ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 121 of 1640

Cylinder Head s

Installatio n

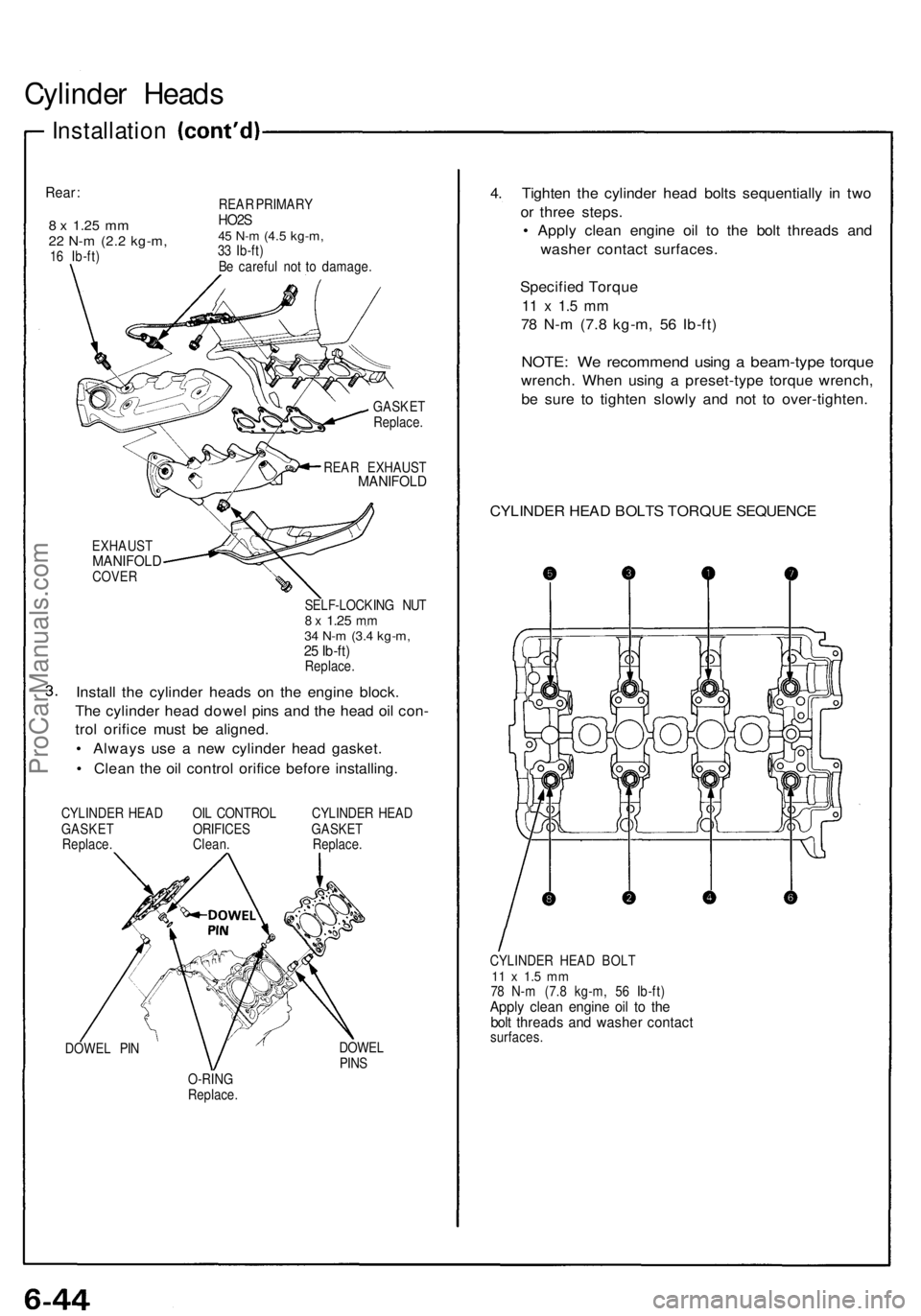

Rear:

8 x 1.2 5 mm22 N- m (2. 2 kg-m ,16 Ib-ft ) REA

R PRIMAR Y

HO2S45 N- m (4. 5 kg-m ,33 Ib-ft )

B e carefu l no t t o damage .

GASKE T

Replace .

REA R EXHAUS T

MANIFOLD

EXHAUSTMANIFOL DCOVER

SELF-LOCKIN G NU T8 x 1.2 5 mm34 N- m (3. 4 kg-m ,25 Ib-ft )Replace .

Install th e cylinde r head s o n th e engin e block .

Th e cylinde r hea d dowe l pin s an d th e hea d oi l con -

tro l orific e mus t b e aligned .

• Alway s us e a ne w cylinde r hea d gasket .

• Clea n th e oi l contro l orific e befor e installing .

CYLINDE R HEA D OI L CONTRO L CYLINDE R HEA D

GASKE T ORIFICE S GASKE T

Replace . Clean . Replace .

DOWE L PI N DOWE

L

PIN S

O-RIN G

Replace .

4. Tighte n th e cylinde r hea d bolt s sequentiall y i n tw o

o r thre e steps .

• Appl y clea n engin e oi l t o th e bol t thread s an d

washe r contac t surfaces .

Specifie d Torqu e

11 x 1. 5 m m

78 N- m (7. 8 kg-m , 5 6 Ib-ft )

NOTE : W e recommen d usin g a beam-typ e torqu e

wrench . Whe n usin g a preset-typ e torqu e wrench ,

b e sur e t o tighte n slowl y an d no t t o over-tighten .

CYLINDE R HEA D BOLT S TORQU E SEQUENC E

CYLINDER HEA D BOL T11 x 1. 5 m m78 N- m (7. 8 kg-m , 5 6 Ib-ft )Apply clea n engin e oi l t o th ebolt thread s an d washe r contac tsurfaces .

