ACURA RL KA9 1996 Service Repair Manual

Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 471 of 1954

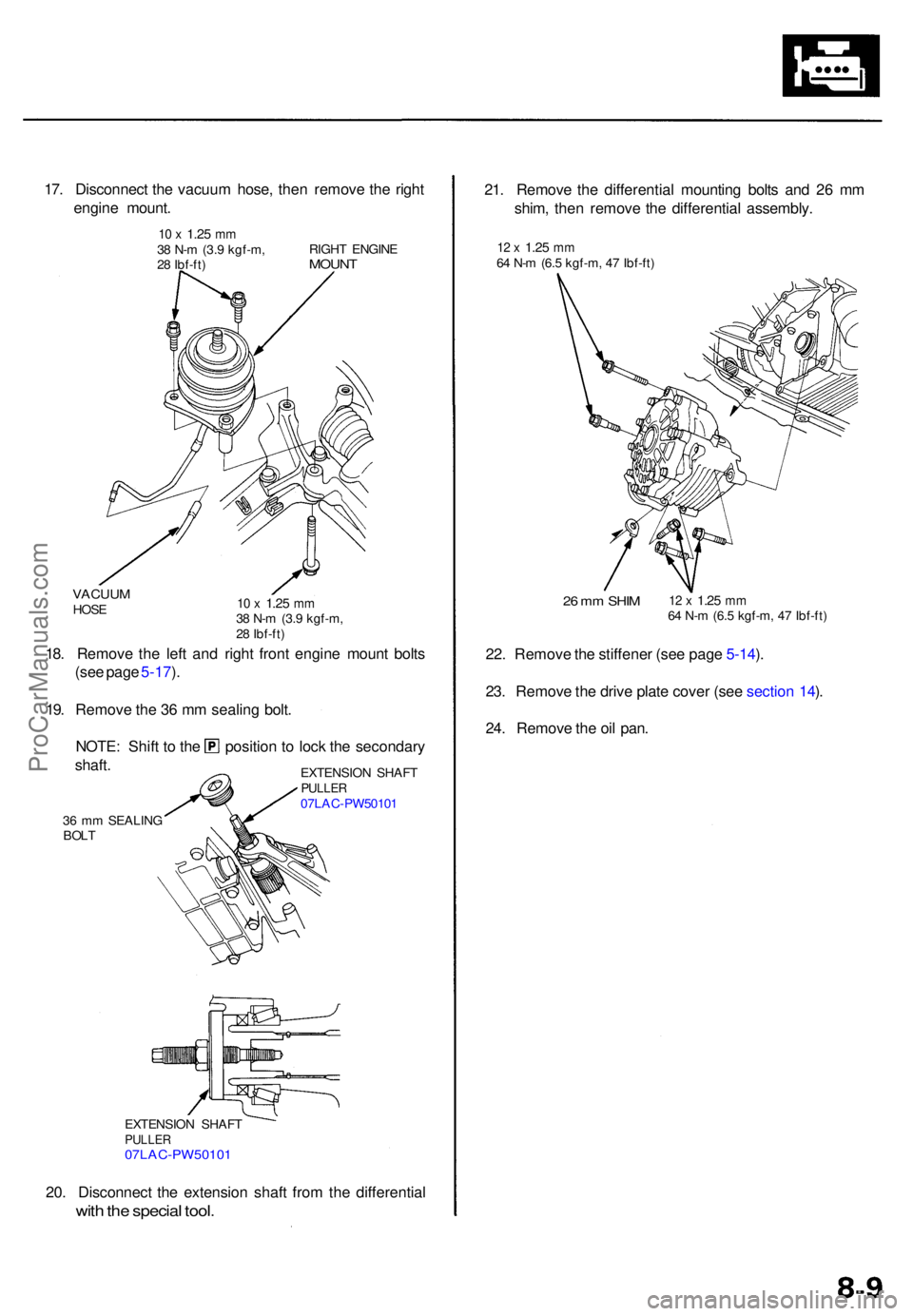

20. Disconnec t th e extensio n shaf t fro m th e differentia l

with th e specia l tool .

EXTENSIO N SHAF TPULLE R07LAC-PW5010 1

36 m m SEALIN G

BOL T EXTENSIO

N SHAF T

PULLE R07LAC-PW5010 1

18. Remov e th e lef t an d righ t fron t engin e moun t bolt s

(se e pag e 5-17 ).

19 . Remov e th e 3 6 m m sealin g bolt .

NOTE : Shif t t o th e

shaft . positio

n t o loc k th e secondar y

VACUUMHOSE10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,

2 8 Ibf-ft )

17. Disconnec t th e vacuu m hose , the n remov e th e righ t

engin e mount .

10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,

2 8 Ibf-ft ) RIGH

T ENGIN EMOUNT

21. Remov e th e differentia l mountin g bolt s an d 2 6 m m

shim , the n remov e th e differentia l assembly .

12 x 1.2 5 mm64 N- m (6. 5 kgf-m , 4 7 Ibf-ft )

22. Remov e th e stiffene r (se e pag e 5-14 ).

23 . Remov e th e driv e plat e cove r (se e sectio n 14 ).

24 . Remov e th e oi l pan .

