ACURA NSX 1997 Service Repair Manual

Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 461 of 1503

Valve Guide s

Replacemen t

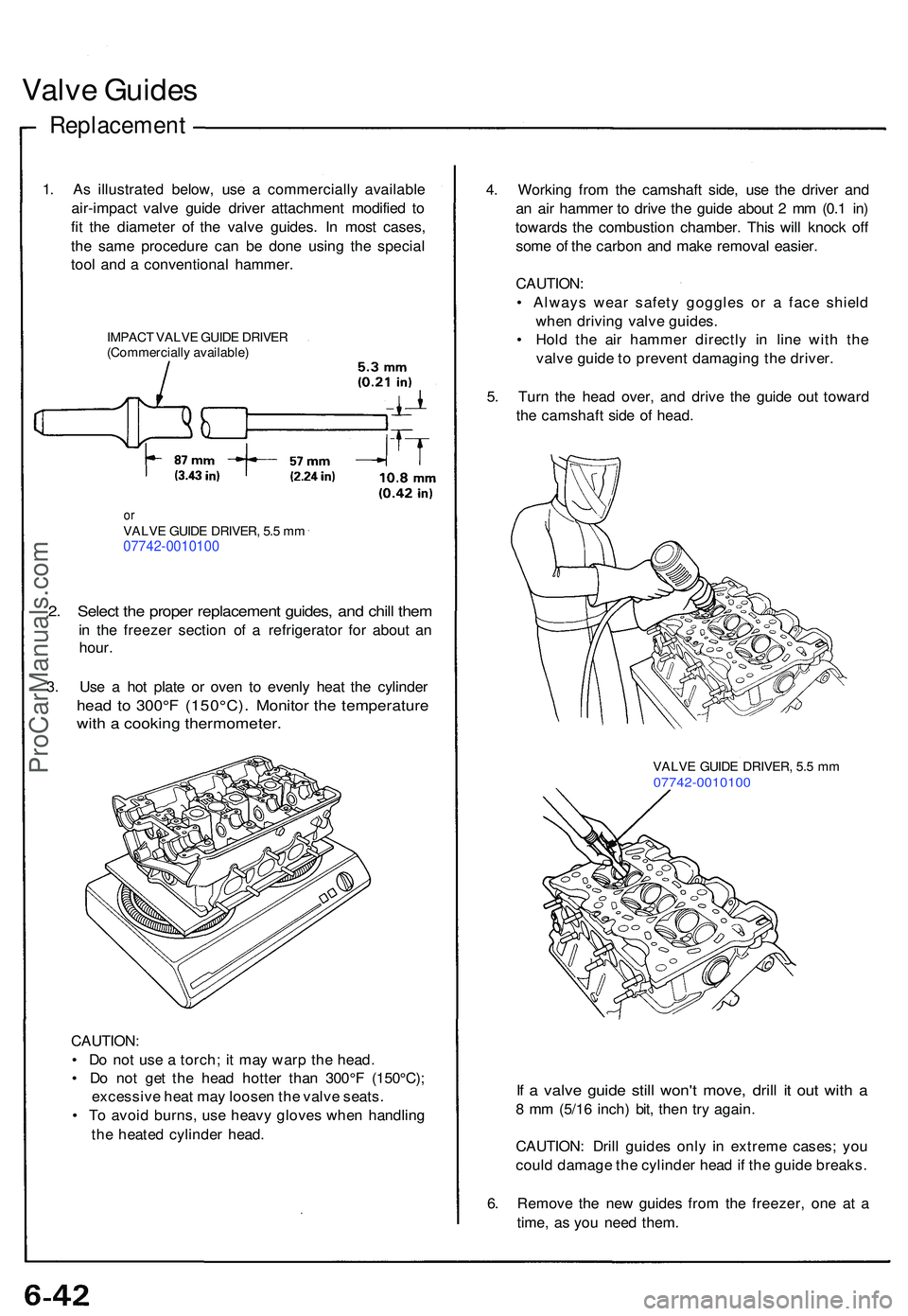

1. A s illustrate d below , us e a commerciall y availabl e

air-impac t valv e guid e drive r attachmen t modifie d t o

fi t th e diamete r o f th e valv e guides . I n mos t cases ,

th e sam e procedur e ca n b e don e usin g th e specia l

too l an d a conventiona l hammer .

IMPACT VALV E GUID E DRIVE R

(Commerciall y available )

orVALV E GUID E DRIVER , 5. 5 m m07742-0010100

2. Selec t th e prope r replacemen t guides , an d chil l the m

in th e freeze r sectio n o f a refrigerato r fo r abou t a n

hour .

3 . Us e a ho t plat e o r ove n t o evenl y hea t th e cylinde r

head t o 300° F (150°C) . Monito r th e temperatur e

with a cookin g thermometer .

CAUTION:

• D o no t us e a torch ; i t ma y war p th e head .

• D o no t ge t th e hea d hotte r tha n 30 0°F (150°C) ;

excessiv e hea t ma y loose n th e valv e seats .

• T o avoi d burns , us e heav y glove s whe n handlin g

th e heate d cylinde r head . 4

. Workin g fro m th e camshaf t side , us e th e drive r an d

a n ai r hamme r t o driv e th e guid e abou t 2 m m (0. 1 in )

toward s th e combustion chamber. Thi s wil l knoc k of f

som e o f th e carbo n an d mak e remova l easier .

CAUTION :

• Alway s wea r safet y goggle s o r a fac e shiel d

whe n drivin g valv e guides .

• Hol d th e ai r hamme r directl y i n lin e wit h th e

valv e guid e t o preven t damagin g th e driver .

5 . Tur n th e hea d over , an d driv e th e guid e ou t towar d

th e camshaf t sid e o f head .

VALV E GUID E DRIVER , 5. 5 m m07742-001010 0

If a valv e guid e stil l won' t move , dril l i t ou t wit h a

8 m m (5/1 6 inch ) bit , the n tr y again .

CAUTION : Dril l guide s onl y i n extrem e cases ; yo u

coul d damag e th e cylinde r hea d if th e guid e breaks .

6 . Remov e th e ne w guide s fro m th e freezer , on e a t a

time , a s yo u nee d them .