ProCarManuals.com

Page 122 of 1640

Camshafts

Installation

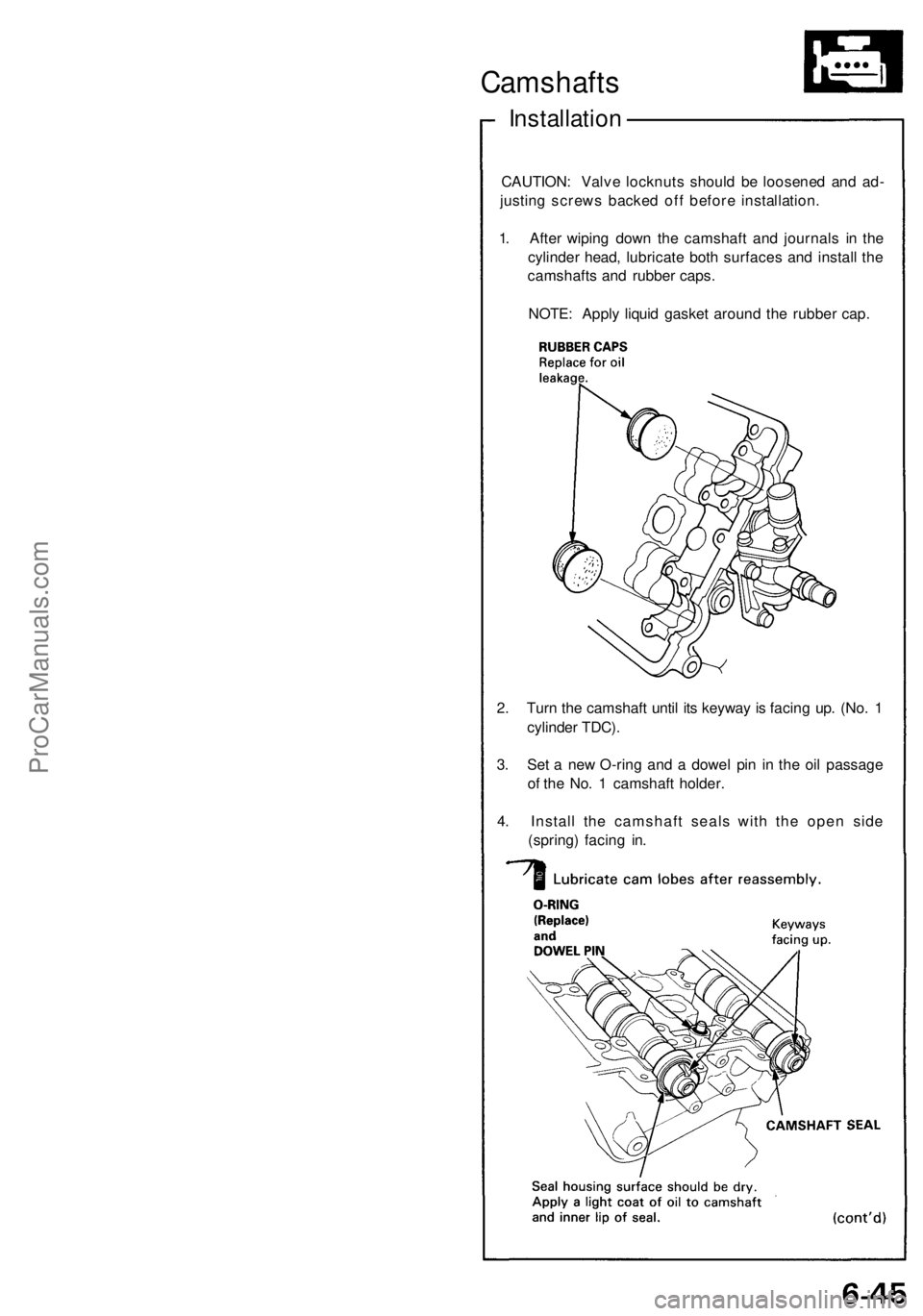

CAUTION : Valv e locknut s shoul d b e loosene d an d ad -

justin g screw s backe d of f befor e installation .

1 . Afte r wipin g dow n th e camshaf t an d journal s i n th e

cylinde r head , lubricat e bot h surface s an d instal l th e

camshaft s an d rubbe r caps.

NOTE : Appl y liqui d gaske t aroun d th e rubbe r cap .

2 . Tur n th e camshaft until it s keywa y i s facin g up . (No . 1

cylinde r TDC) .

3 . Se t a ne w O-rin g an d a dowe l pi n i n th e oi l passag e

o f th e No . 1 camshaf t holder .

4 . Instal l th e camshaf t seal s wit h th e ope n sid e

(spring ) facin g in .

ProCarManuals.com

Page 123 of 1640

Camshafts

Installation

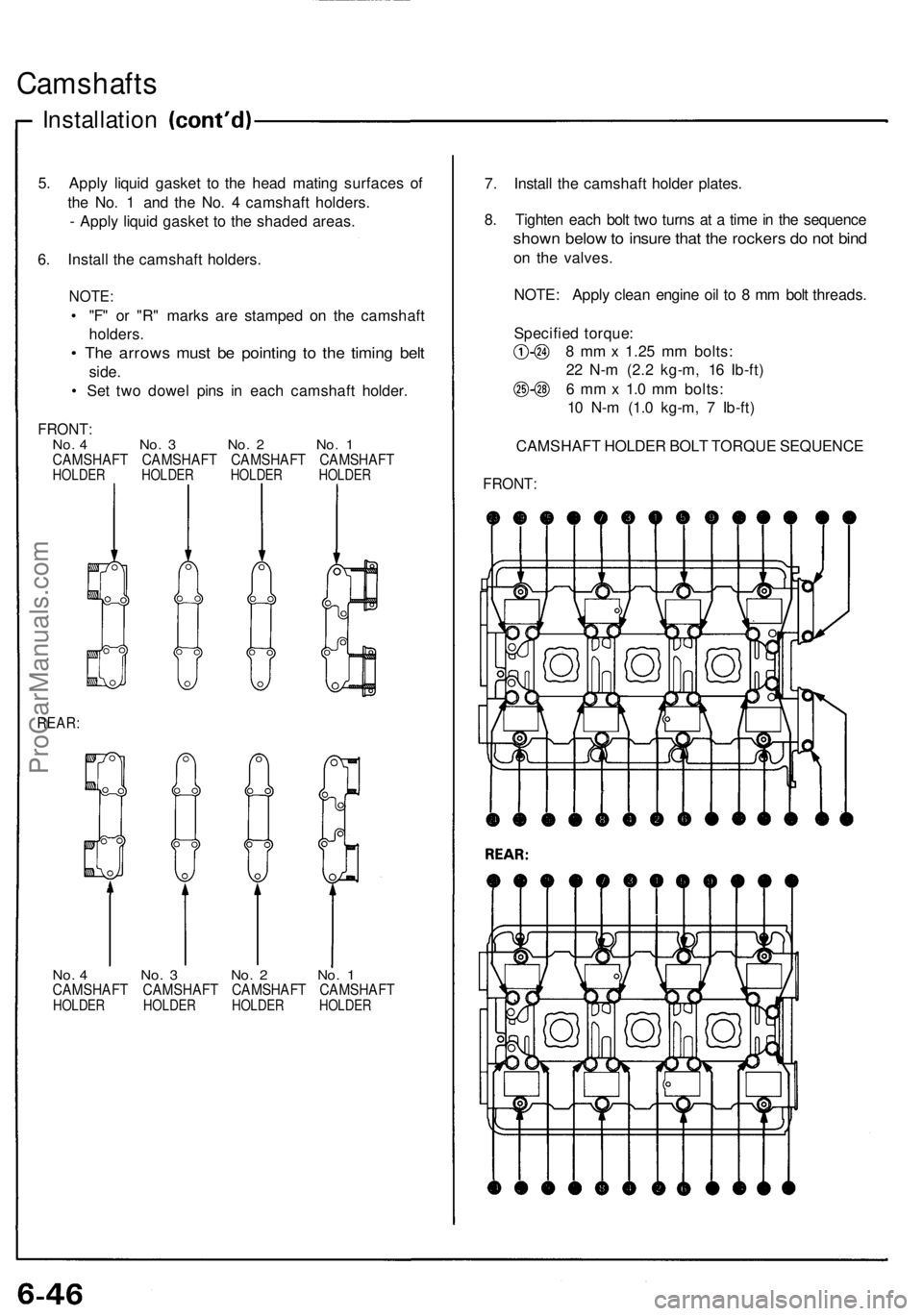

5. Apply liquid gasket to the head mating surfaces of

the No. 1 and the No. 4 camshaft holders.

