ACURA RL KA9 1996 Service Repair Manual

Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 621 of 1954

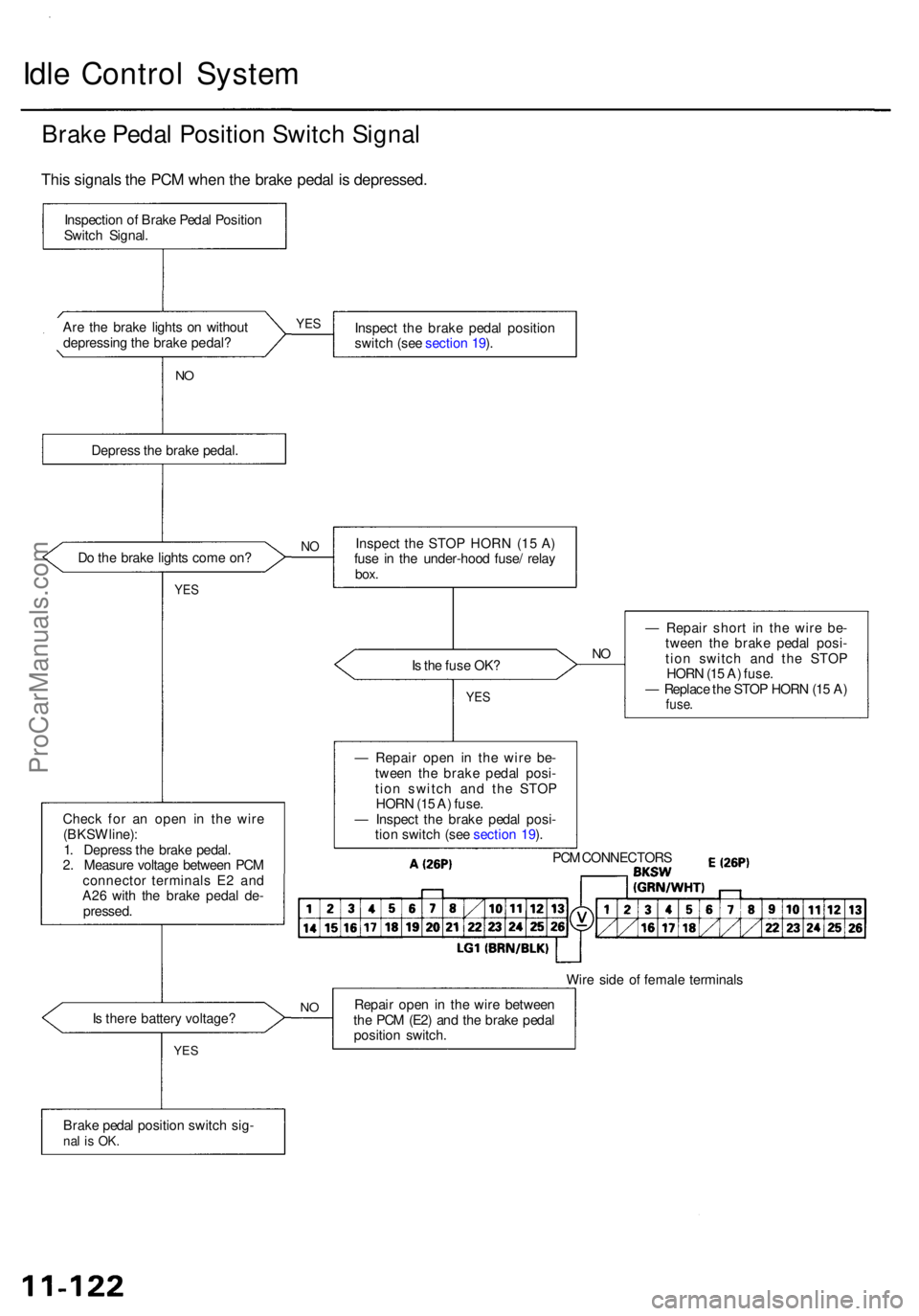

Idle Contro l Syste m

Brake Peda l Positio n Switc h Signa l

Are th e brak e light s o n withou t

depressin g th e brak e pedal ? Inspec

t th e brak e peda l positio n

switc h (se e sectio n 19 ).

N O

Depres s th e brak e pedal .

D o th e brak e light s com e on ?

YES

Is th e fus e OK ?NO

Chec k fo r a n ope n i n th e wir e

(BKS W line) :

1 . Depres s th e brak e pedal .

2 . Measur e voltag e betwee n PC M

connecto r terminal s E 2 an d

A2 6 wit h th e brak e peda l de -

pressed . —

Repai r shor t i n th e wire be-

twee n th e brak e peda l posi -

tio n switc h an d th e STO P

HOR N (1 5 A ) fuse .

— Replac e th e STO P HOR N (1 5 A )

fuse .

Wire sid e o f femal e terminal s

I s ther e batter y voltage ? Repai

r ope n in th e wir e betwee n

th e PC M (E2 ) an d th e brak e peda l

positio n switch .

Brak e peda l positio n switc h sig -

nal i s OK .

YES

NO

— Repai r ope n i n th e wir e be -

twee n th e brak e peda l posi -

tio n switc h an d th e STO P

HOR N (1 5 A ) fuse .

— Inspec t th e brak e peda l posi -

tio n switc h (se e sectio n 19 ).

PC M CONNECTOR S

YES

NOInspec t th e STO P HOR N (1 5 A )

fus e i n th e under-hoo d fuse / rela y

box.

YES

Inspectio n o f Brak e Peda l Positio n

Switc h Signal .