ProCarManuals.com

Page 462 of 1503

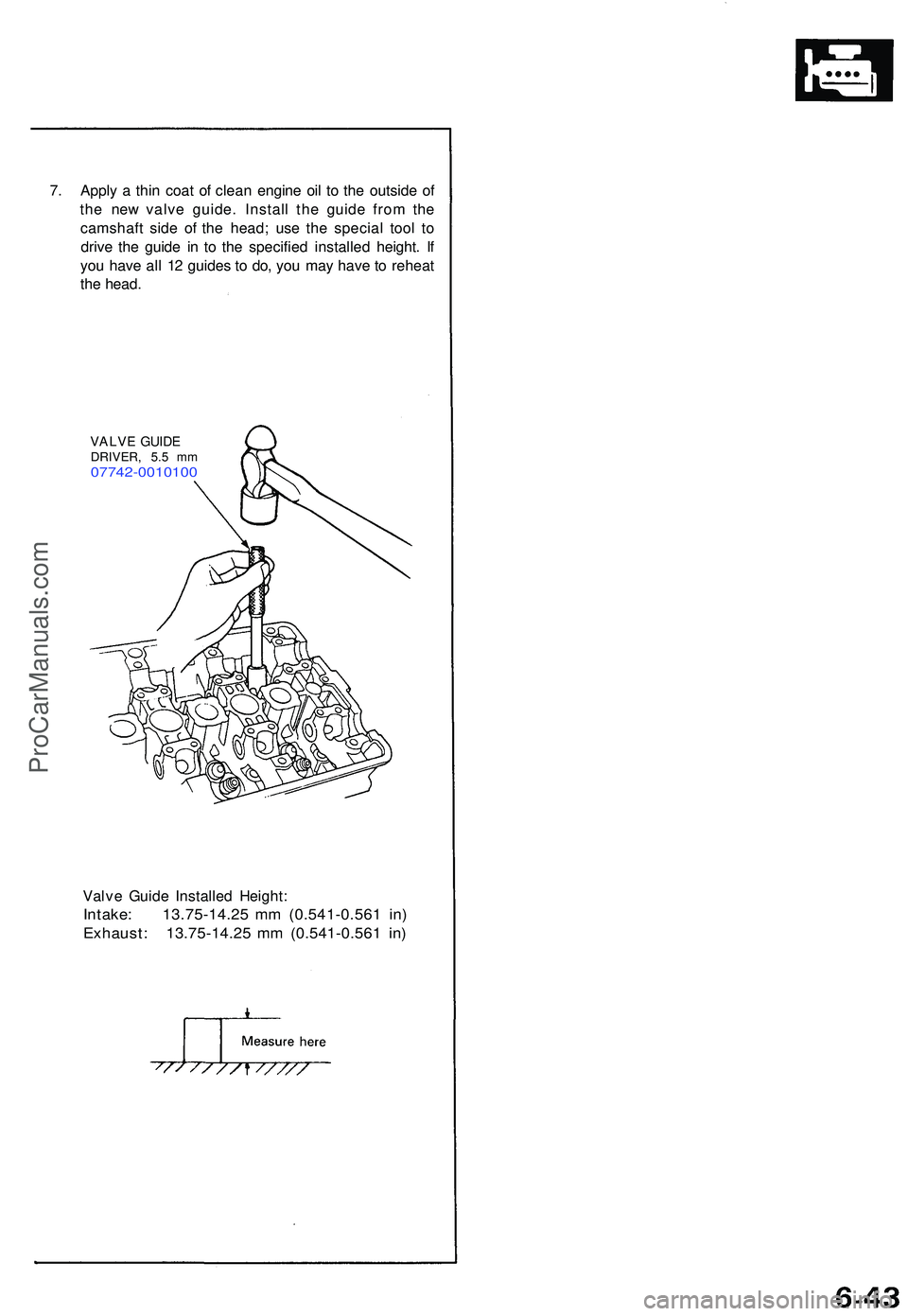

7. Appl y a thi n coa t o f clea n engin e oi l t o th e outsid e o f

th e ne w valv e guide . Instal l th e guid e fro m th e

camshaf t sid e o f th e head ; us e th e specia l too l t o

driv e th e guid e i n t o th e specifie d installe d height . I f

yo u hav e al l 1 2 guide s t o do , yo u ma y hav e t o rehea t

th e head .

VALV E GUID EDRIVER , 5. 5 m m07742-001010 0

Valve Guid e Installe d Height :

Intake: 13.75-14.2 5 m m (0.541-0.56 1 in )

Exhaust : 13.75-14.2 5 m m (0.541-0.56 1 in )