- Apply liquid gasket to the shaded areas.

6. Install the camshaft holders.

NOTE:

• "F" or "R" marks are stamped on the camshaft

holders.

• The arrows must be pointing to the timing belt

side.

• Set two dowel pins in each camshaft holder.

FRONT:

No. 4 No. 3 No. 2 No. 1

CAMSHAFT CAMSHAFT CAMSHAFT CAMSHAFT

HOLDER HOLDER HOLDER HOLDER

REAR:

No. 4 No. 3 No. 2 No. 1

CAMSHAFT CAMSHAFT CAMSHAFT CAMSHAFT

HOLDER HOLDER HOLDER HOLDER

7. Install the camshaft holder plates.

8. Tighten each bolt two turns at a time in the sequence

shown below to insure that the rockers do not bind

on the valves.

NOTE: Apply clean engine oil to 8 mm bolt threads.

Specified torque:

8 mm x 1.25 mm bolts:

22 N-m (2.2 kg-m, 16 Ib-ft)

6 mm x 1.0 mm bolts:

10 N-m (1.0 kg-m, 7 Ib-ft)

CAMSHAFT HOLDER BOLT TORQUE SEQUENCE

FRONT:ProCarManuals.com

Page 124 of 1640

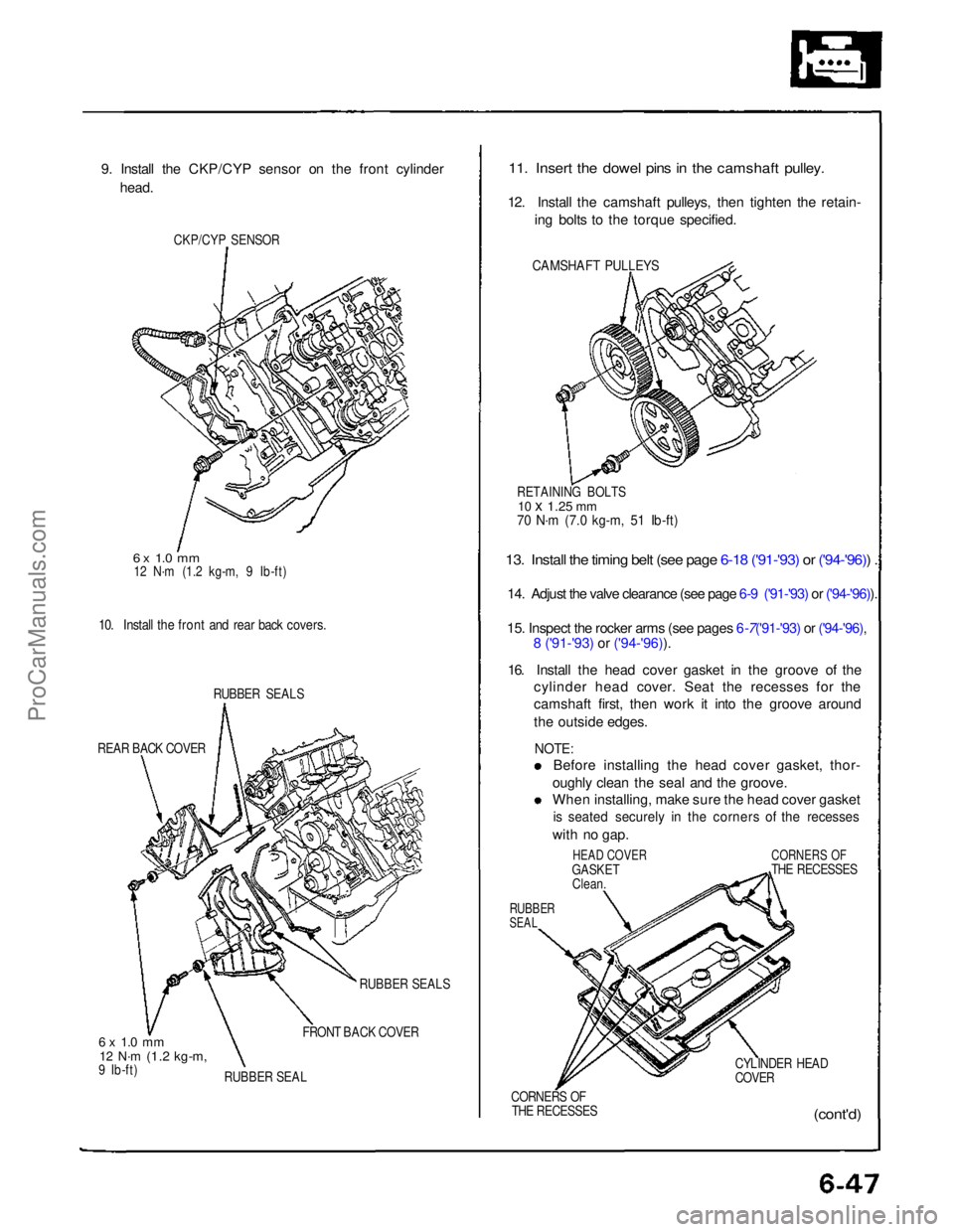

9. Install the CKP/CYP sensor on the front cylinder

head.

CKP/CYP SENSOR

6 x 1.0 mm

12 N·m (1.2 kg-m, 9 Ib-ft)

10. Install the front and rear back covers.

RUBBER SEALS

REAR BACK COVER

6 x 1.0 mm

12 N·m

(1.2 kg-m,

9 Ib-ft) RUBBER SEALS

FRONT BACK COVER

RUBBER SEAL

11. Insert the dowel pins in the camshaft pulley.

12. Install the camshaft pulleys, then tighten the retain- ing bolts to the torque specified.

CAMSHAFT PULLEYS

13. Install the timing belt (see page 6-18 ('91-'93) or ('94-'96)) .

14. Adjust the valve clearance (see page 6-9 ('91-'93) or ('94-'96)).

15. Inspect the rocker arms (see pages

6-7('91-'93) or ('94-'96),8 ('91-'93) or ('94-'96)).

16. Install the head cover gasket in the groove of the

cylinder head cover. Seat the recesses for the

camshaft first, then work it into the groove around

the outside edges.

NOTE:

Before installing the head cover gasket, thor-

oughly clean the seal and the groove. When installing, make sure the head cover gasket

is seated securely in the corners of the recesses

with no gap.

HEAD COVER

GASKET Clean.

