ACURA RL KA9 1996 Service Repair Manual

Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 491 of 1954

Radiator

Engine Coolan t Refillin g an d Bleedin g

'01 model :

CAUTION : Whe n pourin g engin e coolant , b e sur e t o

shu t th e rela y bo x li d an d no t t o le t coolan t spil l o n th e

electrica l part s o r th e paint . I f an y coolan t spills , rins e it

of f immediately .

NOTE:

Perfor m thi s procedur e whe n th e engin e is cool .

Befor e replacin g th e coolant , tur n th e ignitio n O N (II) ,

slowl y tur n th e climat e contro l temperatur e kno b t o

90° , an d tur n of f th e ignition . Thi s wil l allo w th e

coolan t i n th e heate r t o drai n ou t wit h th e res t o f th e

system .

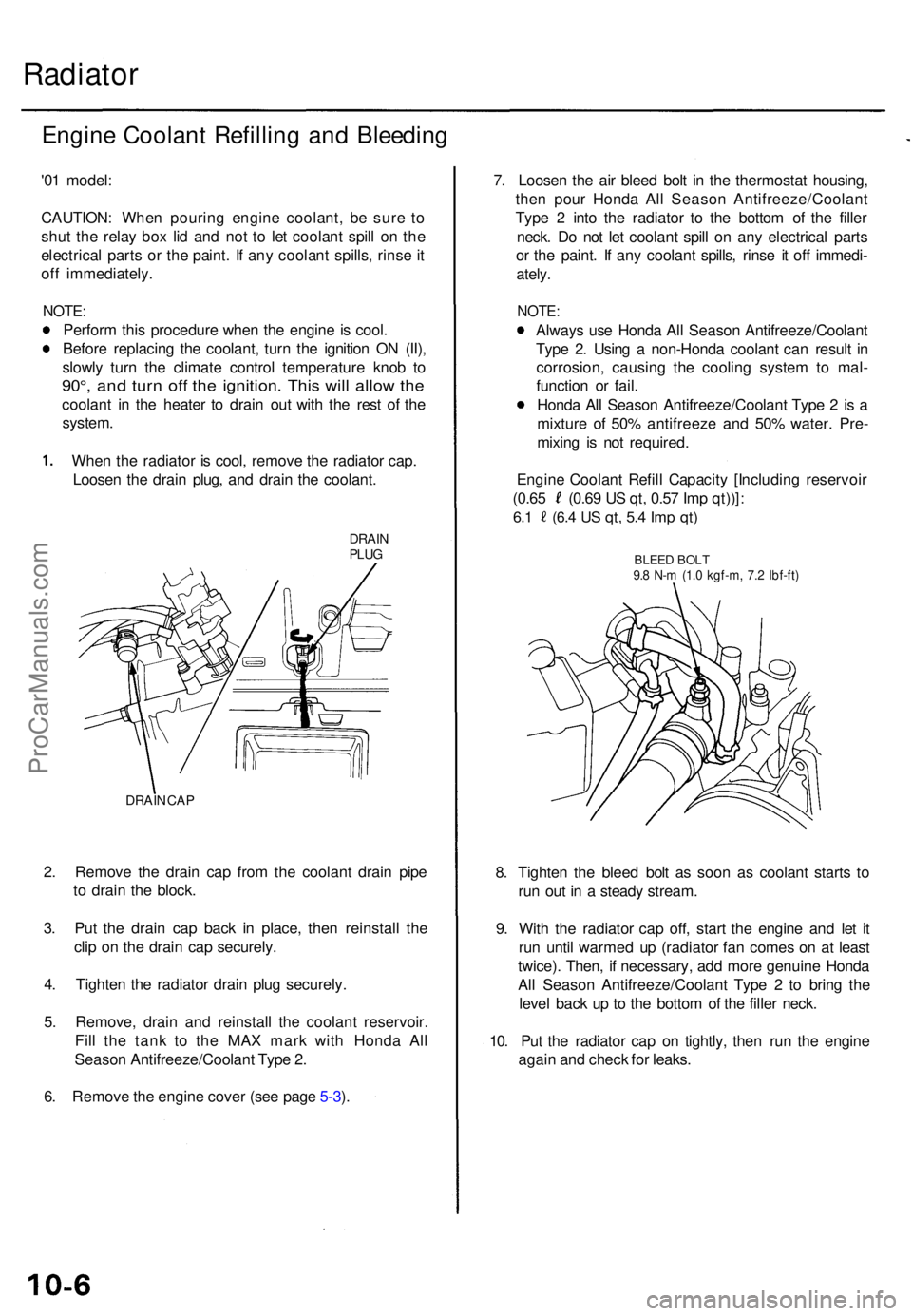

Whe n th e radiato r i s cool , remov e th e radiato r cap .

Loose n th e drai n plug , an d drai n th e coolant .

DRAINPLUG

DRAI N CA P

2. Remov e th e drai n ca p fro m th e coolan t drai n pip e

t o drai n th e block .

3 . Pu t th e drai n ca p bac k i n place , the n reinstal l th e

cli p o n th e drai n ca p securely .

4 . Tighte n th e radiato r drai n plu g securely .

5 . Remove , drai n an d reinstal l th e coolan t reservoir .

Fil l th e tan k t o th e MA X mar k wit h Hond a Al l

Seaso n Antifreeze/Coolan t Typ e 2 .

6 . Remov e th e engine cover (se e pag e 5-3 ). 7

. Loose n th e ai r blee d bol t i n th e thermosta t housing ,

the n pou r Hond a Al l Seaso n Antifreeze/Coolan t

Typ e 2 int o th e radiato r t o th e botto m o f th e fille r

neck . D o no t le t coolan t spil l o n an y electrica l part s

o r th e paint . I f an y coolan t spills , rins e i t of f immedi -

ately .

NOTE :

Alway s us e Hond a Al l Seaso n Antifreeze/Coolan t

Typ e 2 . Usin g a non-Hond a coolan t ca n resul t i n

corrosion , causin g th e coolin g syste m to mal -

functio n o r fail .

Hond a Al l Seaso n Antifreeze/Coolan t Typ e 2 is a

mixtur e o f 50 % antifreez e an d 50 % water . Pre -

mixin g i s no t required .

8 . Tighte n th e blee d bol t a s soo n a s coolan t start s t o

ru n ou t i n a stead y stream .

9 . Wit h th e radiato r cap off, star t th e engin e an d le t i t

ru n unti l warme d u p (radiato r fa n come s o n a t leas t

twice) . Then , i f necessary , ad d mor e genuin e Hond a

Al l Seaso n Antifreeze/Coolan t Typ e 2 to brin g th e

leve l bac k u p t o th e botto m o f th e fille r neck .

