ACURA RL KA9 1996 Service Repair Manual

Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 461 of 1954

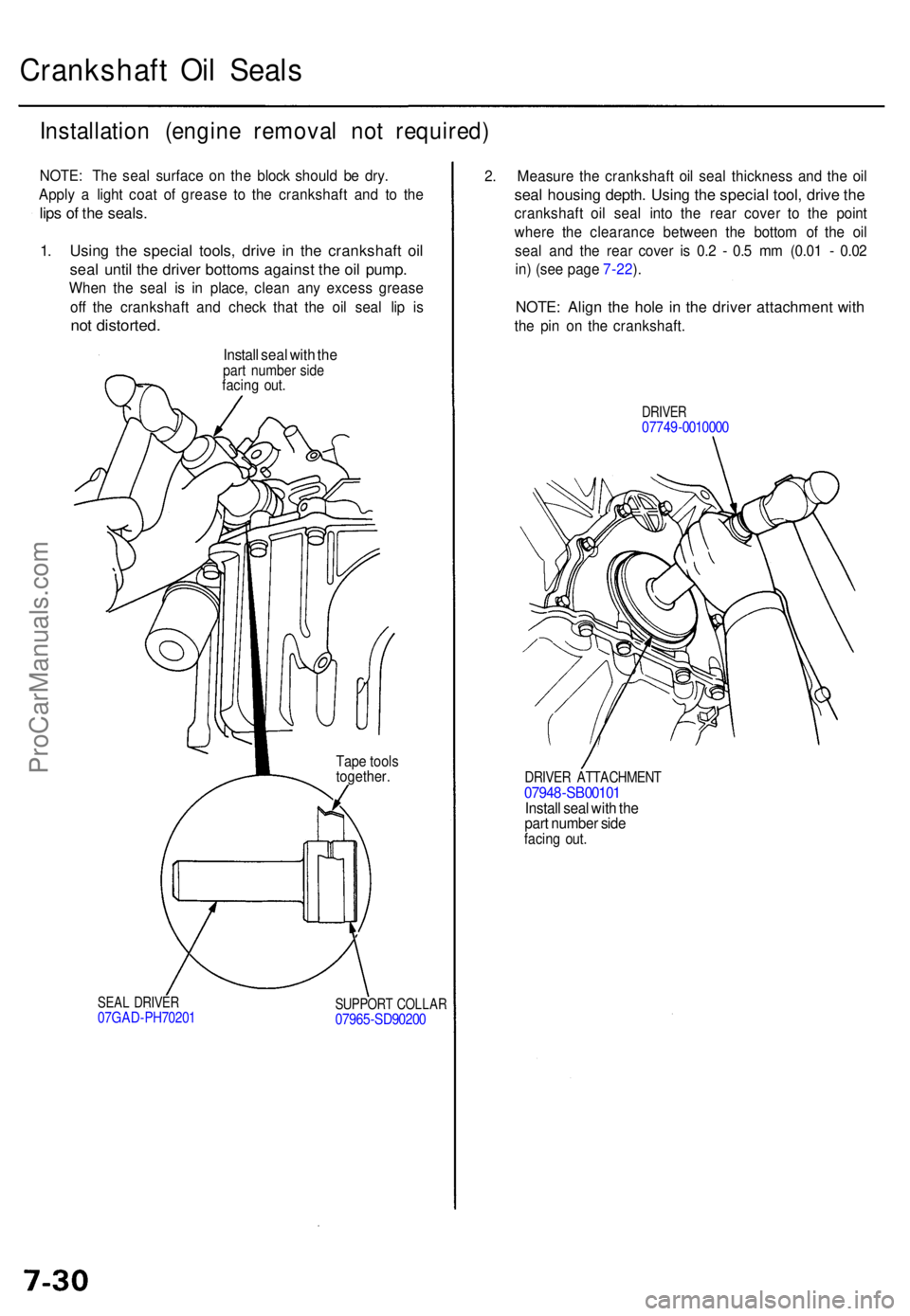

Crankshaft Oi l Seal s

Installatio n (engin e remova l no t required )

NOTE: Th e sea l surfac e o n th e bloc k shoul d b e dry .

Appl y a ligh t coa t o f greas e t o th e crankshaf t an d t o th e

lips o f th e seals .

1. Usin g th e specia l tools , driv e i n th e crankshaf t oi l

sea l unti l th e drive r bottom s agains t th e oi l pump .

When th e sea l i s i n place , clea n an y exces s greas e

of f th e crankshaf t an d chec k tha t th e oi l sea l li p i s

no t distorted .

Install sea l wit h th epar t numbe r sid efacin g out .

Tape tool stogether .

SEAL DRIVE R07GAD-PH7020 1SUPPOR T COLLA R07965-SD9020 0

2. Measur e th e crankshaf t oi l sea l thicknes s an d th e oi l

sea l housin g depth . Usin g th e specia l tool , driv e th e

crankshaf t oi l sea l int o th e rea r cove r t o th e poin t

wher e th e clearanc e betwee n th e botto m o f th e oi l

sea l an d th e rea r cove r i s 0. 2 - 0. 5 m m (0.0 1 - 0.0 2

in ) (se e pag e 7-22 ).

NOTE : Alig n th e hol e i n th e drive r attachmen t wit h

the pi n o n th e crankshaft .

DRIVER07749-001000 0

DRIVER ATTACHMEN T07948-SB0010 1

Instal l sea l wit h th e

par t numbe r sid e

facin g out .

