ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 1081 of 1640

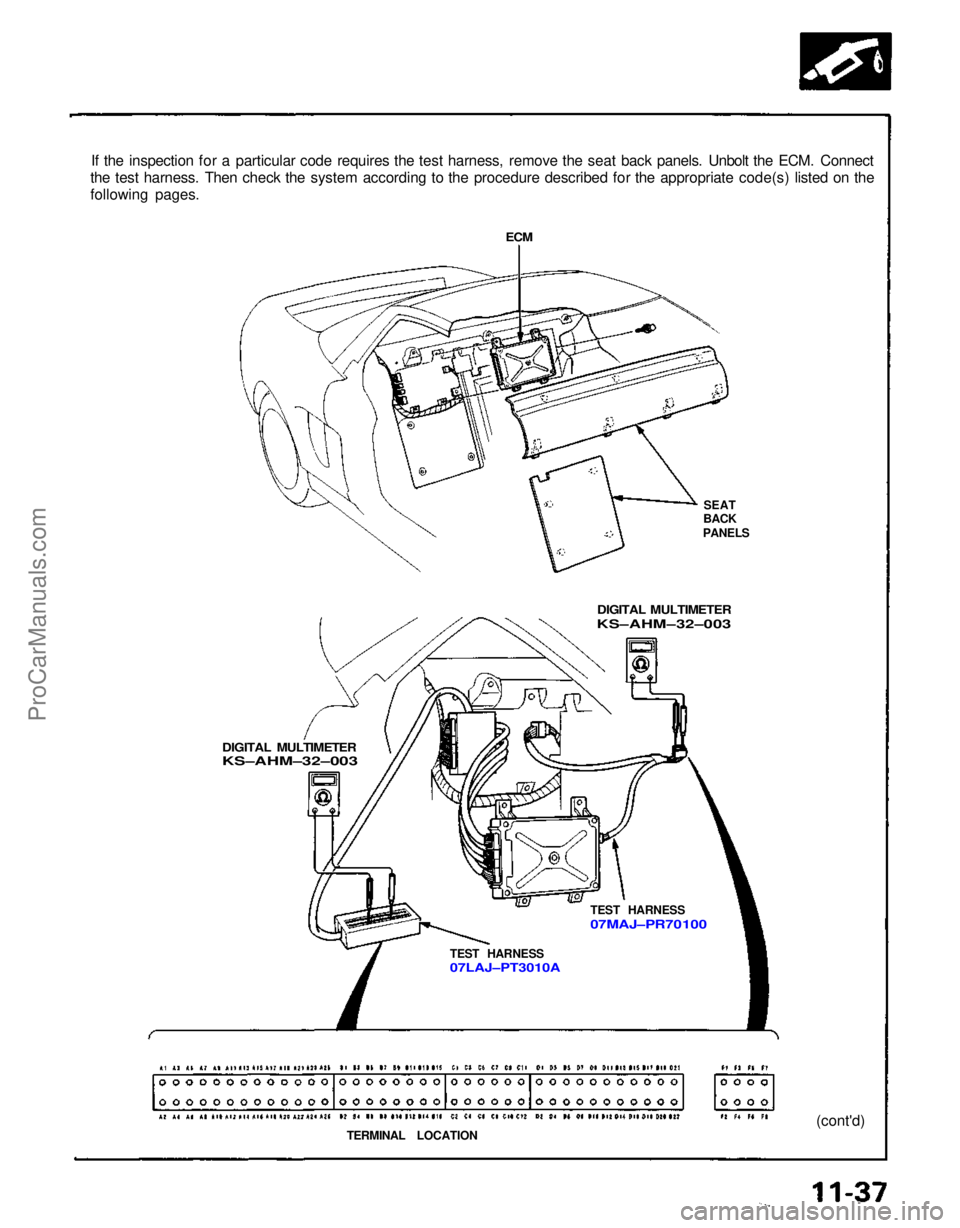

If the inspection for a particular code requires the test harness, remove the seat back panels. Unbolt the ECM. Connect

the test harness. Then check the system according to the procedure described for the appropriate code(s) listed on the

following pages.

ECM

SEAT

BACK

PANELS

DIGITAL MULTIMETER

KS–AHM–32–003

TEST HARNESS

07MAJ–PR 70100

TEST HARNESS

07LAJ–PT3010A

TERMINAL LOCATION (cont'd)

DIGITAL MULTIMETER

KS–AHM–32–003ProCarManuals.com

Page 1082 of 1640

Troubleshooting

Self-diagnostic Procedures (cont'd)

