ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 111 of 1640

Valves, Valv e Spring s an d Valv e Seal s

Replacemen t

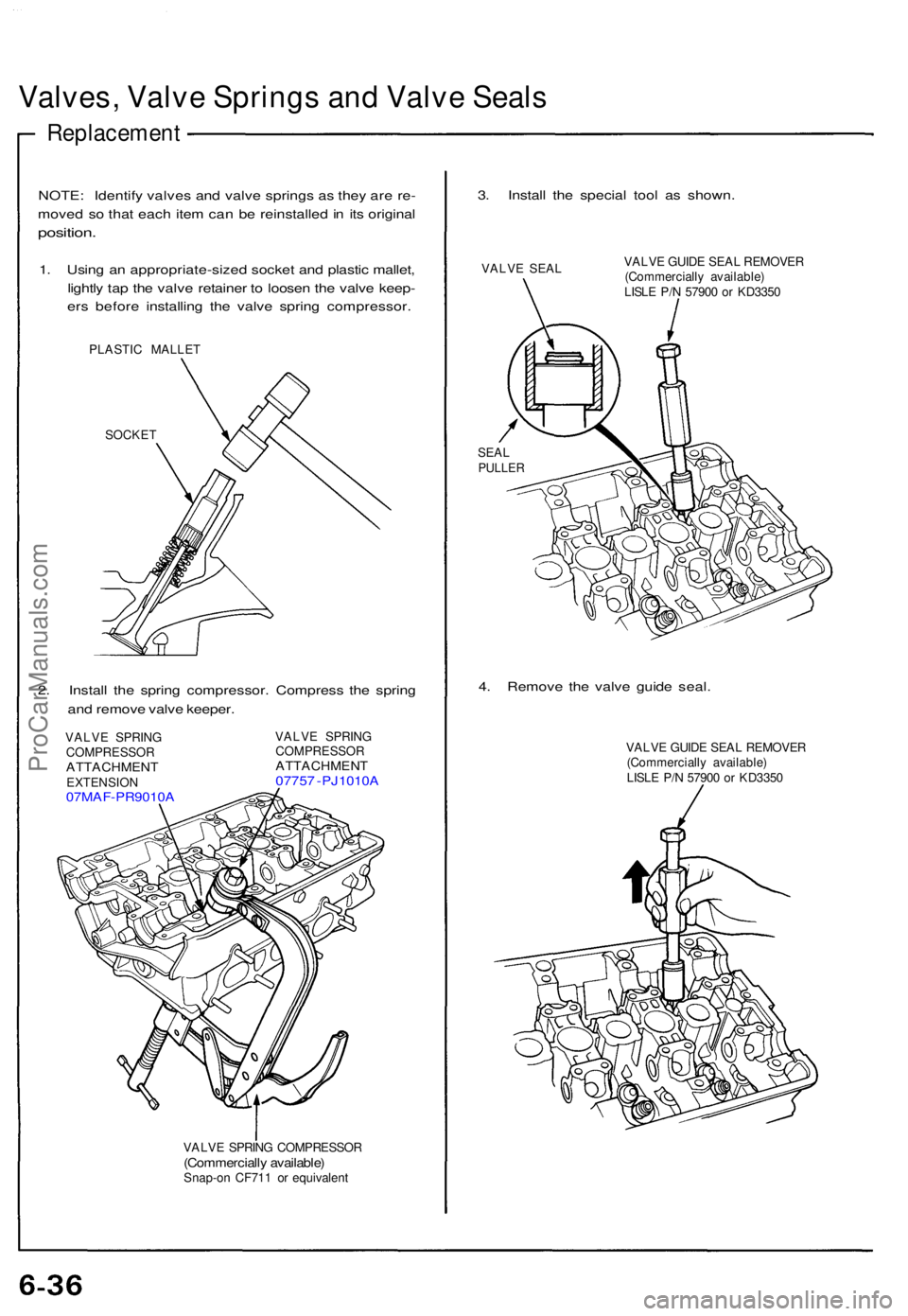

NOTE: Identif y valve s an d valv e spring s a s the y ar e re -

move d s o tha t eac h ite m ca n b e reinstalle d in it s origina l

position .

1. Usin g a n appropriate-size d socke t an d plasti c mallet ,

lightl y ta p th e valv e retaine r t o loose n th e valv e keep -

er s befor e installin g th e valv e sprin g compressor .

PLASTIC MALLE T

SOCKE T

2. Instal l th e sprin g compressor . Compres s th e sprin g

an d remov e valv e keeper .

VALVE SPRIN G

COMPRESSO R

ATTACHMENTEXTENSION07MAF-PR9010 A

VALVE SPRIN G

COMPRESSO R

ATTACHMENT07757 - PJ1010 A

VALVE SPRIN G COMPRESSO R(Commercially available )Snap-on CF71 1 o r equivalen t

3. Instal l th e specia l too l a s shown .

VALVE SEA L VALV

E GUID E SEA L REMOVE R

(Commerciall y available )

LISL E P/ N 5790 0 o r KD335 0

SEALPULLE R

4. Remov e th e valv e guid e seal .

VALV E GUID E SEA L REMOVE R

(Commerciall y available )

