ACURA RL KA9 1996 Service Repair Manual

Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 671 of 1954

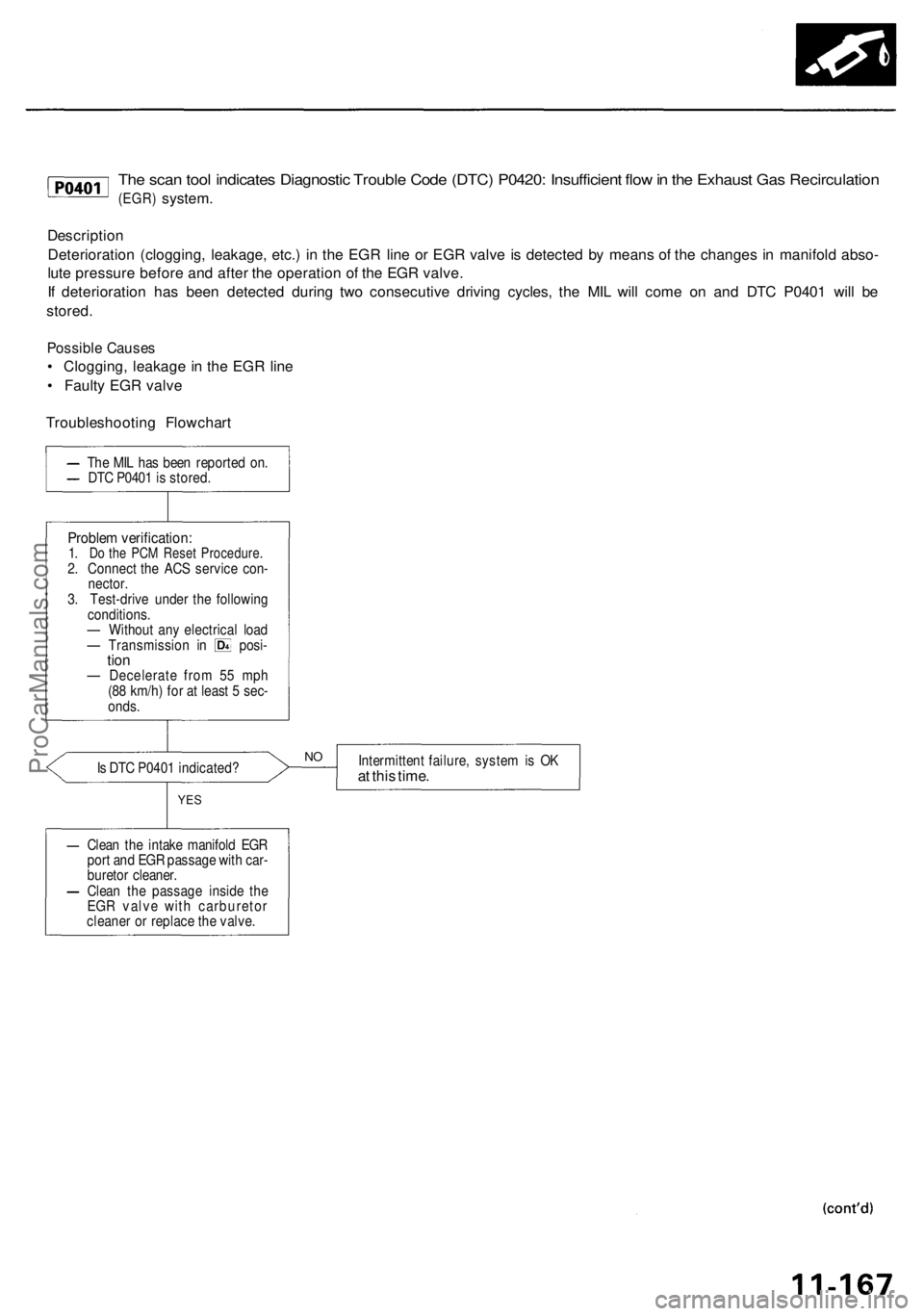

The scan tool indicates Diagnostic Trouble Code (DTC) P0420: Insufficient flow in the Exhaust Gas Recirculation

(EGR)

system.

Description

Deterioration (clogging, leakage, etc.) in the EGR line or EGR valve is detected by means of the changes in manifold abso-

lute pressure before and after the operation of the EGR valve.

If deterioration has been detected during two consecutive driving cycles, the MIL will come on and DTC P0401 will be

stored.

Possible Causes

• Clogging, leakage in the EGR line

• Faulty EGR valve

Troubleshooting Flowchart

Is DTC P0401 indicated?

Intermittent failure, system is OK

at this time.

YES

Clean the intake manifold EGR

port and EGR passage with car-

buretor cleaner.

Clean the passage inside the

EGR valve with carburetor

cleaner or replace the valve.

NO

Problem verification:

1. Do the PCM Reset Procedure.

2. Connect the ACS service con-

nector.

3. Test-drive under the following

conditions.

— Without any electrical load

— Transmission in posi-

tion

— Decelerate from 55 mph

(88 km/h) for at least 5 sec-

onds.

The MIL has been reported on.

DTC P0401 is stored.ProCarManuals.com

Page 672 of 1954

Emission Contro l Syste m

Exhaus t Ga s Recirculatio n (EGR ) Syste m (cont'd )

