engine ACURA NSX 1991 Service Manual PDF

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 252 of 1640

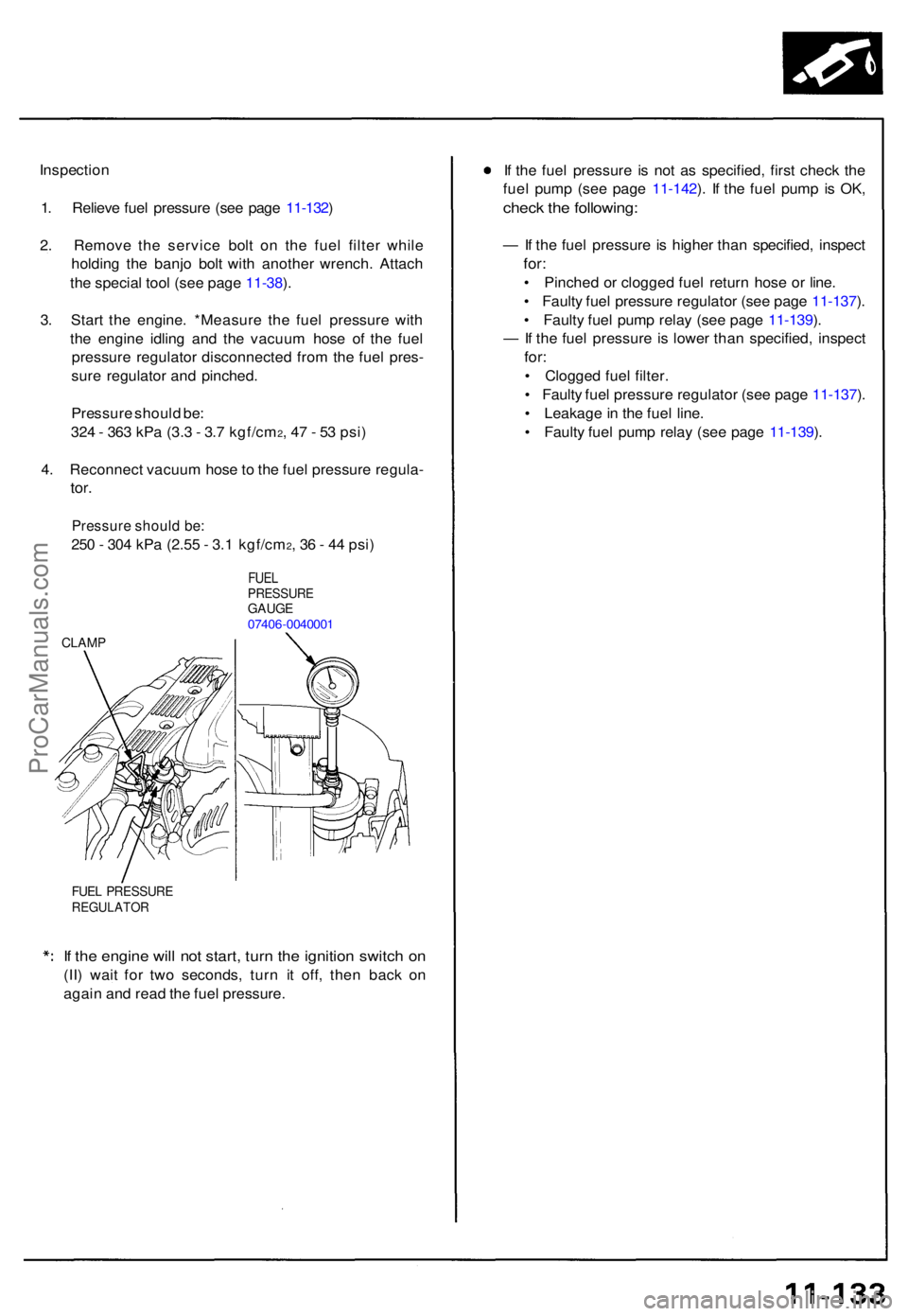

Inspection

1 . Reliev e fue l pressur e (se e pag e 11-132 )

2 . Remov e th e servic e bol t o n th e fue l filte r whil e

holdin g th e banj o bol t wit h anothe r wrench . Attac h

th e specia l too l (se e pag e 11-38 ).

3 . Star t th e engine . *Measur e th e fue l pressur e wit h

th e engin e idlin g an d th e vacuu m hos e o f th e fue l

pressur e regulato r disconnecte d fro m th e fue l pres -

sur e regulato r an d pinched .

Pressur e shoul d be :

32 4 - 36 3 kP a (3. 3 - 3. 7 kgf/cm

2, 4 7 - 5 3 psi )

4 . Reconnec t vacuu m hos e to th e fue l pressur e regula -

tor.

Pressur e shoul d be :

250 - 30 4 kP a (2.5 5 - 3. 1 kgf/cm2, 3 6 - 4 4 psi )

FUE LPRESSUR EGAUGE07406-004000 1

CLAMP

FUEL PRESSUR EREGULATO R

If th e engin e wil l no t start , tur n th e ignitio n switc h o n

(II ) wai t fo r tw o seconds , tur n i t off , the n bac k o n

agai n an d rea d th e fue l pressure . I

f th e fue l pressur e i s no t a s specified , firs t chec k th e

fue l pum p (se e pag e 11-142 ). I f th e fue l pum p i s OK ,

chec k th e following :

— If th e fue l pressur e is highe r tha n specified , inspec t

for:

• Pinche d o r clogge d fue l retur n hos e o r line .

• Fault y fue l pressur e regulato r (se e pag e 11-137 ).

• Fault y fue l pum p rela y (se e pag e 11-139 ).

— If th e fue l pressur e is lowe r tha n specified , inspec t

for:

• Clogge d fue l filter .

• Fault y fue l pressur e regulato r (se e pag e 11-137 ).

• Leakage in th e fue l line .

• Fault y fue l pum p rela y (se e pag e 11-139 ).