LISL E P/ N 5790 0 o r KD335 0

ProCarManuals.com

Page 112 of 1640

ProCarManuals.com

Page 113 of 1640

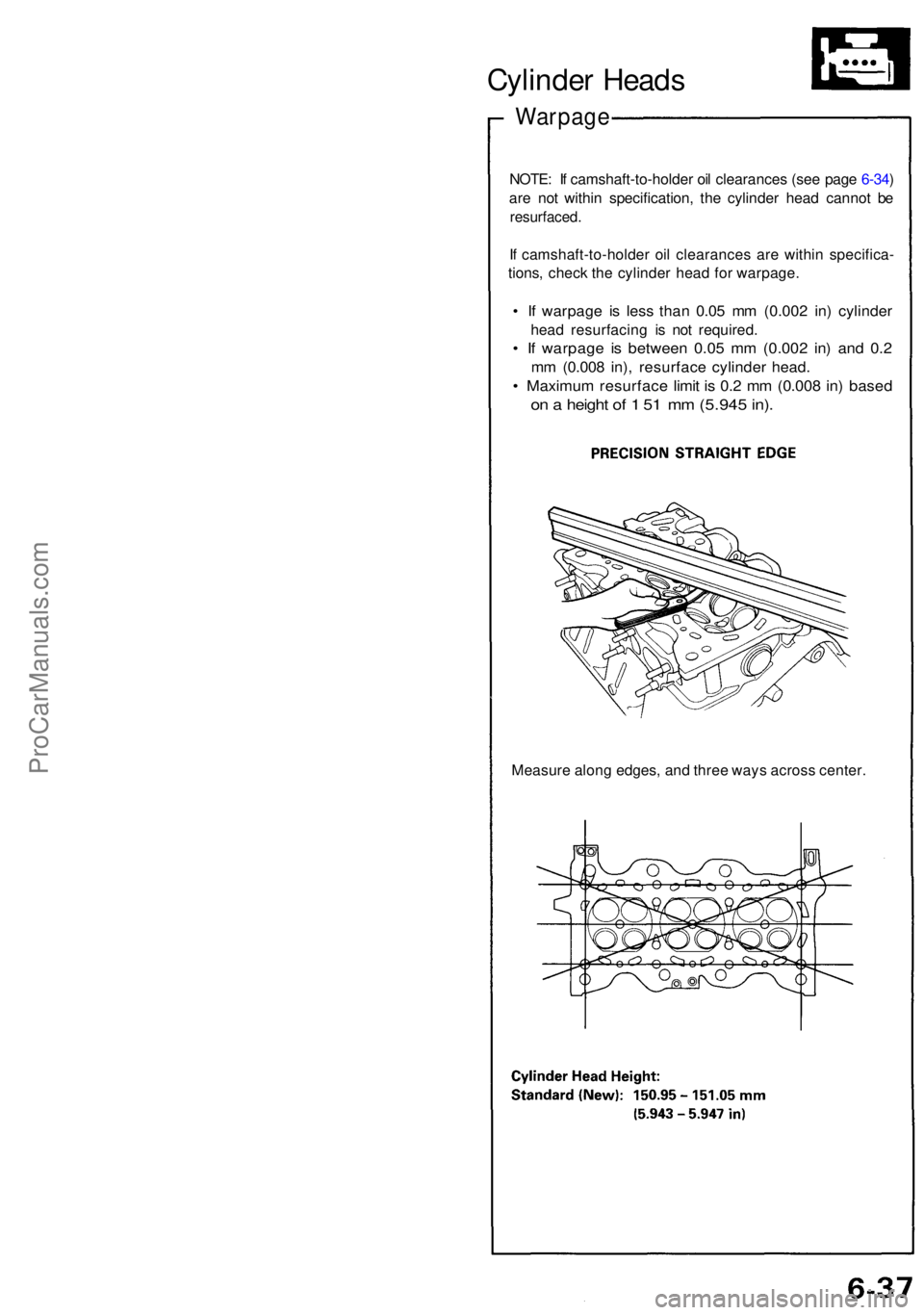

Cylinder Head s

Warpag e

NOTE: I f camshaft-to-holde r oi l clearance s (se e pag e 6-34 )

ar e no t withi n specification , th e cylinde r hea d canno t b e

resurfaced .

If camshaft-to-holde r oi l clearance s ar e withi n specifica -

tions , chec k th e cylinde r hea d fo r warpage .

• I f warpag e i s les s tha n 0.0 5 m m (0.00 2 in ) cylinde r

head resurfacin g i s no t required .

• I f warpag e i s betwee n 0.0 5 m m (0.00 2 in ) an d 0. 2

mm (0.00 8 in) , resurfac e cylinde r head .

• Maximu m resurfac e limi t i s 0. 2 m m (0.00 8 in ) base d

on a heigh t o f 1 51 m m (5.94 5 in) .

Measur e alon g edges , an d thre e way s acros s center .