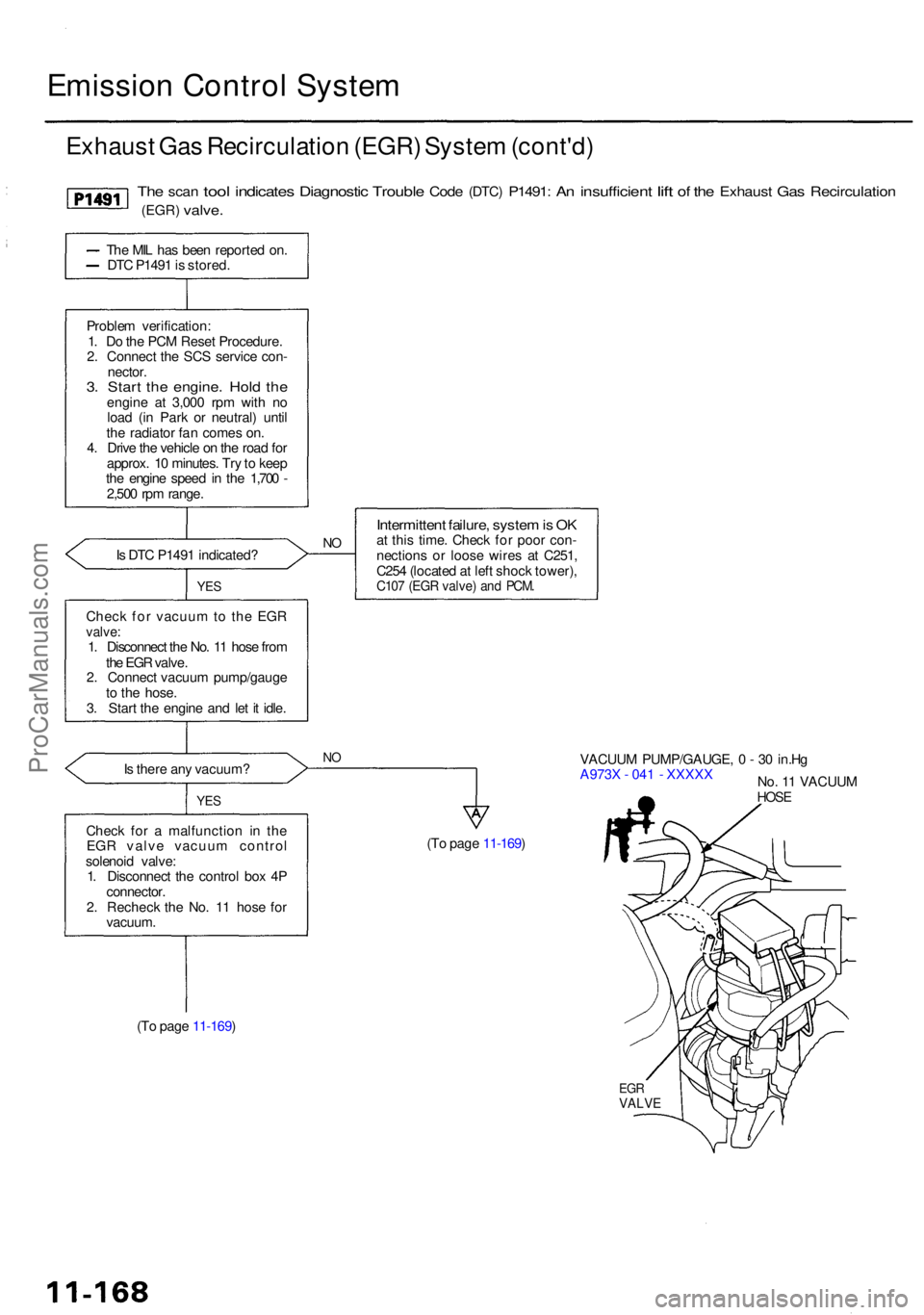

The sca n tool indicate s Diagnosti c Trouble Code (DTC ) P1491 : An insufficien t lift of th e Exhaus t Gas Recirculatio n

(EGR) valve .

Is DT C P149 1 indicated ?

YES

Chec k fo r vacuu m to th e EG Rvalve :1. Disconnec t th e No . 1 1 hos e fro m

th e EG R valve .

2 . Connec t vacuu m pump/gaug e

t o th e hose .

3 . Star t th e engin e an d le t i t idle .

I s ther e an y vacuum ?

YES

Chec k fo r a malfunctio n i n th e

EG R valv e vacuu m contro l

solenoi d valve :

1 . Disconnec t th e contro l bo x 4 P

connector .

2 . Rechec k th e No . 1 1 hos e fo r

vacuum .

(T o pag e 11-169 )

Intermitten t failure , syste m is O Kat thi s time . Chec k fo r poo r con -

nection s o r loos e wire s a t C251 ,

C25 4 (locate d a t lef t shoc k tower) ,

C107 (EG R valve ) an d PCM .

NOVACUU M PUMP/GAUGE , 0 - 3 0 in.H g

A973 X - 04 1 - XXXX X

No. 1 1 VACUU M

HOSE

(To pag e 11-169 )

EGRVALV E

NO

Proble m verification :

1 . D o th e PC M Rese t Procedure .

2 . Connec t th e SC S servic e con -

nector .

3. Star t th e engine . Hol d th eengin e a t 3,00 0 rp m wit h n o

loa d (i n Par k o r neutral ) unti l

th e radiato r fa n come s on .

4 . Driv e th e vehicl e o n th e roa d fo r

approx . 1 0 minutes . Tr y to kee p

th e engin e spee d i n th e 1,70 0 -

2,50 0 rp m range .

Th

e MI L ha s bee n reporte d on .

DT C P149 1 is stored .

ProCarManuals.com

Page 673 of 1954

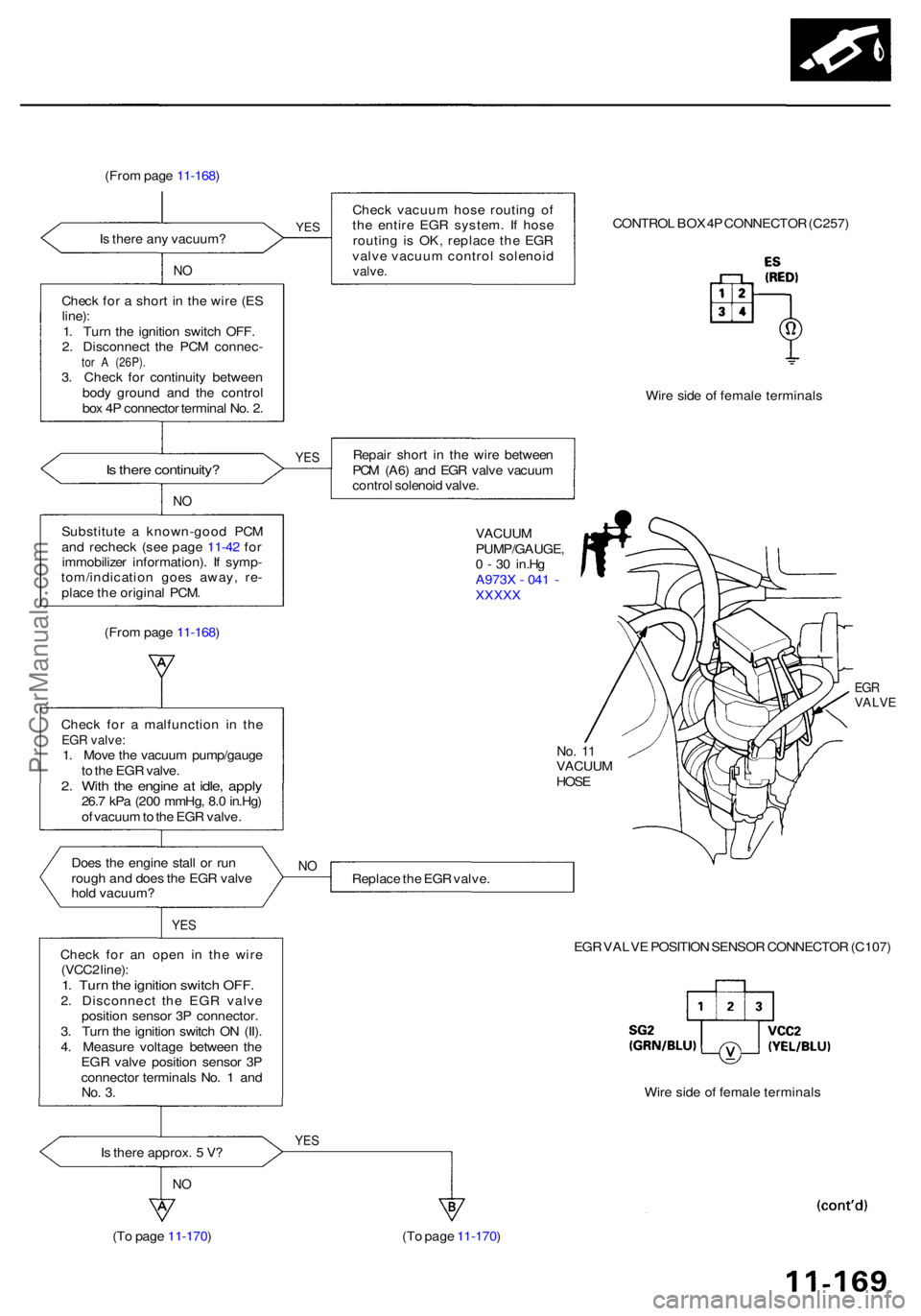

(From pag e 11-168 )

I s ther e an y vacuum ?

