ACURA NSX 1997 Service Repair Manual

Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 871 of 1503

Bearing Preload

Adjustment

NOTE: If any of the items listed below are replaced, the

bearing preload must be adjusted.

TRANSMISSION HOUSING

TORQUE CONVERTER HOUSING

DIFFERENTIAL

TAPERED ROLLER BEARING and OUTER RACE

75 mm THRUST SHIM

90 mm WASHER

OIL GUIDE RING

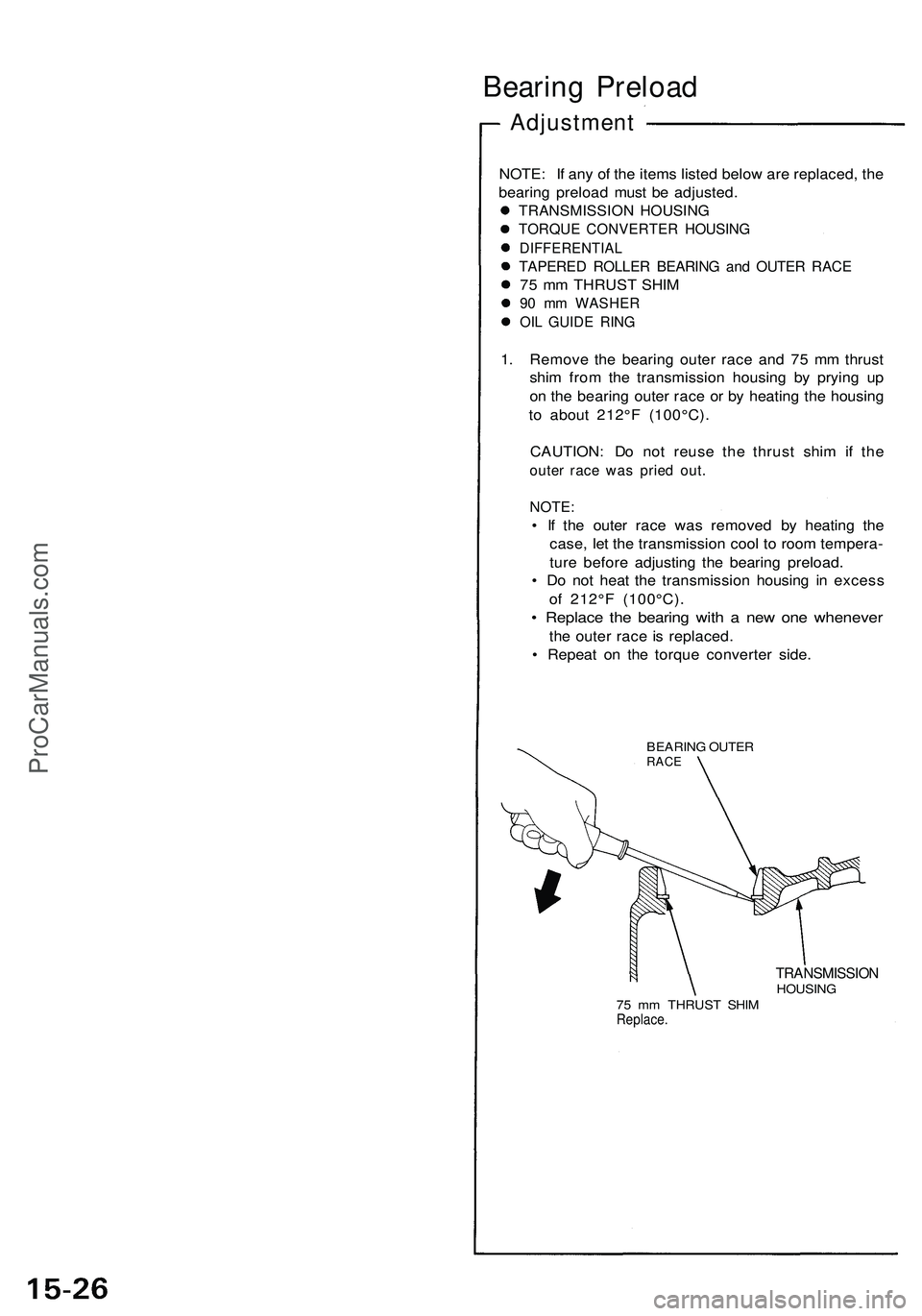

1. Remove the bearing outer race and 75 mm thrust

shim from the transmission housing by prying up

on the bearing outer race or by heating the housing

to about 212°F (100°C).

CAUTION: Do not reuse the thrust shim if the

outer race was pried out.

NOTE:

• If the outer race was removed by heating the

case, let the transmission cool to room tempera-

ture before adjusting the bearing preload.

• Do not heat the transmission housing in excess

of 212°F (100°C).

• Replace the bearing with a new one whenever

the outer race is replaced.

• Repeat on the torque converter side.