ProCarManuals.com

Page 259 of 1640

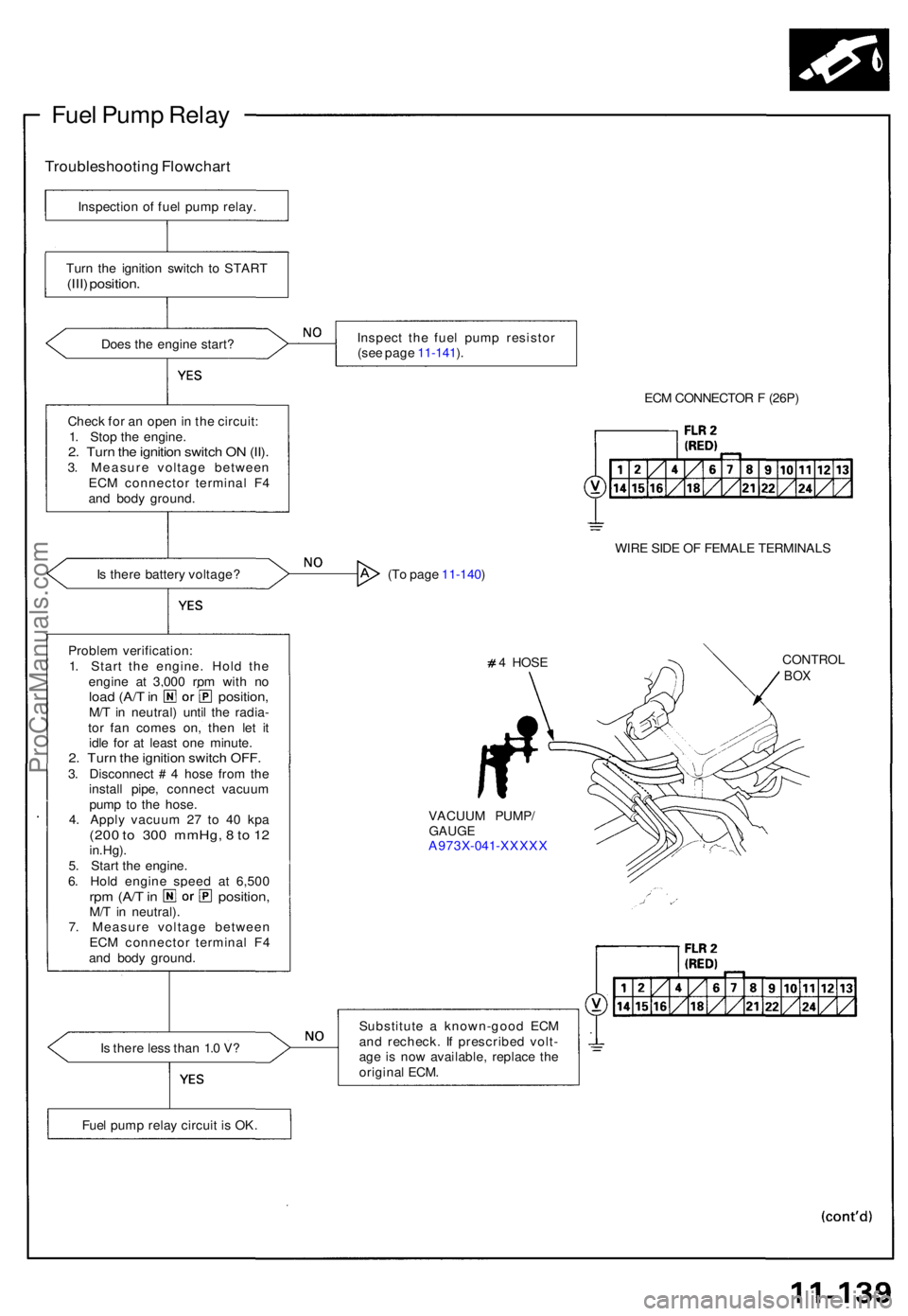

Fuel Pum p Rela y

Troubleshootin g Flowchar t

Inspection o f fue l pum p relay .

Tur n th e ignitio n switc h t o STAR T

(III) position .

Does th e engin e start ?

Chec k fo r a n ope n in th e circuit :

1 . Sto p th e engine .

2. Tur n th e ignitio n switc h O N (II) .3. Measur e voltag e betwee n

EC M connecto r termina l F 4

an d bod y ground .

I s ther e batter y voltage ?

Proble m verification :

1 . Star t th e engine . Hol d th e

engin e a t 3,00 0 rp m wit h n o

loa d (A/ T in position ,M/T in neutral ) unti l th e radia -

to r fa n come s on , the n le t i t

idl e fo r a t leas t on e minute .

2. Tur n th e ignitio n switc h OFF .3. Disconnec t # 4 hos e fro m th e

instal l pipe , connec t vacuu m

pum p t o th e hose .

4 . Appl y vacuu m 2 7 t o 4 0 kp a

(200 t o 300 mmHg , 8 to 1 2in.Hg) .

5 . Star t th e engine .

6 . Hol d engin e spee d a t 6,50 0

rpm (A/ T in position ,M/T in neutral) .

7 . Measur e voltag e betwee n

EC M connecto r termina l F 4

an d bod y ground .

I s ther e les s tha n 1. 0 V ? Inspec

t th e fue l pum p resisto r

(se e pag e 11-141 ).

ECM CONNECTO R F (26P )

WIR E SID E O F FEMAL E TERMINAL S

(T o pag e 11-140 )

4 HOS E

CONTRO LBOX

VACUU M PUMP /GAUGEA973X-04 1-XXXX X

Substitut e a known-goo d EC M

an d recheck . I f prescribe d volt -

ag e i s no w available , replac e th e

origina l ECM .

Fue l pum p rela y circui t i s OK .

