ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 1101 of 1640

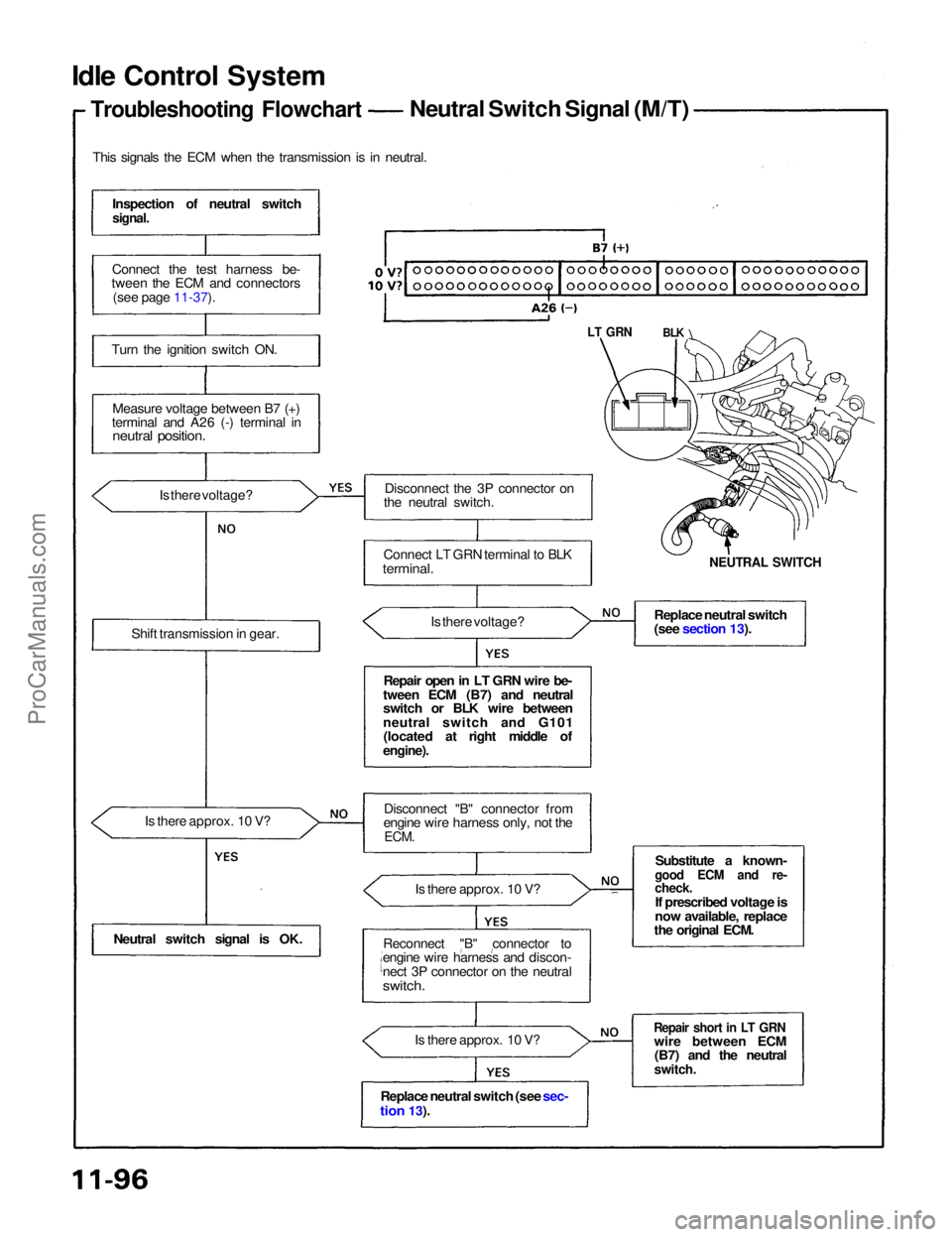

Idle Control System

Troubleshooting Flowchart

Neutral Switch Signal (M/T)

This signals the ECM when the transmission is in neutral.

Inspection of neutral switch

signal.

Connect the test harness be-

tween the ECM and connectors

(see page 11-37).

Turn the ignition switch ON.

Measure voltage between B7 (+)

terminal and A26 (-) terminal in

neutral position.

Is there voltage?

Shift transmission in gear.

Is there approx. 10 V?

Neutral switch signal is OK.

Replace neutral switch (see sec-

tion

13). Is there approx. 10 V?

Reconnect "B" connector to

engine wire harness and discon-

nect 3P connector on the neutral

switch.

Is there approx. 10 V?

Disconnect "B" connector from

engine wire harness only, not the

ECM.

Repair open in LT GRN wire be-

tween ECM (B7) and neutral

switch or BLK wire between

neutral switch and G101 (located at right middle of

engine).

Is there voltage?

Connect LT GRN terminal to BLK

terminal.

Disconnect the 3P connector on

the neutral switch.

Replace neutral switch

(see section 13).

NEUTRAL SWITCH

LT GRN

BLK

Substitute a known-

good ECM and re-

check.

If prescribed voltage is

now available, replace

the original ECM.

