ACURA NSX 1997 Service Repair Manual

Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 881 of 1503

Driveshafts

Reassembly

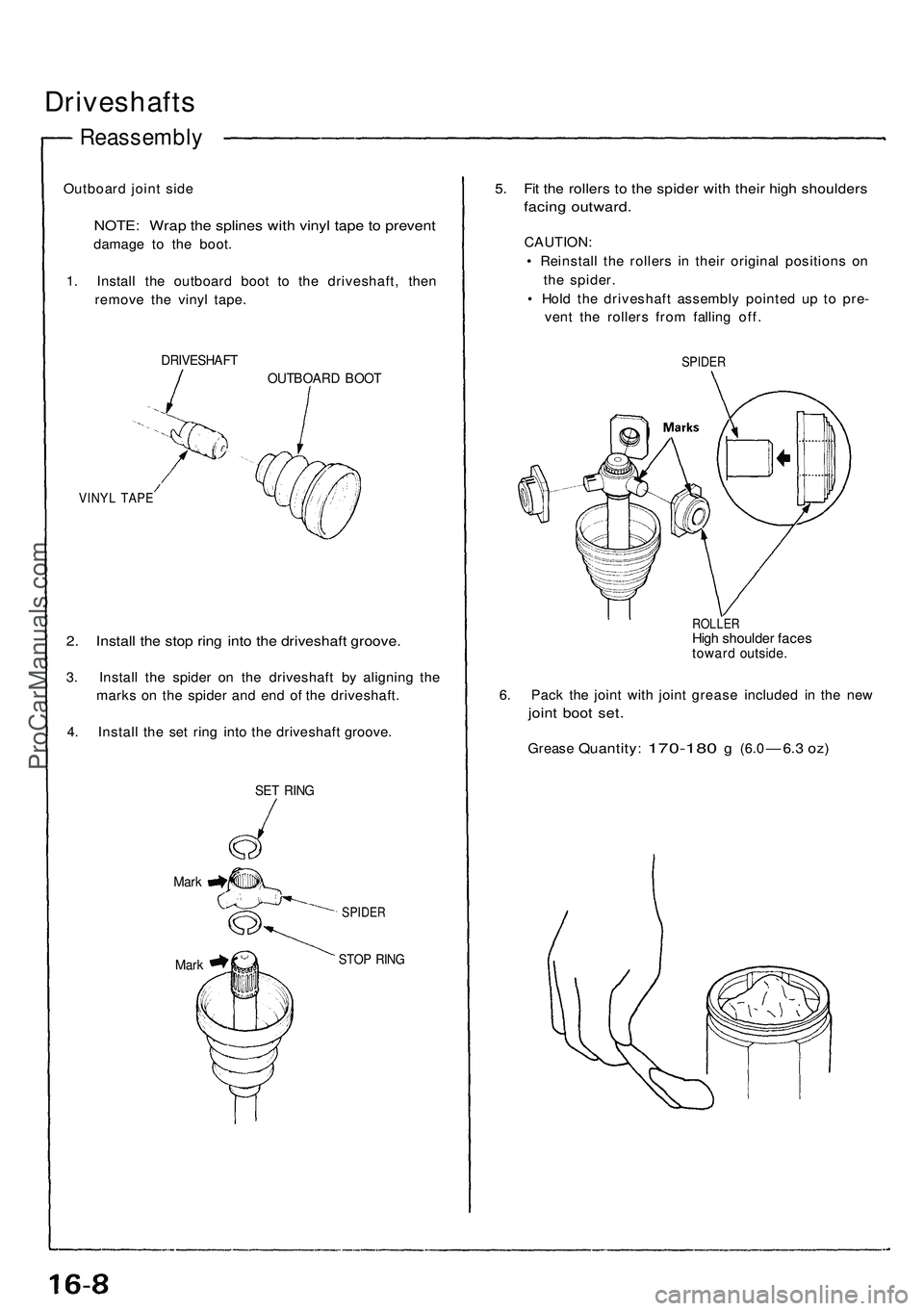

Outboard joint side

NOTE: Wrap the splines with vinyl tape to prevent

damage to the boot.

1. Install the outboard boot to the driveshaft, then

remove the vinyl tape.

DRIVESHAFT

OUTBOARD BOOT

VINYL TAPE

2. Install the stop ring into the driveshaft groove.

3. Install the spider on the driveshaft by aligning the

marks on the spider and end of the driveshaft.

4. Install the set ring into the driveshaft groove.

SET RING

Mark

Mark

SPIDER

STOP RING

5. Fit the rollers to the spider with their high shoulders

facing outward.

CAUTION:

• Reinstall the rollers in their original positions on

the spider.

• Hold the driveshaft assembly pointed up to pre-

vent the rollers from falling off.

SPIDER

ROLLER

High shoulder faces

toward outside.

6. Pack the joint with joint grease included in the new

joint boot set.

Grease

Quantity:

170-180

g

(6.0

— 6.3 oz)ProCarManuals.com

Page 882 of 1503

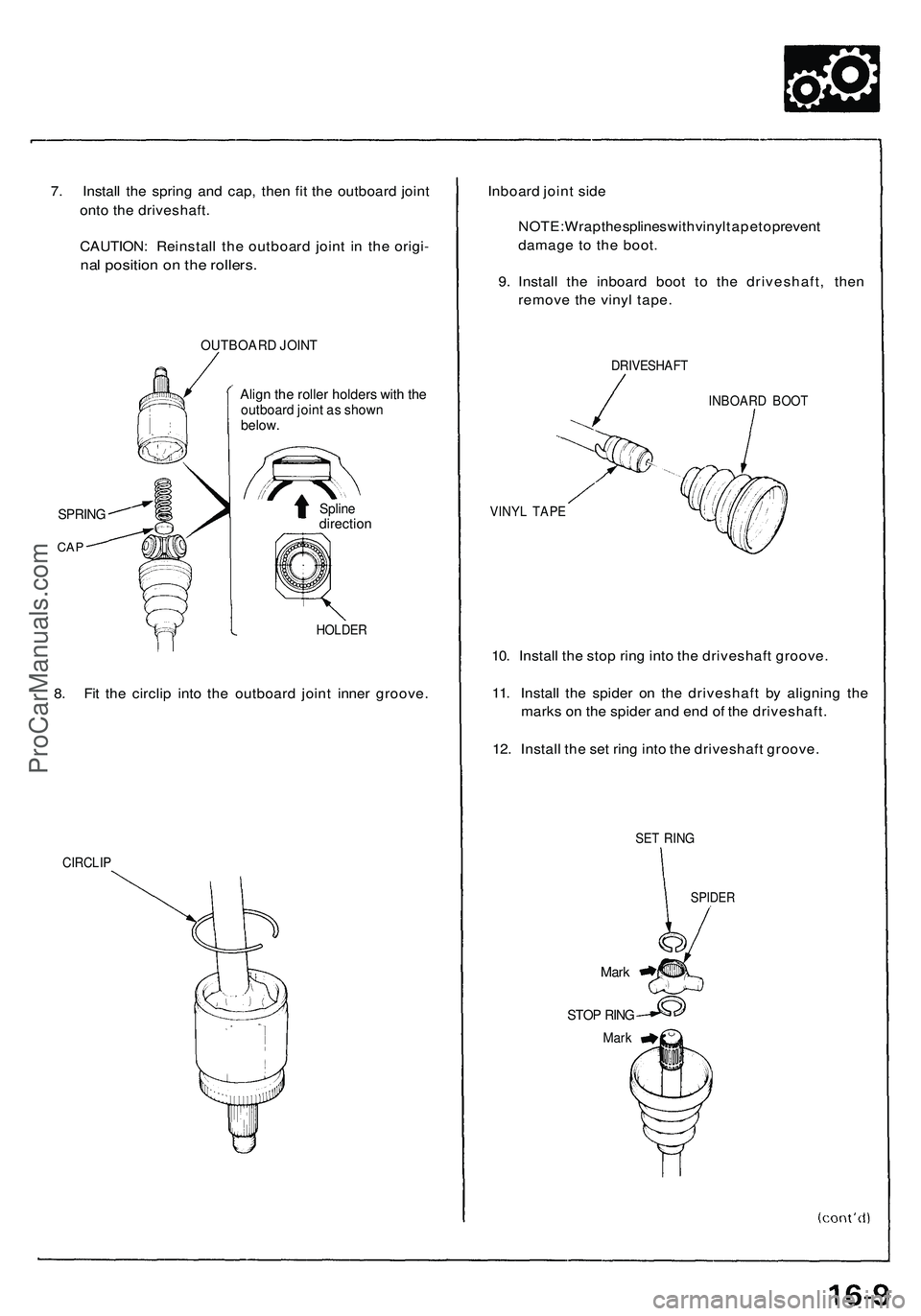

7. Install the spring and cap, then fit the outboard joint

onto the driveshaft.

CAUTION: Reinstall the outboard joint in the origi-

nal position on the rollers.

OUTBOARD JOINT

Align the roller holders with the

outboard joint as shown

below.

Spline

direction

HOLDER

8. Fit the circlip into the outboard joint inner groove.

CIRCLIP

Inboard joint side

NOTE: Wrap the splines with vinyl tape to prevent

damage to the boot.

9. Install the inboard boot to the driveshaft, then

remove the vinyl tape.

DRIVESHAFT

INBOARD BOOT

VINYL TAPE

10. Install the stop ring into the driveshaft groove.

11. Install the spider on the driveshaft by aligning the

marks on the spider and end of the driveshaft.