This signal s th e PC M whe n th e brak e peda l i s depressed .

ProCarManuals.com

Page 622 of 1954

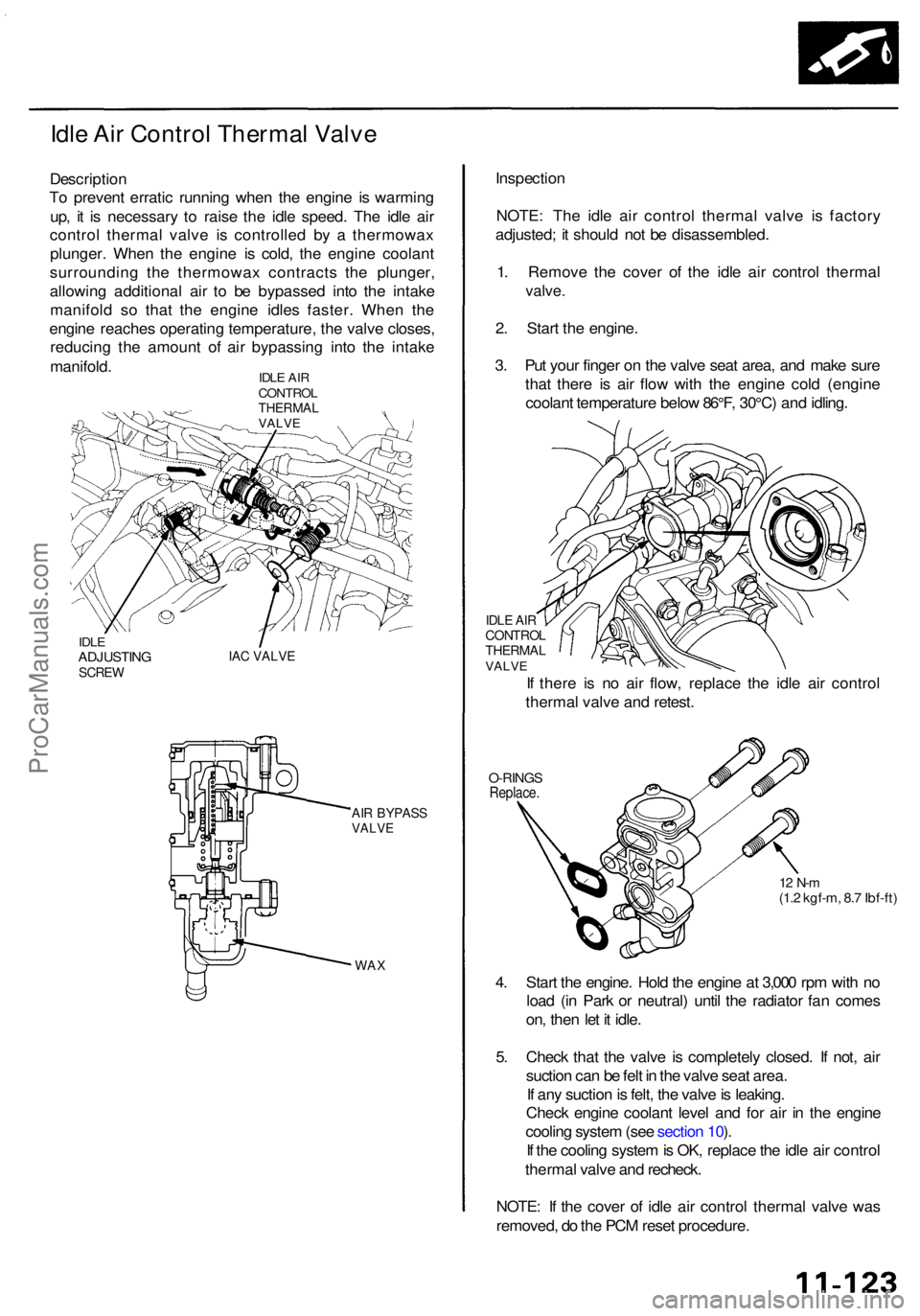

Idle Ai r Contro l Therma l Valv e

Descriptio n

T o preven t errati c runnin g whe n th e engin e i s warmin g

up , i t i s necessar y t o rais e th e idl e speed . Th e idl e ai r

contro l therma l valv e i s controlle d b y a thermowa x

plunger . Whe n th e engin e i s cold , th e engin e coolan t

surroundin g th e thermowa x contract s th e plunger ,

allowin g additiona l ai r t o b e bypasse d int o th e intak e

manifol d s o tha t th e engin e idle s faster . Whe n th e

engin e reache s operatin g temperature , th e valv e closes ,

reducin g th e amoun t o f ai r bypassin g int o th e intak e

manifold .

IDLE AI R

CONTRO L

THERMA LVALVE

IDLEADJUSTIN GSCREWIAC VALV E

AIR BYPAS SVALVE

WAX

Inspectio n

NOTE : Th e idl e ai r contro l therma l valv e i s factor y

adjusted ; i t shoul d no t b e disassembled .

1 . Remov e th e cove r o f th e idl e ai r contro l therma l

valve.

2. Star t th e engine .

3 . Pu t you r finge r o n th e valv e sea t area , an d mak e sur e

tha t ther e i s ai r flo w wit h th e engin e col d (engin e

coolan t temperatur e belo w 86°F , 30°C ) an d idling .

O-RING SReplace .

12 N- m(1.2 kgf-m , 8. 7 Ibf-ft )

4. Star t th e engine . Hol d th e engin e a t 3,00 0 rp m wit h n o

loa d (i n Par k o r neutral ) unti l th e radiato r fa n come s

on , the n le t i t idle .