ProCarManuals.com

Page 463 of 1503

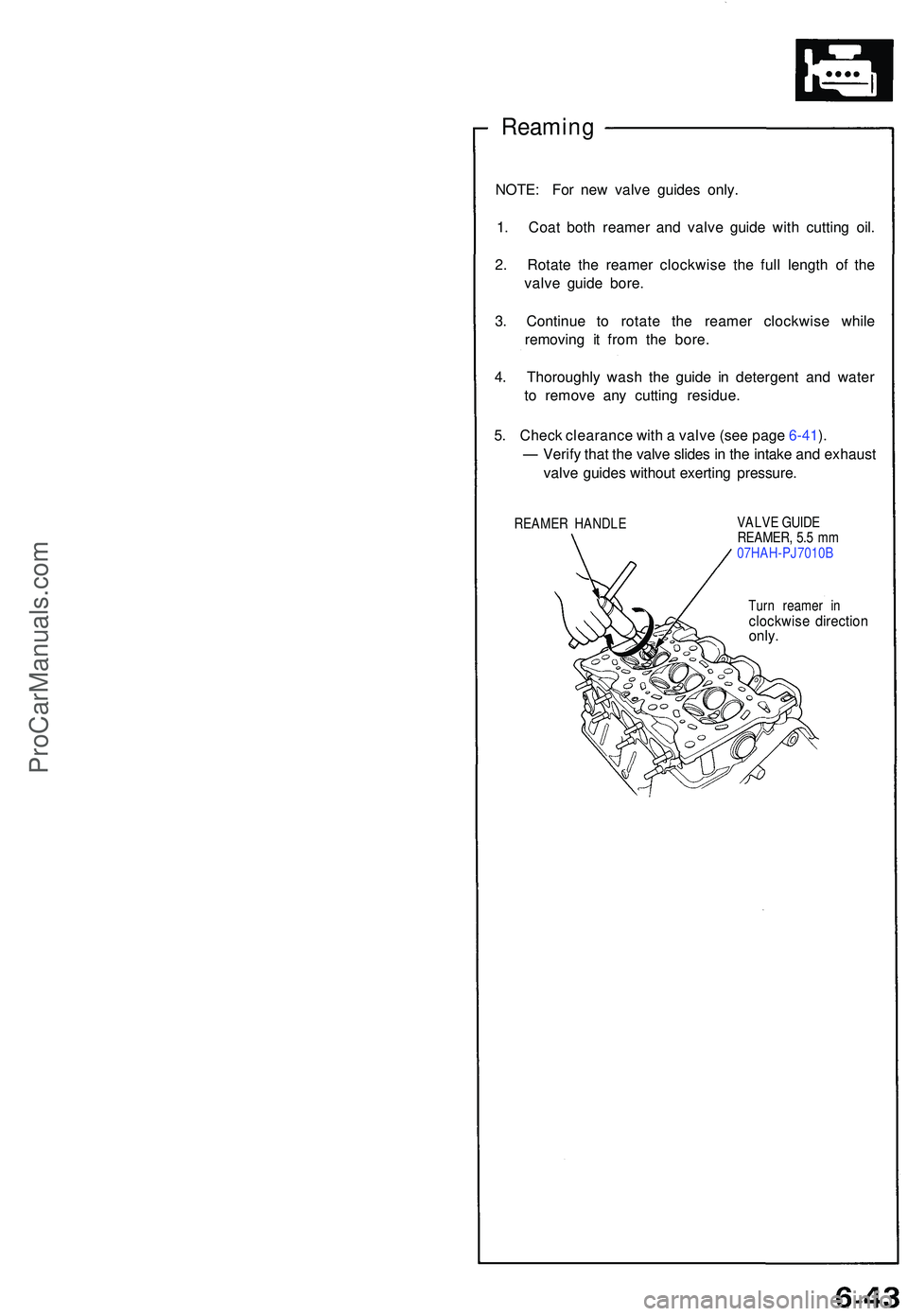

Reaming

NOTE: Fo r ne w valv e guide s only .

1 . Coa t bot h reame r an d valv e guid e wit h cuttin g oil .

2 . Rotat e th e reame r clockwis e th e ful l lengt h o f th e

valv e guid e bore .

3 . Continu e t o rotat e th e reame r clockwis e whil e

removin g i t fro m th e bore .

4 . Thoroughl y was h th e guid e i n detergen t an d wate r

t o remov e an y cuttin g residue .

5 . Chec k clearanc e wit h a valv e (se e pag e 6-41 ).

— Verif y tha t th e valv e slide s in th e intak e an d exhaus t

valv e guide s withou t exertin g pressure .

REAMER HANDL E VALV

E GUID E

REAMER , 5. 5 m m

07HAH-PJ7010 B

Tur n reame r i n

clockwis e directio nonly.

ProCarManuals.com

Page 464 of 1503

Valves, Valve Springs and Valve Seals

Installation Sequence

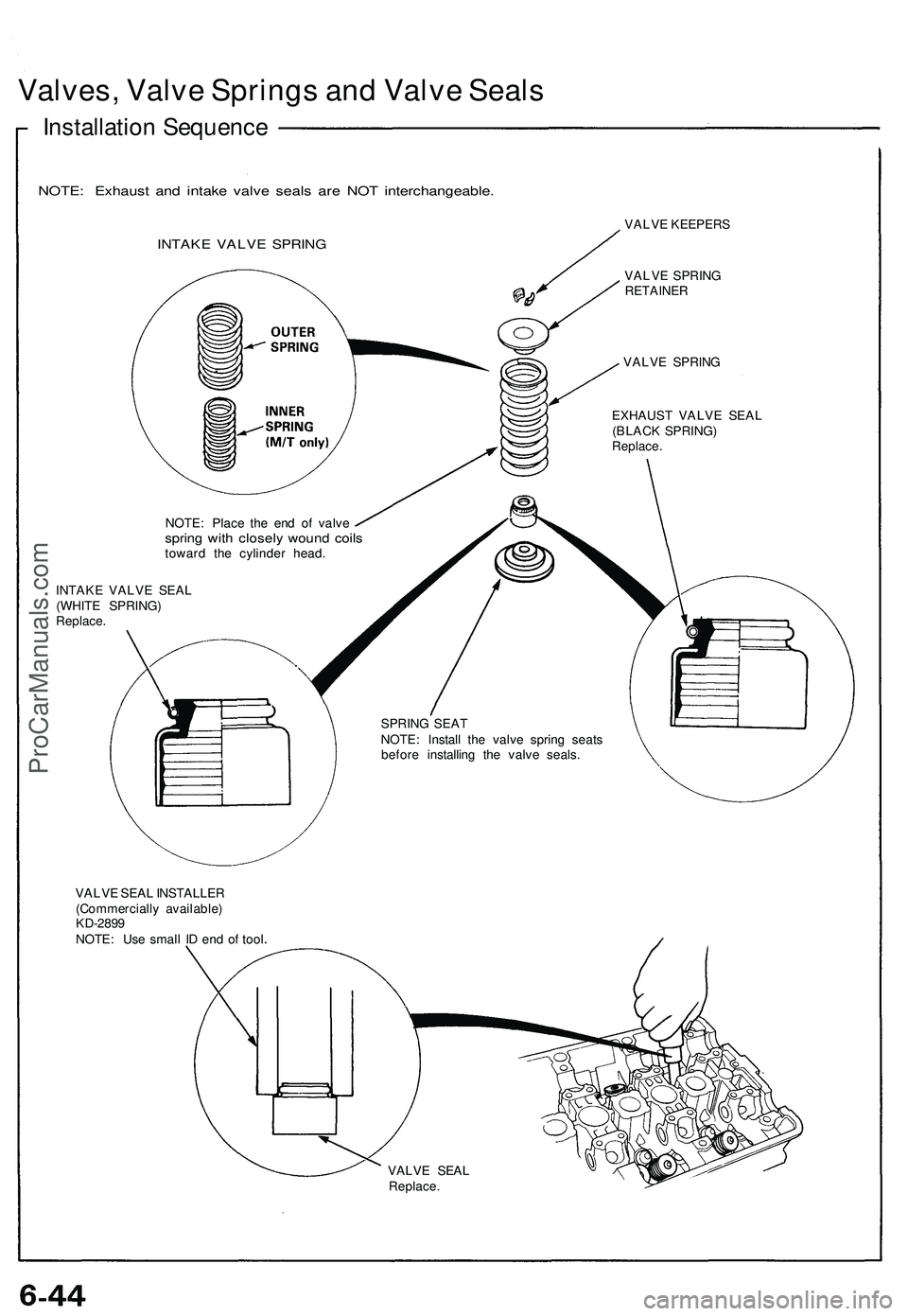

NOTE: Exhaust and intake valve seals are NOT interchangeable.