ProCarManuals.com

Page 462 of 1954

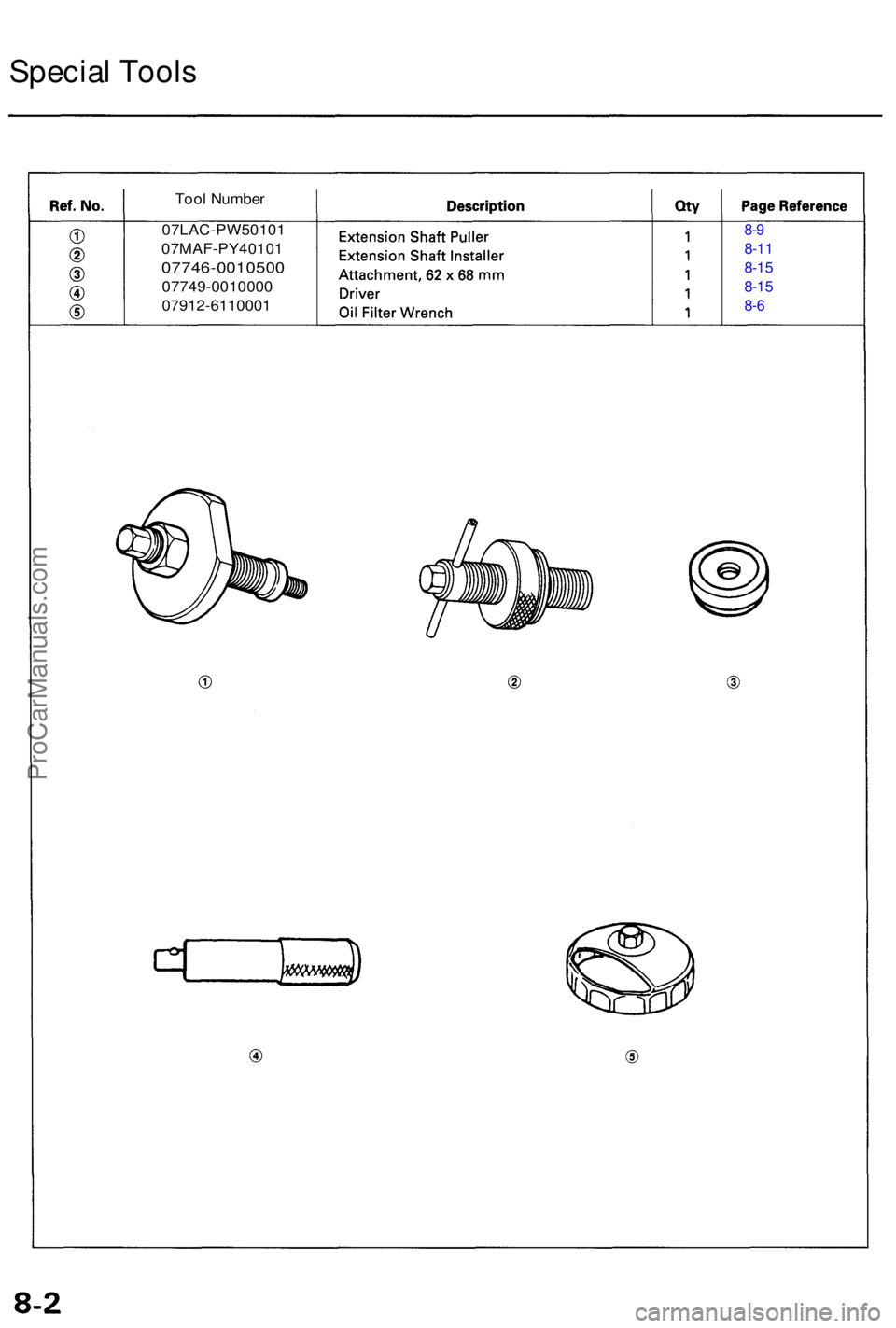

Special Tool s

07LAC-PW5010 1

07MAF-PY4010 1

07746-0010500

07749-0010000

07912-611000 1

Too

l Numbe r

8-9

8-1 1

8-1 5

8-1 5

8-6

ProCarManuals.com

Page 463 of 1954

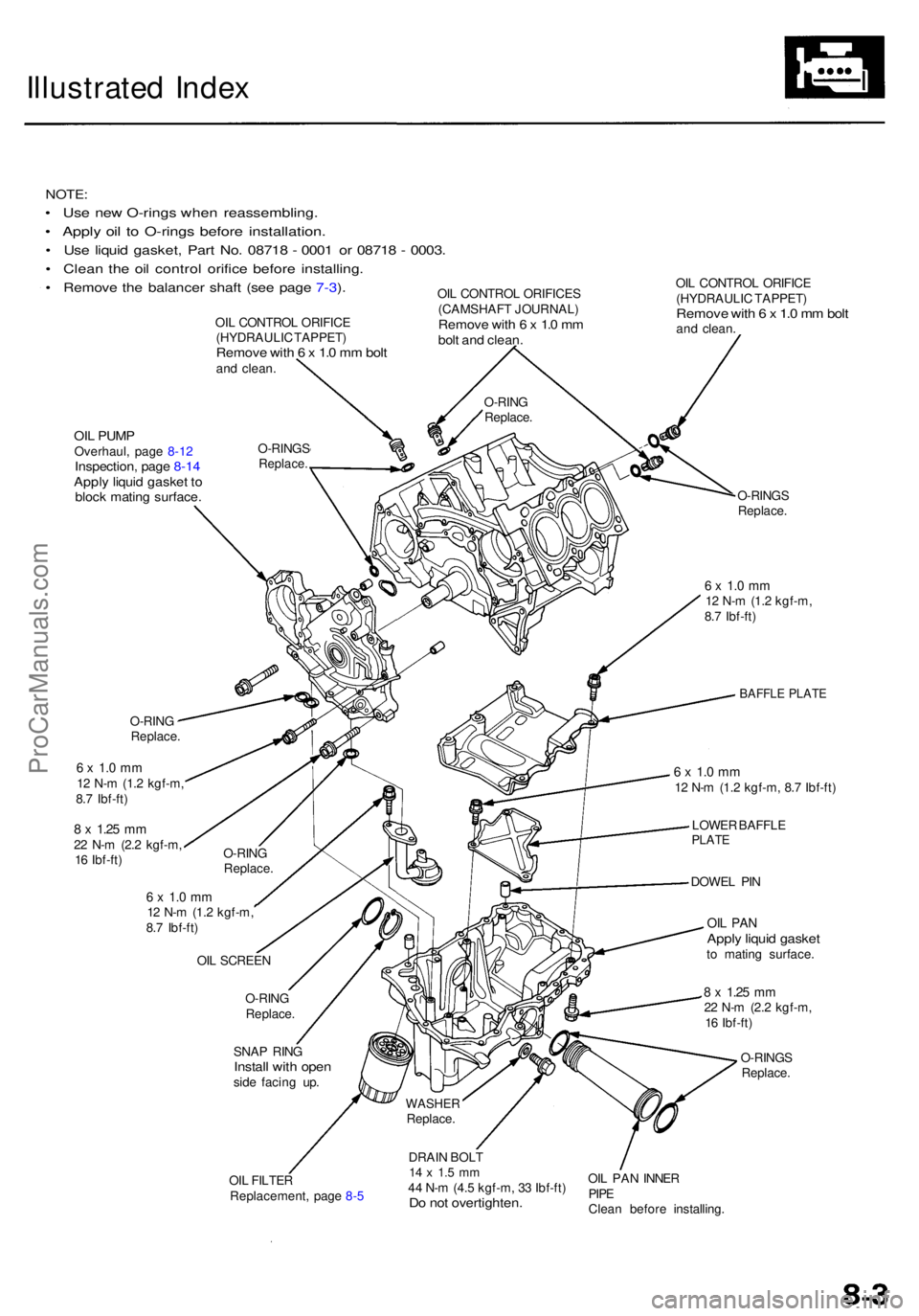

Illustrated Inde x

NOTE :

• Us e ne w O-ring s whe n reassembling .

