ACURA NSX 1991 Service Manual Online

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 81 of 1640

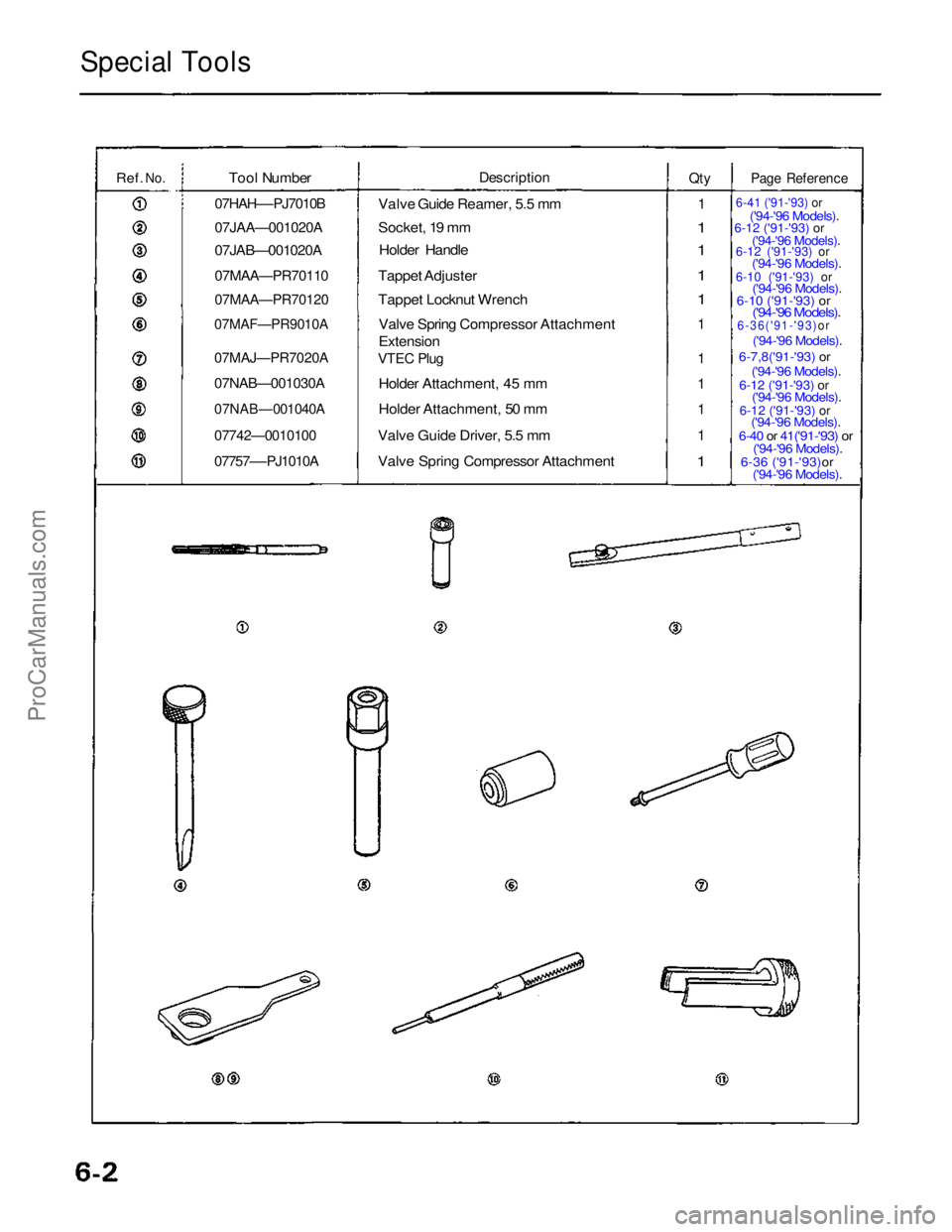

Special Tools

Ref.

No.

Tool Number

07HAH—-PJ7010B

07JAA—001020A

07JAB—001020A

07MAA—PR70110

07MAA—PR70120

07MAF—PR9010A

07MAJ—PR7020A

07NAB—001030A

07NAB — 001040A

07742—0010100

07757—-PJ1010A

Description

Valve Guide Reamer, 5.5 mm

Socket, 19 mm Holder Handle

Tappet Adjuster

Tappet Locknut Wrench Valve Spring Compressor Attachment

Extension

VTEC Plug

Holder Attachment, 45 mm

Holder Attachment, 50 mm

Valve Guide Driver, 5.5 mm

Valve Spring Compressor Attachment

Qty

1

1

1

1

1

1

1

1

1

1

1

Page Reference

6-41 ('91-'93) or

('94-'96 Models).

6-12 ('91-'93) or

('94-'96 Models).

6-12 ('91-'93) or

('94-'96 Models).

6-10 ('91-'93) or

('94-'96 Models).

6-10 ('91-'93) or

('94-'96 Models).

6-36('91-'93)or

('94-'96 Models).

6-7,8('91-'93) or

('94-'96 Models).

6-12 ('91-'93) or

('94-'96 Models).

6-12 ('91-'93) or

('94-'96 Models).

6-40 or 41('91-'93) or

('94-'96 Models).

6-36 ('91-'93)or ('94-'96 Models).