INTAKE VALVE SPRING

VALVE KEEPERS

VALVE SPRING

RETAINER

VALVE SPRING

EXHAUST VALVE SEAL

(BLACK SPRING)

Replace.

NOTE: Place the end of valve

spring with closely wound coils

toward the cylinder head.

INTAKE VALVE SEAL

(WHITE SPRING)

Replace.

SPRING SEAT

NOTE: Install the valve spring seats

before installing the valve seals.

VALVE SEAL INSTALLER

(Commercially available)

KD-2899

NOTE: Use small ID end of tool

VALVE SEAL

Replace.ProCarManuals.com

Page 465 of 1503

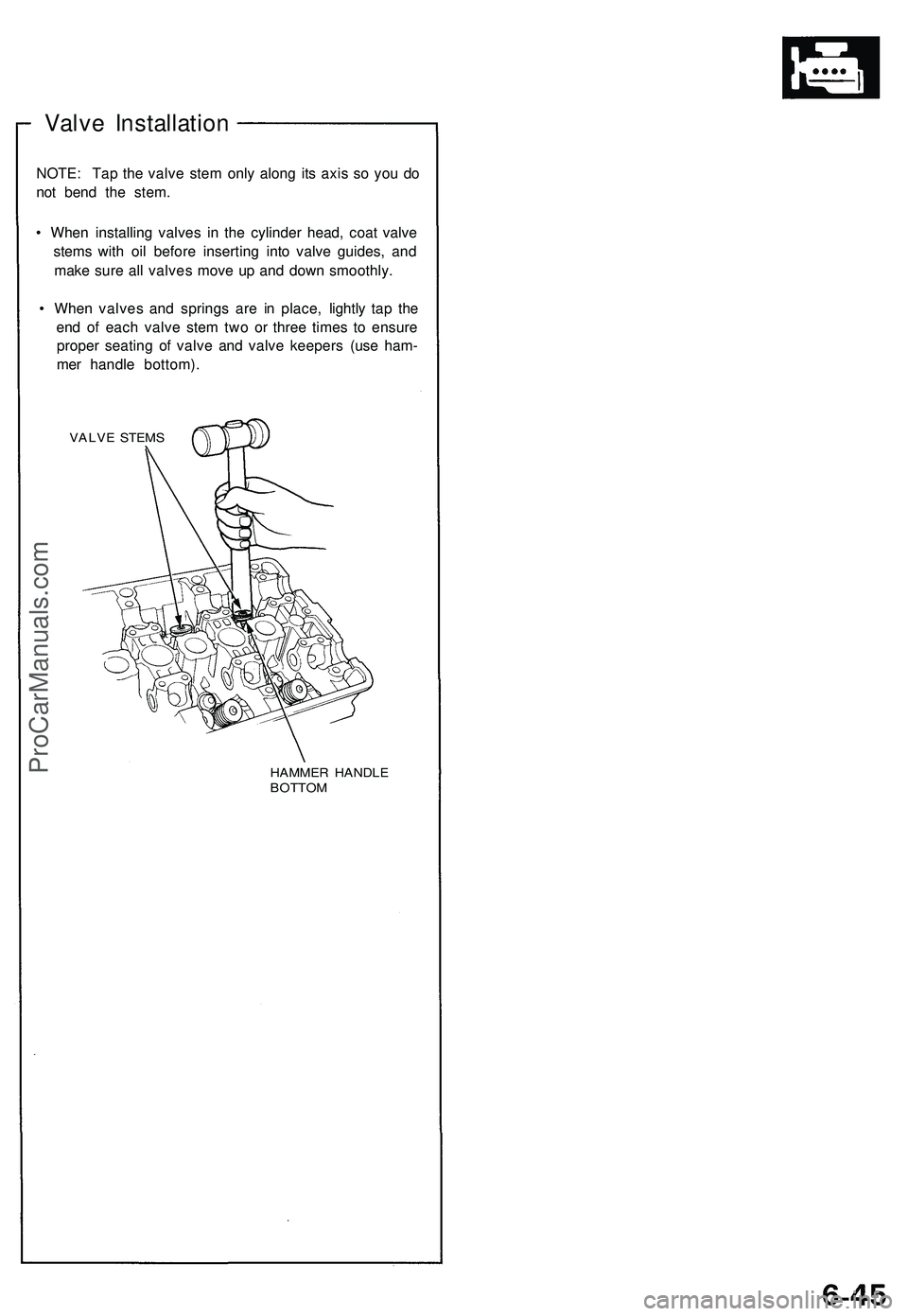

Valve Installation

NOTE: Tap the valve stem only along its axis so you do

not bend the stem.

• When installing valves in the cylinder head, coat valve

stems with oil before inserting into valve guides, and

make sure all valves move up and down smoothly.

• When valves and springs are in place, lightly tap the

end of each valve stem two or three times to ensure

proper seating of valve and valve keepers (use ham-

mer handle bottom).

