high heat source. This may cause the

unit to explode due to excessive gas

pressure.

●

Do not deform or damage the cylin-

ders in any way. Cylinder damage will

result in poor damping performance.

●

Do not dispose of a damaged or worn

out shock absorber assembly your-

self. Take the shock absorber assem-

bly to a Yamaha dealer for any

service.

The spring preload, rebound damping and

compression damping forces of the front

shock absorber assemblies can be adjusted

to suit the operating conditions. NOTICENever turn an adjusting mechanism be-

yond the minimum and maximum settings.

1RB7A_EE.book Page 25 Tuesday, April 24, 2012 9:07 AM

Page 56 of 188

4-26

Spring preload1. Loosen the locknut.

2. Turn the spring preload adjusting nut in direction a to increase the spring pre-

load and thereby harden the suspension,

and in direction b to decrease the spring

preload and thereby soften the suspen-

sion.1. Locknut

2. Spring preload adjusting nut

3. Special wrench

TIP●

A special wrench can be obtained at a

Yamaha dealer to make this adjustment.

●

The spring preload setting is determined

by measuring distance A, shown in the il-

lustration. The shorter distance A is, the

lower the spring preload; the longer dis-

tance A is, the higher the spring preload.

With each complete turn of the adjusting

nut, distance A is changed by 1.5 mm

(0.06 in).

1. Distance A

1RB7A_EE.book Page 26 Tuesday, April 24, 2012 9:07 AM

Page 57 of 188

4-27

3. Tighten the locknut to the specifiedtorque.NOTICEAlways tighten the locknut against the ad-

justing nut, and then tighten it to the spec-

ified torque.

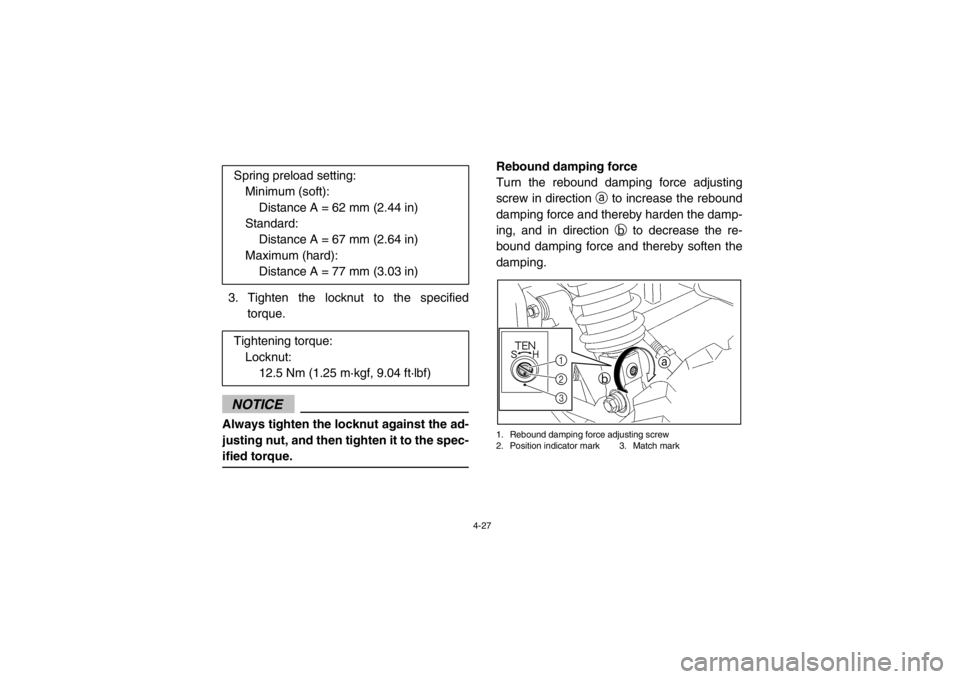

Rebound damping force

Turn the rebound damping force adjusting

screw in direction a to increase the rebound

damping force and thereby harden the damp-

ing, and in direction b to decrease the re-

bound damping force and thereby soften the

damping.1. Rebound damping force adjusting screw

2. Position indicator mark 3. Match mark

Spring preload setting: Minimum (soft):

Distance A = 62 mm (2.44 in)

Standard: Distance A = 67 mm (2.64 in)

Maximum (hard): Distance A = 77 mm (3.03 in)

Tightening torque: Locknut: 12.5 Nm (1.25 m·kgf, 9.04 ft·lbf)