ProCarManuals.com

Page 82 of 1640

VTEC

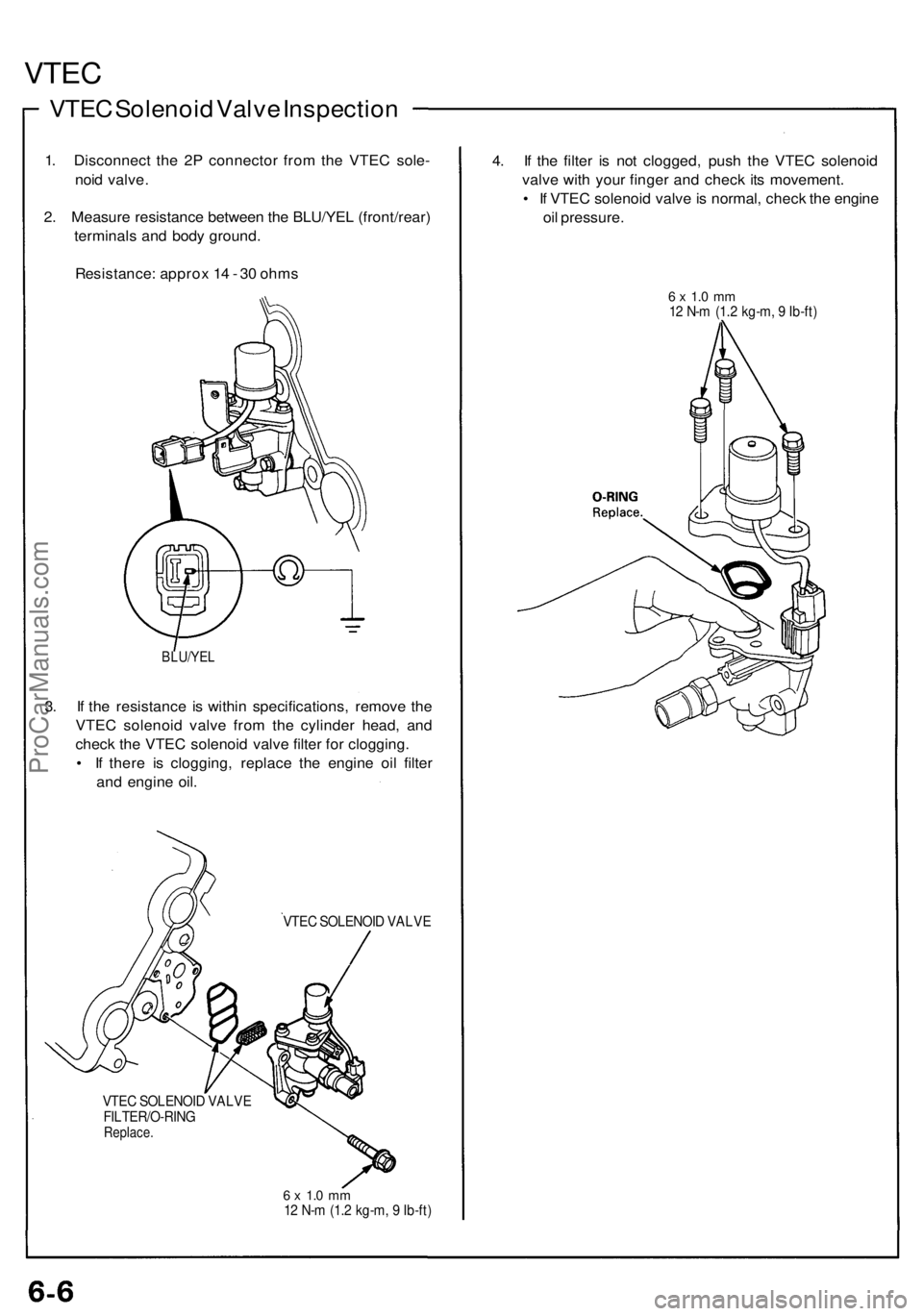

VTEC Solenoi d Valv e Inspectio n

1. Disconnec t th e 2 P connecto r fro m th e VTE C sole -

noi d valve .

2 . Measur e resistanc e betwee n th e BLU/YE L (front/rear )

terminal s an d bod y ground .

Resistance : appro x 1 4 - 3 0 ohm s

BLU/YE L

3. I f th e resistanc e i s withi n specifications , remov e th e

VTE C solenoi d valv e fro m th e cylinde r head , an d

chec k th e VTE C solenoi d valv e filte r fo r clogging .

• I f ther e i s clogging , replac e th e engin e oi l filte r

an d engin e oil .

VTE C SOLENOI D VALV E

VTE C SOLENOI D VALV E

FILTER/O-RIN G

Replace.

6 x 1. 0 m m12 N- m (1. 2 kg-m , 9 Ib-ft )

4. I f th e filte r i s no t clogged , pus h th e VTE C solenoi d

valv e wit h you r finge r an d chec k it s movement .

• I f VTE C solenoi d valv e is normal , chec k th e engin e

oi l pressure .

6 x 1. 0 m m12 N- m (1. 2 kg-m , 9 Ib-ft )