BEARING OUTER

RACE

TRANSMISSION

HOUSING

75 mm THRUST SHIM

Replace.ProCarManuals.com

Page 872 of 1503

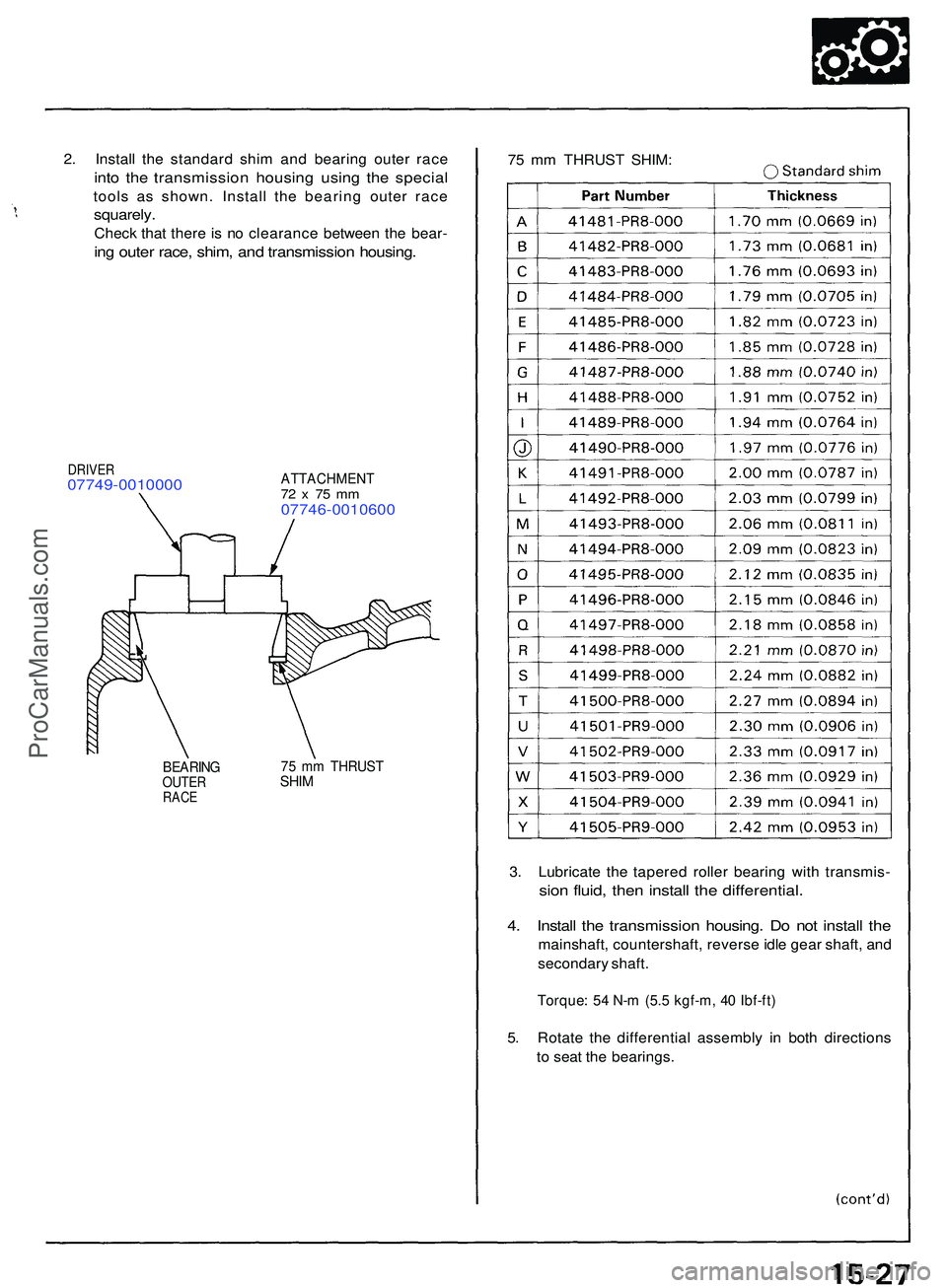

2. Instal l th e standar d shi m an d bearin g oute r rac e

into th e transmissio n housin g usin g th e specia l

tools a s shown . Instal l th e bearin g oute r rac e

squarely .

Check tha t ther e is n o clearanc e betwee n th e bear -

ing oute r race , shim , an d transmissio n housing .

75 m m THRUS T SHIM :

ATTACHMEN T72 x 7 5 m m07746-001060 0

DRIVER07749-001000 0

BEARINGOUTERRACE

75 m m THRUS TSHIM

3. Lubricat e th e tapere d rolle r bearin g wit h transmis -

sion fluid , the n instal l th e differential .

4. Instal l th e transmissio n housing . D o no t instal l th e

mainshaft , countershaft , revers e idl e gea r shaft , an d

secondar y shaft .

Torque : 5 4 N- m (5. 5 kgf-m , 4 0 Ibf-ft )

5. Rotat e th e differentia l assembl y i n bot h direction s

t o sea t th e bearings .

ProCarManuals.com

Page 873 of 1503

Bearing Preloa d

Adjustmen t (cont'd )