10 . Pu t th e radiato r ca p o n tightly , the n ru n th e engin e

agai n an d chec k fo r leaks .

Engin

e Coolan t Refil l Capacit y [Includin g reservoi r

(0.65 (0.6 9 U S qt , 0.5 7 Im p qt))] :

6.1 (6. 4 US qt , 5. 4 Im p qt )

BLEE D BOL T9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

ProCarManuals.com

Page 492 of 1954

Cap Testing

Testing

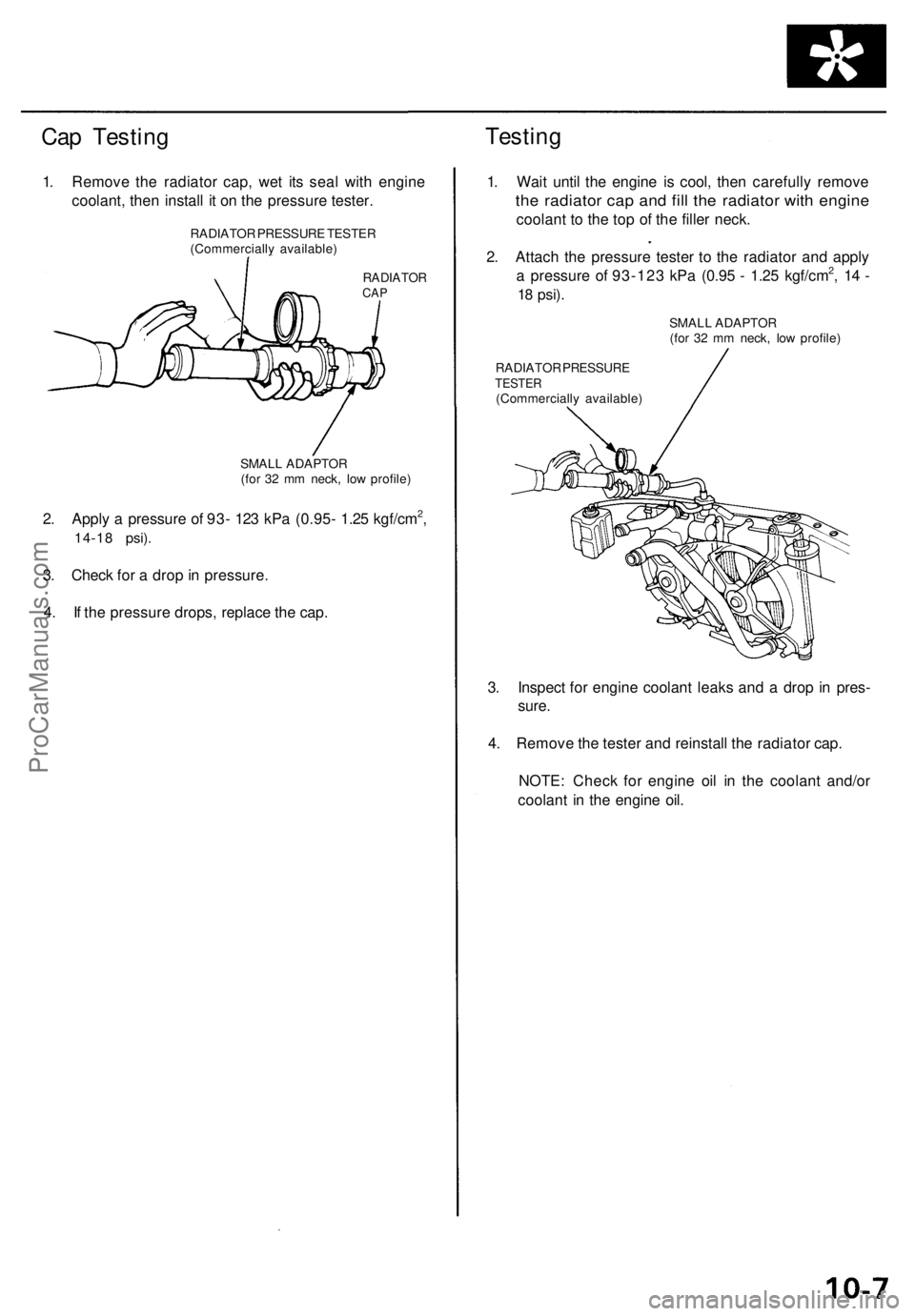

1. Remove the radiator cap, wet its seal with engine

coolant, then install it on the pressure tester.

RADIATOR

CAP

2. Apply a pressure of 93- 123 kPa (0.95- 1.25 kgf/cm2,

14-18 psi).

3. Check for a drop in pressure.

4. If the pressure drops, replace the cap.

1. Wait until the engine is cool, then carefully remove

the radiator cap and fill the radiator with engine

coolant to the top of the filler neck.

2. Attach the pressure tester to the radiator and apply

a pressure of 93-123 kPa (0.95 - 1.25 kgf/cm2, 14 -

18

psi).

RADIATOR PRESSURE

TESTER

(Commercially available)

3. Inspect for engine coolant leaks and a drop in pres-

sure.

4. Remove the tester and reinstall the radiator cap.

NOTE: Check for engine oil in the coolant and/or

coolant in the engine oil.

RADIATOR PRESSURE TESTER

(Commercially available)

SMALL ADAPTOR

(for 32 mm neck, low profile)