ProCarManuals.com

Page 83 of 1640

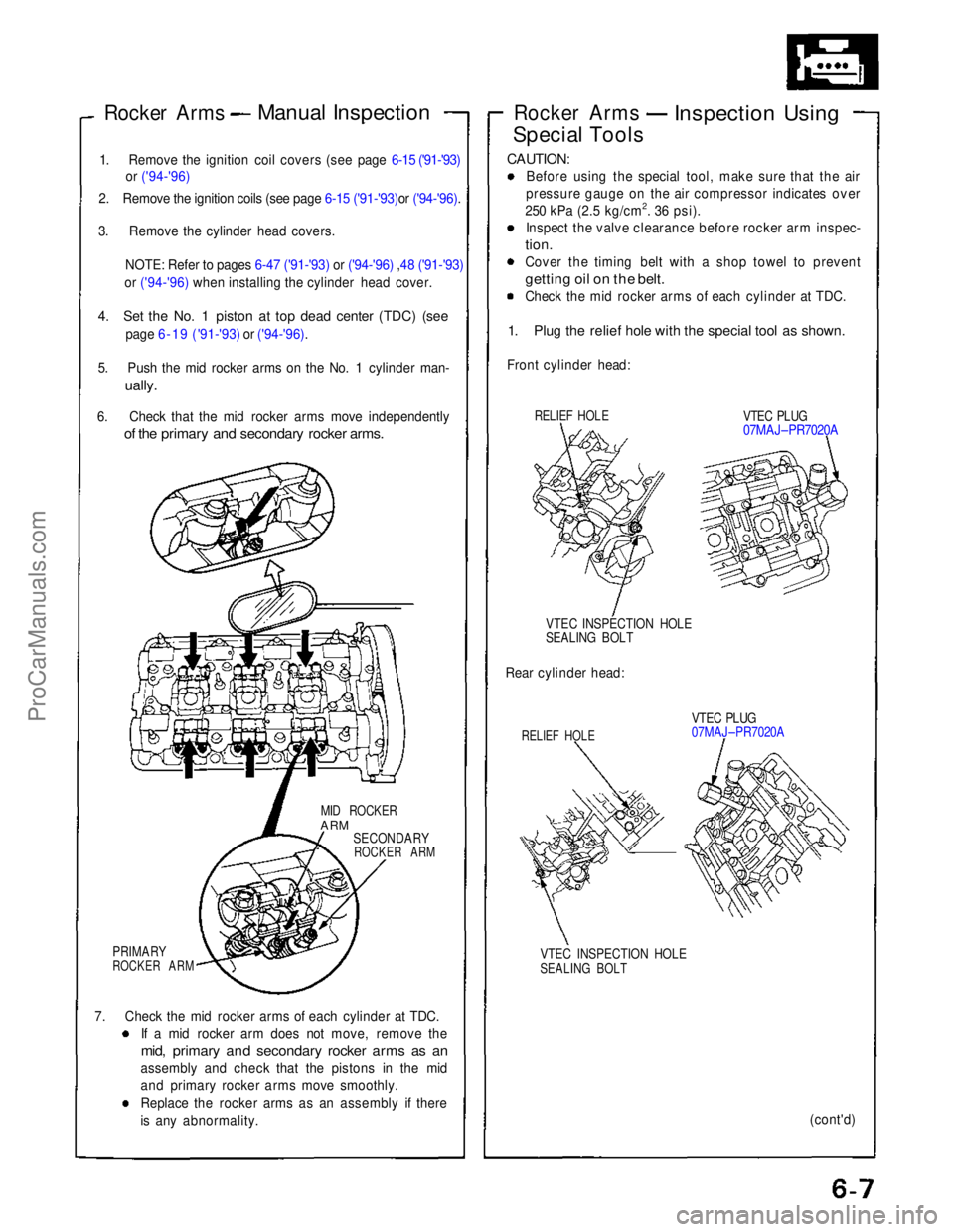

Rocker Arms

Manual Inspection

1. Remove the ignition coil covers (see page 6-15 ('91-'93) or ('94-'96)

2. Remove the ignition coils (see page 6-15 ('91-'93)or ('94-'96).

3. Remove the cylinder head covers.

NOTE: Refer to pages 6-47 ('91-'93)

or ('94-'96) ,48 ('91-'93)

or ('94-'96) when installing the cylinder head cover.

4. Set the No. 1 piston at top dead center (TDC) (see

page 6-19 ('91-'93)

or ('94-'96).

5. Push the mid rocker arms on the No. 1 cylinder man-

ually.

6. Check that the mid rocker arms move independently

of the primary and secondary rocker arms.

MID ROCKER

ARM

SECONDARY

ROCKER ARM

PRIMARY

ROCKER ARM

7. Check the mid rocker arms of each cylinder at TDC. If a mid rocker arm does not move, remove the

mid, primary and secondary rocker arms as an

assembly and check that the pistons in the mid

and primary rocker arms move smoothly.

Replace the rocker arms as an assembly if there

is any abnormality. Rocker Arms

Inspection Using

Special Tools

CAUTION:

Before using the special tool, make sure that the air

pressure gauge on the air compressor indicates over

250 kPa (2.5 kg/cm2. 36 psi). Inspect the valve clearance before rocker arm inspec-

tion.

Cover the timing belt with a shop towel to prevent

getting oil on the belt.

Check the mid rocker arms of each cylinder at TDC.

1. Plug the relief hole with the special tool as shown.

Front cylinder head:

RELIEF HOLE

VTEC PLUG

07MAJ–PR7020A

VTEC INSPECTION HOLE

SEALING BOLT

Rear cylinder head:

RELIEF HOLE

VTEC PLUG

07MAJ–PR7020A

VTEC INSPECTION HOLE

SEALING BOLT

(cont'd)ProCarManuals.com

Page 84 of 1640

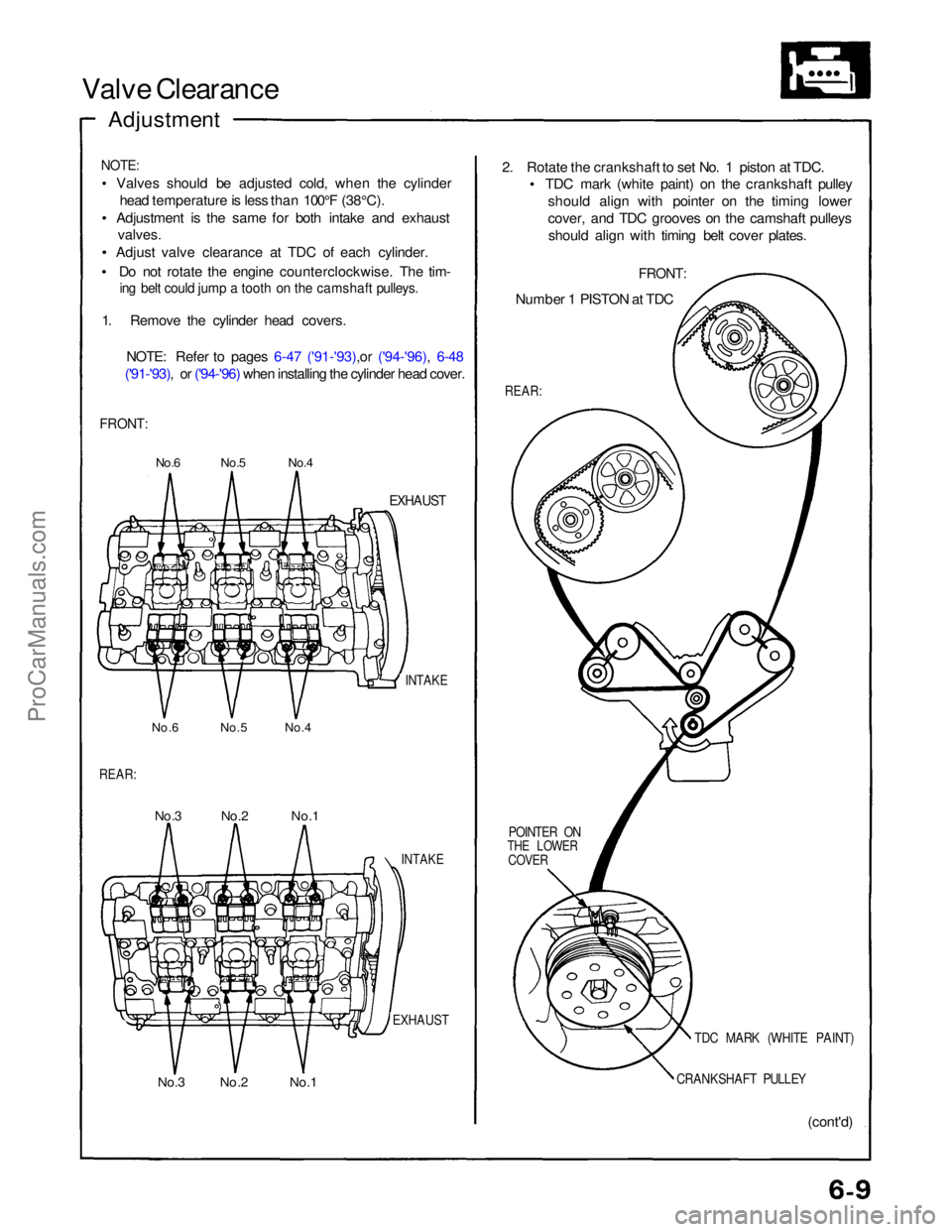

Valve Clearance

Adjustment

NOTE:

Valves should be adjusted cold, when the cylinderhead temperature is less than 100°F (38°C).

Adjustment is the same for both intake and exhaust valves.

Adjust valve clearance at TDC of each cylinder.