Repair short in LT GRN

wire between ECM(B7) and the neutral

switch.ProCarManuals.com

Page 1102 of 1640

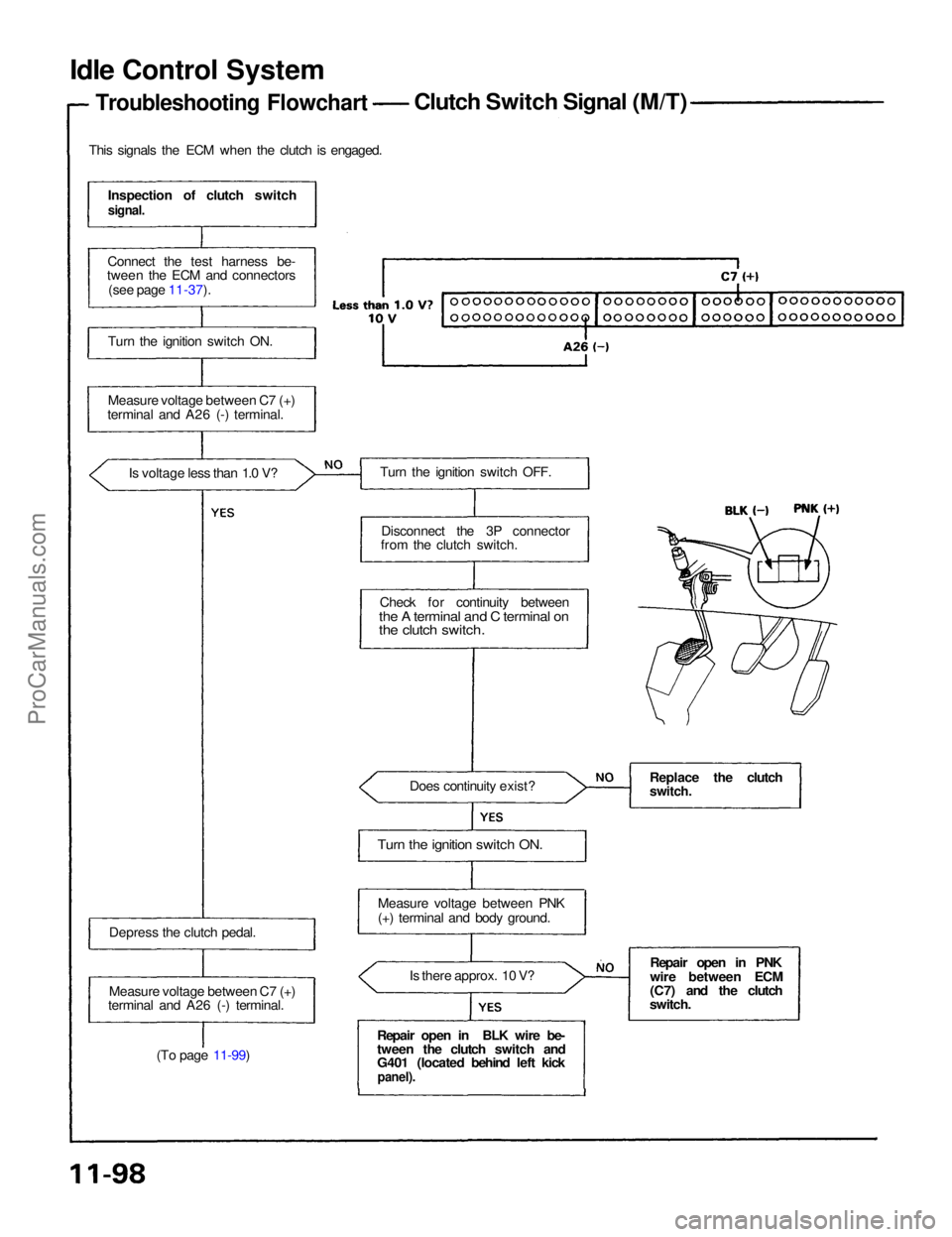

Idle Control System

Troubleshooting Flowchart

Clutch Switch Signal (M/T)

This signals the ECM when the clutch is engaged. Inspection of clutch switch

signal.

Connect the test harness be-

tween the ECM and connectors

(see page 11-37).

Turn the ignition switch ON.

Measure voltage between C7 (+)

terminal and A26 (-) terminal.

Is voltage less than 1.0 V?

Depress the clutch pedal.

Measure voltage between C7 (+)

terminal and A26 (-) terminal.

(To page 11-99) Turn the ignition switch OFF.

Disconnect the 3P connector

from the clutch switch.

Check for continuity between

the A terminal and C terminal on

the clutch switch.

Does continuity exist?

Turn the ignition switch ON.

Measure voltage between PNK

(+) terminal and body ground. Is there approx. 10 V?

Repair open in BLK wire be-

tween the clutch switch and

G401 (located behind left kick

panel).

Replace the clutch

switch.