SMALL ADAPTOR

(for 32 mm neck, low profile)ProCarManuals.com

Page 493 of 1954

Thermostat

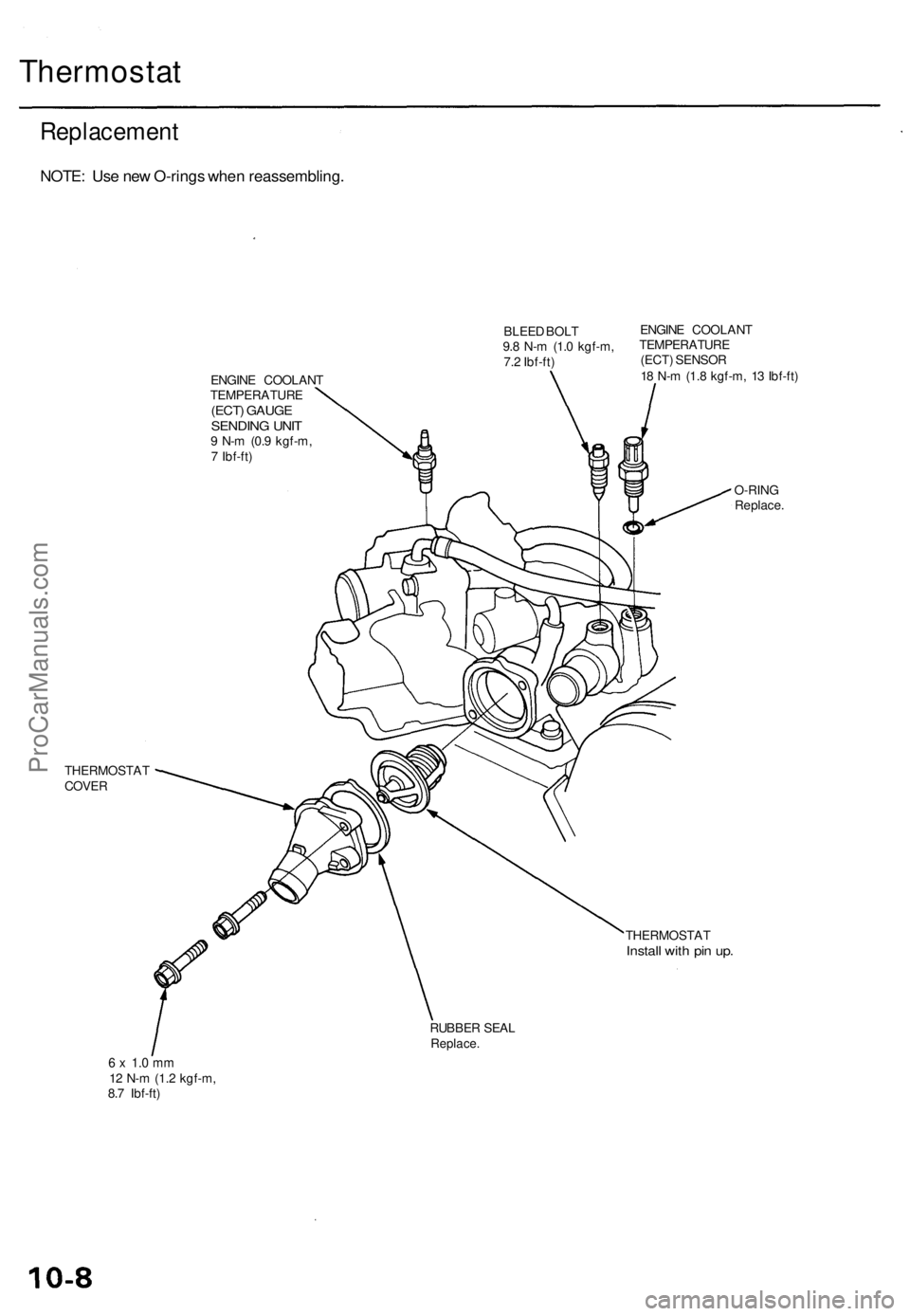

Replacement

NOTE: Use new O-rings when reassembling.

BLEED BOLT

9.8 N-m (1.0 kgf-m,

7.2 Ibf-ft)

ENGINE COOLANT

TEMPERATURE

(ECT) GAUGE

SENDING UNIT

9 N-m (0.9 kgf-m,

7 Ibf-ft)

ENGINE COOLANT

TEMPERATURE

(ECT) SENSOR

18 N-m (1.8 kgf-m, 13 Ibf-ft)

THERMOSTAT

COVER

O-RING

Replace.

THERMOSTAT

Install with pin up.

RUBBER SEAL

Replace.