NO

Chec k fo r a shor t i n th e wir e (E S

line) :

1 . Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e PC M connec -

tor A (26P) .3. Chec k fo r continuit y betwee n

bod y groun d an d th e contro l

bo x 4 P connecto r termina l No . 2 .

Is ther e continuity ?

NO

Substitut e a known-goo d PC M

an d rechec k (se e pag e 11-42 fo r

immobilize r information) . I f symp -

tom/indicatio n goe s away , re -

plac e th e origina l PCM .

(Fro m pag e 11-168 )

Chec k fo r a malfunctio n i n th e

EG R valve :1. Mov e th e vacuu m pump/gaug e

t o th e EG R valve .

2. Wit h th e engin e a t idle , appl y26.7 kP a (20 0 mmHg , 8. 0 in.Hg )

o f vacuu m to th e EG R valve .

Doe s th e engin e stal l o r ru n

roug h an d doe s th e EG R valv e

hol d vacuum ?

YES

Chec k fo r a n ope n i n th e wir e

(VCC 2 line) :

1. Tur n th e ignitio n switc h OFF .2. Disconnec t th e EG R valv e

positio n senso r 3 P connector .

3 . Tur n th e ignitio n switc h O N (II) .

4 . Measur e voltag e betwee n th e

EG R valv e positio n senso r 3 P

connecto r terminal s No . 1 an d

No. 3 .

Is ther e approx . 5 V ?

NO

(T o pag e 11-170 ) Chec

k vacuu m hos e routin g o f

th e entir e EG R system . I f hos e

routin g i s OK , replac e th e EG R

valv e vacuu m contro l solenoi d

valve.

CONTRO L BO X 4P CONNECTO R (C257 )

Wir e sid e o f femal e terminal s

Repai r shor t i n th e wir e betwee n

PC M (A6 ) an d EG R valv e vacuu m

contro l solenoi d valve .

VACUU M

PUMP/GAUGE ,

0 - 3 0 in.H g

A973 X - 04 1 -

XXXX X

Replac e th e EG R valve .

EGRVALV E

No. 1 1VACUU M

HOS E

EG R VALV E POSITIO N SENSO R CONNECTO R (C107 )

Wir e sid e o f femal e terminal s

YES

(To pag e 11-170 )

NO

YE S

YE S

ProCarManuals.com

Page 674 of 1954

Emission Contro l Syste m

Exhaus t Ga s Recirculatio n (EGR ) Syste m (cont'd )

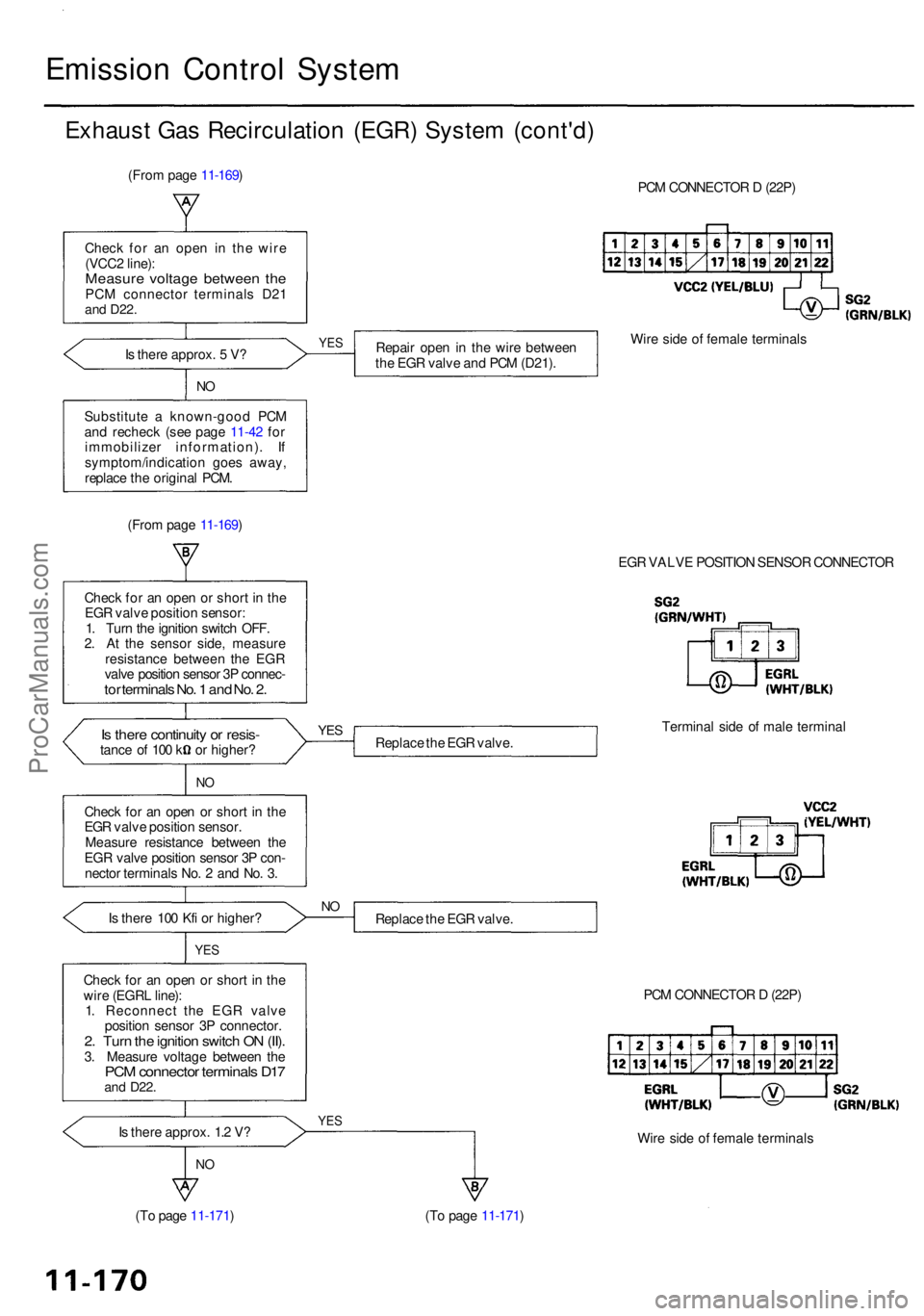

(From pag e 11-169 )

PCM CONNECTO R D (22P )

Chec k fo r a n ope n i n th e wir e

(VCC 2 line) :

Measur e voltag e betwee n th ePC M connecto r terminal s D2 1and D22 .