Repair open in PNK

wire between ECM

(C7) and the clutch

switch.ProCarManuals.com

Page 1103 of 1640

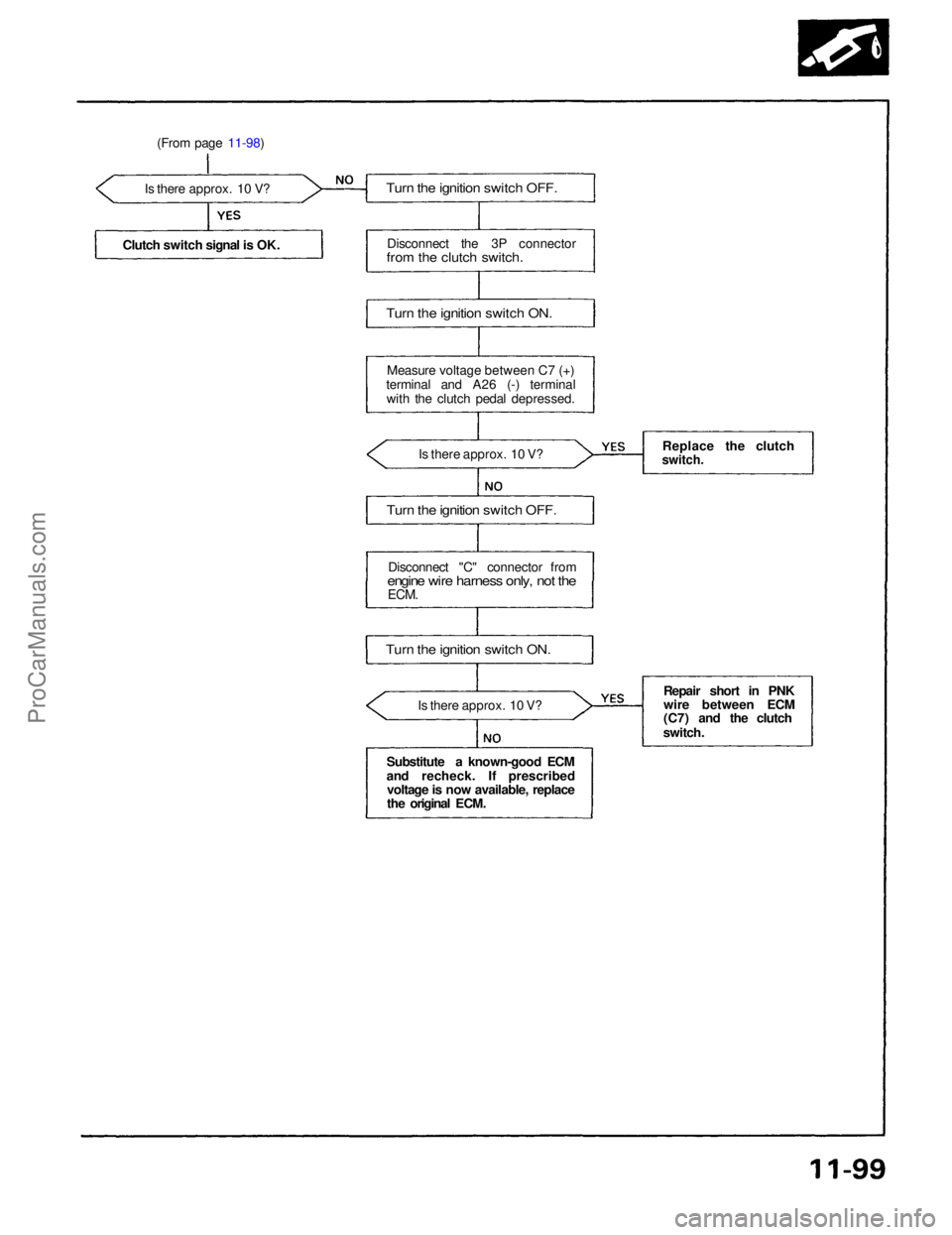

(From page 11-98)

Is there approx. 10 V?

Clutch switch signal is OK.

Turn the ignition switch OFF.

Disconnect the 3P connector

from the clutch switch.

Turn the ignition switch ON.

Measure voltage between C7 (+)

terminal and A26 (-) terminal with the clutch pedal depressed.

Is there approx. 10 V?

Turn the ignition switch OFF.

Disconnect "C" connector from

engine wire harness only, not the

ECM.

Turn the ignition switch ON.

Is there approx. 10 V?

Substitute a known-good ECM

and recheck. If prescribed voltage is now available, replace

the original ECM. Replace the clutch

switch.