ProCarManuals.com

Page 264 of 1640

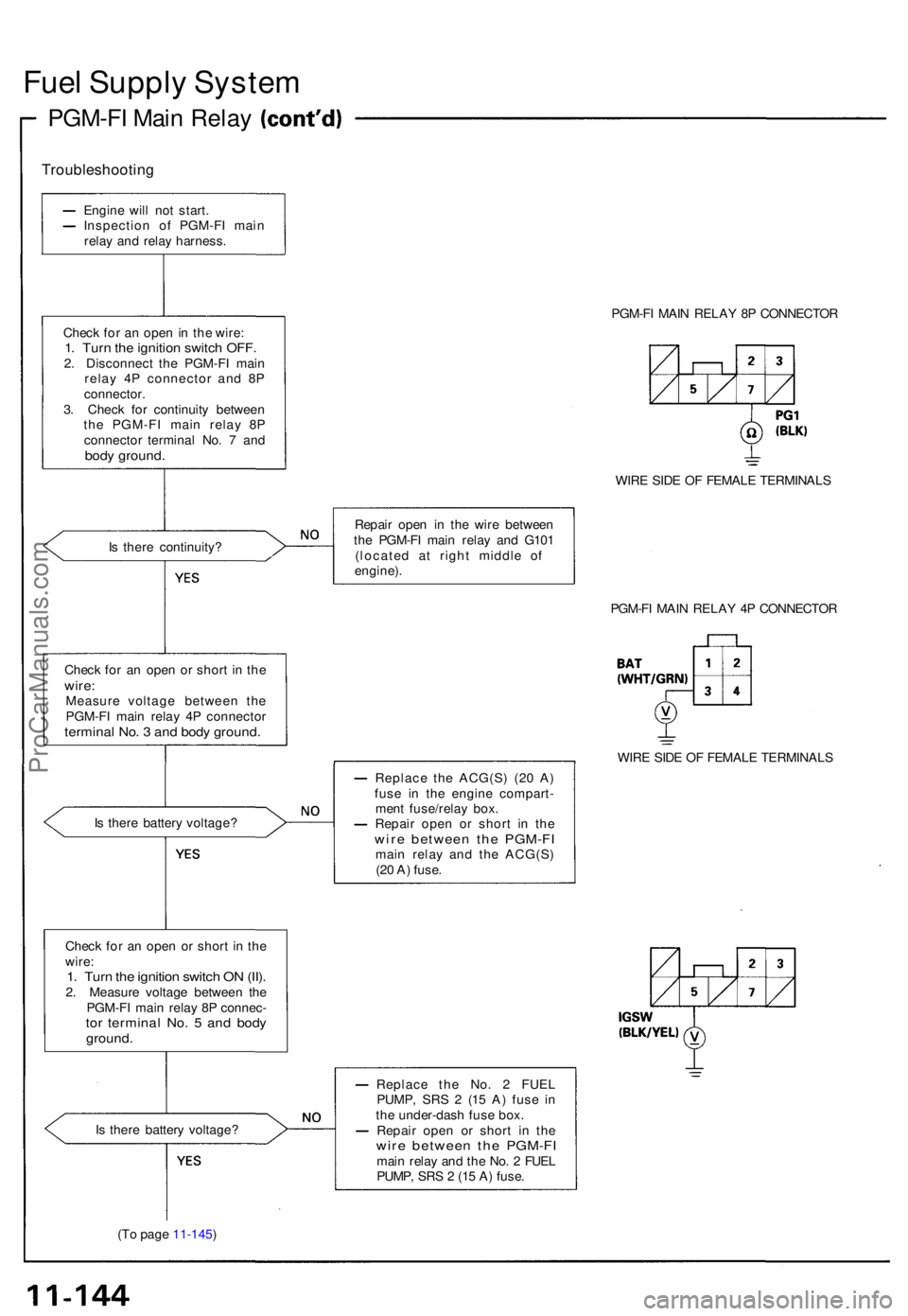

Fuel Suppl y Syste m

PGM-F I Mai n Rela y

Troubleshootin g

Is ther e continuity ?

Chec k fo r a n ope n o r shor t i n th e

wire :Measur e voltag e betwee n th e

PGM-F I mai n rela y 4 P connecto r

terminal No . 3 an d bod y ground .

Is ther e batter y voltage ?

Chec k fo r a n ope n o r shor t i n th e

wire :

1. Tur n th e ignitio n switc h O N (II) .2. Measur e voltag e betwee n th e

PGM-F I mai n rela y 8 P connec -

tor termina l No . 5 an d bod yground .

PGM-FI MAI N RELA Y 8 P CONNECTO R

WIR E SID E O F FEMAL E TERMINAL S

Repai r ope n i n th e wir e betwee n

th e PGM-F I mai n rela y an d G10 1

(locate d a t righ t middl e o fengine) .

PGM-FI MAI N RELA Y 4 P CONNECTO R

Replac e th e ACG(S ) (2 0 A )

fus e i n th e engin e compart -

men t fuse/rela y box .

Repai r ope n o r shor t i n th e

wir e betwee n th e PGM-F Imain rela y an d th e ACG(S )

(2 0 A ) fuse . WIR

E SID E O F FEMAL E TERMINAL S

I s ther e batter y voltage ?

(T o pag e 11-145 ) Replac

e th e No . 2 FUE L

PUMP , SR S 2 (1 5 A ) fus e i n

th e under-das h fus e box .

Repai r ope n o r shor t i n th e

wir e betwee n th e PGM-F Imain rela y an d th e No . 2 FUE L

PUMP , SR S 2 (1 5 A ) fuse .

Engin

e wil l no t start .

Inspectio n o f PGM-F I mai n

rela y an d rela y harness .

Chec k fo r a n ope n in th e wire :

1. Tur n th e ignitio n switc h OFF .2. Disconnec t th e PGM-F I mai n

rela y 4 P connecto r an d 8 P

connector .

3 . Chec k fo r continuit y betwee n

th e PGM-F I mai n rela y 8 P

connecto r termina l No . 7 an d

body ground .