RUBBER

SEAL

CORNERS OF

THE RECESSES

CYLINDER HEAD

COVER

CORNERS OF THE RECESSES

(cont'd)

RETAINING BOLTS

10 x

1.25

mm

70 N·m (7.0 kg-m, 51 Ib-ft)ProCarManuals.com

Page 125 of 1640

Camshafts

Installation

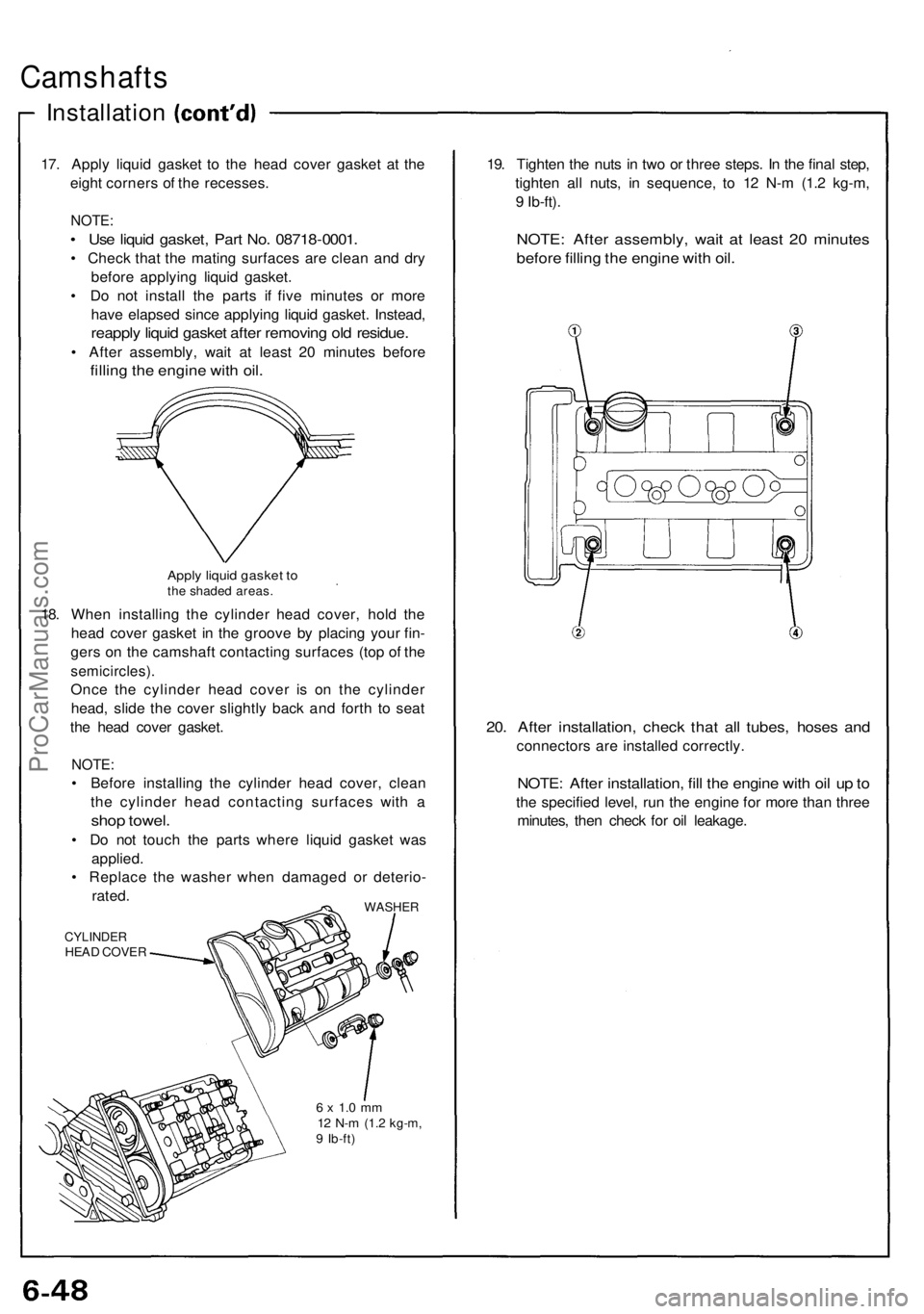

17. Appl y liqui d gaske t t o th e hea d cove r gaske t a t th e

eigh t corner s o f th e recesses .

NOTE:

• Us e liqui d gasket , Par t No . 0871 8-0001 .

• Chec k tha t th e matin g surface s ar e clea n an d dr y

befor e applyin g liqui d gasket .

• D o no t instal l th e part s i f fiv e minute s o r mor e

hav e elapse d sinc e applyin g liqui d gasket . Instead ,

reapply liqui d gaske t afte r removin g ol d residue .

• Afte r assembly , wai t a t leas t 2 0 minute s befor e

filling th e engin e wit h oil .

Appl y liqui d gaske t t oth e shade d areas .

18. Whe n installin g th e cylinde r hea d cover , hol d th e

hea d cove r gaske t i n th e groov e b y placin g you r fin -

ger s o n th e camshaf t contactin g surface s (to p o f th e

semicircles) .

Once th e cylinde r hea d cove r i s o n th e cylinde r

head , slid e th e cove r slightl y bac k an d fort h t o sea t

th e hea d cove r gasket .

NOTE:

• Befor e installin g th e cylinde r hea d cover , clea n

th e cylinde r hea d contactin g surface s wit h a

sho p towel .

• D o no t touc h th e part s wher e liqui d gaske t wa s

applied .

• Replac e th e washe r whe n damage d o r deterio -

rated .

WASHE R

CYLINDE RHEAD COVE R

6 x 1. 0 m m12 N- m (1. 2 kg-m ,9 Ib-ft )

19. Tighte n th e nut s i n tw o o r thre e steps . I n th e fina l step ,

tighte n al l nuts , i n sequence , t o 1 2 N- m (1. 2 kg-m ,

9 Ib-ft) .

NOTE : Afte r assembly , wai t a t leas t 2 0 minute s

before fillin g th e engin e wit h oil .

20. Afte r installation , chec k tha t al l tubes , hose s an d

connector s ar e installe d correctly .

NOTE: Afte r installation , fil l th e engin e wit h oi l u p to

th e specifie d level , ru n th e engin e fo r mor e tha n thre e

minutes , the n chec k fo r oi l leakage .