Repair short in PNK

wire between ECM

(C7) and the clutch

switch.ProCarManuals.com

Page 1104 of 1640

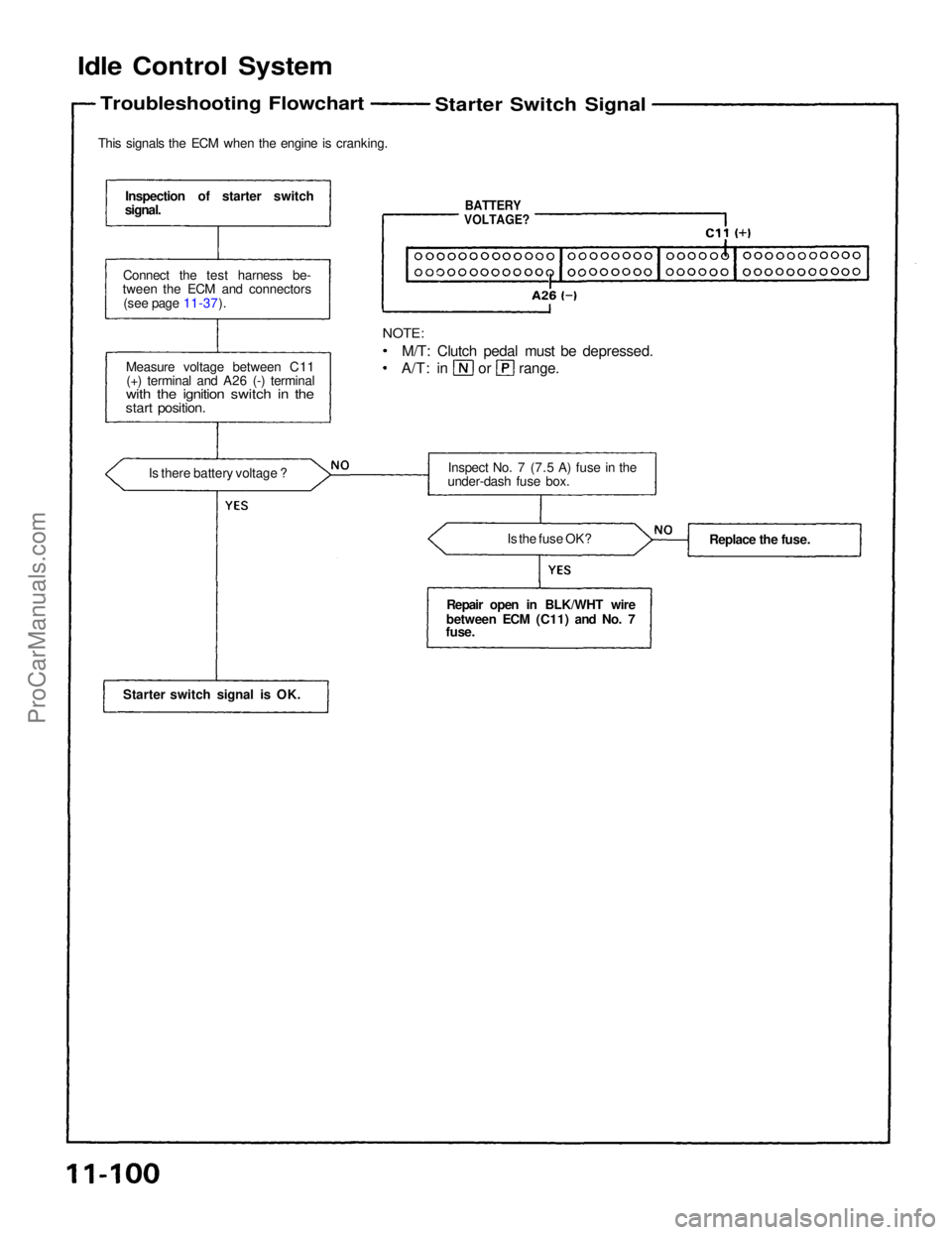

Idle Control System

Troubleshooting Flowchart

This signals the ECM when the engine is cranking.

Inspection of starter switch

signal.

Connect the test harness be-

tween the ECM and connectors

(see page 11-37).

Measure voltage between C11(+) terminal and A26 (-) terminal

with the ignition switch in the

start position.

Is there battery voltage ?

Starter switch signal is OK.

NOTE:

M/T: Clutch pedal must be depressed. A/T: in or range.

Inspect No. 7 (7.5 A) fuse in the

under-dash fuse box.

Is the fuse OK?

Repair open in BLK/WHT wire

between ECM (C11) and No. 7

fuse. Replace the fuse.

Starter Switch Signal

BATTERY

VOLTAGE?ProCarManuals.com

Page 1105 of 1640

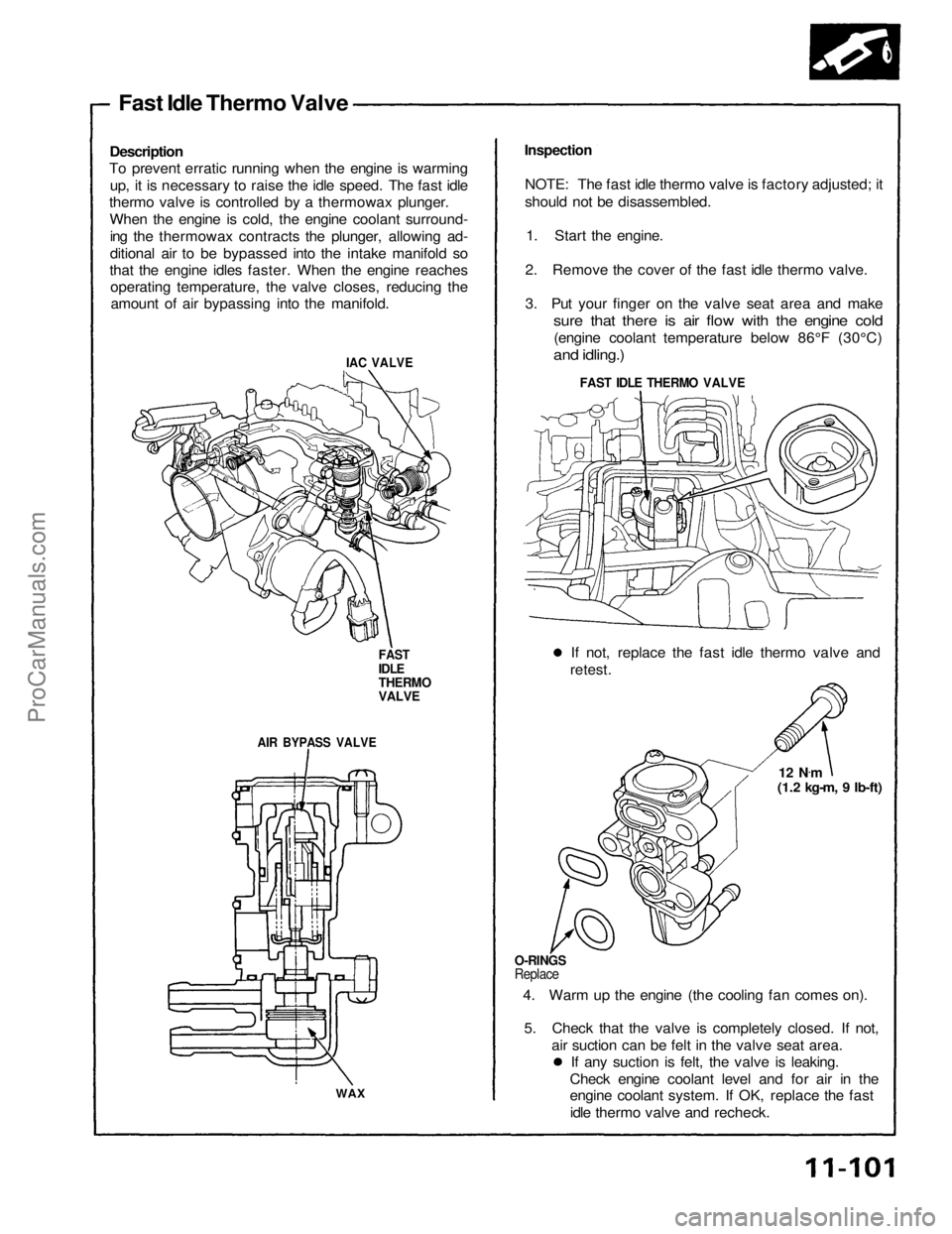

Fast Idle Thermo Valve

Description

To prevent erratic running when the engine is warming

up, it is necessary to raise the idle speed. The fast idle

thermo valve is controlled by a thermowax plunger.