5 . Chec k tha t th e valv e i s completel y closed . I f not , ai r

suctio n ca n b e fel t i n th e valv e sea t area .

I f an y suctio n is felt , th e valv e is leaking .

Chec k engin e coolan t leve l an d fo r ai r i n th e engin e

coolin g syste m (se e sectio n 10 ).

I f th e coolin g syste m is OK , replac e th e idl e ai r contro l

therma l valv e an d recheck .

NOTE : I f th e cove r o f idl e ai r contro l therma l valv e wa s

removed , d o th e PC M rese t procedure .

IDLE AI RCONTRO LTHERMALVALVE

If ther e i s n o ai r flow , replac e th e idl e ai r contro l

therma l valv e an d retest .

ProCarManuals.com

Page 623 of 1954

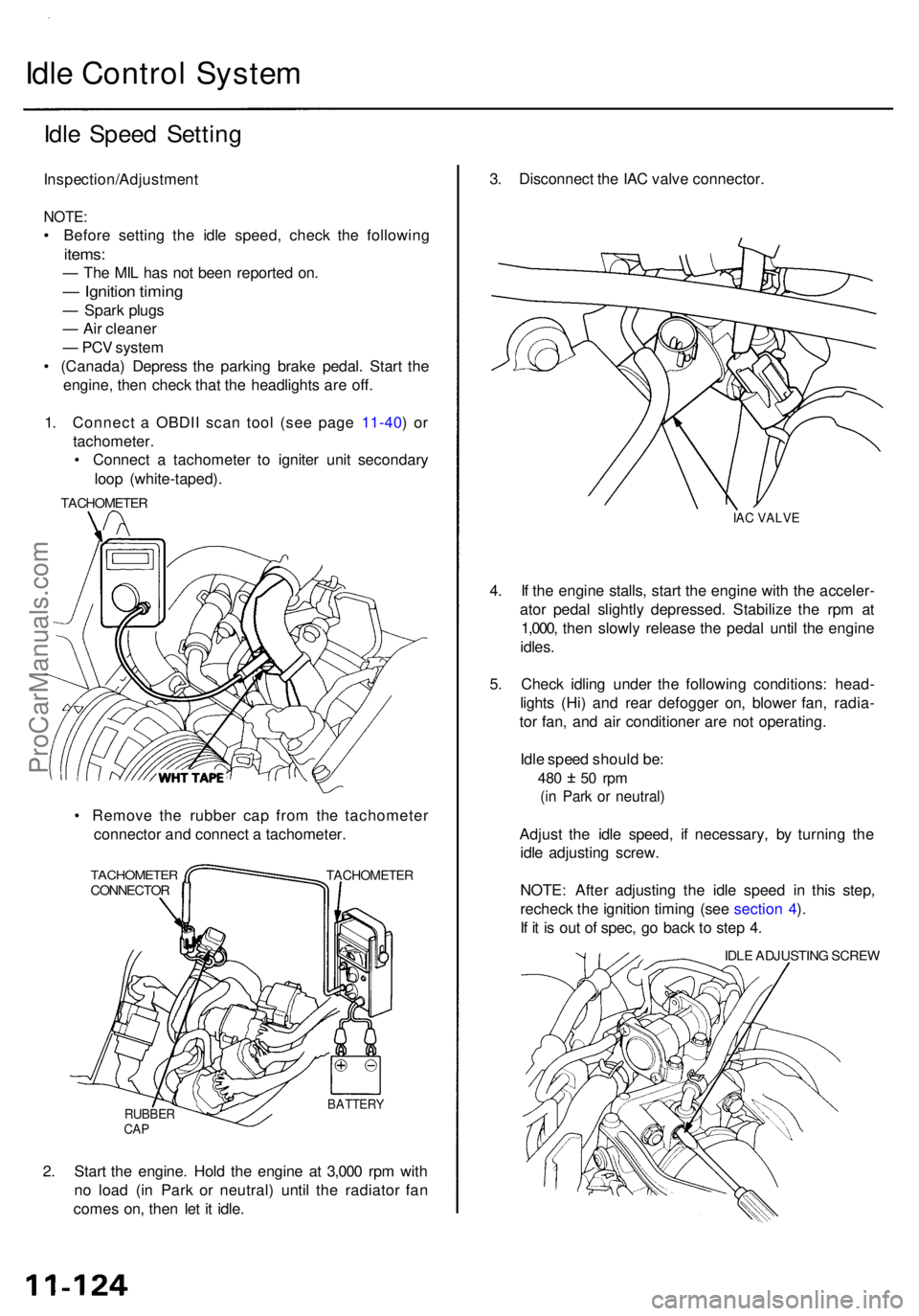

Idle Contro l Syste m

Idle Spee d Settin g

Inspection/Adjustmen t

NOTE:

• Befor e settin g th e idl e speed , chec k th e followin g

items:

— Th e MI L ha s no t bee n reporte d on .

— Ignitio n timin g

— Spar k plug s

— Ai r cleane r

— PC V syste m

• (Canada ) Depres s th e parkin g brak e pedal . Star t th e

engine , the n chec k tha t th e headlight s ar e off .

1 . Connec t a OBDI I sca n too l (se e pag e 11-40 ) o r

tachometer .

• Connec t a tachomete r t o ignite r uni t secondar y

loo p (white-taped) .

• Remov e th e rubbe r ca p fro m th e tachomete r

connecto r an d connec t a tachometer .