ProCarManuals.com

Page 114 of 1640

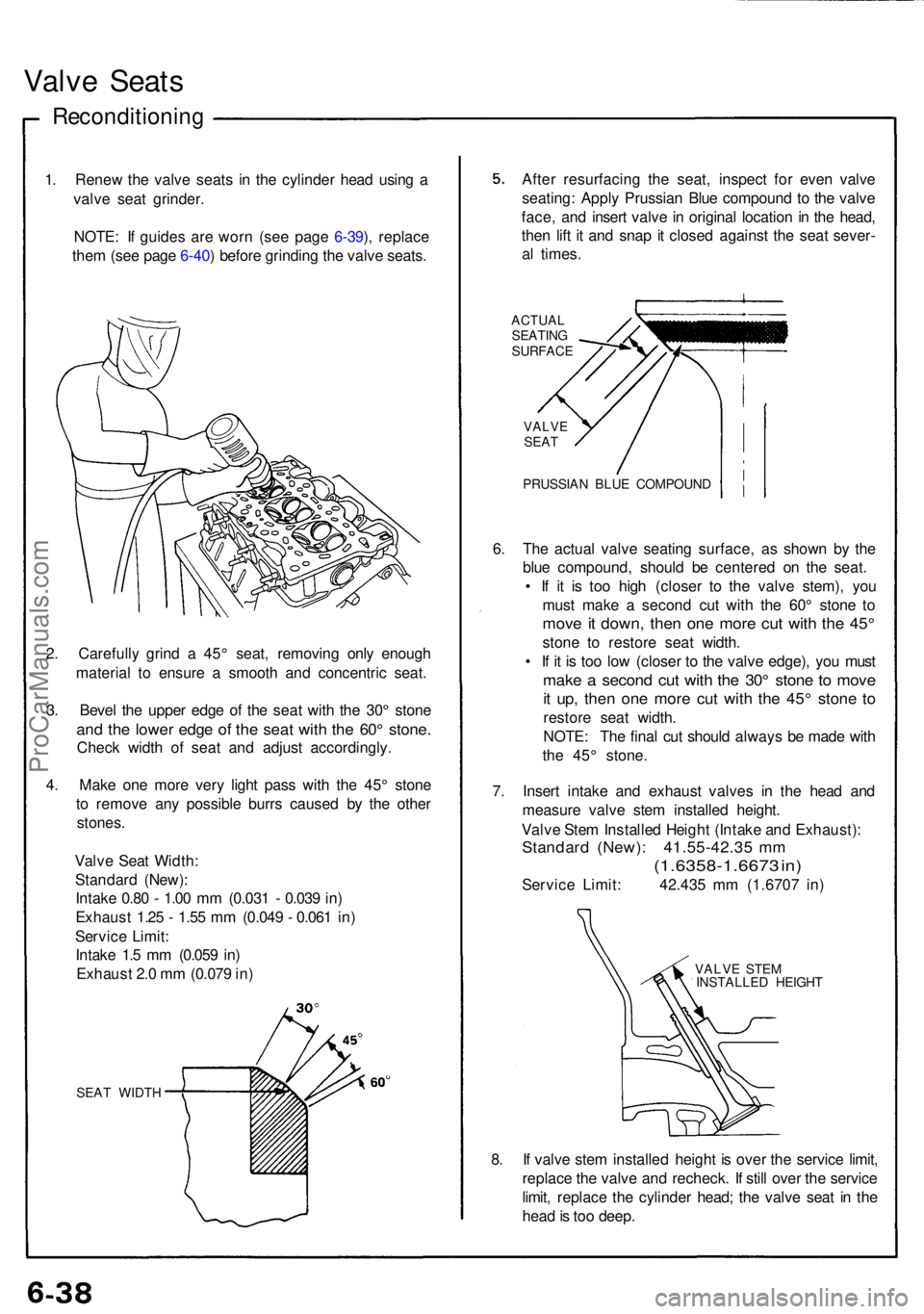

Valve Seat s

Reconditionin g

1. Rene w th e valv e seat s i n th e cylinde r hea d usin g a

valv e sea t grinder .

NOTE : I f guide s ar e wor n (se e pag e 6-39 ), replac e

the m (se e pag e 6-40 ) befor e grindin g th e valv e seats .

2 . Carefull y grin d a 45 ° seat , removin g onl y enoug h

materia l t o ensur e a smoot h an d concentri c seat .

3 . Beve l th e uppe r edg e o f th e sea t wit h th e 30 ° ston e

and th e lowe r edg e of the sea t wit h th e 60 ° stone .

Check widt h o f sea t an d adjus t accordingly .

4 . Mak e on e mor e ver y ligh t pas s wit h th e 45 ° ston e

t o remov e an y possibl e burr s cause d b y th e othe r

stones .

Valv e Sea t Width :

Standar d (New) :

Intak e 0.8 0 - 1.0 0 m m (0.03 1 - 0.03 9 in )

Exhaus t 1.2 5 - 1.5 5 m m (0.04 9 - 0.06 1 in )

Servic e Limit :

Intak e 1. 5 m m (0.05 9 in )

Exhaus t 2. 0 m m (0.07 9 in )

SEA T WIDT H

After resurfacin g th e seat , inspec t fo r eve n valv e

seating : Appl y Prussia n Blu e compoun d t o th e valv e

face , an d inser t valv e in origina l locatio n in th e head ,

the n lif t i t an d sna p it close d agains t th e sea t sever -

a l times .

ACTUA L

SEATIN G

SURFAC E

VALVESEAT

PRUSSIA N BLU E COMPOUN D

6. Th e actua l valv e seatin g surface , a s show n b y th e

blu e compound , shoul d b e centere d o n th e seat .

• I f i t i s to o hig h (close r t o th e valv e stem) , yo u

mus t mak e a secon d cu t wit h th e 60 ° ston e t o

mov e it down , the n on e mor e cu t wit h th e 45 °

ston e t o restor e sea t width .

• I f i t i s to o lo w (close r t o th e valv e edge) , yo u mus t

make a secon d cu t wit h th e 30 ° ston e t o mov e

it up , the n on e mor e cu t wit h th e 45 ° ston e t o

restor e sea t width .

NOTE : Th e fina l cu t shoul d alway s b e mad e wit h

th e 45 ° stone .

7 . Inser t intak e an d exhaus t valve s i n th e hea d an d

measur e valv e ste m installe d height .

Valv e Ste m Installe d Heigh t (Intak e an d Exhaust) :

Standard (New) : 41.55-42.3 5 m m

(1.6358-1.667 3 in )

Servic e Limit : 42.43 5 m m (1.670 7 in )

VALV E STE M

INSTALLE D HEIGH T

8. I f valv e ste m installe d heigh t i s ove r th e servic e limit ,

replac e th e valv e an d recheck . I f stil l ove r th e servic e

limit , replac e th e cylinde r head ; th e valv e sea t i n th e

hea d is to o deep .