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)ProCarManuals.com

Page 494 of 1954

Testing

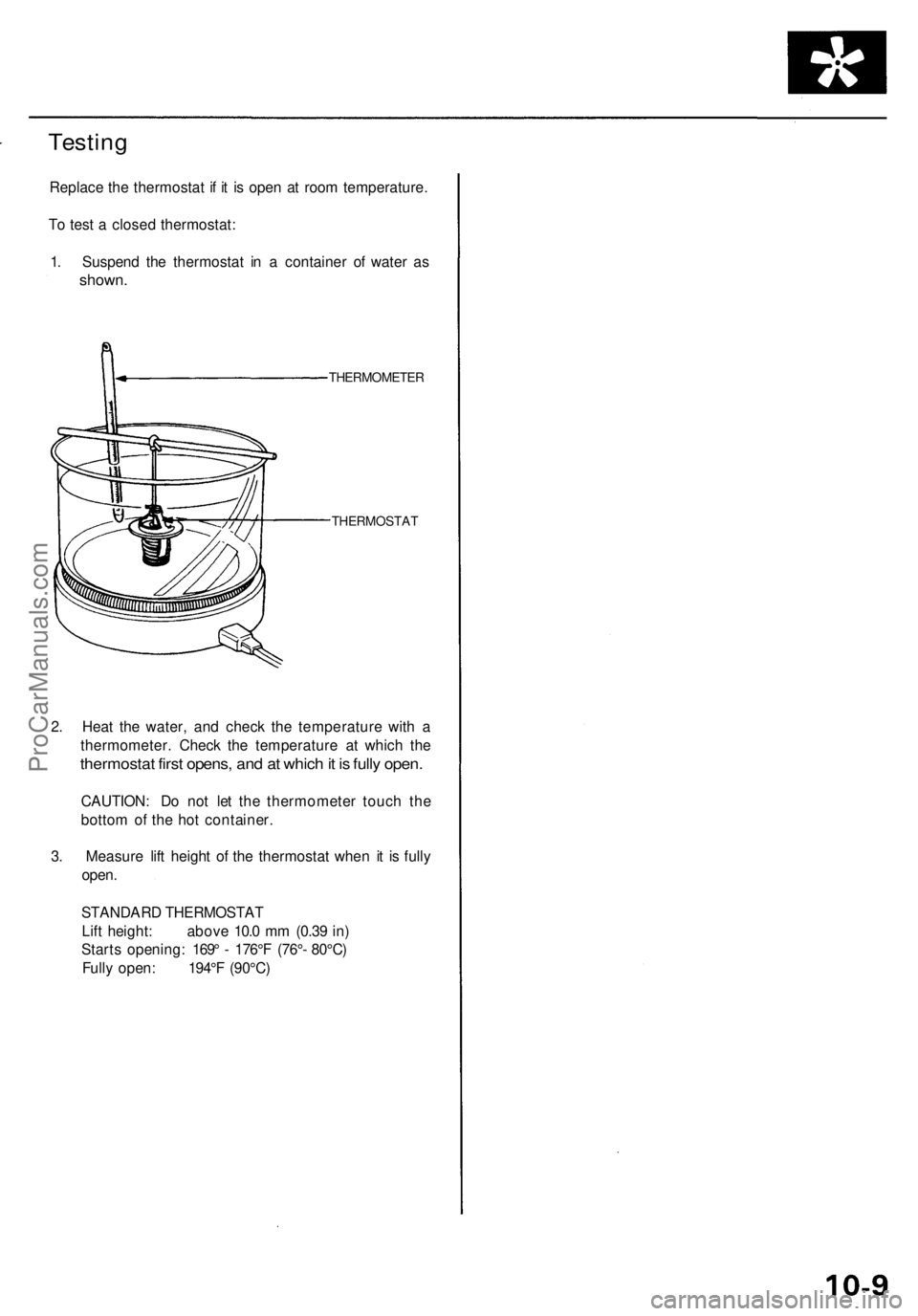

Replac e th e thermosta t i f i t i s ope n a t roo m temperature .

T o tes t a close d thermostat :

1 . Suspen d th e thermosta t i n a containe r o f wate r a s

shown .

THERMOMETE R

THERMOSTA T

2. Hea t th e water , an d chec k th e temperatur e wit h a

thermometer . Chec k th e temperatur e a t whic h th e

thermosta t firs t opens , an d a t whic h it i s full y open .

CAUTION : D o no t le t th e thermomete r touc h th e

botto m o f th e ho t container .

3 . Measur e lif t heigh t o f th e thermosta t whe n i t i s full y

open .

STANDAR D THERMOSTA T

Lif t height : abov e 10. 0 m m (0.3 9 in )

Start s opening : 169 ° - 176° F (76° - 80°C )

Full y open : 194° F (90°C )

ProCarManuals.com

Page 495 of 1954

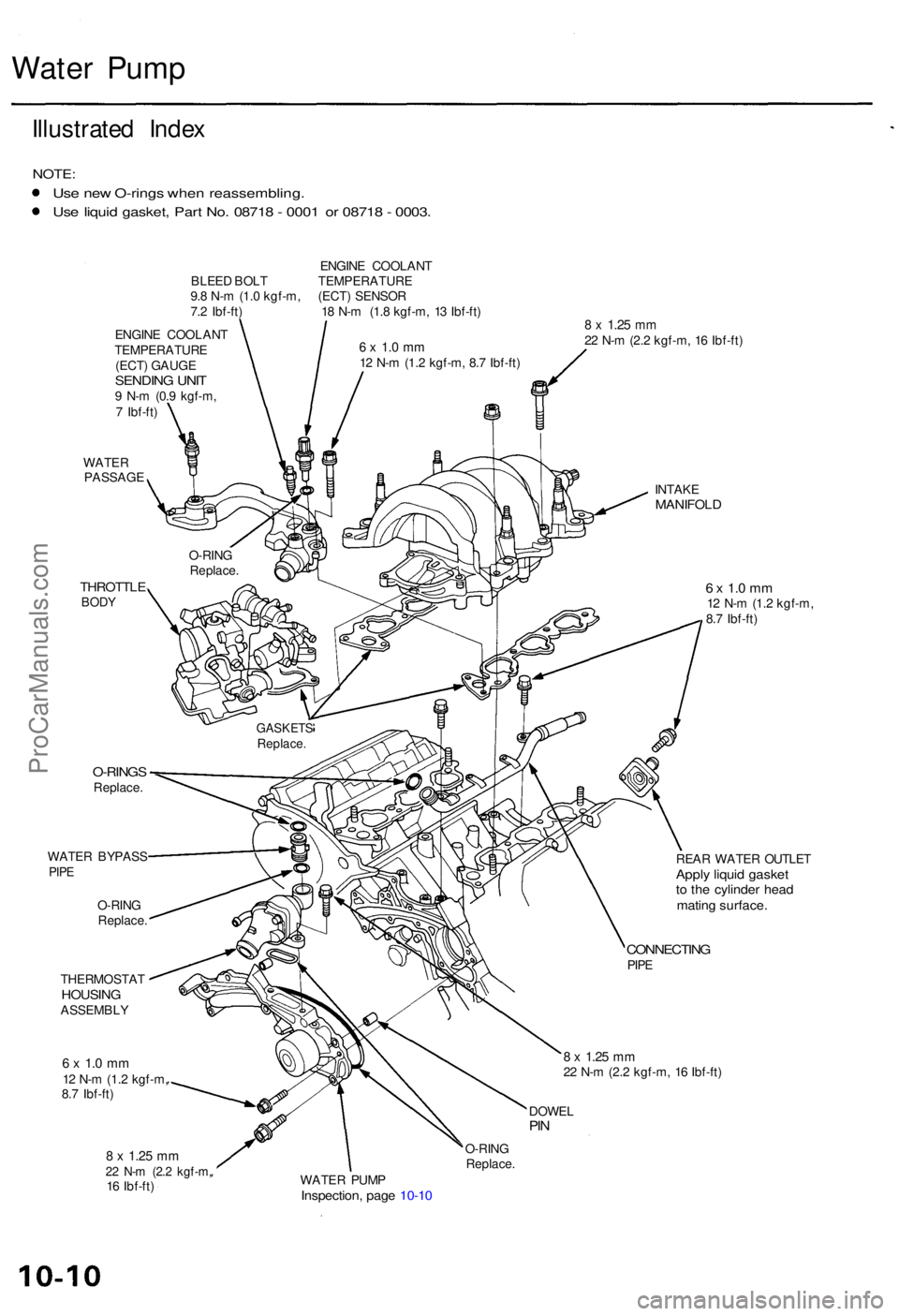

Water Pum p

Illustrate d Inde x

NOTE :

Use ne w O-ring s whe n reassembling .

Use liqui d gasket , Par t No . 0871 8 - 000 1 o r 0871 8 - 0003 .

ENGIN E COOLAN T

BLEE D BOL T TEMPERATUR E

9. 8 N- m (1. 0 kgf-m , (ECT ) SENSO R

7. 2 Ibf-ft ) 1 8 N- m (1. 8 kgf-m , 1 3 Ibf-ft )

ENGIN E COOLAN T

TEMPERATUR E

(ECT ) GAUG E

SENDIN G UNI T9 N- m (0. 9 kgf-m ,

7 Ibf-ft )

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

8 x 1.2 5 mm22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

WATE RPASSAG E

INTAKE

MANIFOL D

THROTTL EBODY

O-RING SReplace .