123 b

a

1RB7A_EE.book Page 27 Tuesday, April 24, 2012 9:07 AM

Page 58 of 188

4-28

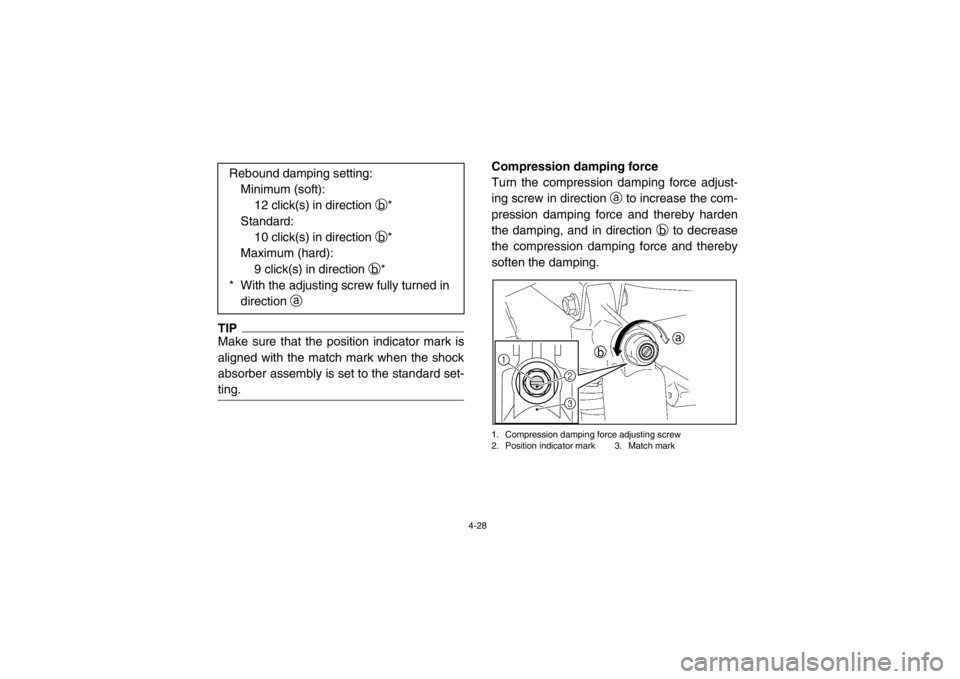

TIPMake sure that the position indicator mark is

aligned with the match mark when the shock

absorber assembly is set to the standard set-

ting.

Compression damping force

Turn the compression damping force adjust-

ing screw in direction a to increase the com-

pression damping force and thereby harden

the damping, and in direction b to decrease

the compression damping force and thereby

soften the damping.1. Compression damping force adjusting screw

2. Position indicator mark 3. Match mark

Rebound damping setting:

Minimum (soft): 12 click(s) in direction b*

Standard: 10 click(s) in direction b*

Maximum (hard):

9 click(s) in direction b*

* With the adjusting screw fully turned in direction a

1

3 2

1RB7A_EE.book Page 28 Tuesday, April 24, 2012 9:07 AM

Page 59 of 188

4-29

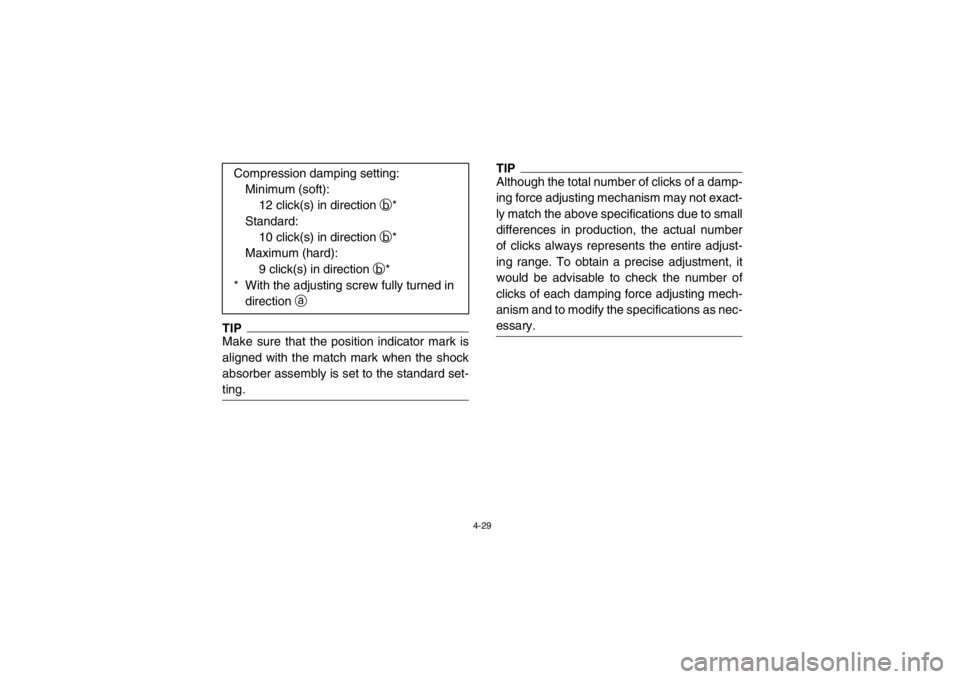

TIPMake sure that the position indicator mark is

aligned with the match mark when the shock

absorber assembly is set to the standard set-

ting.

TIPAlthough the total number of clicks of a damp-

ing force adjusting mechanism may not exact-

ly match the above specifications due to small

differences in production, the actual number

of clicks always represents the entire adjust-

ing range. To obtain a precise adjustment, it

would be advisable to check the number of

clicks of each damping force adjusting mech-

anism and to modify the specifications as nec-

essary.

Compression damping setting:Minimum (soft): 12 click(s) in direction b*

Standard: 10 click(s) in direction b*

Maximum (hard):

9 click(s) in direction b*

* With the adjusting screw fully turned in direction a

1RB7A_EE.book Page 29 Tuesday, April 24, 2012 9:07 AM

Page 60 of 188

4-30

WARNING

●

Suspension components become hot

during operation. Never touch the

compression damping force adjusting

screw, the rebound damping force ad-

justing screw or the oil reservoir with

your bare hand or skin until suspen-

sion components have cooled.

●

Always adjust the shock absorber as-

semblies on the left and right side to

the same setting. Uneven adjustment

can cause poor handling and loss of

stability, which could lead to an acci-

dent.

5UG1B002Adjusting the rear shock absorber

assemblies (YXR7FSPD)

WARNING

These shock absorber assemblies contain

highly pressurized nitrogen gas. Read and

understand the following information be-

fore handling the shock absorber assem-

blies.●

Do not tamper with or attempt to open

the cylinder assemblies.

●

Do not subject the shock absorber as-

semblies to an open flame or other

high heat source. This may cause the

unit to explode due to excessive gas

pressure.

1RB7A_EE.book Page 30 Tuesday, April 24, 2012 9:07 AM