ProCarManuals.com

Page 126 of 1640

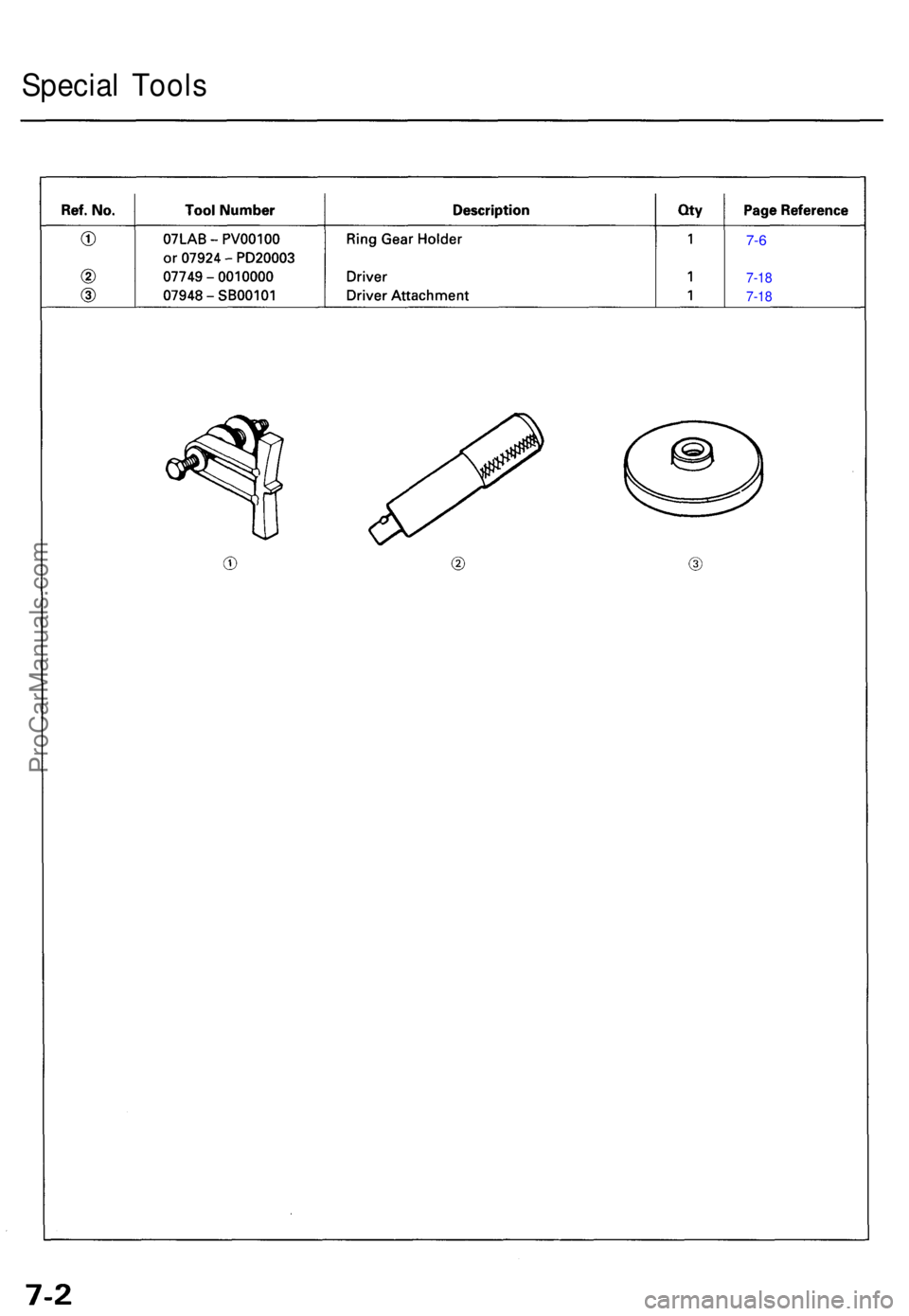

Special Tool s

7-6

7-1 8

7-1 8

ProCarManuals.com

Page 127 of 1640

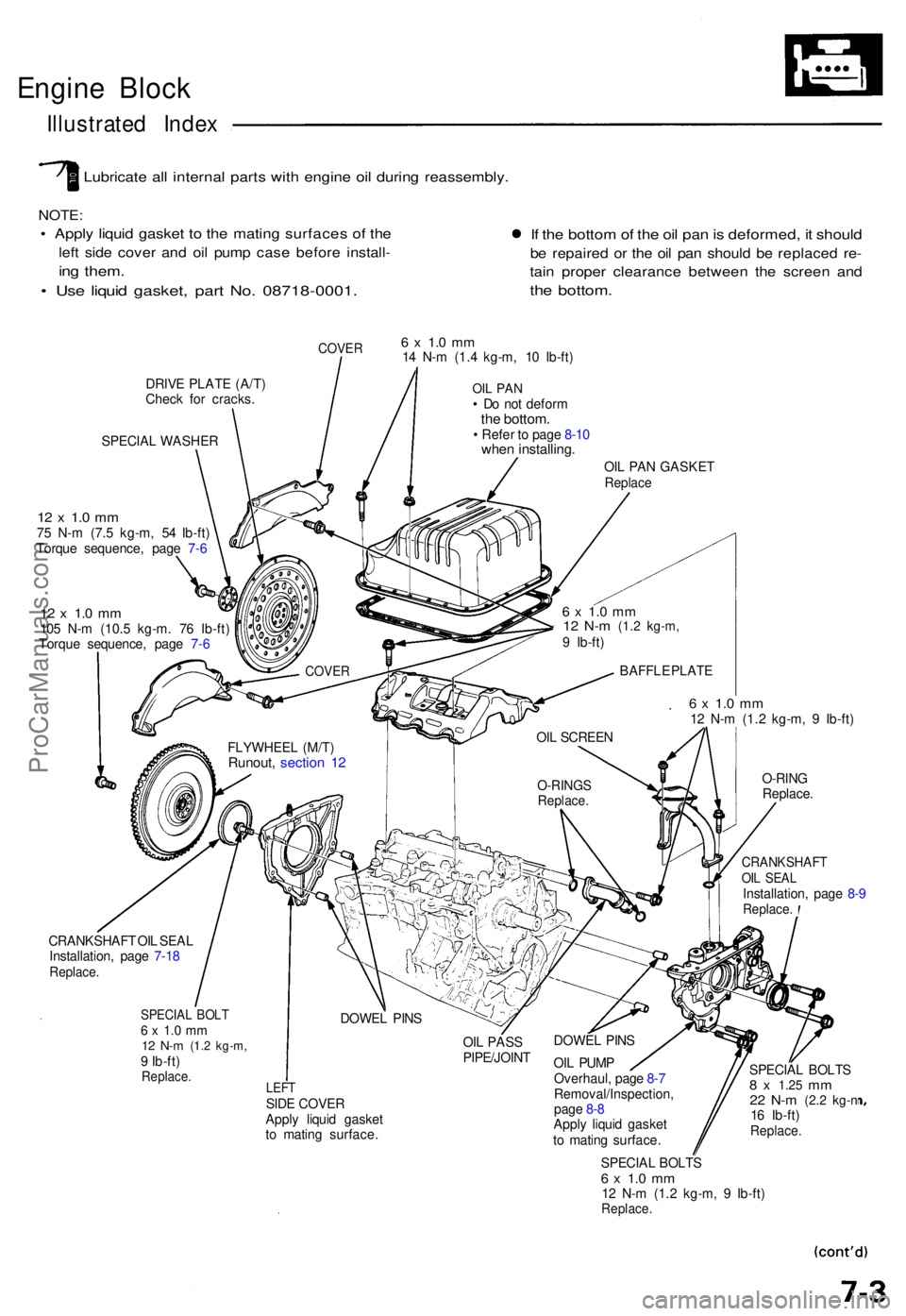

Engine Bloc k

Illustrate d Inde x

Lubricat e al l interna l part s wit h engin e oi l durin g reassembly .