Do not rotate the engine counterclockwise. The tim-

ing belt could jump a tooth on the camshaft pulleys.

1. Remove the cylinder head covers.

NOTE: Refer to pages 6-47 ('91-'93),or ('94-'96), 6-48

('91-'93), or ('94-'96) when installing the cylinder head cover.

FRONT:

No.6 No.5 No.4

EXHAUST

INTAKE

No.6 No.5 No.4

REAR:

No.3 No.2 No.1

INTAKE

EXHAUST

No.3 No.2 No.1 (cont'd)

CRANKSHAFT PULLEY

TDC MARK (WHITE PAINT)

POINTER ON

THE LOWER

COVER

REAR:

Number 1 PISTON at TDC

FRONT:

2. Rotate the crankshaft to set No. 1 piston at TDC.

TDC mark (white paint) on the crankshaft pulley

should align with pointer on the timing lower

cover, and TDC grooves on the camshaft pulleysshould align with timing belt cover plates.ProCarManuals.com

Page 85 of 1640

Valve Clearance

Adjustment (cont'd)

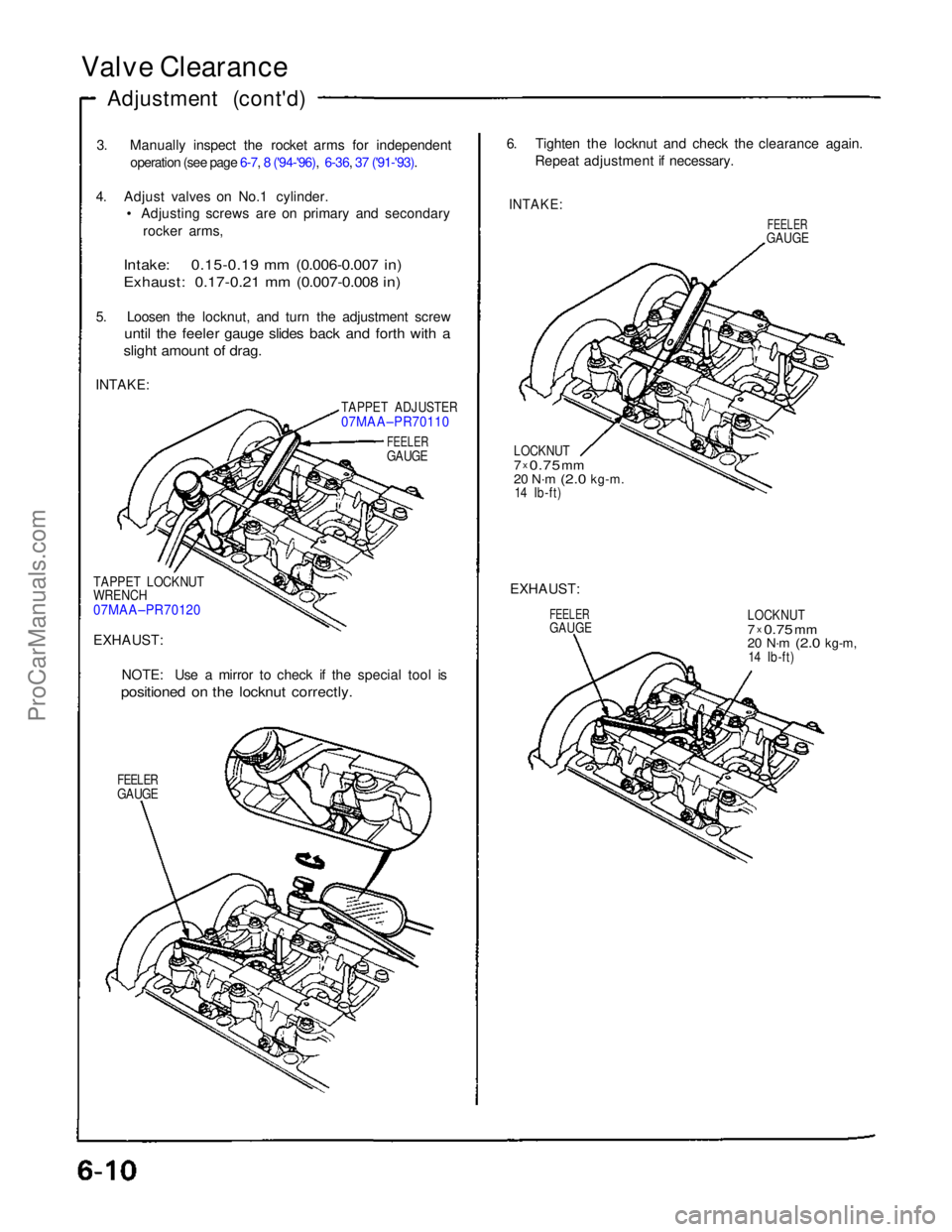

3. Manually inspect the rocket arms for independentoperation (see page 6-7, 8 ('94-'96), 6-36, 37 ('91-'93).

4. Adjust valves on No.1 cylinder.

• Adjusting screws are on primary and secondary

rocker arms,

Intake: 0.15-0.19 mm (0.006-0.007 in)

Exhaust: 0.17-0.21 mm (0.007-0.008 in)

5. Loosen the locknut, and turn the adjustment screw

until the feeler gauge slides back and forth with a

slight amount of drag.

INTAKE:

TAPPET ADJUSTER

07MAA–PR70110

FEELER

GAUGE

TAPPET LOCKNUT

WRENCH

07MAA–PR70120

EXHAUST: NOTE: Use a mirror to check if the special tool is

positioned on the locknut correctly.

FEELER

GAUGE

6. Tighten the locknut and check the clearance again.

Repeat adjustment if necessary.

INTAKE:

FEELER

GAUGE

LOCKNUT

7 x

0.75

mm

20 N·m

(2.0

kg-m.