ProCarManuals.com

Page 115 of 1640

Valve Guides

Valve Movement

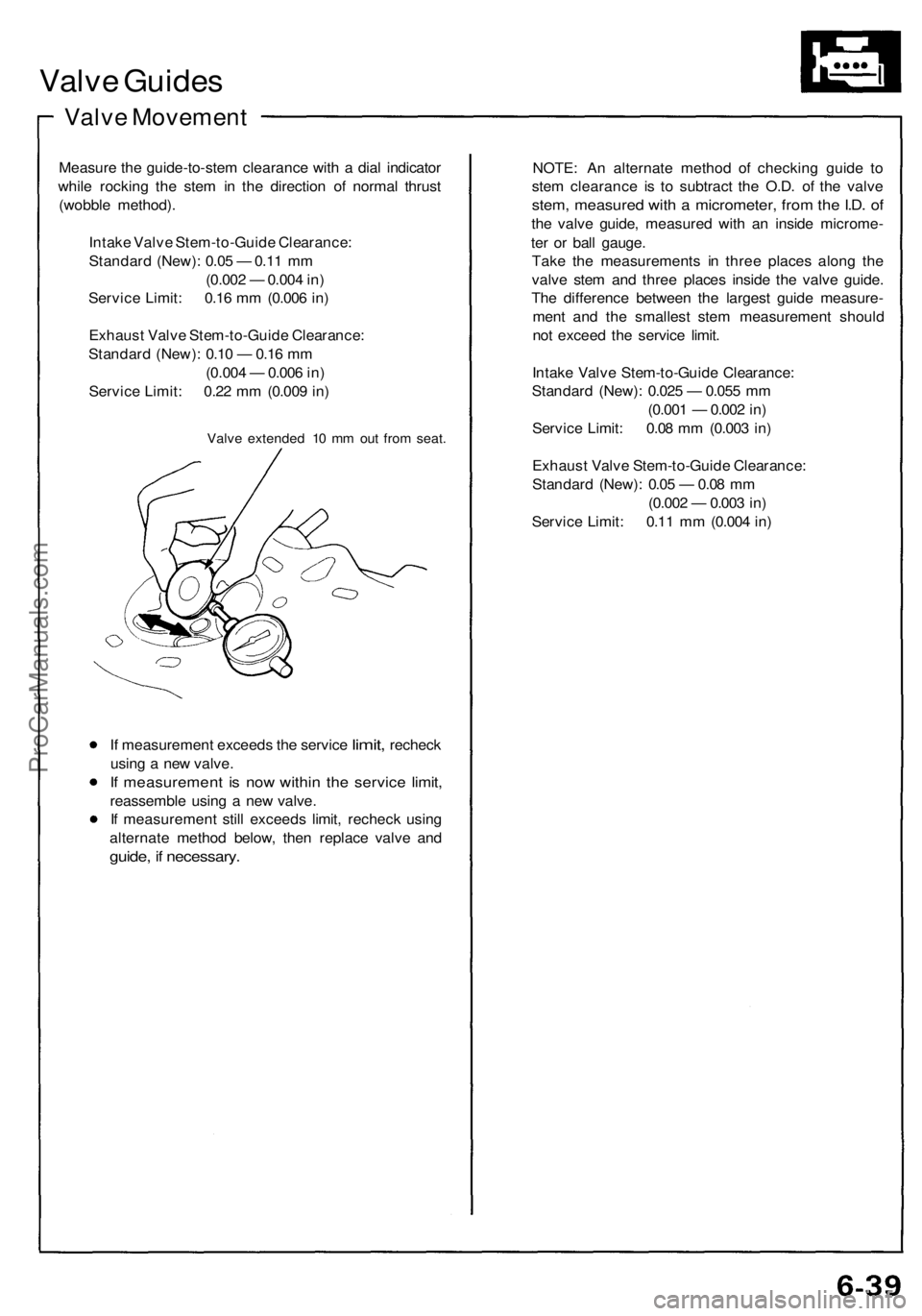

Measure the guide-to-stem clearance with a dial indicator

while rocking the stem in the direction of normal thrust

(wobble method).

Intake Valve Stem-to-Guide Clearance:

Standard (New): 0.05 — 0.11 mm

(0.002 — 0.004 in)

Service Limit: 0.16 mm (0.006 in)

Exhaust Valve Stem-to-Guide Clearance:

Standard (New): 0.10 — 0.16 mm

(0.004 — 0.006 in)

Service Limit: 0.22 mm (0.009 in)

Valve extended 10 mm out from seat.

If

measurement exceeds

the

service

limit,

recheck

using a new valve.

If measurement is now within the service limit,

reassemble using a new valve.

If measurement still exceeds limit, recheck using

alternate method below, then replace valve and

guide, if necessary.

NOTE: An alternate method of checking guide to

stem clearance is to subtract the O.D. of the valve

stem, measured with a micrometer, from the I.D. of

the valve guide, measured with an inside microme-

ter or ball gauge.

Take the measurements in three places along the

valve stem and three places inside the valve guide.

The difference between the largest guide measure-

ment and the smallest stem measurement should

not exceed the service limit.

Intake Valve Stem-to-Guide Clearance:

Standard (New): 0.025 — 0.055 mm

(0.001 — 0.002 in)

Service Limit: 0.08 mm (0.003 in)

Exhaust Valve Stem-to-Guide Clearance:

Standard (New): 0.05 — 0.08 mm

(0.002 — 0.003 in)