Is ther e approx . 5 V ?

NO

Substitut e a known-goo d PC M

an d rechec k (se e pag e 11-42 fo r

immobilize r information) . I f

symptom/indicatio n goe s away ,

replac e th e origina l PCM . Repai

r ope n in th e wir e betwee n

th e EG R valv e an d PC M (D21) .

(Fro m pag e 11-169 )

Chec k fo r a n ope n o r shor t i n th e

EG R valv e positio n sensor :

1 . Tur n th e ignitio n switc h OFF .

2 . A t th e senso r side , measur e

resistanc e betwee n th e EG R

valv e positio n senso r 3 P connec -

tor terminal s No . 1 an d No . 2 .

Is ther e continuit y o r resis -tance o f 10 0 k o r higher ?

NO

Chec k fo r a n ope n o r shor t i n th e

EG R valv e positio n sensor .

Measur e resistanc e betwee n th e

EG R valv e positio n senso r 3 P con -

necto r terminal s No . 2 an d No . 3 .

I s ther e 10 0 Kf i o r higher ?

YES

Chec k fo r a n ope n o r shor t i n th e

wir e (EGR L line) :

1 . Reconnec t th e EG R valv e

positio n senso r 3 P connector .

2. Tur n th e ignitio n switc h O N (II) .3. Measur e voltag e betwee n th ePC M connecto r terminal s D1 7and D22 .

Is ther e approx . 1. 2 V ?

(T o pag e 11-171 ) EG

R VALV E POSITIO N SENSO R CONNECTO R

Replac e th e EG R valve . Termina

l sid e o f mal e termina l

Replac e th e EG R valve .

PCM CONNECTO R D (22P )YES

Wir e sid e o f femal e terminal s

(T o pag e 11-171 )

NO

NO

YE S

YE SWir e sid e o f femal e terminal s

ProCarManuals.com

Page 675 of 1954

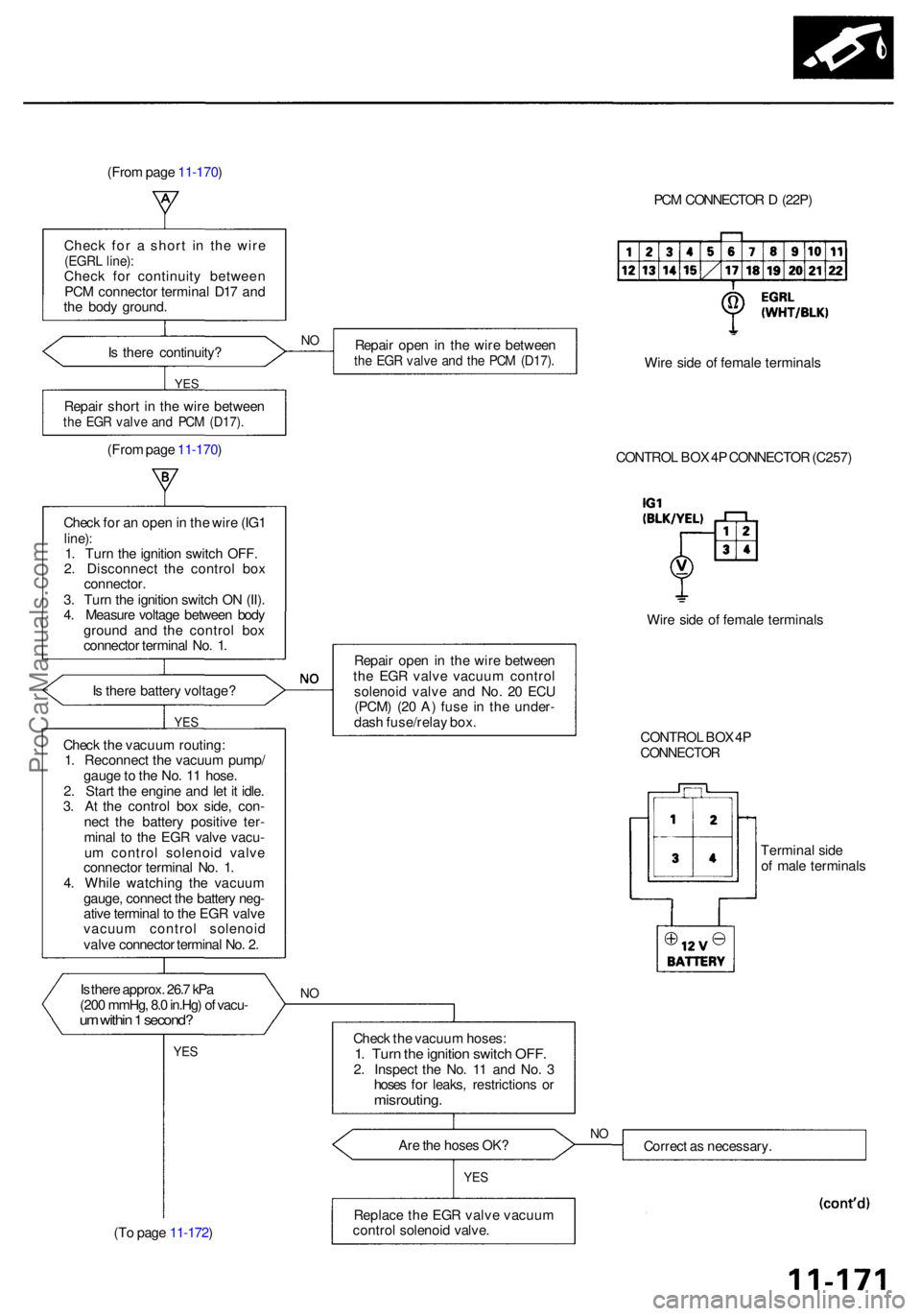

(From pag e 11-170 )

PCM CONNECTO R D (22P )

Chec k fo r a shor t i n th e wir e

(EGR L line) :Chec k fo r continuit y betwee n

PC M connecto r termina l D1 7 an d

th e bod y ground .

I s ther e continuity ? Repai

r ope n in th e wir e betwee n

the EG R valv e an d th e PC M (D17) .

YES

Repai r shor t i n th e wir e betwee nthe EG R valv e an d PC M (D17) .

(From pag e 11-170 )

Chec k fo r a n ope n in th e wir e (IG 1

line) :1. Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e contro l bo x

connector .

3 . Tur n th e ignitio n switc h O N (II) .

4 . Measur e voltag e betwee n bod y

groun d an d th e contro l bo x

connecto r termina l No . 1 . Wir

e sid e o f femal e terminal s

CONTRO L BO X 4P CONNECTO R (C257 )

Wir e sid e o f femal e terminal s

I s ther e batter y voltage ?

YES

Chec k th e vacuu m routing :

1 . Reconnec t th e vacuu m pump /

gaug e to th e No . 1 1 hose .

2 . Star t th e engin e an d le t i t idle .