12. Install the set ring into the driveshaft groove.

SET RING

Mark

STOP RING

Mark

SPIDER

SPRING

CAPProCarManuals.com

Page 883 of 1503

Driveshafts

Reassembly

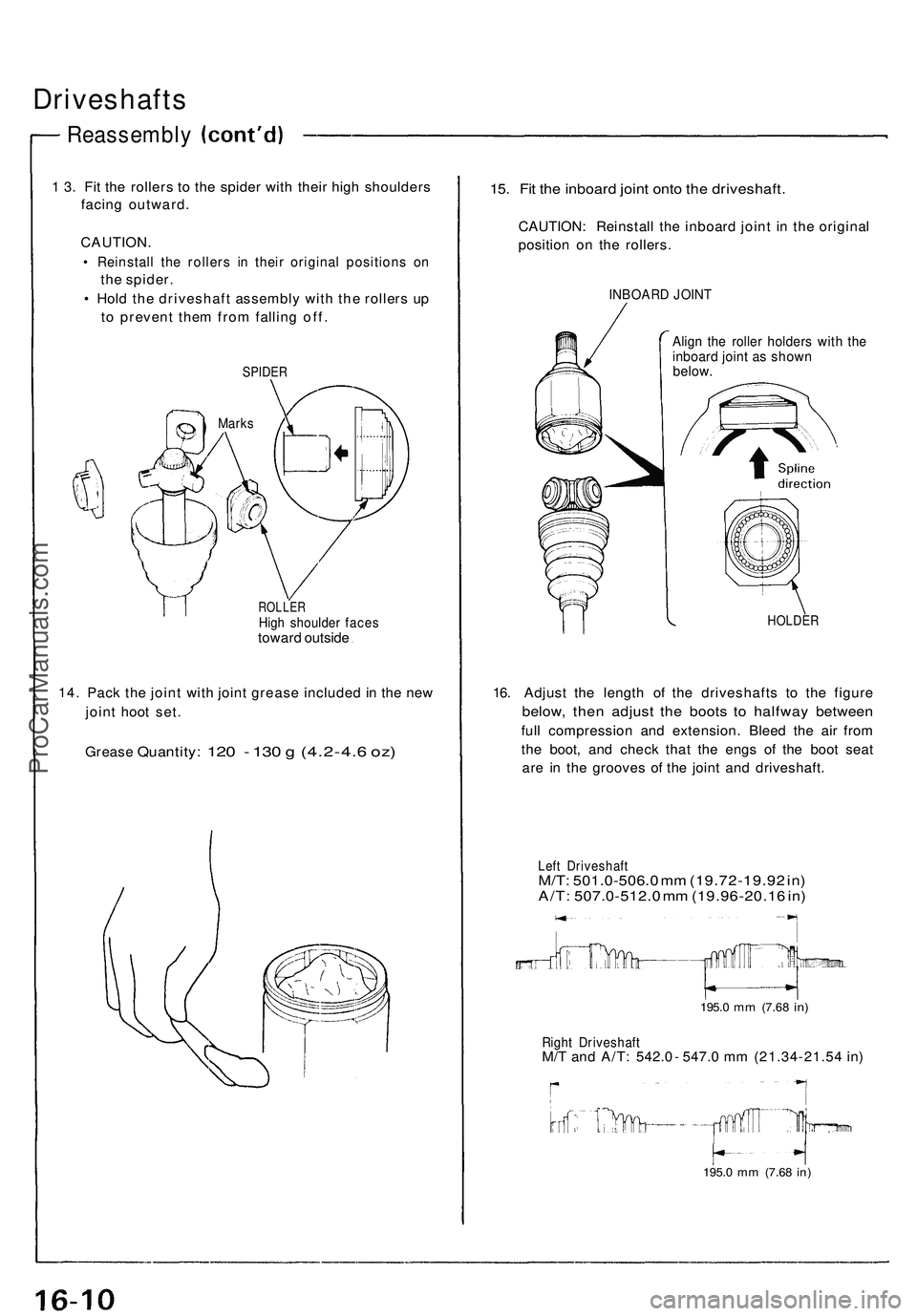

1 3. Fit the rollers to the spider with their high shoulders

facing outward.

CAUTION.

• Reinstall the rollers in their original positions on

the spider.

• Hold the driveshaft assembly with the rollers up

to prevent them from falling off.

SPIDER

ROLLER

High shoulder faces

toward outside

14. Pack the joint with joint grease included in the new

joint hoot set.

Grease

Quantity:

120 - 130 g

(4.2-4.6

oz)

15. Fit the inboard joint onto the driveshaft.

CAUTION: Reinstall the inboard joint in the original

position on the rollers.

INBOARD JOINT

Align the roller holders with the

inboard joint as shown

below.

HOLDER

16. Adjust the length of the driveshafts to the figure

below, then adjust the boots to halfway between

full compression and extension. Bleed the air from

the boot, and check that the engs of the boot seat

are in the grooves of the joint and driveshaft.

Left Driveshaft

M/T: 501.0-506.0 mm (19.72-19.92 in)

A/T: 507.0-512.0 mm (19.96-20.16 in)

195.0

mm

(7.68

in)

Right Driveshaft

M/T and A/T: 542.0 - 547.0 mm (21.34-21.54 in)

195.0

mm

(7.68

in)

MarksProCarManuals.com

Page 884 of 1503

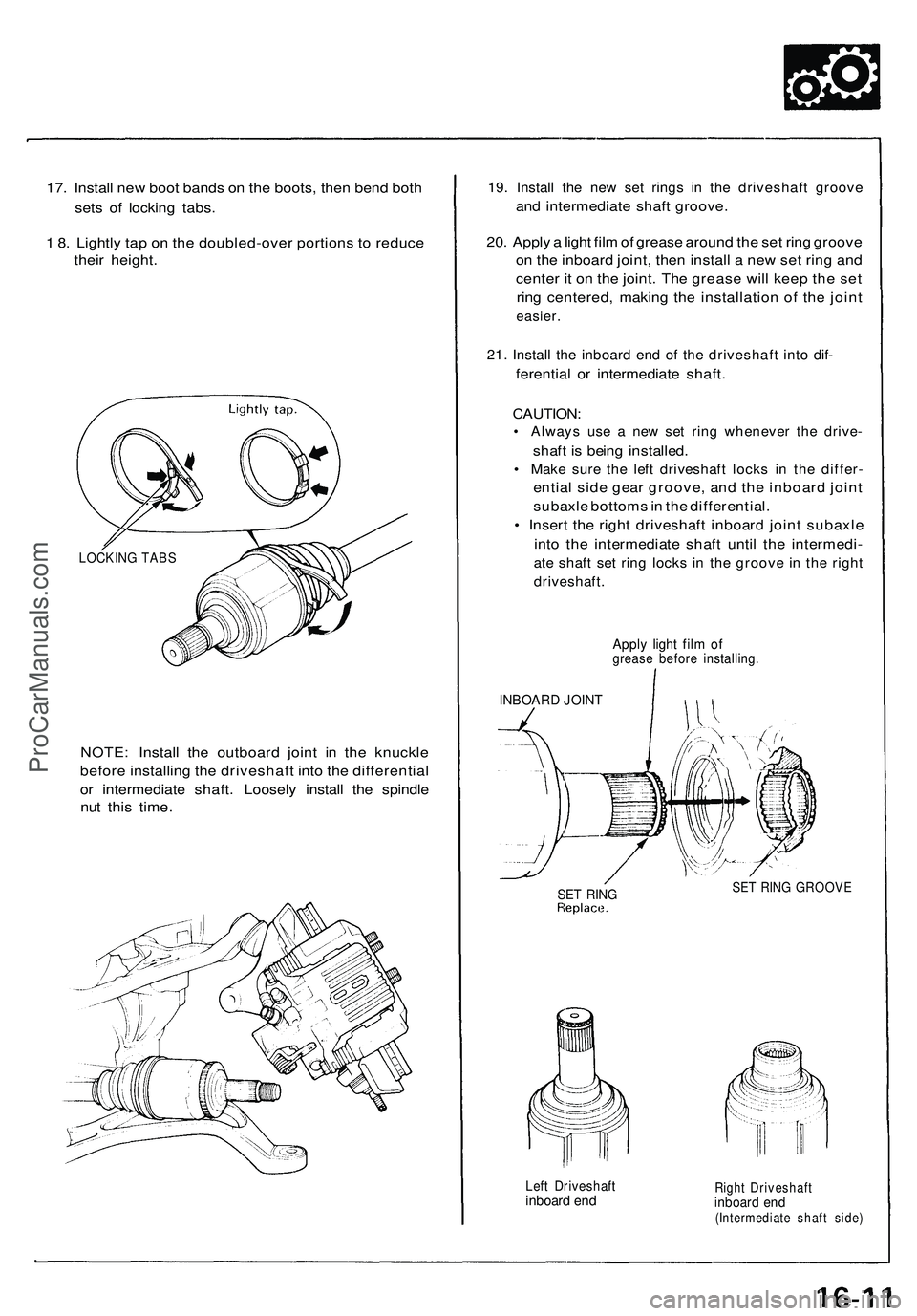

17. Install new boot bands on the boots, then bend both

sets of locking tabs.