When the engine is cold, the engine coolant surround-ing the thermowax contracts the plunger, allowing ad-

ditional air to be bypassed into the intake manifold so

that the engine idles faster. When the engine reaches operating temperature, the valve closes, reducing theamount of air bypassing into the manifold.

IAC VALVE

FAST

IDLE

THERMO

VALVE

AIR BYPASS VALVE

WAX

Inspection

NOTE: The fast idle thermo valve is factory adjusted; it

should not be disassembled. 1. Start the engine.

2. Remove the cover of the fast idle thermo valve.

3. Put your finger on the valve seat area and make

sure that there is air flow with the engine cold

(engine coolant temperature below 86°F (30°C)

and idling.)

FAST IDLE THERMO VALVE

If not, replace the fast idle thermo valve and

retest.

12 N.

m

(1.2 kg-m, 9 Ib-ft)

O-RINGS

Replace

4. Warm up the engine (the cooling fan comes on).

5. Check that the valve is completely closed. If not, air suction can be felt in the valve seat area.If any suction is felt, the valve is leaking.

Check engine coolant level and for air in the

engine coolant system. If OK, replace the fast idle thermo valve and recheck.ProCarManuals.com

Page 1106 of 1640

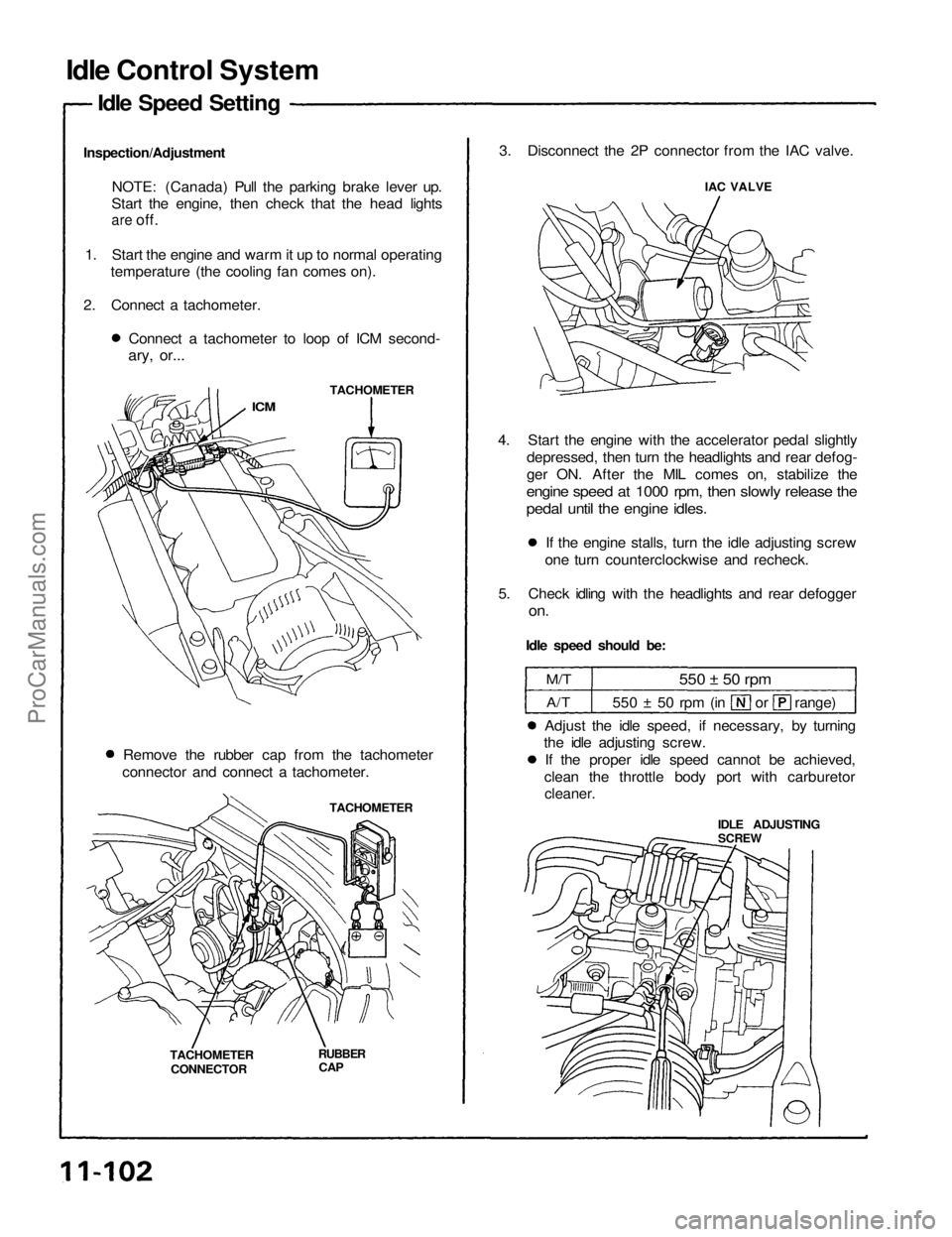

Idle Control System

Idle Speed Setting

Inspection/Adjustment NOTE: (Canada) Pull the parking brake lever up.