26 m m SHI M12 x 1.2 5 mm64 N- m (6. 5 kgf-m , 4 7 Ibf-ft )

ProCarManuals.com

Page 472 of 1954

Oil Pan

Installation

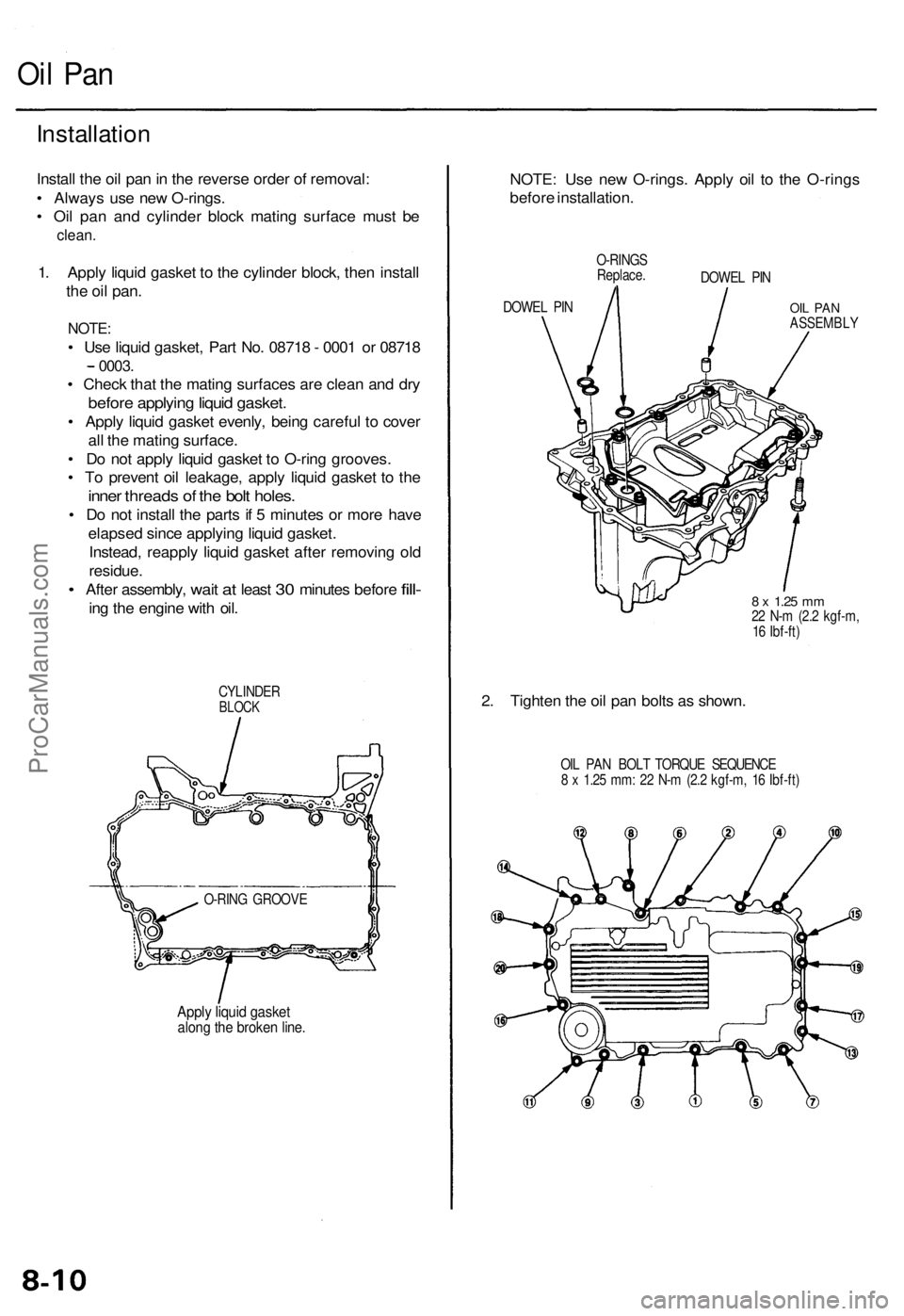

Install the oil pan in the reverse order of removal:

• Always use new O-rings.

• Oil pan and cylinder block mating surface must be

clean.

1. Apply liquid gasket to the cylinder block, then install

the oil

pan.

NOTE:

• Use liquid gasket, Part No. 08718 - 0001 or 08718

0003.

• Check that the mating surfaces are clean and dry

before applying liquid gasket.

• Apply liquid gasket evenly, being careful to cover

all the mating surface.

• Do not apply liquid gasket to O-ring grooves.

• To prevent oil leakage, apply liquid gasket to the

inner threads of the bolt holes.

• Do not install the parts if 5 minutes or more have

elapsed since applying liquid gasket.

Instead, reapply liquid gasket after removing old

residue.

•

After assembly,

wait

at

least

30

minutes before

fill-

ing the engine with oil.

CYLINDER

BLOCK

O-RING GROOVE

Apply liquid gasket

along the broken line.

NOTE: Use new O-rings. Apply oil to the O-rings

before installation.

DOWEL PIN

O-RINGS

Replace.