1 8. Lightly tap on the doubled-over portions to reduce

their height.

NOTE: Install the outboard joint in the knuckle

before installing the driveshaft into the differential

or intermediate shaft. Loosely install the spindle

nut this time.

19. Install the new set rings in the driveshaft groove

and intermediate shaft groove.

20. Apply a light film of grease around the set ring groove

on the inboard joint, then install a new set ring and

center it on the joint. The grease will keep the set

ring centered, making the installation of the joint

easier.

21. Install the inboard end of the driveshaft into dif-

ferential or intermediate shaft.

CAUTION:

• Always use a new set ring whenever the drive-

shaft is being installed.

• Make sure the left driveshaft locks in the differ-

ential side gear groove, and the inboard joint

subaxle bottoms in the differential.

• Insert the right driveshaft inboard joint subaxle

into the intermediate shaft until the intermedi-

ate shaft set ring locks in the groove in the right

driveshaft.

Apply light film of

grease before installing.

INBOARD JOINT

SET RING

SET RING GROOVE

Left Driveshaft

inboard end

Right Driveshaft

inboard end

(Intermediate shaft side)

LOCKING TABSProCarManuals.com

Page 885 of 1503

Intermediate Shaf t

Replacemen t

1. Drai n th e flui d fro m th e transmissio n

(see section 1 3 M/ T o r sectio n 14 A/T) .

2 . Remov e th e righ t driveshaf t assembl y (se e pag e 16-3 ).

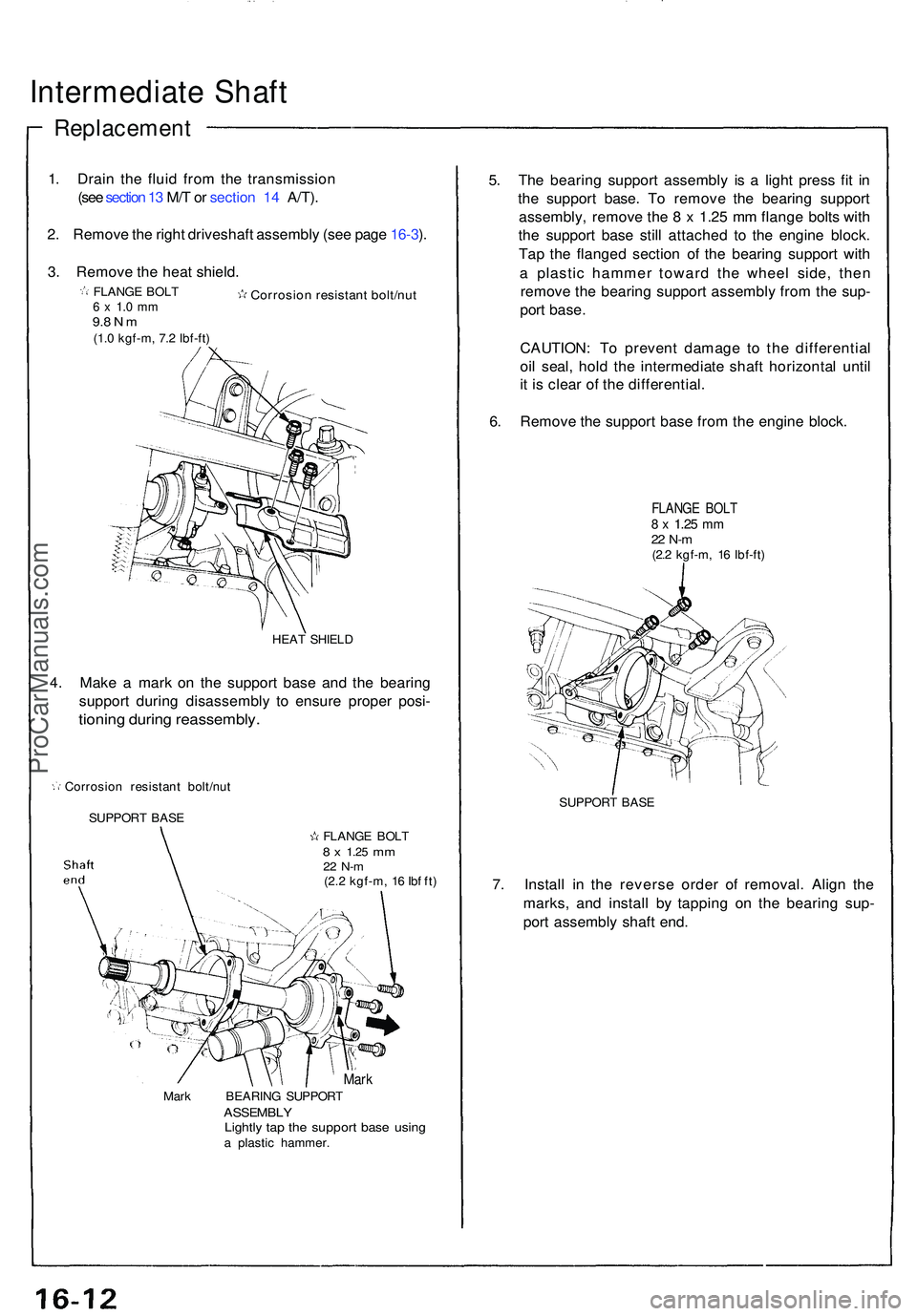

3 . Remov e th e hea t shield .

HEAT SHIEL D

4. Mak e a mar k o n th e suppor t bas e an d th e bearin g

suppor t durin g disassembl y t o ensur e prope r posi -

tionin g durin g reassembly .

Corrosion resistan t bolt/nu t

SUPPOR T BAS E

MarkMark BEARIN G SUPPOR TASSEMBL YLightly ta p th e suppor t bas e usin ga plasti c hammer .

5. Th e bearin g suppor t assembl y i s a ligh t pres s fi t i n

th e suppor t base . T o remov e th e bearin g suppor t

assembly , remov e th e 8 x 1.2 5 m m flang e bolt s wit h

th e suppor t bas e stil l attache d t o th e engin e block .