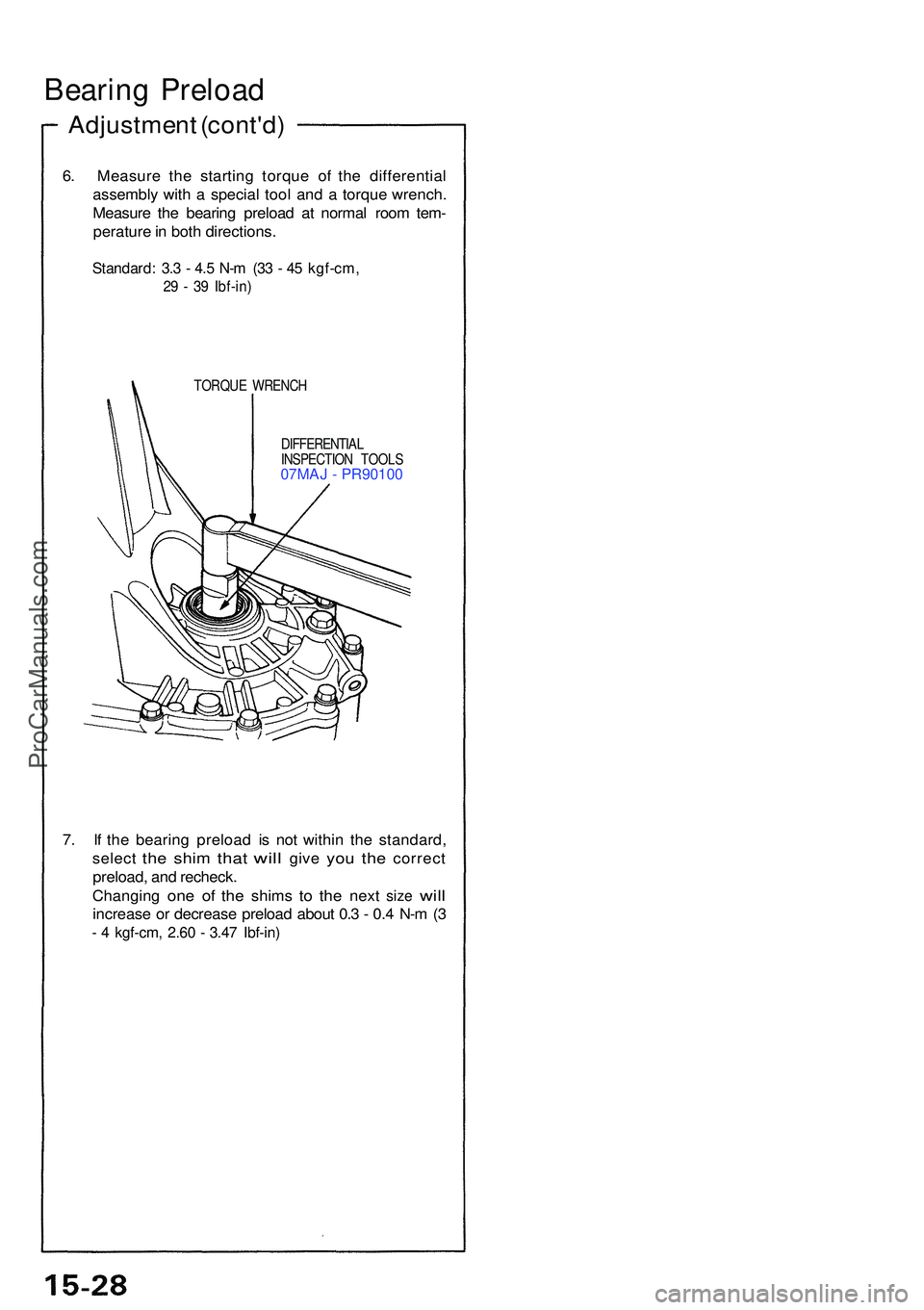

6. Measur e th e startin g torqu e o f th e differentia l

assembl y wit h a specia l too l an d a torqu e wrench .

Measur e th e bearin g preloa d a t norma l roo m tem -

peratur e in bot h directions .

Standard: 3. 3 - 4. 5 N- m (3 3 - 4 5 kgf-cm ,

29 - 3 9 Ibf-in )

TORQU E WRENC H

DIFFERENTIA L

INSPECTIO N TOOL S

07MAJ - PR90100

7. I f th e bearin g preloa d i s no t withi n th e standard ,

selec t

the shi m tha t will giv e you th e correc t

preload , an d recheck .

Changin g

one o f th e shim s to th e nex t size will

increas e o r decreas e preloa d abou t 0. 3 - 0. 4 N- m (3

- 4 kgf-cm , 2.6 0 - 3.4 7 Ibf-in )

ProCarManuals.com

Page 874 of 1503

Oil Seal

Installation

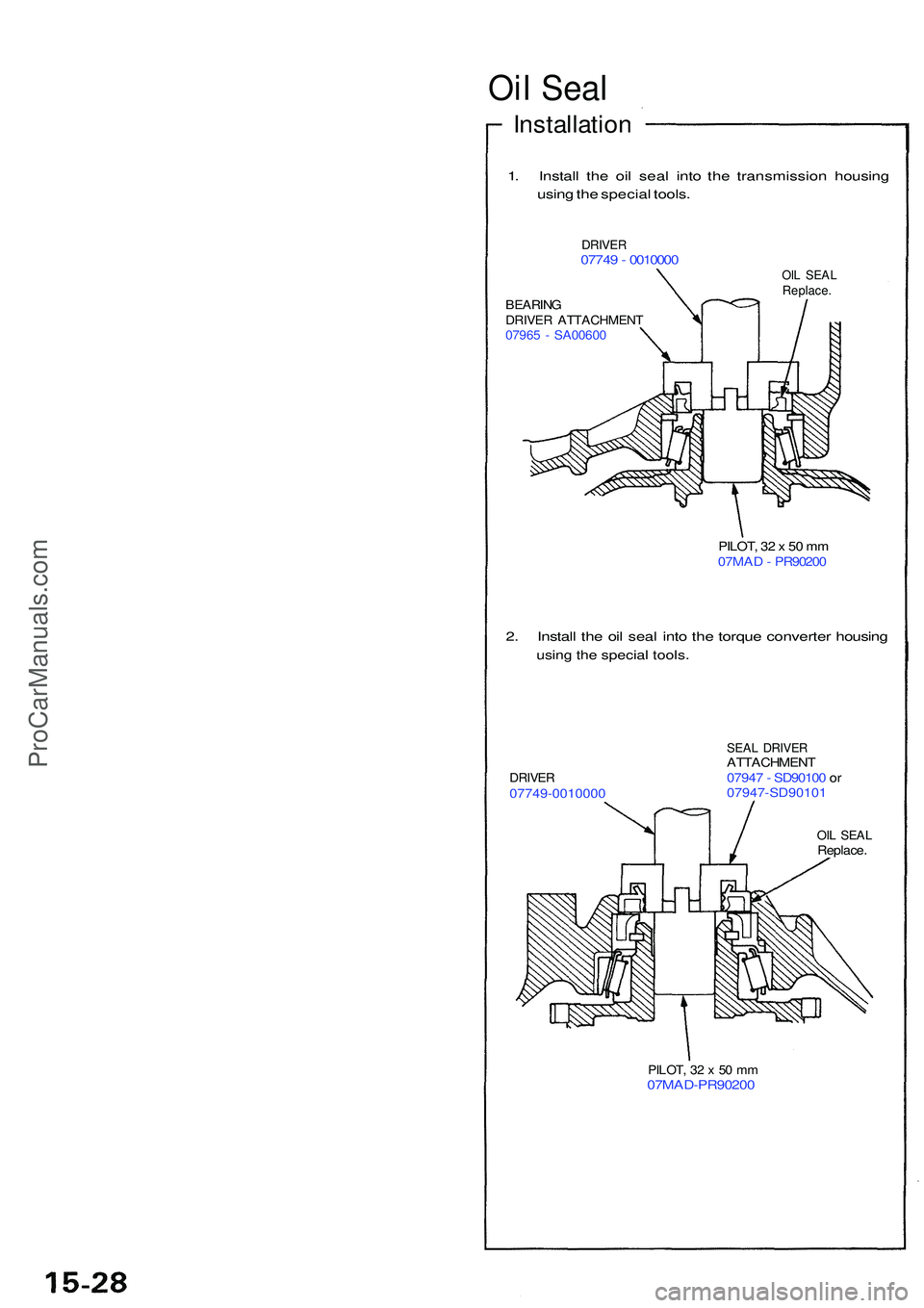

1. Instal l th e oi l sea l int o th e transmissio n housin g

usin g th e specia l tools .

DRIVE R07749 - 001000 0OIL SEA LReplace .BEARINGDRIVER ATTACHMEN T07965 - SA0060 0

PILOT, 3 2 x 50 m m

07MA D - PR9020 0

2. Instal l th e oi l sea l int o th e torqu e converte r housin g

using th e specia l tools .

DRIVE R07749-001000 0

SEAL DRIVE RATTACHMEN T

0794 7 - SD9010 0 o r

07947-SD9010 1

OIL SEA LReplace .