DOWEL PIN

OIL PAN

ASSEMBLY

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

2. Tighten the oil pan bolts as shown.

OIL PAN BOLT TORQUE SEQUENCE

8 x 1.25 mm: 22 N-m (2.2 kgf-m, 16 Ibf-ft)ProCarManuals.com

Page 473 of 1954

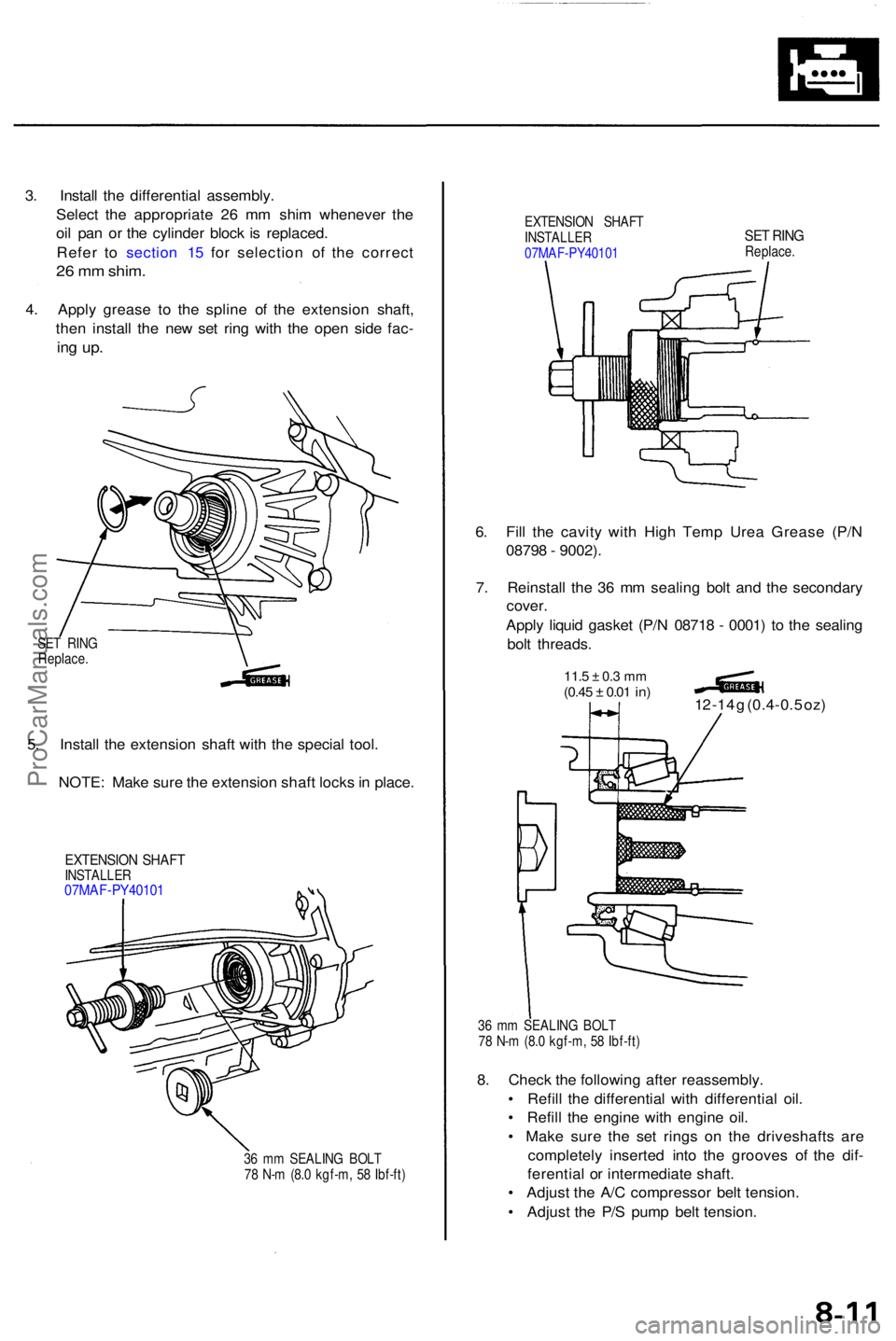

3. Instal l th e differentia l assembly .

Selec t th e appropriat e 2 6 m m shi m wheneve r th e

oi l pa n o r th e cylinde r bloc k i s replaced .

Refe r t o sectio n 1 5 fo r selectio n o f th e correc t

26 m m shim .

4. Appl y greas e t o th e splin e o f th e extensio n shaft ,

the n instal l th e ne w se t rin g wit h th e ope n sid e fac -

ing up .

EXTENSIO N SHAF T

INSTALLE R

07MA F-PY4010 1SET RIN GReplace .

6. Fil l th e cavit y wit h Hig h Tem p Ure a Greas e (P/ N

0879 8 - 9002) .

7 . Reinstal l th e 3 6 m m sealin g bol t an d th e secondar y

cover .

Appl y liqui d gaske t (P/ N 0871 8 - 0001 ) t o th e sealin g

bol t threads .

11.5 ± 0. 3 m m(0.4 5 ± 0.01 in)12 -1 4 g (0.4-0. 5 oz )

36 m m SEALIN G BOL T

7 8 N- m (8. 0 kgf-m , 5 8 Ibf-ft )

8. Chec k th e followin g afte r reassembly .

• Refil l th e differentia l wit h differentia l oil .

• Refil l th e engine with engin e oil .

• Mak e sur e th e se t ring s o n th e driveshaft s ar e

completel y inserte d int o th e groove s o f th e dif -

ferentia l o r intermediat e shaft .

• Adjus t th e A/ C compresso r bel t tension .

• Adjus t th e P/ S pum p bel t tension .

36 m m SEALIN G BOL T

7 8 N- m (8. 0 kgf-m , 5 8 Ibf-ft )

EXTENSIO N SHAF TINSTALLE R07MAF-PY4010 1

5. Instal l th e extensio n shaf t wit h th e specia l tool .

NOTE : Mak e sur e th e extensio n shaf t lock s in place .

SET RIN G

Replace .

