ACURA RL KA9 1996 Service Repair Manual

Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 651 of 1954

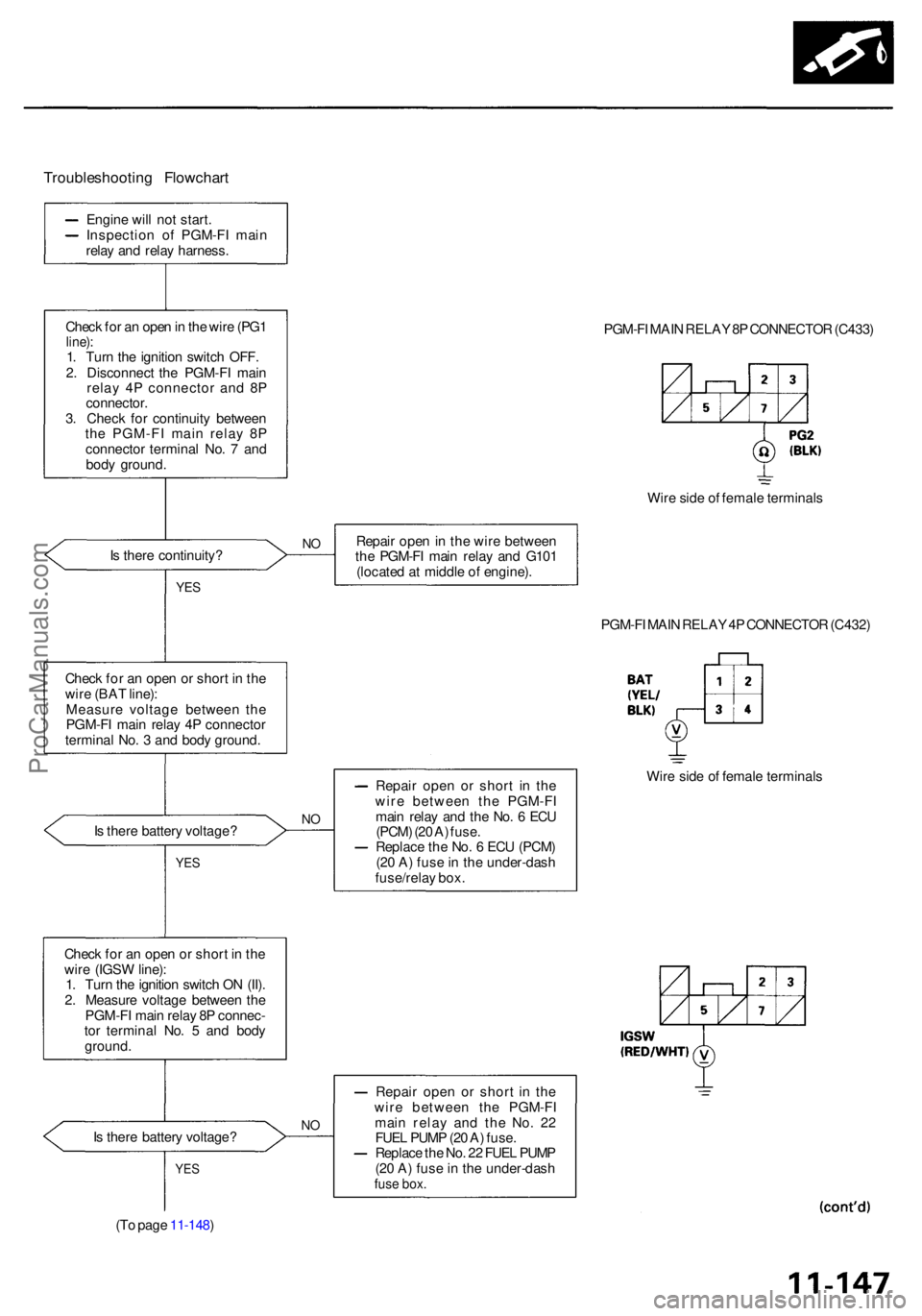

Troubleshooting Flowchar t

Check fo r a n ope n o r shor t i n th e

wir e (BA T line) :

Measur e voltag e betwee n th e

PGM-F I mai n rela y 4 P connecto r

termina l No . 3 an d bod y ground .

I s ther e batter y voltage ?

YES

Chec k fo r a n ope n o r shor t i n th e

wir e (IGS W line) :

1 . Tur n th e ignitio n switc h O N (II) .

2 . Measur e voltag e betwee n th e

PGM-F I mai n rela y 8 P connec -

to r termina l No . 5 an d bod y

ground .

I s ther e batter y voltage ?

YES

(To pag e 11-148 ) PGM-F

I MAI N RELA Y 8P CONNECTO R (C433 )

Wir e sid e o f femal e terminal s

NORepai r ope n in th e wir e betwee n

th e PGM-F I mai n rela y an d G10 1

(locate d a t middl e o f engine) .

NO

Repai r ope n o r shor t i n th e

wir e betwee n th e PGM-F I

mai n rela y an d th e No . 6 EC U

(PCM ) (2 0 A ) fuse .

Replac e th e No . 6 EC U (PCM )

(2 0 A ) fus e in th e under-das h

fuse/rela y box . PGM-F

I MAI N RELA Y 4P CONNECTO R (C432 )

Wir e sid e o f femal e terminal s

NO

Repai r ope n o r shor t i n th e

wir e betwee n th e PGM-F I

mai n rela y an d th e No . 2 2

FUE L PUM P (2 0 A ) fuse .

Replac e th e No . 2 2 FUE L PUM P

(2 0 A ) fus e in th e under-das h

fuse box .

YES

Is ther e continuity ?

Engin

e wil l no t start .

Inspectio n o f PGM-F I mai n

rela y an d rela y harness .

Chec k fo r a n ope n in th e wir e (PG 1

line) :1. Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e PGM-F I mai n

rela y 4 P connecto r an d 8 P

connector .

3 . Chec k fo r continuit y betwee n

th e PGM-F I mai n rela y 8 P

connecto r termina l No . 7 an d

bod y ground .