TACHOMETE RCONNECTORTACHOMETE R

RUBBERCAP

BATTER Y

2. Star t th e engine . Hol d th e engin e a t 3,00 0 rp m wit h

n o loa d (i n Par k o r neutral ) unti l th e radiato r fa n

come s on , the n le t i t idle . 3

. Disconnec t th e IA C valv e connector .

IAC VALV E

4. I f th e engin e stalls , star t th e engin e wit h th e acceler -

ato r peda l slightl y depressed . Stabiliz e th e rp m a t

1,000 , the n slowl y releas e th e peda l unti l th e engin e

idles .

5 . Chec k idlin g unde r th e followin g conditions : head -

light s (Hi ) an d rea r defogge r on , blowe r fan , radia -

to r fan , an d ai r conditione r ar e no t operating .

Idl e spee d shoul d be :

480 5 0 rp m

(in Par k o r neutral )

Adjust th e idl e speed , i f necessary , b y turnin g th e

idl e adjustin g screw .

NOTE : Afte r adjustin g th e idl e spee d i n thi s step ,

rechec k th e ignitio n timin g (se e sectio n 4 ).

I f i t i s ou t o f spec , g o bac k t o ste p 4 .

IDL E ADJUSTIN G SCRE W

TACHOMETE

R

ProCarManuals.com

Page 624 of 1954

6. Tur n th e ignitio n switc h OFF .

7. Reconnec t th e 2 P connecto r o n th e IA C valve , the n

d o th e PC M rese t procedure .

NOTE : Th e PC M memor y settin g i s neede d afte r

resettin g th e PCM .

8 . Restar t an d idl e th e engin e wit h no-loa d condition s

fo r on e minute , the n chec k th e idl e speed .

NOTE : (Canada ) Pul l th e parkin g brak e leve r up .

Star t th e engine , the n chec k tha t th e headlight s ar e

off.

Idle spee d shoul d be :

650 5 0 rp m

(in Par k o r neutral )

NOTE: I f th e idl e spee d i s no t withi n specification ,

se e Sympto m Char t o n pag e 11-44 .

ProCarManuals.com

Page 625 of 1954

PCM Memory Setting

NOTE: The PCM reset procedure and disconnecting the

battery or the BACK UP RADIO (7.5 A) fuse cancels the

PCM memory for idle control. The following procedure

is needed after the PCM reset procedure and reconnect-

ing the battery or the BACK UP RADIO (7.5 A) fuse.

1. Start the engine. Hold the engine at 3,000 rpm with

no load (in Park or neutral) until the radiator fan

comes on.

2. Let the engine idle for approx. 5 minutes under the

following conditions:

• Transmission in Park or neutral

• A/C switch OFF

• Headlights OFF

• Rear defogger OFFProCarManuals.com

Page 626 of 1954

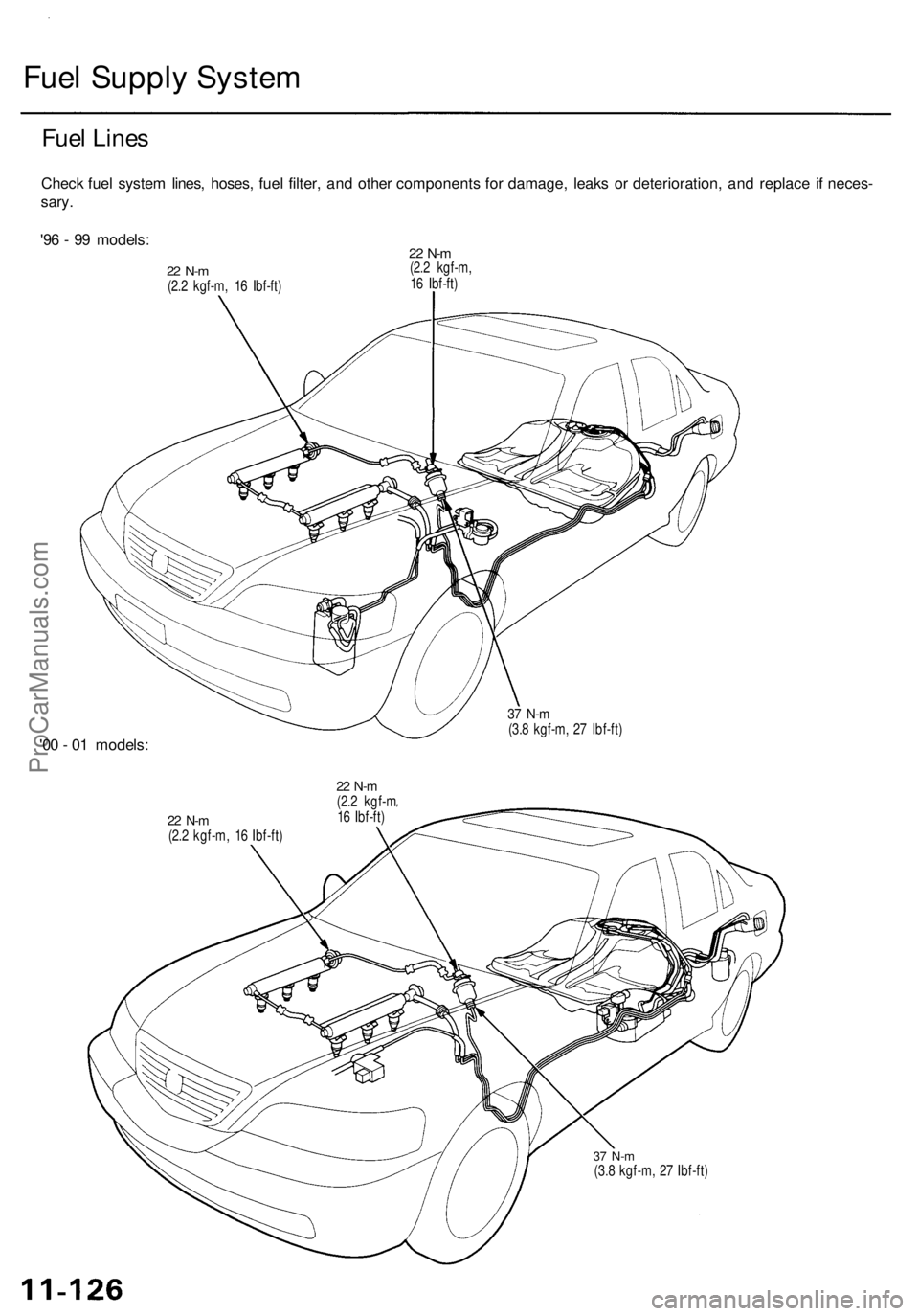

Fuel Supply System

Fuel Lines

Check fuel system lines, hoses, fuel filter, and other components for damage, leaks or deterioration, and replace if neces-

sary.

'96 - 99 models:

22 N-m

(2.2 kgf-m, 16 Ibf-ft)

22 N-m

(2.2 kgf-m,

16 Ibf-ft)

'00 - 01 models:

37 N-m

(3.8 kgf-m, 27 Ibf-ft)

22 N-m

(2.2 kgf-m, 16 Ibf-ft)

22 N-m

(2.2 kgf-m

16 Ibf-ft)

37 N-m

(3.8 kgf-m, 27 Ibf-ft)ProCarManuals.com

Page 627 of 1954

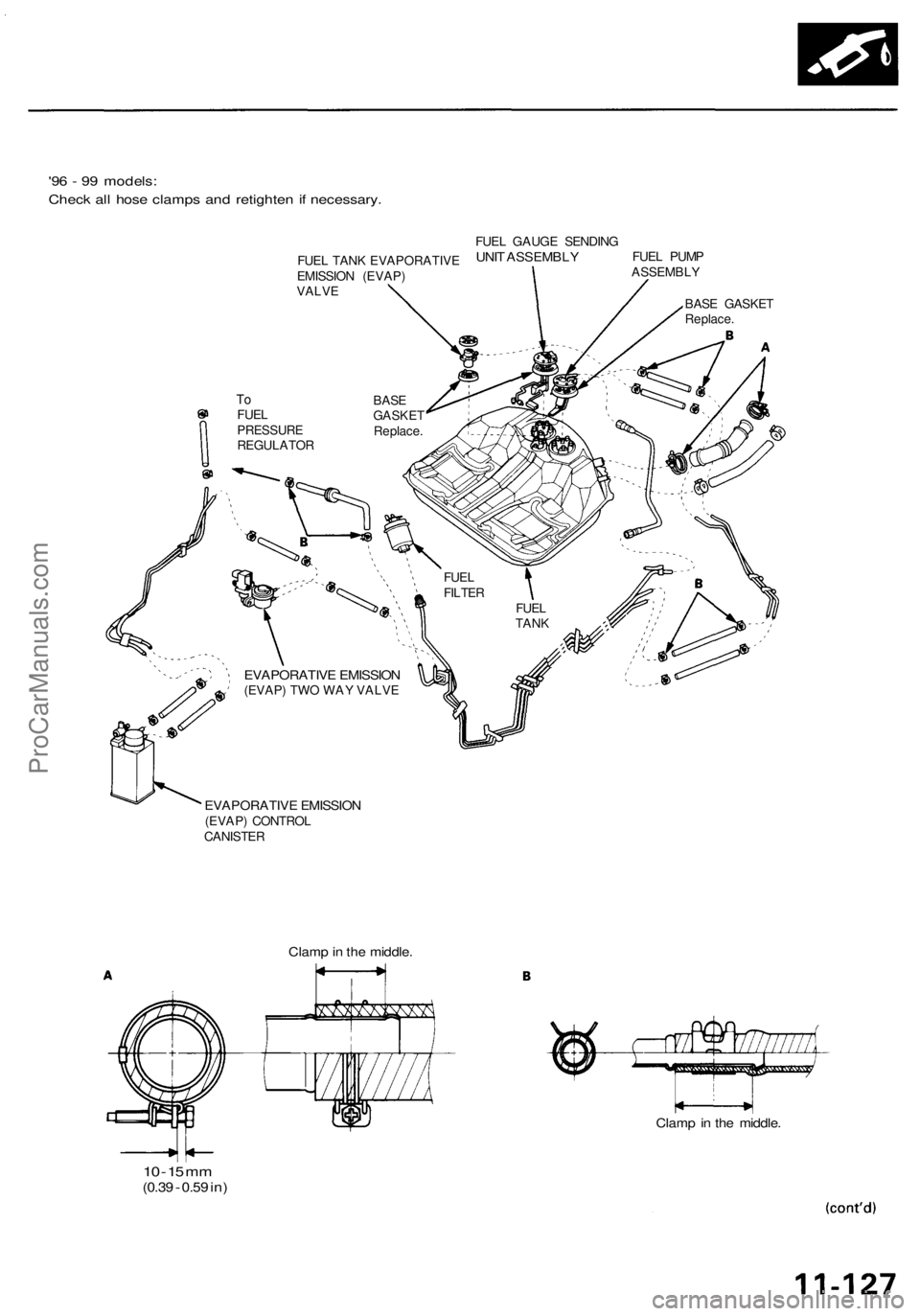

'96 - 99 models:

Check all hose clamps and retighten if necessary.