ProCarManuals.com

Page 474 of 1954

Oil Pum p

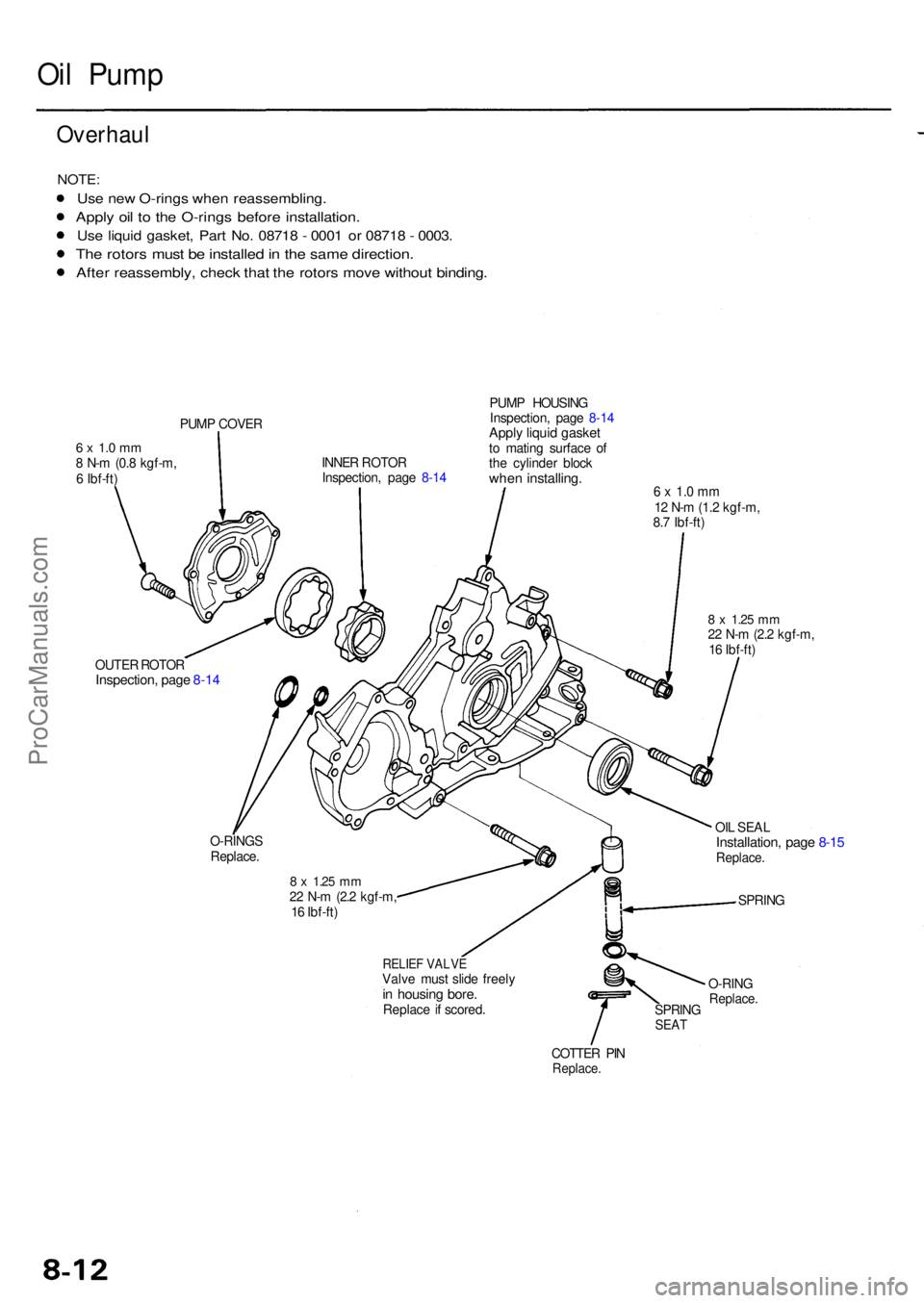

Overhau l

NOTE:

Use ne w O-ring s whe n reassembling .

Apply oi l t o th e O-ring s befor e installation .

Use liqui d gasket , Par t No . 0871 8 - 000 1 o r 0871 8 - 0003 .

The rotor s mus t b e installe d in th e sam e direction .

After reassembly , chec k tha t th e rotor s mov e withou t binding .

6 x 1. 0 m m8 N- m (0. 8 kgf-m ,

6 Ibf-ft ) PUM

P COVE R

INNER ROTO R

Inspection , pag e 8-1 4 PUM

P HOUSIN G

Inspection , pag e 8-1 4

Appl y liqui d gaske tto matin g surfac e o f

th e cylinde r bloc k

when installing .6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

OI L SEA L

Installation , pag e 8-1 5Replace .

SPRING

O-RIN G

Replace .SPRINGSEAT

COTTE R PI NReplace .

RELIEF VALV EValve mus t slid e freel yin housin g bore .Replac e if scored .

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

O-RING

S

Replace .