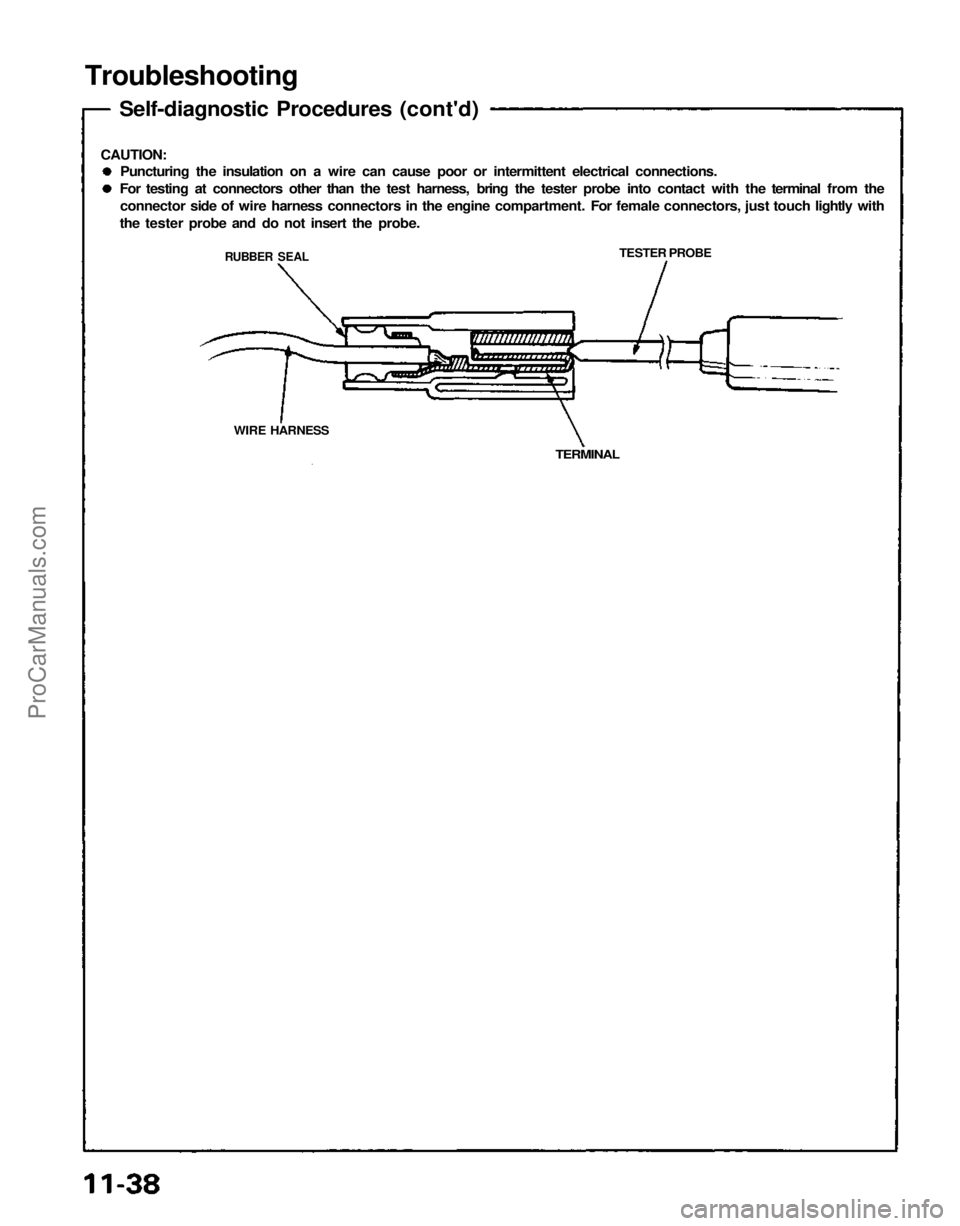

CAUTION:

Puncturing the insulation on a wire can cause poor or intermittent electrical connections.

For testing at connectors other than the test harness, bring the tester probe into contact with the terminal from the

connector side of wire harness connectors in the engine compartment. For female connectors, just touch lightly with

the tester probe and do not insert the probe.

TESTER PROBE

TERMINAL

WIRE HARNESS

RUBBER SEALProCarManuals.com

Page 1083 of 1640

How to Read Flowcharts

A flowchart is designed to be used from start to final repair. It's like a map showing you the shortest distance. But

beware: if you go off the "map" anywhere but a "stop" symbol, you can easily get lost.

(bold type)

(bold type)

Describes the conditions or situation to start a troubleshooting flowchart.

Asks you to do something; perform a test, set up a condition etc.

Asks you about the result of an action, then sends you in the appropriate troubleshooting direction.

The end of a series of actions and decisions, describes a final repair action and sometimes directs you

to an earlier part of the flowchart to confirm your repair.

NOTE:

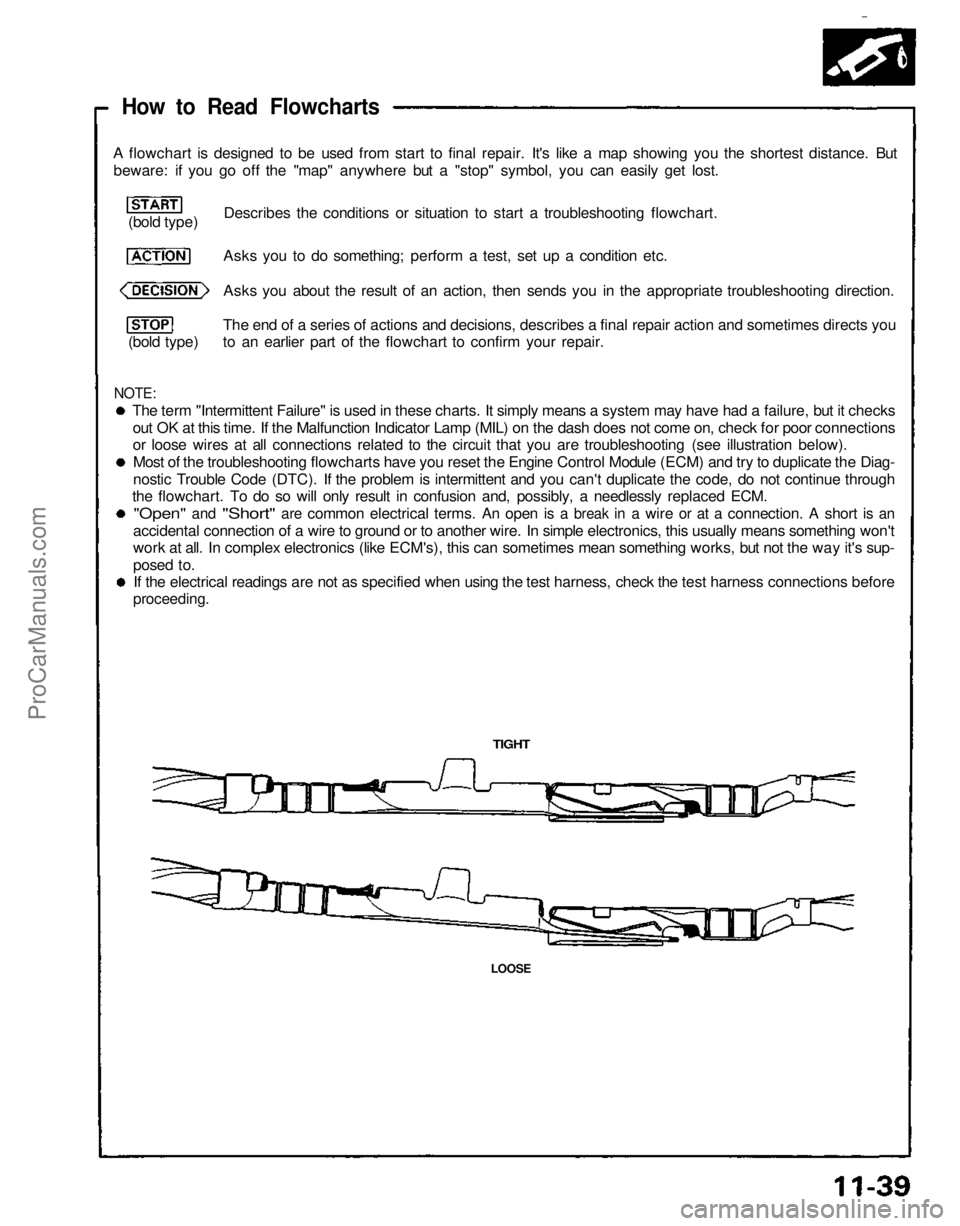

The term "Intermittent Failure" is used in these charts. It simply means a system may have had a failure, but it checks

out OK at this time. If the Malfunction Indicator Lamp (MIL) on the dash does not come on, check for poor connections

or loose wires at all connections related to the circuit that you are troubleshooting (see illustration below).

Most of the troubleshooting flowcharts have you reset the Engine Control Module (ECM) and try to duplicate the Diag-

nostic Trouble Code (DTC). If the problem is intermittent and you can't duplicate the code, do not continue through

the flowchart. To do so will only result in confusion and, possibly, a needlessly replaced ECM.

"Open"

and

"Short"

are

common electrical terms.

An

open

is a

break

in a

wire

or at a

connection.

A

short

is an

accidental connection of a wire to ground or to another wire. In simple electronics, this usually means something won't

work at all. In complex electronics (like ECM's), this can sometimes mean something works, but not the way it's sup-

posed to.

If the electrical readings are not as specified when using the test harness, check the test harness connections before

proceeding.

TIGHT

LOOSEProCarManuals.com

Page 1084 of 1640

PGM-FI System

System Description

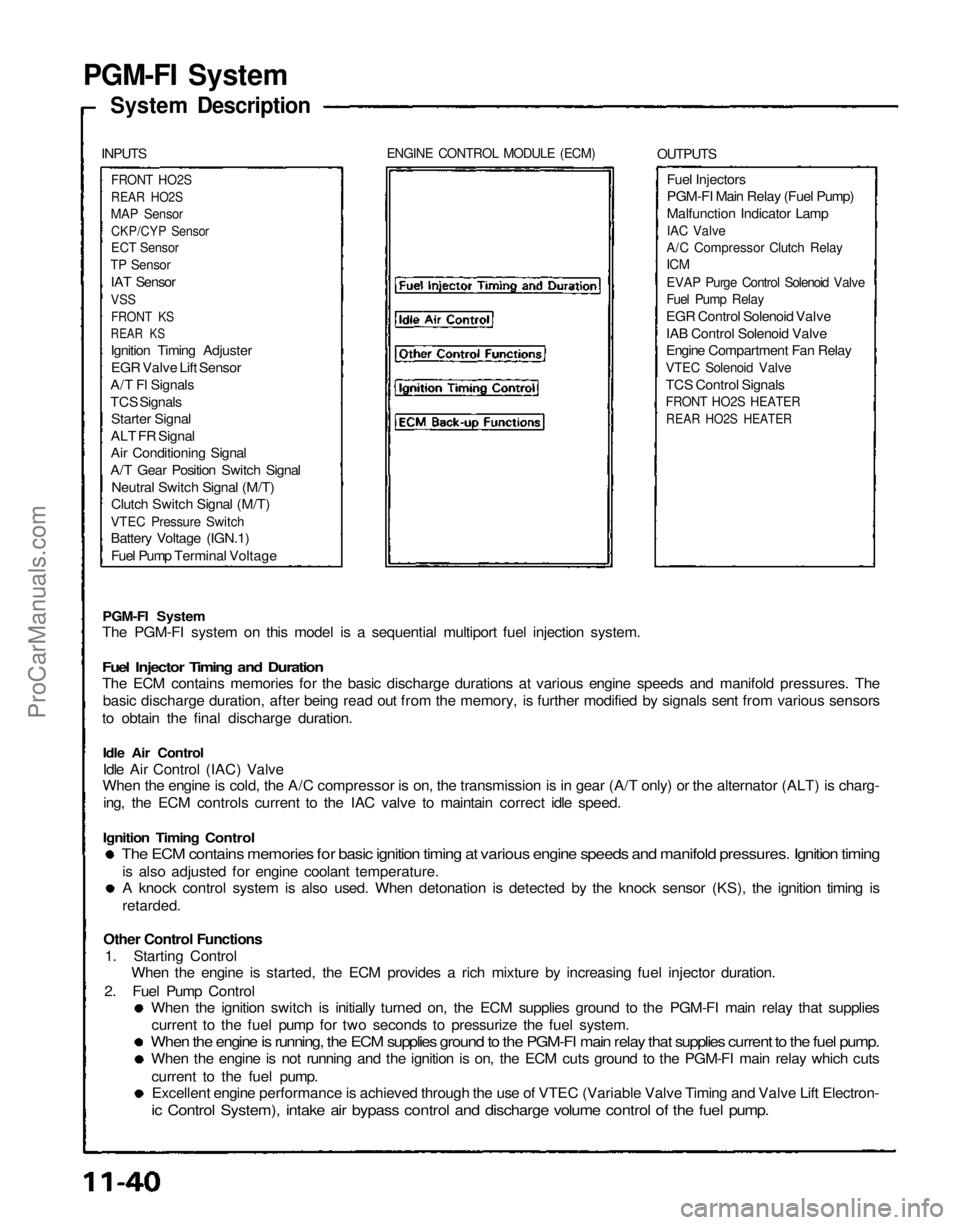

INPUTS

ENGINE CONTROL MODULE (ECM)