PILOT, 3 2 x 50 m m07MAD-PR9020 0

ProCarManuals.com

Page 875 of 1503

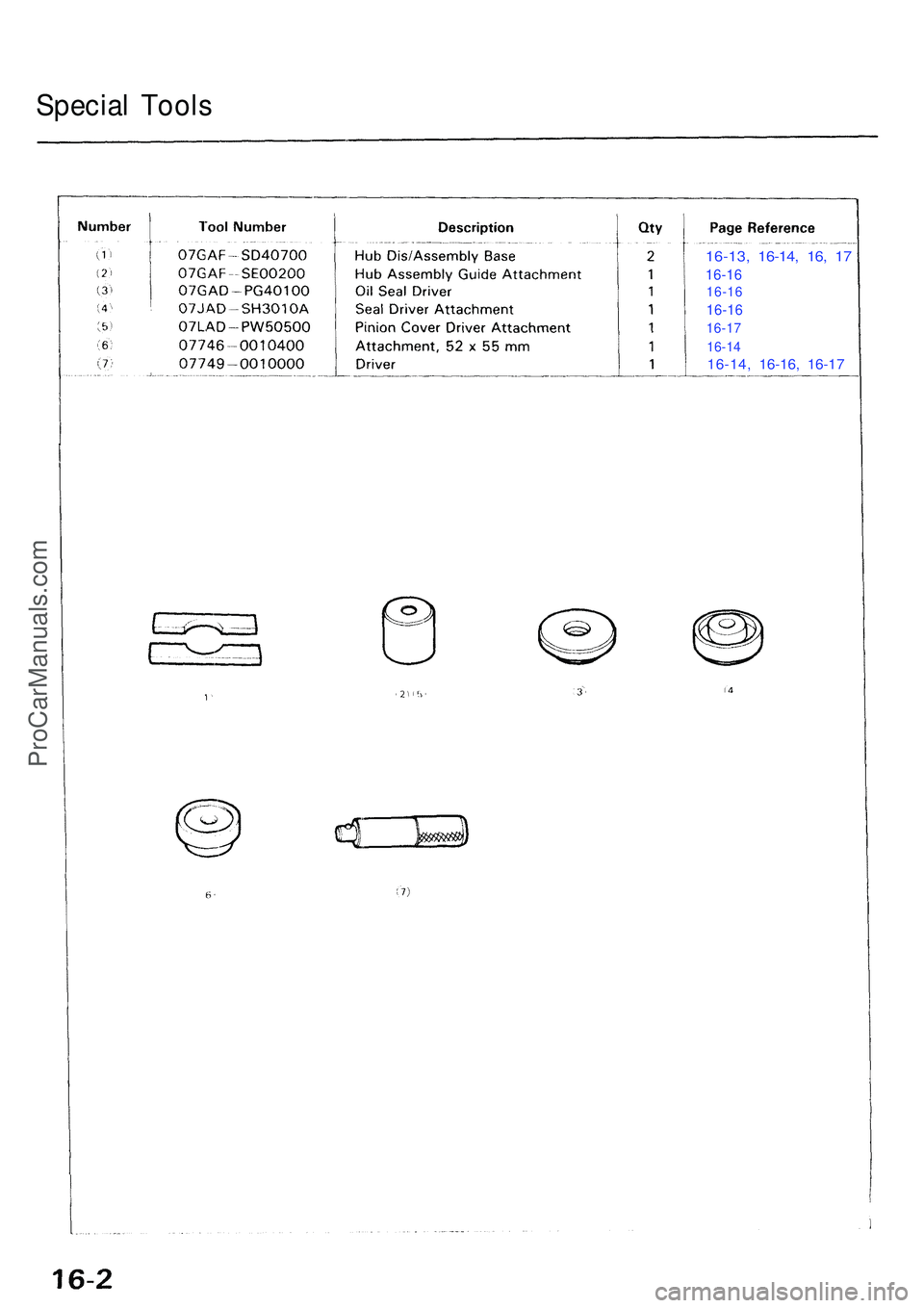

Special Tool s

16-13 , 16-14 , 16 , 1 7

16-1 6

16-1 6

16-16

16-1 7

16-1 4

16-14 , 16-16 , 16-1 7

ProCarManuals.com

Page 876 of 1503

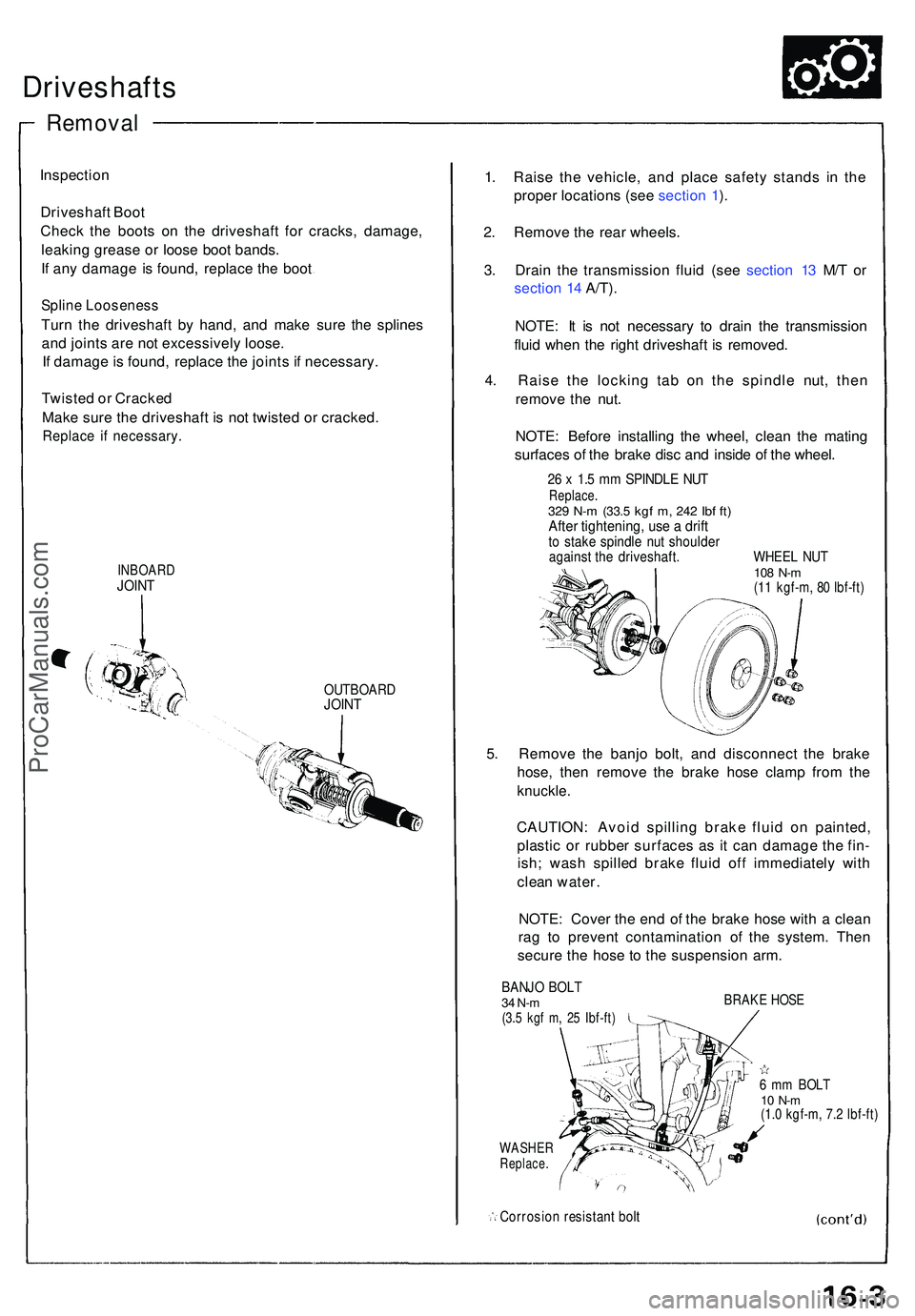

Driveshafts

Inspection

Driveshaf t Boo t

Chec k th e boot s o n th e driveshaf t fo r cracks , damage ,

leakin g greas e o r loos e boo t bands .

I f an y damag e i s found , replac e th e boo t

Splin e Loosenes s

Turn th e driveshaf t b y hand , an d mak e sur e th e spline s

an d joint s ar e no t excessivel y loose .

I f damag e is found , replac e th e joint s i f necessary .

Twiste d o r Cracked

Mak e sur e th e driveshaf t i s not twiste d o r cracked .

Replace i f necessary .

INBOARDJOINT

OUTBOAR DJOINT

1. Rais e th e vehicle , an d plac e safet y stand s i n th e

prope r location s (se e sectio n 1 ).

2 . Remov e th e rea r wheels .

3 . Drai n th e transmissio n flui d (se e sectio n 1 3 M/ T o r

sectio n 1 4 A/T) .

NOTE : I t i s no t necessar y t o drai n th e transmissio n