14 Ib-ft)

EXHAUST:

FEELER

GAUGE

LOCKNUT

7

x

0.75

mm

20 N·m

(2.0

kg-m,

14 Ib-ft)ProCarManuals.com

Page 86 of 1640

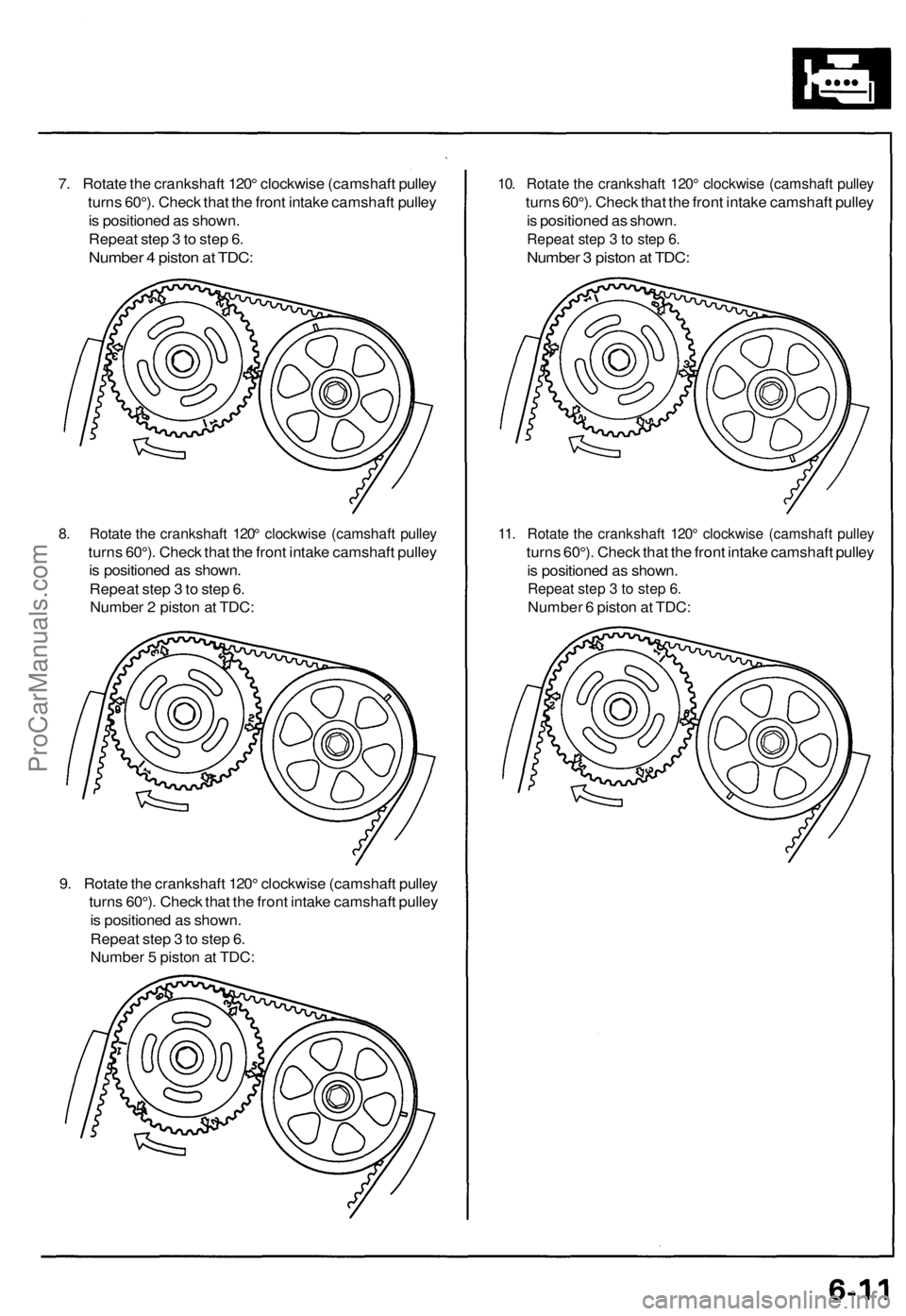

7. Rotate the crankshaft 120° clockwise (camshaft pulley

turns 60°). Check that the front intake camshaft pulley

is positioned as shown.

Repeat step 3 to step 6.

Number 4 piston at TDC:

8. Rotate the crankshaft 120° clockwise (camshaft pulley

turns 60°). Check that the front intake camshaft pulley

is positioned as shown.

Repeat step 3 to step 6.

Number 2 piston at TDC:

9. Rotate the crankshaft 120° clockwise (camshaft pulley

turns 60°). Check that the front intake camshaft pulley

is positioned as shown.

Repeat step 3 to step 6.

Number 5 piston at TDC:

10. Rotate the crankshaft 120° clockwise (camshaft pulley

turns 60°). Check that the front intake camshaft pulley

is positioned as shown.

Repeat step 3 to step 6.

Number 3 piston at TDC:

11. Rotate the crankshaft 120° clockwise (camshaft pulley

turns 60°). Check that the front intake camshaft pulley

is positioned as shown.

Repeat step 3 to step 6.