OUTPUTS

FRONT HO2S

REAR HO2S

MAP Sensor

CKP/CYP Sensor

ECT Sensor

TP Sensor

IAT Sensor

VSS

FRONT KS

REAR KS

Ignition Timing Adjuster

EGR Valve Lift Sensor

A/T Fl Signals

TCS Signals

Starter Signal

ALT FR Signal

Air Conditioning Signal

A/T Gear Position Switch Signal

Neutral Switch Signal (M/T)

Clutch Switch Signal (M/T)

VTEC Pressure Switch

Battery Voltage (IGN.1)

Fuel Pump Terminal Voltage

Fuel Injectors

PGM-FI Main Relay (Fuel Pump)

Malfunction Indicator Lamp

IAC Valve

A/C Compressor Clutch Relay

ICM

EVAP Purge Control Solenoid Valve

Fuel Pump Relay

EGR Control Solenoid Valve

IAB Control Solenoid Valve

Engine Compartment Fan Relay

VTEC Solenoid Valve

TCS Control Signals

FRONT HO2S HEATER

REAR HO2S HEATER

PGM-FI System

The PGM-FI system on this model is a sequential multiport fuel injection system.

Fuel Injector Timing and Duration

The ECM contains memories for the basic discharge durations at various engine speeds and manifold pressures. The

basic discharge duration, after being read out from the memory, is further modified by signals sent from various sensors

to obtain the final discharge duration.

Idle Air Control

Idle Air Control (IAC) Valve

When the engine is cold, the A/C compressor is on, the transmission is in gear (A/T only) or the alternator (ALT) is charg-

ing, the ECM controls current to the IAC valve to maintain correct idle speed.

Ignition Timing Control

The ECM contains memories for basic ignition timing at various engine speeds and manifold pressures. Ignition timing

is also adjusted for engine coolant temperature.

A knock control system is also used. When detonation is detected by the knock sensor (KS), the ignition timing is

retarded.

Other Control Functions

1. Starting Control

When the engine is started, the ECM provides a rich mixture by increasing fuel injector duration.

2. Fuel Pump Control

When the ignition switch is initially turned on, the ECM supplies ground to the PGM-FI main relay that supplies

current to the fuel pump for two seconds to pressurize the fuel system.

When the engine is running, the ECM supplies ground to the PGM-FI main relay that supplies current to the fuel pump.

When the engine is not running and the ignition is on, the ECM cuts ground to the PGM-FI main relay which cuts

current to the fuel pump.

Excellent engine performance is achieved through the use of VTEC (Variable Valve Timing and Valve Lift Electron-

ic Control System), intake air bypass control and discharge volume control of the fuel pump.ProCarManuals.com

Page 1085 of 1640

3. Fuel Cut-off Control

During deceleration with the throttle valve closed, current to the fuel injectors is cut off to improve fuel economy

at speeds over 1,500 rpm.

Fuel cut-off action also takes place when engine speed exceeds, 8,300 rpm, regardless of the position of the

throttle valve, to protect the engine from over-revving.

4. A/C Compressor Clutch Relay

When the ECM receives a demand for cooling from the air conditioning system, it delays the compressor from being

energized, and enriches the mixture to assure smooth translation to the A/C mode.

5. Evaporative Emission (EVAP) Purge Control Solenoid Valve

When the engine coolant temperature is below 1 58 °F (70°C) the ECM supplies a ground to the EVAP purge control

solenoid valve which cuts vacuum to the EVAP purge control diaphragm valve.

6. Intake Air Bypass (IAB) Control Solenoid Valve

When the engine speed is below 4,800 rpm, the IAB control solenoid valve is activated by a signal from the ECM.

Intake air then flows through the smaller chamber, and hight torque is delivered. To increase air flow at engine speeds

higher than 4,800 rpm, the solenoid valve is deactivated by the ECM, and the intake air flows through the larger

chamber.

7. Exhaust Gas Recirculation (EGR) Control Solenoid Valve

When the EGR is required for control of oxides of nitrogen (NOx) emissions, the ECM supplies ground to the EGR

control solenoid valve which supplies regulated vacuum to the EGR valve.

ECM fail-safe/back-up Functions

1. Fail-Safe Function

When an abnormality occurs in a signal from a sensor, the ECM ignores that signal and assumes a pre-programmed

valve for that sensor that allows the engine to continue to run.

2. Back-up Function

When an abnormality occurs in the ECM itself, the fuel injectors are controlled by a back-up circuit independent of

the system in order to permit minimal driving.

3. Self-diagnosis Function [Malfunction Indicator Lamp (MIL)]

When an abnormality occurs in a signal from a sensor, the ECM lights the MIL and stores the diagnostic trouble code

in erasable memory. When the ignition is initially turned in, the ECM supplies ground for the MIL for two seconds