ProCarManuals.com

Page 652 of 1954

Fuel Suppl y Syste m

PGM-F I Mai n Rela y (cont'd )

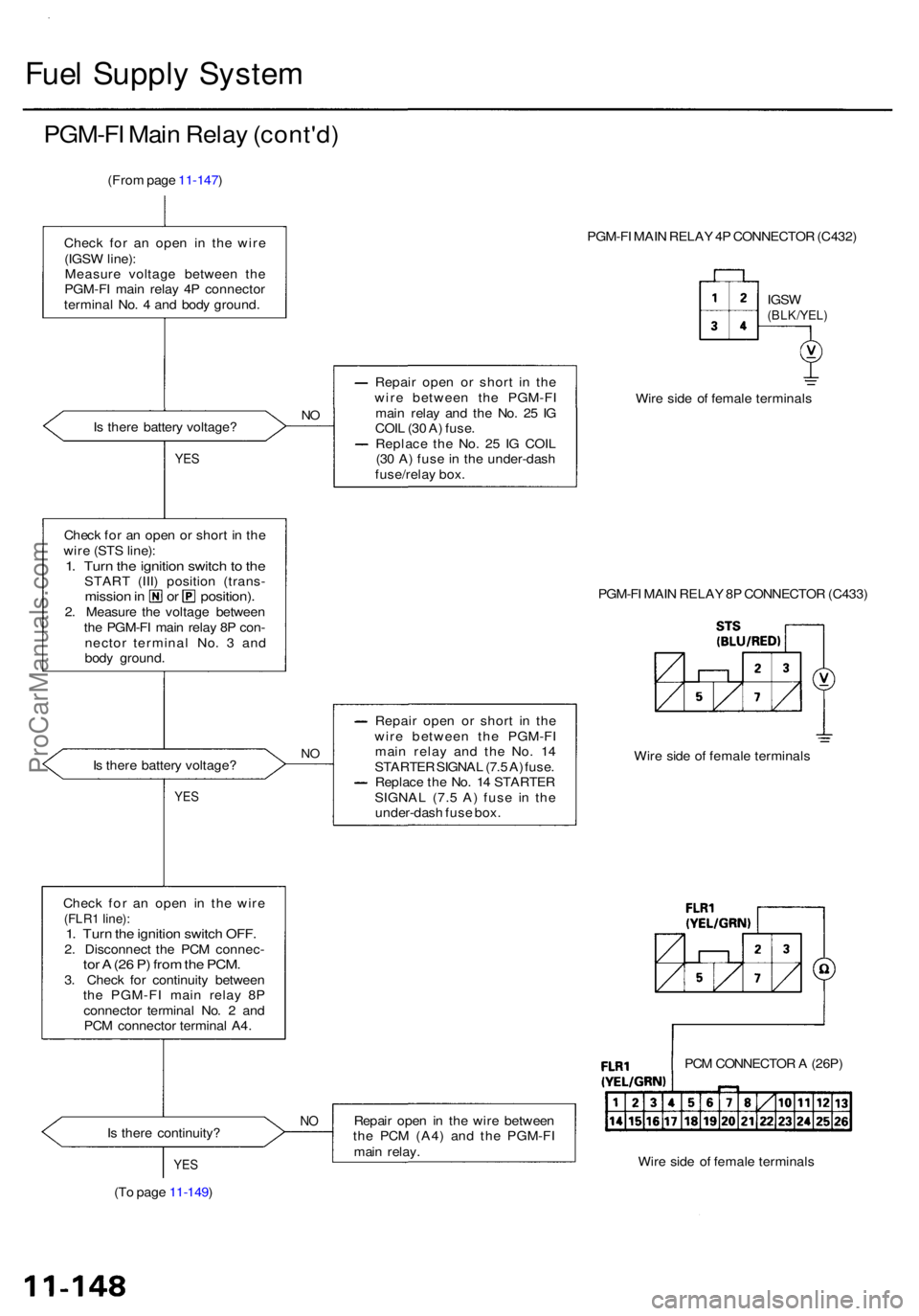

(From pag e 11-147 )

Chec k fo r a n ope n i n th e wir e

(IGS W line) :

Measur e voltag e betwee n th e

PGM-F I mai n rela y 4 P connecto r

termina l No . 4 an d bod y ground .

I s ther e batter y voltage ?

YES

Chec k fo r a n ope n o r shor t i n th e

wir e (ST S line) :

1. Tur n th e ignitio n switc h to th eSTAR T (III ) positio n (trans -mission in o r position) .2. Measur e th e voltag e betwee n

th e PGM-F I mai n rela y 8 P con -

necto r termina l No . 3 an d

bod y ground .

I s ther e batter y voltage ?

YES

Chec k fo r a n ope n i n th e wir e(FLR 1 line) :1. Tur n th e ignitio n switc h OFF .2. Disconnec t th e PC M connec -tor A (2 6 P ) fro m th e PCM .3. Chec k fo r continuit y betwee n

th e PGM-F I mai n rela y 8 P

connecto r termina l No . 2 an d

PC M connecto r termina l A4 . PGM-F

I MAI N RELA Y 4P CONNECTO R (C432 )

IGSW(BLK/YEL )

NO

Repai r ope n o r shor t i n th e

wir e betwee n th e PGM-F I

mai n rela y an d th e No . 2 5 I G

COI L (3 0 A ) fuse .

Replac e th e No . 2 5 I G COI L

(3 0 A ) fus e in th e under-das h

fuse/rela y box . Wir

e sid e o f femal e terminal s

PGM-F I MAI N RELA Y 8 P CONNECTO R (C433 )

NO

Repai r ope n o r shor t i n th e

wir e betwee n th e PGM-F I

mai n rela y an d th e No . 1 4

STARTE R SIGNA L (7. 5 A ) fuse .

Replac e th e No . 1 4 STARTE R

SIGNA L (7. 5 A ) fus e i n the

under-das h fus e box . Wir

e sid e o f femal e terminal s

I s ther e continuity ? Repai

r ope n in th e wir e betwee n

the PC M (A4 ) an d the PGM-F I

mai n relay . PC

M CONNECTO R A (26P )

Wir e sid e o f femal e terminal s

(T o pag e 11-149 )