OUTE

R ROTO R

Inspection , pag e 8-1 4

ProCarManuals.com

Page 475 of 1954

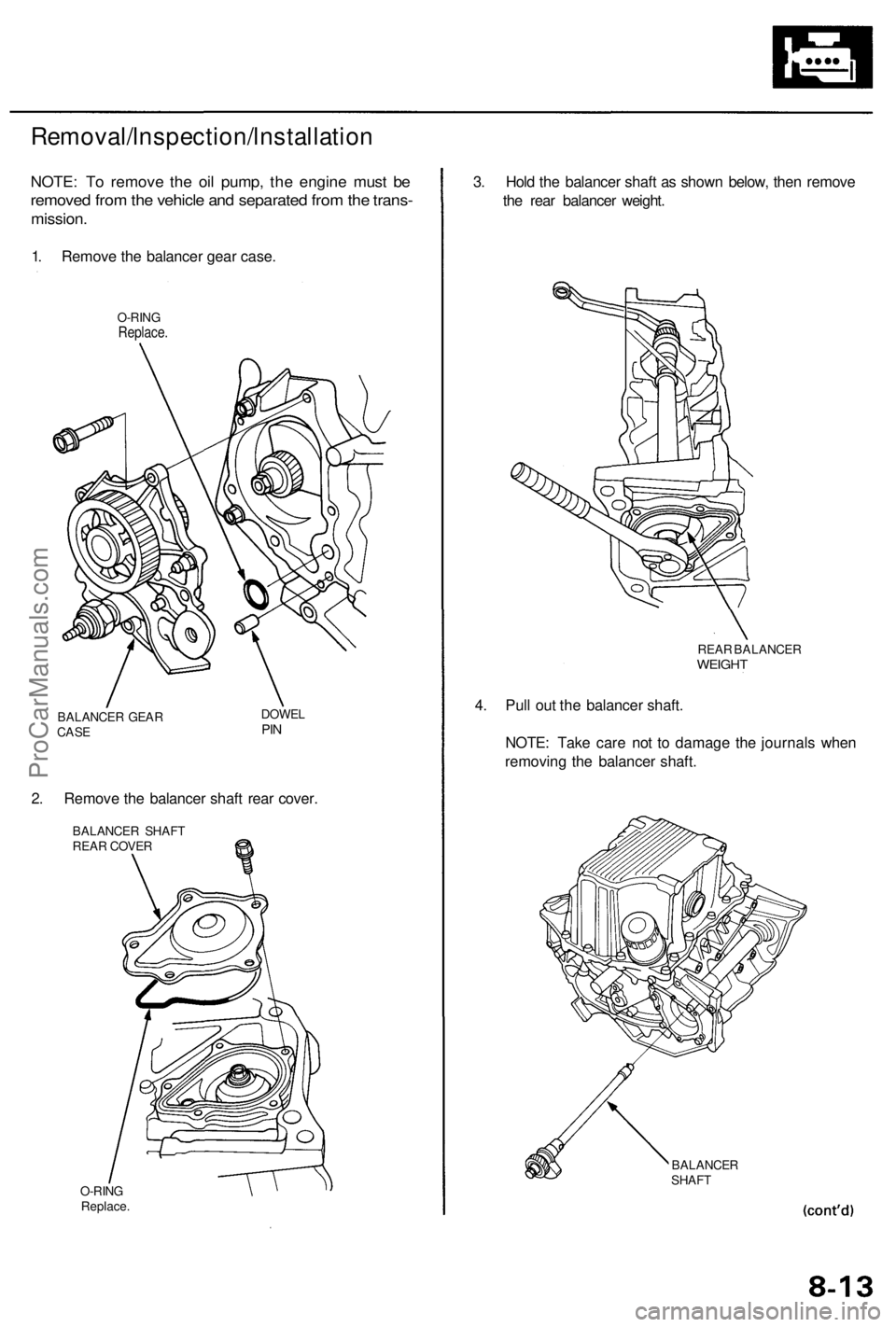

Removal/lnspection/lnstallation

NOTE: To remove the oil pump, the engine must be

removed from the vehicle and separated from the trans-

mission.

1. Remove the balancer gear case.

O-RING

Replace.

BALANCER GEAR

CASE

DOWEL

PIN

2. Remove the balancer shaft rear cover.

BALANCER SHAFT

REAR COVER

O-RING

Replace.

BALANCER

SHAFT

3. Hold the balancer shaft as shown below, then remove

the rear balancer weight.

4. Pull out the balancer shaft.

NOTE: Take care not to damage the journals when

removing the balancer shaft.

REAR BALANCER

WEIGHTProCarManuals.com

Page 476 of 1954

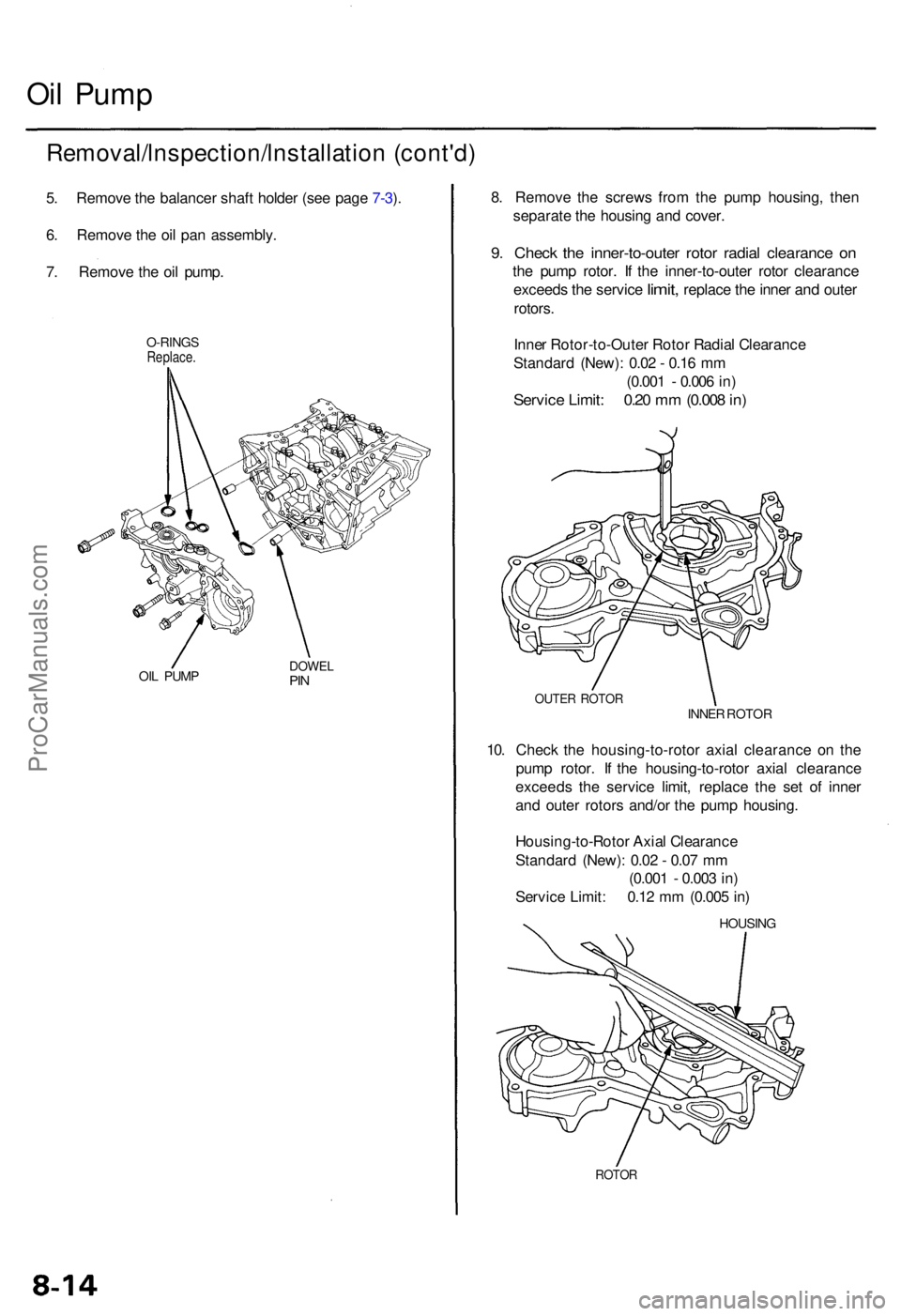

Oil Pum p

Removal/lnspection/lnstallatio n (cont'd )

5. Remov e th e balance r shaf t holde r (se e pag e 7-3 ).

6 . Remov e th e oi l pa n assembly .