NOTE:

• Appl y liqui d gaske t t o th e matin g surface s o f th e

left sid e cove r an d oi l pum p cas e befor e install -

ing them .

• Us e liqui d gasket , par t No . 08718-0001 .

If th e botto m of th e oi l pa n is deformed , i t shoul d

be repaire d o r th e oi l pa n shoul d b e replace d re -

tain prope r clearanc e betwee n th e scree n an d

the bottom .

COVER

DRIVE PLAT E (A/T )

Chec k fo r cracks .

SPECIA L WASHE R

12 x 1. 0 m m75 N- m (7. 5 kg-m , 5 4 Ib-ft )

Torqu e sequence , pag e 7- 6

12 x 1. 0 m m105 N- m (10. 5 kg-m . 7 6 Ib-ft )

Torqu e sequence , pag e 7- 6

6 x 1. 0 m m14 N- m (1. 4 kg-m , 1 0 Ib-ft )

OIL PA N• D o no t defor mthe bottom .• Refe r t o pag e 8-1 0whe n installing .

OIL PA N GASKE TReplace

6 x 1. 0 m m12 N- m (1. 2 kg-m , 9 Ib-ft )

O-RIN G

Replace .

CRANKSHAF TOIL SEA LInstallation , pag e 8- 9Replace .

CRANKSHAF T OI L SEA L

Installation , pag e 7-1 8

Replace .

SPECIAL BOL T6 x 1. 0 m m12 N- m (1. 2 kg-m ,9 Ib-ft )Replace .

OIL PAS S

PIPE/JOIN T

LEFTSIDE COVE R

Appl y liqui d gaske t

t o matin g surface . DOWE

L PIN S

OI L PUM P

Overhaul , pag e 8- 7

Removal/Inspection ,

pag e 8- 8

Appl y liqui d gaske t

t o matin g surface . SPECIA

L BOLT S

8 x 1.2 5 mm22 N- m (2. 2 kg- n16 Ib-ft )Replace .

SPECIAL BOLT S6 x 1. 0 m m12 N- m (1. 2 kg-m , 9 Ib-ft )Replace .

DOWEL PIN S

O-RING SReplace .

OIL SCREE N

FLYWHEE L (M/T )

Runout , sectio n 1 2

BAFFL E PLAT E

6 x 1. 0 m m12 N- m (1. 2 kg-m ,9 Ib-ft )

COVE R

ProCarManuals.com

Page 128 of 1640

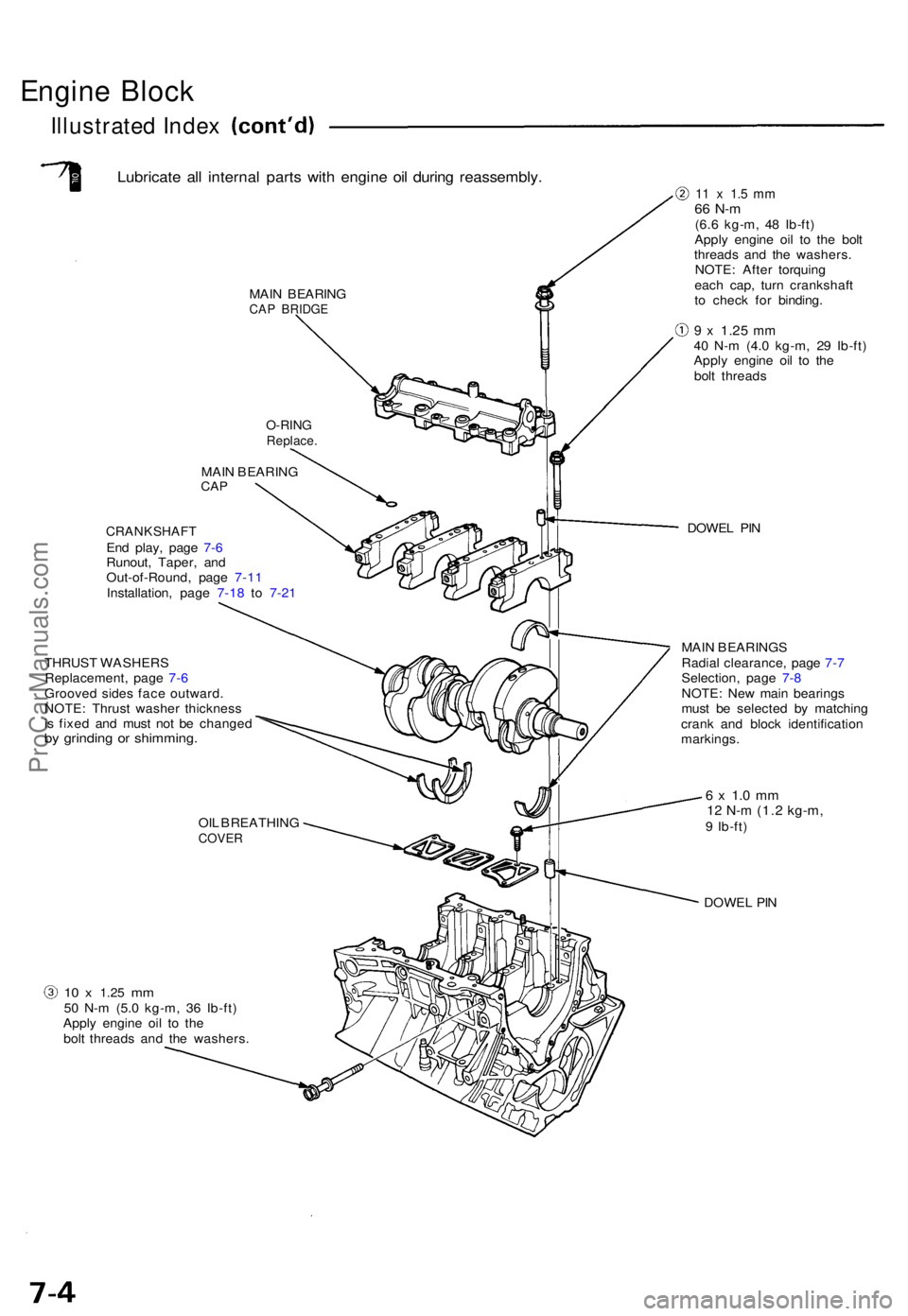

Engine Bloc k

Illustrated Index

Lubricat e al l interna l part s wit h engin e oi l durin g reassembly .

MAIN BEARIN GCAP BRIDG E

10 x 1.2 5 mm50 N- m (5. 0 kg-m , 3 6 Ib-ft )

Appl y engin e oi l t o th e

bol t thread s an d th e washers .

MAI

N BEARIN G

CAP

CRANKSHAF TEnd play , pag e 7- 6

Runout , Taper , an d

Out-of-Round , pag e 7-1 1

Installation , pag e 7-1 8 to 7-2 1

THRUS T WASHER S

Replacement , pag e 7- 6

Groove d side s fac e outward .