YES

NO

ProCarManuals.com

Page 653 of 1954

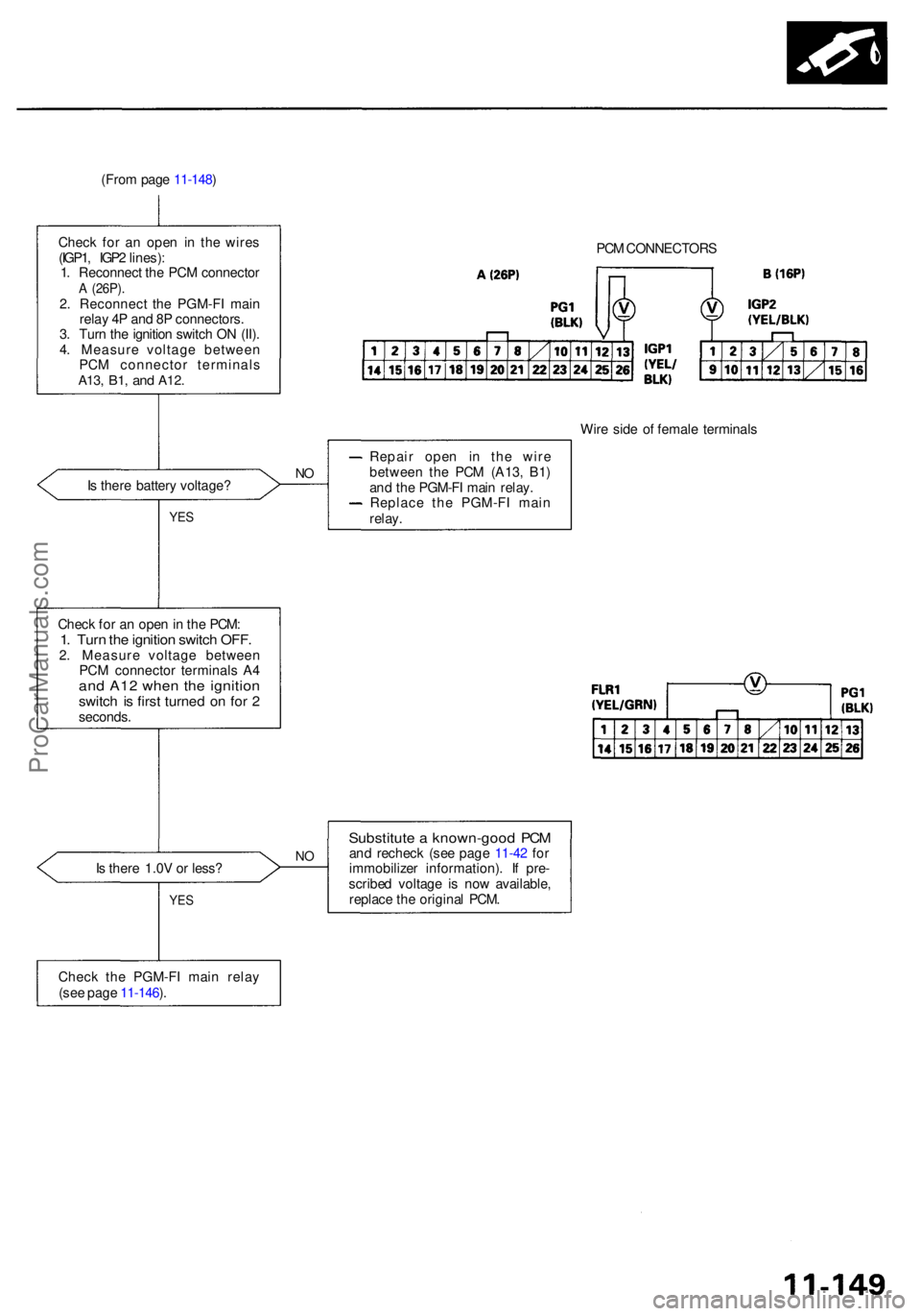

(From pag e 11-148 )

Chec k fo r a n ope n i n th e wire s

(IGP1 , IGP 2 lines) :

1 . Reconnec t th e PC M connecto r

A (26P) .2. Reconnec t th e PGM-F I mai n

rela y 4 P an d 8 P connectors .

3 . Tur n th e ignitio n switc h O N (II) .

4 . Measur e voltag e betwee n

PC M connecto r terminal s

A13, B1, an d A12 .

PCM CONNECTOR S

Wir e sid e o f femal e terminal s

I s ther e batter y voltage ?

YES

Repai r ope n i n th e wir e

betwee n th e PC M (A13 , B1 )

an d th e PGM-F I mai n relay .

Replac e th e PGM-F I mai n

relay .

Chec k fo r a n ope n in th e PCM :

1. Tur n th e ignitio n switc h OFF .2. Measur e voltag e betwee n

PC M connecto r terminal s A 4

an d A1 2 whe n th e ignitio nswitch i s firs t turne d o n fo r 2seconds .

I s ther e 1.0 V o r less ?

YES

Substitut e a known-goo d PC Mand rechec k (se e pag e 11-42 fo r

immobilize r information) . I f pre -

scribe d voltag e i s no w available ,

replac e th e origina l PCM .

Chec k th e PGM-F I mai n rela y

(se e pag e 11-146 ).N O

NO

ProCarManuals.com

Page 654 of 1954

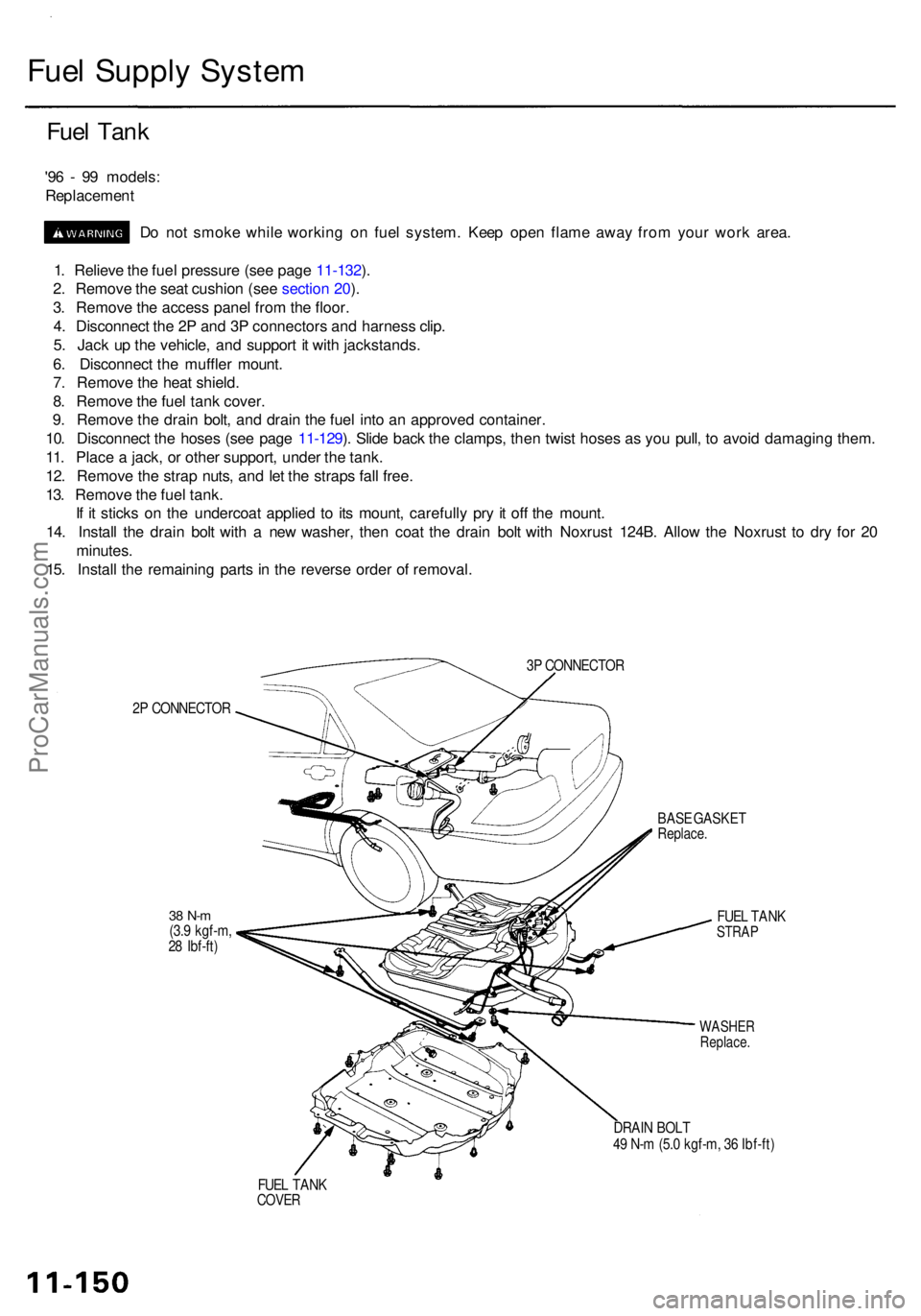

Fuel Suppl y Syste m

Fuel Tan k

'96 - 9 9 models :

Replacemen t

D o no t smok e whil e workin g o n fue l system . Kee p ope n flam e awa y fro m you r wor k area .