Number 6 piston at TDC:ProCarManuals.com

Page 87 of 1640

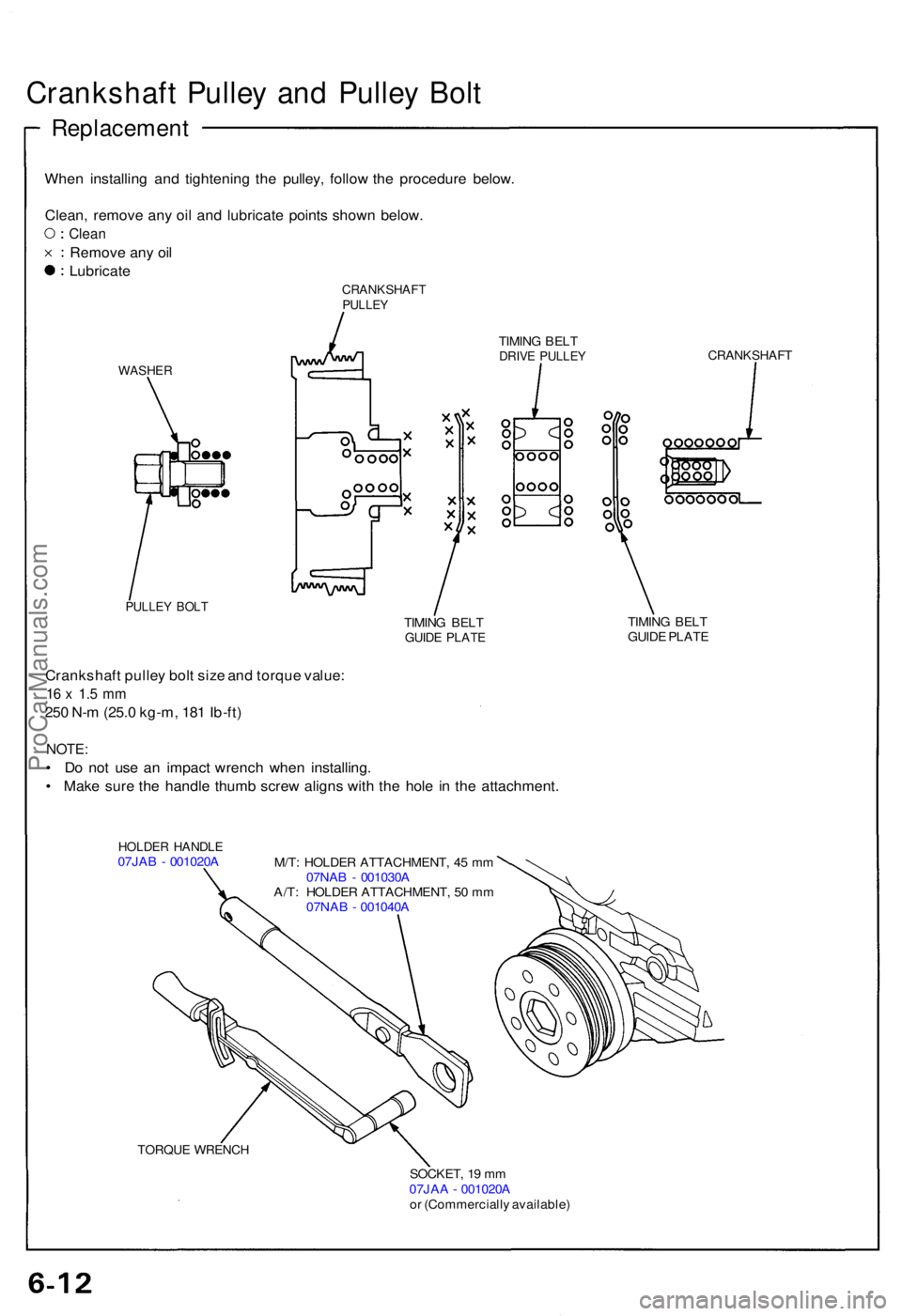

Crankshaft Pulle y an d Pulle y Bol t

Replacemen t

When installin g an d tightenin g th e pulley , follo w th e procedur e below .

Clean , remov e an y oi l an d lubricat e point s show n below .

Clean

Remov e an y oi l

Lubricat e

CRANKSHAF TPULLEY

WASHE R

PULLEY BOL T

TIMIN G BEL TDRIV E PULLE YCRANKSHAF T

TIMING BEL TGUID E PLAT ETIMING BEL T

GUID E PLAT E

Crankshaf t pulle y bol t siz e an d torqu e value :

16 x 1. 5 m m

250 N- m (25. 0 kg-m , 18 1 Ib-ft )

NOTE :

• D o no t us e a n impac t wrenc h whe n installing .

• Mak e sur e th e handl e thum b scre w align s wit h th e hol e i n th e attachment .

HOLDER HANDL E07JAB - 001020 A

M/T: HOLDE R ATTACHMENT , 4 5 m m

07NA B - 001030 A

A/T : HOLDE R ATTACHMENT , 5 0 m m

07NA B - 001040 A

TORQU E WRENC H

SOCKET, 1 9 m m

07JA A - 001020 A

o r (Commerciall y available )

ProCarManuals.com

Page 88 of 1640

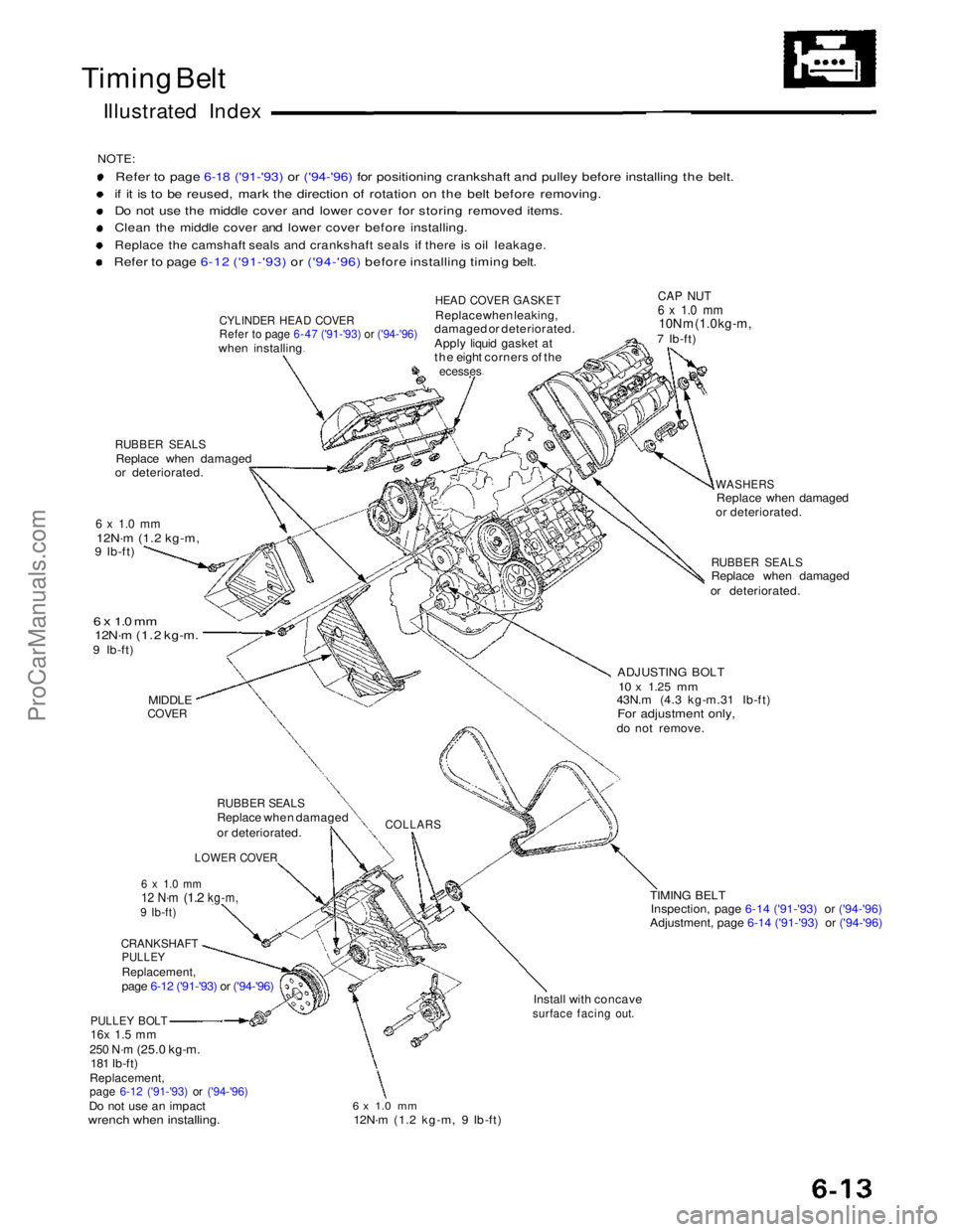

Timing Belt

Illustrated Index

NOTE:

Refer to page 6-18 ('91-'93) or ('94-'96) for positioning crankshaft and pulley before installing the belt.

if it is to be reused, mark the direction of rotation on the belt before removing.