ProCarManuals.com

Page 268 of 1640

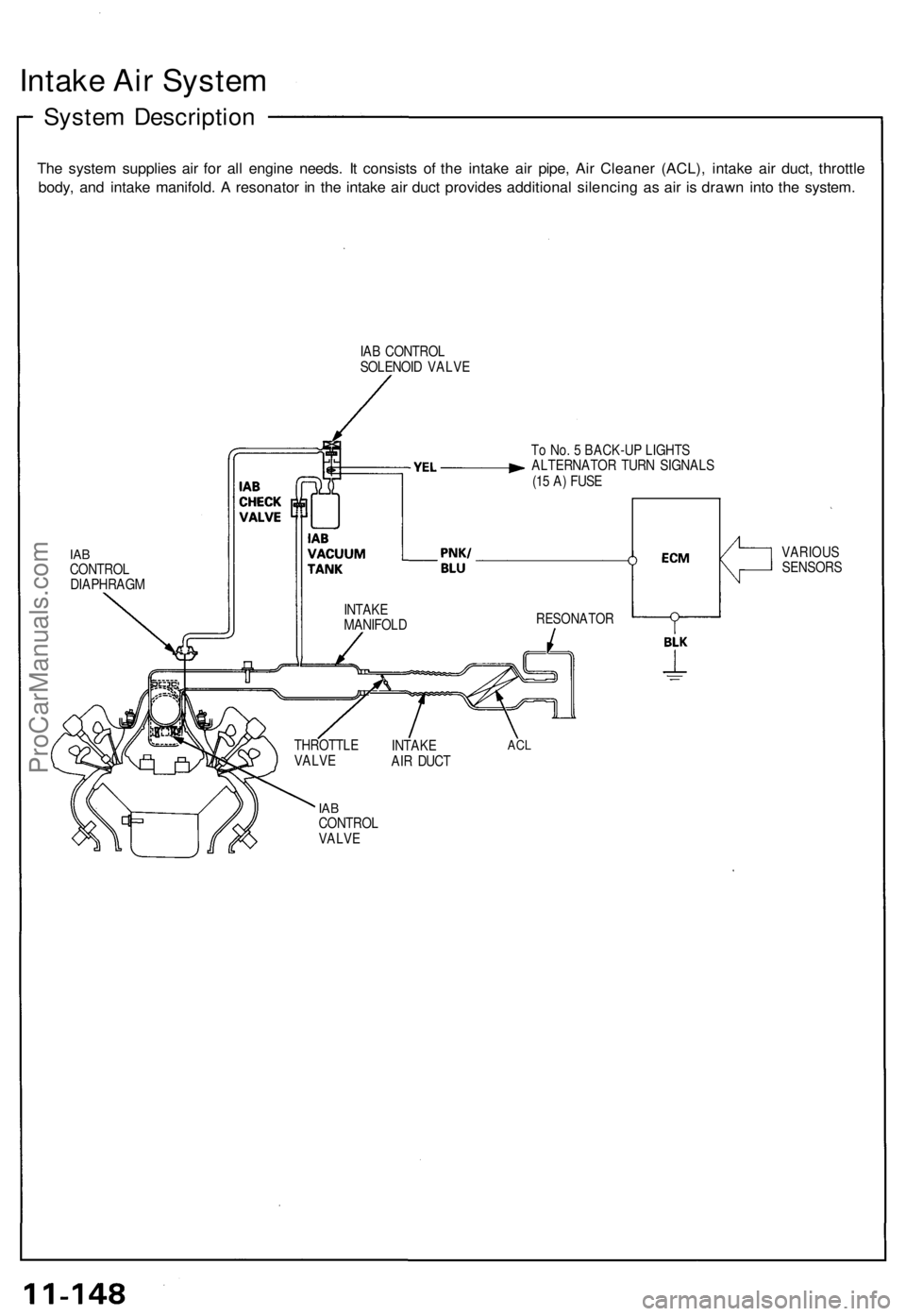

Intake Air System

System Description

The system supplies air for all engine needs. It consists of the intake air pipe, Air Cleaner (ACL), intake air duct, throttle

body, and intake manifold. A resonator in the intake air duct provides additional silencing as air is drawn into the system.