1 . Reliev e th e fue l pressur e (se e pag e 11-132 ).

2 . Remov e th e sea t cushio n (se e sectio n 20 ).

3 . Remov e th e acces s pane l fro m th e floor .

4 . Disconnec t th e 2 P an d 3 P connector s an d harnes s clip .

5 . Jac k u p th e vehicle , an d suppor t i t wit h jackstands .

6 . Disconnec t th e muffle r mount .

7 . Remov e th e hea t shield .

8 . Remov e th e fue l tan k cover .

9 . Remov e th e drai n bolt , an d drai n th e fue l int o a n approve d container .

10 . Disconnec t th e hose s (se e pag e 11-129 ). Slid e bac k th e clamps , the n twis t hose s a s yo u pull , t o avoi d damagin g them .

11 . Plac e a jack , o r othe r support , unde r th e tank .

12 . Remov e th e stra p nuts , an d le t th e strap s fal l free .

13 . Remov e th e fue l tank .

I f i t stick s o n th e undercoa t applie d t o it s mount , carefull y pr y i t of f th e mount .

14 . Instal l th e drai n bol t wit h a ne w washer , the n coa t th e drai n bol t wit h Noxrus t 124B . Allo w th e Noxrus t t o dr y fo r 2 0

minutes .

15 . Instal l th e remainin g part s i n th e revers e orde r o f removal .

3P CONNECTO R

2 P CONNECTO R

BASE GASKE T

Replace .

38 N- m(3.9 kgf-m ,

2 8 Ibf-ft ) FUE

L TAN KSTRA P

WASHE RReplace .

DRAIN BOL T

4 9 N- m (5. 0 kgf-m , 3 6 Ibf-ft )

FUE L TAN K

COVE R

ProCarManuals.com

Page 655 of 1954

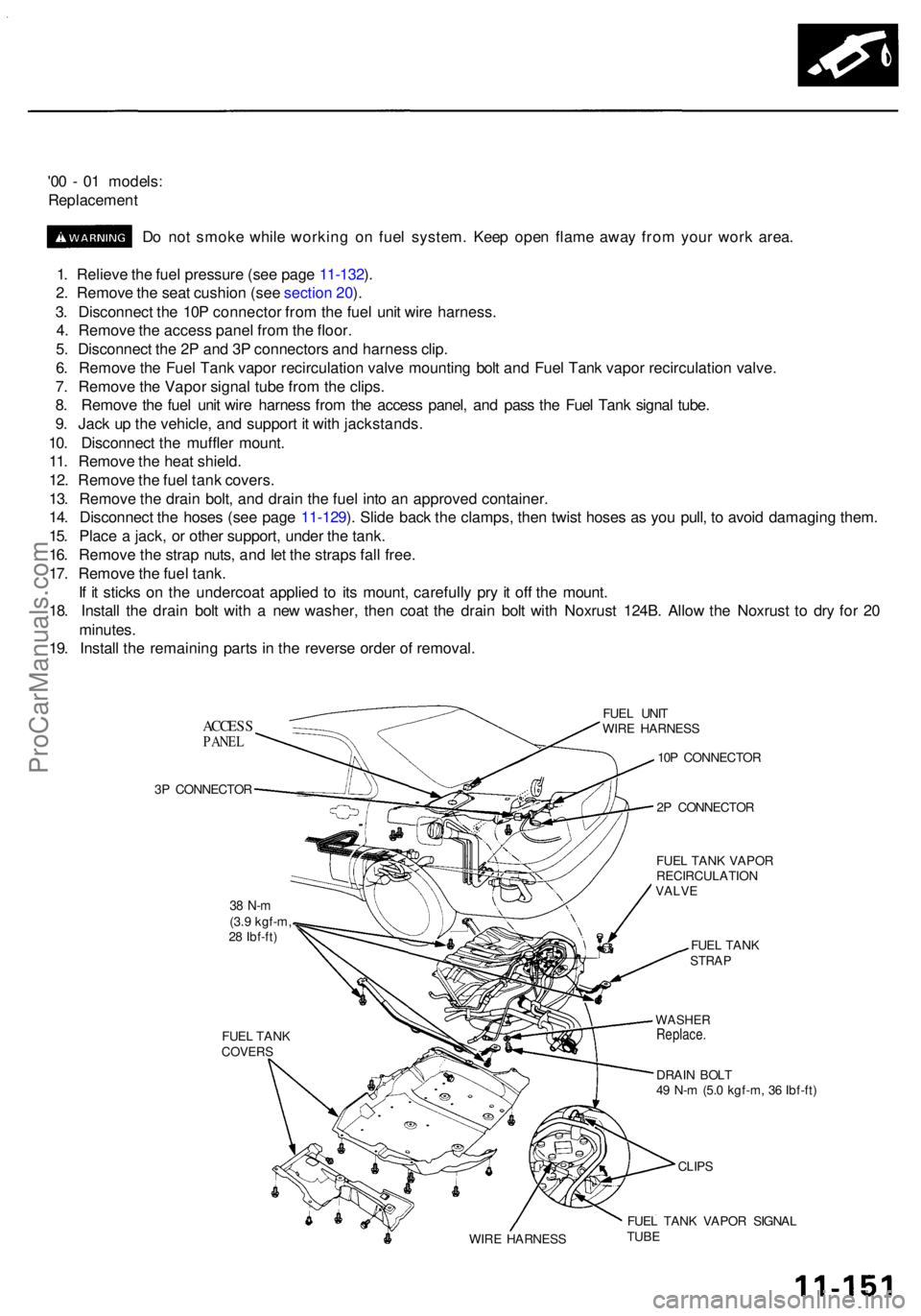

'00 - 0 1 models :

Replacemen t

D o no t smok e whil e workin g o n fue l system . Kee p ope n flam e awa y fro m you r wor k area .

1 . Reliev e th e fue l pressur e (se e pag e 11-132 ).

2 . Remov e th e sea t cushio n (se e sectio n 20 ).

3 . Disconnec t th e 10 P connecto r fro m th e fue l uni t wir e harness .

4 . Remov e th e acces s pane l fro m th e floor .

5 . Disconnec t th e 2 P an d 3 P connector s an d harnes s clip .

6 . Remov e th e Fue l Tan k vapo r recirculatio n valv e mountin g bol t an d Fue l Tan k vapo r recirculatio n valve .