Service Limit: 0.11 mm (0.004 in)ProCarManuals.com

Page 116 of 1640

Valve Guide s

Replacemen t

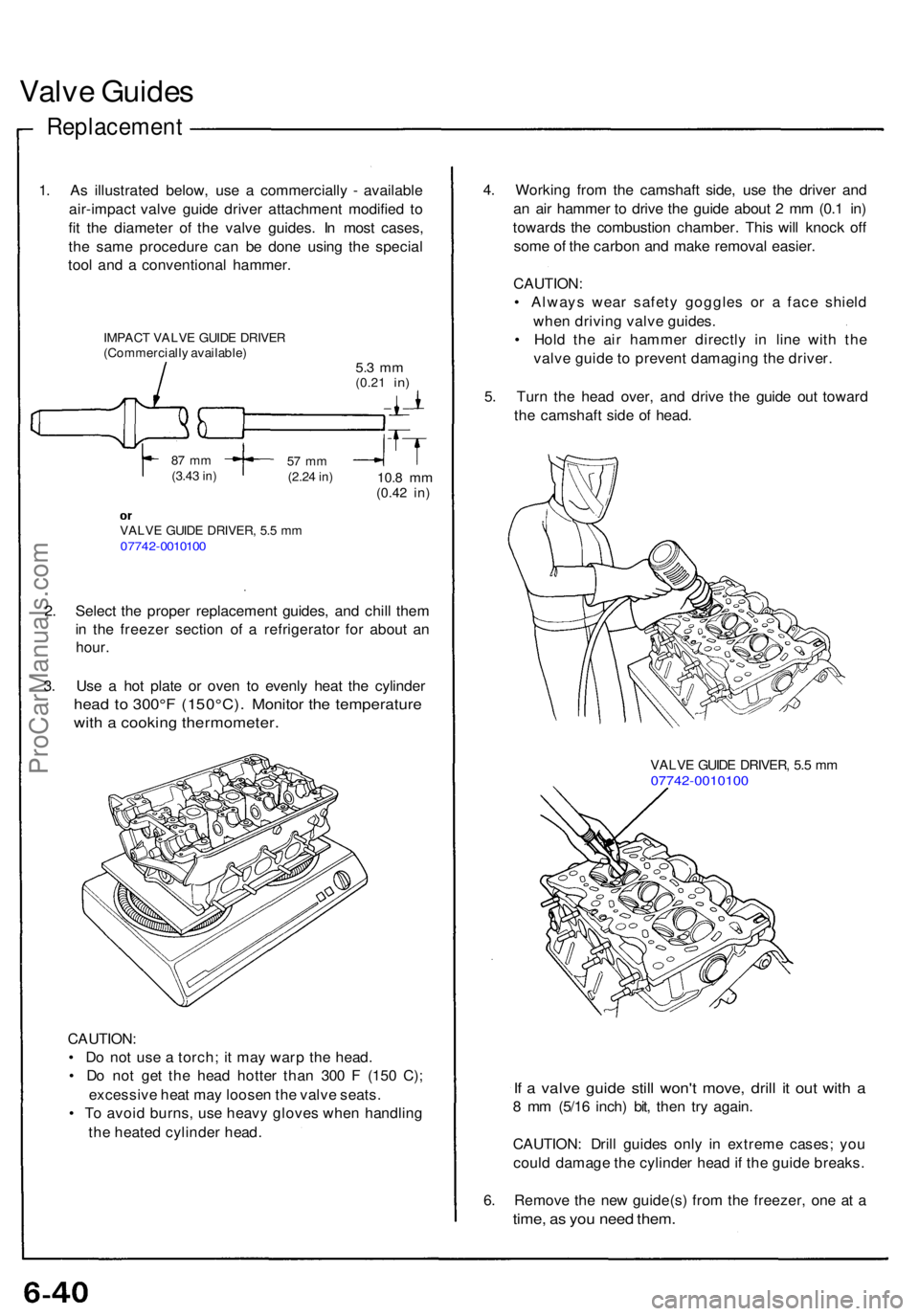

1. A s illustrate d below , us e a commerciall y - availabl e

air-impac t valv e guid e drive r attachmen t modifie d t o

fi t th e diamete r o f th e valv e guides . I n mos t cases ,

th e sam e procedur e ca n b e don e usin g th e specia l

too l an d a conventiona l hammer .

IMPACT VALV E GUID E DRIVE R(Commerciall y available )5.3 m m(0.2 1 in)

87 m m(3.4 3 in)57 m m(2.2 4 in)10. 8 m m(0.4 2 in)

VALV E GUID E DRIVER , 5. 5 m m0774 2-001010 0

2. Selec t th e prope r replacemen t guides , an d chil l the m

i n th e freeze r sectio n o f a refrigerato r fo r abou t a n

hour .

3. Us e a ho t plat e o r ove n t o evenl y hea t th e cylinde r

head t o 300° F ( 150°C) . Monito r th e temperatur e

with a cookin g thermometer .

CAUTION:

• D o no t us e a torch ; i t ma y war p th e head .

• D o no t ge t th e hea d hotte r tha n 30 0 F (15 0 C) ;

excessiv e hea t ma y loose n th e valv e seats .

• T o avoi d burns , us e heav y glove s whe n handlin g

th e heate d cylinde r head . 4

. Workin g fro m th e camshaf t side , us e th e drive r an d

a n ai r hamme r t o driv e th e guid e abou t 2 m m (0. 1 in )

toward s th e combustio n chamber . Thi s wil l knoc k of f

som e o f th e carbo n an d mak e remova l easier .

CAUTION :

• Alway s wea r safet y goggle s o r a fac e shiel d

whe n drivin g valv e guides .

• Hol d th e ai r hamme r directl y i n lin e wit h th e

valv e guid e t o preven t damagin g th e driver .

5 . Tur n th e hea d over , an d driv e th e guid e ou t towar d

th e camshaf t sid e o f head .

VALV E GUID E DRIVER , 5. 5 m m07742-001010 0

If a valv e guid e stil l won' t move , dril l i t ou t wit h a

8 m m (5/1 6 inch ) bit , the n tr y again .

CAUTION : Dril l guide s onl y i n extrem e cases ; yo u

coul d damag e th e cylinde r hea d if th e guid e breaks .

6 . Remov e th e ne w guide(s ) fro m th e freezer , on e a t a

time , a s yo u nee d them .