7 . Remov e th e oi l pump .

O-RING SReplace .

OIL PUM PDOWE LPIN

ROTO R

HOUSIN G

Housing-to-Roto r Axia l Clearanc e

Standar d (New) : 0.0 2 - 0.0 7 m m

(0.00 1 - 0.00 3 in )

Servic e Limit : 0.1 2 m m (0.00 5 in )

10

. Chec k th e housing-to-roto r axia l clearanc e o n th e

pum p rotor . I f th e housing-to-roto r axia l clearanc e

exceed s th e servic e limit , replac e th e se t o f inne r

an d oute r rotor s and/o r th e pum p housing .

8

. Remov e th e screw s fro m th e pum p housing , the n

separat e th e housin g an d cover .

9. Chec k th e inner-to-oute r roto r radia l clearanc e o n

the pum p rotor . I f th e inner-to-oute r roto r clearanc e

exceed s

the servic e limit, replac e the inne r and oute r

rotors .

Inne r Rotor-to-Oute r Roto r Radia l Clearanc e

Standar d (New) : 0.0 2 - 0.1 6 m m

(0.00 1 - 0.00 6 in )

Servic e Limit : 0.2 0 m m (0.00 8 in )

OUTE R ROTO RINNER ROTO R

ProCarManuals.com

Page 477 of 1954

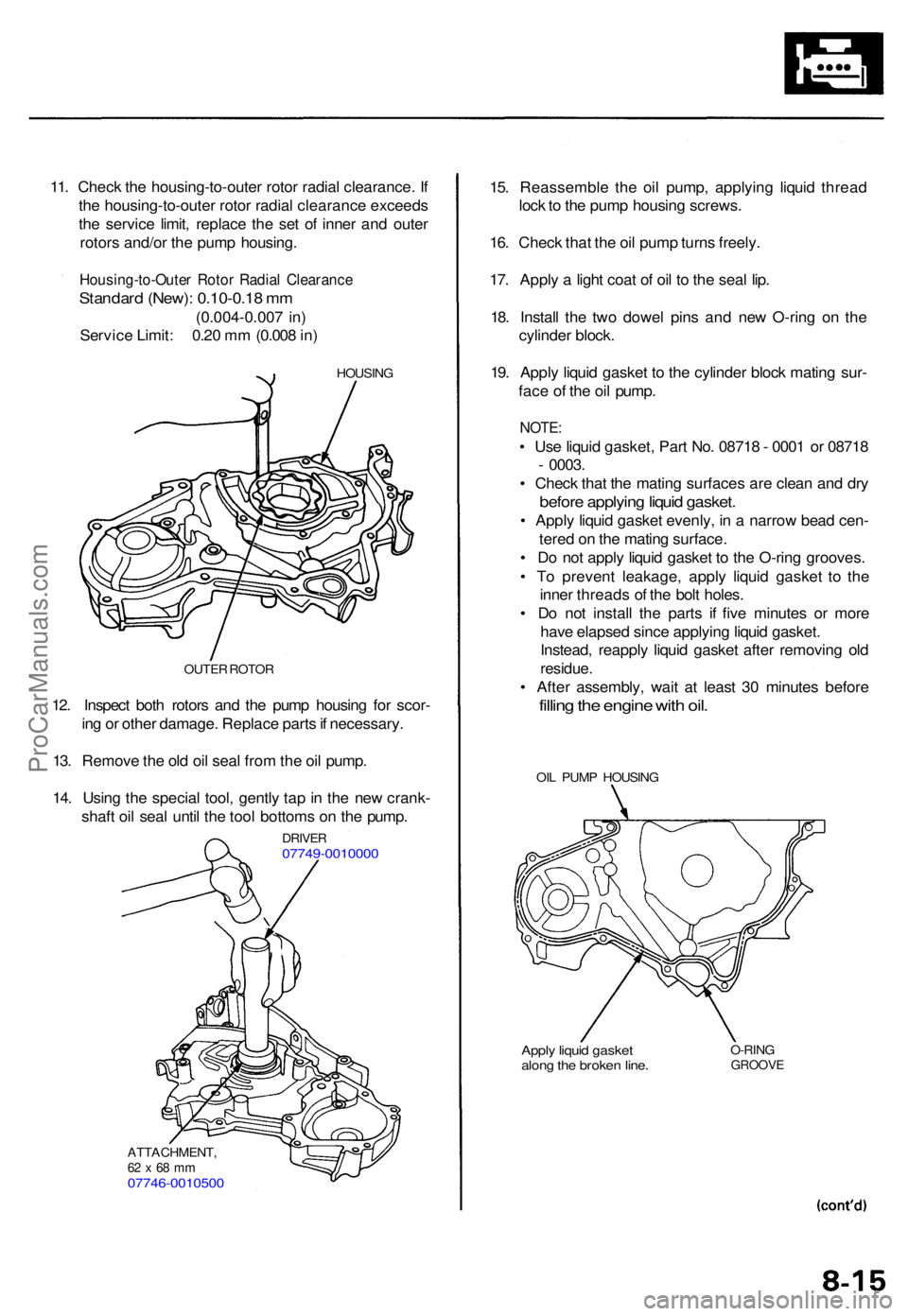

11. Chec k th e housing-to-oute r roto r radia l clearance . I f

th e housing-to-oute r roto r radia l clearanc e exceed s

th e servic e limit , replac e th e se t o f inne r an d oute r

rotor s and/o r th e pum p housing .

Housing-to-Oute r Roto r Radia l Clearanc e

Standard (New) : 0.10-0.1 8 m m

(0.004-0.00 7 in )

Servic e Limit : 0.2 0 m m (0.00 8 in )

HOUSIN G

12. Inspec t bot h rotor s an d th e pum p housin g fo r scor -

in g o r othe r damage . Replac e part s if necessary .

13 . Remov e th e ol d oi l sea l fro m th e oi l pump .

14 . Usin g th e specia l tool , gentl y ta p in th e ne w crank -

shaf t oi l sea l unti l th e too l bottom s o n th e pump .