Start the engine, then check that the head lights

are

off.

1. Start the engine and warm it up to normal operating temperature (the cooling fan comes on).

2. Connect a tachometer. Connect a tachometer to loop of ICM second-

ary, or...

TACHOMETER

ICM

Remove the rubber cap from the tachometer

connector and connect a tachometer.

TACHOMETER

TACHOMETER CONNECTOR

RUBBER

CAP

3. Disconnect the 2P connector from the IAC valve.

IAC VALVE

4. Start the engine with the accelerator pedal slightly depressed, then turn the headlights and rear defog-

ger ON. After the MIL comes on, stabilize the

engine speed at 1000 rpm, then slowly release the

pedal until the engine idles.

If the engine stalls, turn the idle adjusting screw

one turn counterclockwise and recheck.

5. Check idling with the headlights and rear defogger

on.

Idle speed should be:

M/T

A/T

550 ± 50 rpm

550 ± 50 rpm (in or range)

Adjust the idle speed, if necessary, by turning

the idle adjusting screw.

If the proper idle speed cannot be achieved,

clean the throttle body port with carburetor

cleaner.

IDLE ADJUSTING

SCREWProCarManuals.com

Page 1107 of 1640

6. Turn the ignition switch OFF.

7. Reconnect the 2P connector on the IAC valve, then

remove CLOCK fuse in the under-hood fuse/relay

box for 10 seconds to reset ECM.

8. Restart and idle the engine with no-load conditions

in which the headlights, blower fan, rear defogger,

cooling fan, and air conditioner are not operating

for one minute, then check the idle speed.

Idle speed should be:

M/T

A/T

800

50 rpm

750

50 rpm

(in or range)ProCarManuals.com

Page 1108 of 1640

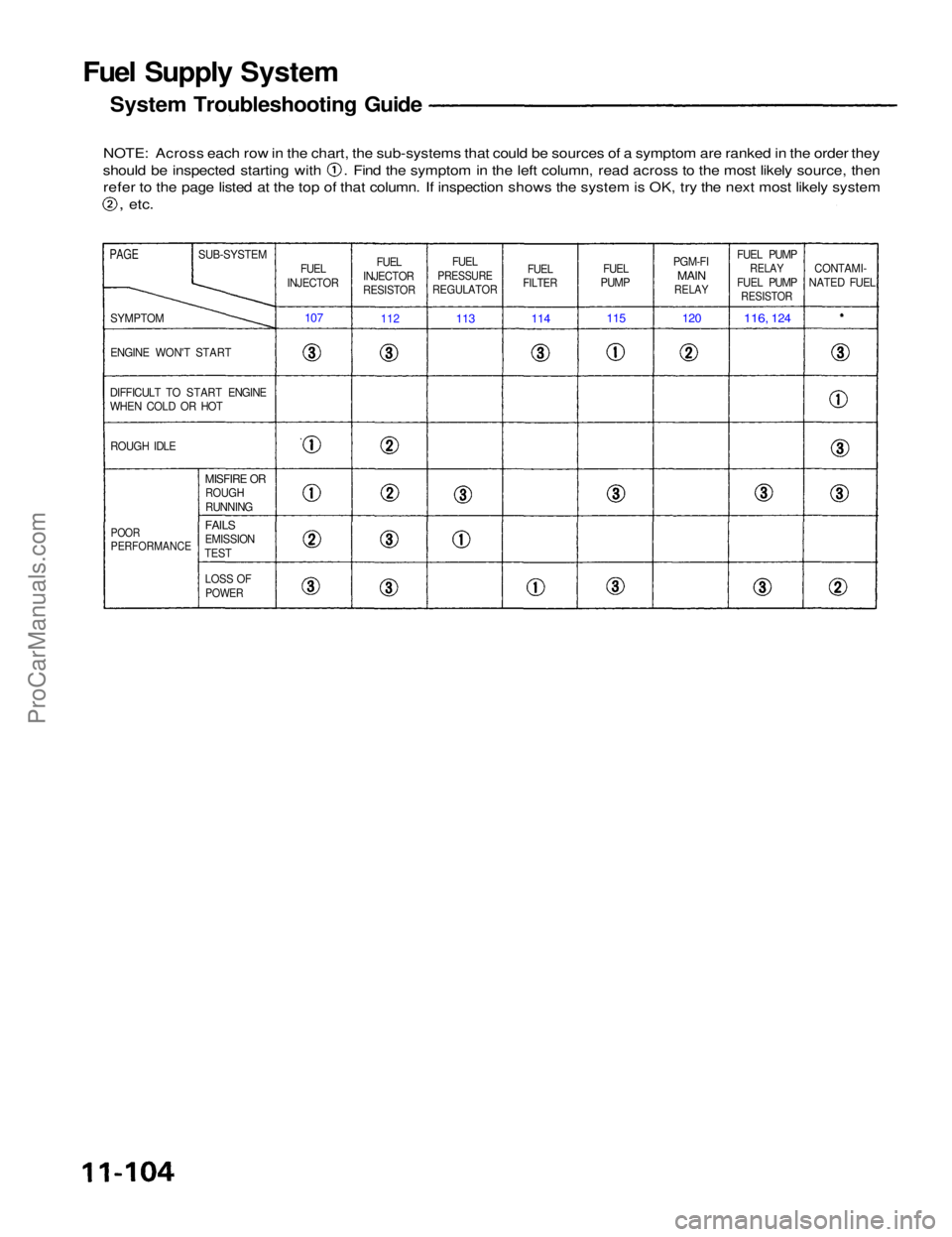

Fuel Supply System

System Troubleshooting Guide

NOTE: Across each row in the chart, the sub-systems that could be sources of a symptom are ranked in the order they should be inspected starting with . Find the symptom in the left column, read across to the most likely source, then

refer to the page listed at the top of that column. If inspection shows the system is OK, try the next most likely system

,

etc.