ProCarManuals.com

Page 117 of 1640

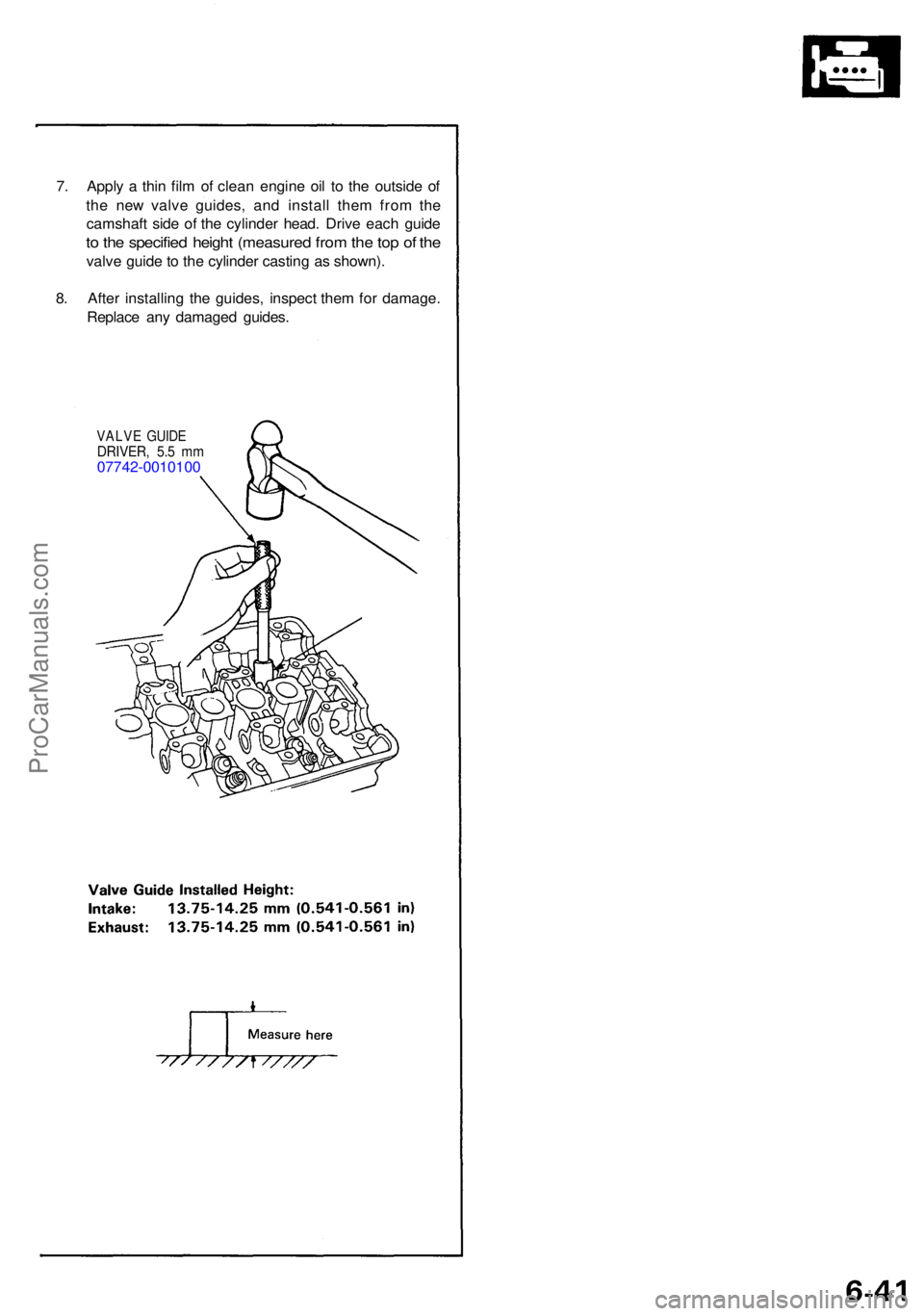

7. Appl y a thi n fil m o f clea n engin e oi l t o th e outsid e o f

th e ne w valv e guides , an d instal l the m fro m th e

camshaf t sid e o f th e cylinde r head . Driv e eac h guid e

to th e specifie d heigh t (measure d fro m th e to p o f th e

valv e guid e to th e cylinde r castin g a s shown) .

8 . Afte r installin g th e guides , inspec t the m fo r damage .

Replac e an y damage d guides .