7 . Remov e th e Vapo r signa l tub e fro m th e clips .

8 . Remov e th e fue l uni t wir e harnes s fro m th e acces s panel , an d pas s th e Fue l Tan k signa l tube .

9 . Jac k u p th e vehicle , an d suppor t i t wit h jackstands .

10 . Disconnec t th e muffle r mount .

11 . Remov e th e hea t shield .

12 . Remov e th e fue l tan k covers .

13 . Remov e th e drai n bolt , an d drai n th e fue l int o a n approve d container .

14 . Disconnec t th e hose s (se e pag e 11-129 ). Slid e bac k th e clamps , the n twis t hose s a s yo u pull , t o avoi d damagin g them .

15 . Plac e a jack , o r othe r support , unde r th e tank .

16 . Remov e th e stra p nuts , an d le t th e strap s fal l free .

17 . Remov e th e fue l tank .

I f i t stick s o n th e undercoa t applie d t o it s mount , carefull y pr y i t of f th e mount .

18 . Instal l th e drai n bol t wit h a ne w washer , the n coa t th e drai n bol t wit h Noxrus t 124B . Allo w th e Noxrus t t o dr y fo r 2 0

minutes .

19 . Instal l th e remainin g part s i n th e revers e orde r o f removal .

ACCESSPANEL

3P CONNECTO R FUE

L UNI T

WIR E HARNES S

38 N- m(3.9 kgf-m ,

2 8 Ibf-ft )

FUE L TAN K

COVER S

WIRE HARNES S 10

P CONNECTO R

2 P CONNECTO R

FUE L TAN K VAPO R

RECIRCULATIO N

VALVE

FUEL TAN KSTRA P

CLIPS

FUE L TAN K VAPO R SIGNA L

TUB E

WASHE RReplace .

DRAIN BOL T

4 9 N- m (5. 0 kgf-m , 3 6 Ibf-ft )

ProCarManuals.com

Page 656 of 1954

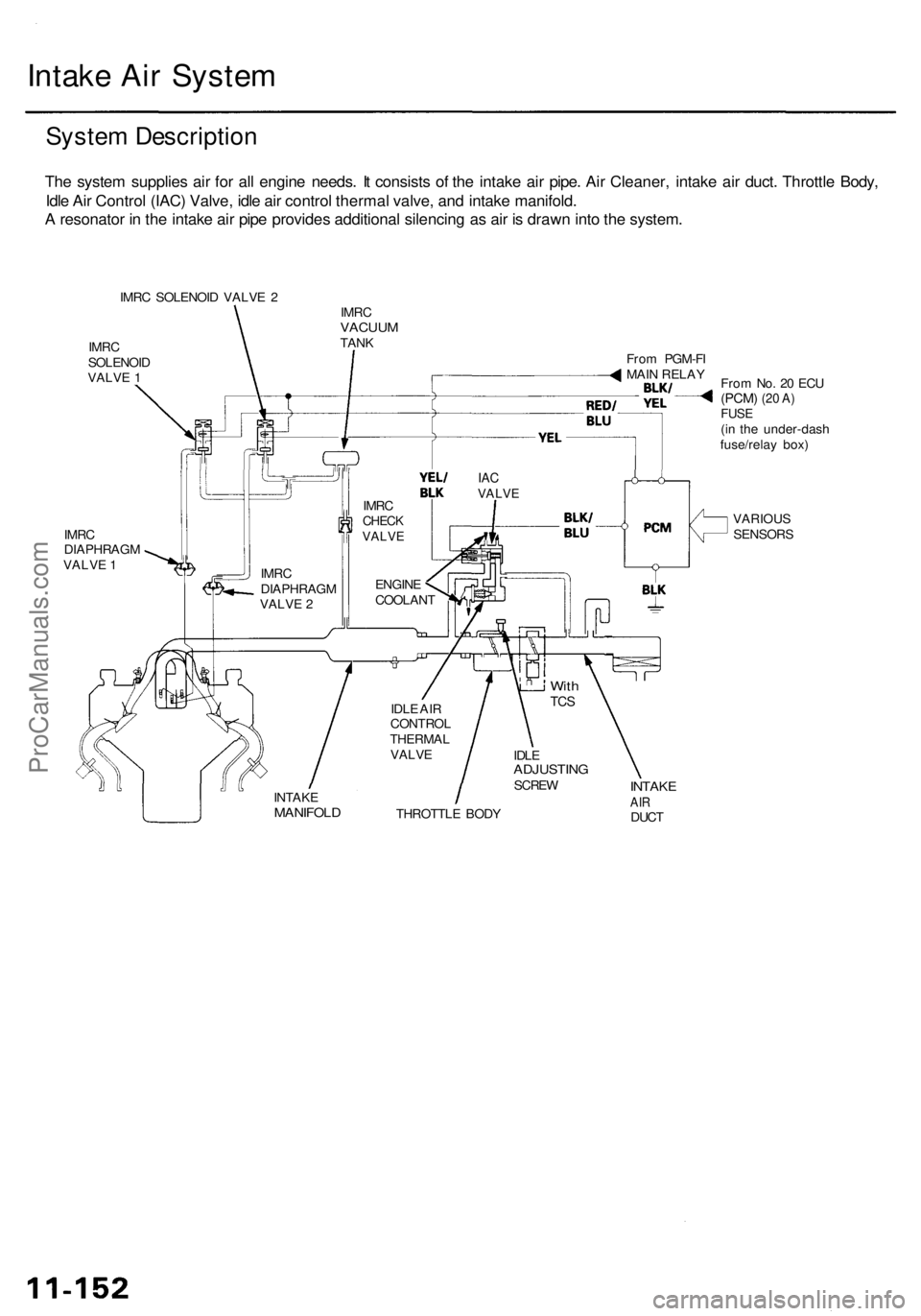

Intake Air System

System Description

The system supplies air for all engine needs. It consists of the intake air pipe. Air Cleaner, intake air duct. Throttle Body,

Idle Air Control (IAC) Valve, idle air control thermal valve, and intake manifold.

A resonator in the intake air pipe provides additional silencing as air is drawn into the system.