Do not use the middle cover and lower cover for storing removed items.

Clean the middle cover and lower cover before installing.

Replace the camshaft seals and crankshaft seals if there is oil leakage.

Refer to page 6-12 ('91-'93) or ('94-'96) before installing timing belt.

CYLINDER HEAD COVER

Refer to page 6-47 ('91-'93) or ('94-'96)

when installing

RUBBER SEALS

Replace when damaged

or deteriorated.

6 x 1.0 mm

12N·m (1.2 kg-m,

9 Ib-ft)

6 x 1.0 mm

12N·m (1.2 kg-m.

9 Ib-ft)

MIDDLE

COVER

RUBBER SEALS

Replace when damaged

or deteriorated.

LOWER COVER

6 x 1.0 mm

12 N·m

(1.2

kg-m,

9 Ib-ft)

CRANKSHAFT

PULLEY

Replacement,

page 6-12 ('91-'93) or ('94-'96)

PULLEY BOLT

16x 1.5 mm

250 N·m

(25.0 kg-m. 181 Ib-ft)

Replacement,

page 6-12 ('91-'93)

or ('94-'96)

Do not use an impact

wrench when installing.

HEAD COVER GASKET

Replace when leaking,

damaged or deteriorated.

Apply liquid gasket at

the eight corners of the

ecesses

CAP NUT

6 x 1.0 mm

10N m (1.0 kg-m,

7 Ib-ft)

WASHERS

Replace when damaged

or deteriorated.

RUBBER SEALS

Replace when damaged

or deteriorated.

ADJUSTING BOLT

10 x

1.25

mm

43N.m (4.3 kg-m.31 Ib-ft)

For adjustment only,

do not remove.

COLLARS

TIMING BELTInspection, page 6-14 ('91-'93) or ('94-'96)

Adjustment, page 6-14 ('91-'93) or ('94-'96)

Install with concave

surface facing out.

6 x 1.0 mm

12N·m (1.2 kg-m, 9 Ib-ft)ProCarManuals.com

Page 89 of 1640

Timing Belt

Inspection

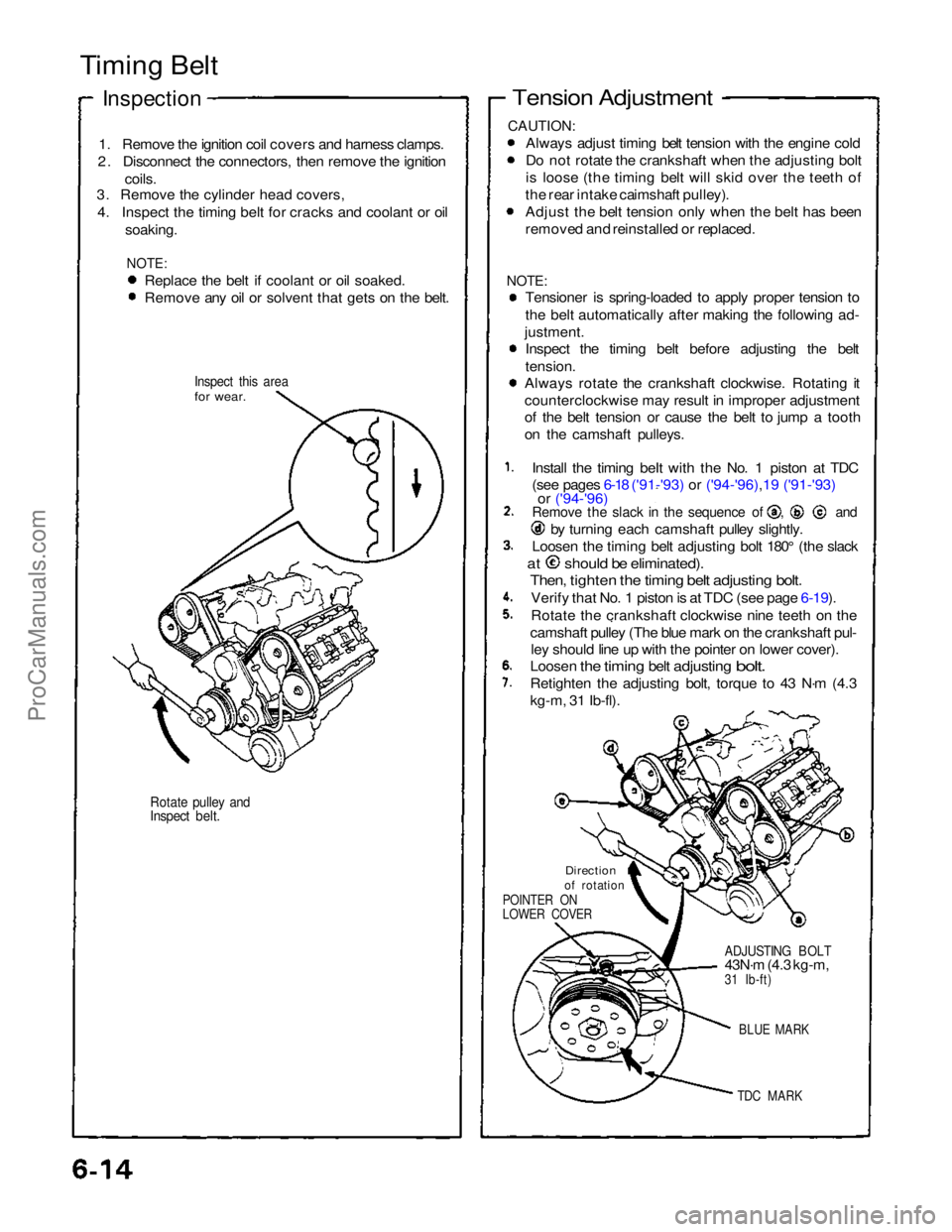

1. Remove the ignition coil covers and harness clamps.

2. Disconnect the connectors, then remove the ignition

coils.

3. Remove the cylinder head covers,

4. Inspect the timing belt for cracks and coolant or oil soaking.

NOTE:

Replace the belt if coolant or oil soaked.

Remove any oil or solvent that gets on the belt.

Inspect this area

for wear.

Rotate pulley and

Inspect belt.

Tension Adjustment

CAUTION:

Always adjust timing belt tension with the engine cold

Do not rotate the crankshaft when the adjusting bolt

is loose (the timing belt will skid over the teeth of

the rear intake caimshaft pulley).

Adjust the belt tension only when the belt has been

removed and reinstalled or replaced.

NOTE:

Tensioner is spring-loaded to apply proper tension to

the belt automatically after making the following ad-

justment. Inspect the timing belt before adjusting the belt

tension.