VALVE GUID EDRIVER , 5. 5 m m07742-001010 0

ProCarManuals.com

Page 118 of 1640

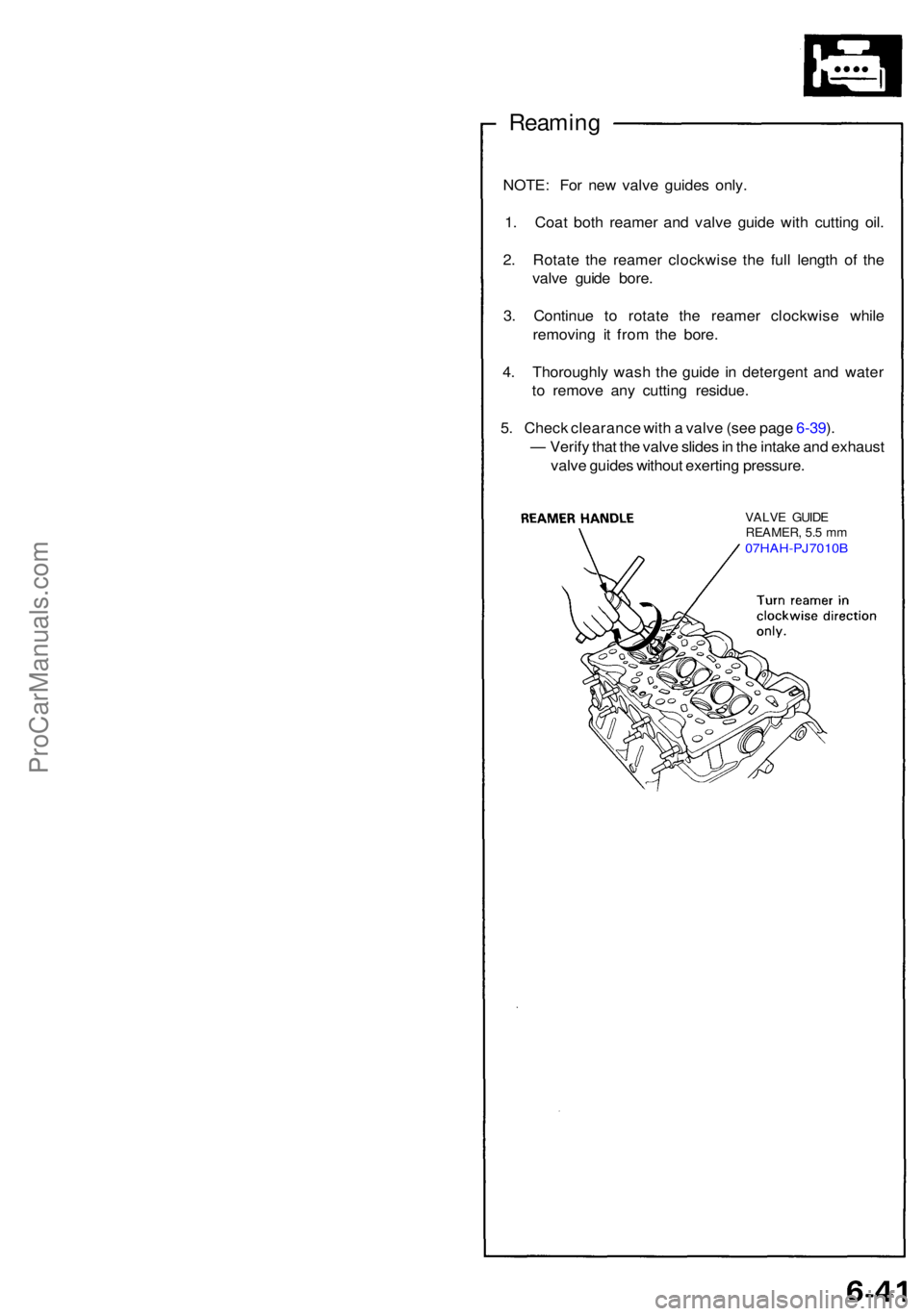

Reaming

NOTE: Fo r ne w valv e guide s only .

1 . Coa t bot h reame r an d valv e guid e wit h cuttin g oil .

2 . Rotat e th e reame r clockwis e th e ful l lengt h o f th e

valv e guid e bore .

3 . Continu e t o rotat e th e reame r clockwis e whil e

removin g i t fro m th e bore .

4 . Thoroughl y was h th e guid e i n detergen t an d wate r

t o remov e an y cuttin g residue .

5 . Chec k clearanc e wit h a valv e (se e pag e 6-39 ).

— Verif y tha t th e valv e slide s in th e intak e an d exhaus t

valv e guide s withou t exertin g pressure .

VALVE GUID E

REAMER , 5. 5 m m

07HAH-PJ7010 B

ProCarManuals.com

Page 119 of 1640

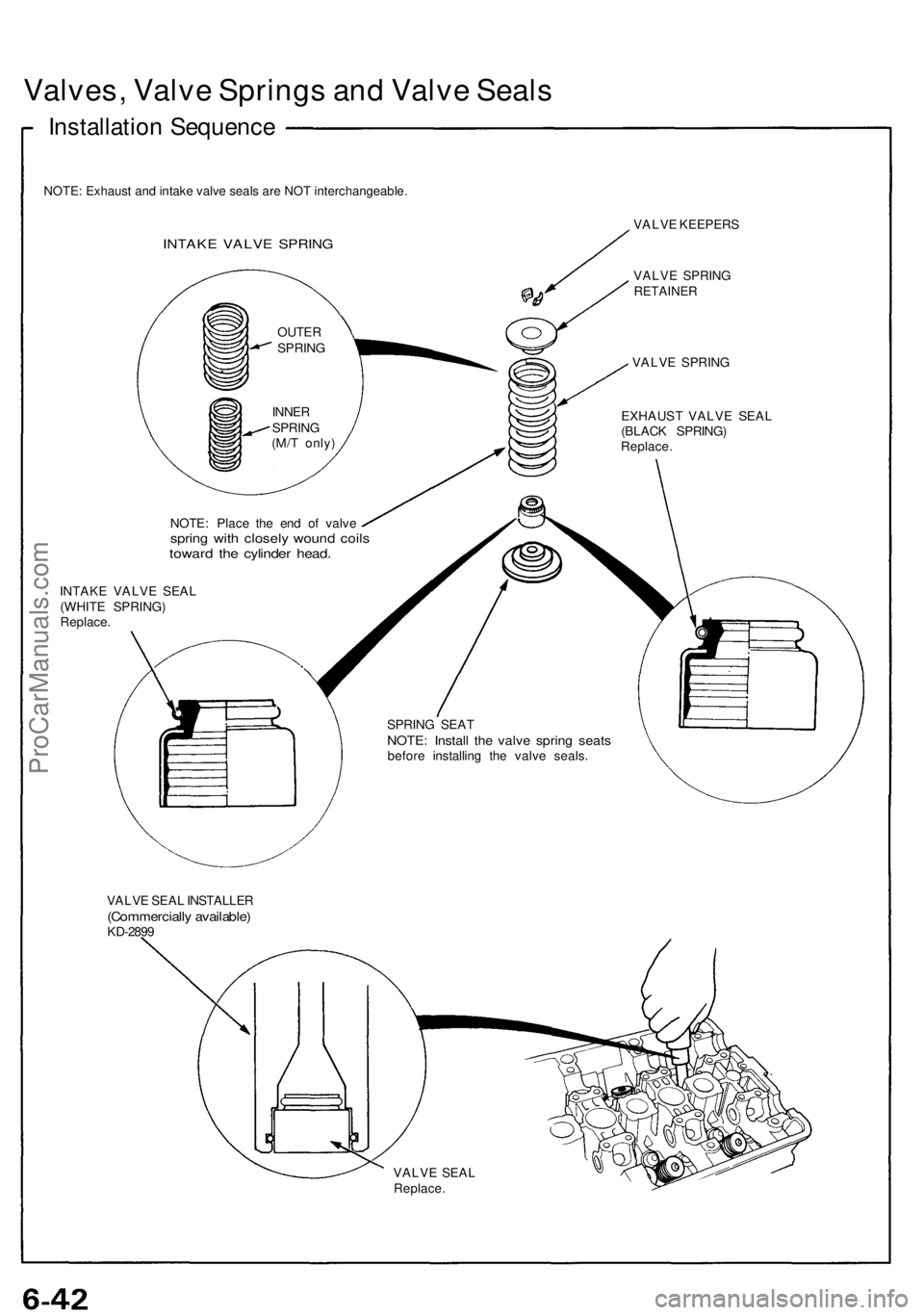

Valves, Valv e Spring s an d Valv e Seal s

Installatio n Sequenc e

NOTE: Exhaust and intake valve seals are NOT interchangeable.