VALVE STEMS

HAMMER HANDLE

BOTTOMProCarManuals.com

Page 466 of 1503

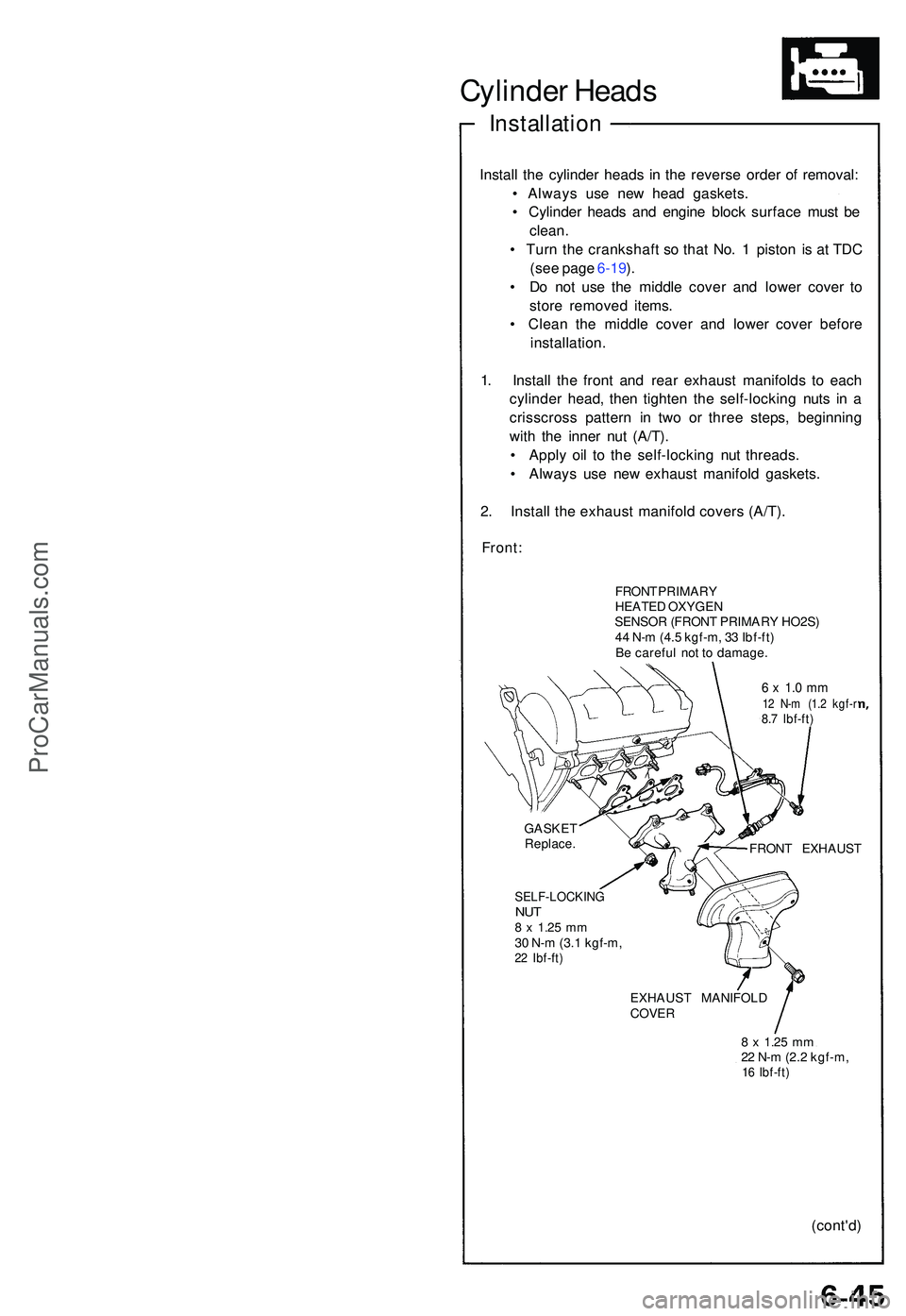

Cylinder Head s

Installatio n

Install th e cylinde r head s i n th e revers e orde r o f removal :

• Alway s us e ne w hea d gaskets .

• Cylinde r head s an d engin e bloc k surfac e mus t b e

clean .

• Tur n th e crankshaf t s o tha t No . 1 pisto n i s a t TD C

(se e pag e 6-19 ).

• D o no t us e th e middl e cove r an d lowe r cove r t o

stor e remove d items .

• Clea n th e middl e cove r an d lowe r cove r befor e

installation .

1 . Instal l th e fron t an d rea r exhaus t manifold s t o eac h

cylinde r head , the n tighte n th e self-lockin g nut s i n a

crisscros s patter n i n tw o o r thre e steps , beginnin g

wit h th e inne r nu t (A/T) .

• Appl y oi l t o th e self-lockin g nu t threads .

• Alway s us e ne w exhaus t manifol d gaskets .

2 . Instal l th e exhaus t manifol d cover s (A/T) .

Front:

FRON T PRIMAR Y

HEATE D OXYGEN

SENSO R (FRON T PRIMAR Y HO2S )

4 4 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

B e carefu l no t t o damage .

6 x 1. 0 m m12 N- m (1. 2 kgf- r8.7 Ibf-ft )

GASKE TReplace .

SELF-LOCKIN GNUT8 x 1.2 5 mm30 N- m (3. 1 kgf-m ,22 Ibf-ft )

FRON T EXHAUS T

EXHAUS T MANIFOL D

COVER

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,16 Ibf-ft )

(cont'd )