• Appl y oi l t o O-ring s befor e installation .

• Us e liqui d gasket , Par t No . 0871 8 - 000 1 o r 0871 8 - 0003 .

• Clea n th e oi l contro l orific e befor e installing .

• Remov e th e balance r shaf t (se e pag e 7-3 ).

OI L CONTRO L ORIFIC E

(HYDRAULI C TAPPET )

Remove wit h 6 x 1. 0 m m bol tand clean . OI

L CONTRO L ORIFICE S

(CAMSHAF T JOURNAL )

Remove wit h 6 x 1. 0 m mbol t an d clean .

OIL PUM POverhaul , pag e 8-1 2Inspection , pag e 8-1 4Appl y liqui d gaske t t obloc k matin g surface .

O-RINGReplace .

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft ) OI

L CONTRO L ORIFIC E

(HYDRAULI C TAPPET )

Remove wit h 6 x 1. 0 m m bol tand clean .

O-RING S

Replace .

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

BAFFL E PLAT E

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

SNAP RIN G

Instal l wit h ope nside facin g up .

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

LOWE R BAFFL E

PLATE

DOWE L PI N

OIL PA NAppl y liqui d gaske tto matin g surface .

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

O-RING S

Replace .

OI L FILTE R

Replacement , pag e 8- 5 DRAI

N BOL T

14 x 1. 5 m m44 N- m (4. 5 kgf-m , 3 3 Ibf-ft )Do no t overtighten .

OIL PA N INNE RPIPEClea n befor e installing .

O-RIN

G

Replace .

O-RING S

Replace .

O-RING

Replace .

OI L SCREE N

O-RIN G

Replace .

WASHE RReplace.

ProCarManuals.com

Page 464 of 1954

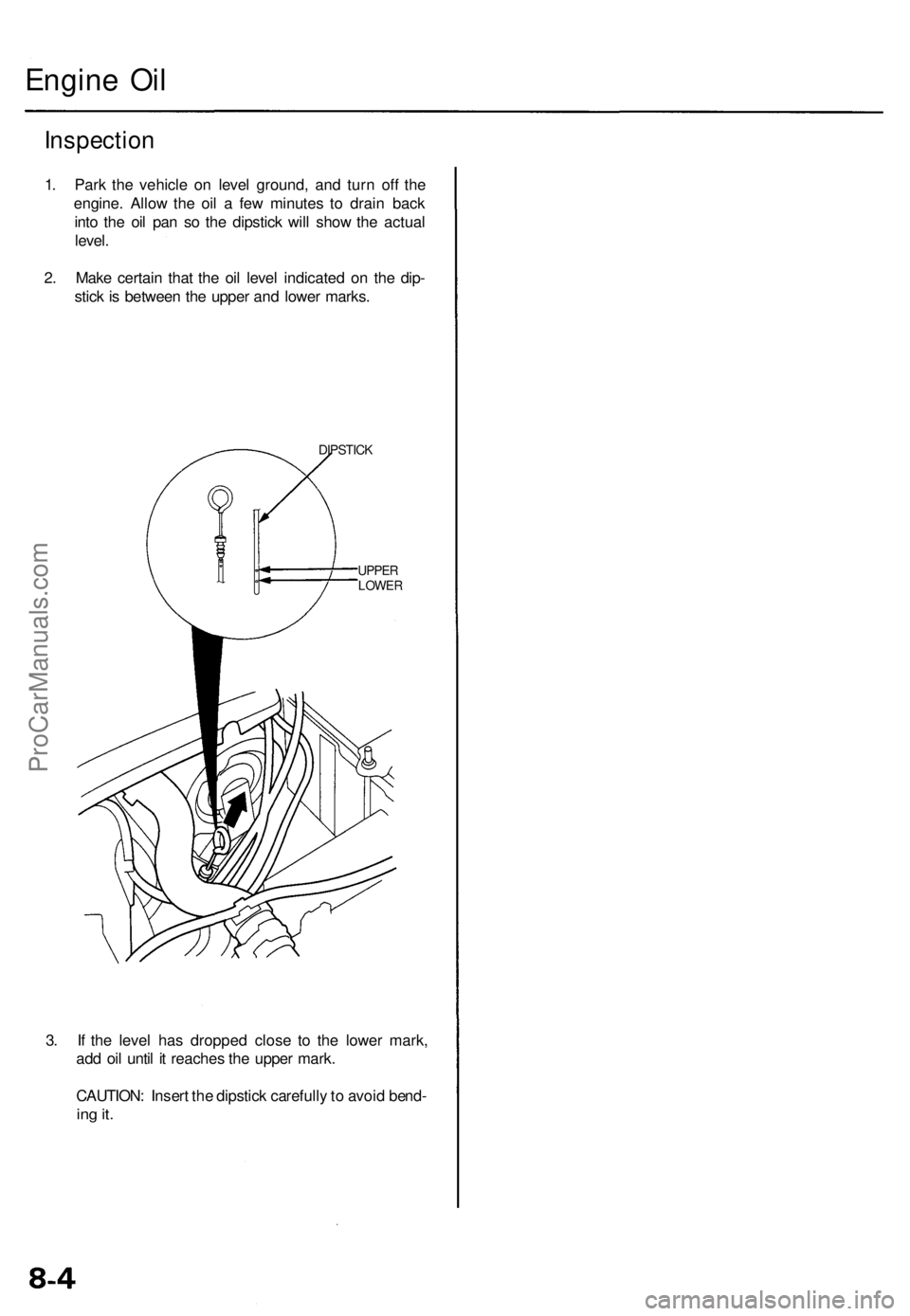

Engine Oi l

1. Par k th e vehicl e o n leve l ground , an d tur n of f th e

engine . Allo w th e oi l a fe w minute s t o drai n bac k

int o th e oi l pa n s o th e dipstic k wil l sho w th e actua l

level .

2 . Mak e certai n tha t th e oi l leve l indicate d o n th e dip -

stic k is betwee n th e uppe r an d lowe r marks .

DIPSTIC K

UPPERLOWE R

3. I f th e leve l ha s droppe d clos e t o th e lowe r mark ,

ad d oi l unti l i t reache s th e uppe r mark .