IAB CONTROL

SOLENOID VALVE

To No. 5 BACK-UP LIGHTS

ALTERNATOR TURN SIGNALS

(15 A) FUSE

IAB

CONTROL

DIAPHRAGM

IAB

CONTROL

VALVE

THROTTLE

VALVE

INTAKE

AIR DUCT

ACL

RESONATOR

VARIOUS

SENSORS

INTAKE

MANIFOLDProCarManuals.com

Page 271 of 1640

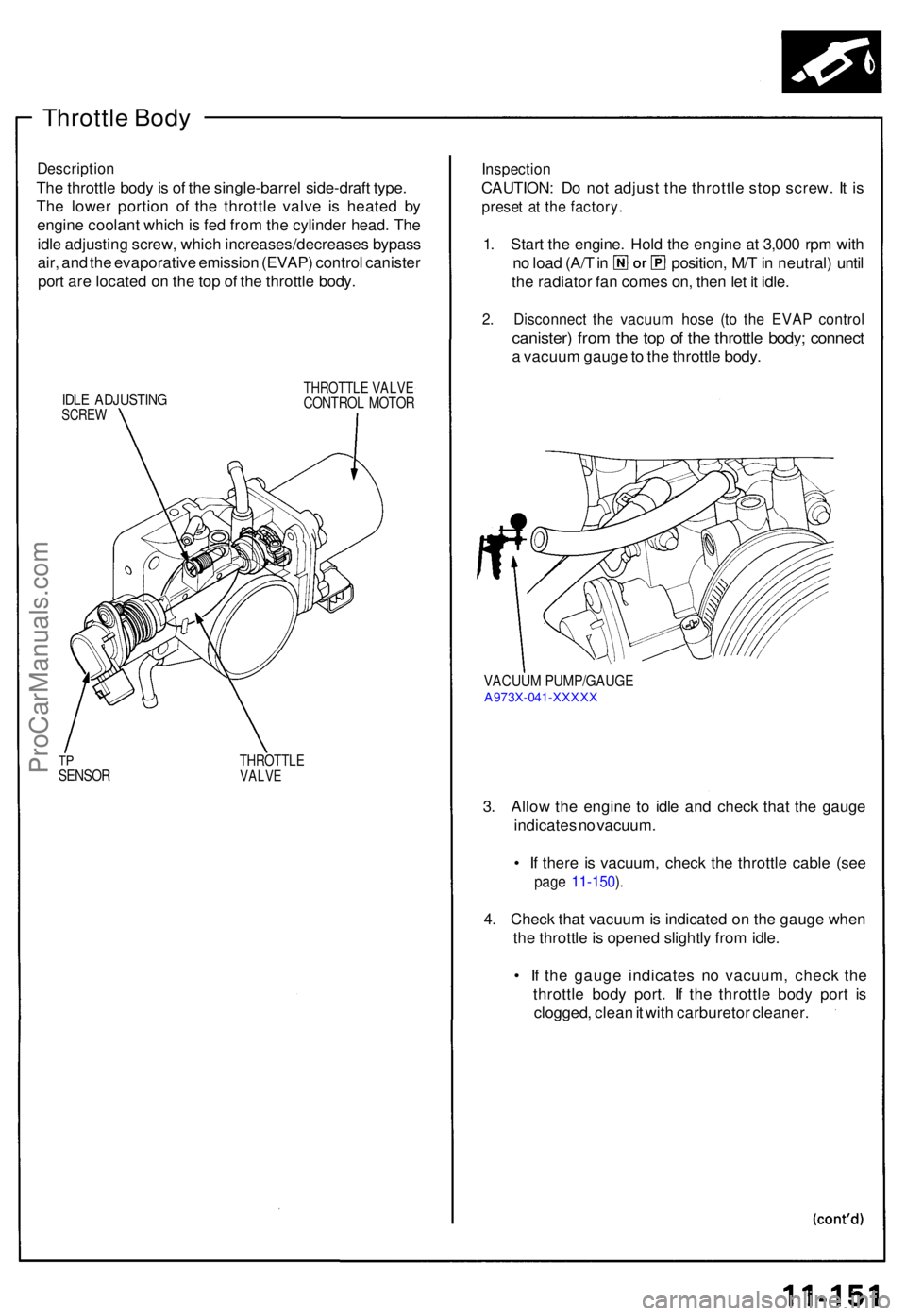

Throttle Bod y

Descriptio n

The throttl e bod y is o f th e single-barre l side-draf t type .

Th e lowe r portio n o f th e throttl e valv e i s heate d b y

engin e coolan t whic h is fe d fro m th e cylinde r head . Th e

idl e adjustin g screw , whic h increases/decrease s bypas s

air , an d th e evaporativ e emissio n (EVAP ) contro l caniste r

por t ar e locate d o n th e to p o f th e throttl e body .

IDLE ADJUSTIN GSCREW

THROTTL E VALV ECONTRO L MOTO R

TPSENSO RTHROTTL EVALVE

Inspectio n

CAUTION : D o no t adjus t th e throttl e sto p screw . I t i s

prese t a t th e factory .

1. Star t th e engine . Hol d th e engin e a t 3,00 0 rp m wit h

no loa d (A/ T in position , M/ T in neutral ) unti l

th e radiato r fa n come s on , the n le t i t idle .

2. Disconnec t th e vacuu m hos e (t o th e EVA P contro l

canister ) fro m th e to p o f th e throttl e body ; connec t

a vacuu m gaug e to th e throttl e body .

VACUU M PUMP/GAUG EA973X-04 1-XXXX X

3. Allo w th e engin e t o idl e an d chec k tha t th e gaug e

indicate s n o vacuum .

• I f ther e i s vacuum , chec k th e throttl e cabl e (se e

page 11-150 ).

4 . Chec k tha t vacuu m is indicate d o n th e gaug e whe n

th e throttl e is opene d slightl y fro m idle .

• I f th e gaug e indicate s n o vacuum , chec k th e

throttl e bod y port . I f th e throttl e bod y por t i s

clogged , clea n it wit h carbureto r cleaner .

ProCarManuals.com

Page 274 of 1640

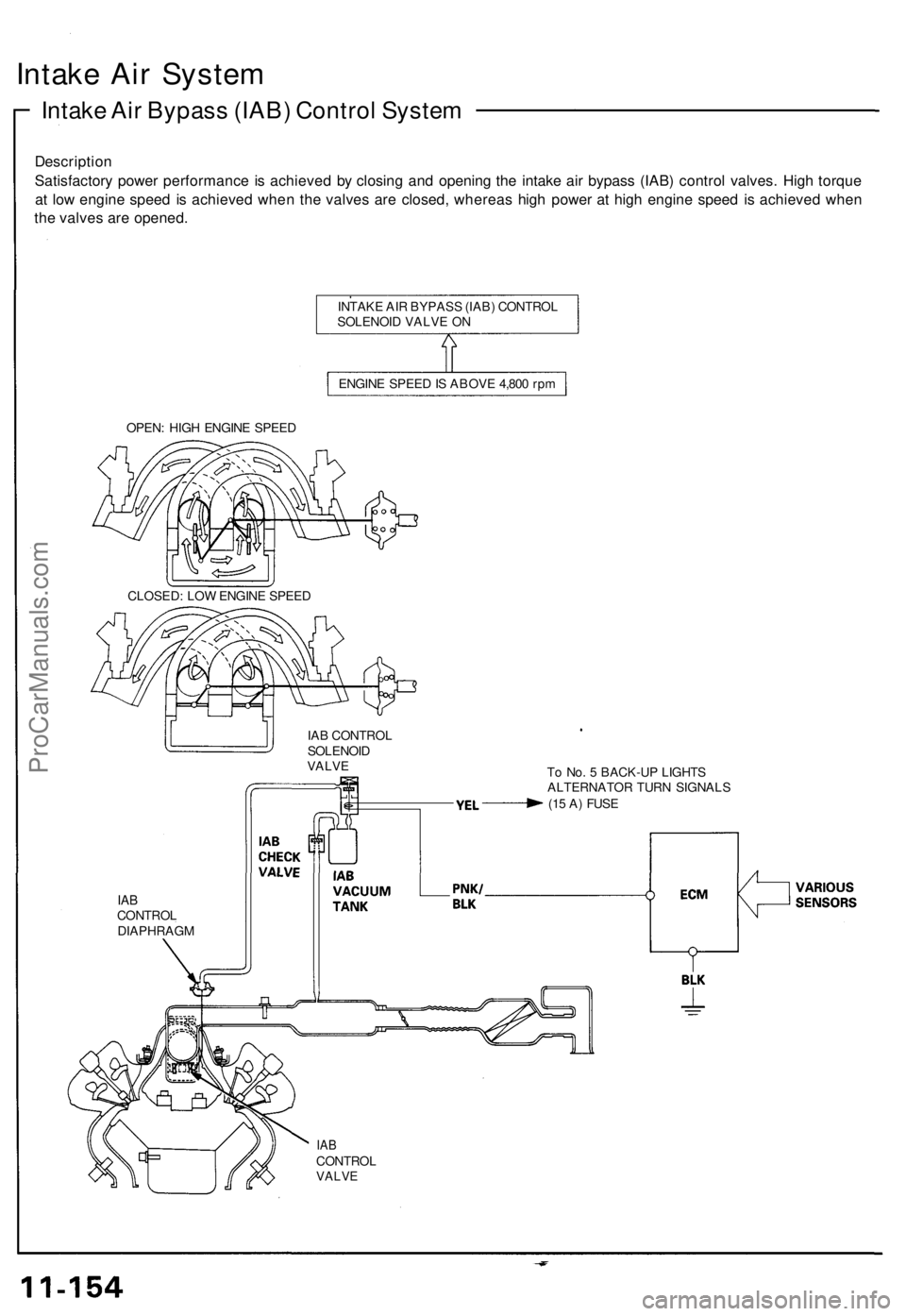

Intake Air System

Intake Air Bypass (IAB) Control System

Description

Satisfactory power performance is achieved by closing and opening the intake air bypass (IAB) control valves. High torque

at low engine speed is achieved when the valves are closed, whereas high power at high engine speed is achieved when

the valves are opened.