PAGE

SUB-SYSTEM

FUEL

INJECTOR FUEL

INJECTOR

RESISTOR

FUEL

PRESSURE

REGULATOR

FUEL

FILTER

FUEL

PUMP PGM-FI

MAIN

RELAY

FUEL PUMP

RELAY

FUEL PUMP

RESISTOR

CONTAMI-

NATED FUEL

SYMPTOM

ENGINE WON'T START

DIFFICULT TO START ENGINE

WHEN COLD OR HOT ROUGH IDLE

107

112

113

114

115

120

116,

124

POOR

PERFORMANCE

MISFIRE OR

ROUGH

RUNNING

FAILS

EMISSION

TEST

LOSS OF

POWERProCarManuals.com

Page 1109 of 1640

System Description

The fuel supply system consists of a fuel tank, in-tank high pressure fuel pump, fuel pump relay, fuel pump

resistor, PGM-FI main relay, fuel filter, fuel pressureregulator, fuel injectors and fuel injector resistor.

This system delivers pressure-regulated fuel to the fuel injectors and cuts the fuel delivery when the engine is

not running. Fuel Pressure

Relieving

Do not smoke while working on the fuel system.

Keep open flames or sparks away from your work

area.

Be sure to relieve fuel pressure while the engine is

off.

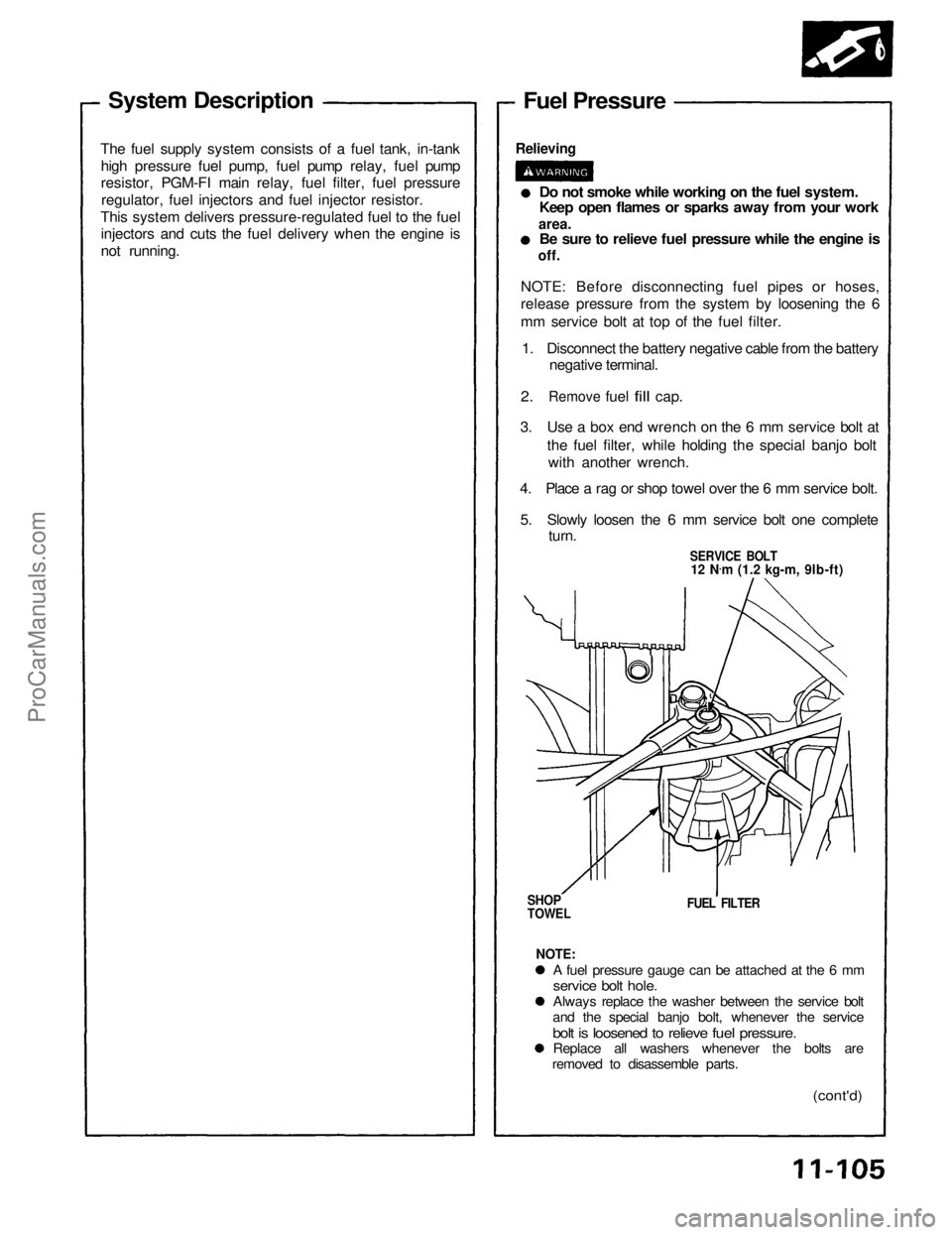

NOTE: Before disconnecting fuel pipes or hoses,

release pressure from the system by loosening the 6

mm service bolt at top of the fuel filter. 1. Disconnect the battery negative cable from the battery negative terminal.

2.

Remove

fuel

fill

cap.

3. Use a box end wrench on the 6 mm service bolt at the fuel filter, while holding the special banjo boltwith another wrench.