CAUTION : Inser t th e dipstic k carefull y to avoi d bend -

ing it .

Inspectio n

ProCarManuals.com

Page 465 of 1954

Engine Oi l

Replacemen t

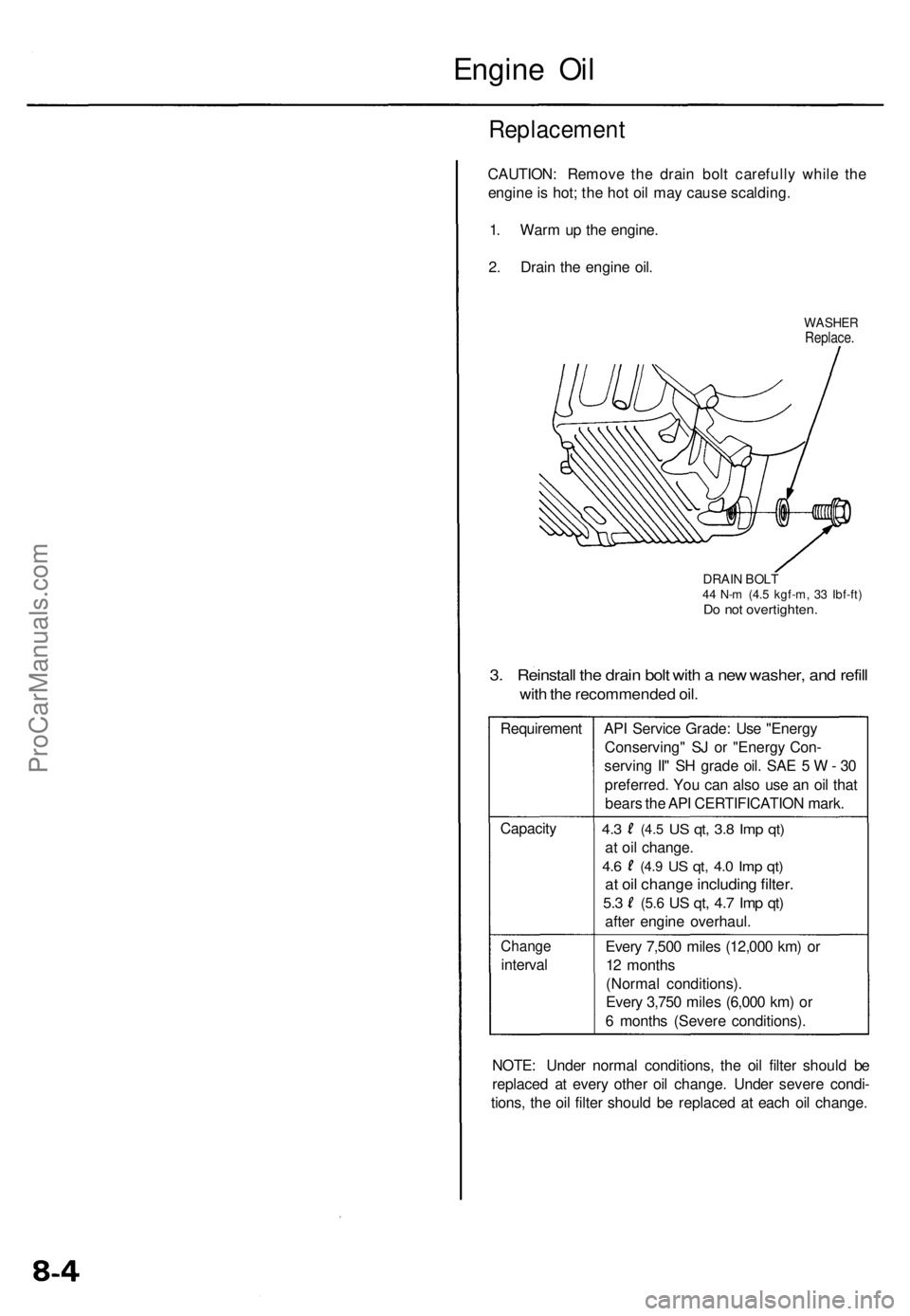

CAUTION: Remov e th e drai n bol t carefull y whil e th e

engin e is hot ; th e ho t oi l ma y caus e scalding .

1 . War m u p th e engine .

2 . Drai n th e engin e oil .

WASHE RReplace.

DRAIN BOL T44 N- m (4. 5 kgf-m , 3 3 Ibf-ft )Do no t overtighten .

3. Reinstal l th e drai n bol t wit h a ne w washer , an d refil l

with th e recommende d oil .

Requiremen tAPI Servic e Grade : Us e "Energ y

Conserving " S J o r "Energ y Con -

servin g II " S H grad e oil . SA E 5 W - 30

preferred . Yo u ca n als o us e a n oi l tha t

bear s th e AP I CERTIFICATIO N mark .

Capacit y

4.3 (4. 5 US qt , 3. 8 Im p qt )

at oi l change .

4.6 (4. 9 US qt , 4. 0 Im p qt )

at oi l chang e includin g filter .

5.3 (5. 6 US qt , 4. 7 Im p qt )

afte r engin e overhaul .

Change

interval Ever

y 7,50 0 mile s (12,00 0 km ) o r

1 2 month s

(Norma l conditions) .

Ever y 3,75 0 mile s (6,00 0 km ) o r

6 month s (Sever e conditions) .

NOTE : Unde r norma l conditions , th e oi l filte r shoul d b e

replace d a t ever y othe r oi l change . Unde r sever e condi -

tions , th e oi l filte r shoul d b e replace d a t eac h oi l change .