INTAKE AIR BYPASS (IAB) CONTROL

SOLENOID VALVE ON

ENGINE SPEED IS ABOVE 4,800 rpm

OPEN: HIGH ENGINE SPEED

IAB CONTROL

SOLENOID

VALVE

To No. 5 BACK-UP LIGHTS

ALTERNATOR TURN SIGNALS

(15 A) FUSE

IAB

CONTROL

DIAPHRAGM

IAB

CONTROL

VALVE

CLOSED: LOW ENGINE SPEEDProCarManuals.com

Page 276 of 1640

Emission Contro l Syste m

System Descriptio n

The emissio n contro l syste m include s tw o Thre e Wa y

Catalyti c Converter s (TWCs) , Exhaus t Ga s Recirculatio n

(EGR ) system , Positiv e Crankcas e Ventilatio n (PCV ) sys -

te m an d Evaporativ e Emissio n (EVAP ) Contro l system .

Th e emissio n contro l syste m is designe d t o mee t federa l

an d stat e emissio n standards .

Tailpipe Emissio n

Inspectio n

Do no t smok e durin g thi s procedure . Kee p

an y ope n flam e awa y fro m you r wor k area .

1 . Star t th e engine . Hol d th e engin e a t 3,00 0 rp m wit h

no loa d (A/ T in position , M/ T in neutral ) unti l

the radiato r fa n come s on , the n le t i t idle .

2 . Connec t a tachometer .

3 . Chec k an d adjus t th e idl e speed , i f necessar y (se e

pag e 11-128 ).

4 . War m u p an d calibrat e th e C O mete r accordin g t o

th e mete r manufacturer' s instructions .

5 . Chec k idl e C O wit h th e headlights , heate r blower ,

rea r windo w defogger , coolin g fan , an d ai r condi -

tione r off .

NOTE : (Canada ) Pul l th e parkin g brak e leve r up .

Star t th e engine , the n chec k tha t th e headlight s ar e

off.

CO mete r shoul d indicat e 0.1 % maximum .

ProCarManuals.com

Page 280 of 1640

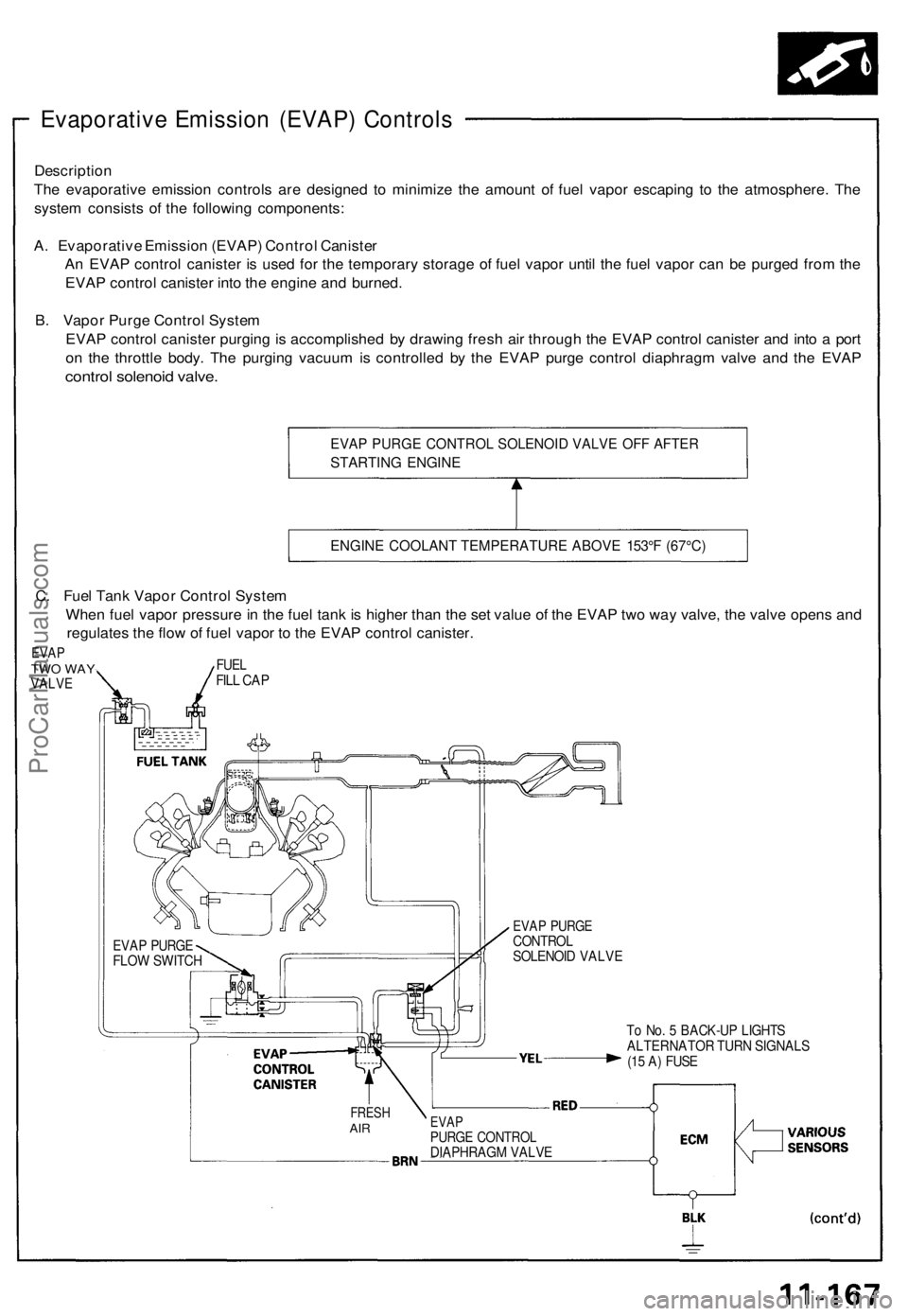

Evaporative Emission (EVAP) Controls

Description

The evaporative emission controls are designed to minimize the amount of fuel vapor escaping to the atmosphere. The

system consists of the following components:

A. Evaporative Emission (EVAP) Control Canister

An EVAP control canister is used for the temporary storage of fuel vapor until the fuel vapor can be purged from the

EVAP control canister into the engine and burned.