WATE R BYPAS S

PIPE

O-RIN G

Replace .

THERMOSTA T

HOUSINGASSEMBL Y

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

REA R WATE R OUTLE T

Apply liqui d gaske tto th e cylinde r hea dmatin g surface .

CONNECTIN GPIPE

8 x 1.2 5 mm22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

DOWE L

PIN

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,16 Ibf-ft ) O-RIN

G

Replace .WATER PUM PInspection , pag e 10-1 0

GASKET SReplace.

O-RING

Replace .

ProCarManuals.com

Page 496 of 1954

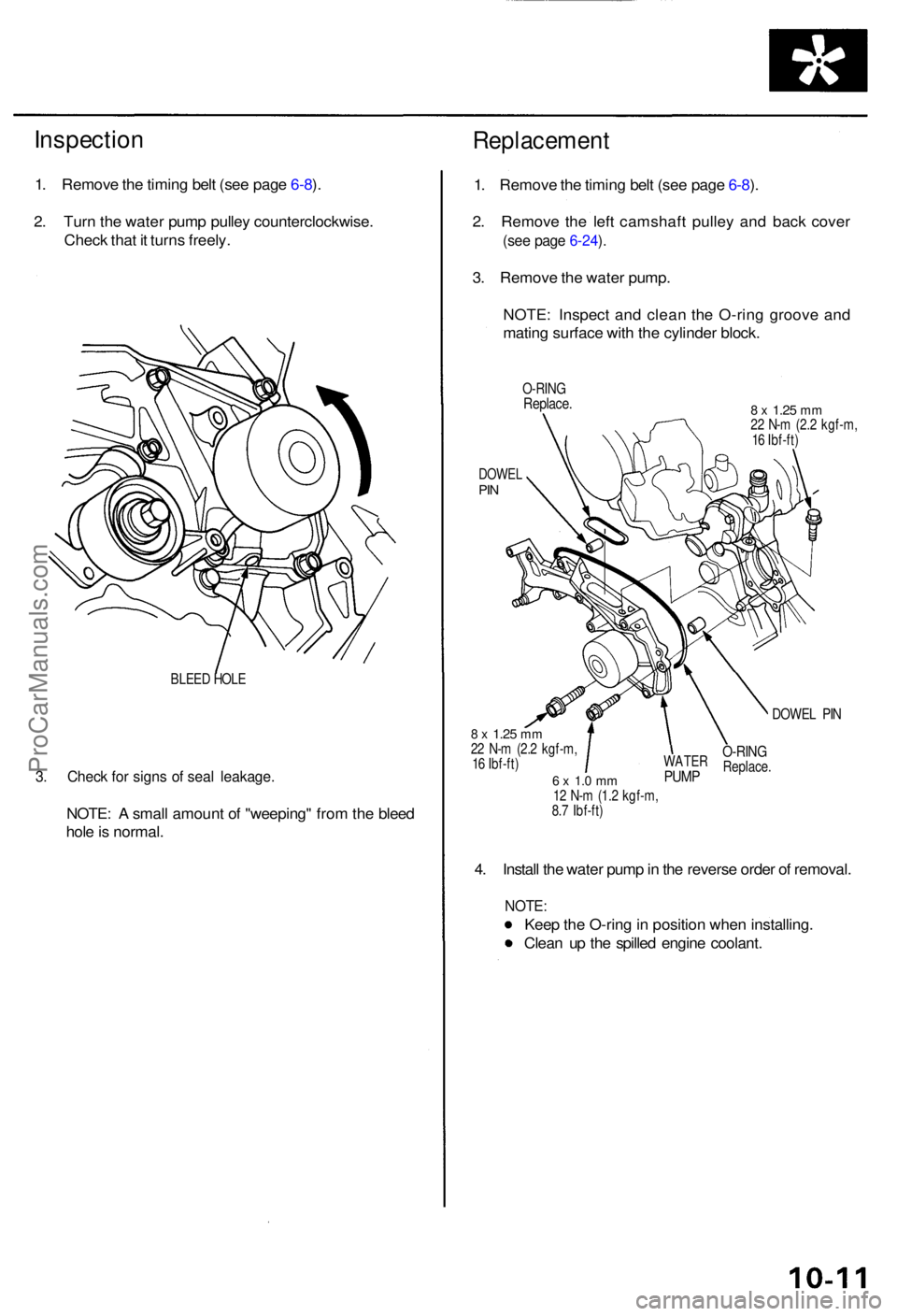

Inspection

1. Remov e th e timin g bel t (se e pag e 6-8 ).

2 . Tur n th e wate r pum p pulle y counterclockwise .

Chec k tha t i t turn s freely .

BLEED HOL E

3. Chec k fo r sign s o f sea l leakage .

NOTE: A smal l amoun t o f "weeping " fro m th e blee d

hol e is normal .

Replacemen t

1. Remov e th e timin g bel t (se e pag e 6-8 ).

2 . Remov e th e lef t camshaf t pulle y an d bac k cove r

(see pag e 6-24 ).

3 . Remov e th e wate r pump .

NOTE : Inspec t an d clea n th e O-rin g groov e an d

matin g surfac e wit h th e cylinde r block .

O-RIN GReplace .8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

DOWE LPIN

DOWE L PI N

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

4. Instal l th e wate r pum p in th e revers e orde r o f removal .

NOTE:

Keep th e O-rin g in positio n whe n installing .

Clea n u p th e spille d engin e coolant .

WATERPUMP

O-RIN GReplace .