INTAKE VALV E SPRIN G

VALVE KEEPER S

VALV E SPRIN G

RETAINE R

VALVE SPRIN G

EXHAUS T VALV E SEA L

(BLAC K SPRING )

Replace.

NOTE: Plac e th e en d o f valv espring wit h closel y woun d coil stowar d th e cylinde r head .

INTAK E VALV E SEA L

(WHIT E SPRING )

Replace .

SPRING SEA T

NOTE : Instal l th e valv e sprin g seat sbefor e installin g th e valv e seals .

VALV E SEA L INSTALLE R

(Commerciall y available )KD-2899

VALVE SEA L

Replace .

OUTER

SPRIN G

INNE R

SPRIN G

(M/ T only )

ProCarManuals.com

Page 120 of 1640

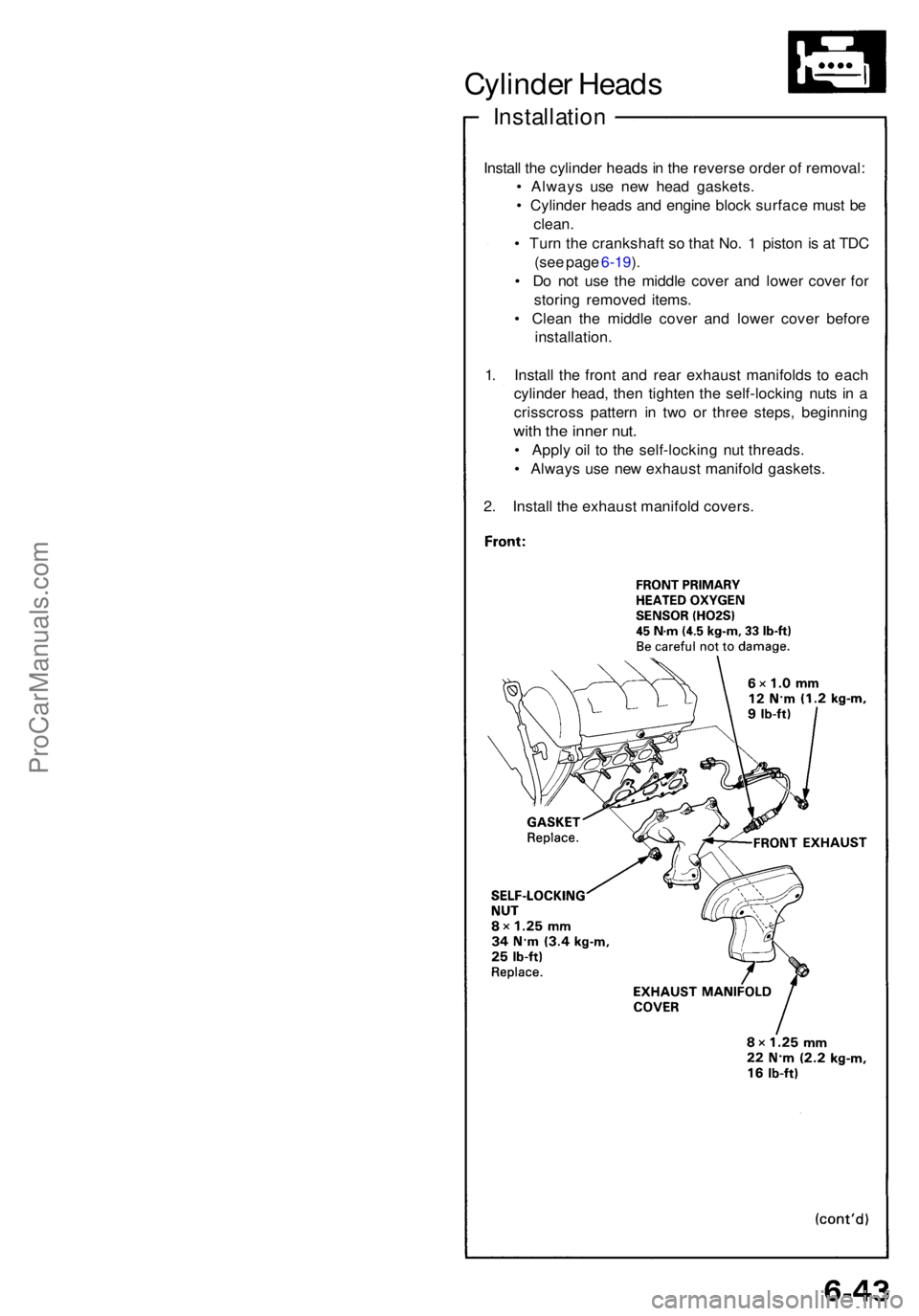

Cylinder Head s

Installatio n

Install th e cylinde r head s in th e revers e orde r o f removal :

• Alway s us e ne w hea d gaskets .

• Cylinde r head s an d engin e bloc k surfac e mus t b e

clean .

• Tur n th e crankshaf t s o tha t No . 1 pisto n i s a t TD C

(se e pag e 6-19 ).

• D o no t us e th e middl e cove r an d lowe r cove r fo r

storin g remove d items .

• Clea n th e middl e cove r an d lowe r cove r befor e

installation .

1 . Instal l th e fron t an d rea r exhaus t manifold s t o eac h

cylinde r head , the n tighte n th e self-lockin g nut s i n a

crisscros s patter n i n tw o o r thre e steps , beginnin g

with th e inne r nut .

• Appl y oi l t o th e self-lockin g nu t threads .

• Alway s us e ne w exhaus t manifol d gaskets .

2 . Instal l th e exhaus t manifol d covers .

ProCarManuals.com