IMRC SOLENOID VALVE 2

IMRC

SOLENOID

VALVE 1

IMRC

VACUUM

TANK

From No. 20 ECU

(PCM)

(20 A)

FUSE

(in the under-dash

fuse/relay box)

IMRC

DIAPHRAGM

VALVE 1

VARIOUS

SENSORS

THROTTLE BODY

INTAKE

AIR

DUCT

INTAKE

MANIFOLD

IDLE

ADJUSTING

SCREW

With

TCS

IDLE AIR

CONTROL

THERMAL

VALVE

IAC

VALVE

From PGM-FI

MAIN RELAY

IMRC

DIAPHRAGM

VALVE 2

IMRC

CHECK

VALVE

ENGINE

COOLANTProCarManuals.com

Page 657 of 1954

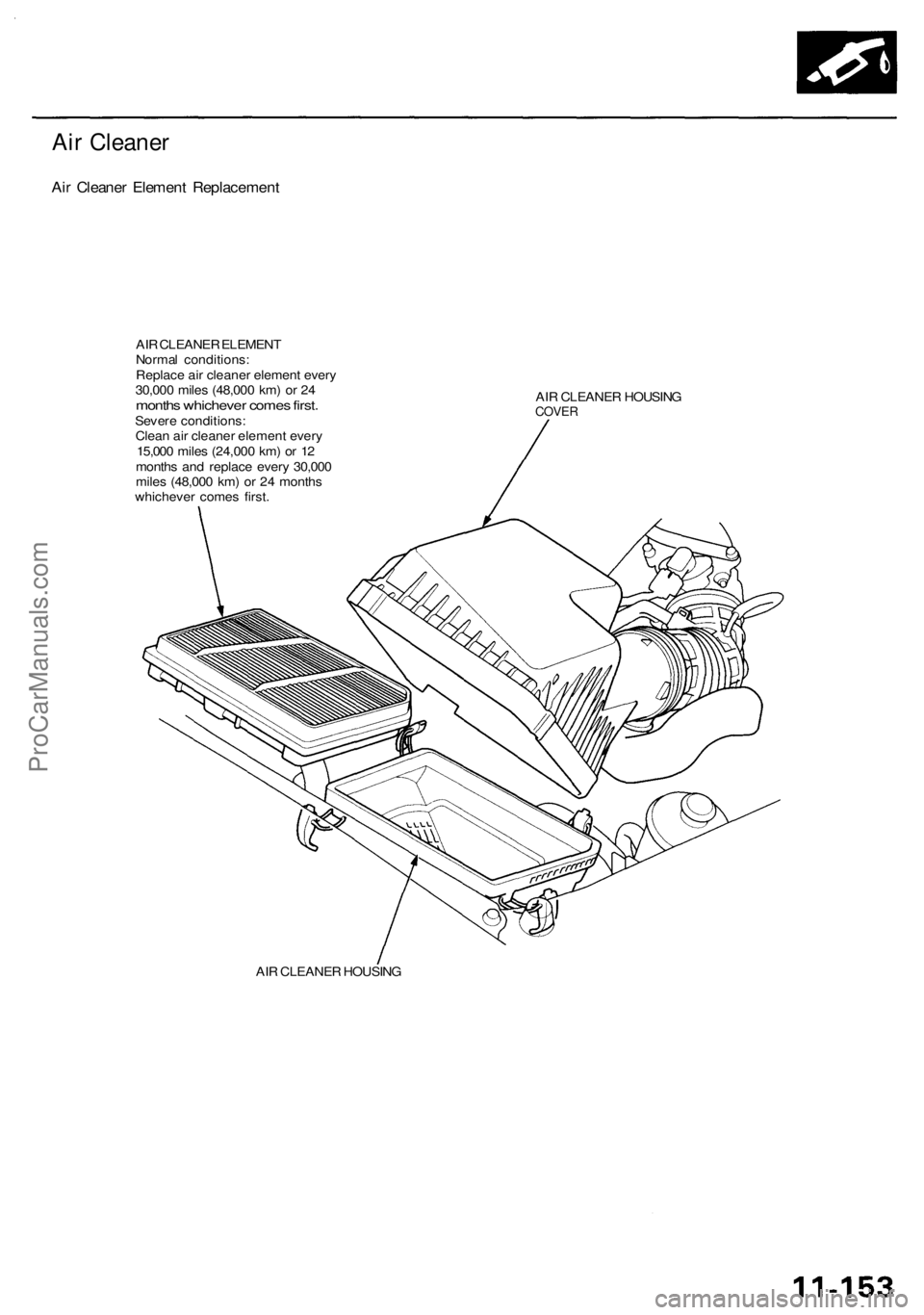

Air Cleaner

Air Cleaner Element Replacement

AIR CLEANER ELEMENT

Normal conditions:

Replace air cleaner element every

30,000 miles (48,000 km) or 24

months whichever comes first.

Severe conditions:

Clean air cleaner element every

15,000 miles (24,000 km) or 12

months and replace every 30,000

miles (48,000 km) or 24 months

whichever comes first.