Always rotate the crankshaft clockwise. Rotating it

counterclockwise may result in improper adjustment

of the belt tension or cause the belt to jump a tooth

on the camshaft pulleys.

Install the timing beIt with the No. 1 piston at TDC

(see pages 6-18 ('91-'93) or ('94-'96),19 ('91-'93)

or ('94-'96) Remove the slack in the sequence of , and

by turning each camshaft pulley slightly.

Loosen the timing belt adjusting bolt 180° (the slack

at should be eliminated).

Then, tighten the timing belt adjusting bolt.

Verify that No. 1 piston is at TDC (see page 6-19).

Rotate the crankshaft clockwise nine teeth on the

camshaft pulley (The blue mark on the crankshaft pul- ley should line up with the pointer on lower cover).

Loosen

the

timing

belt

adjusting

bolt.

Retighten the adjusting bolt, torque to 43 N·m (4.3

kg-m, 31 Ib-fl).

Direction

of rotation

POINTER ON

LOWER COVER

ADJUSTING BOLT

43N·m (4.3 kg-m,

31 Ib-ft)

BLUE MARK

TDC MARK

ProCarManuals.com

Page 90 of 1640

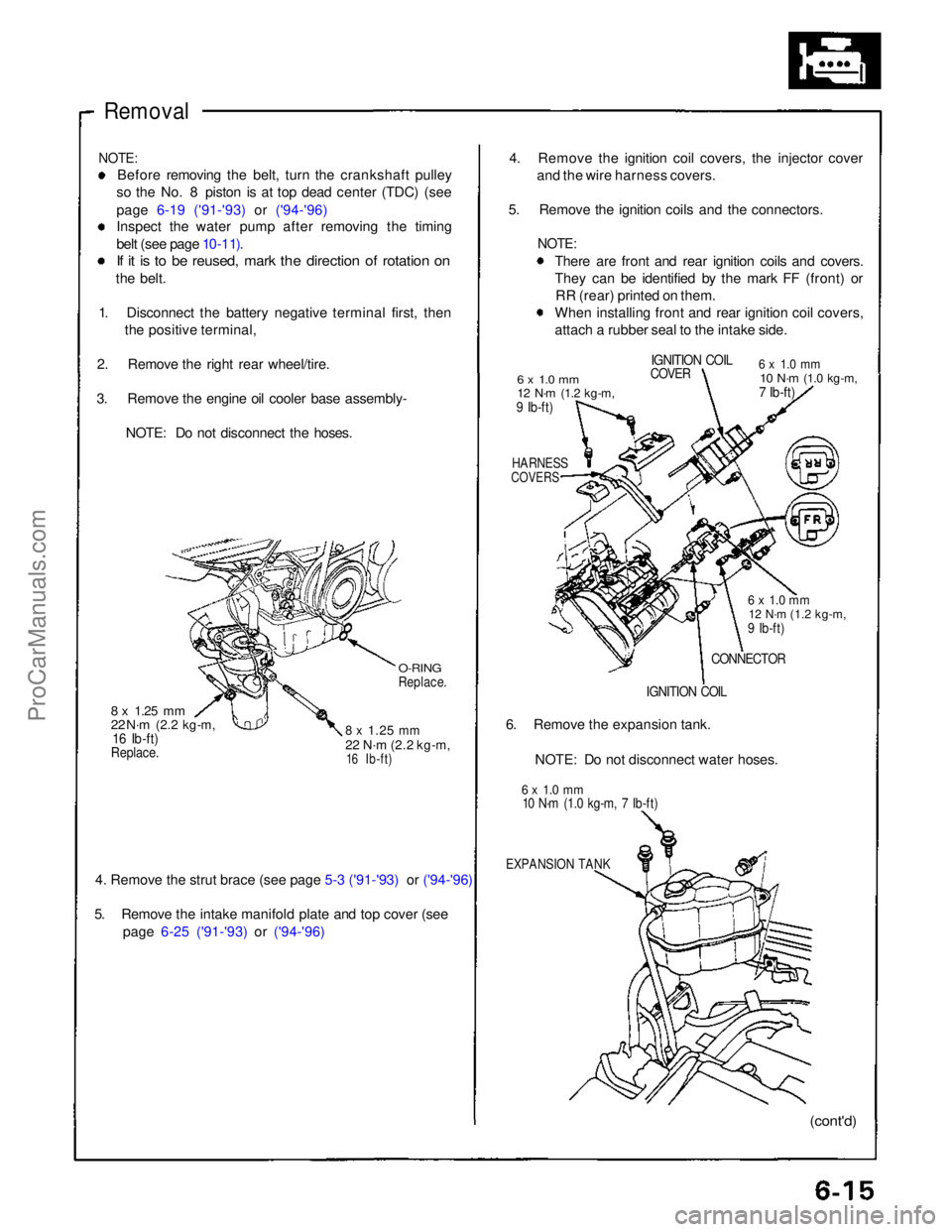

Removal

NOTE:

Before removing the belt, turn the crankshaft pulley

so the No. 8 piston is at top dead center (TDC) (see

page 6-19 ('91-'93) or ('94-'96)

Inspect the water pump after removing the timing

belt (see page 10-11).

If it is to be reused, mark the direction of rotation on

the belt.

1. Disconnect the battery negative terminal first, then the positive terminal,

2. Remove the right rear wheel/tire.

3. Remove the engine oil cooler base assembly- NOTE: Do not disconnect the hoses.

O-RING

Replace.

8 x

1.25

mm

22 N·m

(2.2 kg-m,

16 Ib-ft)

8 x

1.25

mm

22 N·m

(2.2 kg-m,

16 Ib-ft)

Replace.

4. Remove the strut brace (see page 5-3 ('91-'93) or ('94-'96)

5. Remove the intake manifold plate and top cover (see

page 6-25 ('91-'93) or ('94-'96)

4. Remove the ignition coil covers, the injector cover

and the wire harness covers.

5. Remove the ignition coils and the connectors.

NOTE:

There are front and rear ignition coils and covers.

They can be identified by the mark FF (front) orRR (rear) printed on them.

When installing front and rear ignition coil covers,

attach a rubber seal to the intake side.

6 x 1.0 mm

12 N·m

(1.2 kg-m,

9 Ib-ft)

IGNITION COIL

COVER

6 x 1.0 mm

10 N·m

(1.0 kg-m,

7 Ib-ft)

HARNESS

COVERS

6 x 1.0 mm

12 N·m

(1.2 kg-m,

9 Ib-ft)

CONNECTOR

IGNITION COIL

6. Remove the expansion tank.

NOTE: Do not disconnect water hoses.

6 x 1.0 mm

10 N·m (1.0 kg-m, 7 Ib-ft)

EXPANSION TANK

(cont'd)ProCarManuals.com