ProCarManuals.com

Page 466 of 1954

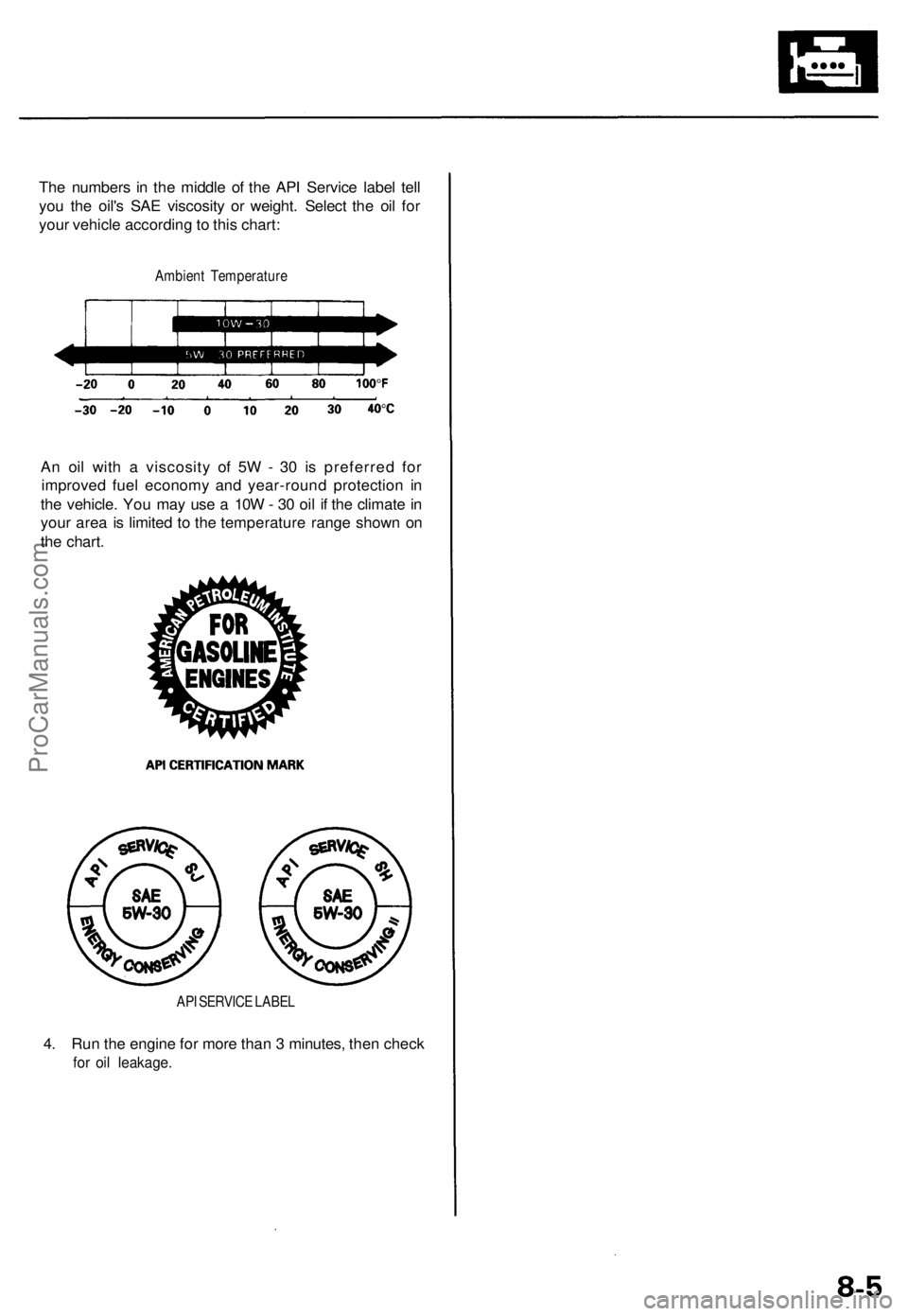

The numbers in the middle of the API Service label tell

you the oil's SAE viscosity or weight. Select the oil for

your vehicle according to this chart:

Ambient Temperature

An oil with a viscosity of 5W - 30 is preferred for

improved fuel economy and year-round protection in

the vehicle. You may use a 10W - 30 oil if the climate in

your area is limited to the temperature range shown on

the chart.

API SERVICE LABEL

4. Run the engine for more than 3 minutes, then check

for oil leakage.ProCarManuals.com

Page 467 of 1954

Oil Filter

Replacement

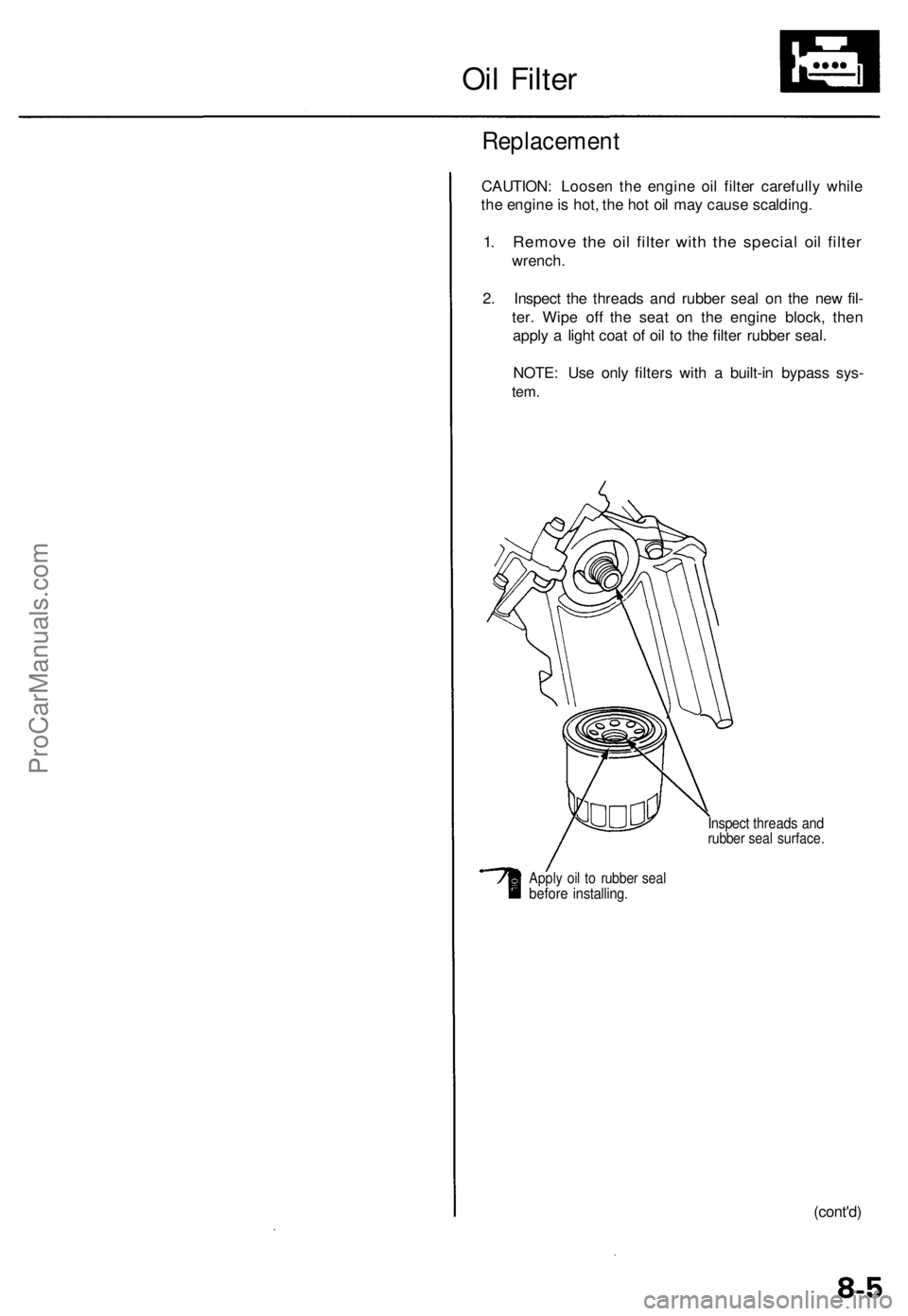

CAUTION: Loosen the engine oil filter carefully while

the engine is hot, the hot oil may cause scalding.