AIR CLEANER HOUSING

COVER

AIR CLEANER HOUSINGProCarManuals.com

Page 658 of 1954

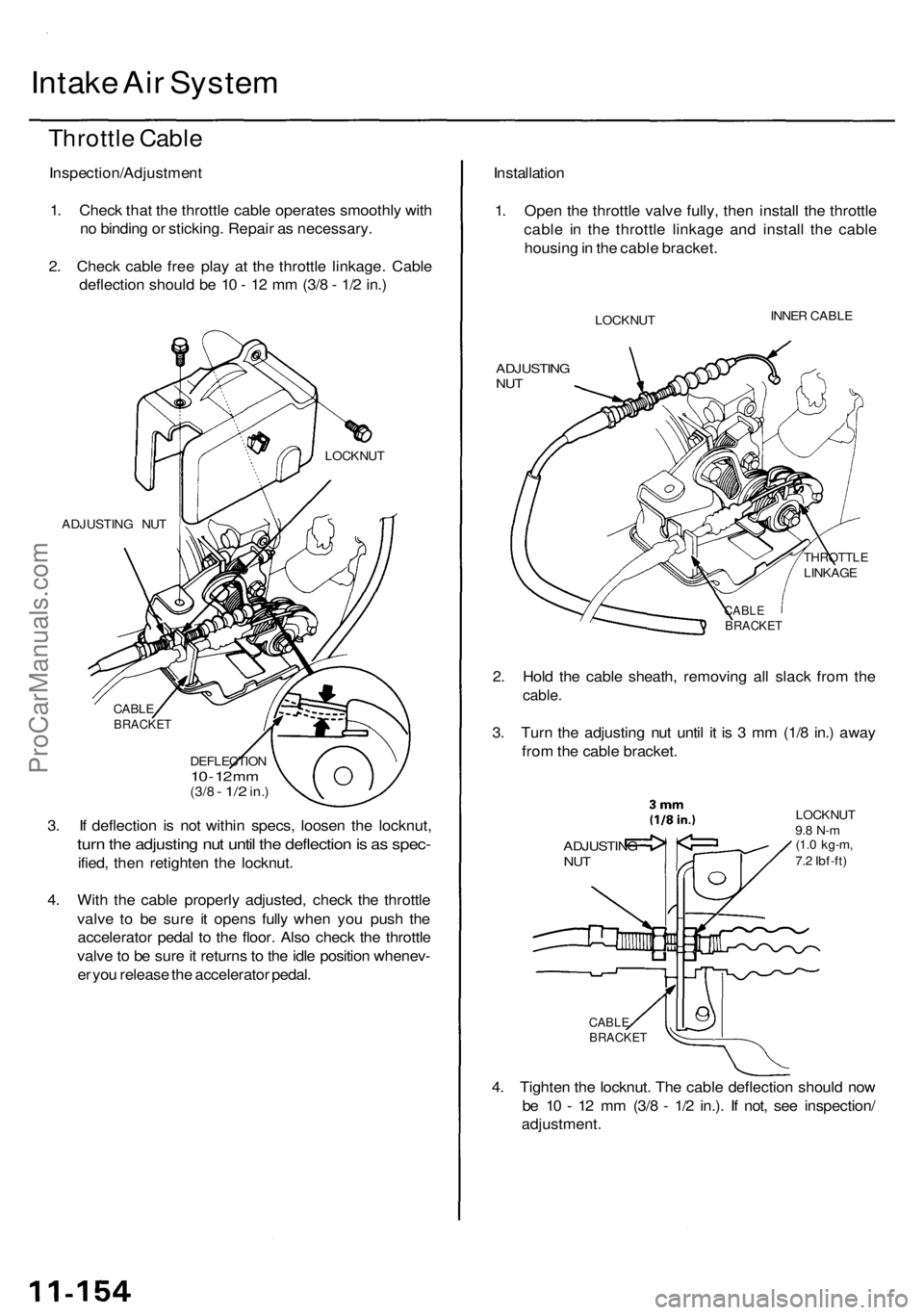

Intake Ai r Syste m

Throttl e Cabl e

Inspection/Adjustmen t

1 . Chec k tha t th e throttl e cabl e operate s smoothl y wit h

n o bindin g o r sticking . Repai r a s necessary .

2 . Chec k cabl e fre e pla y a t th e throttl e linkage . Cabl e

deflectio n shoul d b e 1 0 - 1 2 m m (3/ 8 - 1/ 2 in. )

ADJUSTIN G NU T

CABL EBRACKE T

DEFLECTIO N10 - 1 2 m m(3/ 8 - 1/ 2 in. )

3. I f deflectio n i s no t withi n specs , loose n th e locknut ,

turn th e adjustin g nu t unti l th e deflectio n is a s spec -

ified, the n retighte n th e locknut .

4 . Wit h th e cabl e properl y adjusted , chec k th e throttl e

valv e t o b e sur e i t open s full y whe n yo u pus h th e

accelerato r peda l t o th e floor . Als o chec k th e throttl e

valv e to b e sur e it return s t o th e idl e positio n whenev -

e r yo u releas e th e accelerato r pedal . Installatio

n

1 . Ope n th e throttl e valv e fully , the n instal l th e throttl e

cabl e i n th e throttl e linkag e an d instal l th e cabl e

housin g in th e cabl e bracket .

LOCKNU TINNER CABL E

ADJUSTIN GNUT

THROTTL ELINKAGE

CABLEBRACKE T

2. Hol d th e cabl e sheath , removin g al l slac k fro m th e

cable .

3. Tur n th e adjustin g nu t unti l i t i s 3 m m (1/ 8 in. ) awa y

fro m th e cabl e bracket .

LOCKNU T9.8 N- m(1.0 kg-m ,7.2 Ibf-ft )

CABL EBRACKE T

4. Tighte n th e locknut . Th e cabl e deflectio n shoul d no w

b e 1 0 - 1 2 m m (3/ 8 - 1/ 2 in.) . I f not , se e inspection /

adjustment .

ADJUSTINGNUT

LOCKNU T

ProCarManuals.com

Page 659 of 1954

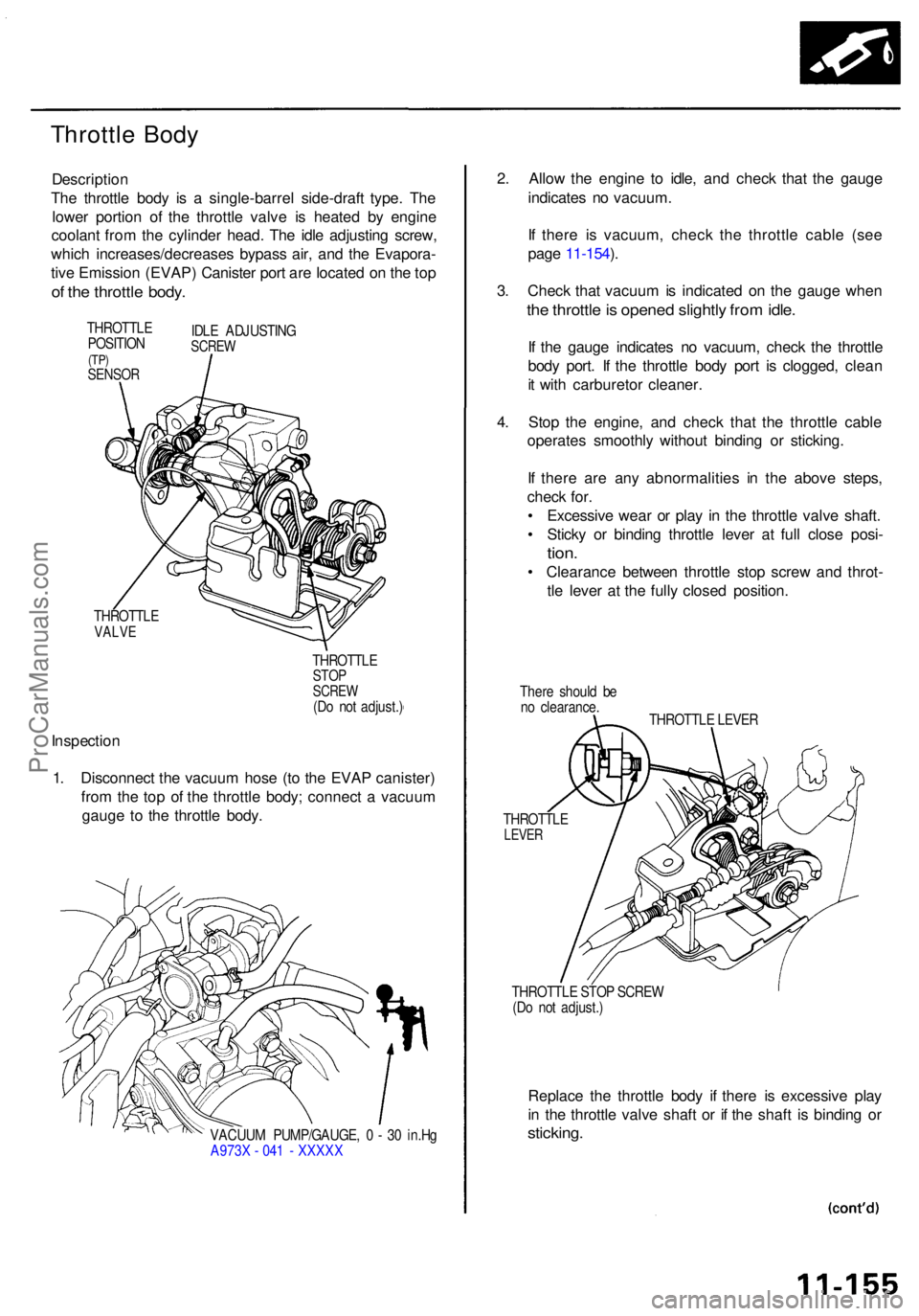

Throttle Bod y

Descriptio n

The throttl e bod y i s a single-barre l side-draf t type . Th e

lowe r portio n o f th e throttl e valv e i s heate d b y engin e

coolan t fro m th e cylinde r head . Th e idl e adjustin g screw ,

whic h increases/decrease s bypas s air , an d th e Evapora -

tiv e Emissio n (EVAP ) Caniste r por t ar e locate d o n th e to p

of th e throttl e body .