OUTER ROTO R

DRIVE R07749-001000 0

ATTACHMENT ,62 x 68 m m07746-001050 0

Apply liqui d gaske talong th e broke n line .O-RIN GGROOV E

OIL PUM P HOUSIN G

15. Reassembl e th e oi l pump , applyin g liqui d threa d

loc k to th e pum p housin g screws .

16 . Chec k tha t th e oi l pum p turn s freely .

17 . Appl y a ligh t coa t o f oi l t o th e sea l lip .

18 . Instal l th e tw o dowe l pin s an d ne w O-rin g o n th e

cylinde r block .

19 . Appl y liqui d gaske t t o th e cylinde r bloc k matin g sur -

fac e o f th e oi l pump .

NOTE:

• Us e liqui d gasket , Par t No . 0871 8 - 000 1 o r 0871 8

- 0003 .

• Chec k tha t th e matin g surface s ar e clea n an d dr y

befor e applyin g liqui d gasket .

• Appl y liqui d gaske t evenly , i n a narro w bea d cen -

tere d o n th e matin g surface .

• D o no t appl y liqui d gaske t t o th e O-rin g grooves .

• T o preven t leakage , appl y liqui d gaske t t o th e

inne r thread s o f th e bol t holes .

• D o no t instal l th e part s i f fiv e minute s o r mor e

hav e elapse d sinc e applyin g liqui d gasket .

Instead , reappl y liqui d gaske t afte r removin g ol d

residue .

• Afte r assembly , wai t a t leas t 3 0 minute s befor e

filling th e engin e wit h oil .

ProCarManuals.com

Page 478 of 1954

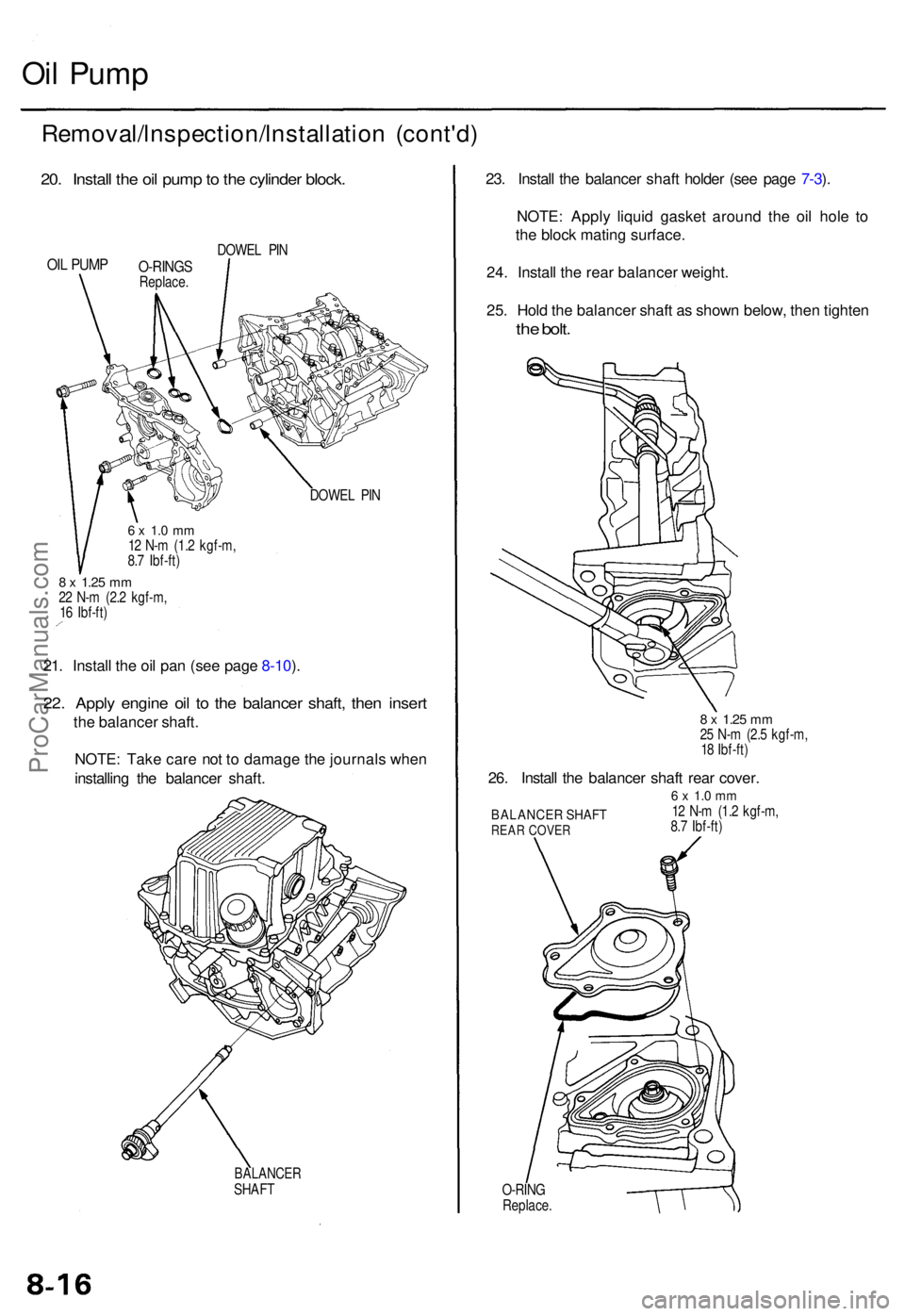

Oil Pum p

Removal/lnspection/lnstallatio n (cont'd )

20. Instal l th e oi l pum p to th e cylinde r block .

OIL PUM PO-RING SReplace .DOWE

L PI N

DOWE L PI N

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

21. Instal l th e oi l pa n (se e pag e 8-10 ).

22 . Appl y engin e oi l t o th e balance r shaft , the n inser t

the balance r shaft .

NOTE : Tak e car e no t t o damag e th e journal s whe n

installin g th e balance r shaft .