1. Remove the oil filter with the special oil filter

wrench.

2. Inspect the threads and rubber seal on the new fil-

ter. Wipe off the seat on the engine block, then

apply a light coat of oil to the filter rubber seal.

NOTE: Use only filters with a built-in bypass sys-

tem.

Inspect threads and

rubber seal surface.

Apply oil to rubber seal

before installing.

(cont'd)ProCarManuals.com

Page 468 of 1954

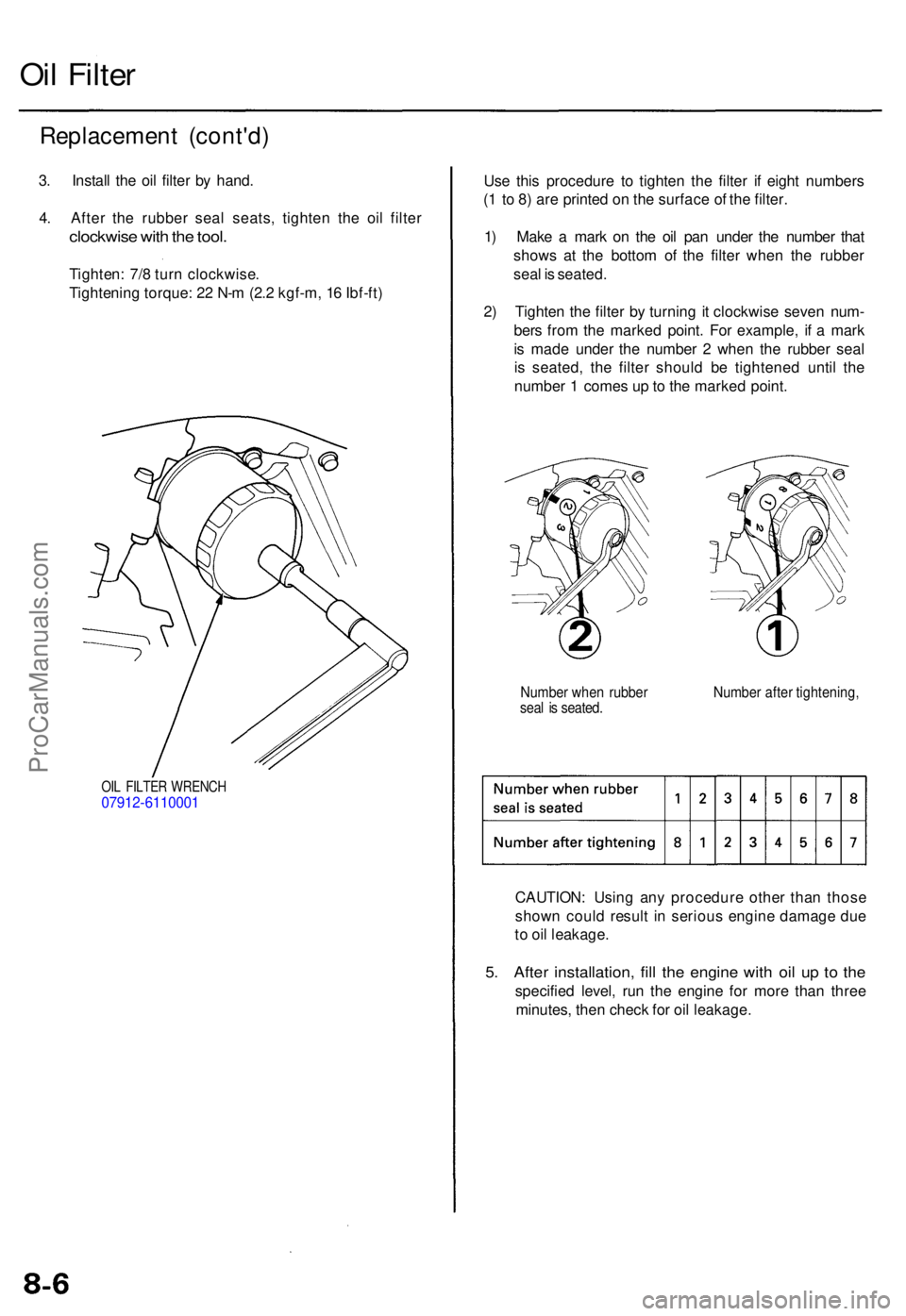

Replacement (cont'd )

3. Instal l th e oi l filte r b y hand .

4 . Afte r th e rubbe r sea l seats , tighte n th e oi l filte r

clockwis e wit h th e tool .

Tighten : 7/ 8 tur n clockwise .

Tightenin g torque : 2 2 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

Oil Filte r

OIL FILTE R WRENC H07912-611000 1

Use thi s procedur e t o tighte n th e filte r i f eigh t number s

( 1 t o 8 ) ar e printe d o n th e surfac e o f th e filter .

1 ) Mak e a mar k o n th e oi l pa n unde r th e numbe r tha t

show s a t th e botto m o f th e filte r whe n th e rubbe r

sea l i s seated .

2 ) Tighte n th e filte r b y turnin g i t clockwis e seve n num -

ber s fro m th e marke d point . Fo r example , i f a mar k

i s mad e unde r th e numbe r 2 whe n th e rubbe r sea l

i s seated , th e filte r shoul d b e tightene d unti l th e

numbe r 1 come s u p to th e marke d point .

Numbe r whe n rubbe r Numbe r afte r tightening ,seal i s seated .

CAUTION : Usin g an y procedur e othe r tha n thos e

show n coul d resul t i n seriou s engin e damag e du e

t o oi l leakage .

5. Afte r installation , fil l th e engin e wit h oi l u p t o th e

specifie d level , ru n th e engine for mor e tha n thre e

minutes , the n chec k fo r oi l leakage .