ProCarManuals.com

Page 467 of 1503

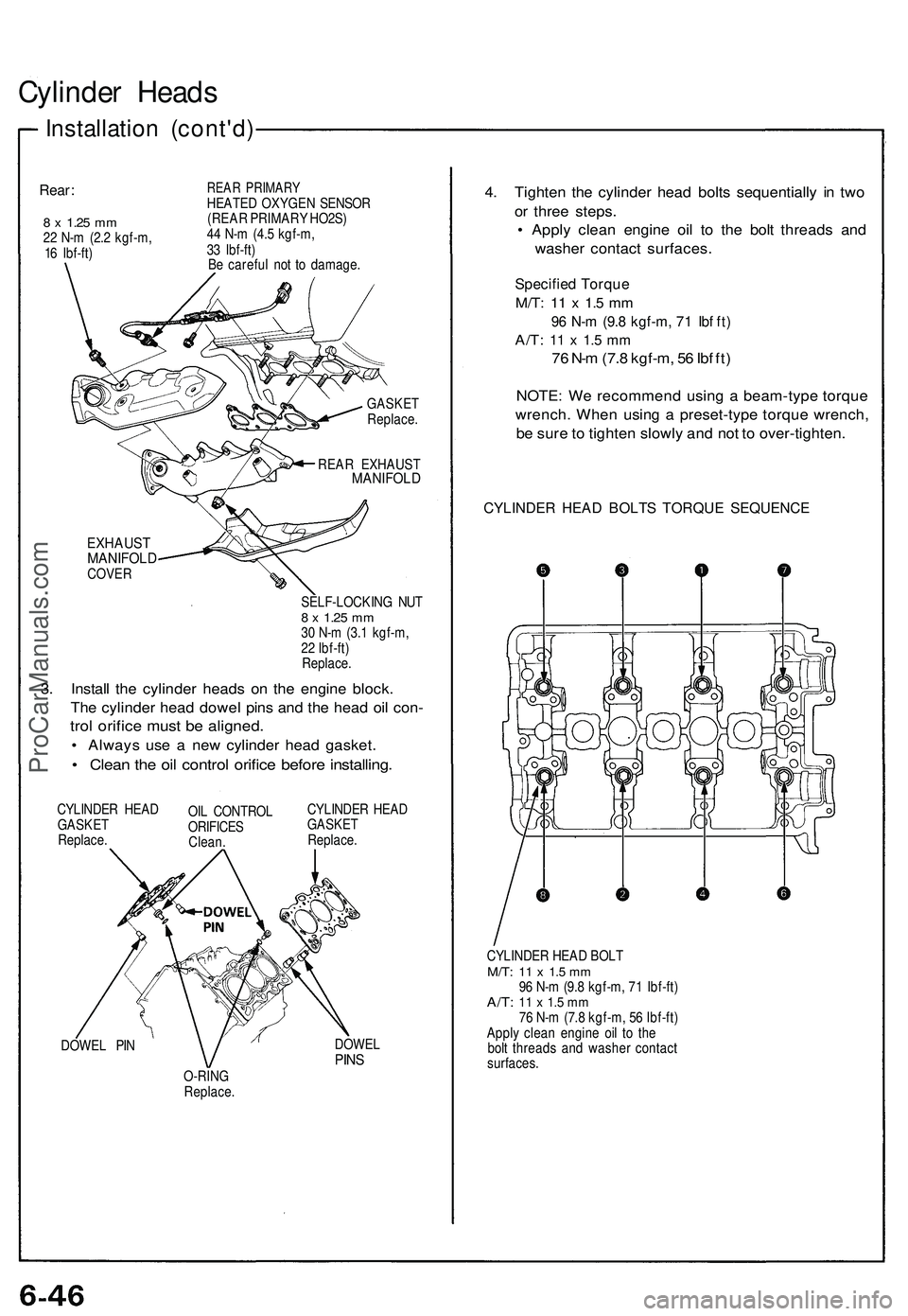

Cylinder Heads

Installation (cont'd)

Rear:

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

REAR PRIMARY

HEATED OXYGEN SENSOR

(REAR PRIMARY HO2S)

44 N-m (4.5 kgf-m,

33 Ibf-ft)

Be careful not to damage.

GASKET

Replace.

REAR EXHAUST

MANIFOLD

EXHAUST

MANIFOLD

COVER

SELF-LOCKING NUT

8 x

1.25

mm

30 N-m (3.1 kgf-m,

22 Ibf-ft)

Replace.

3. Install the cylinder heads on the engine block.

The cylinder head dowel pins and the head oil con-

trol orifice must be aligned.

• Always use a new cylinder head gasket.

• Clean the oil control orifice before installing.

CYLINDER HEAD

GASKET

Replace.

OIL CONTROL

ORIFICES

Clean.

CYLINDER HEAD

GASKET

Replace.

DOWEL PIN

DOWEL

PINS

O-RING

Replace.

4. Tighten the cylinder head bolts sequentially in two

or three steps.

• Apply clean engine oil to the bolt threads and

washer contact surfaces.

Specified Torque

M/T:

11 x 1.5 mm

96 N-m (9.8 kgf-m, 71 Ibf ft)

A/T:

11 x 1.5 mm

76 N-m (7.8 kgf-m, 56 Ibf ft)

NOTE: We recommend using a beam-type torque

wrench. When using a preset-type torque wrench,

be sure to tighten slowly and not to over-tighten.

CYLINDER HEAD BOLTS TORQUE SEQUENCE

CYLINDER HEAD BOLT

M/T:

11 x 1.5 mm

96 N-m (9.8 kgf-m, 71 Ibf-ft)

A/T:

11 x 1.5 mm

76 N-m (7.8 kgf-m, 56 Ibf-ft)

Apply clean engine oil to the

bolt threads and washer contact

surfaces.ProCarManuals.com

Page 468 of 1503

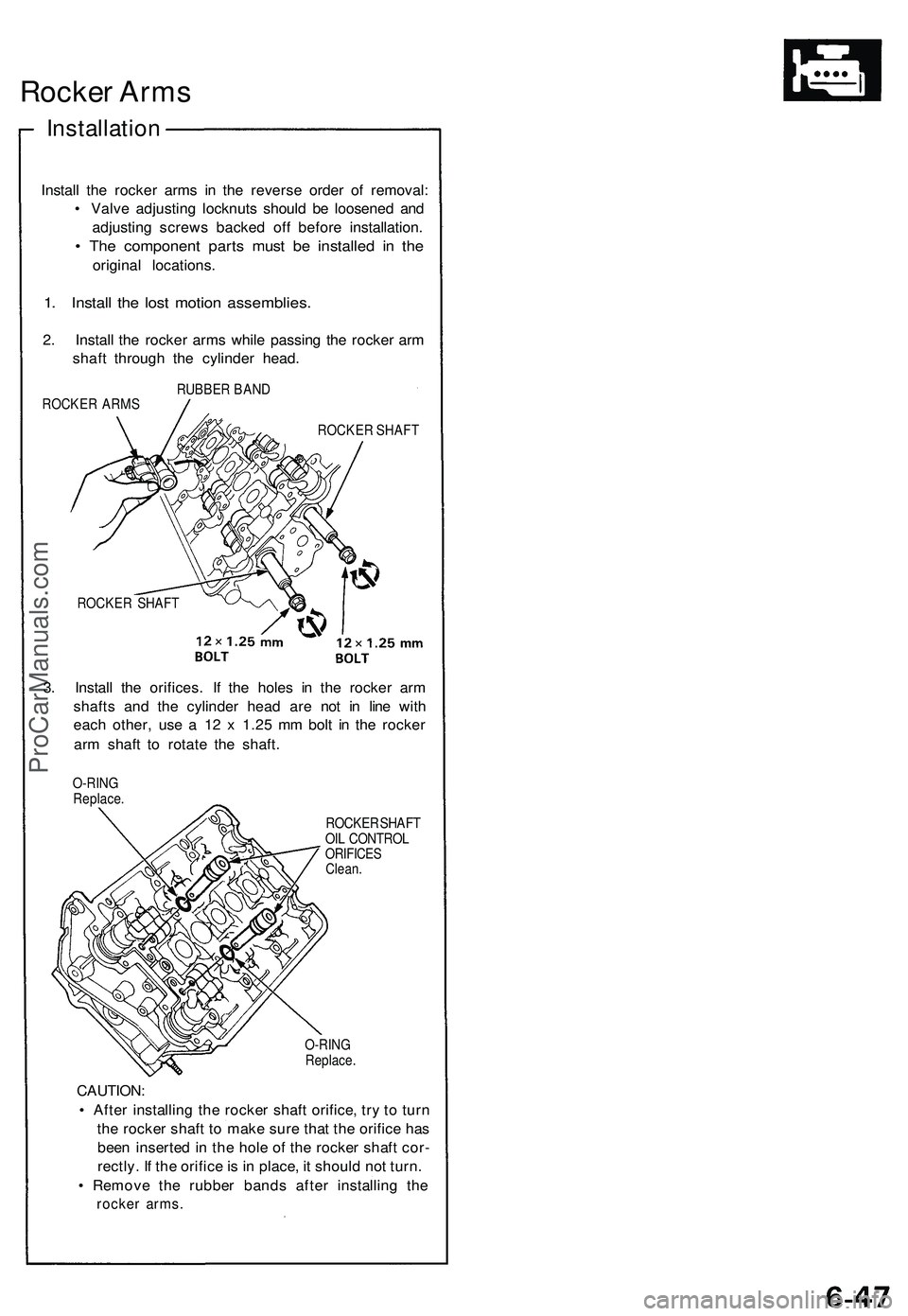

Rocker Arms

Installation

Install the rocker arms in the reverse order of removal:

• Valve adjusting locknuts should be loosened and

adjusting screws backed off before installation.

• The component parts must be installed in the

original locations.

1. Install the lost motion assemblies.

2. Install the rocker arms while passing the rocker arm

shaft through the cylinder head.

ROCKER ARMS

ROCKER SHAFT

ROCKER SHAFT

O-RING

Replace.

CAUTION:

• After installing the rocker shaft orifice, try to turn

the rocker shaft to make sure that the orifice has

been inserted in the hole of the rocker shaft cor-

rectly. If the orifice is in place, it should not turn.

• Remove the rubber bands after installing the

rocker arms.

RUBBER BAND

3. Install the orifices. If the holes in the rocker arm

shafts and the cylinder head are not in line with

each other, use a 12 x 1.25 mm bolt in the rocker

arm shaft to rotate the shaft.

O-RING

Replace.

ROCKER SHAFT

OIL CONTROL

ORIFICES

Clean.ProCarManuals.com

Page 469 of 1503

Camshafts

Installation

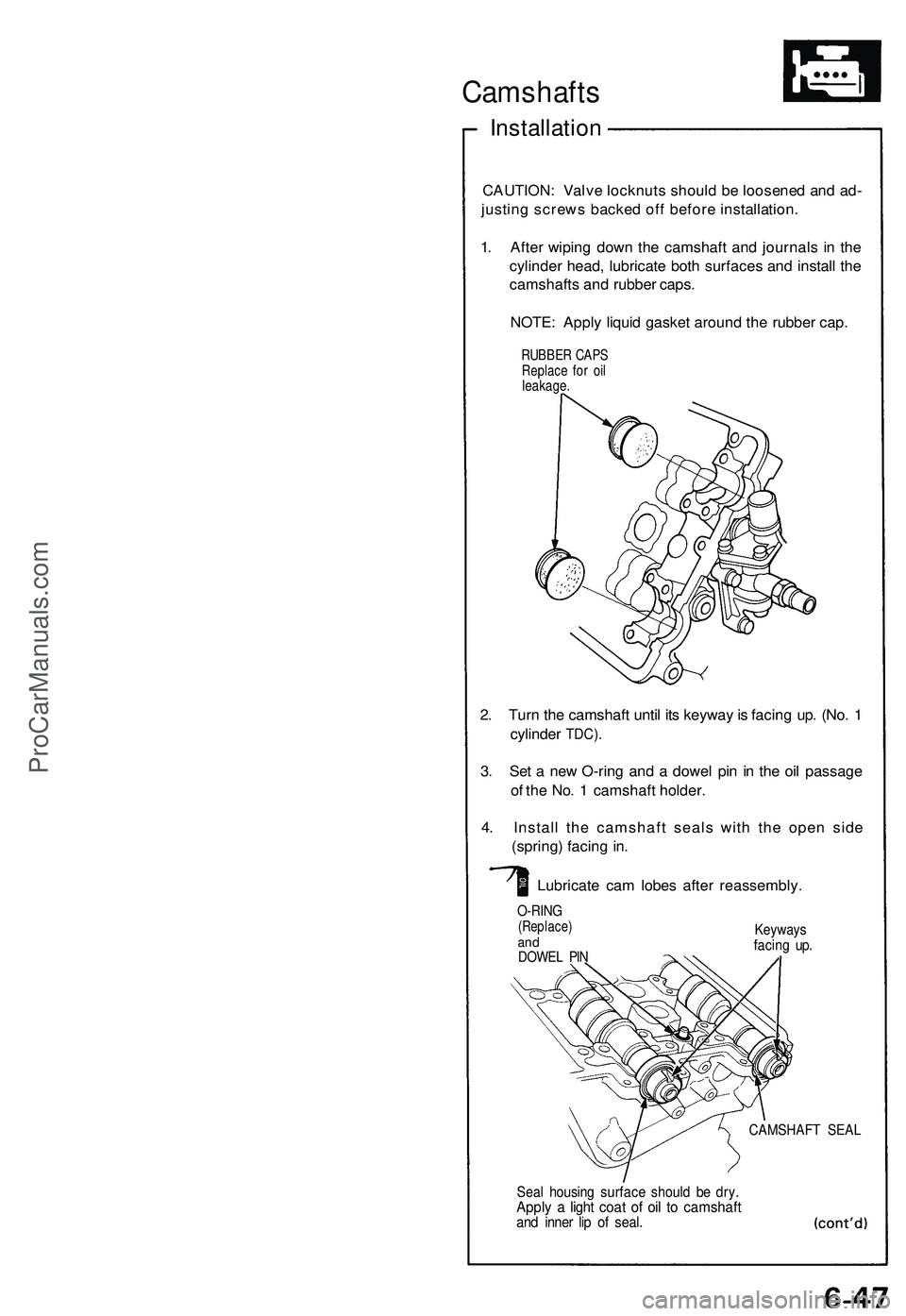

CAUTION: Valve locknuts should be loosened and ad-

justing screws backed off before installation.