Ta p th e flange d sectio n o f th e bearin g suppor t wit h

a plasti c hamme r towar d th e whee l side , the n

remov e th e bearin g suppor t assembl y fro m th e sup -

por t base .

CAUTION : T o preven t damag e t o th e differentia l

oi l seal , hol d th e intermediat e shaf t horizonta l unti l

i t i s clea r o f th e differential .

6 . Remov e th e suppor t bas e fro m th e engin e block .

FLANG E BOL T8 x 1.2 5 mm22 N- m(2.2 kgf-m , 1 6 Ibf-ft )

SUPPOR T BAS E

7. Instal l i n th e revers e orde r o f removal . Alig n th e

marks , an d instal l b y tappin g o n th e bearin g sup -

por t assembl y shaf t end .

FLANG E BOL T8 x 1.2 5 mm22 N- m(2.2 kgf-m , 1 6 Ib f ft )

Corrosio n resistan t bolt/nu tFLANGE BOL T6 x 1. 0 m m9.8 N m(1. 0 kgf-m , 7. 2 Ibf-ft )

ProCarManuals.com

Page 886 of 1503

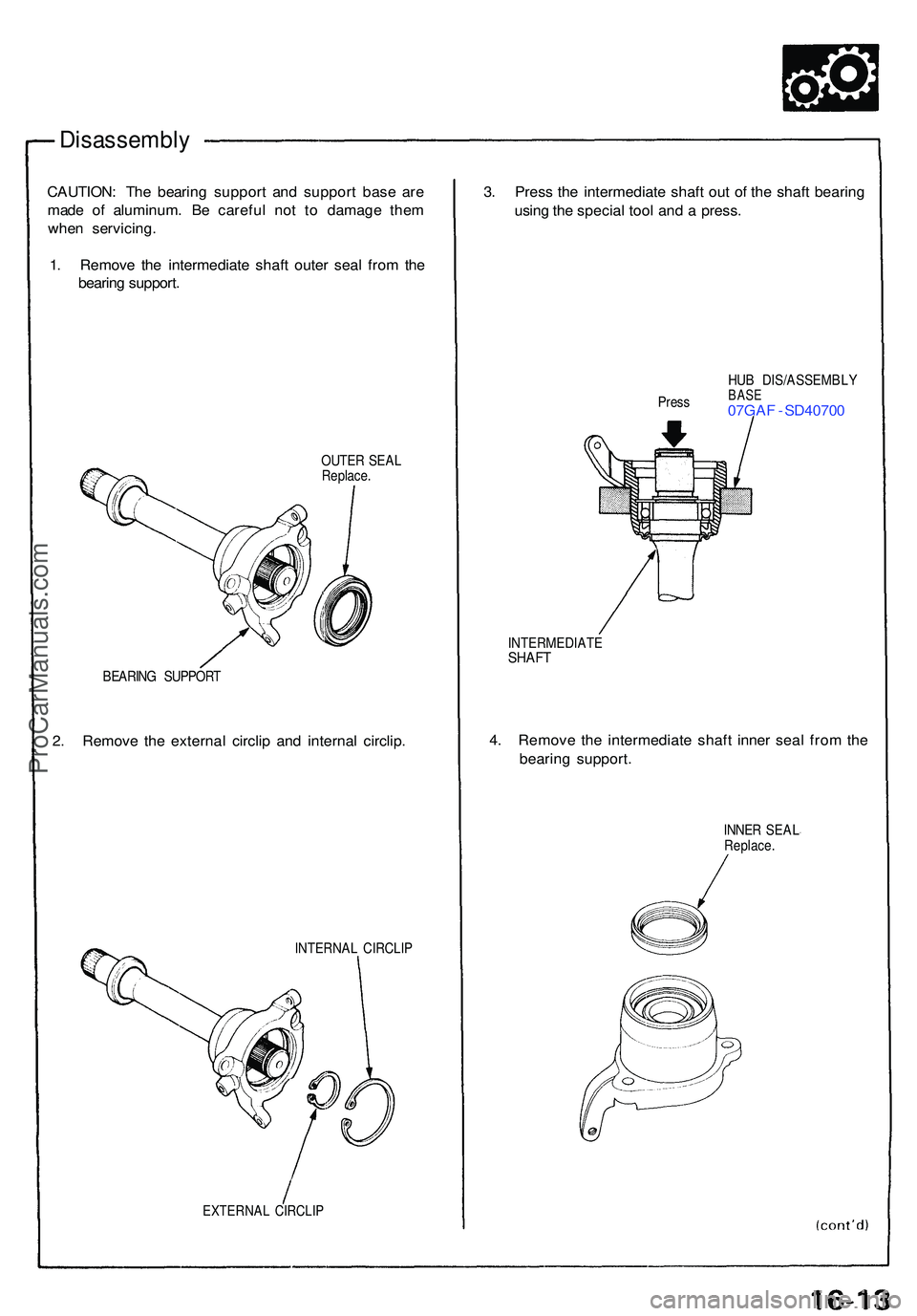

Disassembly

CAUTION: Th e bearin g suppor t an d suppor t bas e ar e

mad e o f aluminum . B e carefu l no t t o damag e the m

whe n servicing .

1 . Remov e th e intermediat e shaf t oute r sea l fro m th e

bearin g support .

OUTER SEA L

Replace .

BEARIN G SUPPOR T

2. Remov e th e externa l circli p an d interna l circlip .

INTERNA L CIRCLI P

EXTERNA L CIRCLI P

3. Pres s th e intermediat e shaf t ou t o f th e shaf t bearin g

usin g th e specia l too l an d a press .

Press

HUB DIS/ASSEMBL YBASE07GA F - SD4070 0

INTERMEDIAT ESHAFT

4. Remov e th e intermediat e shaf t inne r sea l fro m th e

bearin g support .

INNER SEA LReplace .