flui d whe n th e righ t driveshaf t i s removed .

4 . Rais e th e lockin g ta b o n th e spindl e nut , the n

remov e th e nut .

NOTE : Befor e installin g th e wheel , clea n th e matin g

surface s o f th e brak e dis c an d insid e o f th e wheel .

26 x 1. 5 m m SPINDL E NU TReplace .329 N- m (33. 5 kgf m , 24 2 Ib f ft )Afte r tightening , us e a drif tto stak e spindl e nu t shoulde ragainst th e driveshaft . WHEE L NU T108 N- m(11 kgf-m , 8 0 Ibf-ft )

5. Remov e th e banj o bolt , an d disconnec t th e brak e

hose , the n remov e th e brak e hos e clam p fro m th e

knuckle .

CAUTION : Avoi d spillin g brak e flui d o n painted ,

plasti c o r rubbe r surface s a s i t ca n damag e th e fin -

ish ; was h spille d brak e flui d of f immediatel y wit h

clea n water .

NOTE : Cove r th e en d o f th e brak e hos e wit h a clea n

ra g t o preven t contaminatio n o f th e system . The n

secur e th e hos e t o th e suspensio n arm .

BANJ O BOL T34 N-m(3.5 kg f m , 2 5 Ibf-ft )

WASHE RReplace .

Corrosio n resistan t bol t

BRAK E HOS E

6 m m BOL T10 N- m(1.0 kgf-m , 7. 2 Ibf-ft )