ProCarManuals.com

Page 497 of 1954

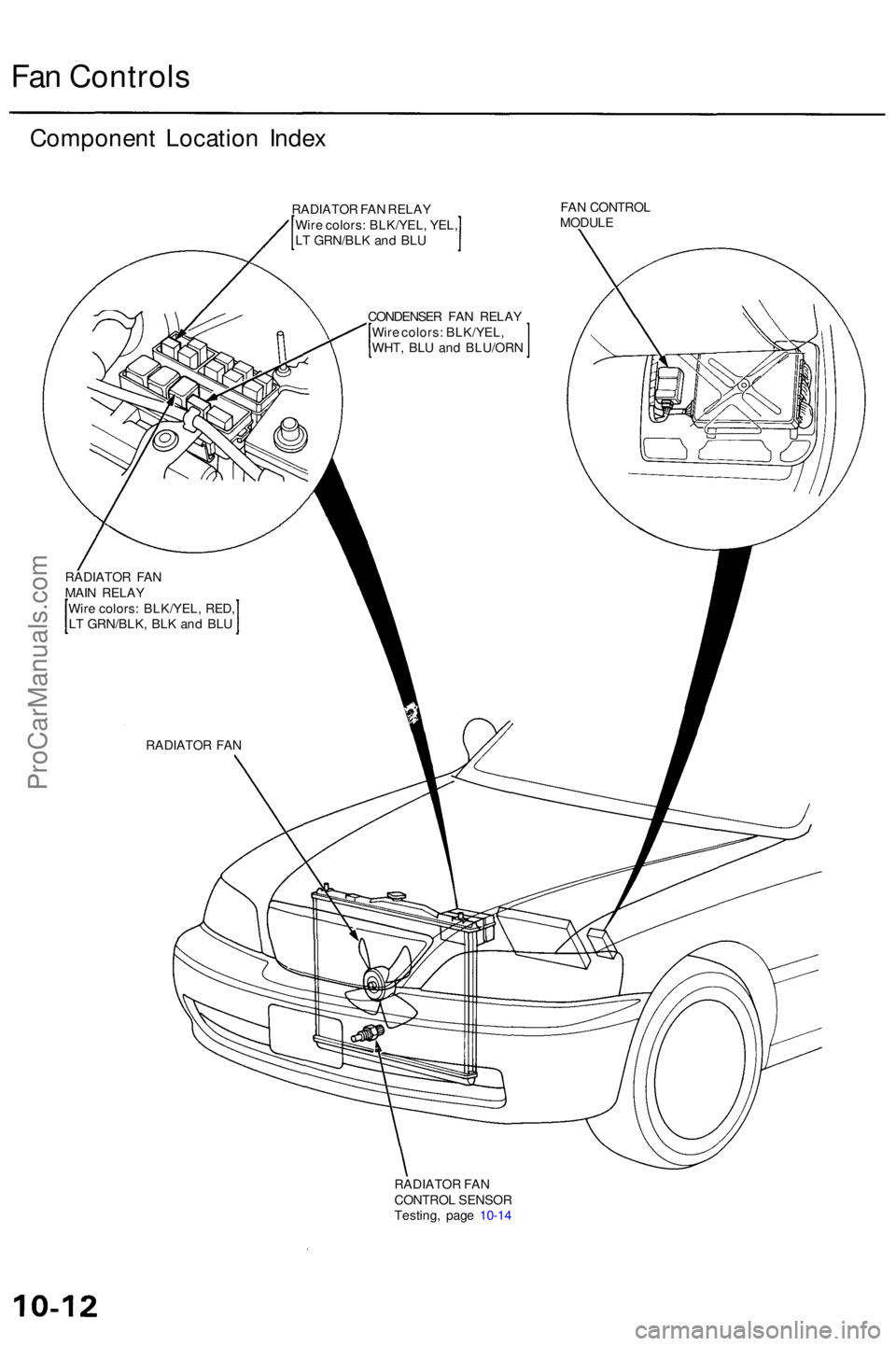

Fan Control s

Componen t Locatio n Inde x

RADIATO R FA N RELA Y

Wir e colors : BLK/YEL , YEL ,

L T GRN/BL K an d BL U FA

N CONTRO L

MODUL E

CONDENSE R FA N RELA Y

Wir e colors : BLK/YEL ,

WHT , BL U an d BLU/OR N

RADIATO R FA N

MAI N RELA Y

Wir e colors : BLK/YEL , RED ,

L T GRN/BLK , BL K an d BL U

RADIATO R FA N

RADIATOR FA N

CONTRO L SENSO R

Testing , pag e 10-1 4

ProCarManuals.com

Page 498 of 1954

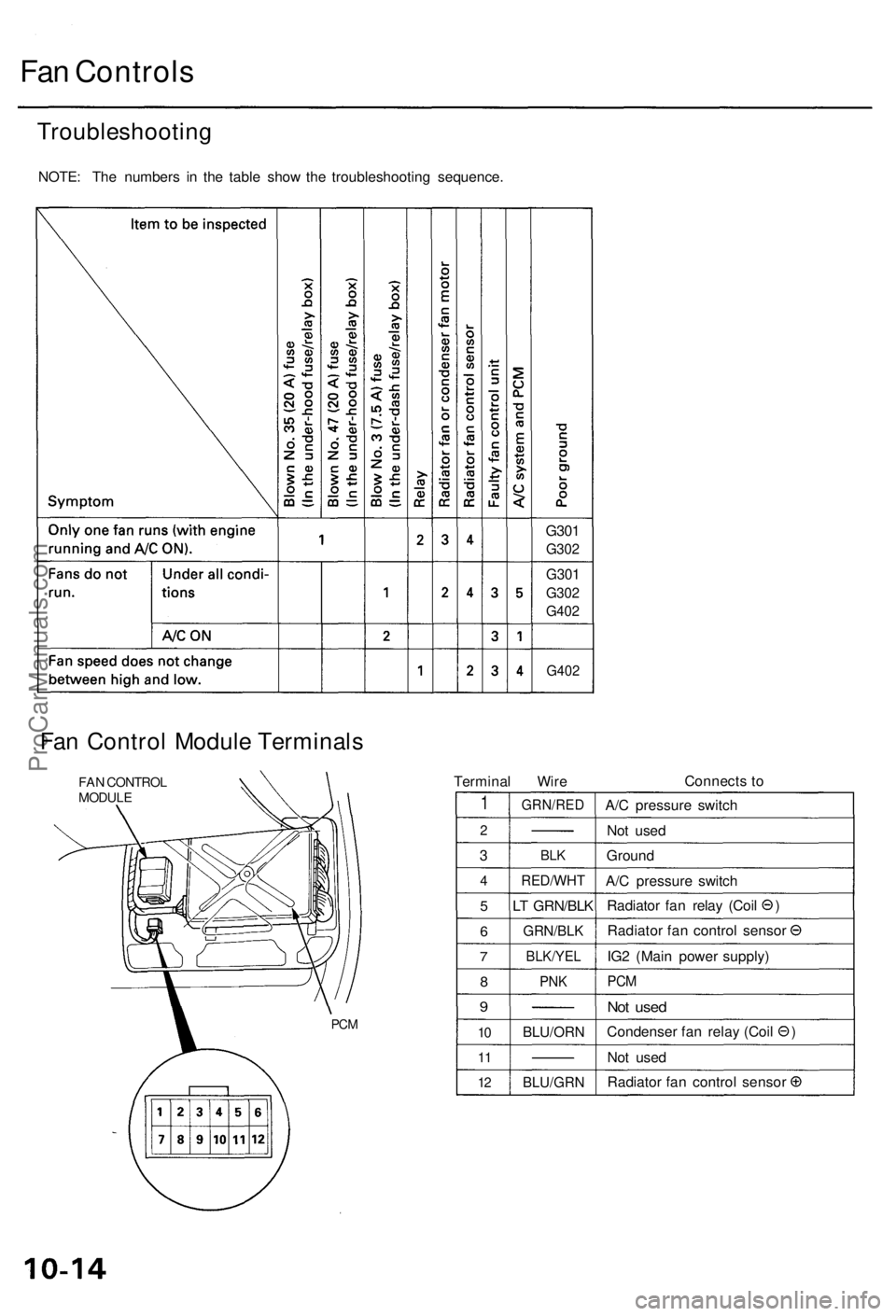

Fan Controls

Troubleshooting

NOTE: The numbers in the table show the troubleshooting sequence.