3 . A t th e contro l bo x side , con -

nec t th e batter y positiv e ter -

mina l t o th e EG R valv e vacu -

u m contro l solenoi d valv e

connecto r termina l No . 1 .

4 . Whil e watchin g th e vacuu m

gauge , connec t th e batter y neg -

ativ e termina l t o th e EG R valv e

vacuu m contro l solenoi d

valv e connecto r termina l No . 2 . Repai

r ope n in th e wir e betwee n

th e EG R valv e vacuu m contro l

solenoi d valv e an d No . 2 0 EC U

(PCM ) (2 0 A ) fus e i n th e under -

das h fuse/rela y box .

CONTROL BO X 4PCONNECTO R

Is ther e approx . 26. 7 kP a

(20 0 mmHg , 8. 0 in.Hg ) o f vacu -

um withi n 1 second ?

Termina l sid e

o f mal e terminal s

NO

YE SChec k th e vacuu m hoses :1. Tur n th e ignitio n switc h OFF .2. Inspec t th e No . 1 1 an d No . 3

hose s fo r leaks , restriction s o r

misrouting .

Are th e hose s OK ?

(T o pag e 11-172 ) Correc

t a s necessary .

YES

NO

N

O

Replac e th e EG R valv e vacuu m

contro l solenoi d valve .

ProCarManuals.com

Page 676 of 1954

Emission Contro l Syste m

Exhaus t Ga s Recirculatio n (EGR ) Syste m (cont'd )

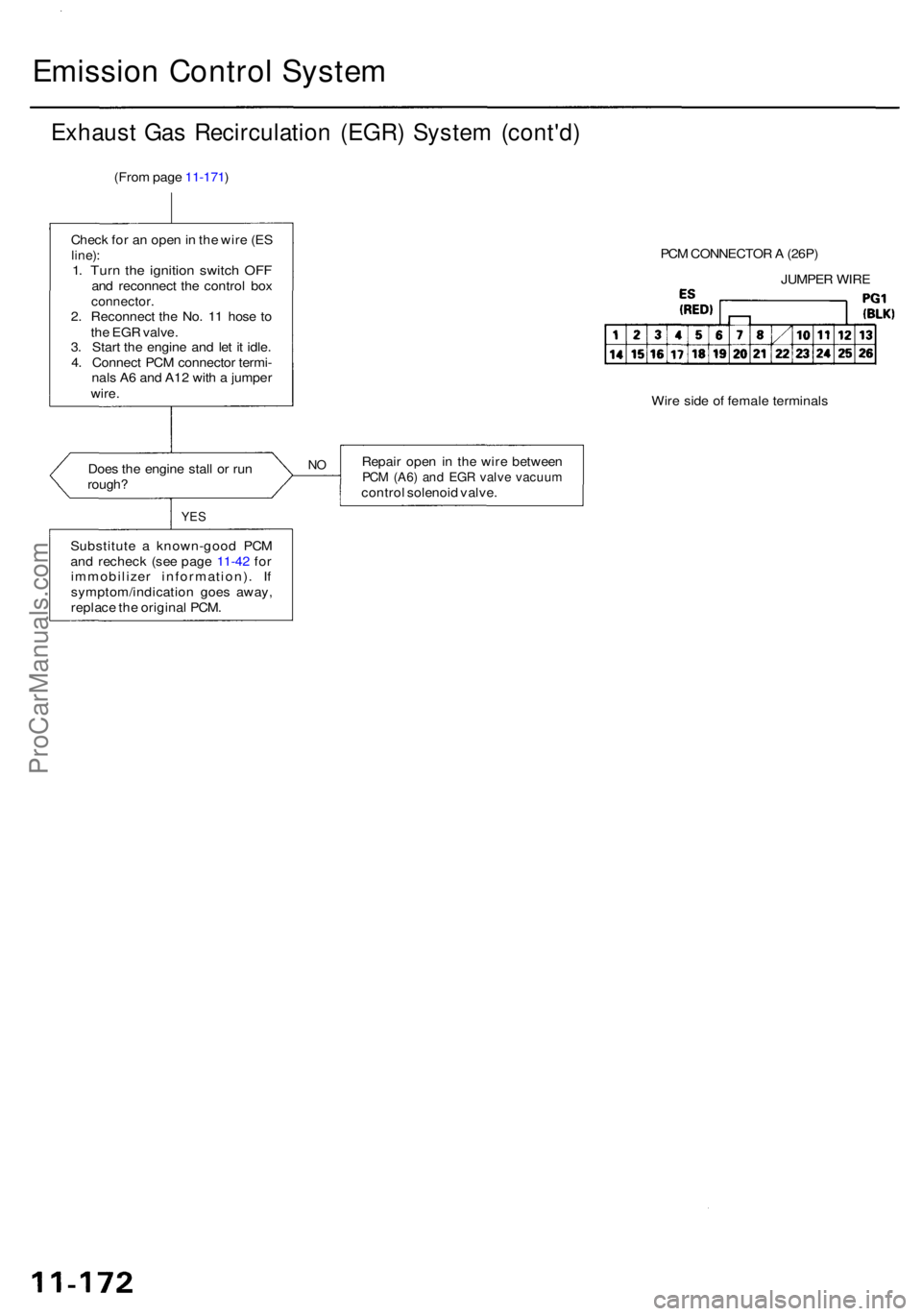

(From pag e 11-171 )

PCM CONNECTO R A (26P )

JUMPE R WIR E

Wir e sid e o f femal e terminal s

Doe s th e engin e stal l o r ru n

rough ? Repai

r ope n in th e wir e betwee n

PCM (A6 ) an d EG R valv e vacuu mcontrol solenoi d valve .

YES

Substitut e a known-goo d PC M

an d rechec k (se e pag e 11-42 fo r

immobilize r information) . I f

symptom/indicatio n goe s away ,

replac e th e origina l PCM .

Chec

k fo r a n ope n in th e wir e (E S

line) :1. Tur n th e ignitio n switc h OF Fand reconnec t th e contro l bo xconnector .2. Reconnec t th e No . 1 1 hos e t o

th e EG R valve .

3 . Star t th e engin e an d le t i t idle .

4 . Connec t PC M connecto r termi -

nal s A 6 an d A1 2 wit h a jumpe r

wire .