to check the MIL bulb condition.ProCarManuals.com

Page 1086 of 1640

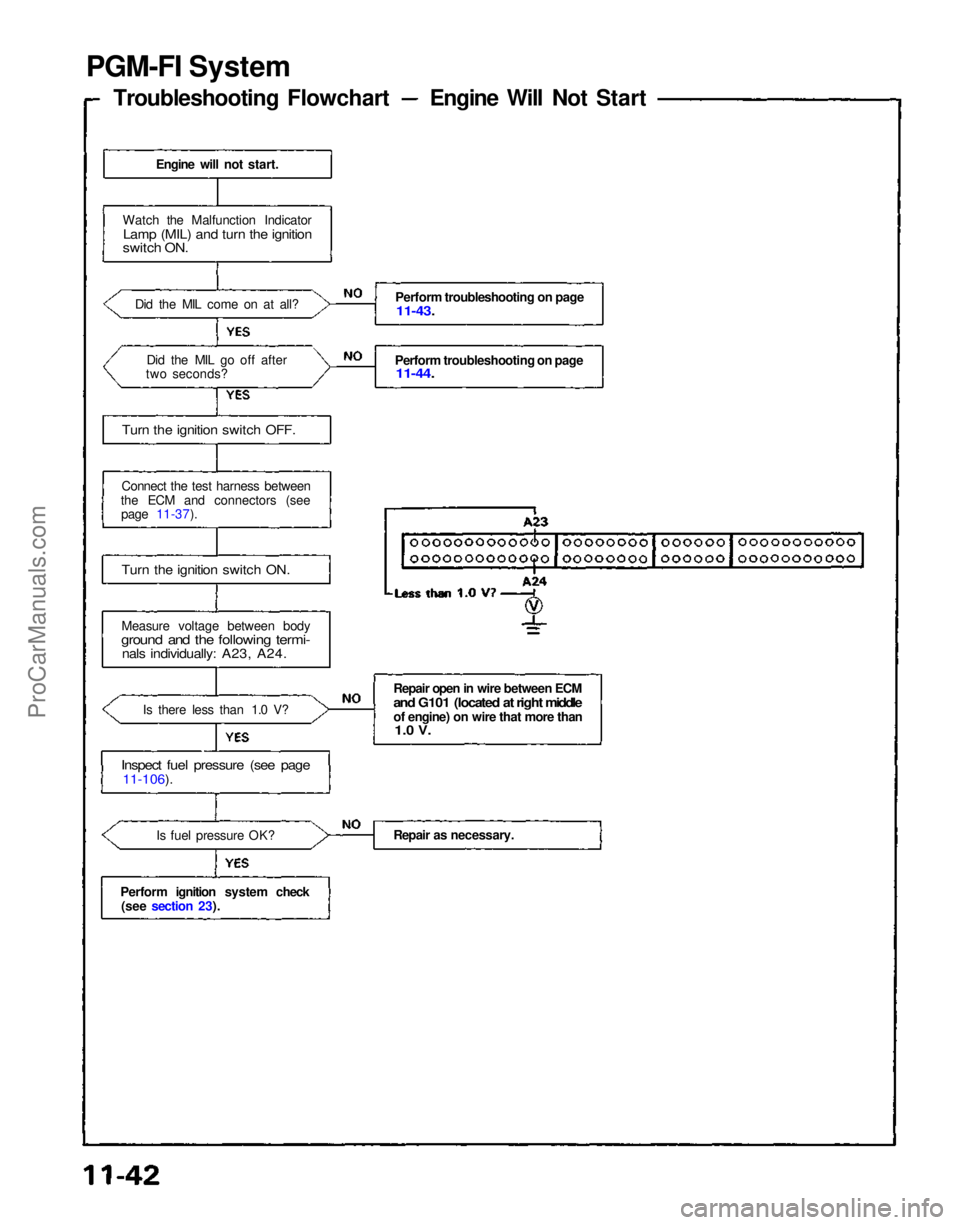

PGM-FI System

Troubleshooting Flowchart Engine Will Not Start

Engine will not start.

Watch the Malfunction Indicator

Lamp (MIL) and turn the ignition

switch ON.

Did the MIL come on at all?Did the MIL go off after

two seconds?

Turn the ignition switch OFF.

Connect the test harness between

the ECM and connectors (see page 11-37).

Turn the ignition switch ON.

Measure voltage between body

ground and the following termi-

nals individually: A23, A24.

Is there less than 1.0 V?

Inspect fuel pressure (see page

11-106).

Is fuel pressure OK?

Perform ignition system check (see section 23

).

Perform troubleshooting on page

11-43.

Perform troubleshooting on page

11-44.