B. Vapor Purge Control System

EVAP control canister purging is accomplished by drawing fresh air through the EVAP control canister and into a port

on the throttle body. The purging vacuum is controlled by the EVAP purge control diaphragm valve and the EVAP

control solenoid valve.

EVAP PURGE CONTROL SOLENOID VALVE OFF AFTER

STARTING ENGINE

ENGINE COOLANT TEMPERATURE ABOVE 153°F (67°C)

To No. 5 BACK-UP LIGHTS

ALTERNATOR TURN SIGNALS

(15 A) FUSE

FRESH

AIR

EVAP

PURGE CONTROL

DIAPHRAGM VALVE

EVAP PURGE

CONTROL

SOLENOID VALVE

EVAP PURGE

FLOW SWITCH

C. Fuel Tank Vapor Control System

When fuel vapor pressure in the fuel tank is higher than the set value of the EVAP two way valve, the valve opens and

regulates the flow of fuel vapor to the EVAP control canister.

EVAP

TWO WAY

VALVE

FUEL

FILL CAPProCarManuals.com

Page 296 of 1640

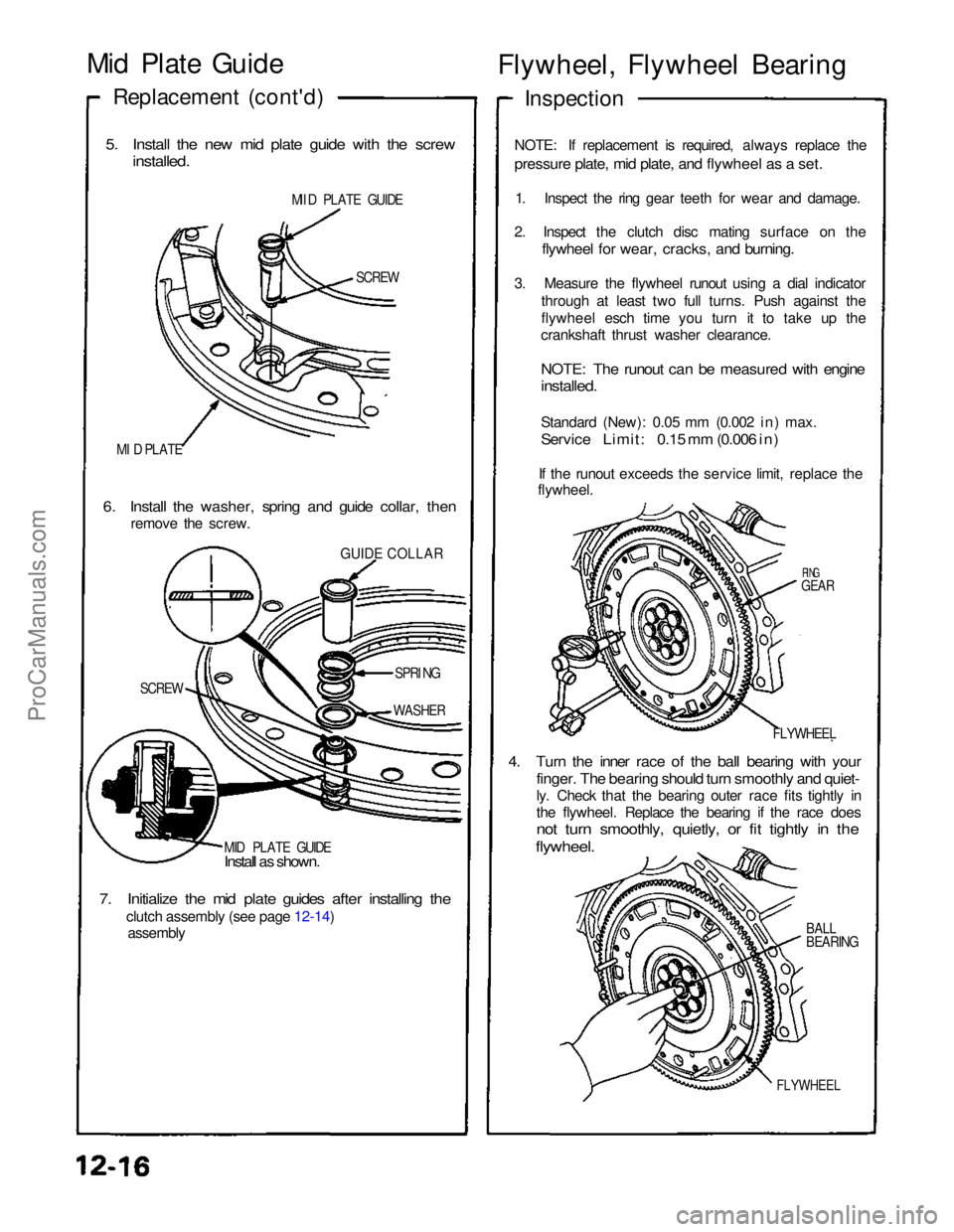

Mid Plate Guide

Replacement (cont'd)

5. Install the new mid plate guide with the screw

installed.

MII D PLATE GUIDE

SCREW

MI D PLATE

6. Install the washer, spring and guide collar, then

remove the screw.

GUIDE COLLAR

SCREW SPRI

NG

WASHER

MID PLATE GUIDE

Install as shown.

7. Initialize the mid plate guides after installing the

clutch assembly (see page 12-14)

assembly Flywheel, Flywheel Bearing

Inspection

NOTE: If replacement is required, always replace the

pressure plate, mid plate, and flywheel as a set.