EVAPORATIVE EMISSION

(EVAP) TWO WAY VALVE

EVAPORATIVE EMISSION

(EVAP) CONTROL

CANISTER

10 -

15

mm

(0.39

-

0.59

in)

Clamp in the middle.

Clamp in the middle.

FUEL

TANK

FUEL

FILTER

To

FUEL

PRESSURE

REGULATOR

BASE

GASKET

Replace.

BASE GASKET

Replace.

FUEL PUMP

ASSEMBLY

FUEL GAUGE SENDING

UNIT ASSEMBLY

FUEL TANK EVAPORATIVE

EMISSION (EVAP)

VALVEProCarManuals.com

Page 628 of 1954

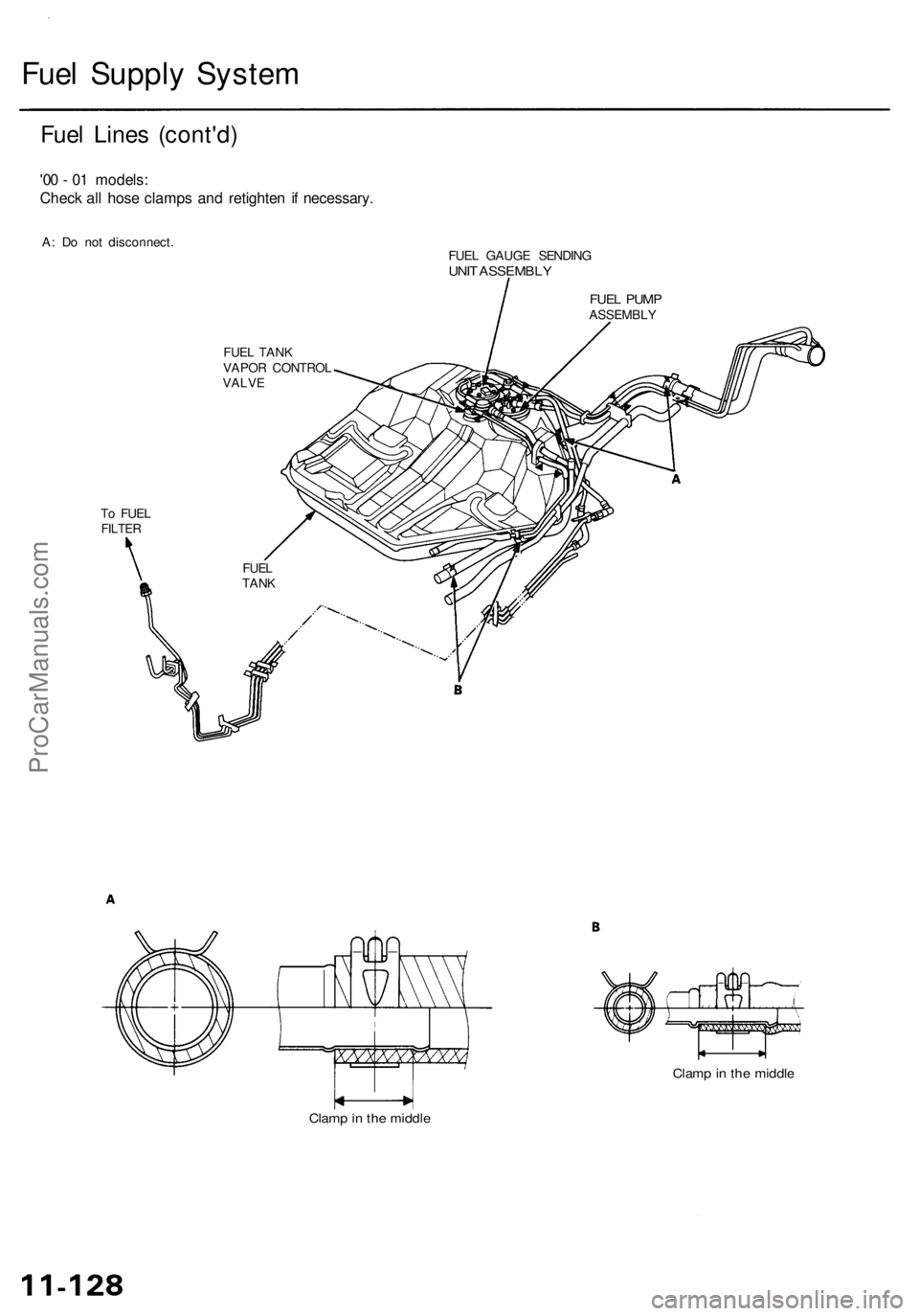

Fuel Supply System

Fuel Lines (cont'd)

'00 - 01 models:

Check all hose clamps and retighten if necessary.

A: Do not disconnect.