Remova l

ProCarManuals.com

Page 877 of 1503

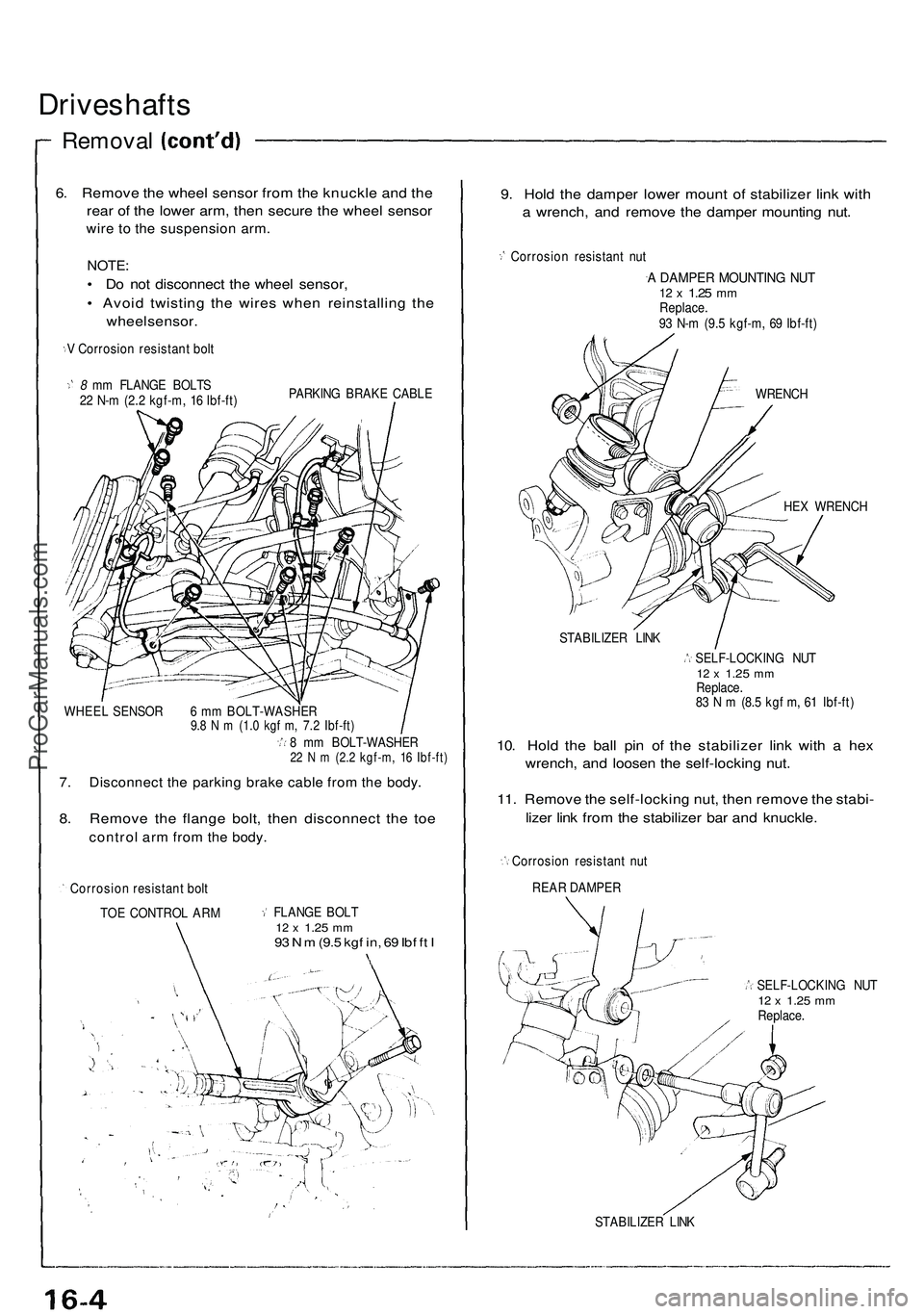

Driveshafts

Removal

6. Remove the wheel sensor from the knuckle and the

rear of the lower arm, then secure the wheel sensor

wire to the suspension arm.

NOTE:

• Do not disconnect the wheel sensor,

• Avoid twisting the wires when reinstalling the

wheel sensor.

V Corrosion resistant bolt

8 mm FLANGE BOLTS

22 N-m (2.2 kgf-m, 16 Ibf-ft)

PARKING BRAKE CABLE

WHEEL SENSOR 6 mm BOLT-WASHER

9.8 N m (1.0 kgf m, 7.2 Ibf-ft)

8 mm BOLT-WASHER

22 N m (2.2 kgf-m, 16 Ibf-ft)

7. Disconnect the parking brake cable from the body.

8. Remove the flange bolt, then disconnect the toe

control arm from the body.

Corrosion resistant bolt

TOE CONTROL ARM

FLANGE BOLT

12 x

1.25

mm

93 N m

(9.5

kgf in, 69 Ibf ft I

9. Hold the damper lower mount of stabilizer link with

a wrench, and remove the damper mounting nut.

Corrosion resistant nut

A DAMPER MOUNTING NUT

12 x

1.25

mm

Replace.

93 N-m (9.5 kgf-m, 69 Ibf-ft)

WRENCH

HEX WRENCH

STABILIZER LINK

SELF-LOCKING NUT

12 x

1.25

mm

Replace.

83 N m (8.5 kgf m, 61 Ibf-ft)

10. Hold the ball pin of the stabilizer link with a hex

wrench, and loosen the self-locking nut.

11. Remove the self-locking nut, then remove the stabi-

lizer link from the stabilizer bar and knuckle.

Corrosion resistant nut

REAR DAMPER

SELF-LOCKING NUT

12 x

1.25

mm

Replace.

STABILIZER LINKProCarManuals.com

Page 878 of 1503

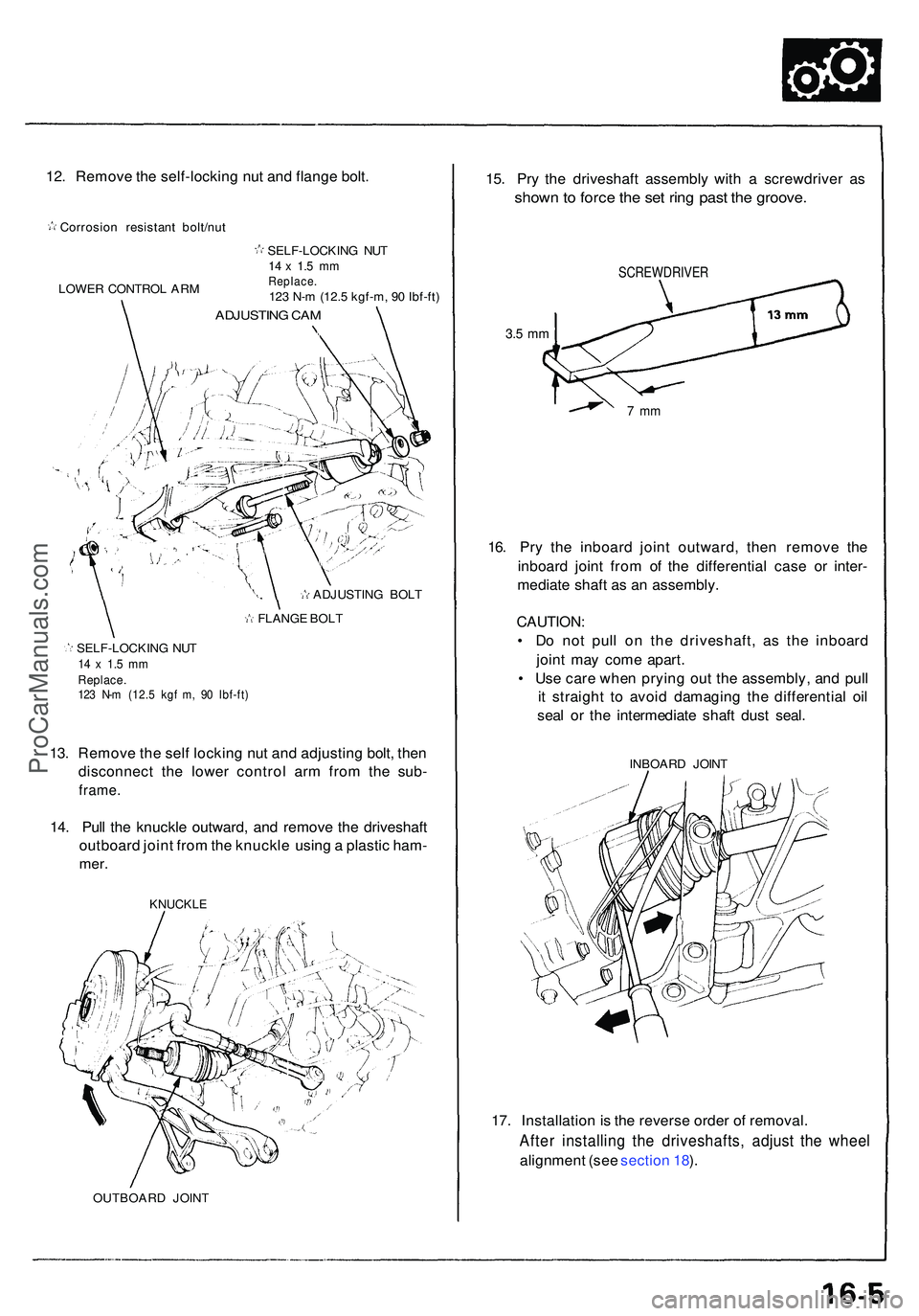

12. Remov e th e self-lockin g nu t an d flang e bolt .

Corrosio n resistan t bolt/nu t

LOWE R CONTRO L AR M SELF-LOCKIN

G NU T

14 x 1. 5 m mReplace .123 N- m (12. 5 kgf-m , 9 0 Ibf-ft )