ProCarManuals.com

Page 469 of 1954

3. I f th e switc h fail s t o operate , chec k th e engin e oi l

level . I f th e engin e oi l leve l i s OK , chec k th e engin e

oi l pressure .

YEL/RED WIR E(Covere d wit hinsulation )

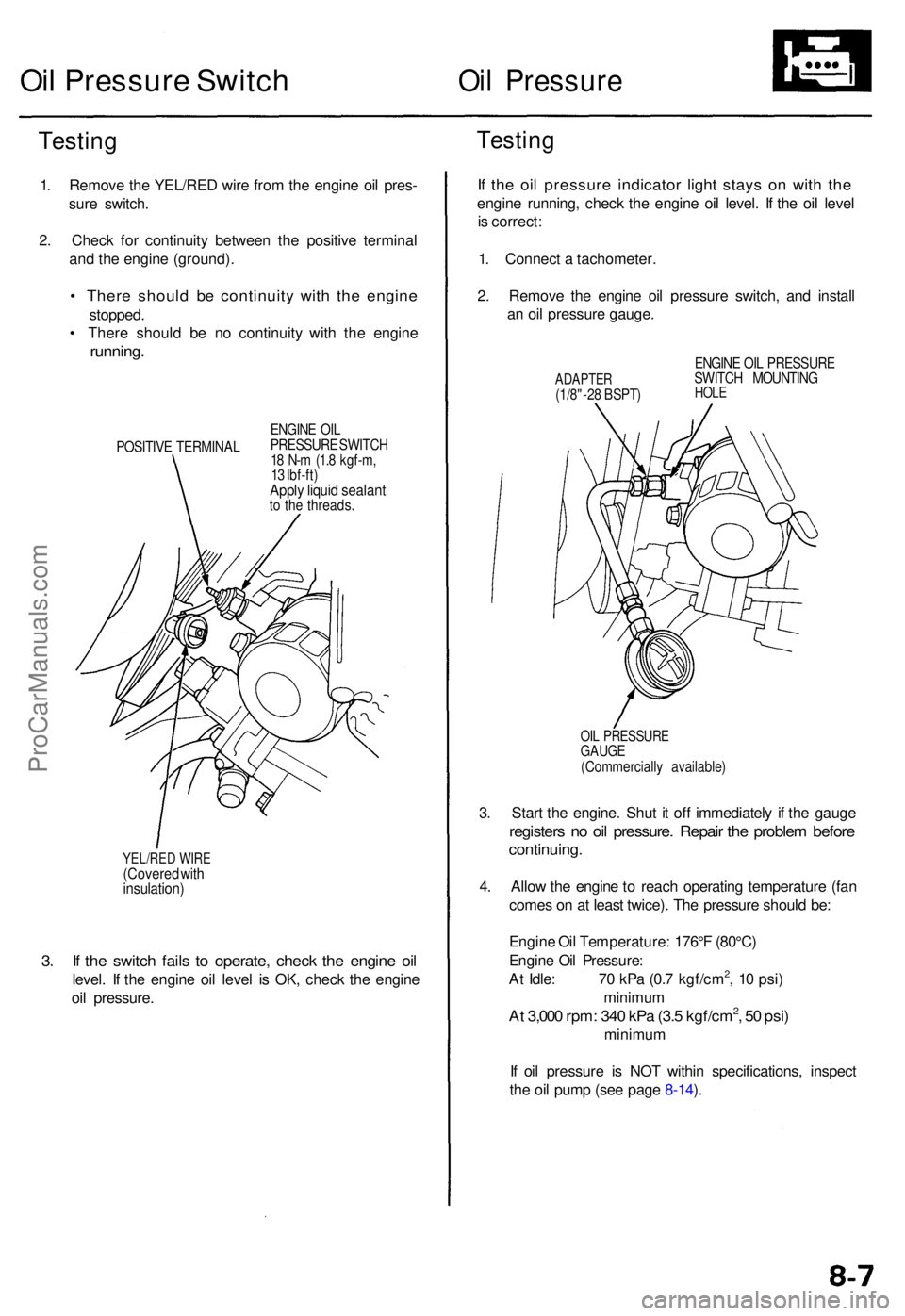

Testing

1. Remov e th e YEL/RE D wir e fro m th e engin e oi l pres -

sur e switch .

2 . Chec k fo r continuit y betwee n th e positiv e termina l

an d th e engin e (ground) .

• Ther e shoul d b e continuit y wit h th e engin e

stopped .

• Ther e shoul d b e n o continuit y wit h th e engin e

running .

POSITIV E TERMINA LENGIN

E OI L

PRESSUR E SWITC H

1 8 N- m (1. 8 kgf-m ,

1 3 Ibf-ft )

Apply liqui d sealan tto th e threads .

Oil Pressur e Switc hOil Pressur e

Testing

If th e oi l pressur e indicato r ligh t stay s o n wit h th e

engin e running , chec k th e engin e oi l level . I f th e oi l leve l

i s correct :

1 . Connec t a tachometer .

2 . Remov e th e engin e oi l pressur e switch , an d instal l

a n oi l pressur e gauge .

ADAPTE R(1/8"-28 BSPT ) ENGIN

E OI L PRESSUR E

SWITC H MOUNTIN GHOLE

OIL PRESSUR EGAUGE(Commerciall y available )

3. Star t th e engine . Shu t i t of f immediatel y i f th e gaug e

register s n o oi l pressure . Repai r th e proble m befor e

continuing .

4. Allo w th e engin e to reac h operatin g temperatur e (fa n

come s o n a t leas t twice) . Th e pressur e shoul d be :

Engin e Oi l Temperature : 176° F (80°C )

Engin e Oi l Pressure :

A t Idle : 7 0 kP a (0. 7 kgf/cm

2, 1 0 psi )

minimu m

At 3,00 0 rpm : 34 0 kP a (3. 5 kgf/cm2, 5 0 psi )

minimu m

I f oi l pressur e i s NO T withi n specifications , inspec t

th e oi l pum p (se e pag e 8-14 ).