Repair open in wire between ECM

and G101 (located at right middle

of engine) on wire that more than

1.0 V.

Repair as necessary.ProCarManuals.com

Page 1087 of 1640

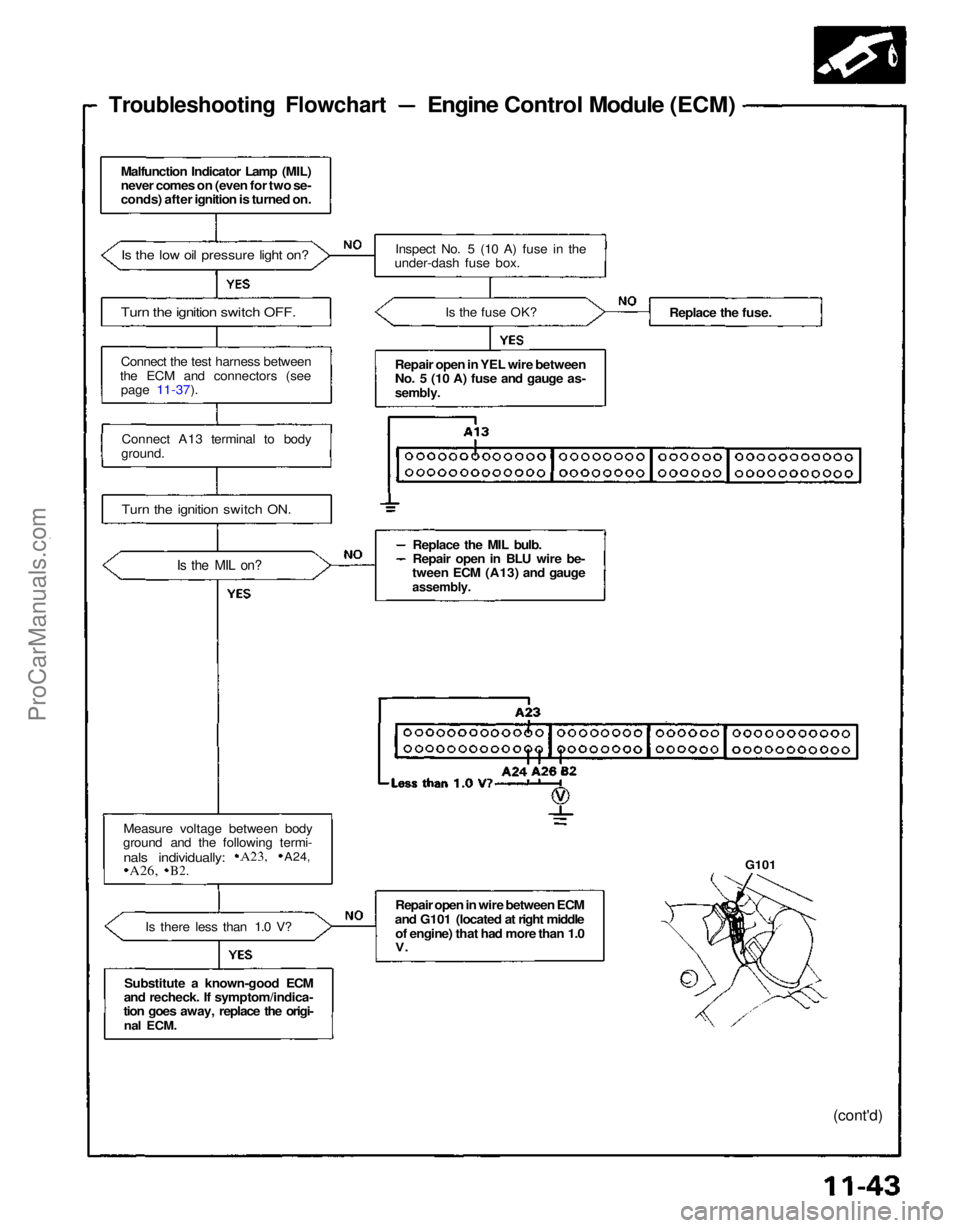

Troubleshooting Flowchart

Engine Control Module (ECM)

Malfunction Indicator Lamp (MIL)

never comes on (even for two se-

conds) after ignition is turned on.

Is the low oil pressure light on?

Turn the ignition switch OFF.

Connect the test harness between

the ECM and connectors (see page 11-37).

Connect A13 terminal to body

ground.

Turn the ignition switch ON.

Is the MIL on?

Measure voltage between body

ground and the following termi-

Is there less than 1.0 V?

Substitute a known-good ECM

and recheck. If symptom/indica-

tion goes away, replace the origi-

nal

ECM. Inspect No. 5 (10 A) fuse in the

under-dash fuse box.

Is the fuse OK?

Repair open in YEL wire between

No. 5 (10 A) fuse and gauge as-

sembly.

Replace the MIL bulb.

Repair open in BLU wire be-

tween ECM (A13) and gauge

assembly.

Repair open in wire between ECM

and G101 (located at right middle of engine) that had more than 1.0

V.

Replace the fuse.

G101

(cont'd)

nals individually:

A23,

A24,

A26,

B2.ProCarManuals.com

Page 1088 of 1640

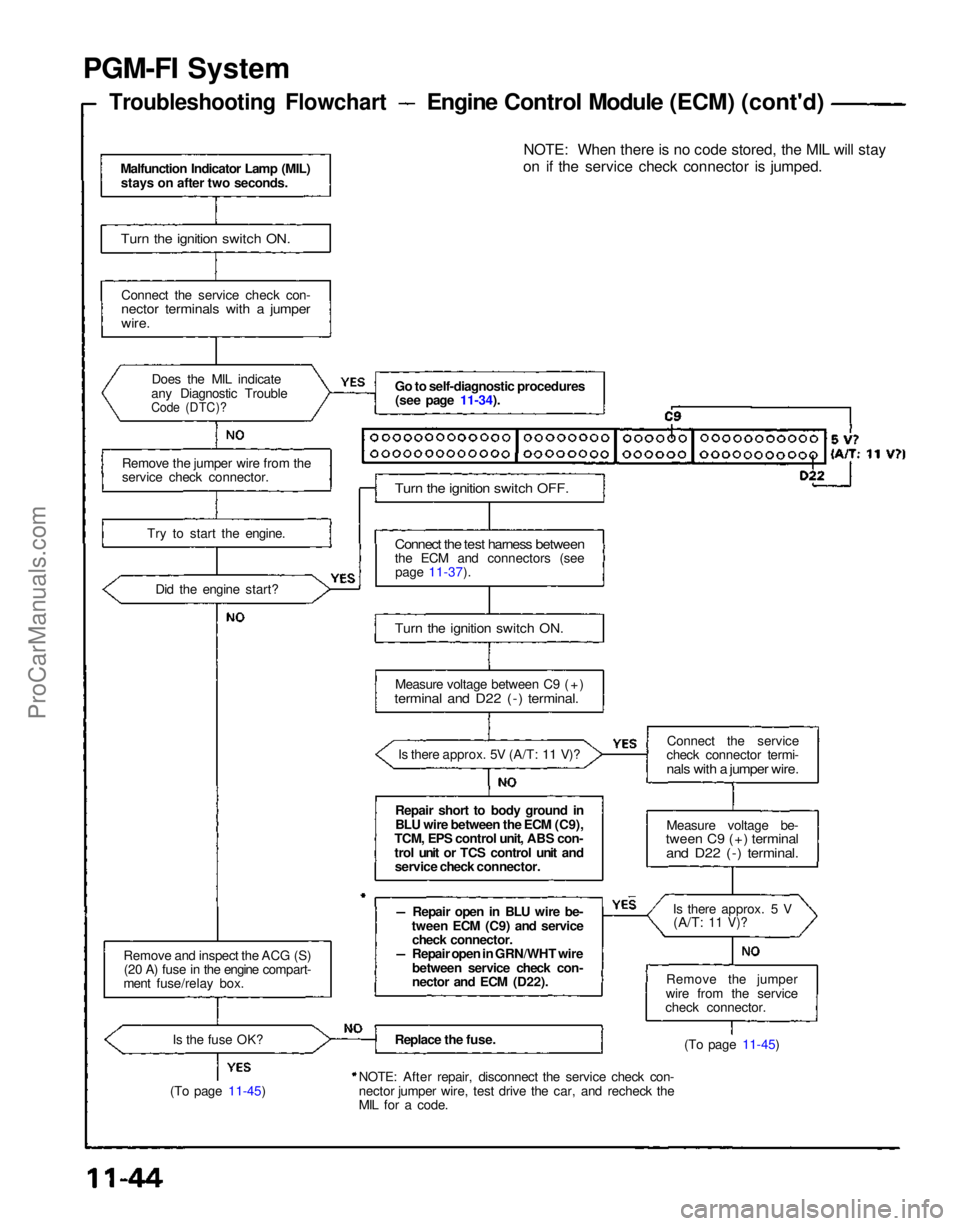

PGM-FI System

Troubleshooting Flowchart

Engine Control Module (ECM) (cont'd)

Malfunction Indicator Lamp (MIL) stays on after two seconds.