To FUEL

FILTER

FUEL TANK

VAPOR CONTROL

VALVE

FUEL GAUGE SENDING

UNIT ASSEMBLY

Clamp in the middle

Clamp in the middle

FUEL

TANK

FUEL PUMP

ASSEMBLYProCarManuals.com

Page 629 of 1954

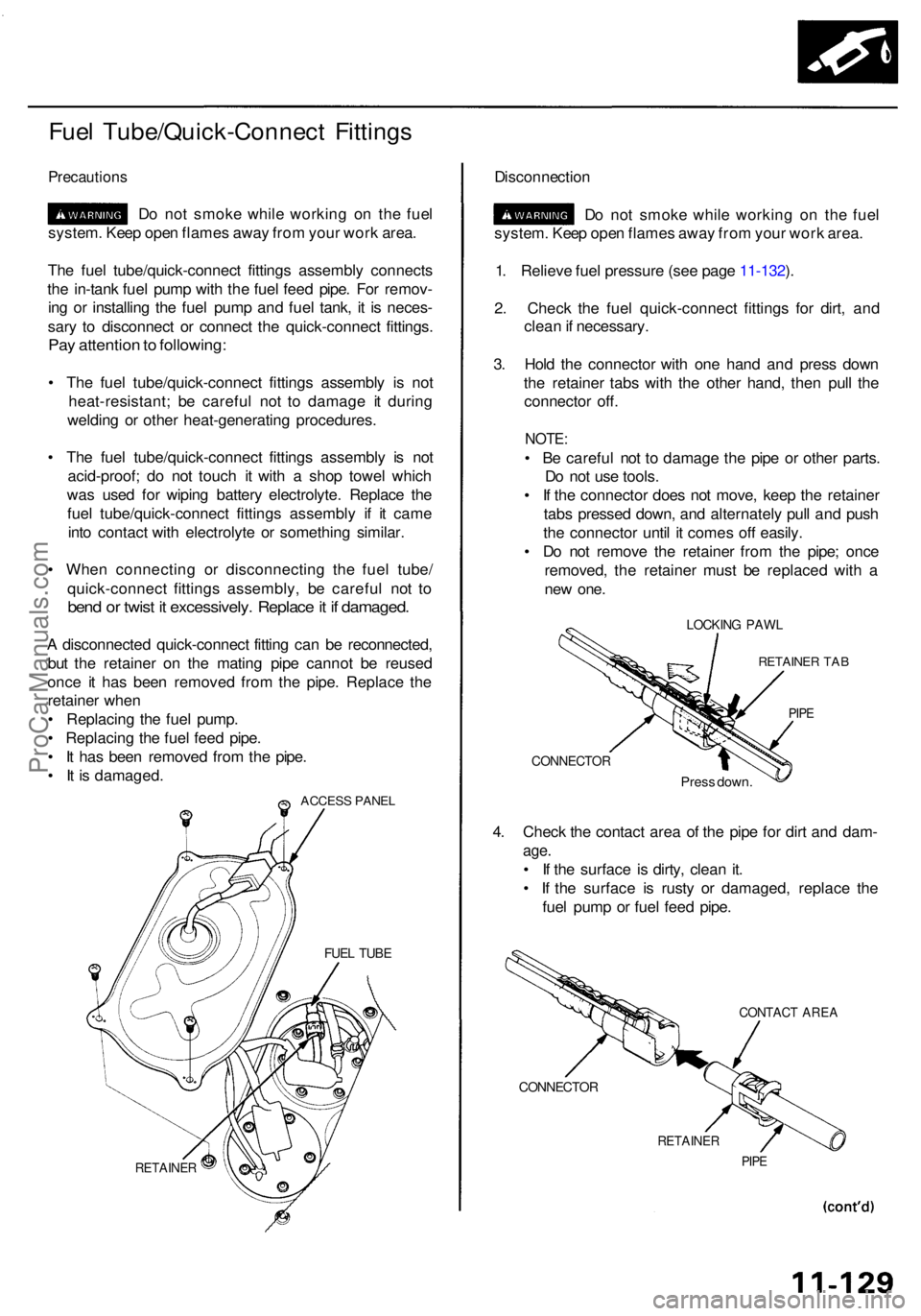

Fuel Tube/Quick-Connec t Fitting s

Precaution s

Do no t smok e whil e workin g o n th e fue l

system . Kee p ope n flame s awa y fro m you r wor k area .

Th e fue l tube/quick-connec t fitting s assembl y connect s

th e in-tan k fue l pum p wit h th e fue l fee d pipe . Fo r remov -

in g o r installin g th e fue l pum p an d fue l tank , i t i s neces -

sar y t o disconnec t o r connec t th e quick-connec t fittings .

Pay attentio n to following :

• Th e fue l tube/quick-connec t fitting s assembl y i s no t

heat-resistant ; b e carefu l no t t o damag e i t durin g

weldin g o r othe r heat-generatin g procedures .

• Th e fue l tube/quick-connec t fitting s assembl y i s no t

acid-proof ; d o no t touc h i t wit h a sho p towe l whic h

wa s use d fo r wipin g batter y electrolyte . Replac e th e

fue l tube/quick-connec t fitting s assembl y i f i t cam e

int o contac t wit h electrolyt e o r somethin g similar .

• Whe n connectin g o r disconnectin g th e fue l tube /

quick-connec t fitting s assembly , b e carefu l no t t o

ben d o r twis t i t excessively . Replac e it i f damaged .

A disconnecte d quick-connec t fittin g ca n b e reconnected ,

bu t th e retaine r o n th e matin g pip e canno t b e reuse d

onc e i t ha s bee n remove d fro m th e pipe . Replac e th e

retaine r whe n

• Replacin g th e fue l pump .

• Replacin g th e fue l fee d pipe .

• I t ha s bee n remove d fro m th e pipe .

• I t i s damaged .

ACCESS PANE L

RETAINE R

Disconnectio n

D o no t smok e whil e workin g o n th e fue l

system . Kee p ope n flame s awa y fro m you r wor k area .

1 . Reliev e fue l pressur e (se e pag e 11-132 ).

2 . Chec k th e fue l quick-connec t fitting s fo r dirt , an d

clea n if necessary .

3 . Hol d th e connecto r wit h on e han d an d pres s dow n

th e retaine r tab s wit h th e othe r hand , the n pul l th e

connecto r off .

NOTE :

• B e carefu l no t t o damag e th e pip e o r othe r parts .

D o no t us e tools .