NO

ProCarManuals.com

Page 677 of 1954

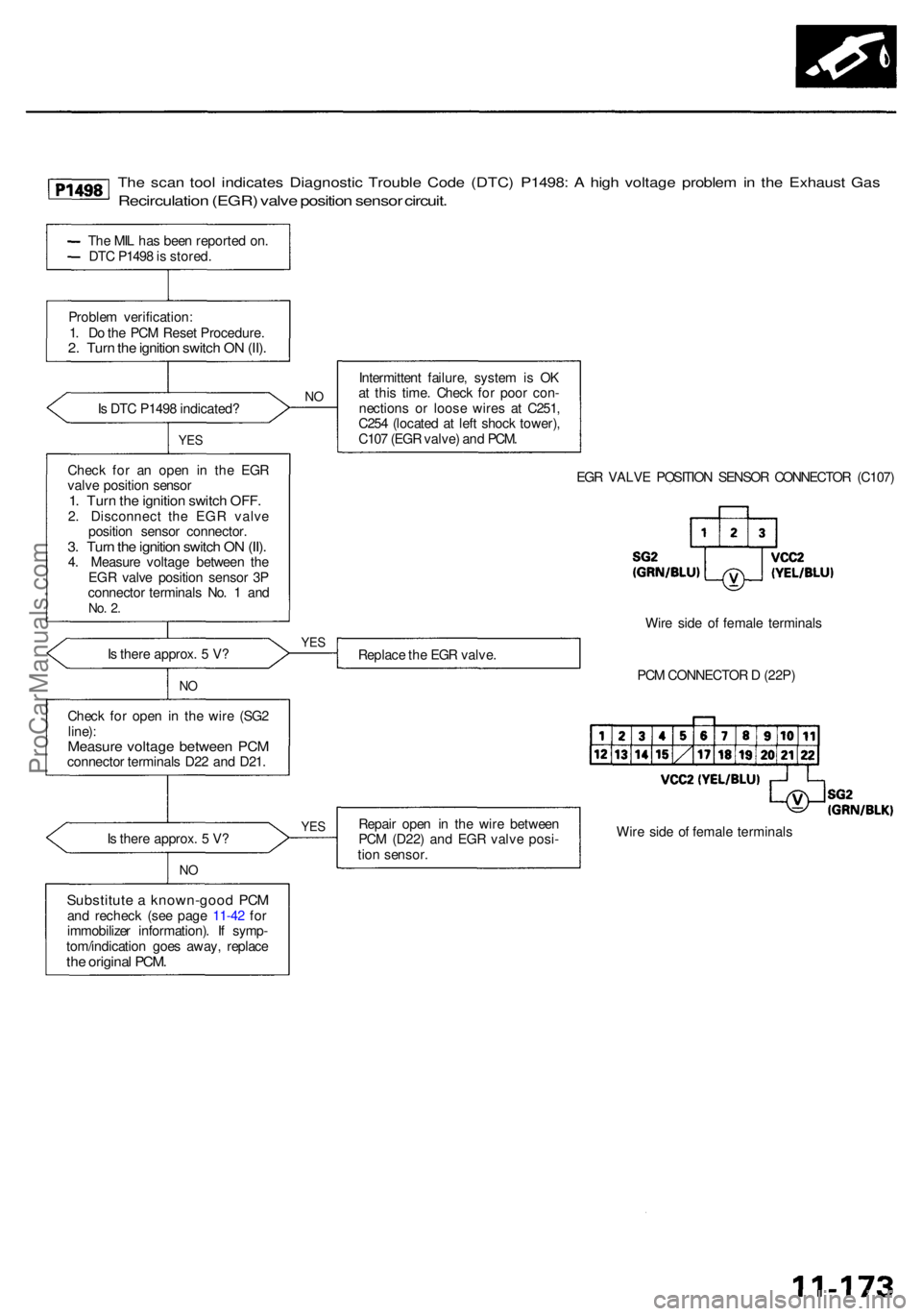

The sca n too l indicate s Diagnosti c Troubl e Cod e (DTC ) P1498 : A hig h voltag e proble m in th e Exhaus t Ga s

Recirculatio n (EGR ) valv e positio n senso r circuit .

The MI L ha s bee n reporte d on .

DT C P149 8 is stored .

Proble m verification :

1 . D o th e PC M Rese t Procedure .

2. Tur n th e ignitio n switc h O N (II) .

Is DT C P149 8 indicated ?

YES

Chec k fo r a n ope n i n th e EG R

valv e positio n senso r

1. Tur n th e ignitio n switc h OFF .2. Disconnec t th e EG R valv e

positio n senso r connector .

3. Tur n th e ignitio n switc h O N (II) .4. Measur e voltag e betwee n th e

EG R valv e positio n senso r 3 P

connecto r terminal s No . 1 an d

No. 2 .

Is ther e approx . 5 V ?

NO

Chec k fo r ope n i n th e wir e (SG 2

line) :

Measur e voltag e betwee n PC Mconnecto r terminal s D2 2 an d D21 .

I s ther e approx . 5 V ?

NO

Substitut e a known-goo d PC Mand rechec k (se e pag e 11-42 fo r

immobilize r information) . I f symp -

tom/indicatio n goe s away , replac e

the origina l PCM .

Intermitten t failure , syste m is O K

a t thi s time . Chec k fo r poo r con -

nection s o r loos e wire s a t C251 ,

C25 4 (locate d a t lef t shoc k tower) ,

C10 7 (EG R valve ) an d PCM .

EGR VALV E POSITIO N SENSO R CONNECTO R (C107 )

Replac e th e EG R valve . Wir

e sid e o f femal e terminal s

PC M CONNECTO R D (22P )