G301

G302

G301

G302

G402

G402

Fan Control Module Terminals

FAN CONTROL

MODULE

Terminal Wire

Connects to

1

2

3

4

5

6

7

8

9

10

11

12

GRN/RED

BLK

RED/WHT

LT GRN/BLK

GRN/BLK

BLK/YEL

PNK

BLU/ORN

BLU/GRN

A/C pressure switch

Not used

Ground

A/C pressure switch

Radiator fan relay (Coil )

Radiator fan control sensor

IG2 (Main power supply)

PCM

Not used

Condenser fan relay (Coil )

Not used

Radiator fan control sensor

PCMProCarManuals.com

Page 499 of 1954

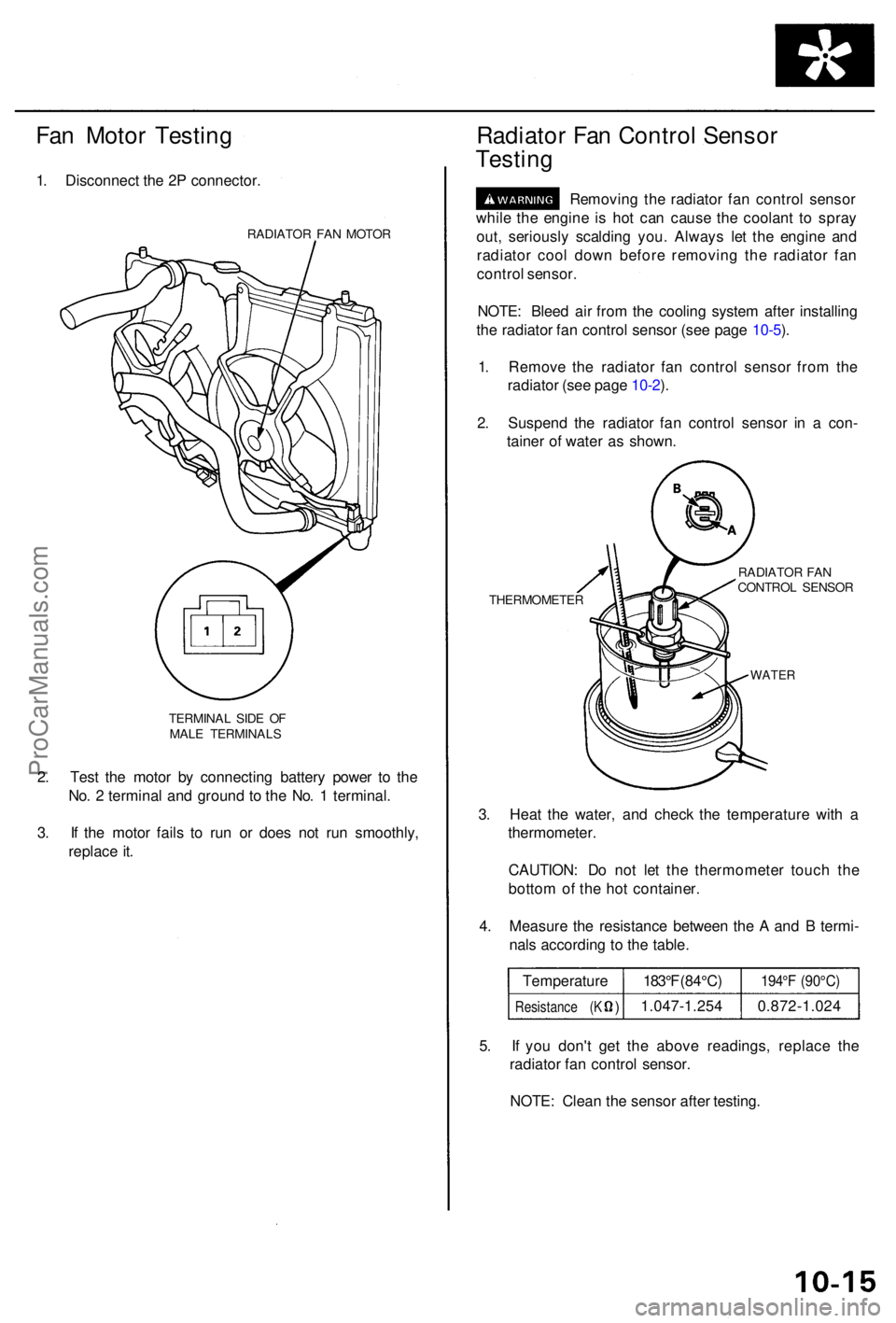

Fan Moto r Testin g

1. Disconnec t th e 2 P connector .

RADIATOR FA N MOTO R

TERMINA L SID E O F

MAL E TERMINAL S

2. Tes t th e moto r b y connectin g batter y powe r t o th e

No . 2 termina l an d groun d t o th e No . 1 terminal .

3 . I f th e moto r fail s t o ru n o r doe s no t ru n smoothly ,

replac e it .

Radiato r Fa n Contro l Senso r

Testin g

Removin g th e radiato r fa n contro l senso r

whil e th e engin e i s ho t ca n caus e th e coolan t t o spra y

out , seriousl y scaldin g you . Alway s le t th e engin e an d

radiato r coo l dow n befor e removin g th e radiato r fa n

contro l sensor .

NOTE : Blee d ai r fro m th e coolin g syste m afte r installin g

th e radiato r fa n contro l senso r (se e pag e 10-5 ).

1 . Remov e th e radiato r fa n contro l senso r fro m th e

radiato r (se e pag e 10-2 ).

2 . Suspen d th e radiato r fa n contro l senso r i n a con -

taine r o f wate r a s shown .