4. Place a rag or shop towel over the 6 mm service bolt.

5. Slowly loosen the 6 mm service bolt one complete turn.

SERVICE BOLT

12 N .

m (1.2 kg-m, 9lb-ft)

SHOP

TOWEL

FUEL FILTER

NOTE:

A fuel pressure gauge can be attached at the 6 mm

service bolt hole.

Always replace the washer between the service bolt

and the special banjo bolt, whenever the service

bolt is loosened to relieve fuel pressure.

Replace all washers whenever the bolts are

removed to disassemble parts.

(cont'd)ProCarManuals.com

Page 1110 of 1640

Fuel Supply System

Fuel Pressure (cont'd)

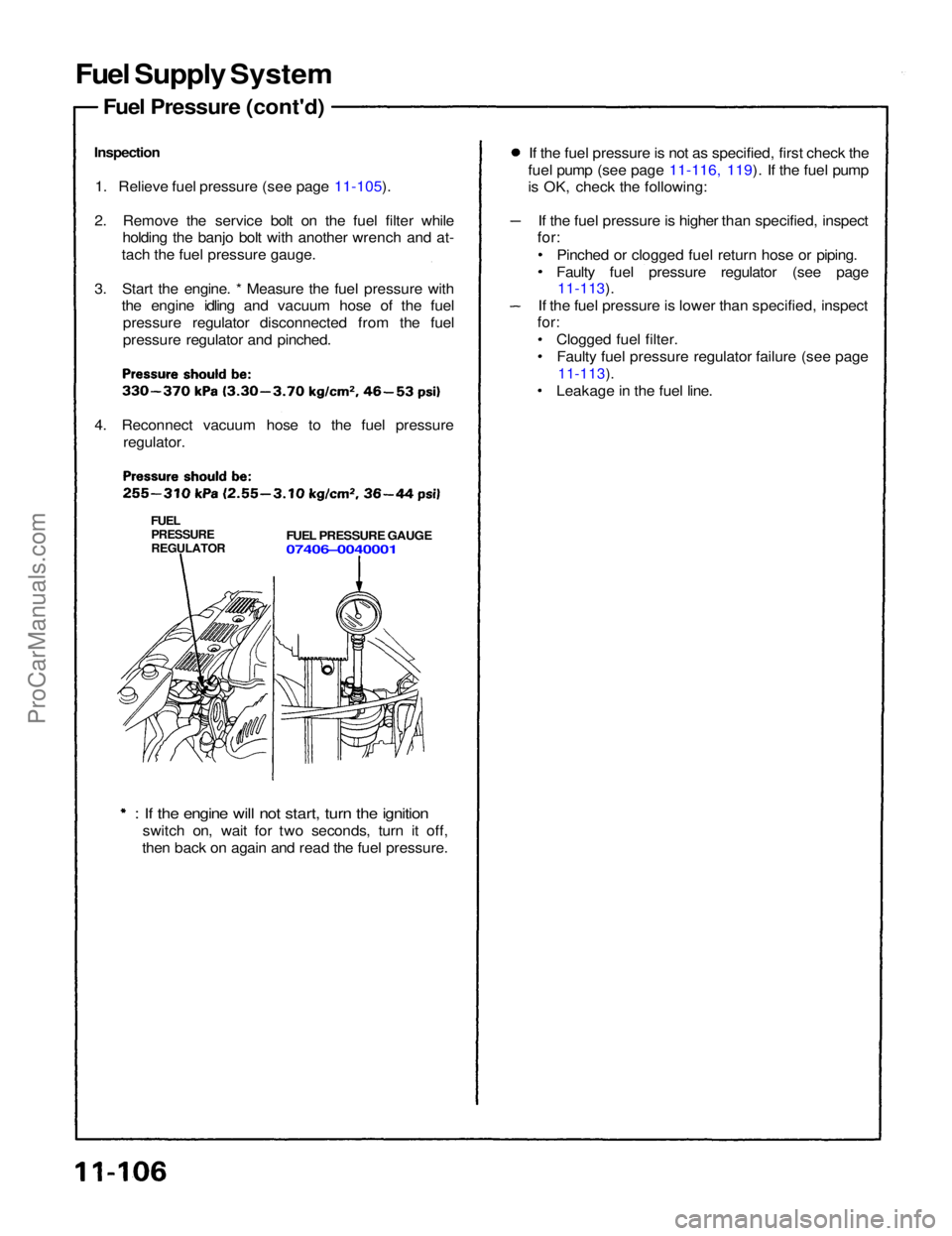

Inspection 1. Relieve fuel pressure (see page 11-105).

2. Remove the service bolt on the fuel filter while holding the banjo bolt with another wrench and at-

tach the fuel pressure gauge.

3. Start the engine. * Measure the fuel pressure with the engine idling and vacuum hose of the fuel

pressure regulator disconnected from the fuel

pressure regulator and pinched.

4. Reconnect vacuum hose to the fuel pressure regulator.

FUEL

PRESSURE

REGULATOR

FUEL PRESSURE GAUGE

07406–0040001

: If the engine will not start, turn the ignition

switch on, wait for two seconds, turn it off,

then back on again and read the fuel pressure. If the fuel pressure is not as specified, first check the

fuel pump (see page 11-116, 119). If the fuel pump

is OK, check the following:

If the fuel pressure is higher than specified, inspect

for:

Pinched or clogged fuel return hose or piping.

Faulty fuel pressure regulator (see page

11-113).

If the fuel pressure is lower than specified, inspect

for:

Clogged fuel filter.Faulty fuel pressure regulator failure (see page

11-113).

Leakage in the fuel line.ProCarManuals.com