• I f th e connecto r doe s no t move , kee p th e retaine r

tab s presse d down , an d alternatel y pul l an d pus h

th e connecto r unti l i t come s of f easily .

• D o no t remov e th e retaine r fro m th e pipe ; onc e

removed , th e retaine r mus t b e replace d wit h a

ne w one .

LOCKIN G PAW L

RETAINE R TA B

PIPE

CONNECTO R

Press down .

4. Chec k th e contac t are a o f th e pip e fo r dir t an d dam -

age.

• I f th e surfac e i s dirty , clea n it .

• I f th e surfac e i s rust y o r damaged , replac e th e

fue l pum p o r fue l fee d pipe .

CONTAC T ARE A

CONNECTO R

RETAINER

PIPE

FUE L TUB E

ProCarManuals.com

Page 630 of 1954

Fuel Supply System

Fuel Tube/Quick-Connect Fittings (cont'd)

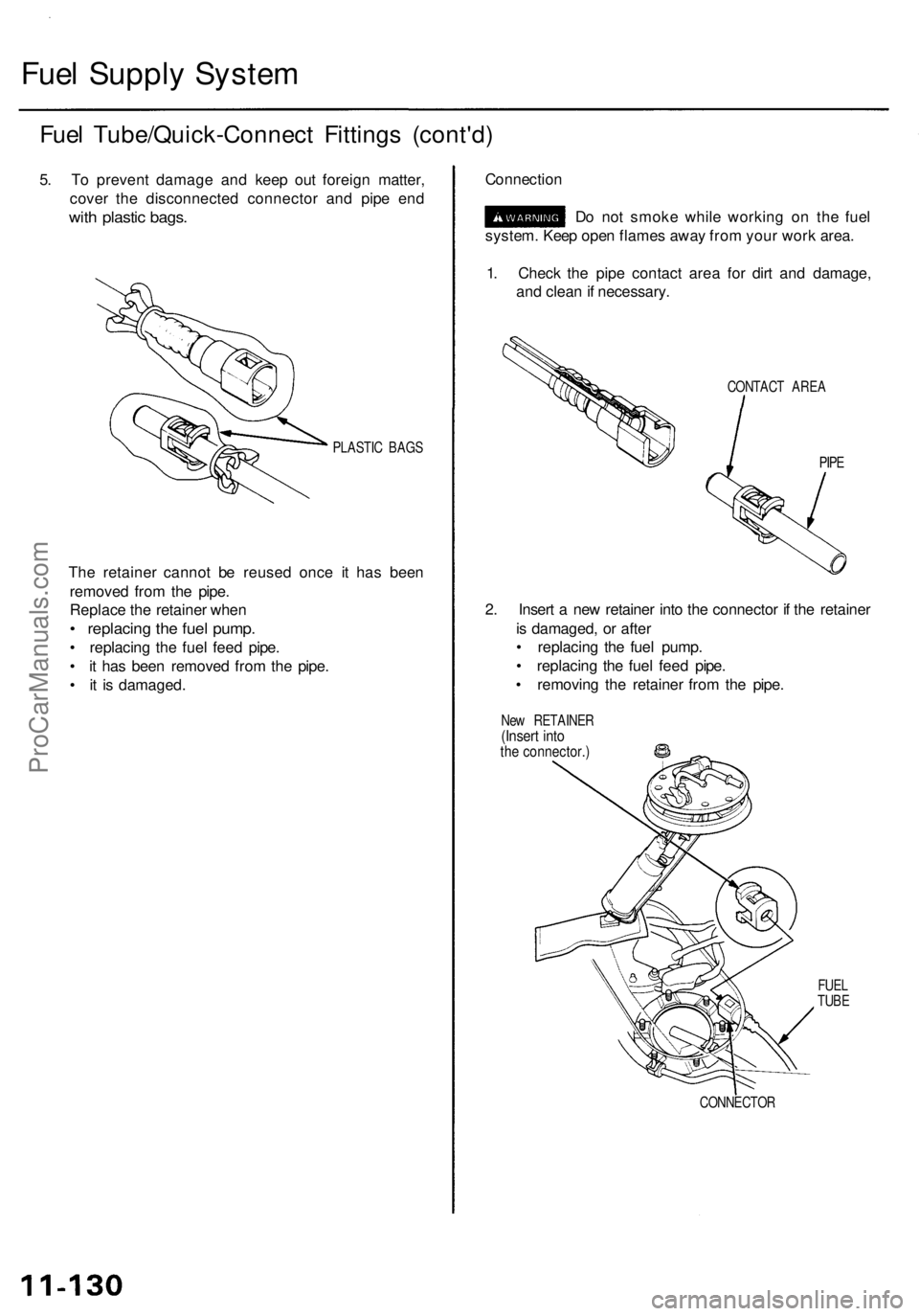

5. To prevent damage and keep out foreign matter,

cover the disconnected connector and pipe end

with plastic bags.

PLASTIC BAGS

The retainer cannot be reused once it has been

removed from the pipe.

Replace the retainer when

• replacing the fuel pump.

• replacing the fuel feed pipe.

• it has been removed from the pipe.

• it is damaged.

Connection

Do not smoke while working on the fuel

system. Keep open flames away from your work area.

1. Check the pipe contact area for dirt and damage,

and clean if necessary.

CONTACT AREA

PIPE

2. Insert a new retainer into the connector if the retainer

is damaged, or after

• replacing the fuel pump.

• replacing the fuel feed pipe.

• removing the retainer from the pipe.

New RETAINER

(Insert into

the connector.)

CONNECTOR

FUEL

TUBEProCarManuals.com