Repai r ope n i n th e wir e betwee n

PC M (D22 ) an d EG R valv e posi -

tio n sensor . Wir

e sid e o f femal e terminal s

YES

YE

S

NO

ProCarManuals.com

Page 678 of 1954

Emission Contro l Syste m

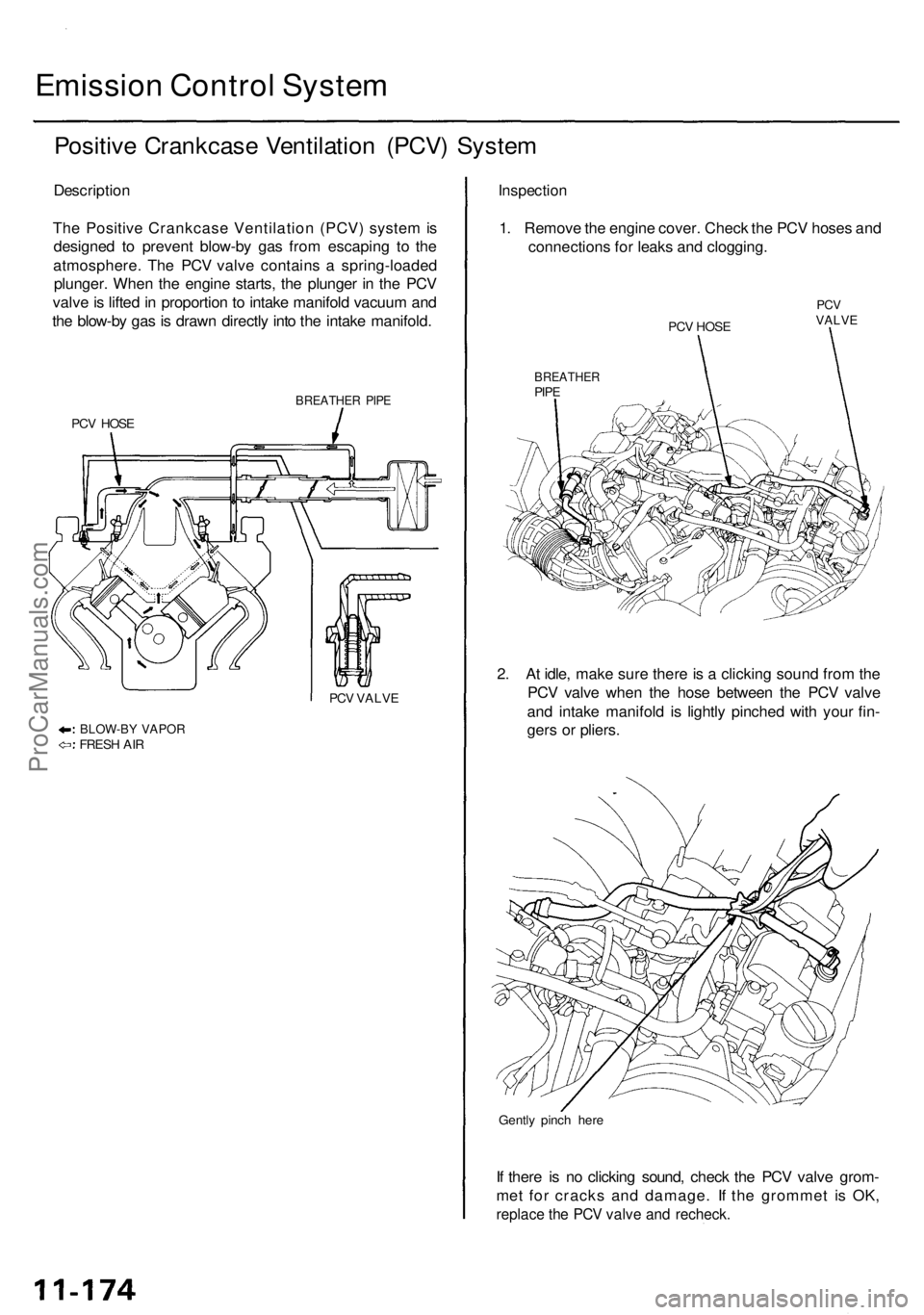

Positiv e Crankcas e Ventilatio n (PCV ) Syste m

Descriptio n

Th e Positiv e Crankcas e Ventilatio n (PCV ) syste m is

designe d t o preven t blow-b y ga s fro m escapin g t o th e

atmosphere . Th e PC V valv e contain s a spring-loade d

plunger . Whe n th e engin e starts , th e plunge r i n th e PC V

valv e is lifte d in proportio n to intak e manifol d vacuu m an d

th e blow-b y ga s is draw n directl y int o th e intak e manifold .

BREATHE R PIP E

PCV HOS E

PCV VALV E

BLOW-B Y VAPO RFRESH AI R

Inspectio n

1. Remov e th e engin e cover . Chec k th e PC V hose s an d

connection s fo r leak s an d clogging .

PCV HOS E

PCVVALV E

BREATHE RPIPE

2. A t idle , mak e sur e ther e is a clickin g soun d fro m th e

PC V valv e whe n th e hos e betwee n th e PC V valv e

an d intak e manifol d i s lightl y pinche d wit h you r fin -

ger s o r pliers .

Gently pinc h her e

If ther e i s n o clickin g sound , chec k th e PC V valv e grom -

me t fo r crack s an d damage . I f th e gromme t i s OK ,

replac e th e PC V valv e an d recheck .

ProCarManuals.com

Page 679 of 1954

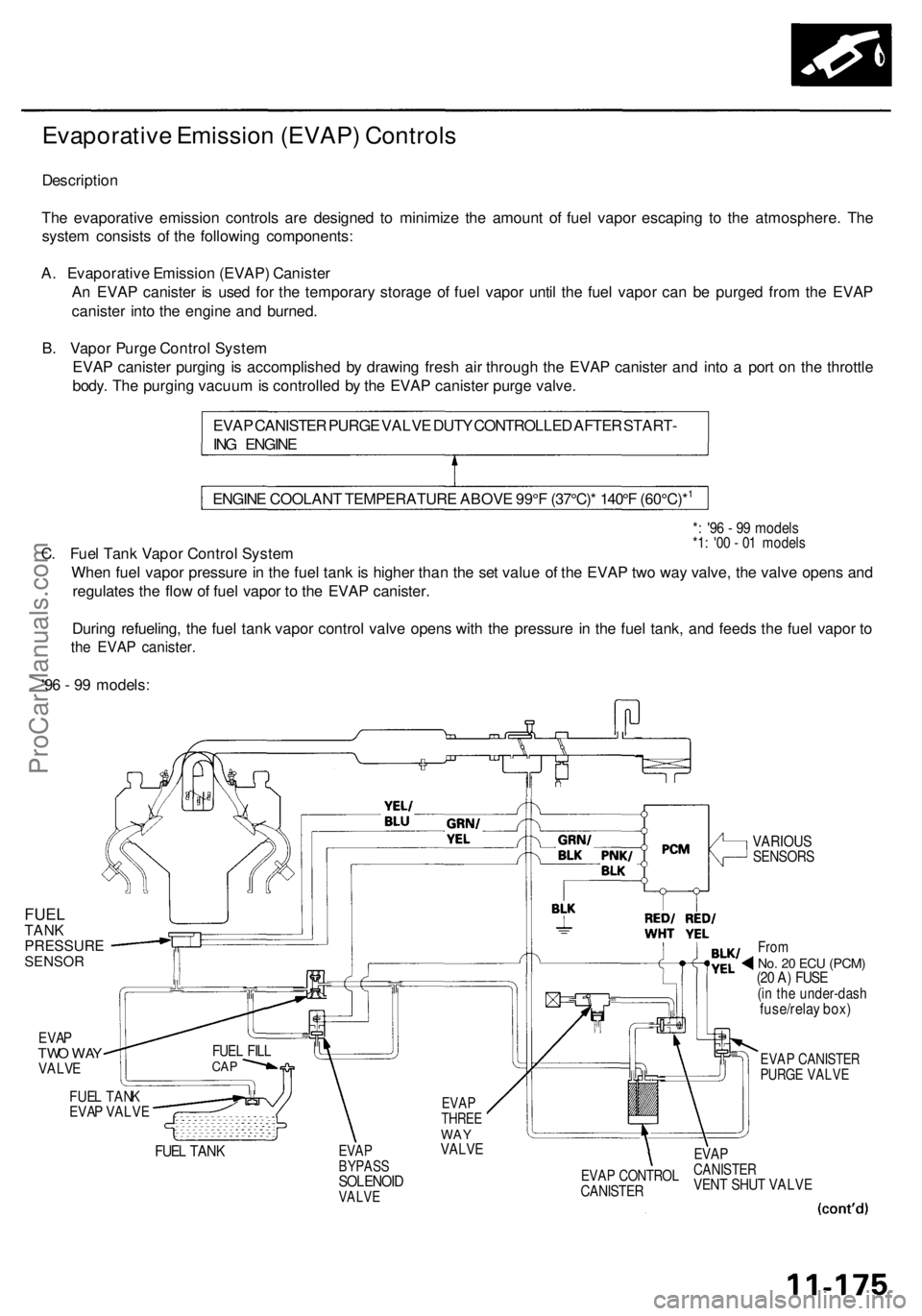

Evaporative Emissio n (EVAP ) Control s

Descriptio n

Th e evaporativ e emissio n control s ar e designe d t o minimiz e th e amoun t o f fue l vapo r escapin g t o th e atmosphere . Th e

syste m consist s o f th e followin g components :

A . Evaporativ e Emissio n (EVAP ) Caniste r

A n EVA P caniste r i s use d fo r th e temporar y storag e o f fue l vapo r unti l th e fue l vapo r can be purge d fro m th e EVA P

caniste r int o th e engin e an d burned .