ADJUSTIN G CA M

ADJUSTIN G BOL T

FLANG E BOL T

SELF-LOCKIN G NU T

14 x 1. 5 m mReplace .123 N- m (12. 5 kg f m , 9 0 Ibf-ft )

13. Remov e th e sel f lockin g nu t an d adjustin g bolt , the n

disconnec t th e lowe r contro l ar m fro m th e sub -

frame .

14. Pul l th e knuckl e outward , an d remov e th e driveshaf t

outboar d join t fro m th e knuckl e usin g a plasti c ham -

mer.

KNUCKL E

OUTBOAR D JOIN T

15. Pr y th e driveshaf t assembl y wit h a screwdrive r a s

show n to forc e th e se t rin g pas t th e groove .

SCREWDRIVE R

3.5 m m

7 m m

16. Pr y th e inboar d join t outward , the n remov e th e

inboar d join t fro m o f th e differentia l cas e o r inter -

mediat e shaf t a s a n assembly .

CAUTION :

• D o no t pul l o n th e driveshaft , a s th e inboar d

join t ma y com e apart .

• Us e car e whe n pryin g ou t th e assembly , an d pul l

i t straigh t t o avoi d damagin g th e differentia l oi l

sea l o r th e intermediat e shaf t dus t seal .

INBOAR D JOIN T

17. Installatio n is th e revers e orde r o f removal .

After installin g th e driveshafts , adjus t th e whee l

alignmen t (se e sectio n 18 ).

ProCarManuals.com

Page 879 of 1503

Driveshafts

Disassembly

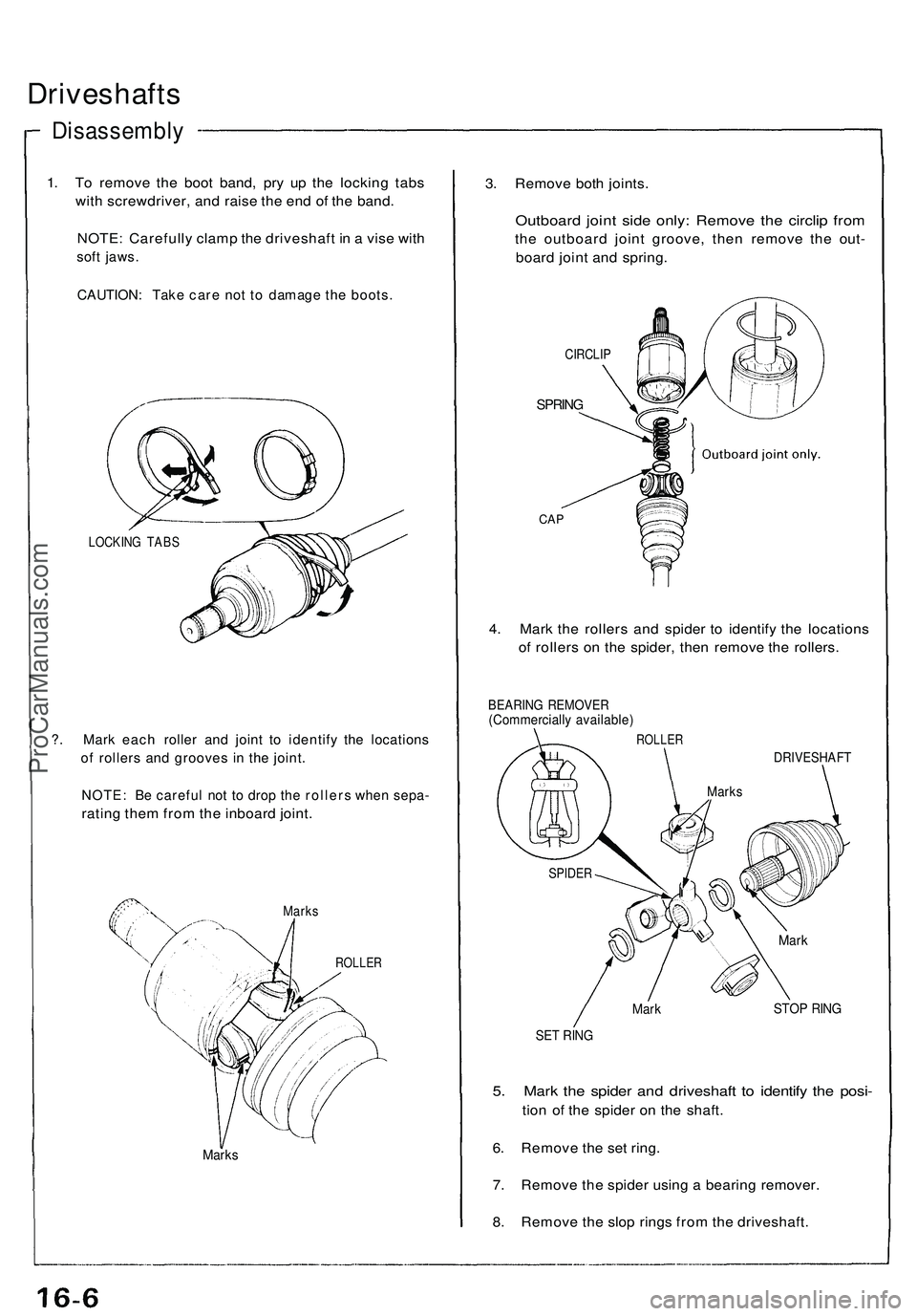

1. To remove the boot band, pry up the locking tabs

with screwdriver, and raise the end of the band.

NOTE: Carefully clamp the driveshaft in a vise with

soft jaws.

CAUTION: Take care not to damage the boots.