ProCarManuals.com

Page 887 of 1503

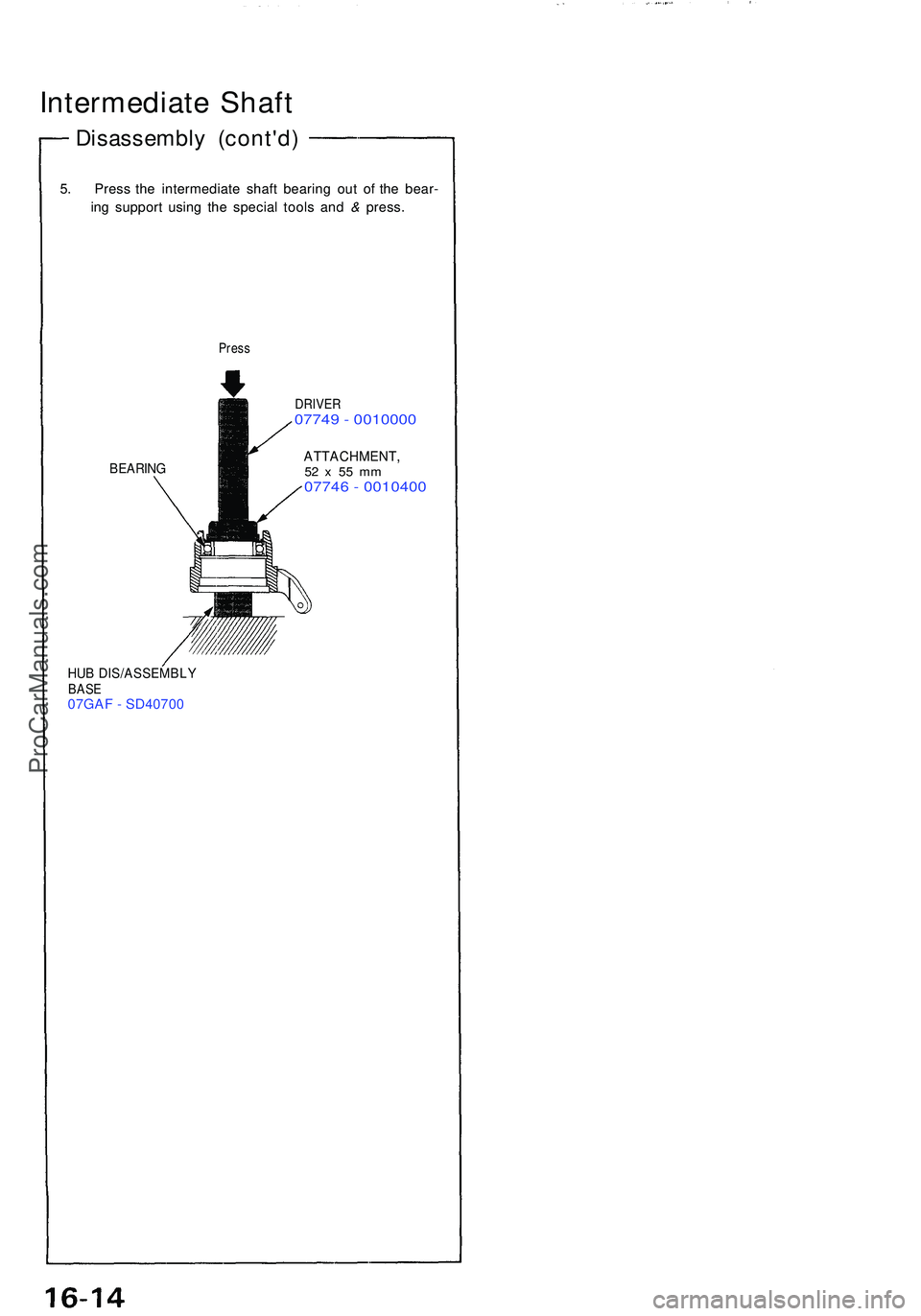

Intermediate Shaf t

Disassembl y (cont'd )

5. Pres s th e intermediat e shaf t bearin g ou t o f th e bear -

in g suppor t usin g th e specia l tool s an d & press .