1. After wiping down the camshaft and journals in the

cylinder head, lubricate both surfaces and install the

camshafts and rubber caps.

NOTE: Apply liquid gasket around the rubber cap.

2. Turn the camshaft until its keyway is facing up. (No. 1

cylinder

TDC).

3. Set a new O-ring and a dowel pin in the oil passage

of the No. 1 camshaft holder.

4. Install the camshaft seals with the open side

(spring) facing in.

Lubricate cam lobes after reassembly.

O-RING

(Replace)

and

DOWEL PIN

Keyways

facing up.

CAMSHAFT SEAL

Seal housing surface should be dry.

Apply a light coat of oil to camshaft

and inner lip of seal.

RUBBER CAPS

Replace for oil

leakage.ProCarManuals.com

Page 470 of 1503

Camshafts

Installation (cont'd)

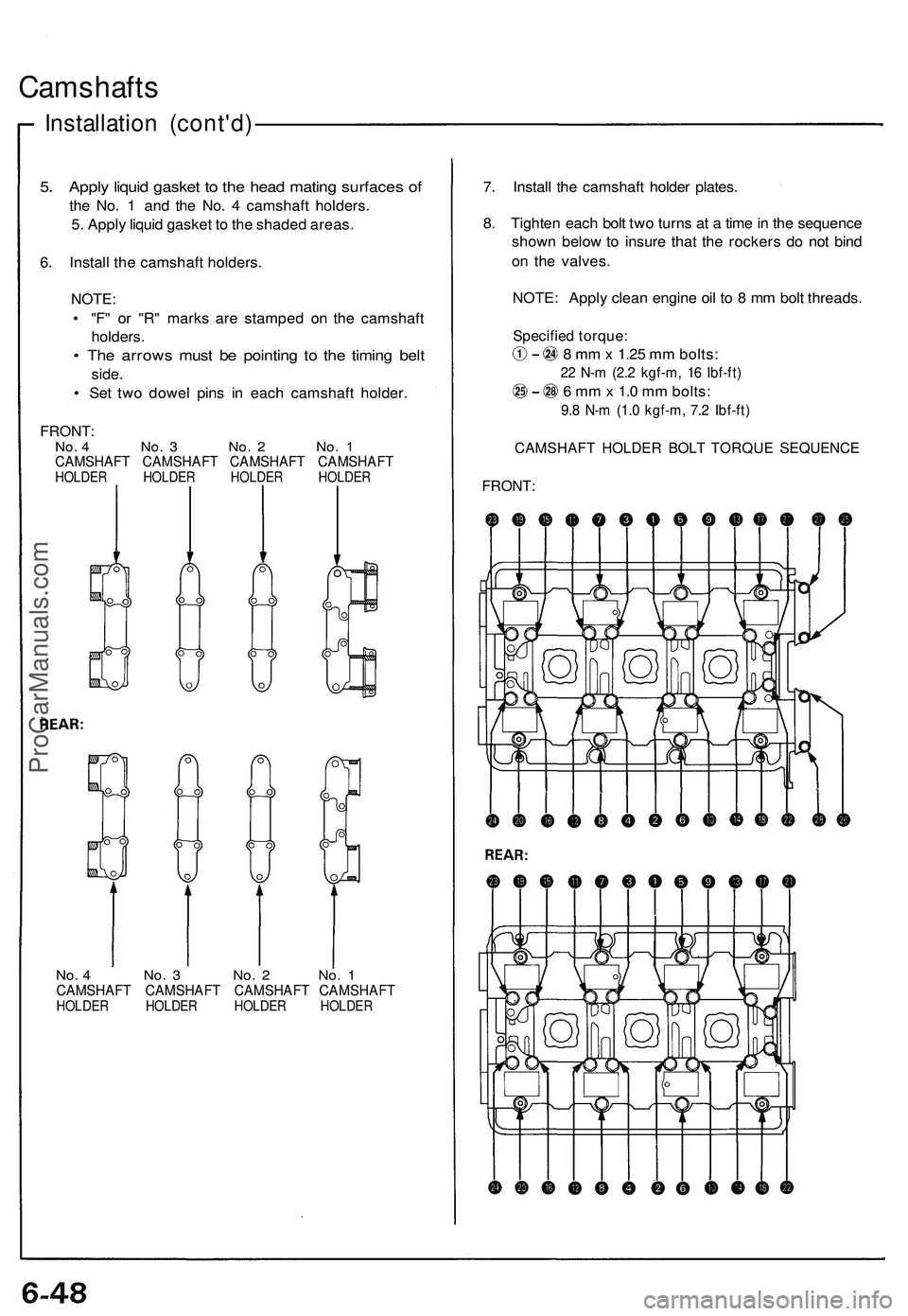

5. Apply liquid gasket to the head mating surfaces of

the No. 1 and the No. 4 camshaft holders.

5. Apply liquid gasket to the shaded areas.

6. Install the camshaft holders.

NOTE:

• "F" or "R" marks are stamped on the camshaft

holders.

• The arrows must be pointing to the timing belt

side.

• Set two dowel pins in each camshaft holder.

FRONT:

No. 4 No. 3 No. 2 No. 1

CAMSHAFT CAMSHAFT CAMSHAFT CAMSHAFT

HOLDER HOLDER HOLDER HOLDER

No. 4 No. 3 No. 2 No. 1

CAMSHAFT CAMSHAFT CAMSHAFT CAMSHAFT

HOLDER HOLDER HOLDER HOLDER

7. Install the camshaft holder plates.

8. Tighten each bolt two turns at a time in the sequence

shown below to insure that the rockers do not bind

on the valves.

NOTE: Apply clean engine oil to 8 mm bolt threads.

Specified torque:

8 mm x 1.25 mm bolts:

22 N-m (2.2 kgf-m, 16 Ibf-ft)

6 mm x 1.0 mm bolts:

9.8 N-m (1.0 kgf-m, 7.2 Ibf-ft)

CAMSHAFT HOLDER BOLT TORQUE SEQUENCE

FRONT:ProCarManuals.com