LOCKING TABS

?. Mark each roller and joint to identify the locations

of rollers and grooves in the joint.

NOTE: Be careful not to drop the rollers when sepa-

rating them from the inboard joint.

Marks

ROLLER

Marks

3. Remove both joints.

Outboard joint side only: Remove the circlip from

the outboard joint groove, then remove the out-

board joint and spring.

CIRCLIP

SPRING

CAP

4. Mark the rollers and spider to identify the locations

of rollers on the spider, then remove the rollers.

BEARING REMOVER

(Commercially available)

ROLLER

DRIVESHAFT

Mark

STOP RING

SET RING

5. Mark the spider and driveshaft to identify the posi-

tion of the spider on the shaft.

6. Remove the set ring.

7. Remove the spider using a bearing remover.

8. Remove the slop rings from the driveshaft.

SPIDER

Marks

MarkProCarManuals.com

Page 880 of 1503

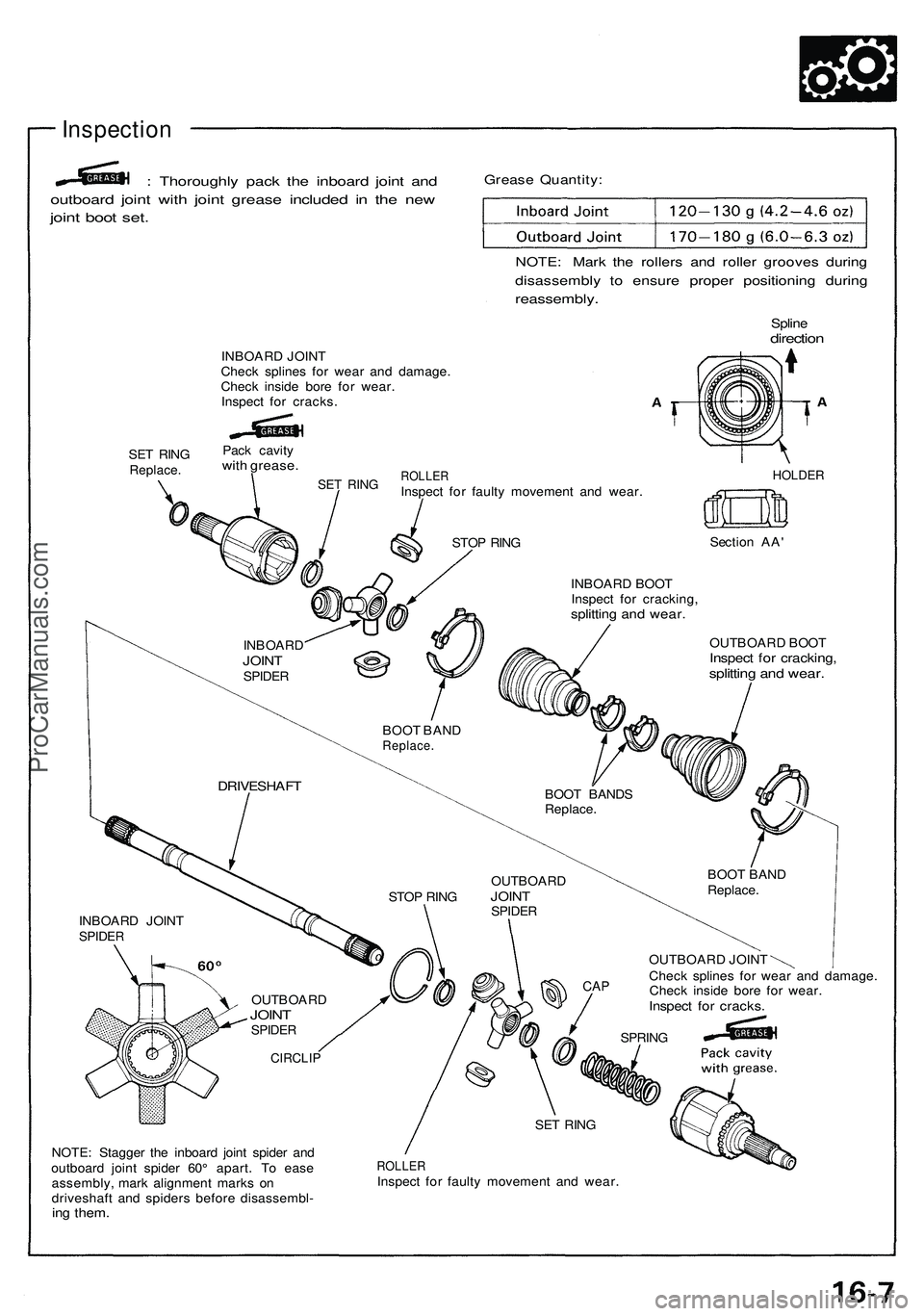

Inspection

: Thoroughl y pac k th e inboar d join t an d

outboar d join t wit h join t greas e include d i n th e ne w

joint boo t set .

Greas e Quantity :

NOTE: Mar k th e roller s an d rolle r groove s durin g

disassembl y t o ensur e prope r positionin g durin g

reassembly .

Splinedirectio n

INBOAR D JOIN T

Chec k spline s fo r wea r an d damage .

Chec k insid e bor e fo r wear .

Inspec t fo r cracks .

SE T RIN G

Replace .

Pack cavit ywith grease .

SET RIN GROLLE RInspect fo r fault y movemen t an d wear .HOLDE R

STOP RIN G Sectio

n AA '

INBOAR D BOO T

Inspec t fo r cracking ,

splitting an d wear .

OUTBOAR D BOO TInspec t fo r cracking ,splitting an d wear .

OUTBOAR D JOIN T

Chec k spline s fo r wea r an d damage .

Chec k insid e bor e fo r wear .

Inspec t fo r cracks .

NOTE: Stagge r th e inboar d join t spide r an d

outboar d join t spide r 60 ° apart . T o eas e

assembly , mar k alignmen t mark s o n

driveshaf t an d spider s befor e disassembl -

ing them .

ROLLE RInspect fo r fault y movemen t an d wear .

INBOAR

D

JOINTSPIDE R

BOOT BAN DReplace .

BOOT BAND S

Replace .

BOOT BAN D

Replace .

DRIVESHAF T

STOP RIN G OUTBOAR

DJOINTSPIDE R

CAP

SPRIN G

SE T RIN G

CIRCLI P

OUTBOAR DJOINTSPIDE R

INBOAR D JOIN TSPIDE R

ProCarManuals.com