Turn the ignition switch ON.

Connect the service check con-

nector terminals with a jumper

wire.

Does the MIL indicate

any Diagnostic Trouble

Code (DTC)?

Remove the jumper wire from the

service check connector.

Try to start the engine.Did the engine start?

Remove and inspect the ACG (S) (20 A) fuse in the engine compart-

ment fuse/relay box.

Is the fuse OK?

(To page 11-45) Go to self-diagnostic procedures

(see page 11-34).

Turn the ignition switch OFF.

Connect the test harness between

the ECM and connectors (see page 11-37).

Turn the ignition switch ON.

Measure voltage between C9 (+)

terminal and D22 (-) terminal.

Is there approx. 5V (A/T: 11 V)?

Repair short to body ground in

BLU wire between the ECM (C9),

TCM, EPS control unit, ABS con-

trol unit or TCS control unit and service check connector.

Repair open in BLU wire be-

tween ECM (C9) and service check connector.

Repair open in GRN/WHT wire

between service check con-

nector and ECM (D22).

Replace the fuse.

NOTE: After repair, disconnect the service check con-

nector jumper wire, test drive the car, and recheck the

MIL for a code. NOTE: When there is no code stored, the MIL will stay

on if the service check connector is jumped.

Connect the service

check connector termi-

nals with a jumper wire.

Measure voltage be-

tween C9 (+) terminal

and D22 (-) terminal.

Is there approx. 5 V(A/T:

11 V)?

Remove the jumper

wire from the service

check connector.

(To page 11-45)ProCarManuals.com

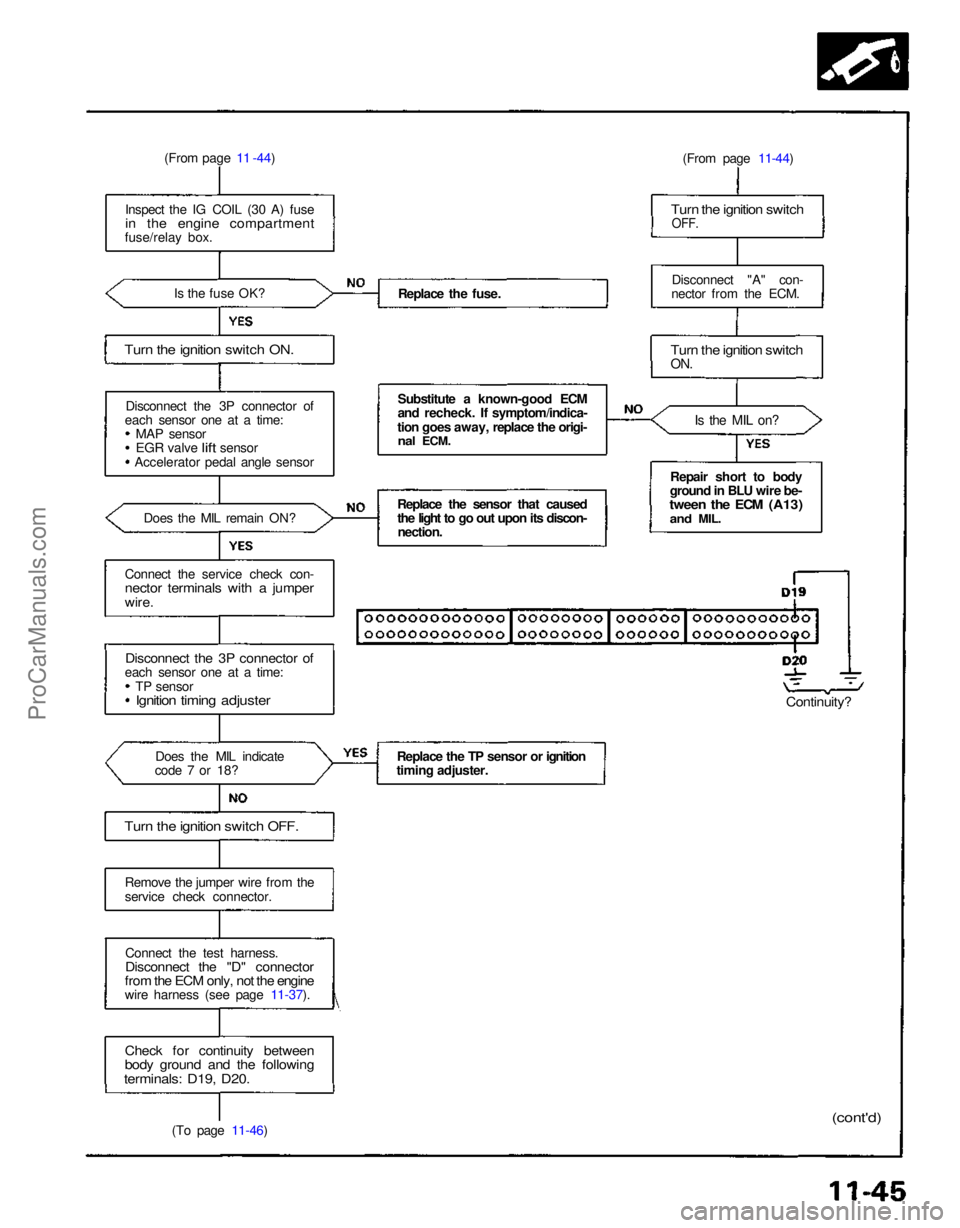

Page 1089 of 1640

(From page 11 -44)

Inspect the IG COIL (30 A) fuse

in the engine compartment

fuse/relay box.

Is the fuse OK?

Turn the ignition switch ON.

Disconnect the 3P connector of

each sensor one at a time: MAP sensor

EGR

valve

lift

sensor

Accelerator pedal angle sensor

Does the MIL remain ON?

Connect the service check con-

nector terminals with a jumper

wire.