NOTE : Thrus t washe r thicknes s

i s fixe d an d mus t no t b e change d

by grindin g o r shimming .

11 x 1. 5 m m66 N- m(6.6 kg-m , 4 8 Ib-ft )

Appl y engin e oi l t o th e bol t

threads and th e washers .

NOTE : Afte r torquin g

eac h cap , tur n crankshaf t

t o chec k fo r binding .

9 x 1.2 5 mm40 N- m (4. 0 kg-m , 2 9 Ib-ft )

Appl y engin e oi l t o th e

bol t thread s

DOWE L PI N

MAI N BEARING S

Radia l clearance , pag e 7- 7

Selection , pag e 7- 8

NOTE : Ne w mai n bearing s

mus t b e selecte d b y matchin g

cran k an d bloc k identificatio n

markings .

6 x 1. 0 m m12 N- m (1. 2 kg-m ,9 Ib-ft )

DOWE L PI N

OI

L BREATHIN GCOVER

O-RINGReplace .

ProCarManuals.com

Page 129 of 1640

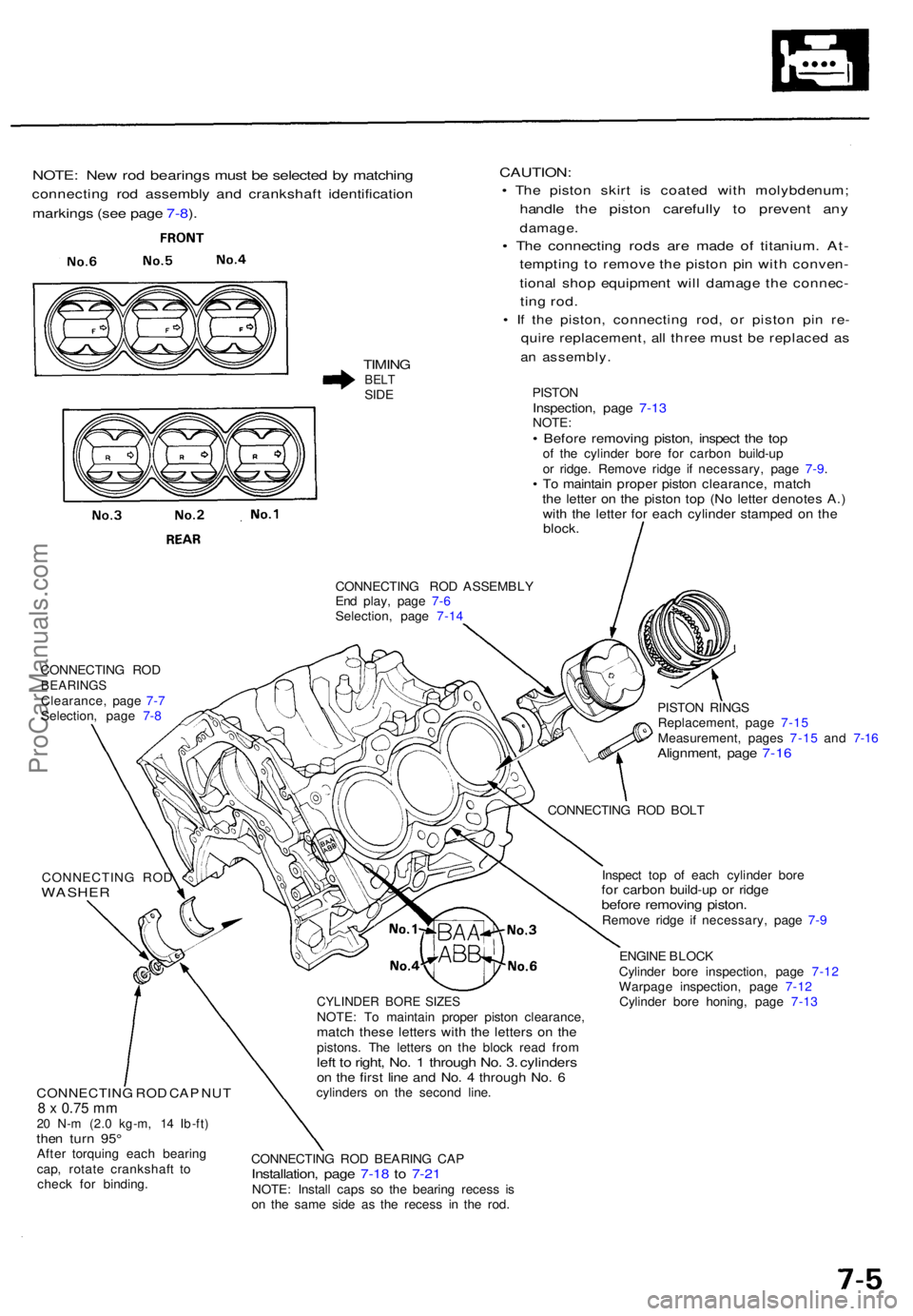

NOTE: Ne w ro d bearing s mus t b e selecte d b y matchin g

connectin g ro d assembl y an d crankshaf t identificatio n

markings (se e pag e 7-8 ).

TIMIN GBELTSIDE

CAUTION :

• Th e pisto n skir t i s coate d wit h molybdenum ;

handle th e pisto n carefull y t o preven t an y

damage .

• Th e connectin g rod s ar e mad e o f titanium . At -

temptin g t o remov e th e pisto n pi n wit h conven -

tional sho p equipmen t wil l damag e th e connec -

ting rod .

• I f th e piston , connectin g rod , o r pisto n pi n re -

quir e replacement , al l thre e mus t b e replace d a s

an assembly .

PISTONInspection , pag e 7-13NOTE :• Befor e removin g piston , inspec t th e to pof th e cylinde r bor e fo r carbo n build-u p

o r ridge . Remov e ridg e i f necessary , pag e 7-9 .

• T o maintai n prope r pisto n clearance , matc hthe lette r o n th e pisto n to p (N o lette r denote s A. )with th e lette r fo r eac h cylinde r stampe d o n th eblock .

CONNECTIN G RO D ASSEMBL Y

En d play , pag e 7- 6

Selection , pag e 7-1 4

CONNECTIN G RO D

BEARING SClearance , pag e 7- 7

Selection , pag e 7- 8

CONNECTIN G RO D

WASHE R

CONNECTIN G RO D CA P NU T8 x 0.75 mm20 N- m (2. 0 kg-m , 1 4 Ib-ft )then tur n 95 °Afte r torquin g eac h bearin g

cap , rotat e crankshaf t t o

chec k fo r binding .

CYLINDE R BOR E SIZE SNOTE : T o maintai n prope r pisto n clearance ,match thes e letter s wit h th e letter s o n th epistons . Th e letter s o n th e bloc k rea d fro mleft t o right , No . 1 throug h No . 3 . cylinder son th e firs t lin e an d No . 4 throug h No . 6cylinder s o n th e secon d line .