Press

BEARIN G

DRIVER07749 - 001000 0

ATTACHMENT ,52 x 5 5 m m07746 - 001040 0

HUB DIS/ASSEMBL YBASE07GA F - SD4070 0

ProCarManuals.com

Page 888 of 1503

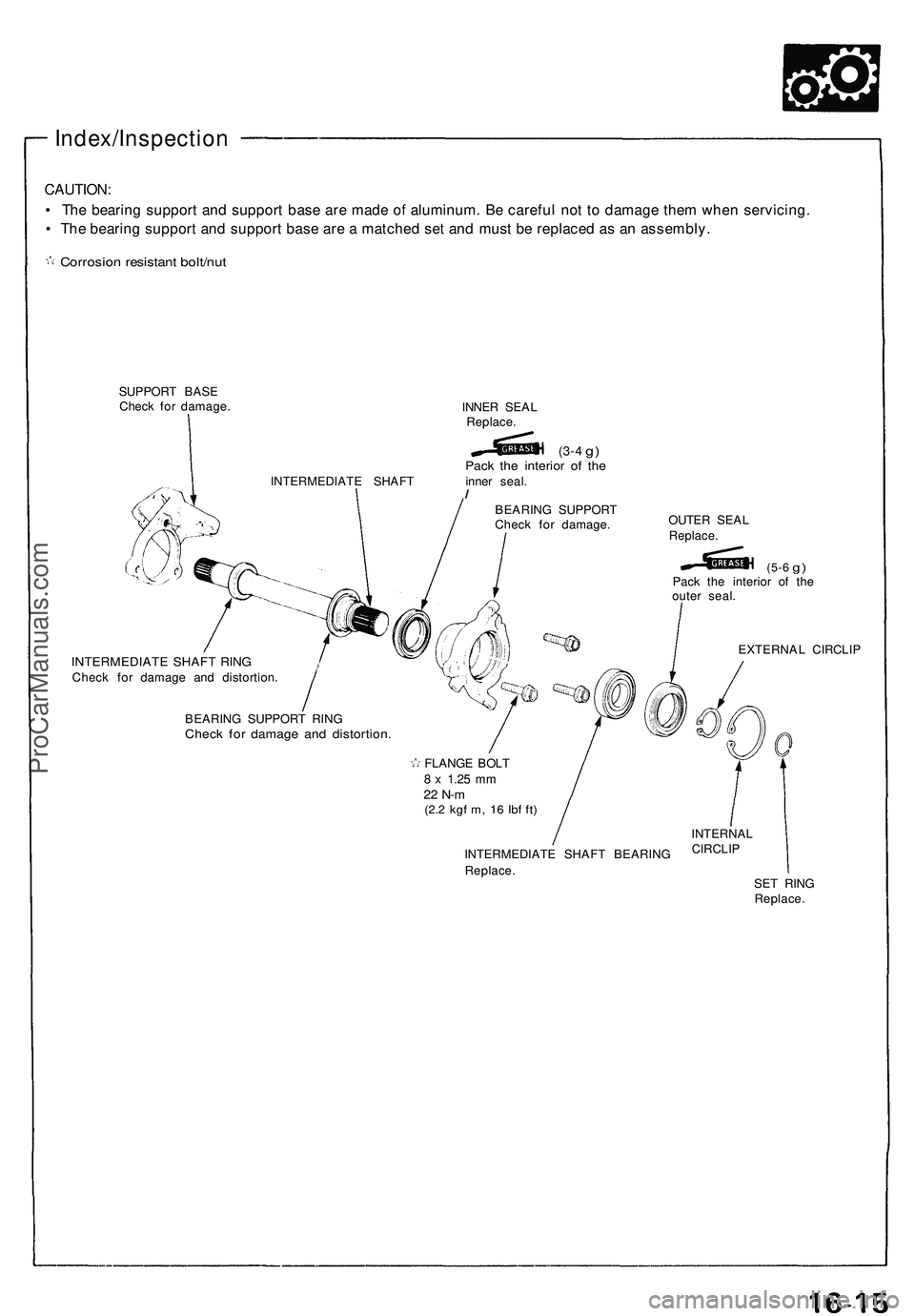

Index/Inspection

CAUTION:

• Th e bearin g suppor t an d suppor t bas e ar e mad e o f aluminum . B e carefu l no t t o damag e the m whe n servicing .

• Th e bearin g suppor t an d suppor t bas e ar e a matche d se t an d mus t b e replace d a s a n assembly .

Corrosion resistan t bolt/nu t

SUPPOR T BAS E

Chec k fo r damage .

INNER SEA L

Replace .

(3-4 g)Pac k th e interio r o f th einne r seal .IBEARIN G SUPPOR T

Chec k fo r damage . OUTE

R SEA L

Replace .

(5-6 g)Pac k th e interio r o f th e

oute r seal .

INTERMEDIAT E SHAF T RIN GChec k fo r damag e an d distortion .

BEARIN G SUPPOR T RIN G

Chec k fo r damag e an d distortion .

EXTERNA L CIRCLI P

SE T RIN G

Replace .

INTERMEDIAT

E SHAF T

FLANG E BOL T

8 x 1.2 5 mm22 N- m(2.2 kg f m , 1 6 Ib f ft )

INTERMEDIAT E SHAF T BEARIN G

Replace . INTERNA

L

CIRCLI P

ProCarManuals.com

Page 889 of 1503

Intermediate Shaf t

Reassembl y

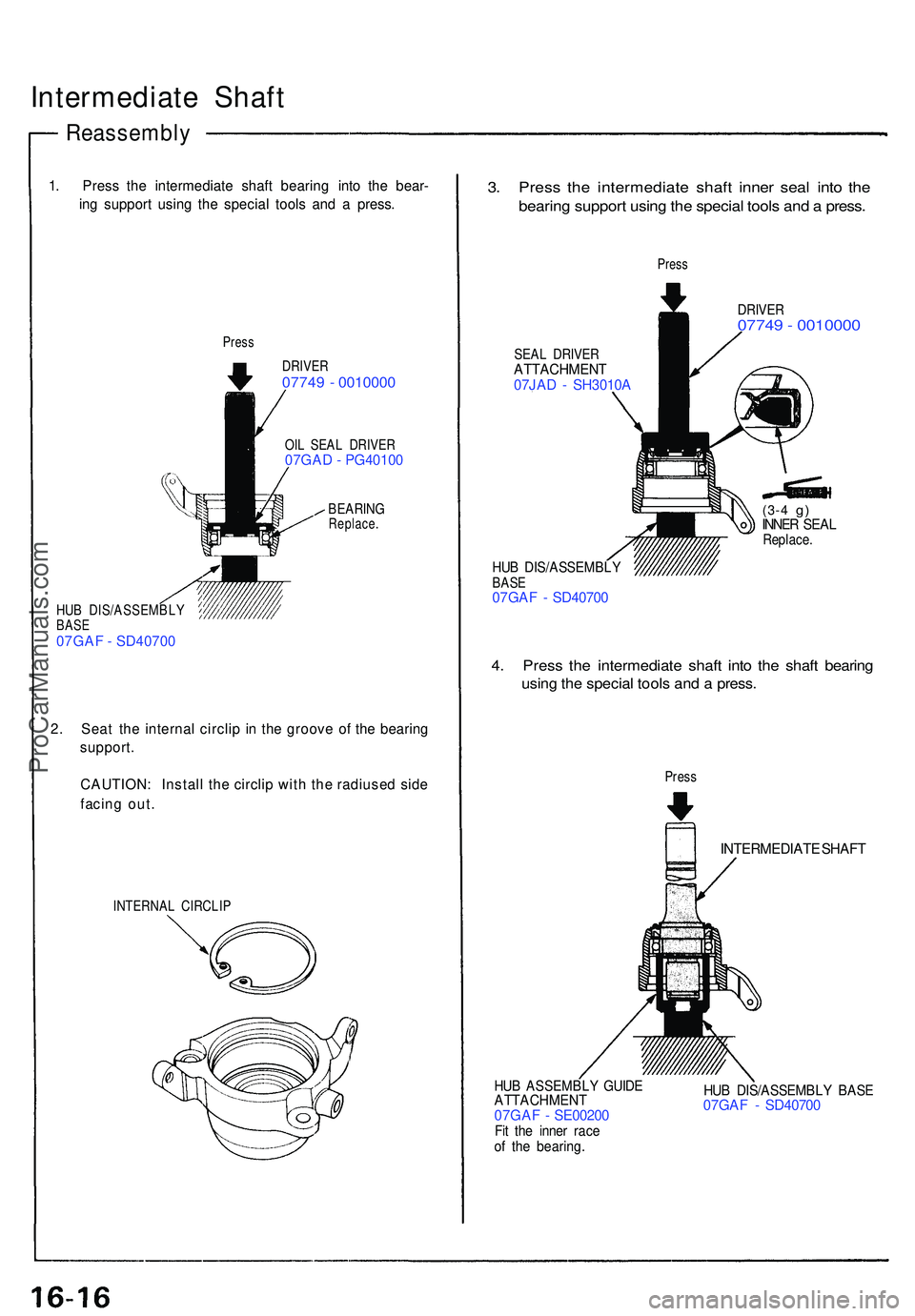

1. Pres s th e intermediat e shaf t bearin g int o th e bear -

in g suppor t usin g th e specia l tool s an d a press .