THERMOMETE R RADIATO

R FA N

CONTRO L SENSO R

WATER

3. Hea t th e water , an d chec k th e temperatur e wit h a

thermometer .

CAUTION : D o no t le t th e thermomete r touc h th e

botto m o f th e ho t container .

4 . Measur e th e resistanc e betwee n th e A an d B termi -

nal s accordin g t o th e table .

Temperatur e

Resistance ( K ) 183°

F (84°C )

1.047-1.25 4

194°F (90°C )

0.872-1.02 4

5 . I f yo u don' t ge t th e abov e readings , replac e th e

radiato r fa n contro l sensor .

NOTE : Clea n th e senso r afte r testing .

ProCarManuals.com

Page 500 of 1954

Engine Coolan t Temperatur e (ECT ) Gaug e

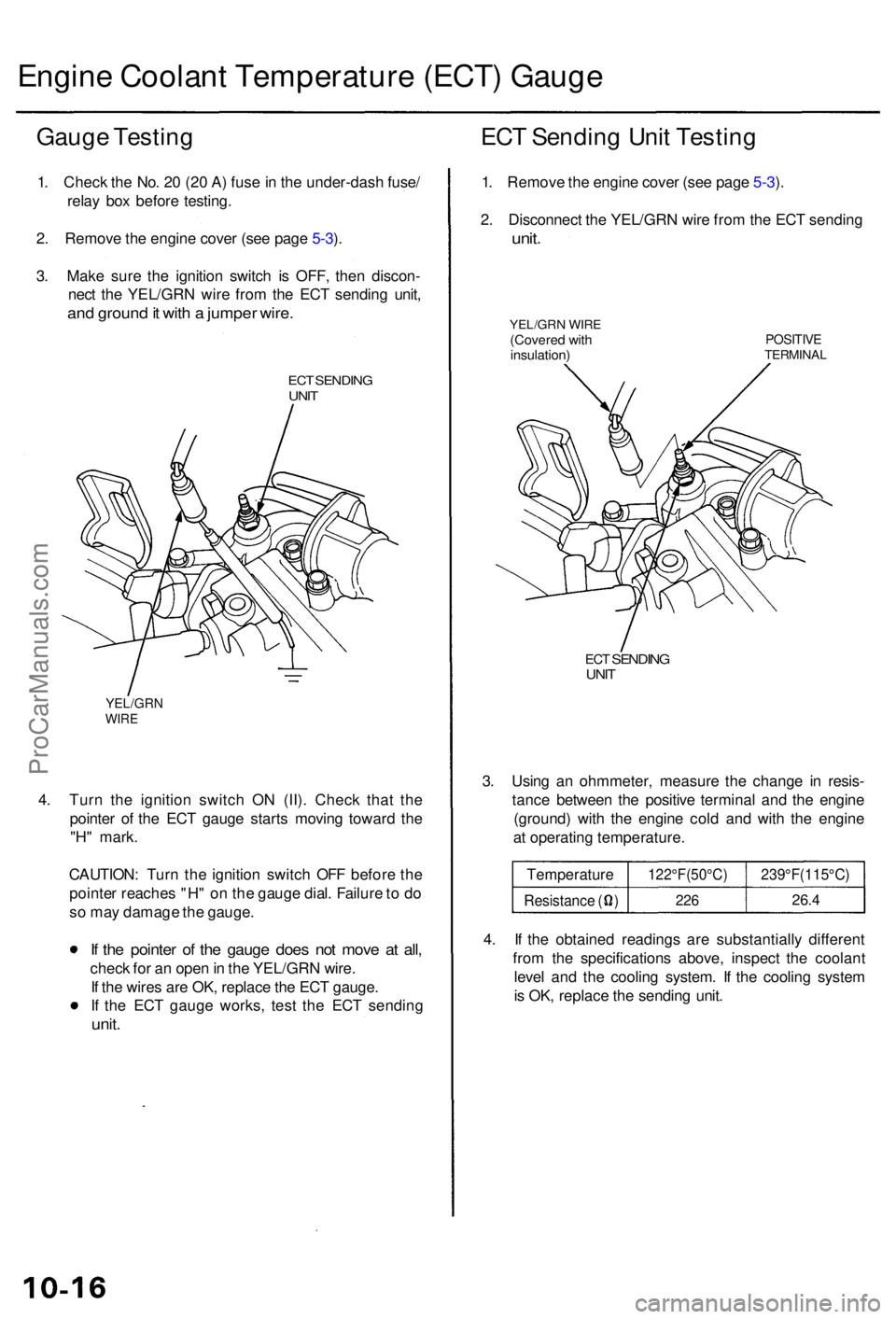

Gauge Testin g

1. Chec k th e No . 2 0 (2 0 A ) fus e in th e under-das h fuse /

rela y bo x befor e testing .

2 . Remov e th e engin e cove r (se e pag e 5-3 ).

3 . Mak e sur e th e ignitio n switc h i s OFF , the n discon -

nec t th e YEL/GR N wir e fro m th e EC T sendin g unit ,

and groun d it wit h a jumpe r wire .

ECT SENDIN GUNIT

YEL/GR NWIRE

4. Tur n th e ignitio n switc h O N (II) . Chec k tha t th e

pointe r o f th e EC T gaug e start s movin g towar d th e

"H " mark .

CAUTION : Tur n th e ignitio n switc h OF F befor e th e

pointe r reache s "H " o n th e gaug e dial . Failur e to d o

s o ma y damag e th e gauge .

If th e pointe r o f th e gaug e doe s no t mov e a t all ,

chec k fo r a n ope n in th e YEL/GR N wire .

I f th e wire s ar e OK , replac e th e EC T gauge .

I f th e EC T gaug e works , tes t th e EC T sendin g

unit.

ECT Sendin g Uni t Testin g

1. Remov e th e engin e cove r (se e pag e 5-3 ).

2 . Disconnec t th e YEL/GR N wir e fro m th e EC T sendin g

unit.

YEL/GR N WIR E(Covere d wit hinsulation )POSITIVETERMINA L

ECT SENDIN GUNIT

3. Usin g a n ohmmeter , measur e th e chang e i n resis -

tanc e betwee n th e positiv e termina l an d th e engin e

(ground ) wit h th e engin e col d an d wit h th e engin e

a t operatin g temperature .

Temperature

Resistance ( )

122°F(50°C )

226

239°F(115°C )

26.4

4. I f th e obtaine d reading s ar e substantiall y differen t

fro m th e specification s above , inspec t th e coolan t

leve l an d th e coolin g system . I f th e coolin g syste m

i s OK , replac e th e sendin g unit .

ProCarManuals.com