CONNECTIN G RO D BEARIN G CA P

Installation , pag e 7-1 8 to 7-2 1NOTE : Instal l cap s s o th e bearin g reces s i s

o n th e sam e sid e a s th e reces s i n th e rod . PISTO

N RING S

Replacement , pag e 7-1 5

Measurement , page s 7-1 5 an d 7-1 6

Alignment , pag e 7-1 6

CONNECTIN G RO D BOL T

Inspec t to p o f eac h cylinde r bor e

for carbo n build-u p o r ridg ebefor e removin g piston .Remov e ridg e i f necessary , pag e 7- 9

ENGIN E BLOC K

Cylinde r bor e inspection , pag e 7-12

Warpag e inspection , pag e 7-12

Cylinde r bor e honing , pag e 7-13

ProCarManuals.com

Page 130 of 1640

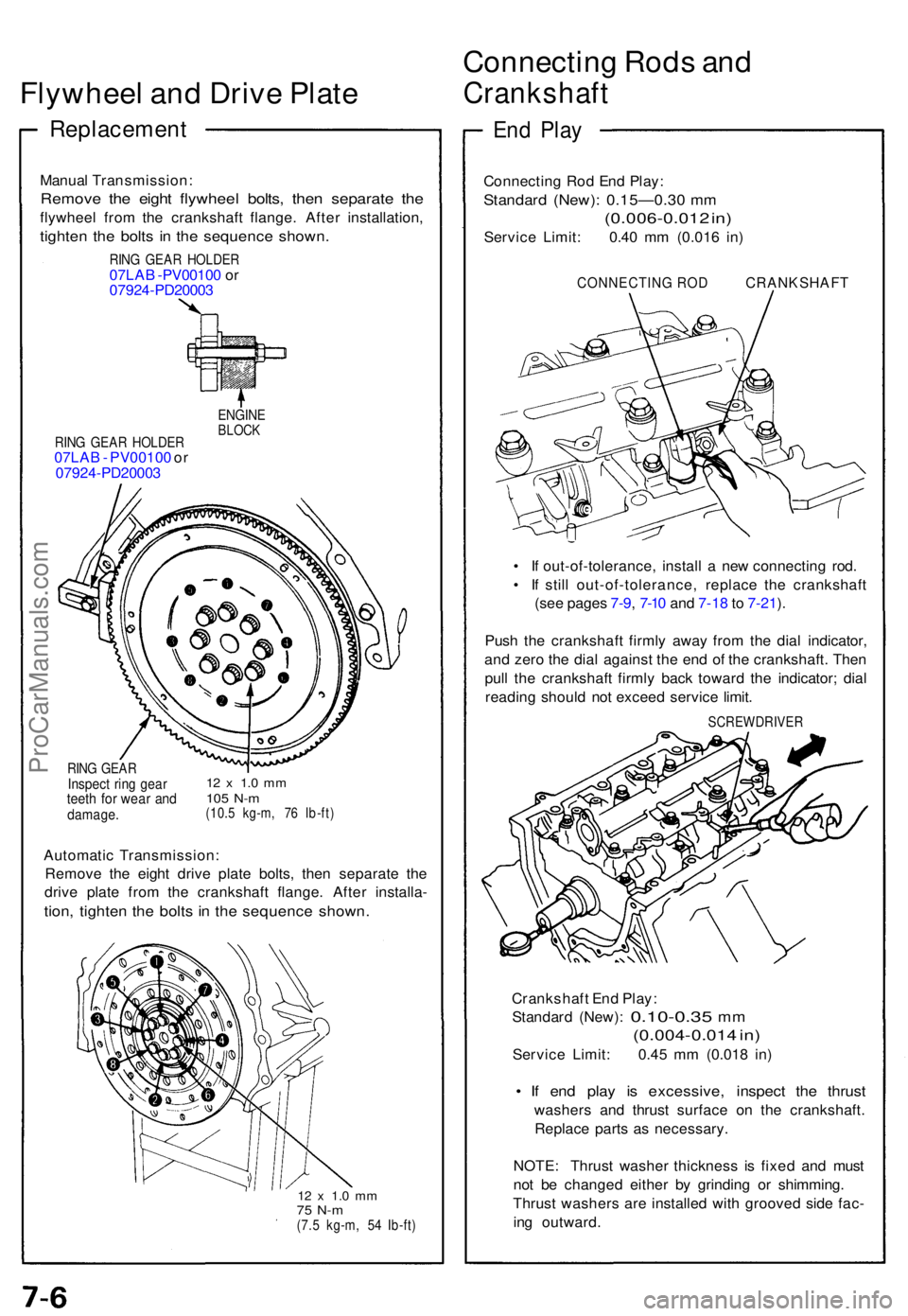

Flywheel an d Driv e Plat e

Replacemen t

Manual Transmission :

Remove th e eigh t flywhee l bolts , the n separat e th e

flywhee l fro m th e crankshaf t flange . Afte r installation ,

tighten th e bolt s i n th e sequenc e shown .

RING GEA R HOLDE R07LAB -PV0010 0 o r

0792 4-PD2000 3

RING GEA R HOLDE R07LAB - PV00100 or

0792 4-PD2000 3

ENGINEBLOCK

RING GEA RInspec t rin g gea rteeth fo r wea r an ddamage .

12 x 1. 0 m m105 N- m(10. 5 kg-m , 7 6 Ib-ft )

Automati c Transmission :

Remov e th e eigh t driv e plat e bolts , the n separat e th e

driv e plat e fro m th e crankshaf t flange . Afte r installa -

tion, tighte n th e bolt s i n th e sequenc e shown .

12 x 1. 0 m m75 N- m(7.5 kg-m , 5 4 Ib-ft )

Connectin g Rod s an d

Crankshaf t

End Pla y

Connectin g Ro d En d Play :

Standar d (New) : 0.15—0.3 0 m m

(0.006-0.01 2 in )

Servic e Limit : 0.4 0 m m (0.01 6 in )

CONNECTIN G RO D CRANKSHAF T

• I f out-of-tolerance , instal l a ne w connectin g rod .

• I f stil l out-of-tolerance , replac e th e crankshaf t

(se e page s 7-9 , 7-1 0 an d 7-1 8 to 7-21 ).

Pus h th e crankshaf t firml y awa y fro m th e dia l indicator ,

an d zer o th e dia l agains t th e en d o f th e crankshaft . The n

pul l th e crankshaf t firml y bac k towar d th e indicator ; dia l

readin g shoul d no t excee d servic e limit .

SCREWDRIVE R

Crankshaft En d Play :

Standar d (New) :

0.10-0.3 5 mm

(0.004-0.01 4 in )

Servic e Limit : 0.4 5 m m (0.01 8 in )

• I f en d pla y i s excessive , inspec t th e thrus t

washer s an d thrus t surfac e o n th e crankshaft .

Replac e part s a s necessary .

NOTE : Thrus t washe r thicknes s i s fixe d an d mus t

no t b e change d eithe r b y grindin g o r shimming .

Thrus t washer s ar e installe d wit h groove d sid e fac -

in g outward .

ProCarManuals.com