ProCarManuals.com

Page 470 of 1954

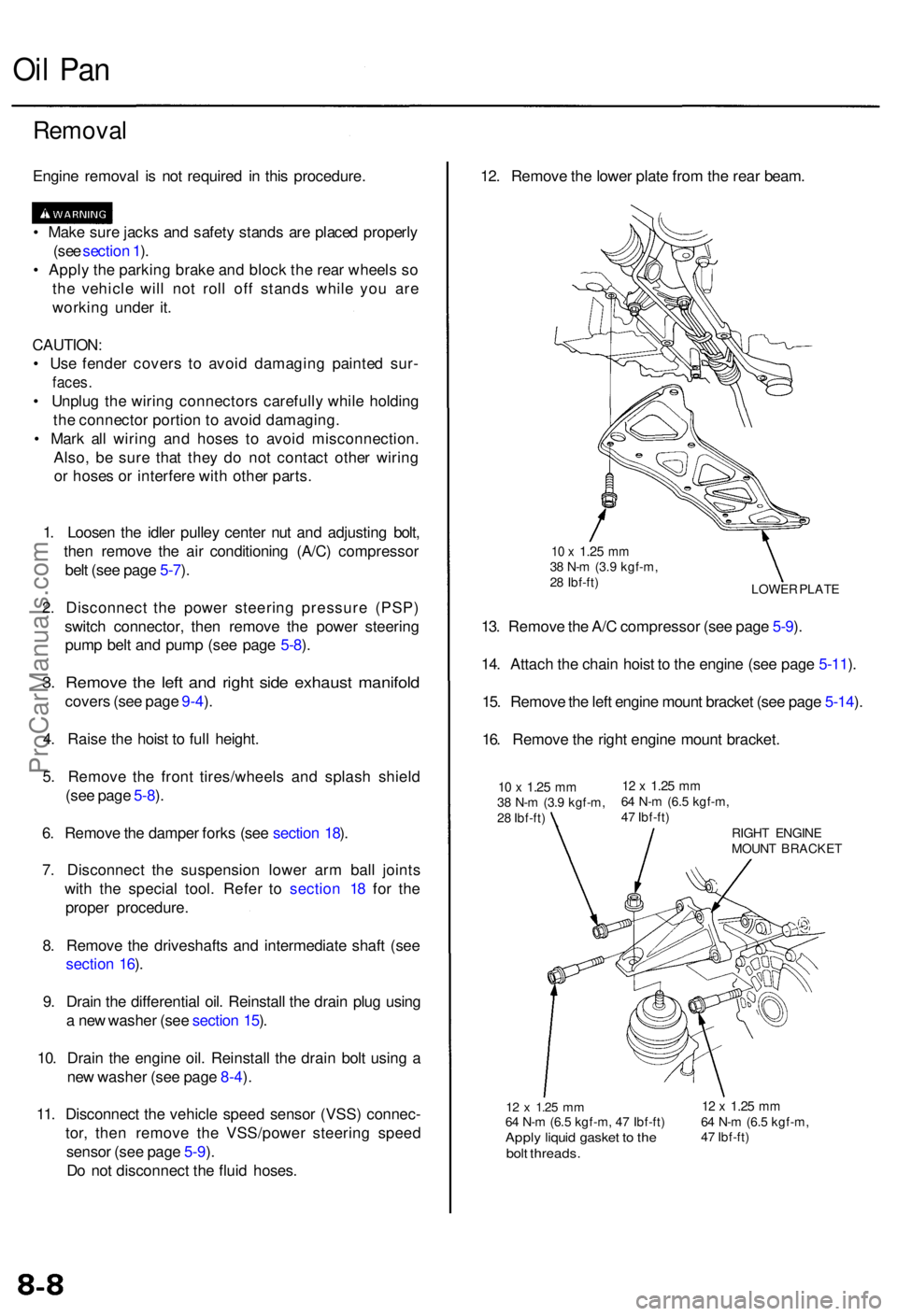

Oil Pa n

Remova l

Engine remova l i s no t require d i n thi s procedure .

• Mak e sur e jack s an d safet y stand s ar e place d properl y

(se e sectio n 1 ).

• Appl y th e parkin g brak e an d bloc k th e rea r wheel s s o

th e vehicl e wil l no t rol l of f stand s whil e yo u ar e

workin g unde r it .

CAUTION :

• Us e fende r cover s t o avoi d damagin g painte d sur -

faces .

• Unplu g th e wirin g connector s carefull y whil e holdin g

th e connecto r portio n to avoi d damaging .

• Mar k al l wirin g an d hose s t o avoi d misconnection .

Also , b e sur e tha t the y d o no t contac t othe r wirin g

o r hose s o r interfer e wit h othe r parts .

1 . Loose n th e idle r pulle y cente r nu t an d adjustin g bolt ,

the n remov e th e ai r conditionin g (A/C ) compresso r

bel t (se e pag e 5-7 ).

2 . Disconnec t th e powe r steerin g pressur e (PSP )

switc h connector , the n remov e th e powe r steerin g

pum p bel t an d pum p (se e pag e 5-8 ).

3 . Remov e th e lef t an d righ t sid e exhaus t manifol d

covers (se e pag e 9-4 ).

4 . Rais e th e hois t t o ful l height .

5 . Remov e th e fron t tires/wheel s an d splas h shiel d

(se e pag e 5-8 ).

6 . Remov e th e dampe r fork s (se e sectio n 18 ).

7 . Disconnec t th e suspensio n lowe r ar m bal l joint s

with the specia l tool . Refe r t o sectio n 1 8 fo r th e

prope r procedure .

8 . Remov e th e driveshaft s an d intermediat e shaf t (se e

sectio n 16 ).

9 . Drai n th e differentia l oil . Reinstal l th e drai n plu g usin g

a ne w washe r (se e sectio n 15 ).

10 . Drai n th e engin e oil . Reinstal l th e drai n bol t usin g a

ne w washe r (se e pag e 8-4 ).

11 . Disconnec t th e vehicl e spee d senso r (VSS ) connec -

tor , the n remov e th e VSS/powe r steerin g spee d

senso r (se e pag e 5-9 ).

D o no t disconnec t th e flui d hoses .

12 x 1.2 5 mm64 N- m (6. 5 kgf-m , 4 7 Ibf-ft )Apply liqui d gaske t t o th ebol t threads .

12 x 1.2 5 mm64 N- m (6. 5 kgf-m ,

4 7 Ibf-ft )

12. Remov e th e lowe r plat e fro m th e rea r beam .

LOWE R PLAT E

10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,

2 8 Ibf-ft )

13. Remov e th e A/ C compresso r (se e pag e 5-9 ).

14 . Attac h th e chai n hois t t o th e engin e (se e pag e 5-11 ).

15 . Remov e th e lef t engin e moun t bracke t (se e pag e 5-14 ).

16 . Remov e th e righ t engin e moun t bracket .

10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,

2 8 Ibf-ft )12 x 1.2 5 mm64 N- m (6. 5 kgf-m ,

4 7 Ibf-ft )

RIGHT ENGIN E

MOUN T BRACKE T

ProCarManuals.com