1. Inspect the ring gear teeth for wear and damage.

2. Inspect the clutch disc mating surface on the

flywheel for wear, cracks, and burning.

3. Measure the flywheel runout using a dial indicator through at least two full turns. Push against the

flywheel esch time you turn it to take up the

crankshaft thrust washer clearance.

NOTE: The runout can be measured with engine

installed.

Standard (New): 0.05 mm (0.002 in) max.

Service Limit: 0.15 mm (0.006 in)

If the runout exceeds the service limit, replace the

flywheel.

RING

GEAR

FLYWHEEL

4. Turn the inner race of the ball bearing with your

finger. The bearing should turn smoothly and quiet-

ly. Check that the bearing outer race fits tightly in

the flywheel. Replace the bearing if the race does

not turn smoothly, quietly, or fit tightly in the

flywheel.

BALL

BEARING

FLYWHEELProCarManuals.com

Page 306 of 1640

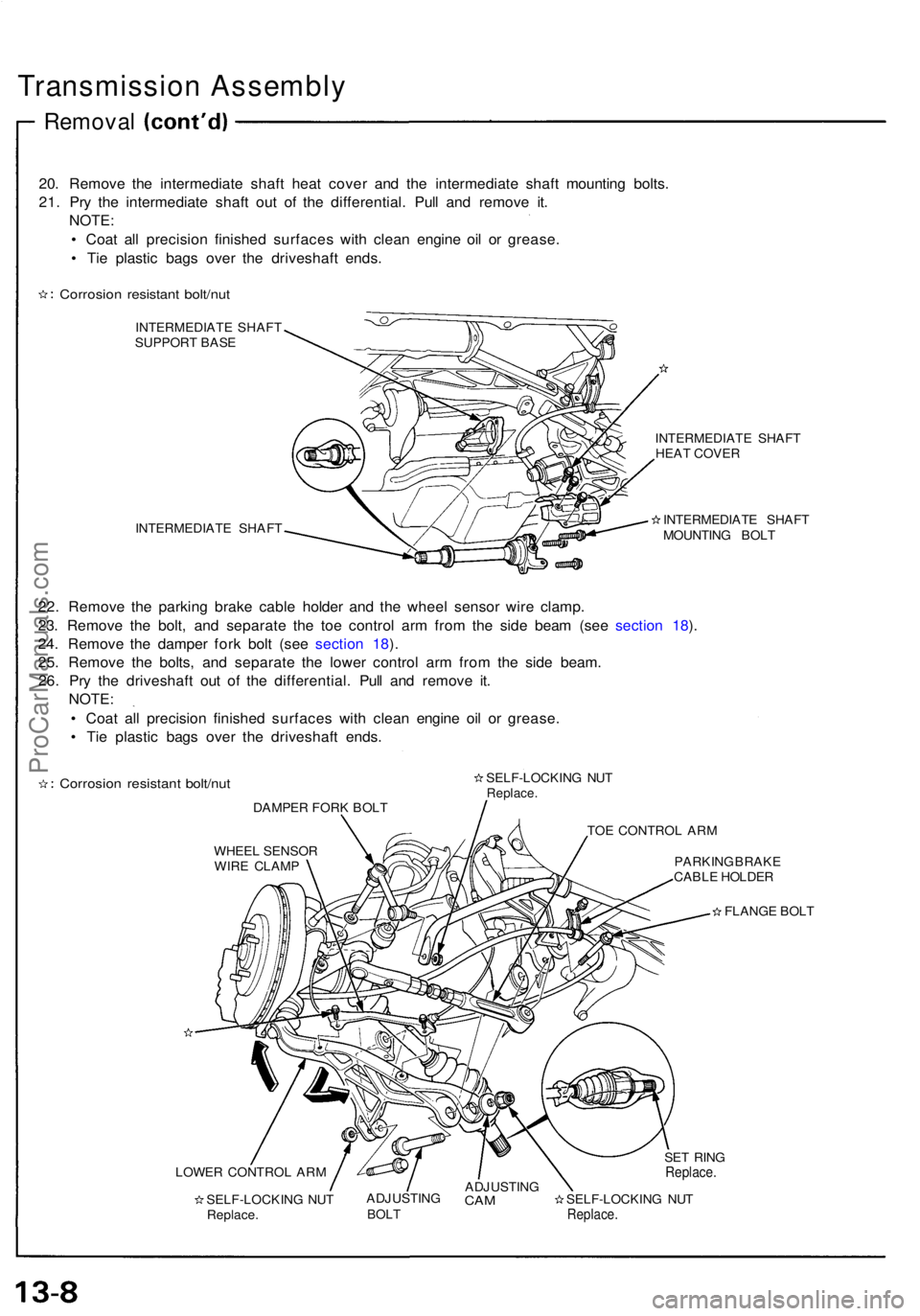

Transmission Assembly

Removal

20. Remove the intermediate shaft heat cover and the intermediate shaft mounting bolts.

21. Pry the intermediate shaft out of the differential. Pull and remove it. NOTE:

• Coat all precision finished surfaces with clean engine oil or grease.

• Tie plastic bags over the driveshaft ends.

Corrosion resistant bolt/nut

INTERMEDIATE SHAFT

SUPPORT BASE

INTERMEDIATE SHAFT INTERMEDIATE SHAFT

HEAT COVER

INTERMEDIATE SHAFT

MOUNTING BOLT

22. Remove the parking brake cable holder and the wheel sensor wire clamp.

23. Remove the bolt, and separate the toe control arm from the side beam (see section 18).

24. Remove the damper fork bolt (see section 18).

25. Remove the bolts, and separate the lower control arm from the side beam. 26. Pry the driveshaft out of the differential. Pull and remove it. NOTE:

• Coat all precision finished surfaces with clean engine oil or grease.

• Tie plastic bags over the driveshaft ends.

Corrosion resistant bolt/nut

DAMPER FORK BOLT SELF-LOCKING NUT

Replace.

TOE CONTROL ARM

WHEEL SENSOR WIRE CLAMP PARKING BRAKE

CABLE HOLDER

FLANGE BOLT

LOWER CONTROL ARM SELF-LOCKING NUTReplace. ADJUSTING

BOLT

ADJUSTING

CAM

SELF-LOCKING NUT

Replace.

SET RING

Replace.ProCarManuals.com