B . Vapo r Purg e Contro l Syste m

EVA P caniste r purgin g is accomplishe d b y drawin g fres h ai r throug h th e EVA P caniste r an d int o a por t o n th e throttl e

body . Th e purgin g vacuu m is controlle d b y th e EVA P caniste r purg e valve .

EVA P CANISTE R PURG E VALV E DUT Y CONTROLLE D AFTE R START -

IN G ENGIN E

*: '9 6 - 9 9 model s*1: '0 0 - 0 1 model sC. Fue l Tan k Vapo r Contro l Syste m

Whe n fue l vapo r pressur e in th e fue l tan k is highe r tha n th e se t valu e o f th e EVA P tw o wa y valve , th e valv e open s an d

regulate s th e flo w o f fue l vapo r t o th e EVA P canister .

Durin g refueling , th e fue l tan k vapo r contro l valv e open s wit h th e pressur e in th e fue l tank , an d feed s th e fue l vapo r t o

th e EVA P canister .

'96 - 9 9 models :

FUELTANKPRESSURESENSOR

EVAPTWO WAYVALVE

FUEL TANKEVAP VALVE

FUEL TAN K

EVAP CANISTE RPURGE VALV E

EVAPBYPAS SSOLENOI DVALVE

EVAPCANISTE RVENT SHU T VALV EEVAP CONTRO LCANISTER

EVAPTHRE EWAYVALV E

FUEL FIL LCAP

Fro mNo. 2 0 EC U (PCM )(20 A ) FUS E(in th e under-das hfuse/relay box )

VARIOU SSENSOR S

ENGINE COOLAN T TEMPERATUR E ABOV E 99° F (37°C) * 140° F (60°C)*1

ProCarManuals.com

Page 680 of 1954

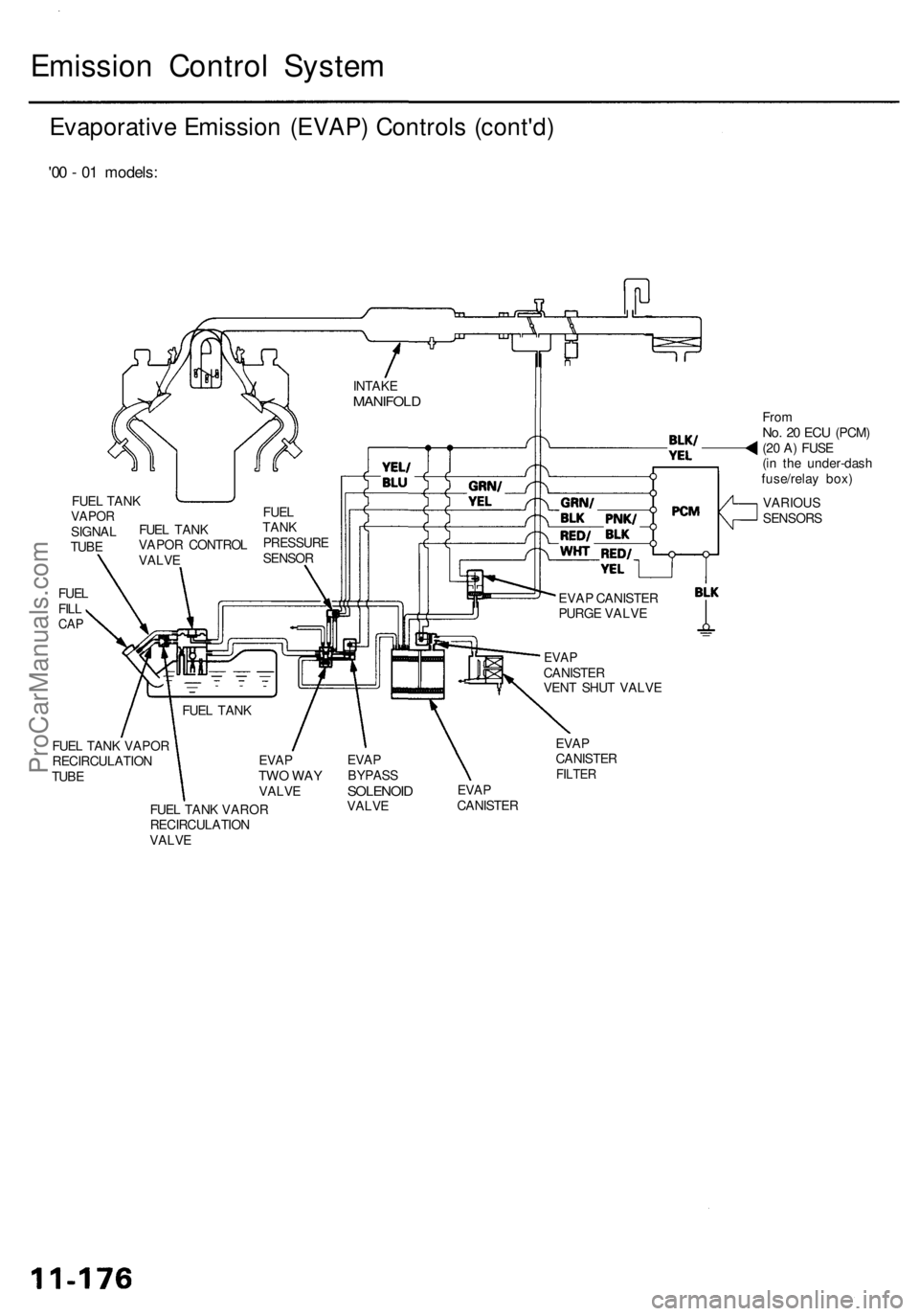

Emission Control System

Evaporative Emission (EVAP) Controls (cont'd)

'00 - 01 models:

From

No. 20 ECU

(PCM)

(20 A) FUSE

(in the under-dash

fuse/relay box)

FUEL TANK VAPOR

RECIRCULATION

TUBE

EVAP

BYPASS

SOLENOID

VALVE

EVAP

CANISTER

FILTER

EVAP

CANISTER

FUEL TANK VAROR

RECIRCULATION

VALVE

EVAP

TWO WAY

VALVE

FUEL TANK

EVAP

CANISTER

VENT SHUT VALVE

EVAP CANISTER

PURGE VALVE

VARIOUS

SENSORS

INTAKE

MANIFOLD

FUEL

TANK

PRESSURE

SENSOR

FUEL TANK

VAPOR CONTROL

VALVE

FUEL

FILL

CAP

FUEL TANK

VAPOR

SIGNAL

TUBEProCarManuals.com