Disconnect the 3P connector of

each sensor one at a time:

TP sensor

Ignition timing adjuster

Does the MIL indicate

code 7 or 18?

Turn the ignition switch OFF.

Remove the jumper wire from the

service check connector.

Connect the test harness.

Disconnect the "D" connector

from the ECM only, not the engine

wire harness (see page 11-37).

Check for continuity between

body ground and the following

terminals: D19, D20.

(To page 11-46) Replace the fuse.

Substitute a known-good ECM

and recheck. If symptom/indica-

tion goes away, replace the origi-

nal

ECM.

Replace the sensor that caused

the light to go out upon its discon- nection.

Replace the TP sensor or ignition

timing adjuster. (From page 11-44)

Turn the ignition switch

OFF.

Disconnect "A" con-

nector from the ECM.

Turn the ignition switch

ON.

Is the MIL on?

Repair short to body

ground in BLU wire be-

tween the ECM (A13)

and

MIL.

Continuity?

(cont'd)ProCarManuals.com

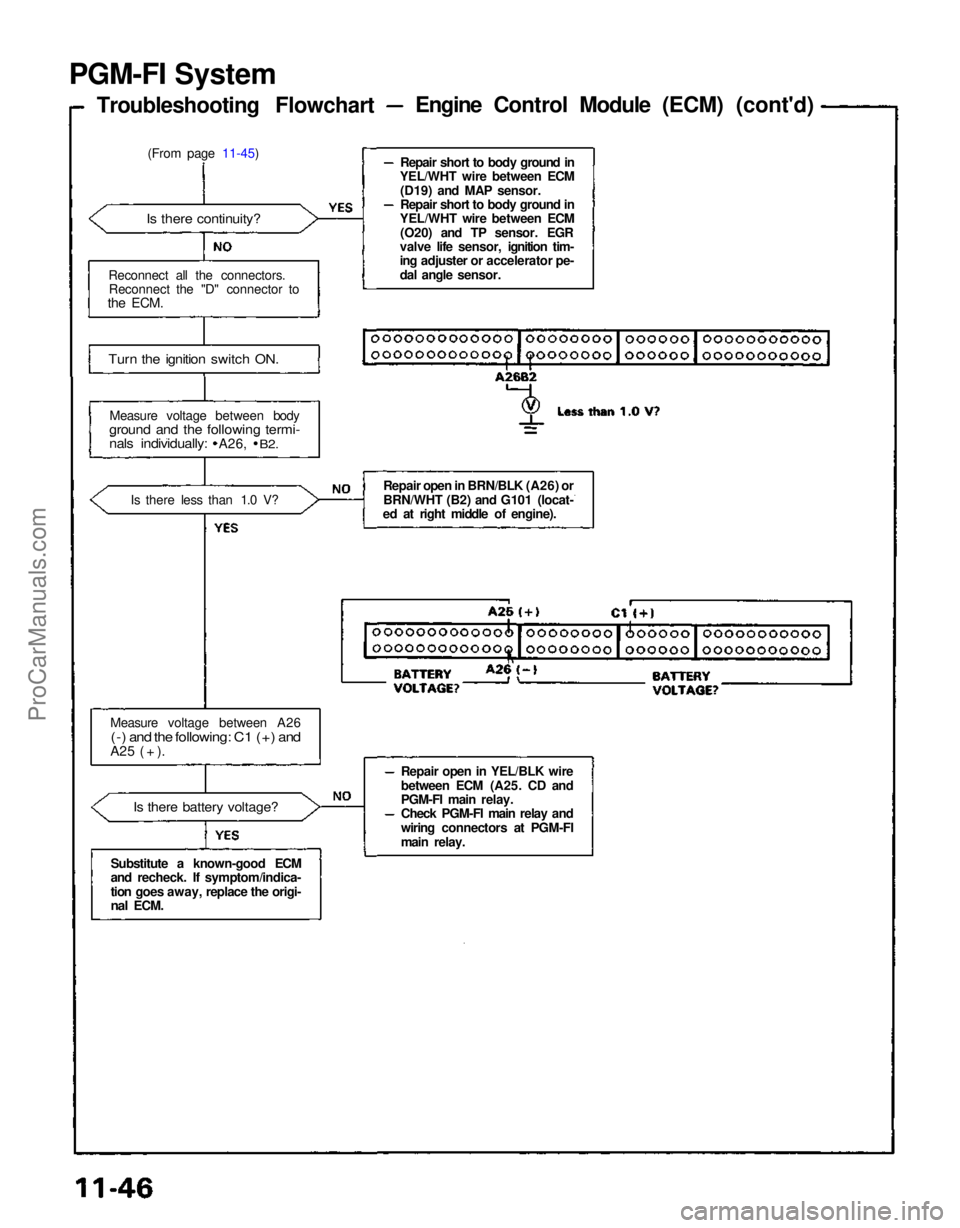

Page 1090 of 1640

PGM-FI System

Troubleshooting Flowchart Engine Control Module (ECM) (cont'd)

(From page 11-45)

Is there continuity?

Reconnect all the connectors. Reconnect the "D" connector to

the

ECM.

Turn the ignition switch ON.

Measure voltage between body

ground and the following termi-

nals individually:

A26,

B2.

Is there less than 1.0 V?

Measure voltage between A26

(-) and the following: C1 (+) and

A25 ( + ).

Is there battery voltage?

Substitute a known-good ECM

and recheck. If symptom/indica-

tion goes away, replace the origi-

nal

ECM. Repair short to body ground in

YEL/WHT wire between ECM

(D19) and MAP sensor.

Repair short to body ground in

YEL/WHT wire between ECM

(O20) and TP sensor. EGR

valve life sensor, ignition tim-

ing adjuster or accelerator pe-

dal angle sensor.

Repair open in BRN/BLK (A26) or

BRN/WHT (B2) and G101 (locat-

ed at right middle of engine).

Repair open in YEL/BLK wire

between ECM (A25. CD and

PGM-FI main relay.

Check PGM-FI main relay and

wiring connectors at PGM-FI

main relay.ProCarManuals.com