Press

DRIVE R07749 - 001000 0

OIL SEA L DRIVE R07GAD - PG4010 0

BEARINGReplace .

HUB DIS/ASSEMBL YBASE07GA F - SD4070 0

2 . Sea t th e interna l circli p i n th e groov e o f th e bearin g

support .

CAUTION : Instal l th e circli p wit h the radiuse d sid e

facin g out .

INTERNA L CIRCLI P

3. Pres s th e intermediat e shaf t inne r sea l int o th e

bearin g suppor t usin g th e specia l tool s an d a press .

Press

SEAL DRIVE RATTACHMEN T07JAD - SH3010 A

DRIVER07749 - 001000 0

(3-4 g)INNE R SEA LReplace .

HUB DIS/ASSEMBL YBASE07GAF - SD4070 0

4. Pres s th e intermediat e shaf t int o th e shaf t bearin g

using th e specia l tool s an d a press .

Press

INTERMEDIAT E SHAF T

HUB ASSEMBL Y GUID EATTACHMEN T07GAF - SE0020 0Fit th e inne r rac eof th e bearing .

HUB DIS/ASSEMBL Y BAS E07GA F - SD4070 0

ProCarManuals.com

Page 890 of 1503

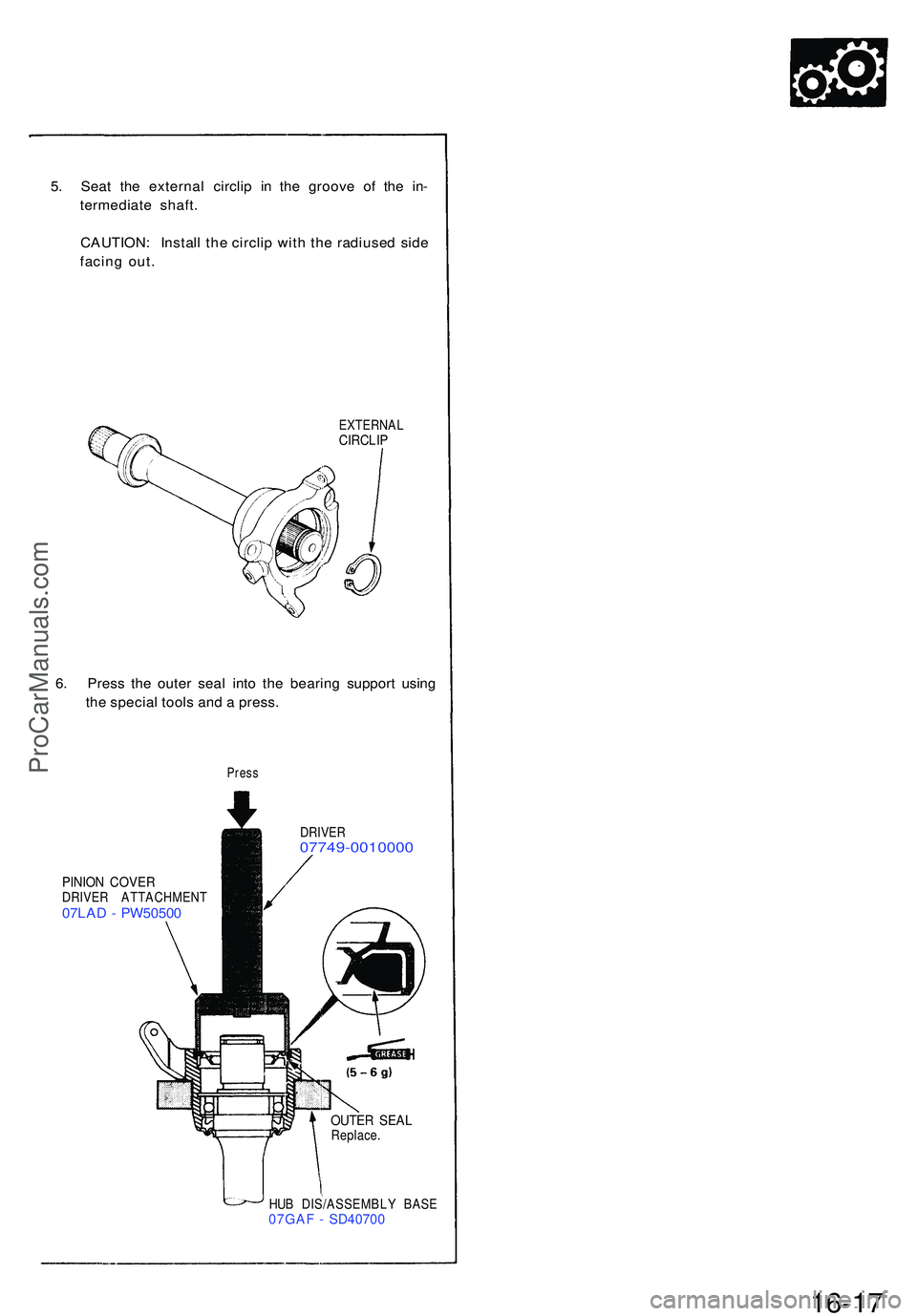

5. Sea t th e externa l circli p i n th e groov e o f th e in -

termediat e shaft .

CAUTION : Instal l th e circli p wit h the radiuse d sid e

facin g out .

EXTERNA LCIRCLIP

6. Pres s th e oute r sea l int o th e bearin g suppor t usin g

th e specia l tool s an d a press .

Press

PINIO N COVE RDRIVER ATTACHMEN T07LAD - PW5050 0

DRIVER07749-001000 0

HUB DIS/ASSEMBL Y BAS E07GA F - SD4070 0

16-17

OUTE R SEA LReplace .

ProCarManuals.com