THROTTL E

POSITIO N

(TP)SENSO R

IDLE ADJUSTIN GSCREW

THROTTL EVALVE

THROTTL ESTOPSCRE W(Do no t adjust. )

Inspectio n

1 . Disconnec t th e vacuu m hos e (t o th e EVA P canister )

fro m th e to p o f th e throttl e body ; connec t a vacuu m

gaug e t o th e throttl e body .

VACUU M PUMP/GAUGE , 0 - 3 0 in.H g

A973 X - 04 1 - XXXX X

2. Allo w th e engin e t o idle , an d chec k tha t th e gaug e

indicate s n o vacuum .

I f ther e i s vacuum , chec k th e throttl e cabl e (se e

pag e 11-154 ).

3 . Chec k tha t vacuu m is indicate d o n th e gaug e whe n

the throttl e is opene d slightl y fro m idle .

If th e gaug e indicate s n o vacuum , chec k th e throttl e

bod y port . I f th e throttl e bod y por t i s clogged , clea n

i t wit h carbureto r cleaner .

4 . Sto p th e engine , an d chec k tha t th e throttl e cabl e

operate s smoothl y withou t bindin g o r sticking .

I f ther e ar e an y abnormalitie s i n th e abov e steps ,

chec k for .

• Excessiv e wea r o r pla y i n th e throttl e valv e shaft .

• Stick y o r bindin g throttl e leve r a t ful l clos e posi -

tion.

• Clearanc e betwee n throttl e sto p scre w an d throt -

tl e leve r a t th e full y close d position .

There shoul d b e

n o clearance .

THROTTL E LEVE R

THROTTL E

LEVER

THROTTL E STO P SCRE W

(D o no t adjust. )

Replace th e throttl e bod y i f ther e i s excessiv e pla y

i n th e throttl e valv e shaf t o r i f th e shaf t i s bindin g o r

sticking .

ProCarManuals.com

Page 660 of 1954

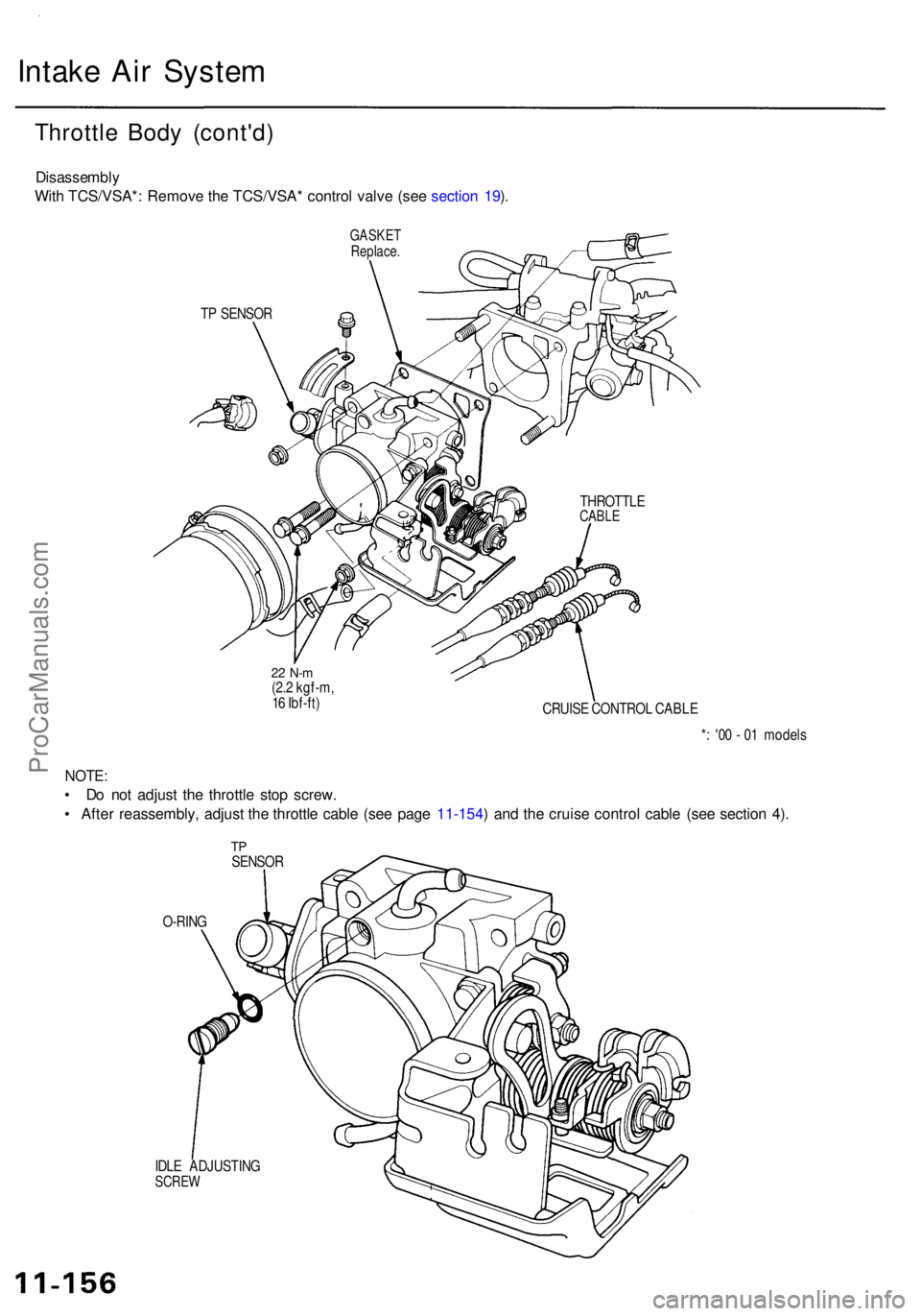

Intake Ai r Syste m

TP SENSO R

22 N- m(2.2 kgf-m ,

1 6 Ibf-ft )

CRUISE CONTRO L CABL E

*: '0 0 - 0 1 model s

O-RIN G

IDL E ADJUSTIN G

SCREW

TPSENSO R

NOTE:

• D o no t adjus t th e throttl e sto p screw .

• Afte r reassembly , adjus t th e throttl e cabl e (se e pag e 11-154 ) an d th e cruis e contro l cabl e (se e sectio n 4) .

THROTTL ECABLE

GASKE TReplace .

Disassembl y

Wit h TCS/VSA* : Remov e th e TCS/VSA * contro l valv e (se e sectio n 19 ).

Throttl e Bod y (cont'd )

ProCarManuals.com