BALANCE RSHAFT

O-RING

Replace .

BALANCE R SHAF TREAR COVE R

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

23. Instal l th e balance r shaf t holde r (se e pag e 7-3 ).

NOTE : Appl y liqui d gaske t aroun d th e oi l hol e t o

th e bloc k matin g surface .

24 . Instal l th e rea r balance r weight .

25 . Hol d th e balance r shaf t a s show n below , the n tighte n

the bolt .

8 x 1.2 5 mm25 N- m (2. 5 kgf-m ,

1 8 Ibf-ft )

26. Instal l th e balance r shaf t rea r cover .

ProCarManuals.com

Page 479 of 1954

31. Remov e th e 6 m m bolt . Instal l th e sealin g bol t i n th e

maintenanc e hole . Us e a ne w washer .

Apply liqui d gaske talong th e broke n line .O-RIN GGROOV E

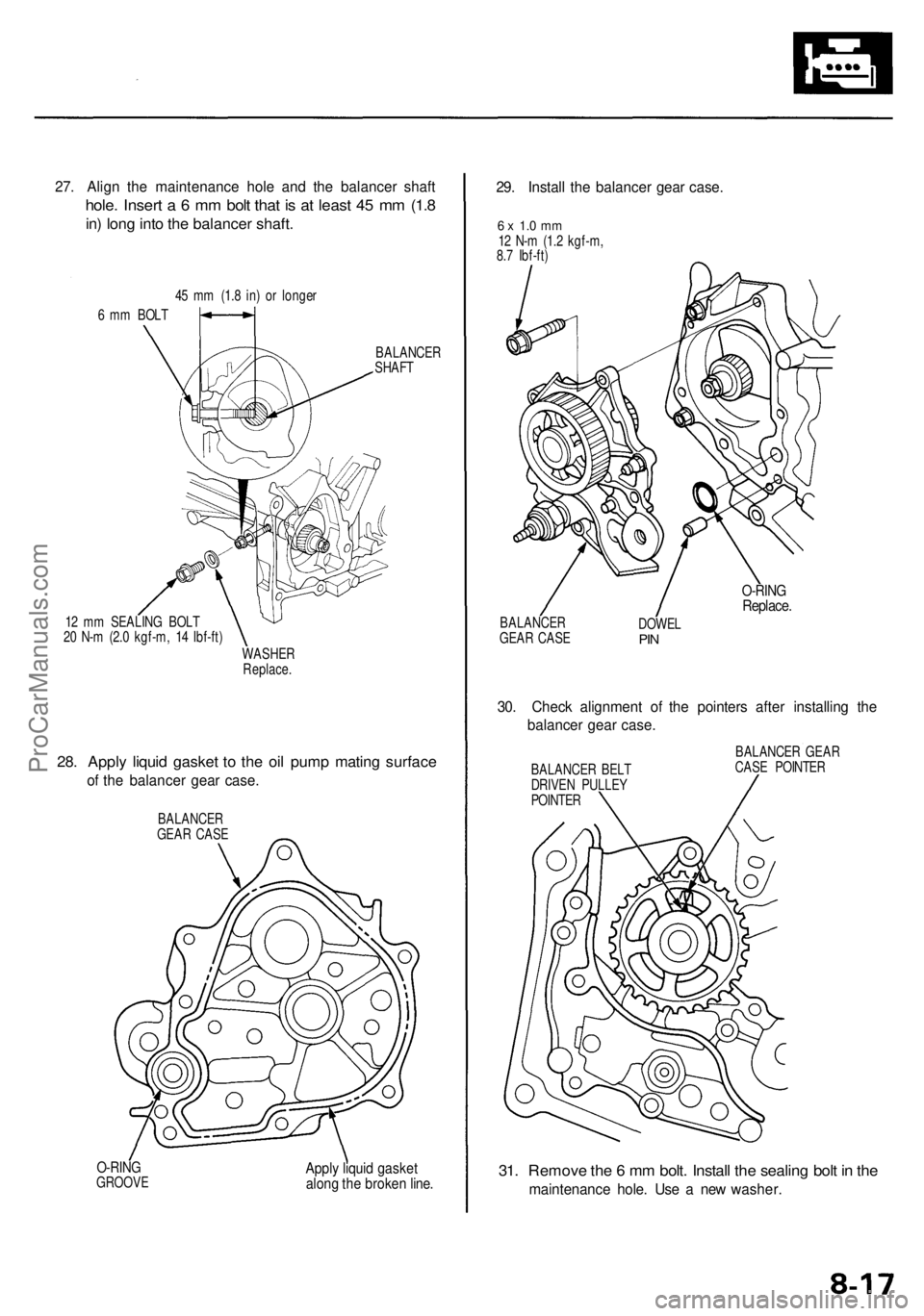

27. Alig n th e maintenanc e hol e an d th e balance r shaf t

hole. Inser t a 6 mm bol t tha t i s a t leas t 4 5 m m (1. 8

in) lon g int o th e balance r shaft .

6 m m BOL T4

5 m m (1. 8 in ) o r longe r

BALANCER

SHAF T

1 2 m m SEALIN G BOL T

2 0 N- m (2. 0 kgf-m , 1 4 Ibf-ft )

WASHE R

Replace .

28. Appl y liqui d gaske t t o th e oi l pum p matin g surfac e

of th e balance r gea r case .

BALANCE R

GEA R CAS E

29. Instal l th e balance r gea r case .

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

BALANCE R

GEA R CAS E DOWE

L

PIN

O-RIN GReplace .

30. Chec k alignmen t o f th e pointer s afte r installin g th e

balance r gea r case .

BALANCE R BEL T

DRIVE N PULLE Y

POINTE R BALANCE

R GEA R

CAS E POINTE R

ProCarManuals.com

Page 480 of 1954

Special Tool s

Ref. No .Too l Numbe rDescriptio nQtyPag e Referenc e

07LAA-PT5010 1 02 Senso r Socke t Wrenc h 9- 6

ProCarManuals.com